Gas machine tempering simulation experiment device and use method

A technology that simulates experimental devices and gas machines. It is used in measurement devices, engine testing, and mechanical component testing. It can solve problems such as pressure shock, inaccurate test data, and uncontrollable pressure peaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

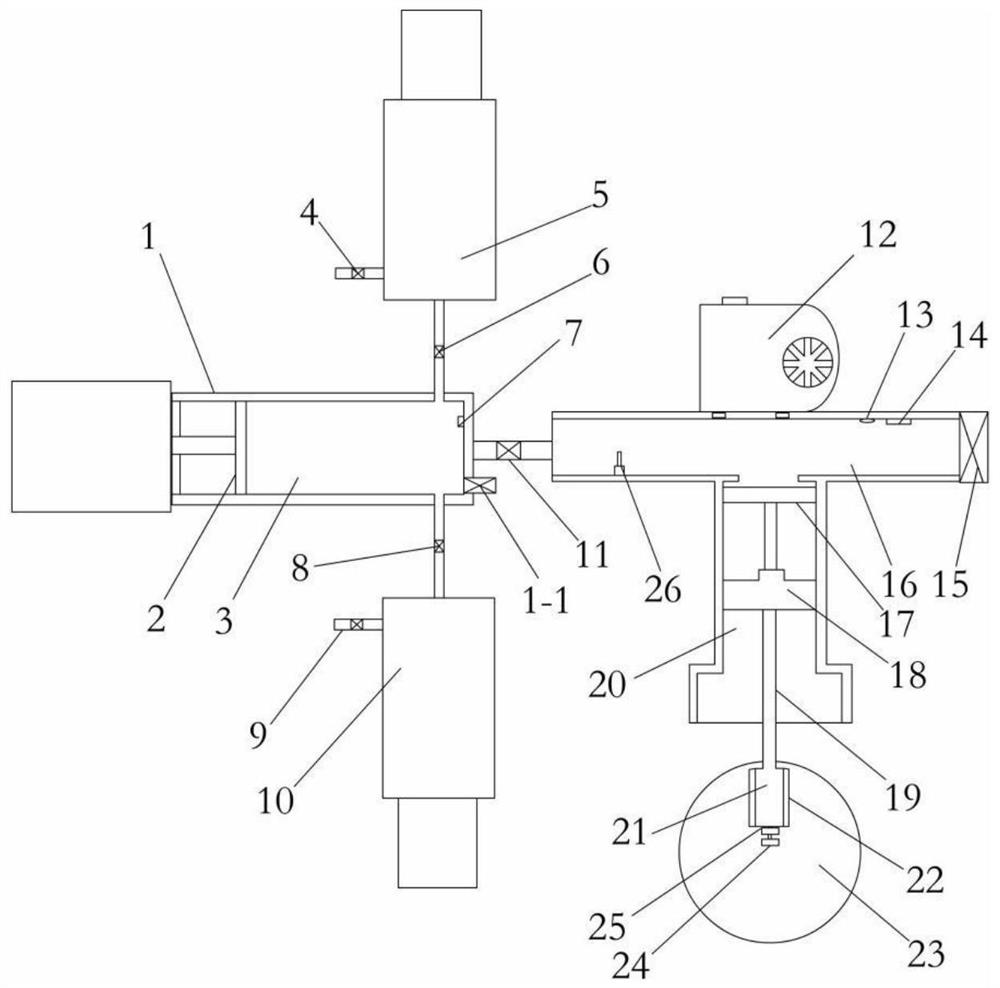

[0026] A gas machine tempering analog experimental device, including a tempering analog combustion tube 16, and the middle and lower portion of the backfire analog combustion tube 16 are vertically connected to the telescopic gas cylinder 20; the upper portion of the backfire simulated combustion tube 16 is connected to electronic The throttle sample 12 is distributed in the inside of the ignition 26, the first air pressure sensor 14, and the temperature sensor 13; the left end of the backfire simulation combustion tube 16 connects the constant voltage mixing gas supply assembly. The right end of the backfire simulation combustion tube 16 is also connected to a safe exhaust valve 15 for an open protection device to prevent explosion when the air pressure is too large or the equipment. When the test is tested, the electronic throttle sample 12 opening degree is 3 to 5 degrees, and the outside is in communication with the atmosphere.

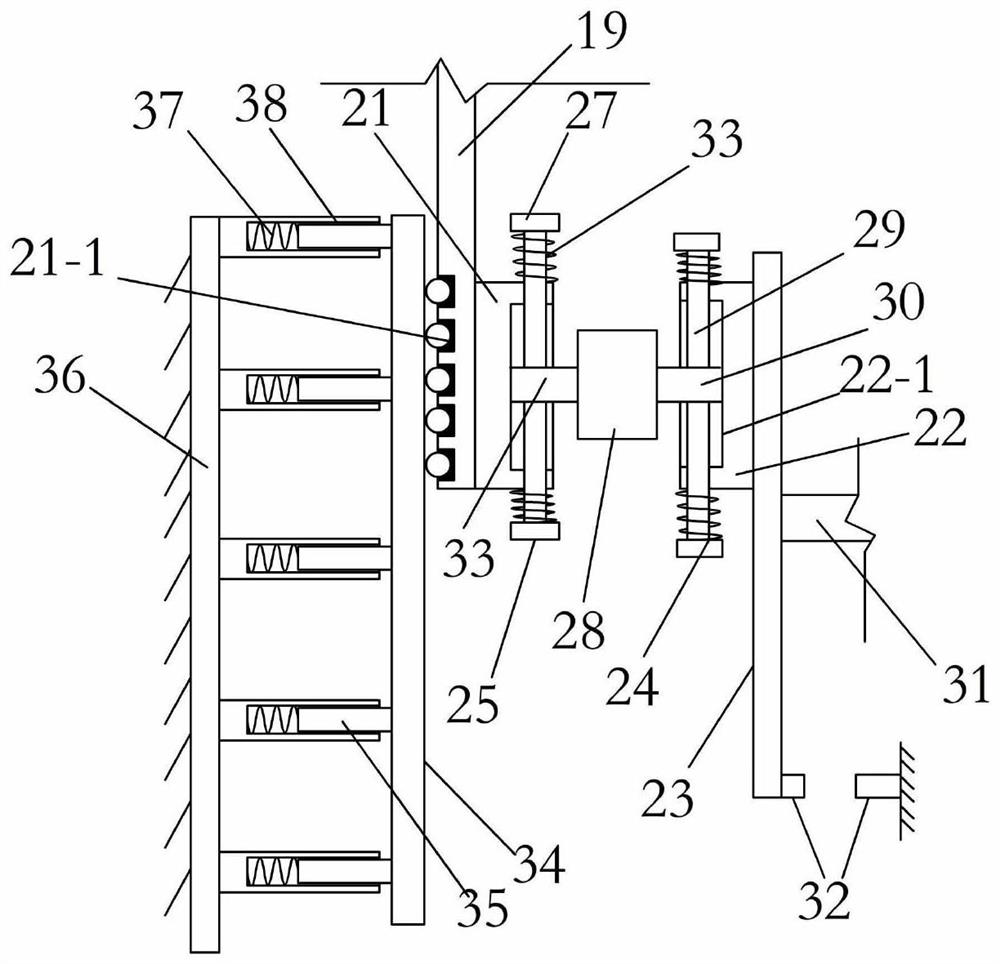

[0027] The compensated telescopic gas cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com