Production method of cement clinker by calcination with oxygen-rich reinforced lignite

A cement clinker and production method technology, applied in clinker production, cement production, etc., can solve the problems of low flame temperature, low ignition point of lignite, insufficient combustion, etc., and achieve the effects of reducing system heat consumption and increasing flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

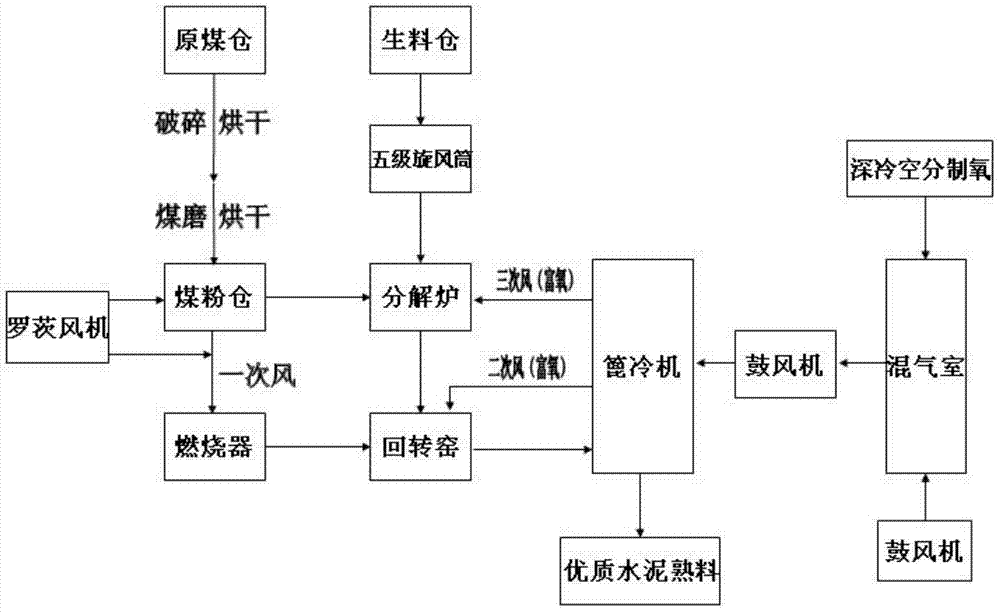

[0029] 1. First, the raw coal is crushed, hot-air dried, coal milled, and hot-air dried to make coal powder with a fineness of less than 80 μm. The sieve rate of 200-mesh square hole sieve is less than 10%, and the moisture content is controlled at 10%— Between 15%;

[0030] 2. Send the pulverized coal ground in step 1 into the pulverized coal bin, and send the pulverized coal into the rotary kiln and the calciner for combustion through the Roots blower respectively;

[0031] 3. Mix industrial pure oxygen and air evenly in the gas mixing chamber to obtain oxygen-enriched gas, and the oxygen concentration in the oxygen-enriched gas reaches 36%. The oxygen-enriched gas enters the grate cooler through the blower to exchange heat, and the oxygen-enriched gas after heat exchange enters the rotary kiln and the calciner respectively as secondary air and tertiary air;

[0032] 4. The present invention uses a four-channel burner as the combustion equipment. The wind blown from the in...

Embodiment 2

[0037] 1. First, the raw coal is crushed, hot-air dried, coal milled, and hot-air dried to make coal powder with a fineness of less than 80 μm. The sieve rate of 200-mesh square hole sieve is less than 10%, and the moisture content is controlled at 10%— Between 15%;

[0038] 2. Send the pulverized coal ground in step 1 into the pulverized coal bin, and send the pulverized coal into the rotary kiln and the calciner for combustion through the Roots blower respectively;

[0039]3. Mix industrial pure oxygen and air evenly in the gas mixing chamber to obtain oxygen-enriched gas, and the oxygen concentration in the oxygen-enriched gas reaches 40%. The oxygen-enriched gas enters the grate cooler through the blower to exchange heat, and the oxygen-enriched gas after heat exchange enters the rotary kiln and the calciner respectively as secondary air and tertiary air;

[0040] 4. The present invention uses a four-channel burner as the combustion equipment. The wind blown from the ins...

Embodiment 3

[0045] 1. First, the raw coal is crushed, hot-air dried, coal milled, and hot-air dried to make coal powder with a fineness of less than 80 μm. The sieve rate of 200-mesh square hole sieve is less than 10%, and the moisture content is controlled at 10%— Between 15%;

[0046] 2. Send the pulverized coal ground in step 1 into the pulverized coal bin, and send the pulverized coal into the rotary kiln and the calciner for combustion through the Roots blower respectively;

[0047] 3. Mix industrial pure oxygen and air evenly in the gas mixing chamber to obtain oxygen-enriched gas, and the oxygen concentration in the oxygen-enriched gas reaches 50%. The oxygen-enriched gas enters the grate cooler through the blower to exchange heat, and the oxygen-enriched gas after heat exchange enters the rotary kiln and the calciner respectively as secondary air and tertiary air;

[0048] 4. The present invention uses a four-channel burner as the combustion equipment. The wind blown from the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com