Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

A sulfur-resistant conversion and split-flow technology, which is applied in the chemical industry, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the problems of overheating of the by-product steam of the conversion, large temperature rise of the adiabatic conversion furnace, and excessive steam-to-gas ratio. Achieve the effect of adding less steam, producing the most waste water, and improving the filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

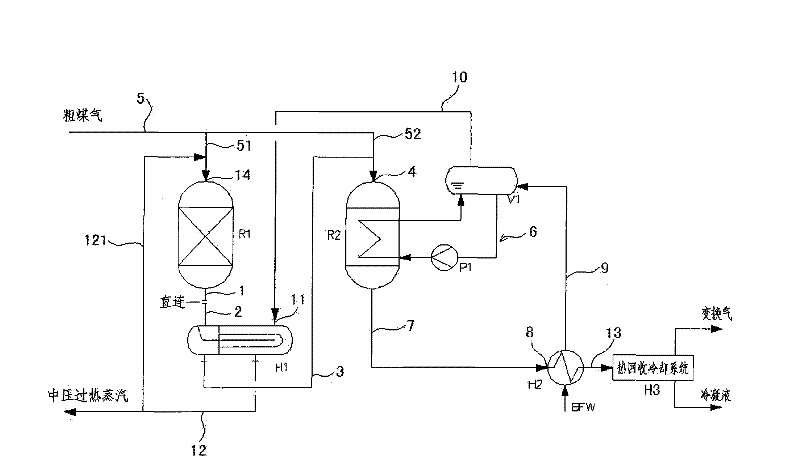

[0047] see figure 1 , figure 1 The split-flow isothermal sulfur-tolerant shift equipment shown is suitable for gas shift with high CO content.

[0048]The split-type isothermal sulfur-resistant shift equipment includes the first shift reactor R1, the second shift reactor R2, the steam superheater H1, the steam drum V1, the boiler feed water preheater H2 and the heat recovery cooling system H3, the first shift reactor R1 is an axial type adiabatic shift reactor or an axial radial type adiabatic shift reactor. The second shift reactor is one of vertical shell-and-tube type, vertical cold-tube type, vertical plate-type, horizontal shell-and-tube type, horizontal cold-tube type, and horizontal plate-type isothermal shift reactor.

[0049] The first shift gas outlet pipe 1 of the first shift reactor R1 is directly connected to the first shift gas inlet pipe 2 of the steam superheater H1, and the first shift gas delivery pipe 3 of the steam superheater H1 is connected to the raw m...

Embodiment 2

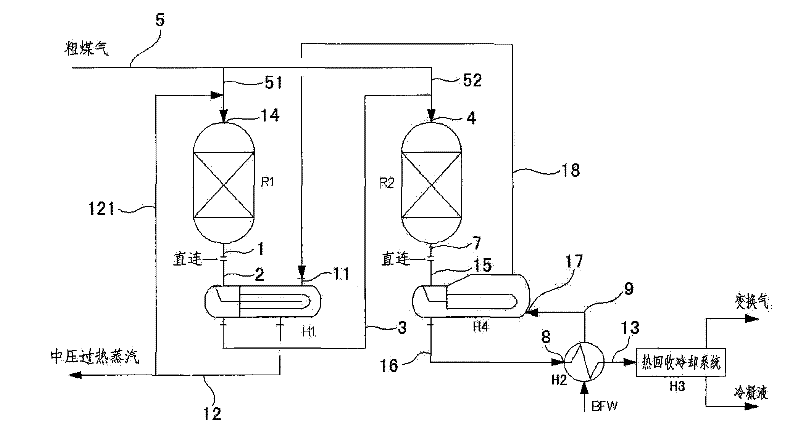

[0060] see figure 2 , figure 2 The split-flow isothermal sulfur-tolerant shift equipment shown is suitable for gas shift with high CO content.

[0061] The split flow isothermal sulfur-resistant shift equipment includes the first shift reactor R1, the second shift reactor R2, the steam superheater H1, the waste heat boiler H4, the boiler feed water preheater H2 and the heat recovery cooling system H3,

[0062] The first shift reactor R1 and the second shift reactor R2 are axial type adiabatic shift reactors or axial radial type adiabatic shift reactors.

[0063] The first shift gas outlet pipe 1 of the first shift reactor R1 is directly connected to the first shift gas inlet pipe 2 of the steam superheater H1, and the first shift gas delivery pipe 3 of the steam superheater H1 is connected to the raw material of the second shift reactor R2 The gas inlet 4 is connected, and the raw gas inlet 4 of the second shift reactor R2 is also connected to the raw gas 5 . The second s...

Embodiment 3

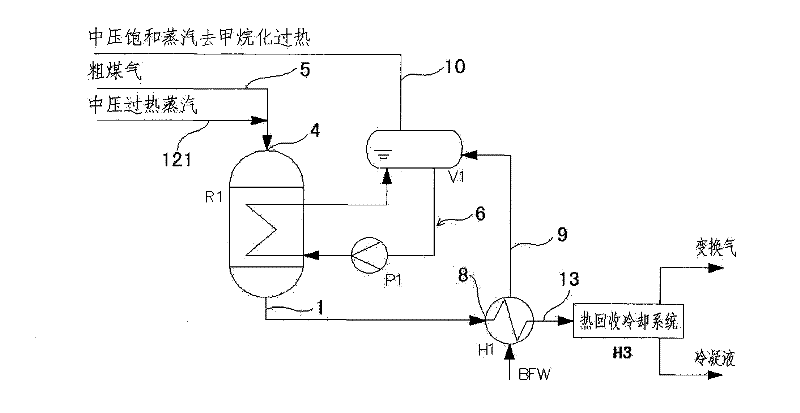

[0069] see image 3 , image 3 The split-flow isothermal sulfur-tolerant shift equipment shown is suitable for gas shift with medium and low CO content.

[0070] The split flow isothermal sulfur resistant shift equipment includes the first shift reactor R1, steam drum V1, boiler feed water preheater H2 and heat recovery cooling system H3,

[0071] The first shift reactor R1 is one of vertical shell-and-tube type, vertical cold-tube type, vertical plate-type, horizontal shell-and-tube type, horizontal cold-tube type, and horizontal plate-type isothermal shift reactor.

[0072] The first shifted gas outlet pipe 1 of the first shift reactor R1 is connected to the inlet 8 of the boiler feed water preheater H2, and the boiler feed water pipe 9 of the boiler feed water preheater H2 is connected to the steam drum V1 and delivered to the steam drum V1 Preheated boiler feed water; the first shift reactor R1 is connected to the steam drum V1 through a forced circulation heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com