Multi-stage combustion energy-saving environment-friendly burner

An energy-saving, environmentally friendly, and staged combustion technology, which is applied in the direction of burners, combustion methods, and combustion types, can solve the problems of high fuel consumption, incomplete combustion, and short spread, so as to improve the radiation heat transfer effect and suppress the formation of NOx , Eliminate the effect of local high temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

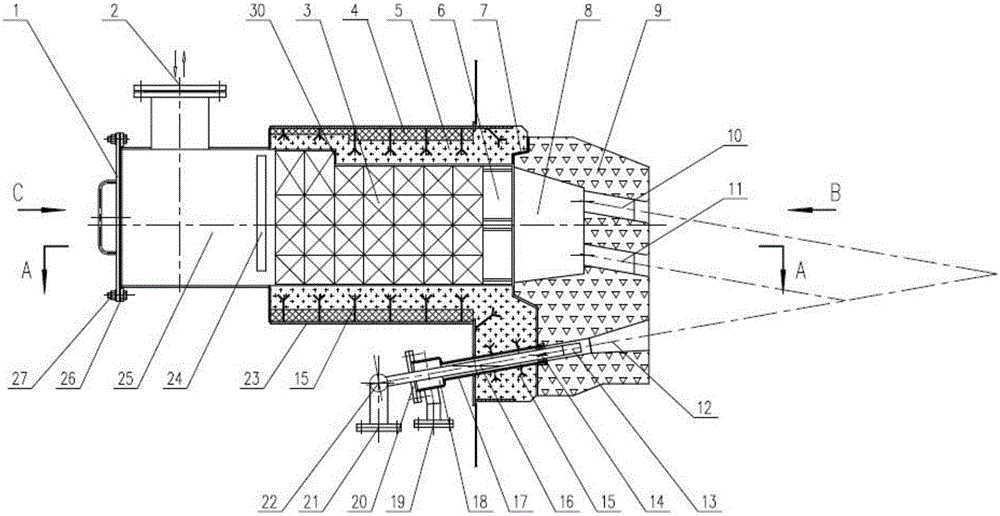

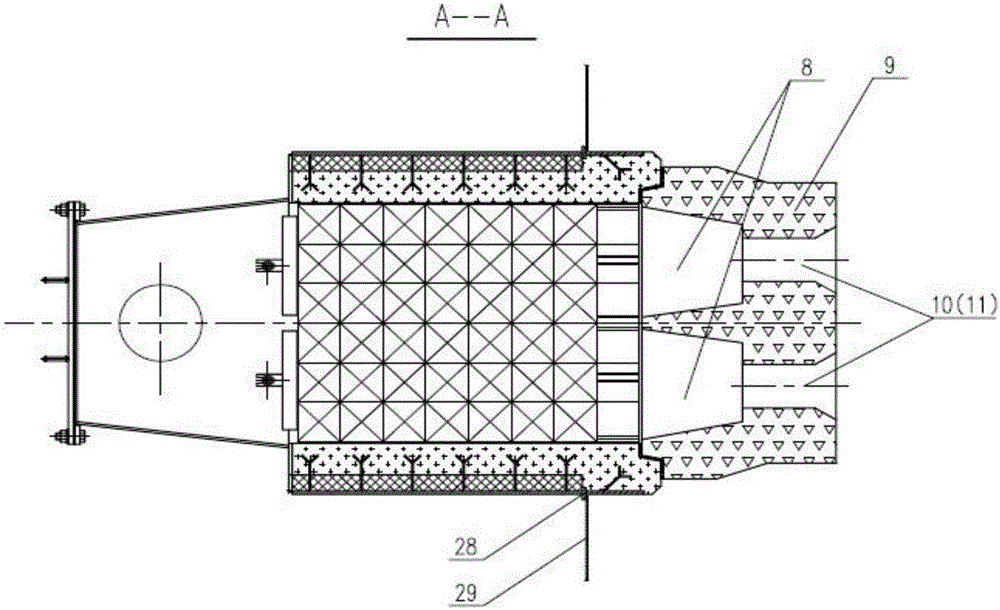

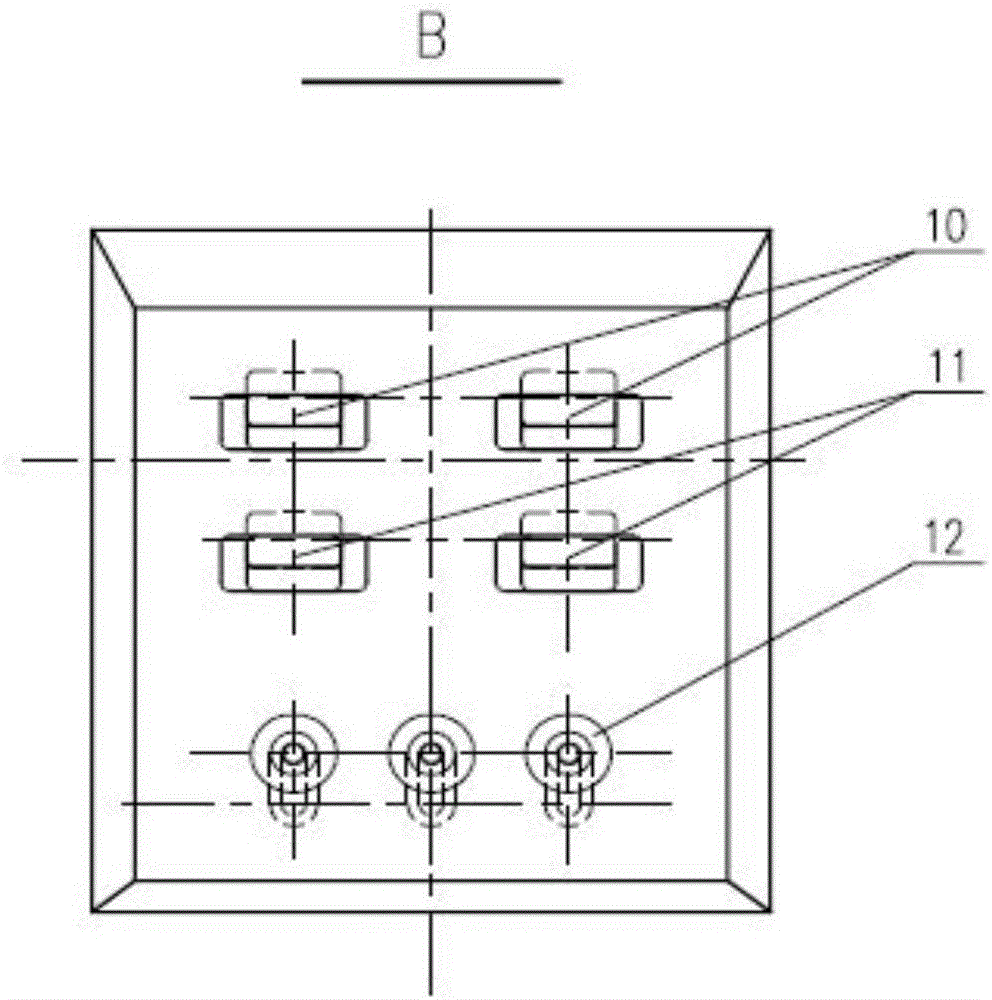

[0033] Such as Figure 1-4As shown, a multi-stage combustion energy-saving and environment-friendly burner in this embodiment includes a burner inspection cover plate 1, a combustion air inlet 2, a heat storage body 3, a heat insulating material 4, a refractory castable 5, and a large-eye baffle brick 6 , high temperature gas distribution chamber 8, natural gas nozzle 13, primary air swirl plate 14, anchor nail 15, primary air inlet 19, first connecting flange 20, natural gas inlet 21, grid plate 24, second connecting flange 26, Bolt connector 27 and burner installation positioning plate 28, said burner inspection cover plate 1 is fixed in the low-temperature gas distribution chamber 25 with bolt connector 27 through the second connecting flange 26, used for regenerator 3, big eye The installation or removal of the baffle brick 6 and the grid plate 24. The flue gas outlet of the above-mentioned combustion-supporting air inlet 2 adopts ordinary carbon steel pipe and round flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com