Low-moisture low-variable serial saturation tower thermal CO transformation technology

An isothermal shift and water-gas technology, which is applied in the field of CO shift technology, can solve the problems of short catalyst life, long shift process, and easy overheating of the shift furnace in medium-temperature shift furnaces, and achieve long service life, simplified process flow, and low operating temperature. low effect

Active Publication Date: 2013-01-23

CHINA PETROCHEMICAL CORP +2

View PDF11 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical problem to be solved by the present invention is to provide an isothermal CO conversion process of low water-gas ratio and low variable series saturated towers in order to solve the problem of long CO conversion process of existing low water-gas ratio series sat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

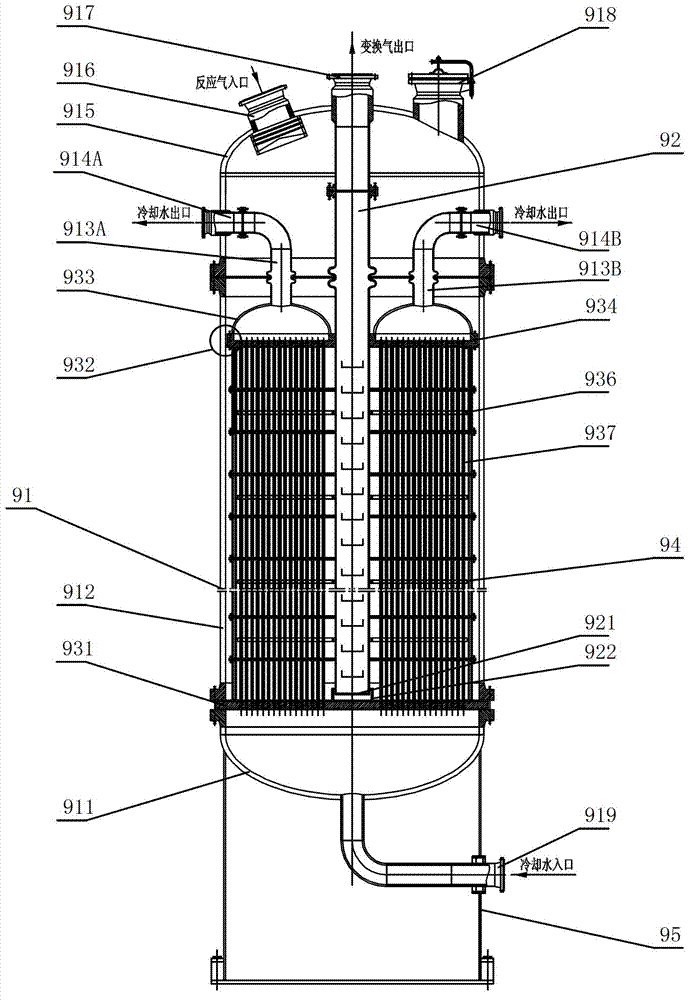

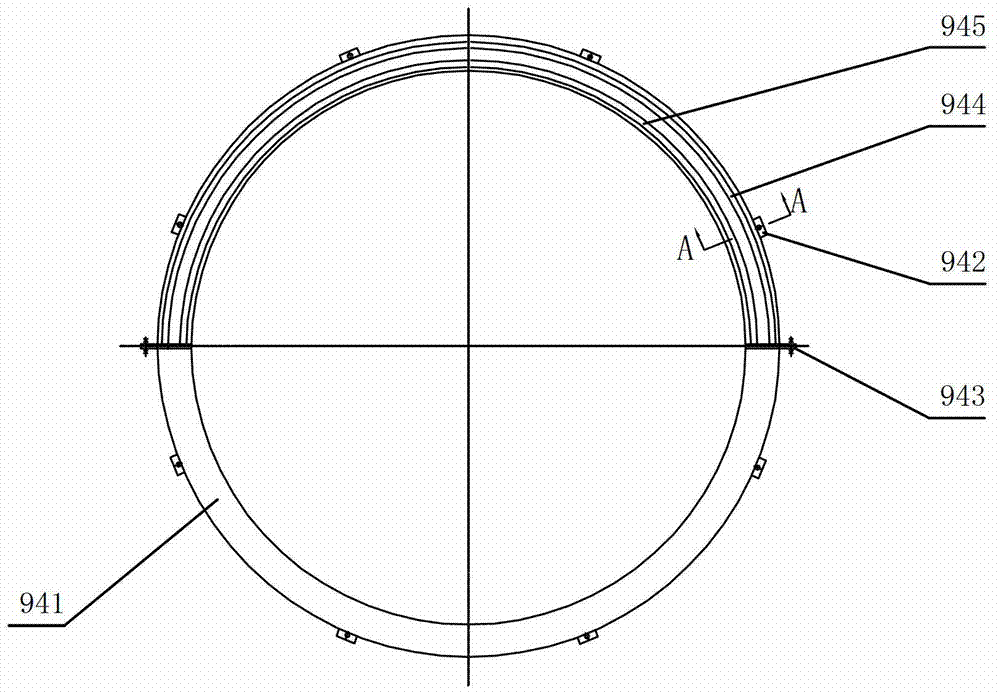

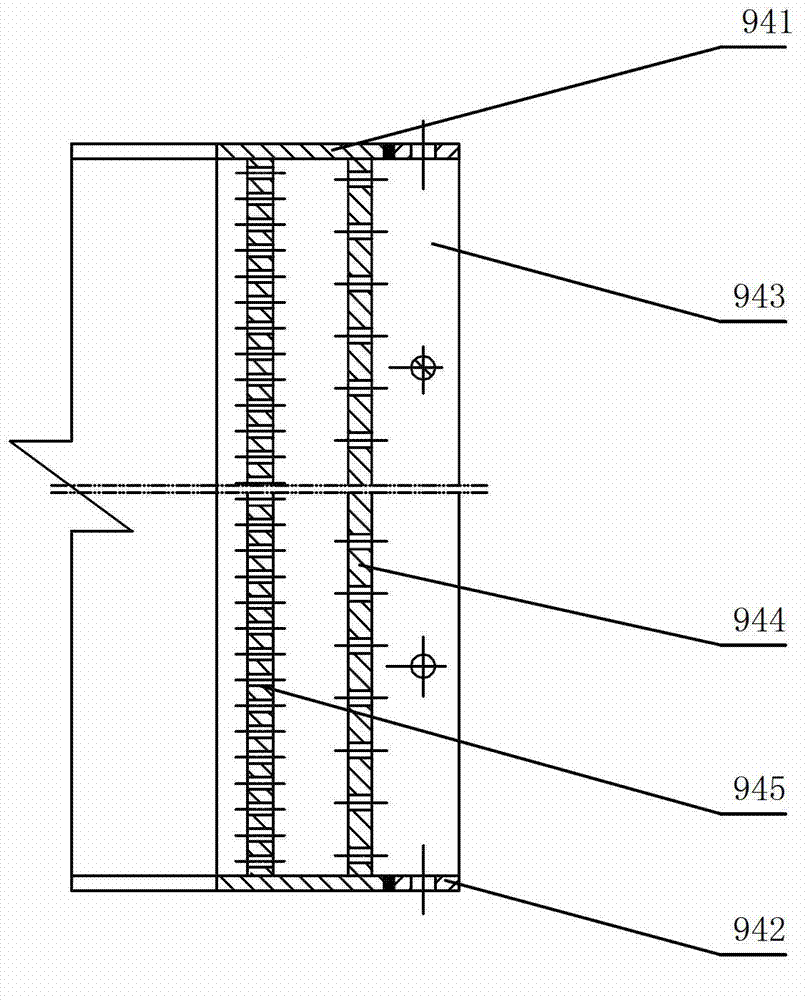

The invention relates to low-moisture low-variable serial saturation tower thermal CO transformation technology, which comprises the following steps: after processing gas-liquid separation, heat exchange and detoxification to crude gas, feeding the crude gas into a pre-transformation furnace to process initial transformation reaction; controlling the mol ratio of crude gas water/dry gas which enters the pre-transformation furnace within 0.19-0.23, and controlling the temperature thereof within 200-220 degrees centigrade; feeding pre-transformed mixing gas from a crude pre-heater into a saturation tower and contact with technical circular water of a hot water tower reversely so as to transmit heat and quality; increasing humidity and temperature of the pre-transformed mixing gas, feeding into the pre-transformed mixing gas into an isothermal transformation furnace so as to process depth transformation; exchanging gas and heat of the isothermal exchange gas of the isothermal transformation furnace so as to feed into the hot water tower to transmit the heat and quality; and recycling low-order heat energy. Compared with the prior art, the isothermal transformation furnace substitutes at least two grades of heat isolating transformation furnaces; the number of transformation furnaces is reduced; equipment investment and catalyst cost are saved; in addition, a transformation procedure is short, resistance is small, energy consumption is low and operation is stable.

Description

technical field [0001] The invention relates to a CO conversion process, in particular to an isothermal CO conversion process for a low-moisture, low-variation series saturation tower. Background technique [0002] In recent years, my country's coal chemical industry has entered a stage of rapid development due to the increasingly tense petroleum resources. At the end of the last century and the beginning of this century, my country successively introduced more than ten sets of Shell's pulverized coal gasification technology to produce syngas. Shell's coal gasification technology has low requirements on coal quality, high effective components in syngas, low operating costs, convenient start-up and parking, and is environmentally friendly. The raw syngas generated by this technology is cooled by a waste heat boiler. The dry basis volume content of CO in the crude syngas generated by this technology is as high as 60%, while the water vapor volume content is less than 20%. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10K3/04C10K3/02C10K1/00C01B3/16

Inventor 许仁春唐永超张玮涂林

Owner CHINA PETROCHEMICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com