High-temperature-resistant anti-radiation inorganic coating construction method

A technology of inorganic coating and construction method, which is applied in the construction field of high-temperature resistant and anti-radiation inorganic coating, and can solve problems such as lining collapse, cracking, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

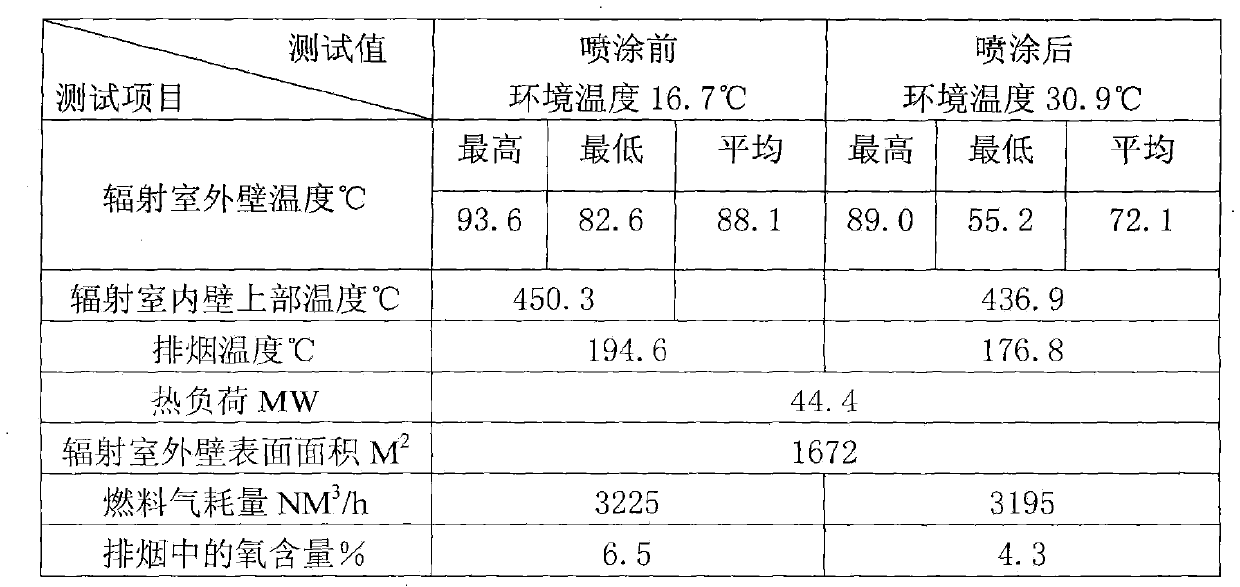

Examples

Embodiment 1

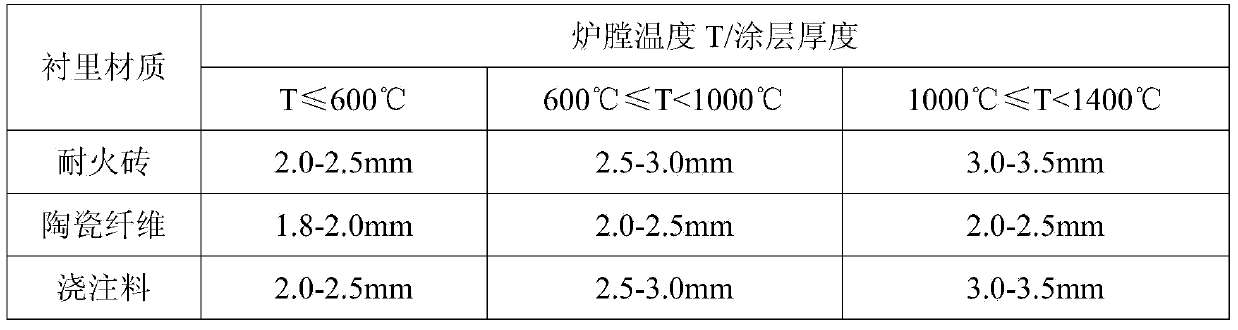

[0051] Working surface conditions: heating furnace temperature 800 ℃, lining with light castables.

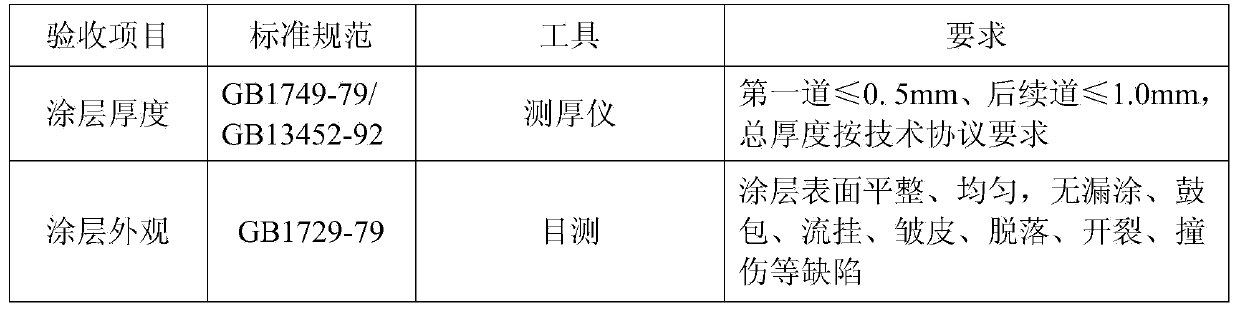

[0052] Preparation of construction machinery and testing instruments

[0053] equipment quantity Remark Air compressor 2 units supply high pressure air Sprayer 4 units mixer 2 units Stir the paint evenly Four in one gas detector 1 set Harmful gas detection in the furnace Coating Thickness Gauge 2 units Coating Thickness Inspection

[0054] plastic film some wrapped, covered

[0055] Scaffolding at the construction interface: meet the safety construction requirements and be accepted by professionals.

[0056]Protection of facilities in the heating furnace: use plastic film to wrap the furnace tube from top to bottom, cover the burner and other facilities, and protect the facilities in the furnace from damage and pollution during the coating forming process.

[0057] Lining inspection and surface c...

Embodiment 2

[0071] Working surface conditions: the temperature of the heating furnace is 1100°C, and the lining is ceramic fiber modules.

[0072] Preparation of construction machinery and testing instruments

[0073] equipment quantity Remark Air compressor 2 units supply high pressure air Sprayer 4 units mixer 2 units Stir the paint evenly Four in one gas detector 1 set Harmful gas detection in the furnace Coating Thickness Gauge 2 units Coating Thickness Inspection plastic film some wrapped, covered

[0074] The erection of scaffolding at the construction interface meets the safety construction requirements and has been checked and accepted by professionals.

[0075] Protection of facilities in the heating furnace: use plastic film to wrap the furnace tube from top to bottom, cover the burner and other facilities, and protect the facilities in the furnace from damage and pollution during the coating forming process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com