Inward convex spoiling tube and manufacture method thereof

A spoiler tube and wall tube technology, which is applied in the field of large-scale ethylene industrialized complete sets of equipment, can solve the problems of complex structure of heat transfer furnace tubes, cumbersome production, high cost, etc., and achieve good radiation heat transfer effect, low production cost, and low calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

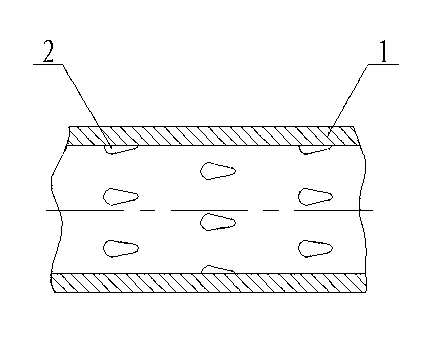

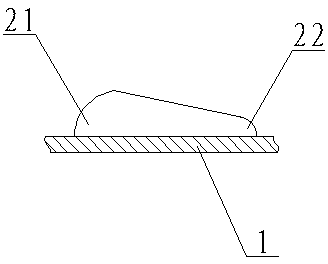

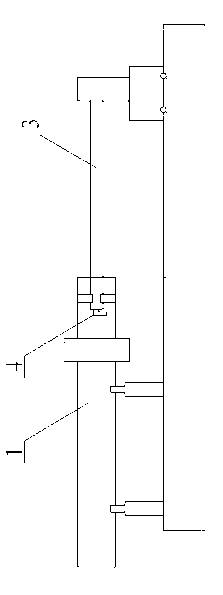

[0020] figure 1 , 2 As shown, a kind of inner convex spoiler includes a smooth wall tube 1 and an inner convex factor 2, and the inner hole of the smooth wall tube 1 is provided with more than one circle of inner convex factor groups along the axial direction of the smooth wall tube, and each circle of inner convex factor groups It is composed of a plurality of inner convex factors 2, and the two closest inner convex factors in the circumferential direction of the smooth-walled tube in two adjacent inner convex factor groups form a helix centered on the axis of the smooth-walled tube; the inner convex factor group consists of A plurality of convex factors are uniformly distributed on the same radial circumference of the smooth-walled tube; figure 2 The inner convex factor is in the structure of large and small along the axial direction of the smooth-walled tube. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com