Patents

Literature

195results about How to "Play the role of saving energy and reducing consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

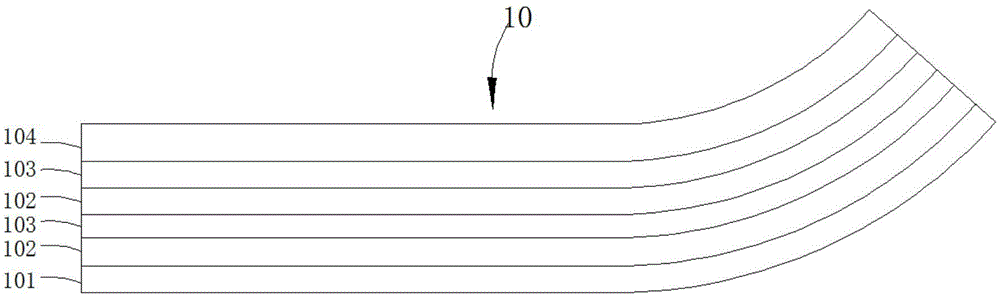

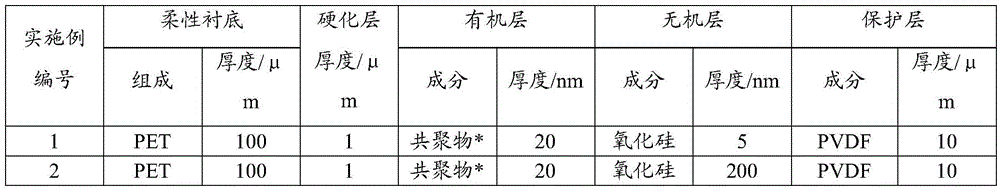

Flexible transparent barrier film and preparation method thereof

InactiveCN106711345ALess structural defectsHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceOptical thin film

The invention relates to an optical thin film, and particularly relates to a flexible transparent barrier film and a preparation method thereof, so as to solve the problems that low transmittance is likely to happen to a composite barrier film and barrier performance generated after rolling drops. The barrier film comprises a flexible substrate; a barrier layer is arranged on the flexible substrate; a protection layer is arranged on the barrier layer; the flexible substrate is a transparent thin film; the barrier layer comprises at least two organic layers and at least two inorganic layers; the organic layers and the inorganic layers are arranged alternately; and the flexible substrate is connected with the organic layers in the barrier layer. The flexible transparent barrier film has good transmittance, and the barrier performance is still excellent after multiple times of rolling.

Owner:NINGBO CHANGYANG TECH

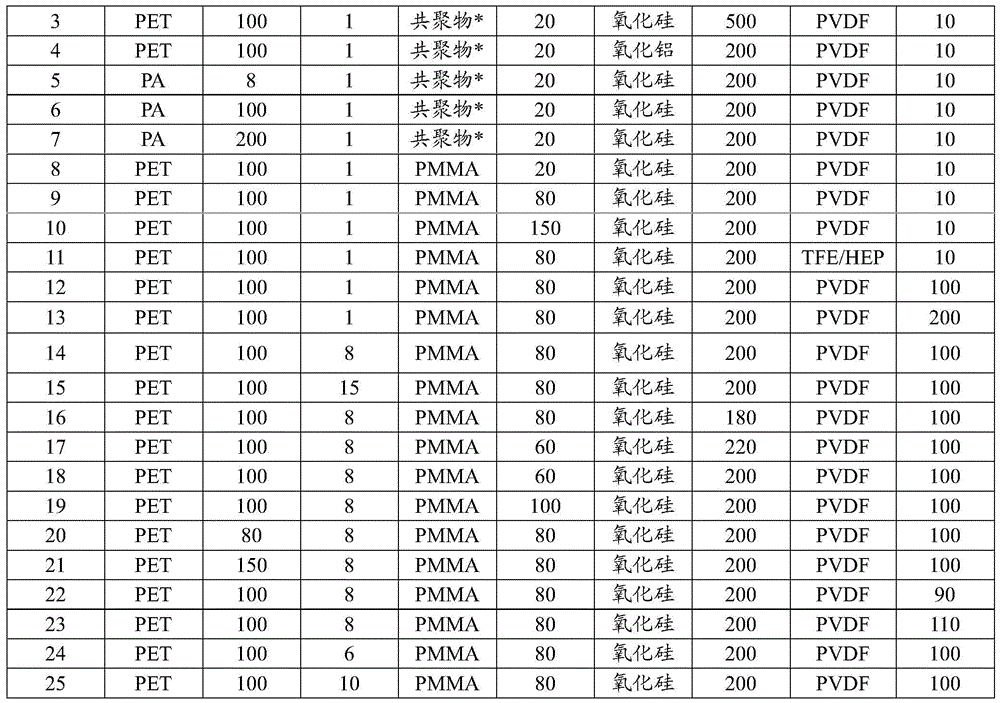

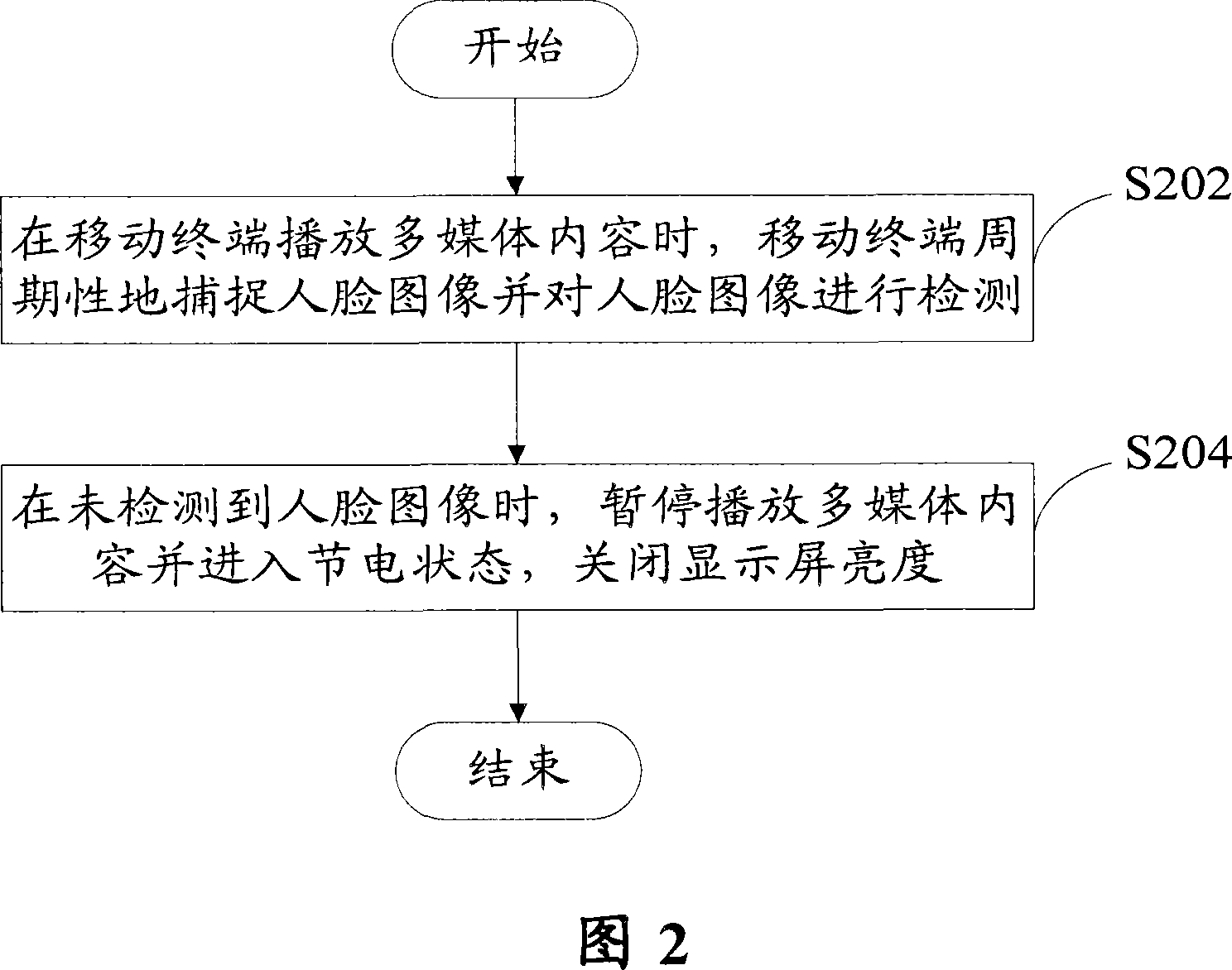

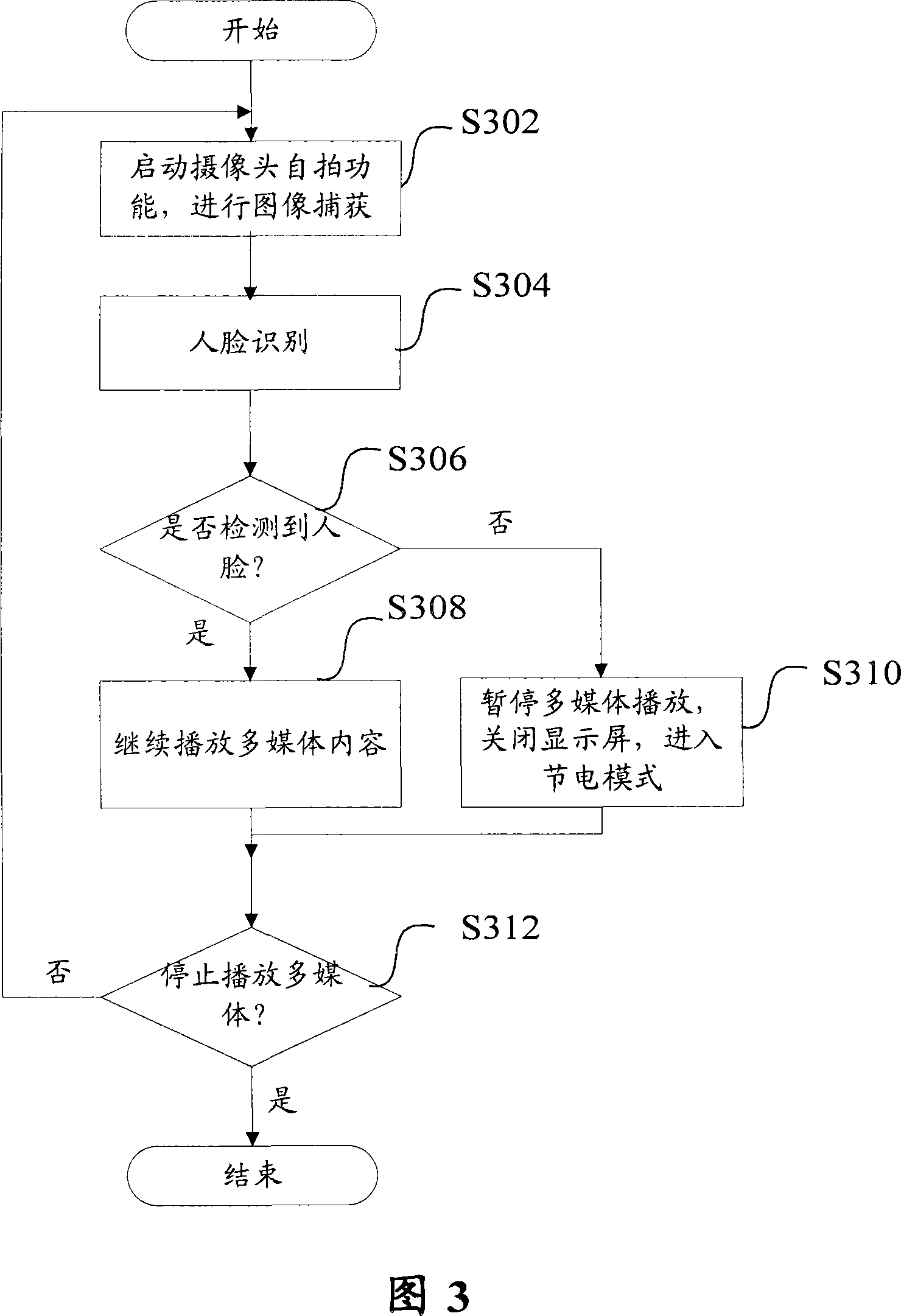

Mobile terminal and multimedium playing method therwith

InactiveCN101076170APlayback controlPlay the role of saving energy and reducing consumptionCurrent supply arrangementsCharacter and pattern recognitionFace detectionImage transfer

The mobile terminal comprises: an automatically shooting module used for periodically capturing the human face image when the mobile terminal plays multimedia content, and sending the captured human face image to the human face image detecting module; a human face detecting module used for indicating the multimedia playing module to play the multimedia content when the received image is a human face image, and indicating the multimedia playing module to pause the play of multimedia content and to make the mobile terminal enter into energy-saving mode; and a multimedia playing module used for playing the multimedia content according to the indication from the human face detecting module.

Owner:ZTE CORP

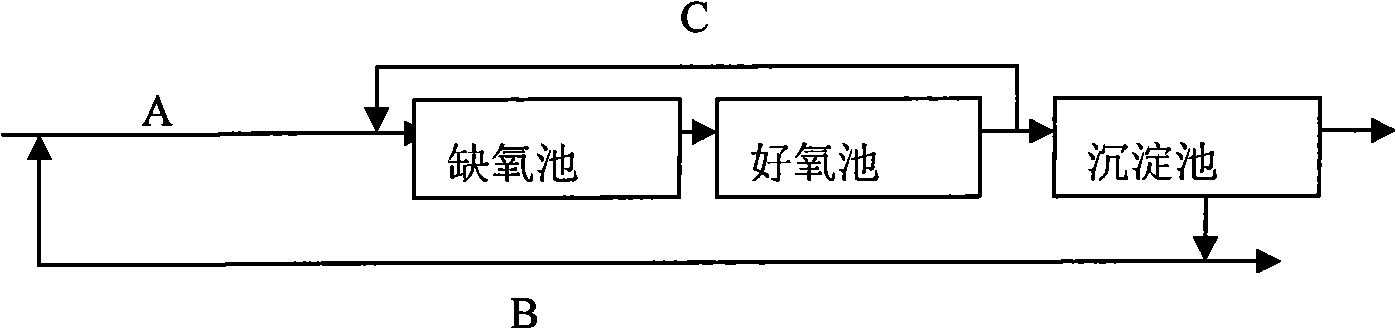

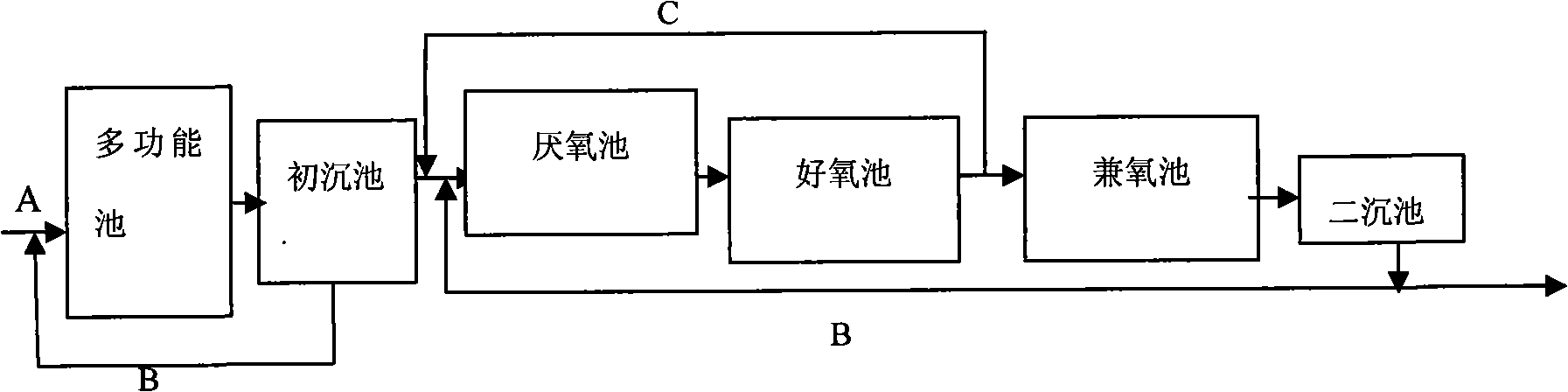

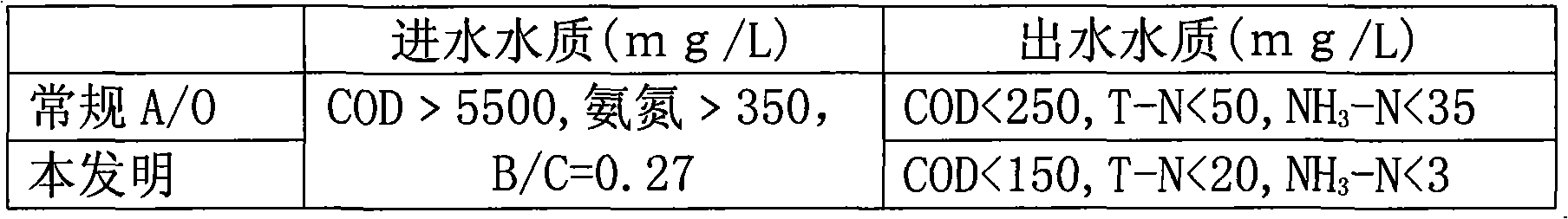

Method for removing total nitrogen by using microorganism

ActiveCN101259977ANo biochemical reactionSimple processTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentMicroorganismIndustrial effluent

The invention relates to a method of removing total nitrogen in urban sewage and highly concentrated nitrogen industrial wastewater with microorganisms. Wastewater passes an anaerobic pool, an aerobic pool and a secondary sedimentation pool in sequence for two-stage biochemical treatment. The method is characterized in that the wastewater enters a multifunctional pond before entering the anaerobic pool, wherein the multifunctional pond is provided with an aeration pipe and a stirring device. When B / C of the wastewater treated is less than 0.3, the multifunctional pond runs in the stirring way; when B / C of the wastewater treated is more than or equal to 0.3, the multifunctional pond runs in the aeration way. Effluent in the aerobic pool passes a facultative tank before entering the secondary sedimentation pool. The method is simple in technology procedures, is suitable for inflow with different natures, reduces the construction cost, improves the treating ability and meanwhile plays a role in energy conservation and consumption reduction. The facultative tank arranged at the rear section carries out anti-digestion total nitrogen removal for the whole system and the total nitrogen removing effect is notably better than the prior A / O technology.

Owner:浙江汉蓝环境科技有限公司

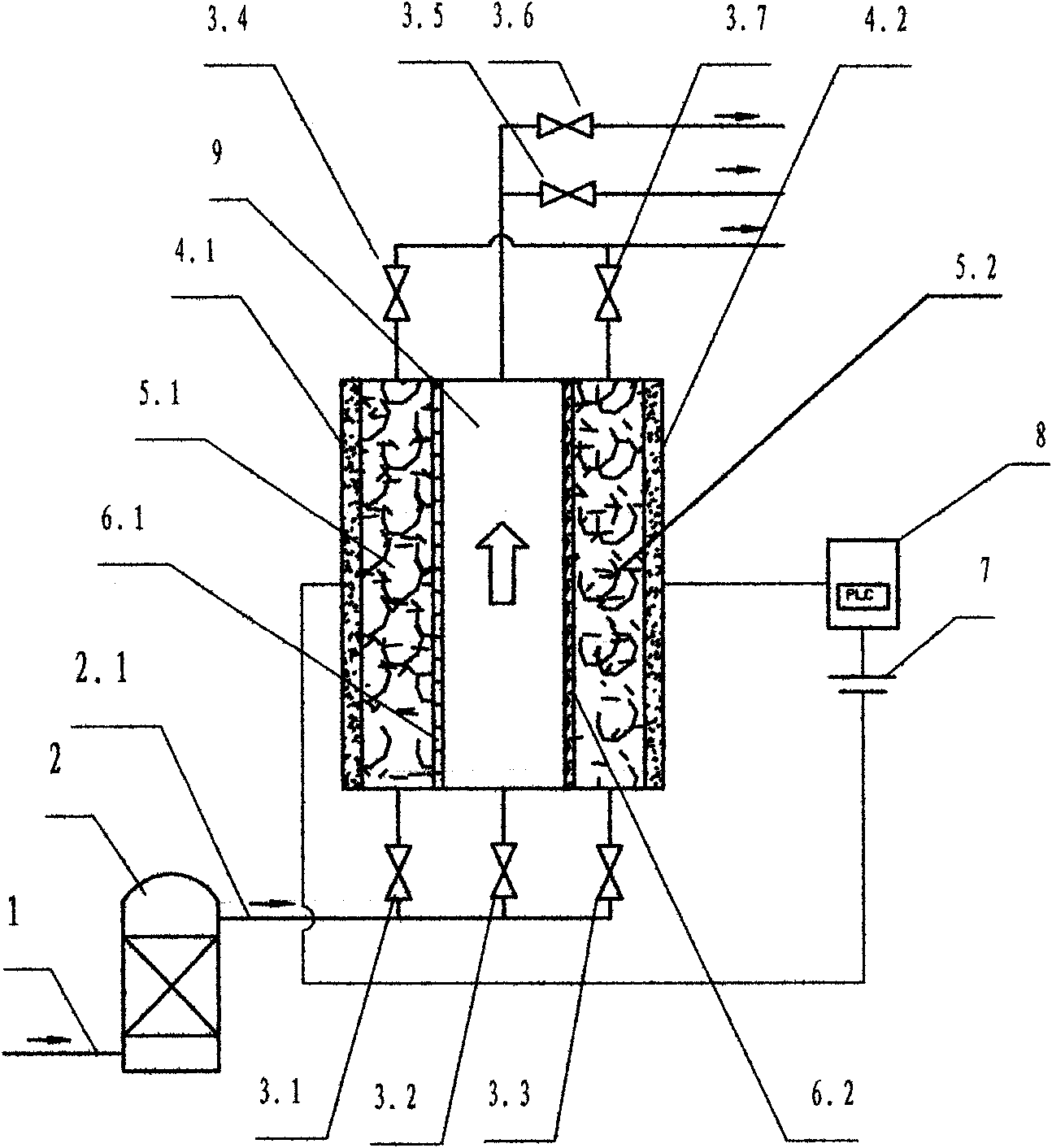

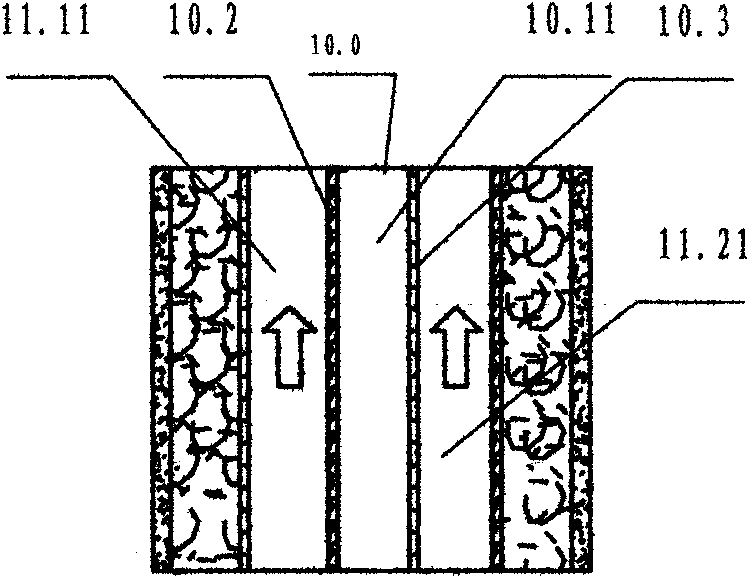

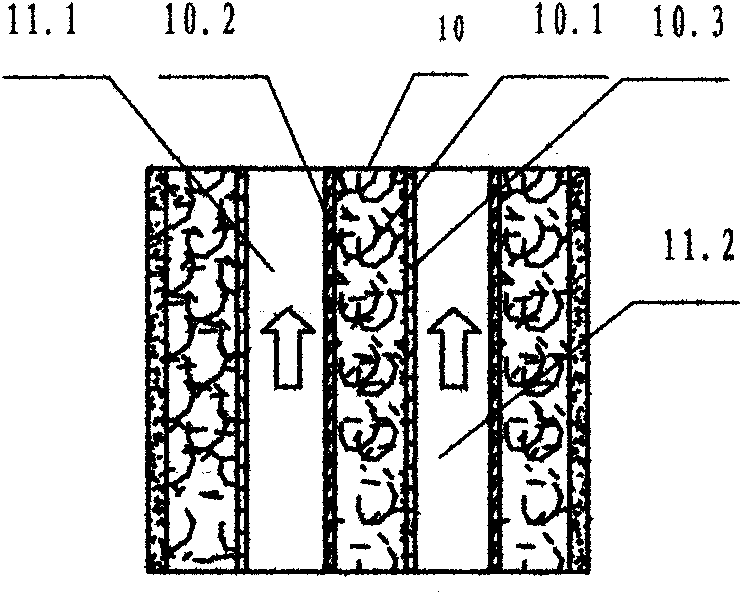

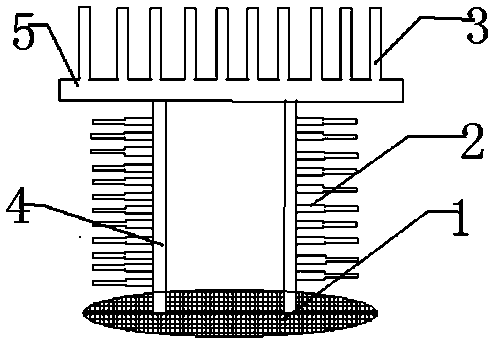

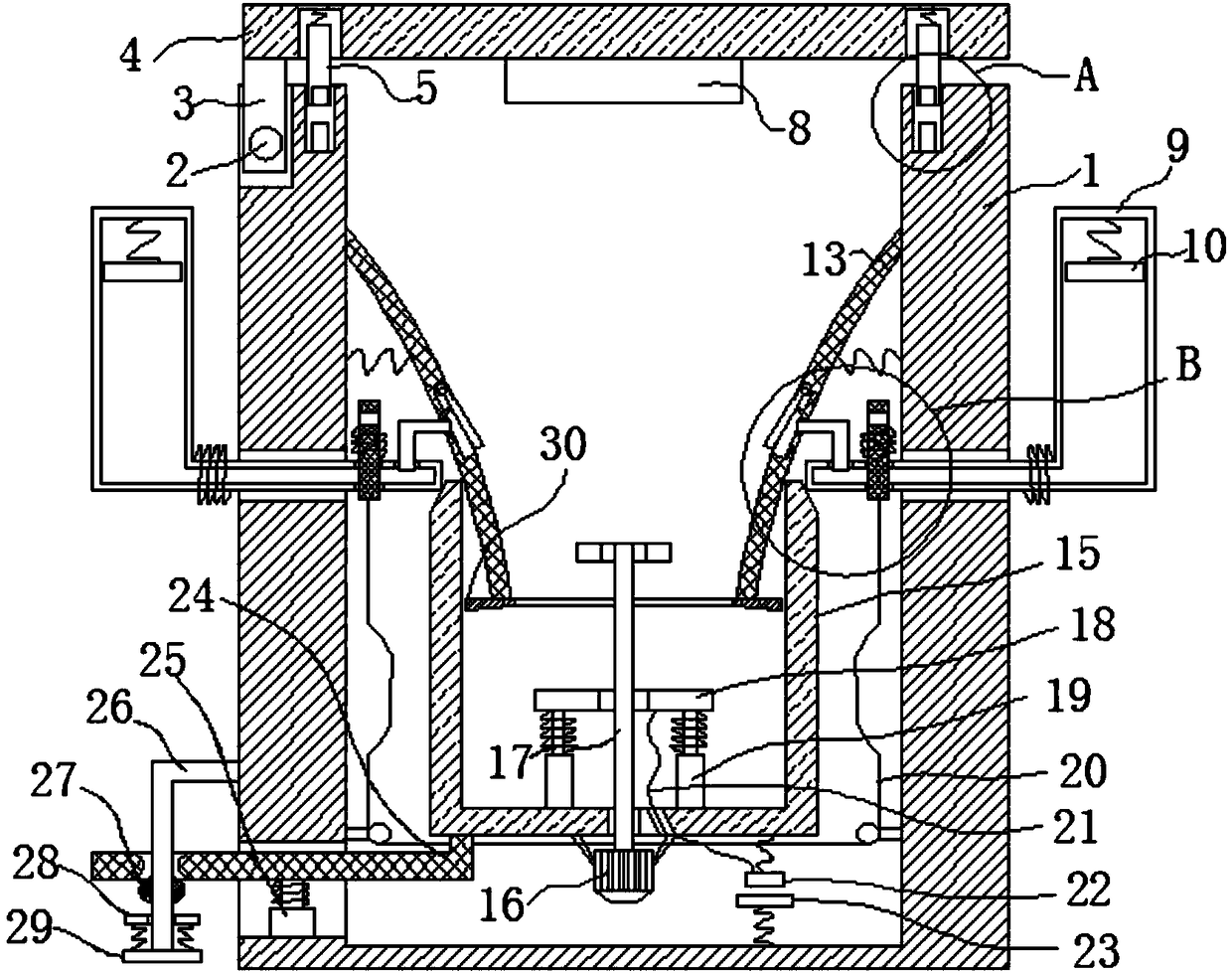

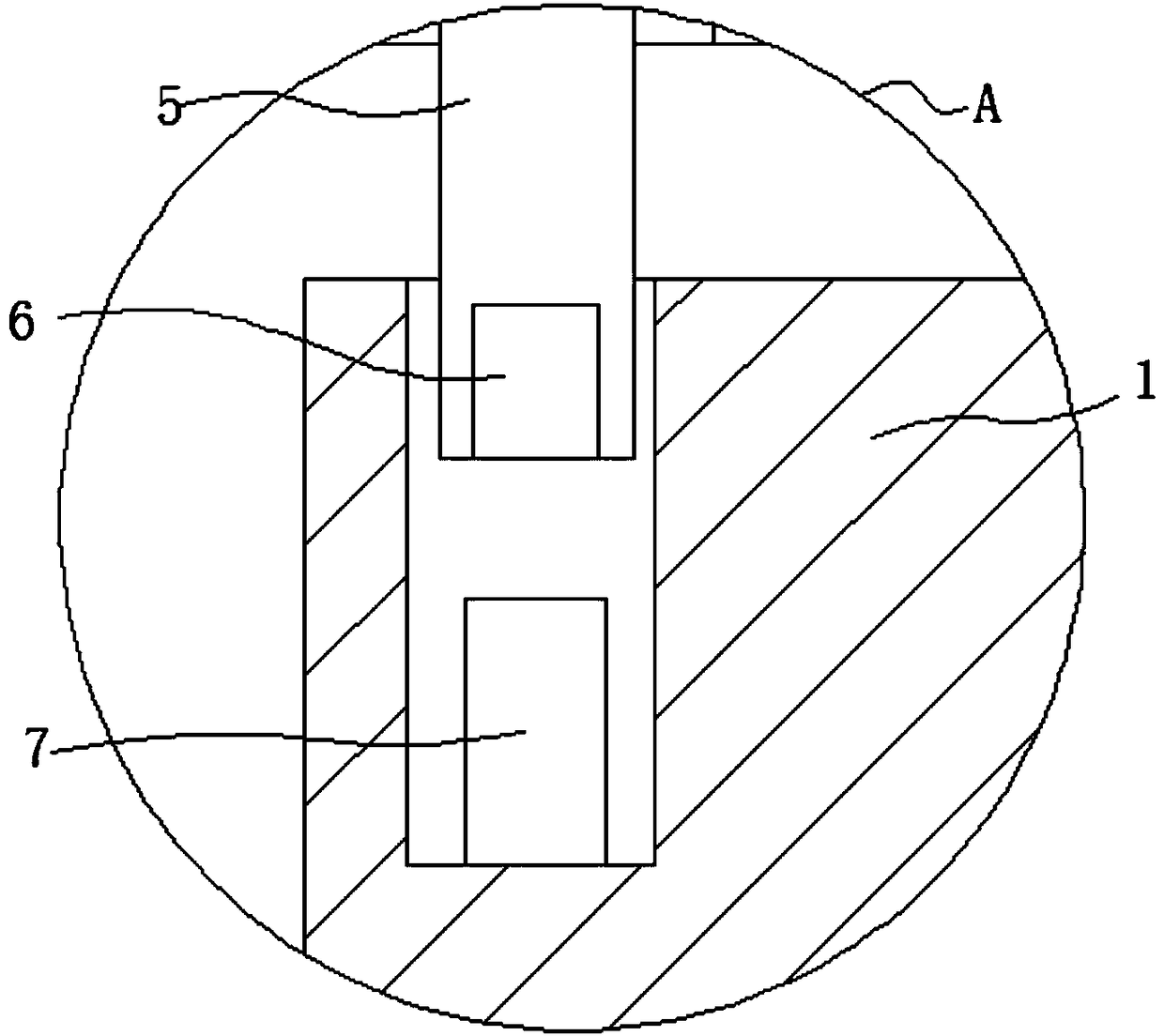

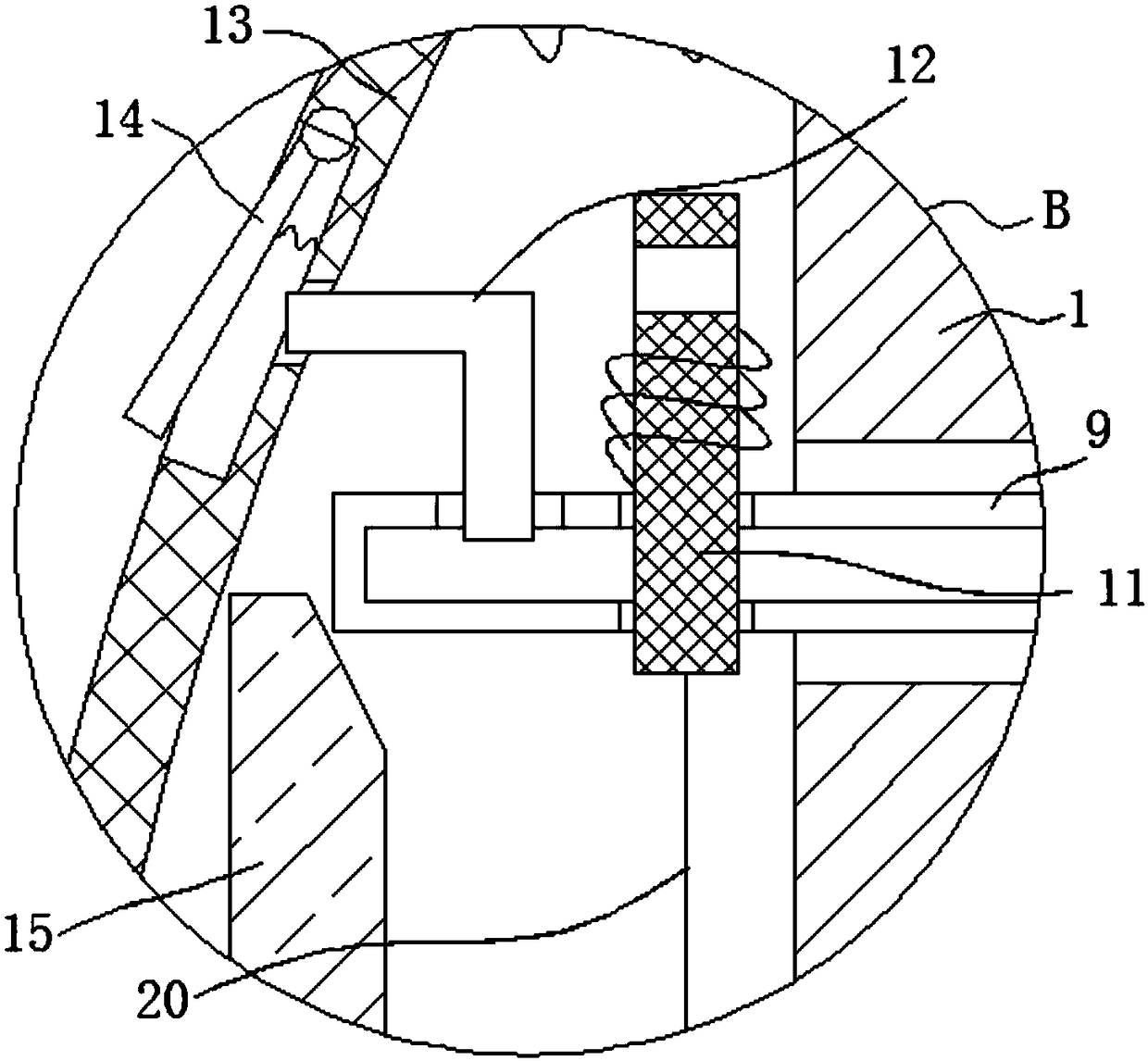

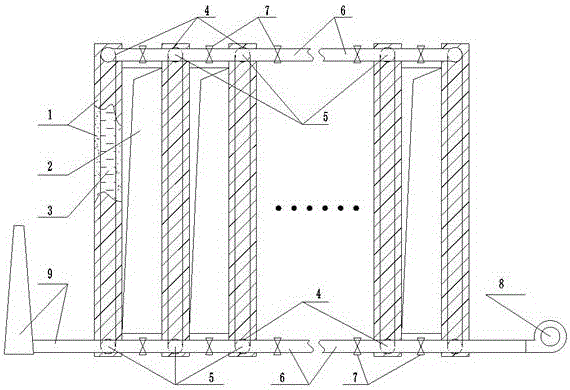

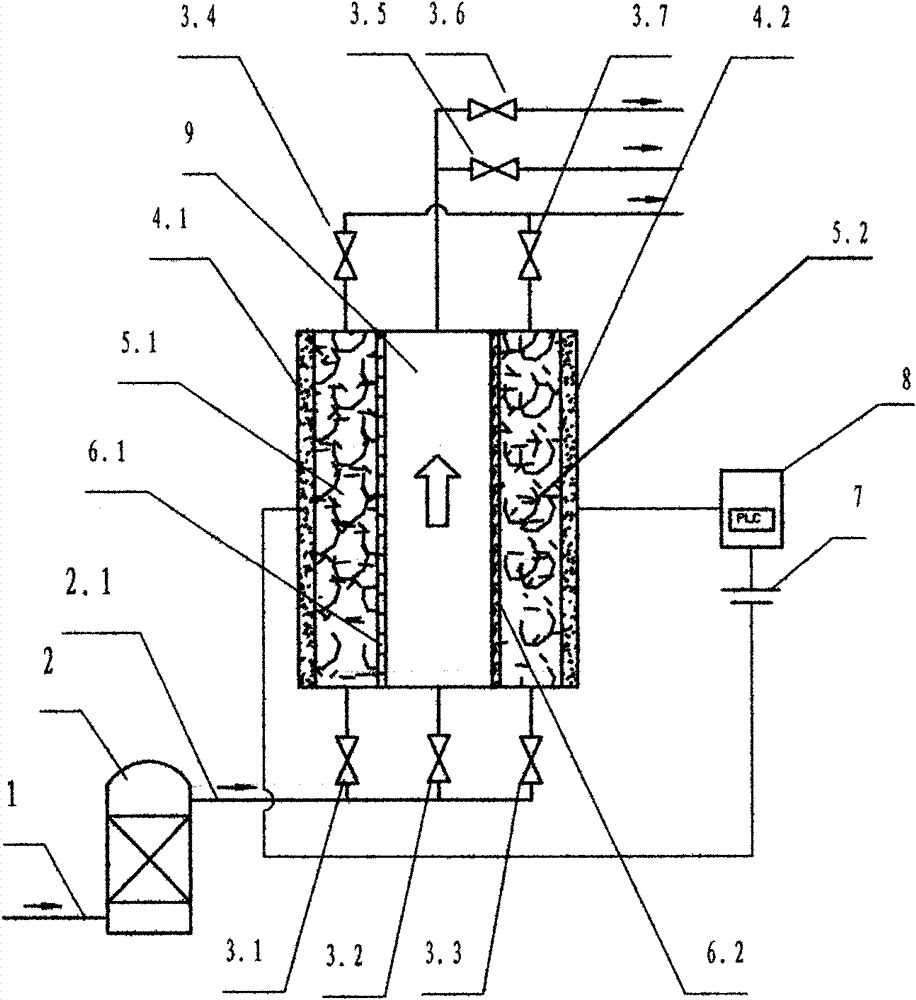

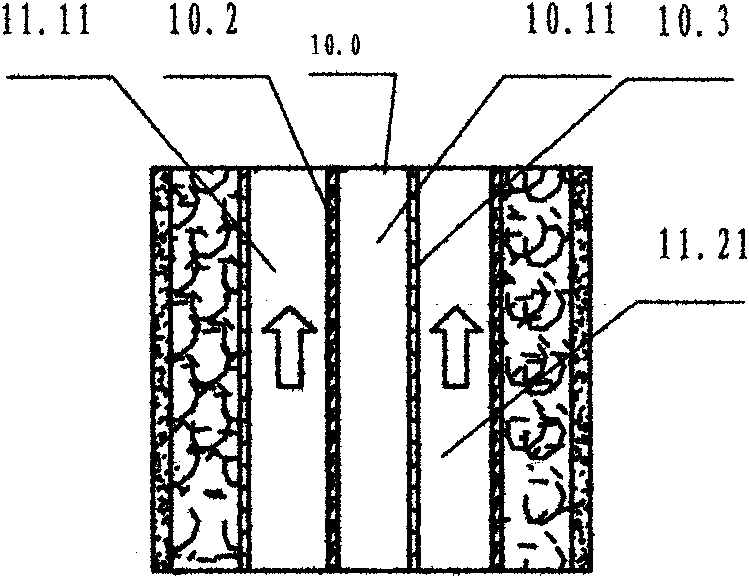

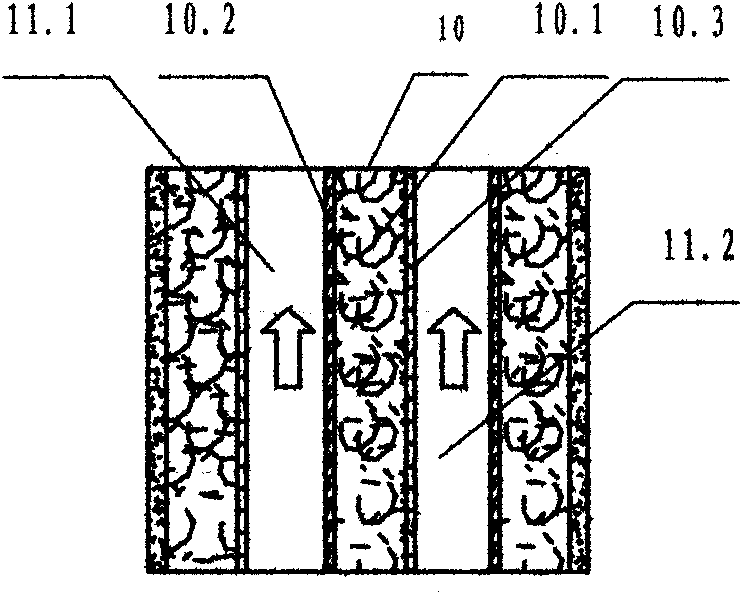

Device for separating electro-adsorption water-based solution ions and operation method thereof

InactiveCN102211803ALower performance requirementsEasy to separateDispersed particle separationWater/sewage treatment by ion-exchangeWater basedElectricity

The invention discloses a device for separating electro-adsorption water-based solution ions. The device is provided with a direct current power supply and one or more compound adsorption units, wherein each compound adsorption unit is provided with an electrode plate which is respectively connected with the direct current power supply to form a positive electrode plate and a negative electrode plate; an anion exchange resin layer and a cation exchange resin layer are respectively arranged on the inner side of the positive electrode plate and the inner side of the negative electrode plate; ananion exchange membrane and a cation exchange membrane are respectively arranged on the inner side of the anion exchange resin layer and the inner side of the cation exchange resin layer; a channel for accommodating a treated water-based solution is arranged between the anion exchange membrane and the cation exchange membrane; two ends of the channel are respectively communicated with an inlet pipe and an outlet pipe; the outlet pipe is respectively communicated with a concentrated liquid outlet pipe and a weak liquid outlet pipe through two electrical control valves; and the inlet pipe is communicated with an inlet pipe of a water-based solution to be treated through the electrical control valves. The device can be further provided with a PLC (Programmable Logic Controller) for automatically controlling. The device disclosed by the invention is suitable for desalting sea water and brackish water and separating ions in the water-based solutions as well as has the advantages of complete structure, flexibility in control, high efficiency, energy saving and environment friendliness.

Owner:苏润西

High-voltage electrostatic plasma oil smoke purifier for continuous woven belt dyeing machine

InactiveCN103285703AWith adsorption and purificationStrong degradation and purification functionCombination devicesHigh pressureHigh voltage

The invention discloses a high-voltage electrostatic plasma oil smoke purifier for a continuous woven belt dyeing machine. The oil smoke purifier comprises a smoke inlet, a smoke outlet, a front flow equalizing plate, a coarse filter screen, plasma electric fields, and a rear flow equalizing plate, the front flow equalizing plate, the coarse filter screen, the plasma electric fields and the rear flow equalizing plate are sequentially arranged between the smoke inlet and the smoke outlet of the oil smoke purifier, through holes are uniformly distributed on the flow equalizing plate, the coarse filter screen is composed of a plurality of metal filter screens, each of the plasma electric fields has a drawer-shaped shape, a plurality of electric field pole plates are uniformly distributed in each of the plasma electric fields, a high-frequency high-voltage electrostatic generator is installed in each of the plasma electric fields, and an oil collection plate is arranged on the inner wall of each of the plasma electric fields. The high-voltage electrostatic plasma oil smoke purifier for a continuous woven belt dyeing machine can adsorb and purify the oil smoke-containing gas, and has a very strong degradation purifying function to toxic and harmful exhaust gases comprising non-methane hydrocarbons in the oil smoke gas, and purifying heat can be continuously used for the cycle use, so the heat energy discharge is reduced, and energy saving and consumption reduction are realized.

Owner:任敏

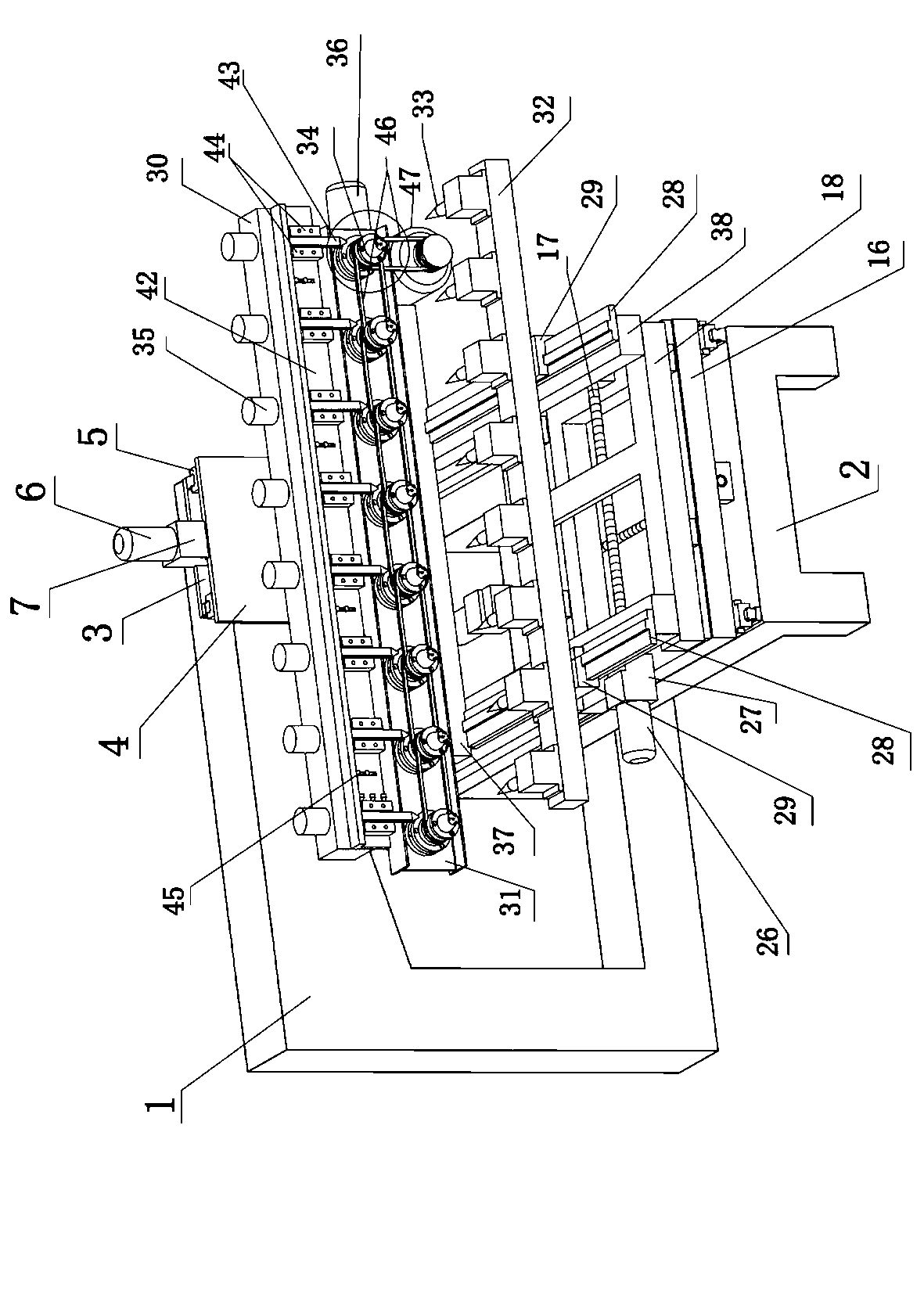

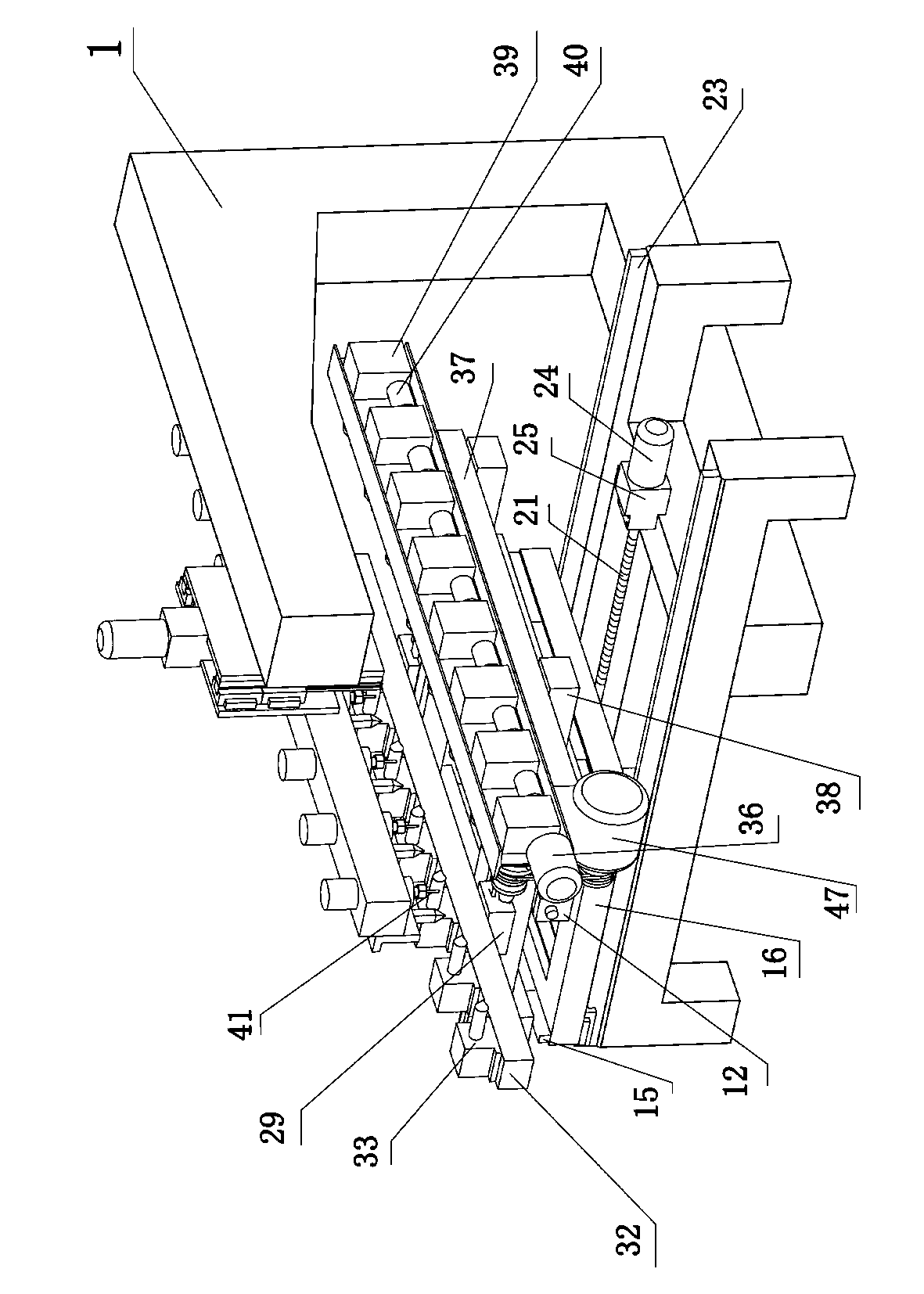

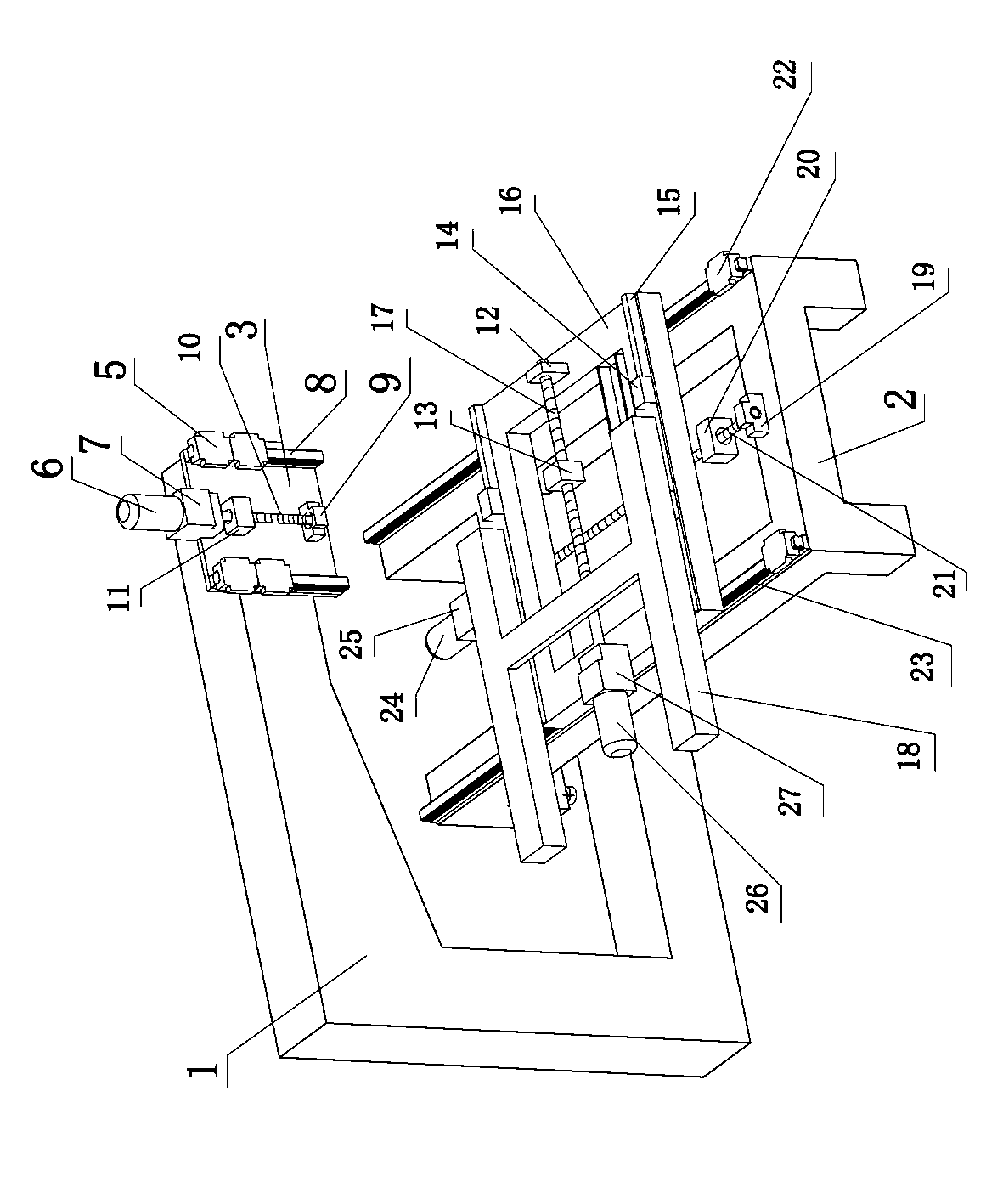

Numerical control wood working lathe and carving integrated machine

ActiveCN102699961AImprove machining accuracyReduce labor costsWood-turning machinesModel makingNumerical controlElectric machinery

The invention relates to a numerical control wood working lathe and carving integrated machine, and belongs to the technical field of wood-working machinery. The numerical control wood working lathe and carving integrated machine comprise a machine frame, a cross beam, a vertical driving mechanism, a cutter device, a horizontal driving mechanism, a vertical driving mechanism and a workpiece clamping driving mechanism. The cross beam is arranged on the upper part of the machine frame, and the vertical driving mechanism is arranged on the cross beam. The vertical driving mechanism comprises a first driving motor, a first motor fixing seat, a first block, a vertical guide rail, a first screw rod, a first connecting block, a vertical guide rail mounting board and a vertical planker. The cutter device comprises a cutter frame, a lathe tool frame, a carving cutter, a lathe tool, a lathe tool fixing plate, an adjusting screw and a motor. The vertical driving mechanism comprises a vertical worktable, a vertical guide rail, a fourth sliding block, a third driving motor, a third motor fixing seat, a third screw rod, a third connecting block and a third bearing supporting block. The horizontal driving mechanism comprises a horizontal worktable, a horizontal guide rail, a third sliding block, a second driving motor, a second motor fixing seat, a second screw rod, a second connecting block and a second bearing supporting block.

Owner:NANTONG OUKE CNC EQUIP CO LTD

Mercury-free synthetic method of chloroethylene

ActiveCN102911007ATackling Mercury PollutionPlay the role of saving energy and reducing consumptionPreparation by hydrogen halide split-offPreparation by halogen halide additionMercury pollutionEthane Dichloride

The invention relates to a mercury-free synthetic method of chloroethylene and relates to chloroethylene. The method includes at least one of hydrogen chloride or dichloroethane steam and acetylene are used as raw materials to be mixed to obtain mixed raw material gases; the mixed raw material gases are pre-heated and fed into a pipe reactor loaded with catalytic agents for reaction; the flowing speeds of the mixed raw material gases are controlled, and the pressure of a reaction system is adjusted so that the conversion rate of at least one of the mixed raw material gases reaches above 80%; andthe reaction product which is obtained from the third step is compressed, frozen, separated and rectified to obtain a chloroethylene monomer which meets polymerization requirements. According to the mercury-free synthetic method, the problem of mercury pollution in chloroethylene industry can be solved, and byproduct steam can be produced so that energy saving and consumption actions can be achieved. Simultaneously, by means of a pipe type cooling system, hot spot temperatures of a catalysis bed can be controlled in a smaller range so that long-term sable work of the catalytic agent is facilitated. The mercury-free synthetic method is capable of achieving comprehensive utilization of energy.

Owner:ZHONGKE YIGONG SHANGHAI CHEM TECH CO LTD

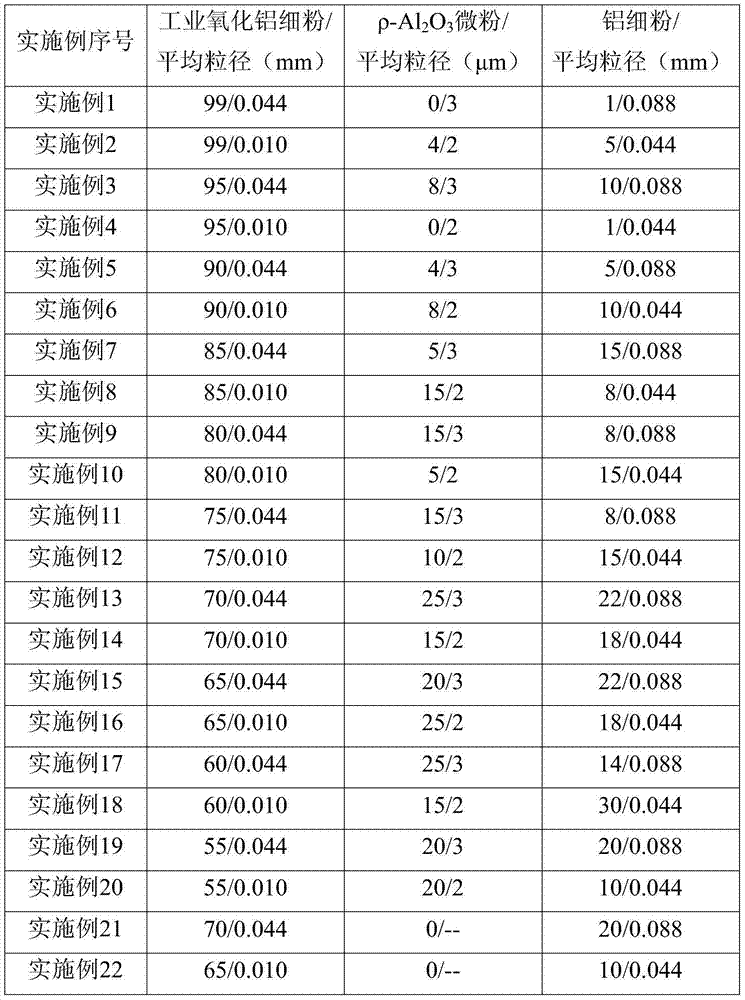

Light weight microporous corundum aggregate and preparation method thereof

The invention discloses light weight microporous corundum aggregate and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing components of raw materials and balling, wherein the balling water addition is 5-30%; and then, insulating for 0.5-6 hours at 1600-1950 DEG C to obtain the light weight microporous corundum aggregate. The raw materials comprise the following components in parts by weight: 55-99 parts of industrial aluminum oxide fine powder, 0-30 parts of p-Al2O3 micropowder and 1-20% of aluminum micropowder. The light weight microporous corundum aggregate provided by the invention is simple in preparation method, low in apparent porosity, lower than sintered plate corundum in volume density and high in refractoriness.

Owner:浙江自立新材料股份有限公司

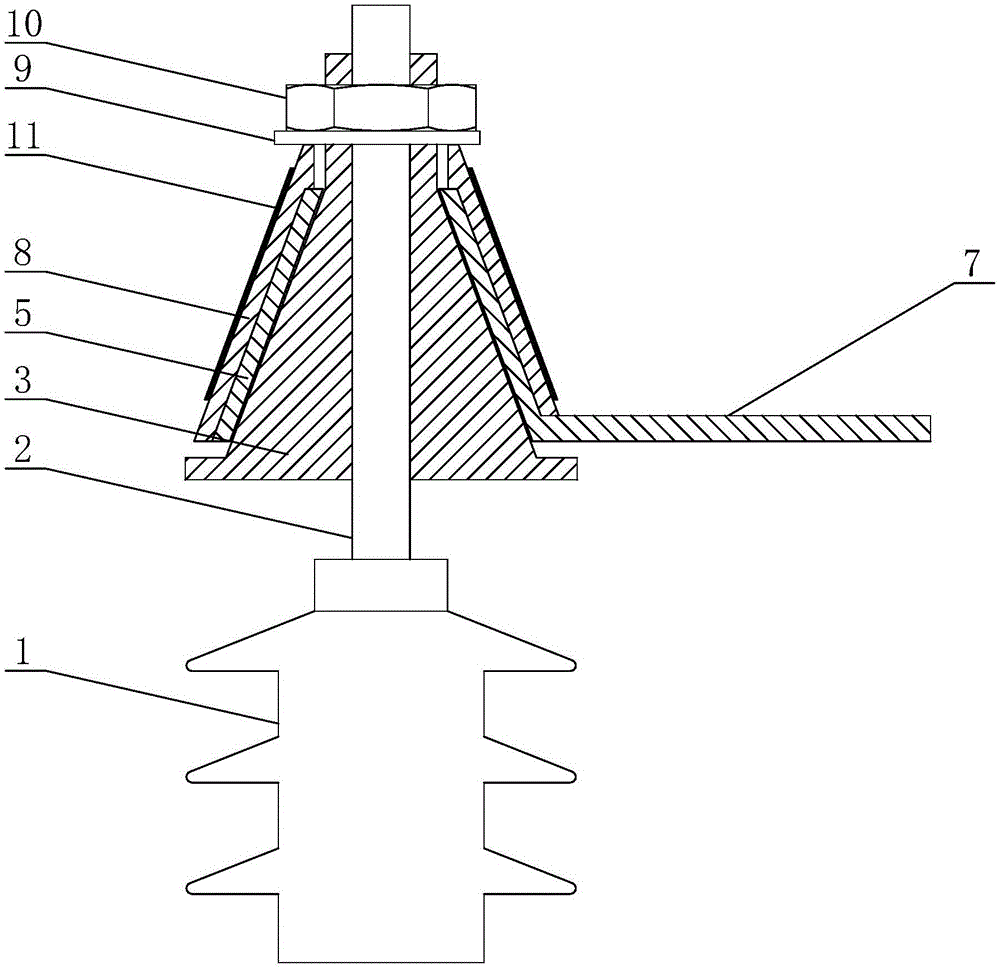

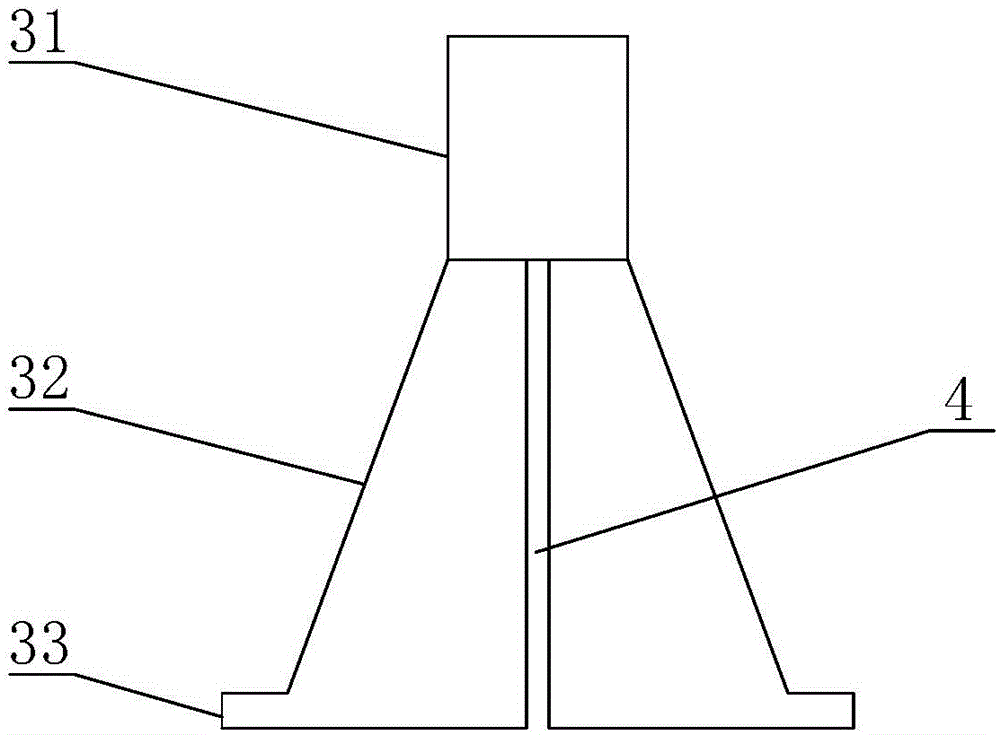

Digital substation transformer high-voltage porcelain bush wiring chuck

InactiveCN105119069AReduce volumeIncrease profitElectric connection structural associationsInsulating bodiesMaterial consumptionConductive materials

The invention discloses a digital substation transformer high-voltage porcelain bush wiring chuck and belongs to the power engineering power distribution construction field. The digital r substation transformer high-voltage porcelain bush wiring chuck comprises a substation transformer high-voltage porcelain bush; the substation transformer high-voltage porcelain bush is provided with an electric conduction rod; the electric conduction rod is provided with an inner lock sleeve; a first opening is formed in the side wall of the inner lock sleeve; the inner lock sleeve is provided with an outer lock sleeve; a second opening is formed in the side wall of the outer lock sleeve; the bottom of the side wall of the outer lock sleeve is provided with a lead pressing plate; the outer lock sleeve is provided with a pressing sleeve; the top of the pressing sleeve is provided with a gasket; and a nut is arranged on the gasket. According to the digital substation transformer high-voltage porcelain bush wiring chuck of the invention, a tapered opening locking mode which is different from a traditional clamp is adopted; the size of the chuck is decreased; material consumption is decreased; the utilization rate of electric conduction materials can be improved; a high-temperature self-healing effect can be realized; and the color of thermochromic paint can change with the change of temperature, and a special temperature measuring device is not required to perform detection, and therefore, inspection work can be simplified.

Owner:国网山东夏津县供电公司

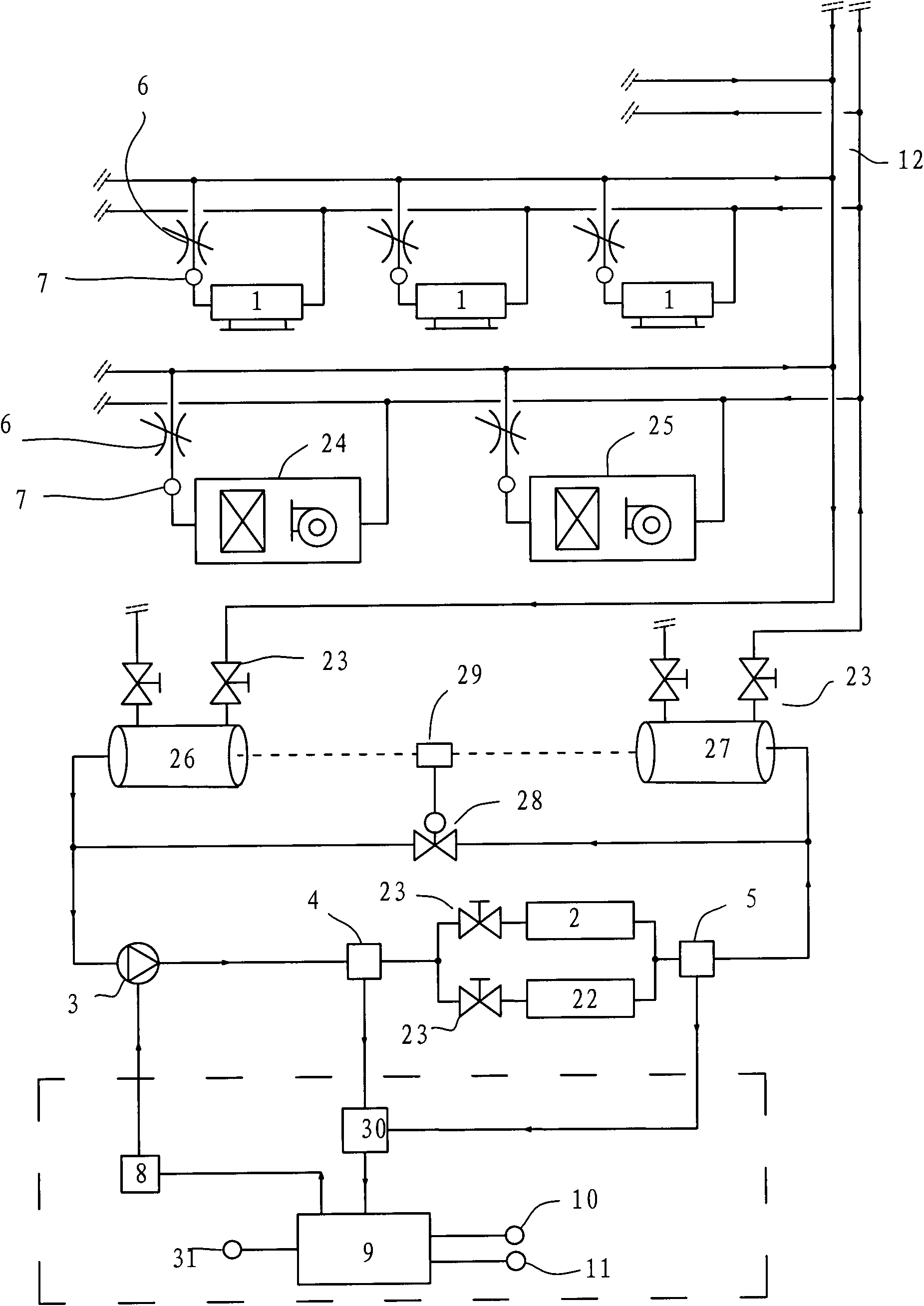

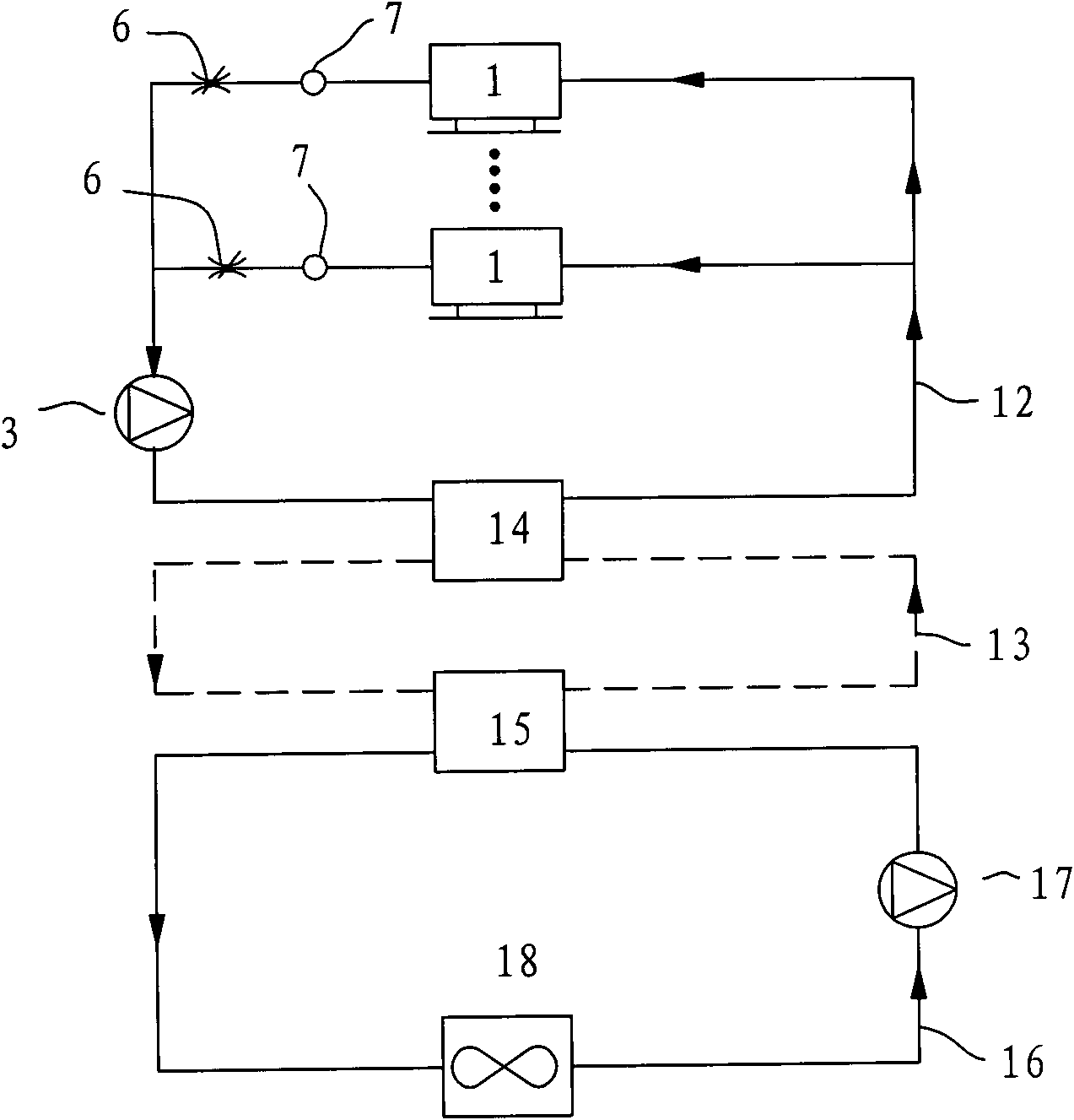

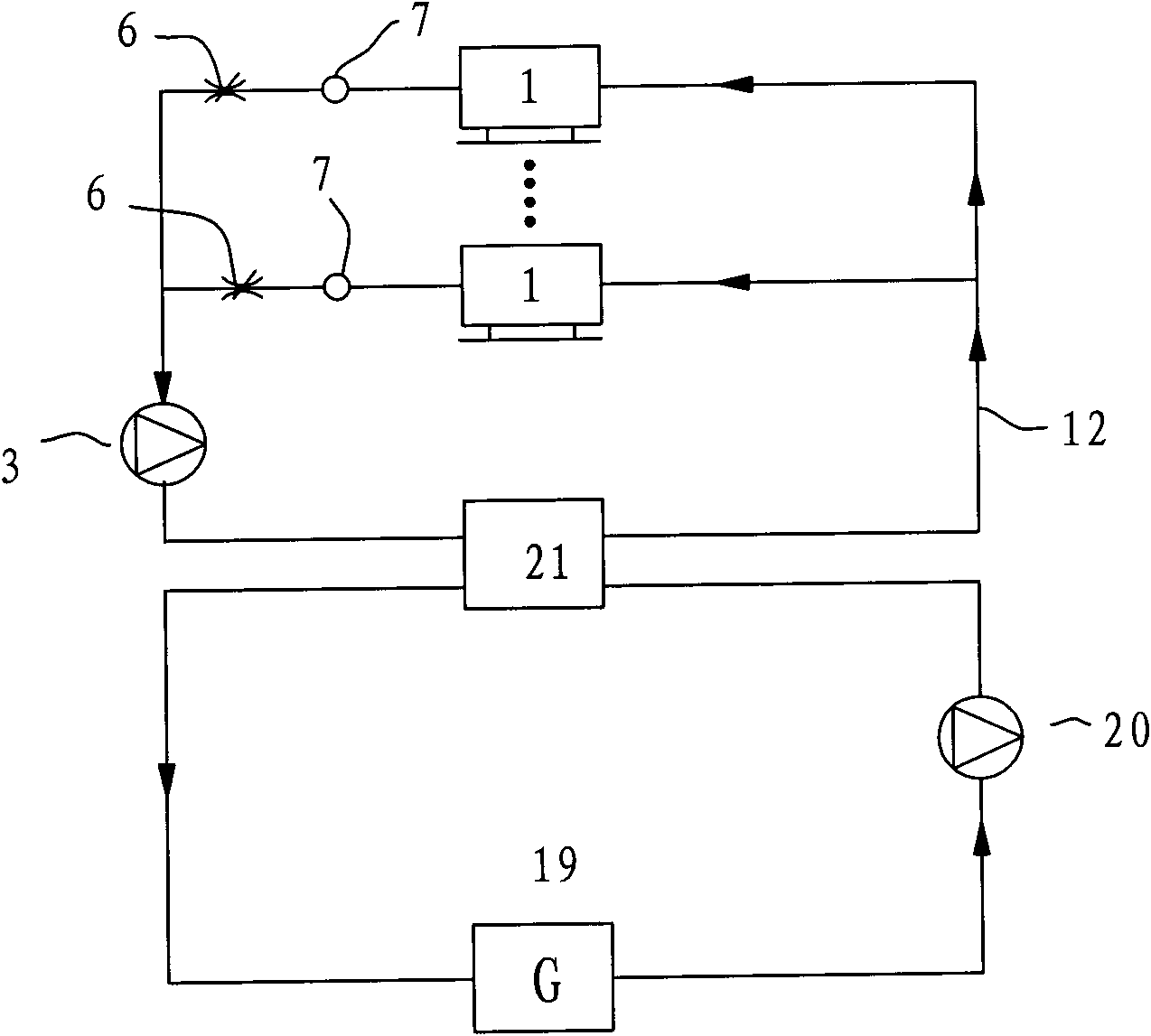

Air-conditioning system and control method thereof

InactiveCN101660815AReduce loadReduce operating frequencySpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerFrequency conversion

The invention discloses an air-conditioning system and a control method thereof. The air-conditioning system comprises a controller, a frequency converter, a circulating pump, a cold water machine set, a hot water machine set and a coil pipe blower group of each user end, wherein the controller is provided with a frequency-conversion protecting device used for refrigeration; the frequency converter is used for controlling the working frequency of the circulating pump; the circulating pump, the cold water machine set, the hot water machine set and the coil pipe blower group of each user end arepositioned on a circulating water loop, the coil pipe blower groups are respectively connected and arranged on the circulating water loop in parallel, a flow rate automatic balance adjusting valve and a temperature sensor which outputs a temperature signal to the flow rate automatic balance adjusting valve are respectively arranged on the connection pipelines of the coil pipe blower groups, the temperature signal output by the temperature sensor is used for switching the maximum flow rate setting value of the flow rate automatic balance adjusting valve under a refrigeration mode and a heatingmode, the controller controls the constancy of the temperature difference of an inlet and an outlet of the cold water machine set or the hot water machine set by adjusting the working frequency of the circulating pump, and the frequency-conversion protecting device used for refrigeration is switched to a bypass under the heating mode. The invention can correspondingly adjust the frequency of thecirculating pump according to the load change of the system, save energy, lower consumption and control the flow rate in the circulating loop accurately.

Owner:谭仲禧 +1

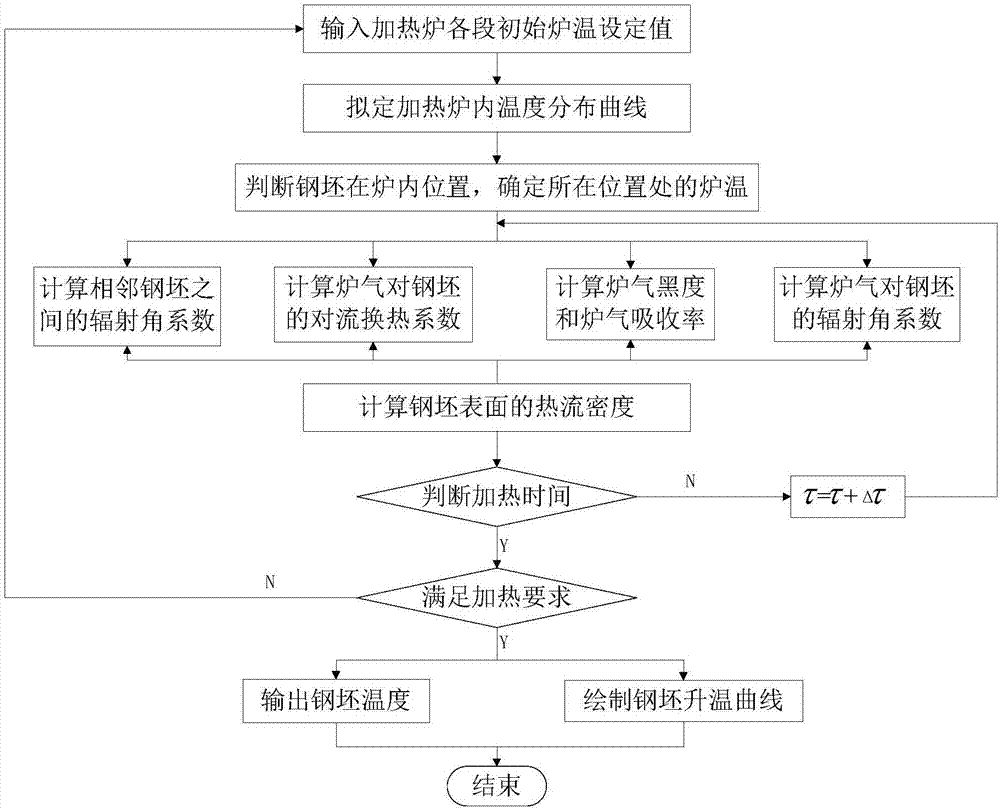

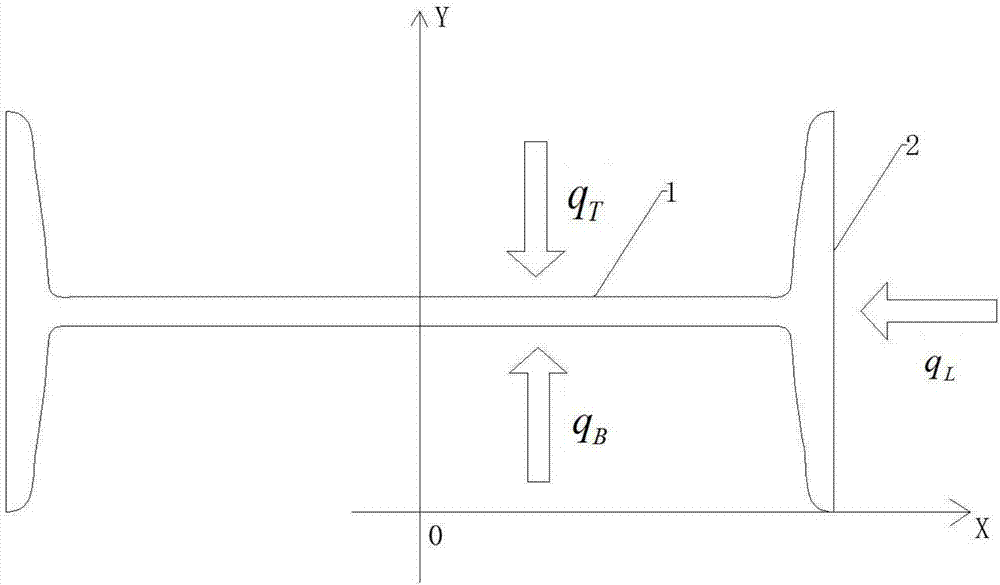

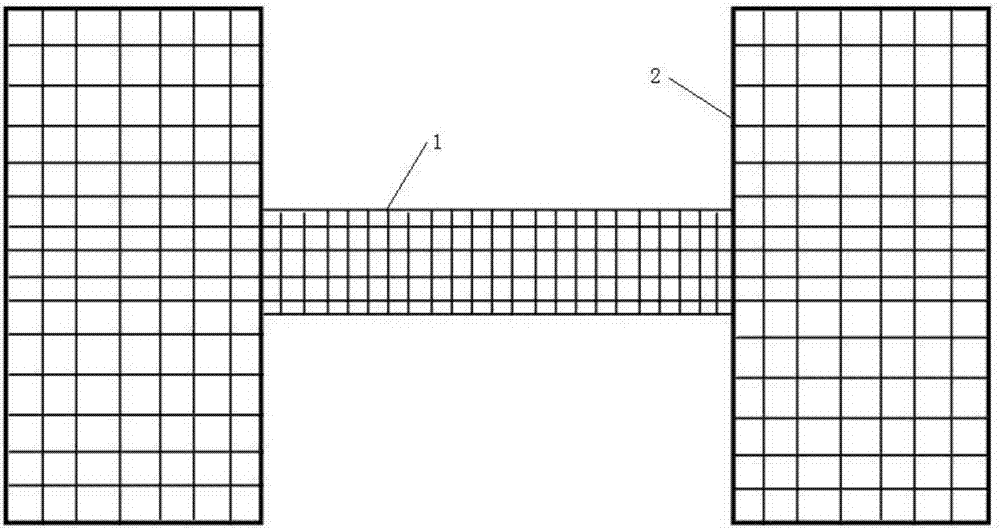

Temperature distribution calculation method in H-shaped steel billet heating process

ActiveCN106906350APlay the role of saving energy and reducing consumptionFurnace typesHeat treatment process controlFurnace temperatureHeat flow

The invention discloses a temperature distribution calculation method in the H-shaped steel billet heating process, and belongs to the field of metallurgical automation process control. The calculation method comprises the steps of determining the furnace temperature of the position where a steel billet in a furnace is located according to the initial furnace temperature set value; selecting the calculation area including a water beam, and carrying out mesh division; calculating the heat flow density of the surface of the steel billet; and outputting the steel billet temperature after the heating time is up, and the heating requirement is met, and drawing the steel billet temperature rise curve. According to the method, heat exchange generated between the water beam and the steel billet and the heat exchange generated due to the water beam shielding effect are fully considered, the value of the drawn stele billet temperature rise curve is more close to the actual measurement value, and during online production, energy is saved, and consumption is reduced.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

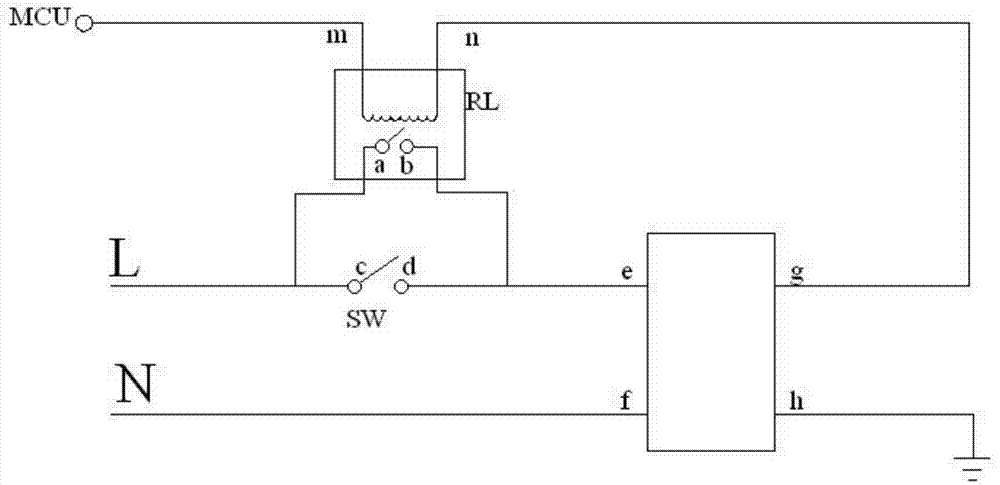

Door opening power-on circuit and washing machine using circuit

InactiveCN104278482ARealize automatic power offImprove convenienceOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention relates to the technical field of washing machines, and discloses a door opening power-on circuit and a washing machine using the circuit. The door opening power-on circuit comprises a power unit, an inching switch, a relay and a control unit, wherein an input end of the power unit is connected to a mains supply through the inching switch; an output end of the power unit is connected to the control unit to provide power for the control unit; the control unit is connected with a control end of the relay to control opening and closing of a relay switch; the relay switch is connected in parallel with the inching switch. The inching switch and the relay are used by the door opening power-on circuit, so that the circuit has a simple structure and is low in cost. According to the washing machine using the door opening power-on circuit, the user experience is improved, the convenience for use of the washing machine is enhanced, and energy saving and consumption reduction effects are achieved.

Owner:WHIRLPOOL CHINA

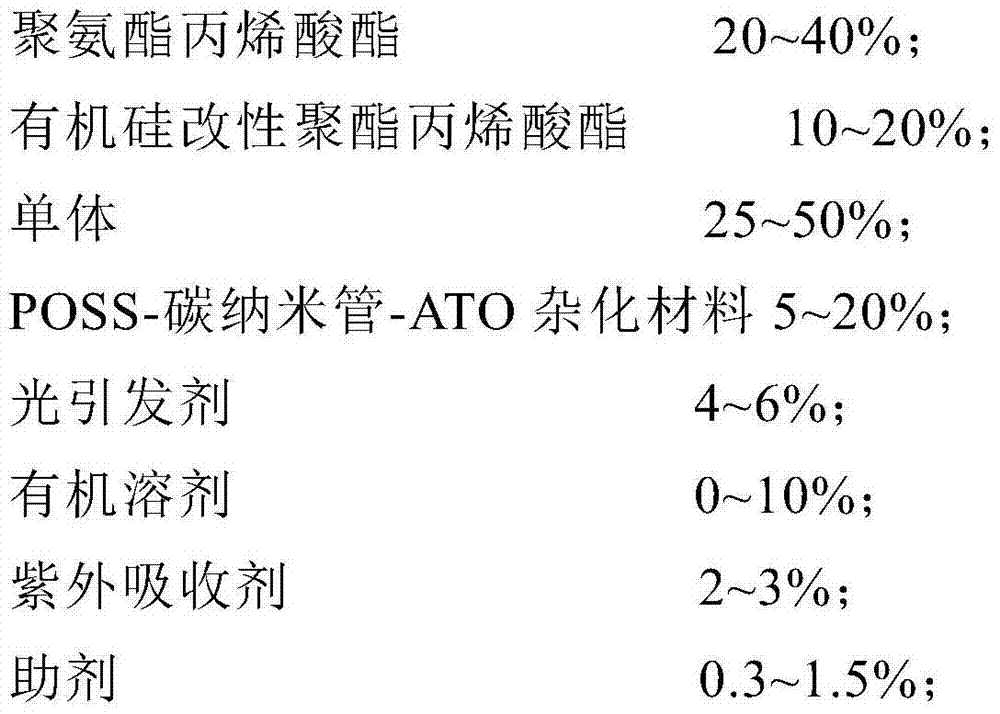

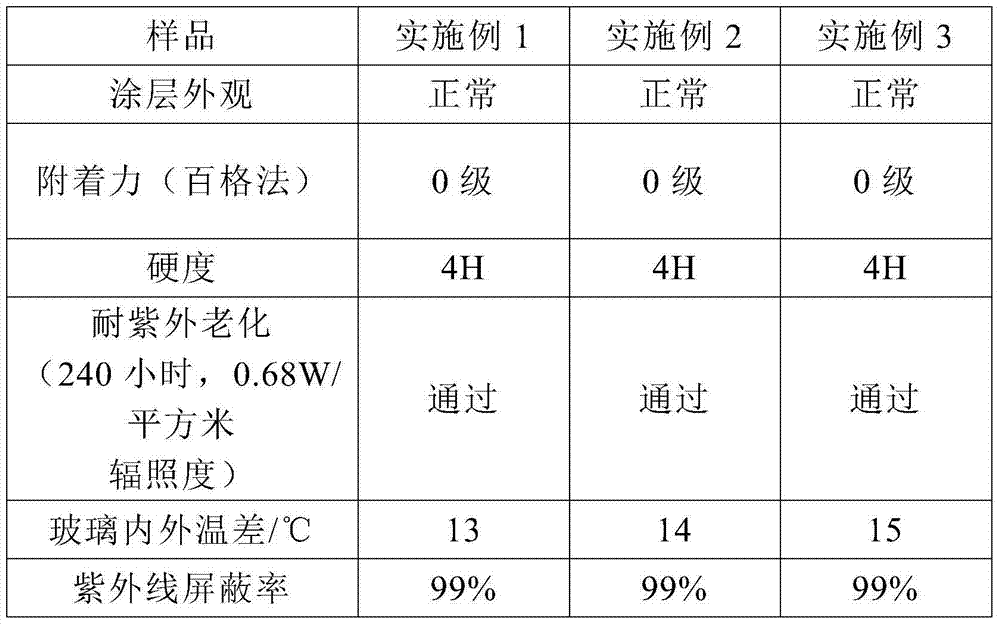

Transparent heat insulation film and preparation method thereof

ActiveCN104231910AImproves UV resistanceImprove performancePolyurea/polyurethane coatingsPolyester coatingsPolyesterCarbon nanotube

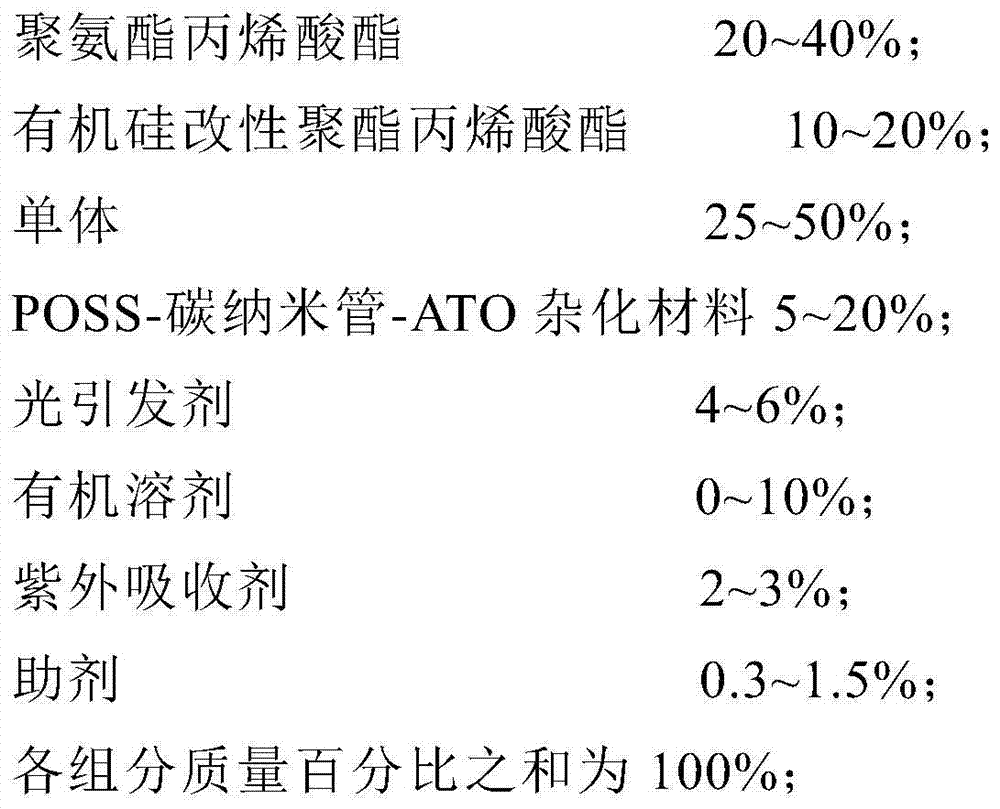

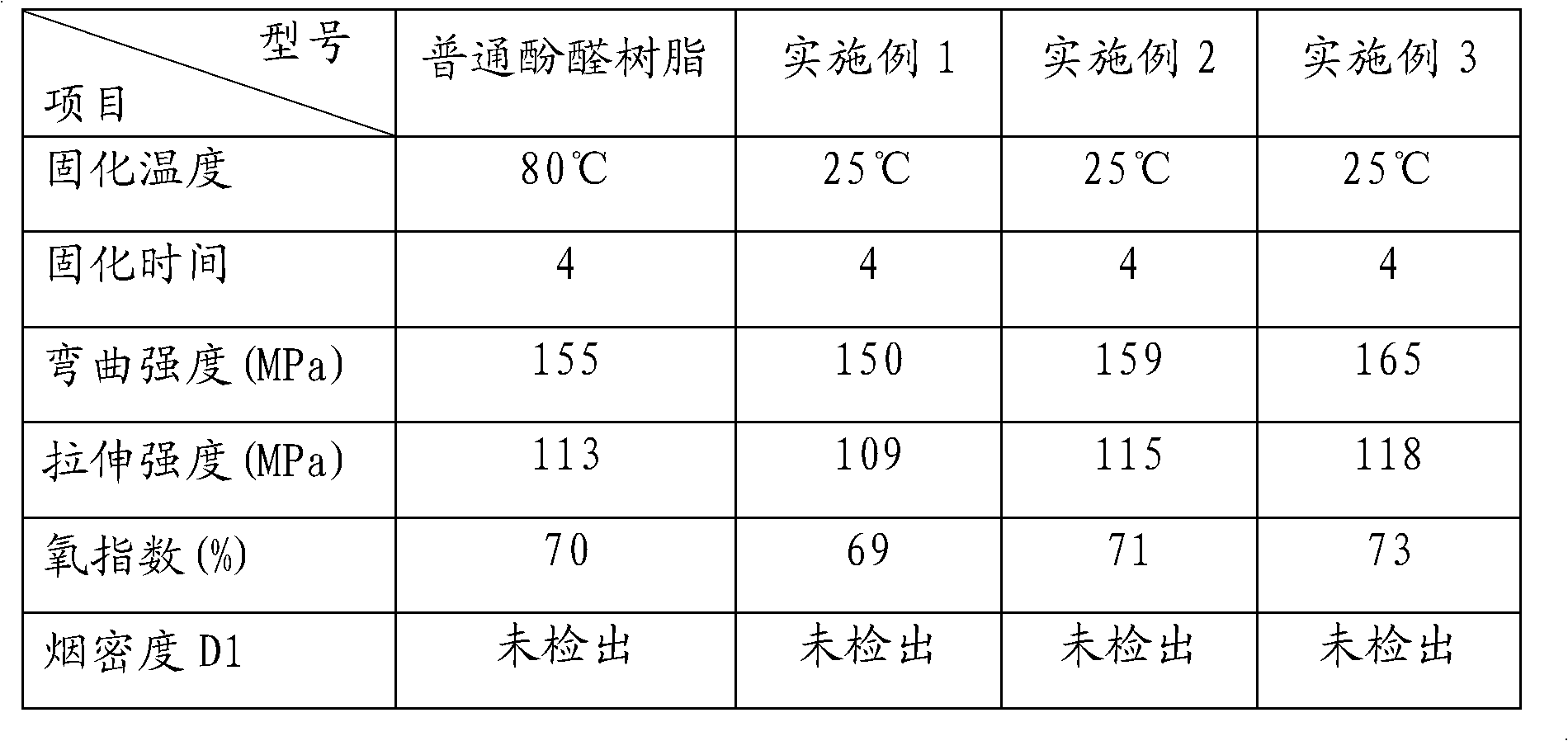

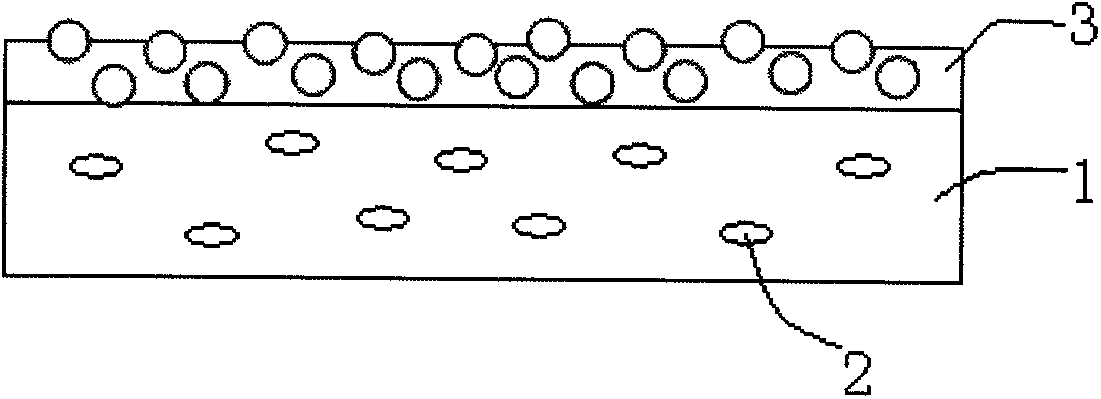

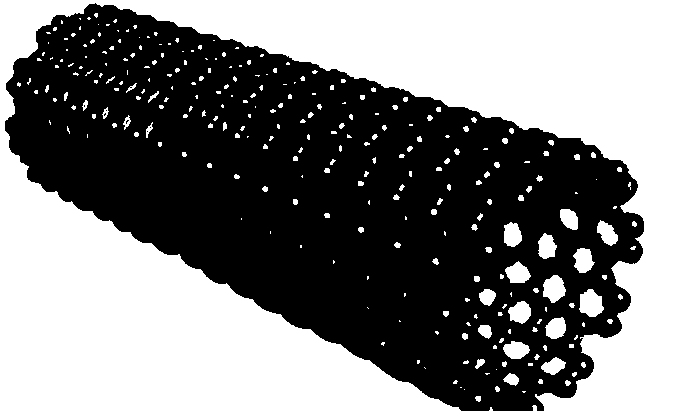

The invention discloses a transparent heat insulation film which is characterized by comprising a transparent film substrate and a heat insulation coating; the heat insulation coating comprises the following components in mass percent: 20%-40% of polyurethane acrylate, 10%-20% of organosilicon modified polyester acrylate, 25%-50% of monomer, 5%-20% of POSS-carbon-nano-tube-ATO hybrid material, 4%-6% of photoinitiator, 0-10% of organic solvent, 2%-3% of ultraviolet absorber, and 0.3%-1.5% of additive; the sum of the mass percent of all the components is 100%, wherein through the use of the POSS-carbon-nano-tube-ATO hybrid material, not only is the heat insulation effect enhanced, but also the ultraviolet ageing resistance and the wear resisting property of the coating can be improved. The invention further provides a preparation method of the transparent heat insulation film; the prepared transparent heat insulation film is good in transparency, heat insulation effect and anti-ultraviolet effect, is simple in technology and low in cost.

Owner:JIANGHAN UNIVERSITY

Method for preparing glass steel phenolic resin substrate

The invention discloses a method for preparing a glass steel phenolic resin substrate, which comprises the following steps of: 1, putting phenol, aldehyde and alkali into a reaction kettle in a molar ratio of 1.0:(1.5-3.0):(0.001-0.1) and performing polycondensation reaction; 2, adding a pH value regulator into a product in the step 1 to regulate the pH value to 3 to 9, and distilling under reduced pressure until the viscosity of the product is between 1,000 and 3,000 centipoises at 25 DEG C; and 3, adding acidic components into the product in the step 2, and stirring uniformly, wherein a weight percent ratio of the acidic components to the product is (70-99.5):(0.5-30). The phenolic resin substrate prepared by the method is mainly used for manually-molded glass steel, and can be solidified at normal temperature, so energy is saved to a great degree, labor intensity is reduced, and the aims of energy conservation and consumption reduction are fulfilled.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

High-stiffness reflecting film and manufacturing method thereof

The invention discloses a high-stiffness reflecting film. The high-stiffness reflecting film comprises a reflecting film basic layer, where microbubbles are arranged inside the reflecting film basic layer, the reflecting film basic layer is made of PET, and a diffusion layer is arranged on the reflecting film basic layer. The reflecting film is composed of, by mass, 20 parts of polymethyl methacrylate, 15 parts of polyisocyanates and 1-3 parts of diffusion particles. According to the manufacturing method of the high-stiffness reflecting film, the reflecting film basic layer is prepared firstly; then coating liquid is prepared, wherein the coating liquid is prepared by even mixing of the 20 parts of polymethyl methacrylate, the 15 parts of polyisocyanates and the 1-3 parts of diffusion particles; the coating liquid coats the reflecting film basic layer after being prepared, then the reflecting film basic layer is placed in an oven to be dried for one minute at the temperature of 130 DEGC, and the reflecting film is obtained. The high-stiffness reflecting film has the advantages that light reflected by the reflecting film is evener and softer, and production cost can be reduced due to the fact that both the reflecting property and the diffusion property can be achieved by one reflecting film.

Owner:NINGBO DXC NEW MATERIAL TECH

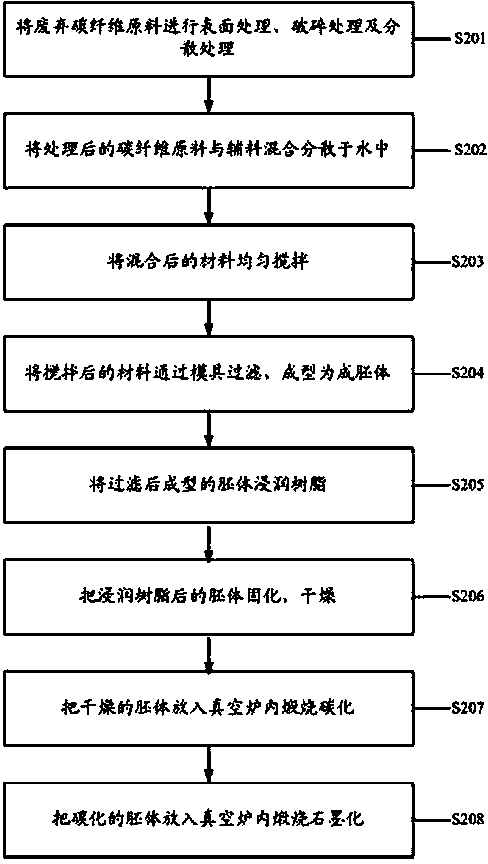

Compound thermal insulation material manufactured by using waste fibers and manufacturing method thereof

The invention provides a compound thermal insulation material manufactured by using waste fibers and a manufacturing method of the compound thermal insulation material and is applied to the field of insulation materials on a high-temperature furnace body. The compound thermal insulation material comprises basic materials and auxiliary materials, wherein the basic materials are waste fiber raw materials and are fiber raw materials which can be carbonized after being subjected to high-temperature calcination, the auxiliary materials comprise graphite, an adhesive and resin, and the waste fiber raw materials comprise one or multiple of polypropylene fibers, asphalt fibers, viscose, pre-oxidized fibers, phenolic fibers, carbon fibers, graphite fibers, wood fibers and cotton fibers. The compound thermal insulation material manufactured by adopting the materials according to the method have relatively thin fiber diameters, relatively small heat conductivity coefficient, relatively good ablation resistance and relatively good purity; and as the compound thermal insulation material is manufactured by using the waste fibers, the cost is reduced, and the benefits and the product competitive power of enterprises are increased.

Owner:上海骐碳复合材料科技有限公司

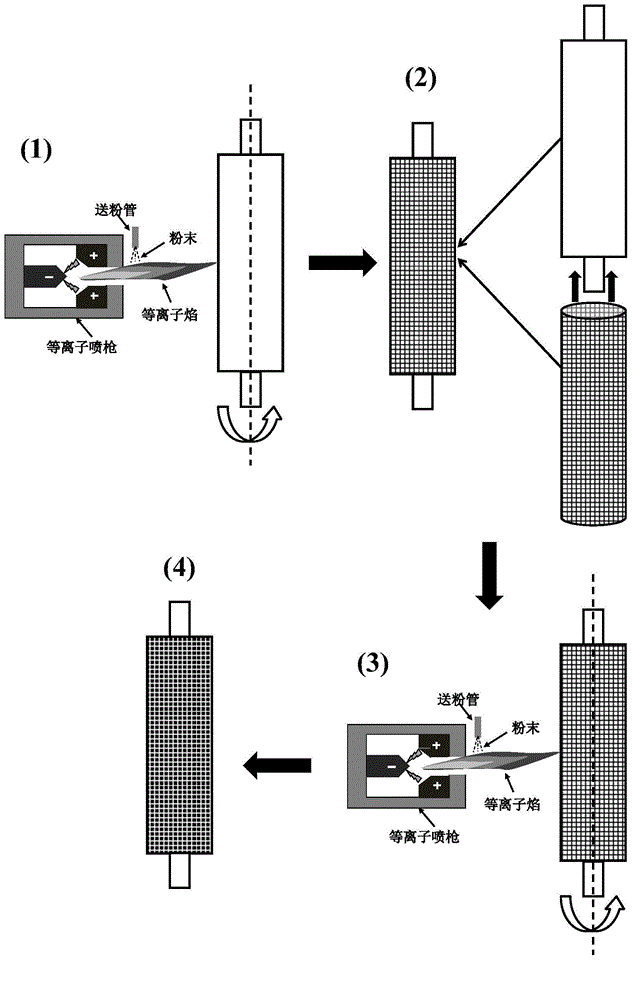

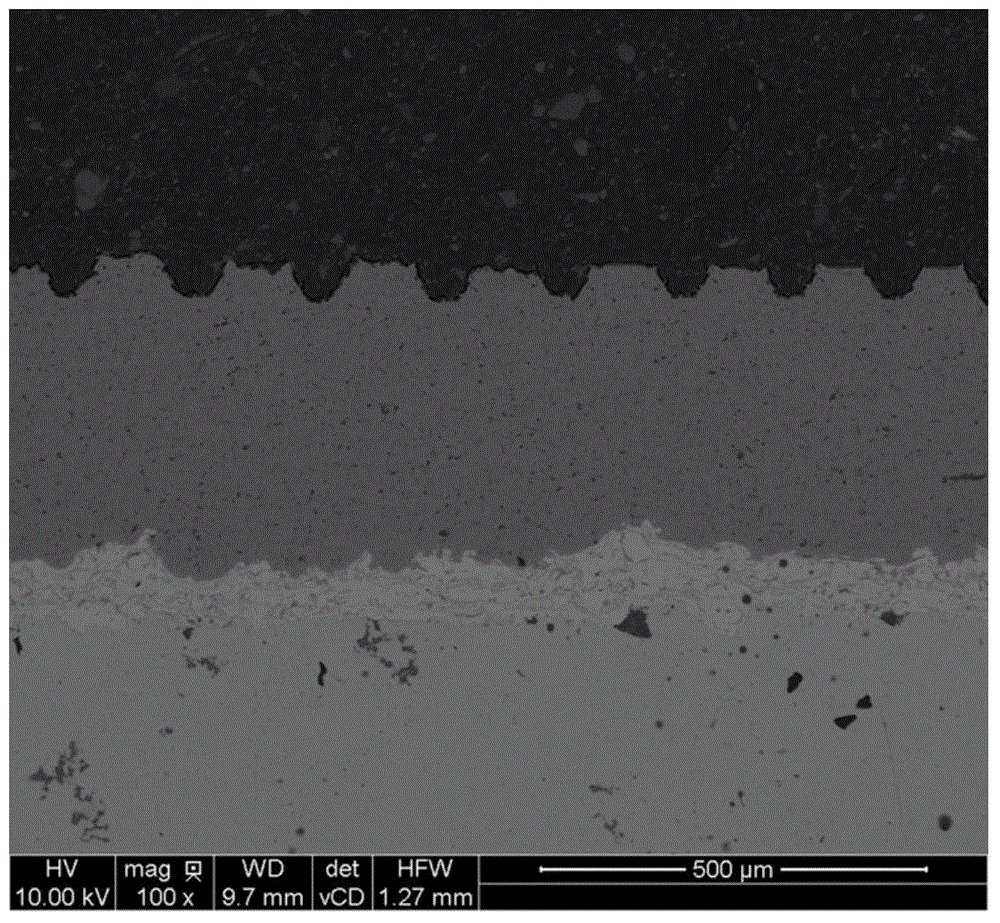

Method for preparing printer anilox roller based on thermal spraying technology

ActiveCN105886997AExtended service lifeWide choiceMolten spray coatingPrinting press partsMetal coatingCoated surface

The invention relates to a method for preparing a printer anilox roller based on the thermal spraying technology. A hollow thick-wall roller or a solid roller serves as a base body, and the base body is cleaned and subjected to oil and dust removal and surface roughening. A metal coating is prepared on the surface of the base body through a thermal spraying method. A ceramic coating is prepared on the surface of the metal coating through the thermal spraying method. A layer of cylindrical screen is tightly fixed to the surface of the ceramic coating. Ceramic powder continues to be sprayed on the surface shielded by the screen through the thermal spraying method, the screen is taken down after five to fifteen times of scanning with a spraying gun, and a plurality of protrusions arranged regularly are formed on the surface of the coating, so that the printer anilox roller is manufactured. The base body of the anilox roller treated through the method is small in deformation and shallow in heat influence area. The selection range of materials is wide, the hardness of the surface of the roller is high(>70 HRC), and the service life of the anilox roller can be effectively prolonged. Meanwhile, the method is simple in process, not only is suitable for preparing the novel anilox roller, but also can be used for repairing a waste anilox roller and plays a role in energy saving and consumption reduction.

Owner:苏州朋众新材料科技有限公司

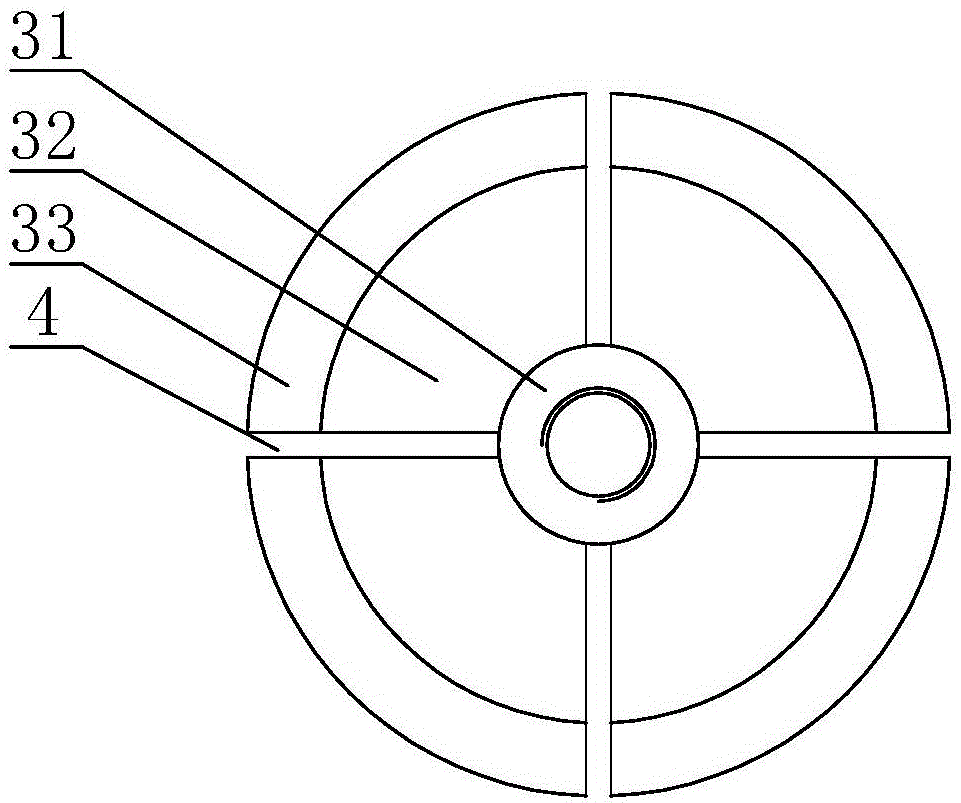

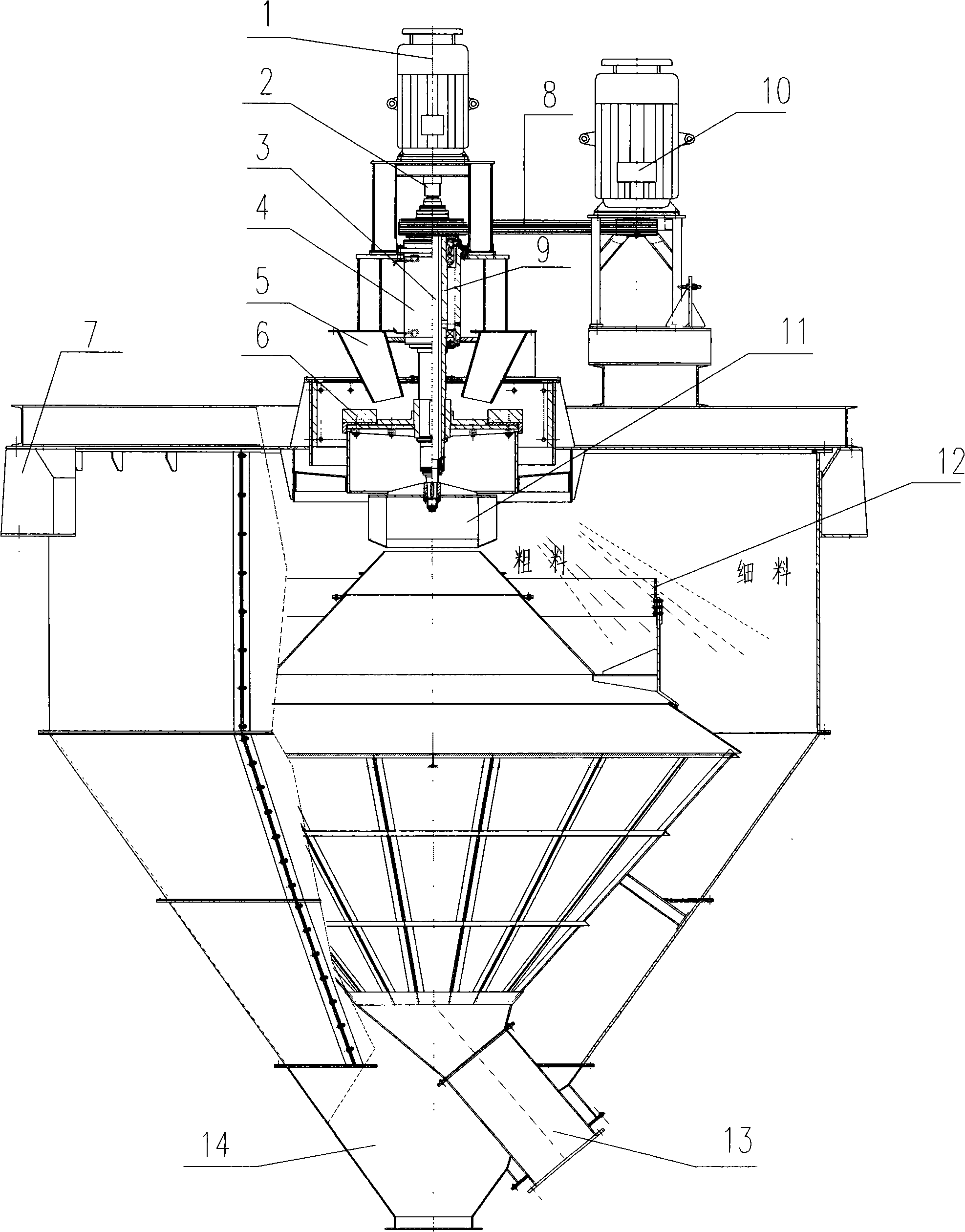

Apparatus for breaking up and classifying cake material

InactiveCN101318181AImprove shunt efficiencyReduce energy consumptionGas current separationRotary stirring mixersGranularityEngineering

The invention relates to a device that integrates cake breaking and grading. A tower-structured feed inlet (5) is fixed in the center of a tubular support (7); a wind wheel motor (1) is arranged on the feed inlet (5); a shaft joint (3) is jointed with a mandrel (3); the mandrel extends to 1 / 3 part in the cavity of the support and is connected with a wind wheel (11); a breaking disk motor (10) which is fixed above the support is connected with a hollow shaft (9) through a belt (8) and extends to a breaking disk (6) arranged above the wind wheel; the hollow shaft and the mandrel share the same center; a protective case (4) is provided; a filter-shaped fines collecting tube (14) is arranged below the support; a coarse material collecting tube (13) with a necking upper part and a filter-shaped lower part is fixed in the support; the lower end outlet of the coarse material collecting tube runs through the fines collecting tube, and the upper end necking thereof is provided with a regulating plate (12) to adjust the upper and lower height through a bolt. The device integrates cake breaking and grading, completes breaking and grading simultaneously, can control the discharging granularity through adjusting the rotation speed of the wind wheel or the height of the regulating plate, and has large grading range.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

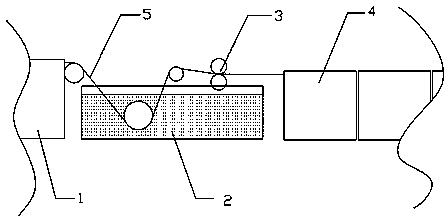

Production method of colored tape with long printing service life

ActiveCN104309340AConvenient supplementImprove adsorption speedInk ribbonsFibre typesBreaking strengthYarn

The invention provides a production method of a colored tape with the long printing service life. The method comprises the following steps that a, colored tape grey cloth is manufactured by selecting nylon 66 yarns with high breaking strength; b, preshrinking and washing treatment of a new process are carried out on the colored tape grey cloth; c, the washed colored tape grey cloth is soaked in ink adsorption accelerant solution pool and is extruded by a compression roller to sufficiently adsorb accelerant solutions; d, the colored tape grey cloth is dried and shaped through the standard of the new process; e, a professional fusion cutting machine is used for carrying out fusion cutting on the colored tape grey cloth, and a colored backing tape is formed; f, a professional ink coating machine is used for coating the colored backing tape with ink. After the six production procedures are carried out, the ink adsorption speed and volume of the colored backing tape are increased, the ink adsorption volume of the colored backing tape is increased by 10-15%, printing characters of the colored tape are improved to be 260-280 thousands per meter from 200 thousands per meter, and the service life of the whole printing colored tape is prolonged.

Owner:HUZHOU TENKA SPECIAL PRINT MATERIAL

Scaling inhibitor applied to industry cooling water systems, and preparation method thereof

InactiveCN106396136AImprove operational efficiencyInhibition of attachmentTreatment using complexing/solubilising chemicalsGrapheneAqueous solution

The invention provides a scaling inhibitor applied to industry cooling water systems. The scaling inhibitor is an aqueous solution of flake-like graphene oxide, the concentration of the scaling inhibitor ranges from 0.001 to 10g / L, and particle size ranges from 15 to 800nm. The invention also provides a preparation method of the scaling inhibitor; according to the preparation method, flake-like graphene oxide scaling inhibitor is added in cooling water, and the flake-like graphene oxide aqueous solution is obtained via magnetic stirring and ultrasonic dispersion. According to applications, the flake-like graphene oxide scaling inhibitor is added into industrial recycling cooling water, when the concentration of scale-forming ions in cooling water is relatively large, and scaling is caused, the surfaces of scale-forming particles (such as calcium carbonate) are coated by graphene oxide, the crystal type of scale-forming substances, such as calcium carbonate, is changed, and flocculent mild scale is formed, so that adhesion of the scale-forming substances, such as calcium carbonate, in water onto the metal surfaces of heat exchange equipment is not easily caused, the flocculent mild scale is removed via drainaging of the cooling water systems, and scaling inhibition is achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

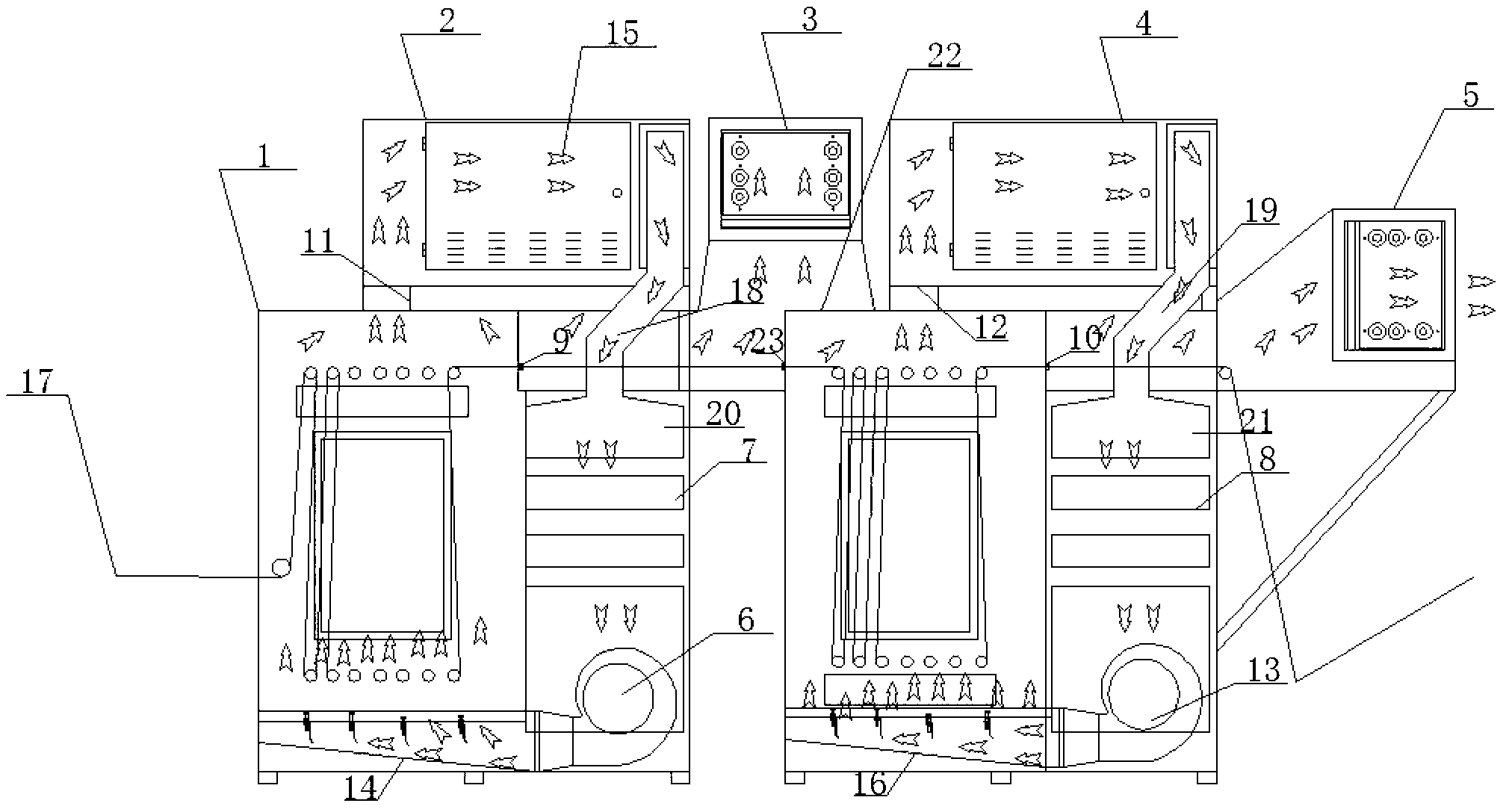

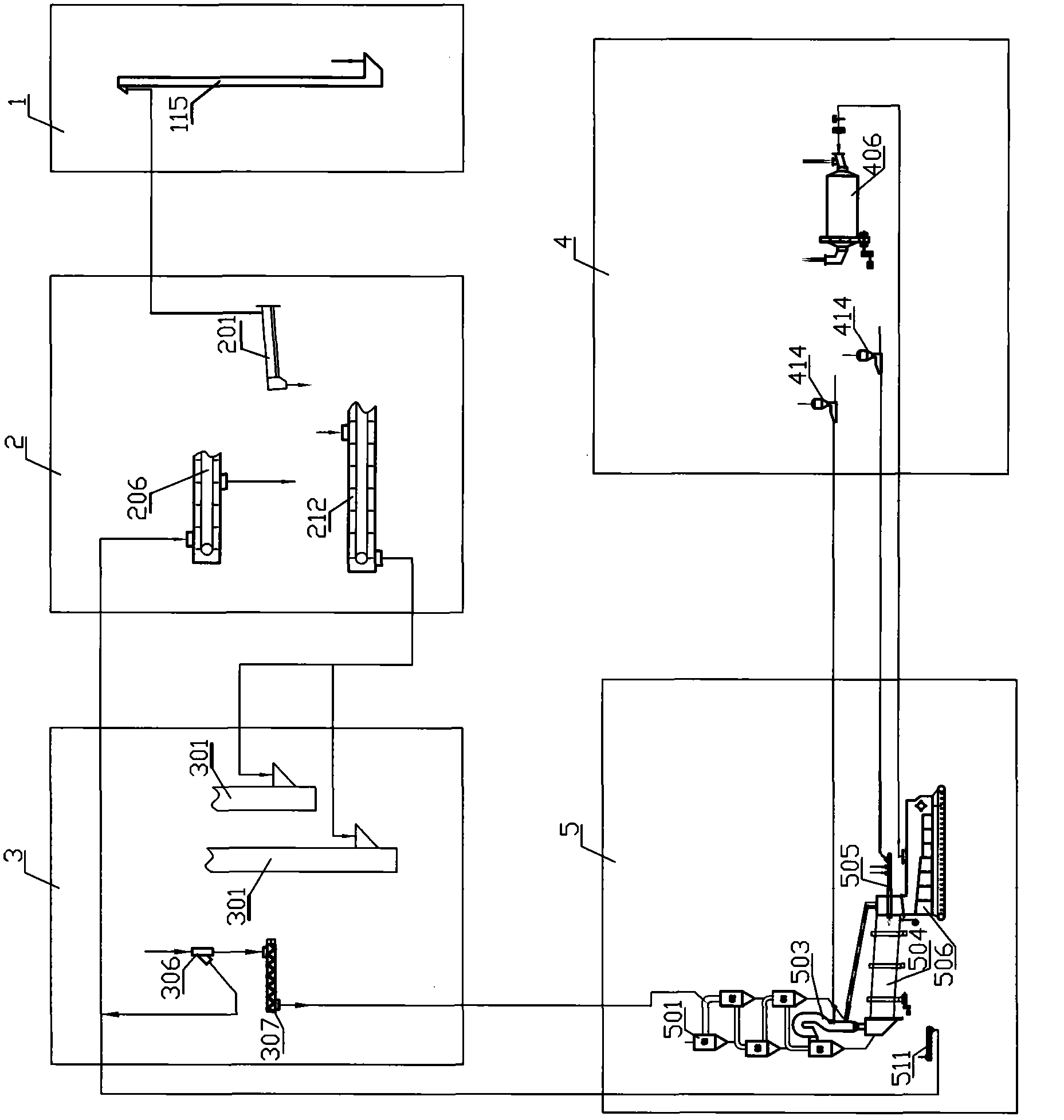

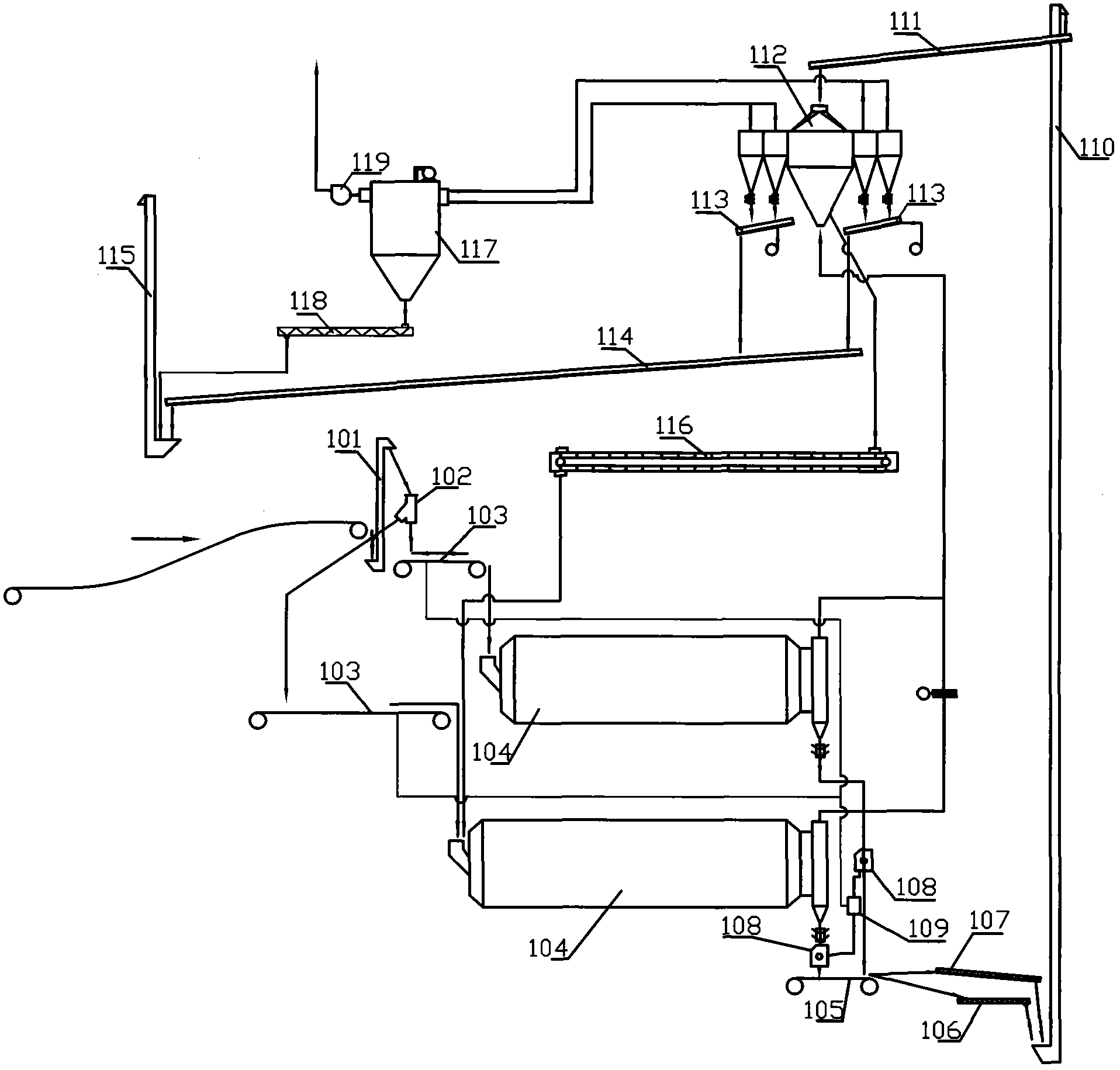

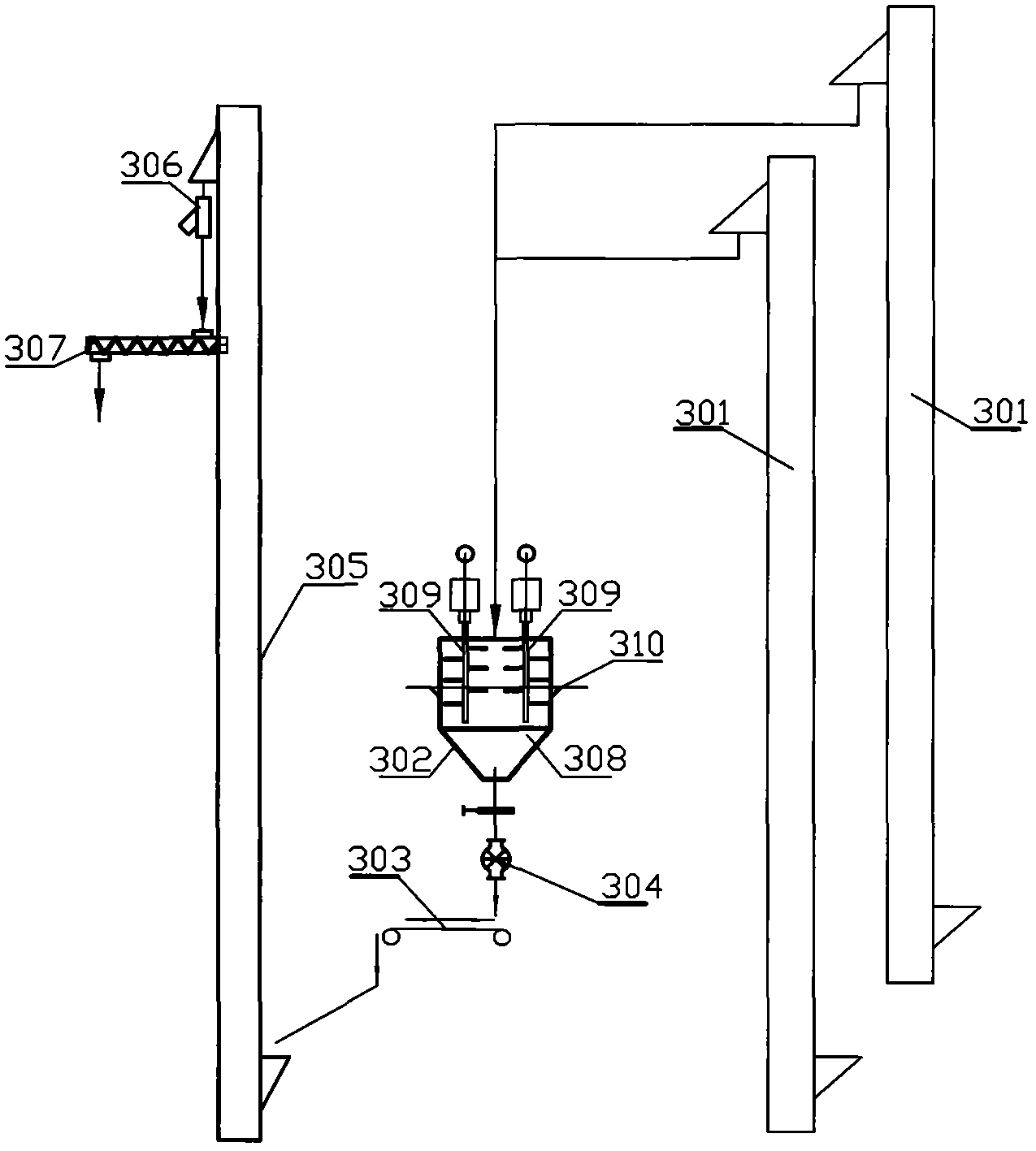

Energy-saving and environment-friendly cement clinker preparation system

ActiveCN103351106AUniform and stable qualityQuality improvementClinker productionDecompositionScrew conveyor

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

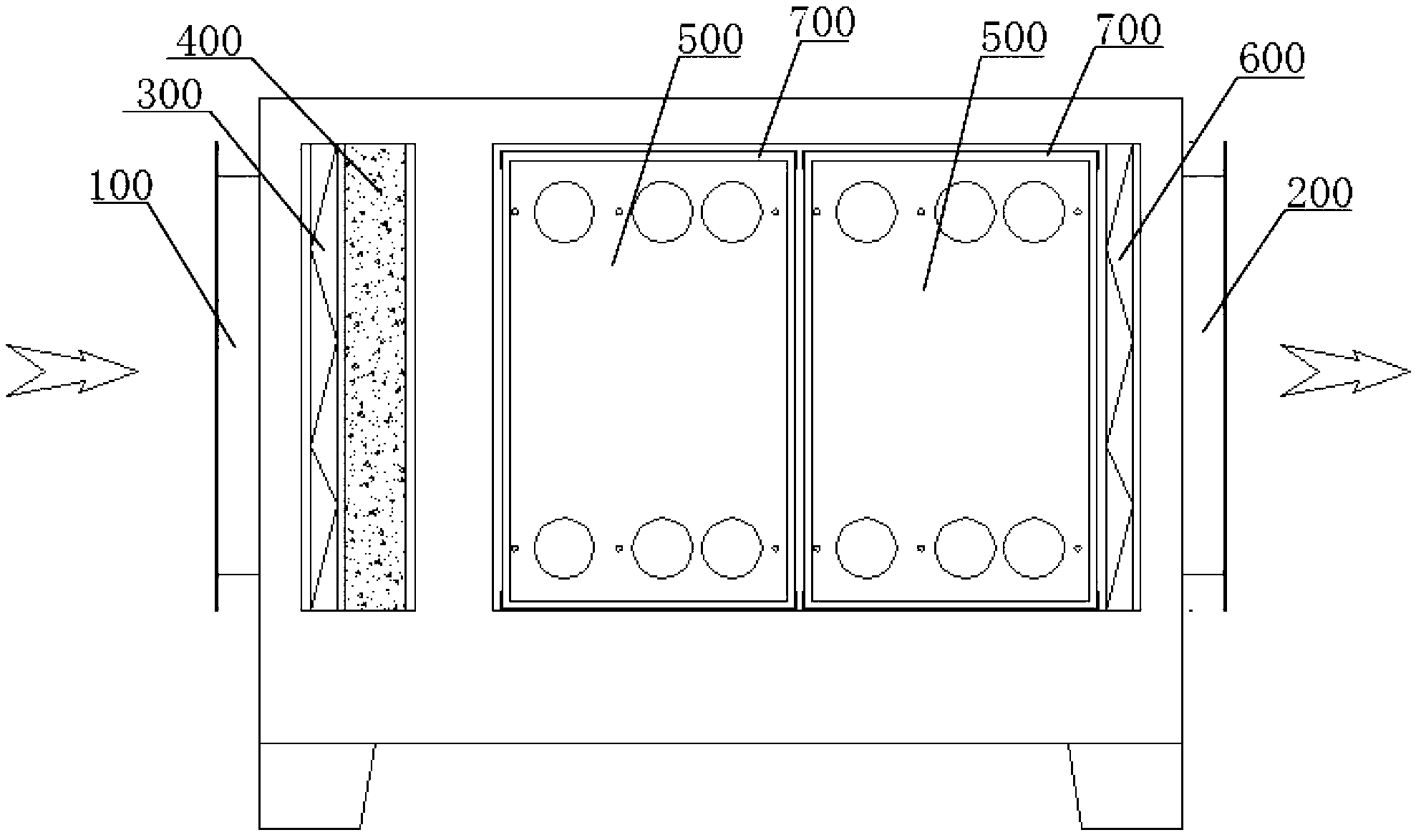

Double-row radiator for environment-friendly device

InactiveCN103917075ASimple structureIngenious designCooling/ventilation/heating modificationsDouble rowEngineering

The invention discloses a double-row radiator for an environment-friendly device. The double-row radiator mainly comprises a base, supports and cooling fins connected to the support, the cross section of the base is a circle, the two sides of the base are connected with the supports parallel to each other, the cooling fins extending to the outer side of the base are arranged on the side edge of one side of each support, an extending frame in the horizontal direction is arranged on the supports, sheets parallel to one another are arranged at the upper end of the extending frame, and the sheets are located at the top end of the base. The double-row radiator for the environment-friendly device is simple in structure, ingenious in design, environment-friendly and energy-saving, and has the advantages of being convenient to transport and install, low in production cost, high in conductivity, high in heat dispersion and capable of being recycled and reused.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Waste special barrel for gastrology department with sterilization function

InactiveCN108408299APlay a sealing roleFast disinfectionRefuse receptaclesRefuse cleaningEngineeringMechanical engineering

The invention discloses a waste special barrel for a gastrology department with a sterilization function. The waste special barrel comprises a barrel body, the side wall of a groove which is formed inthe barrel body is rotatably connected with two ends of a rotating rod, and a first connecting rod is fixedly connected to the rotating rod in a sleeving mode. When a moving plate moves to an original position, a first contact plate is in contact with a second contact plate again under the action of a sixth spring, a series circuit communicates again, the above movement process is repeated, and in the process of cycle of power outage, energy saving and consumption reducing are achieved; and a pedal is stepped again after sterilization and disinfection, the downward movement of the pedal can abut against an elastic plate, the pedal is released, a limiting ball crosses a limiting slot again and returns to an original position under the action of the elastic force of the elastic plate, and the device returns to an original position under the action of a spring, so that the device can achieve a high efficiency sterilization effect.

Owner:唐峰

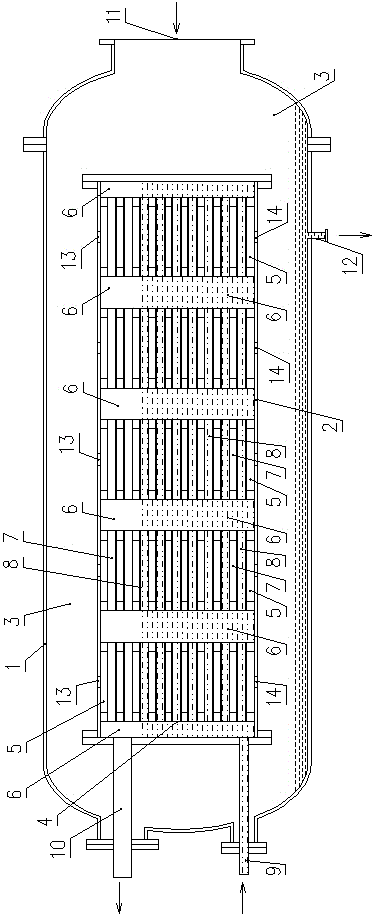

Horizontal type double phase change heat exchanger

InactiveCN104390492AReduce consumptionSimple structureEvaporators/condensersStationary tubular conduit assembliesHeat fluxHeat flow

The invention discloses a horizontal type double phase change heat exchanger. The horizontal type double phase change heat exchanger comprises a horizontal type shell, a phase change drum is horizontally arranged inside the horizontal type shell, and a plurality of heat exchanging units is arranged inside the phase change drum; each heat exchanging unit comprises a vertical barrel; a plurality of communicating pipes are horizontally arranged inside the vertical barrel, at least one communicating pipe at the top of the vertical barrel is a heat-insulated pipe, and at least one communicating pipe at the bottom of the vertical barrel is a heat-insulated pipe; other communicating pipes are double phase change heat exchanging pipes; the bottom portion at one end of the phase change drum is connected with a low temperature liquid inlet pipe, the top portion at the same end of the phase change drum, which is provided with the low temperature liquid inlet pipe, is connected with a low temperature steam outlet pipe, a high temperature steam inlet is arranged at the other end of the side wall of the horizontal type shell, and the bottom wall at the same end of the horizontal type shell is provided with a high temperature liquid outlet; the top wall and the bottom wall of the phase change drum at a position of a condensation cavity are respectively provided with an upper opening and a lower opening. The horizontal type double phase change heat exchanger has the advantages that structure is simple, energy consumption is saved, installation is convenient, the heat flux density of a heat exchanging surface is greatly improved compared with the prior art, the size of the heat exchanger is greatly reduced, and media can automatically pass through by means of a phase change effect instead of extra conveying power.

Owner:ZHENGZHOU SIWEI STARCH TECH DEV

Energy-saving method and device of lengthwise graphitization furnace

InactiveCN105841500AReduce power consumptionSpeed up coolingEnergy inputWaste heat treatmentSmall footprintThermal energy

The invention discloses an energy-saving method and device of a lengthwise graphitization furnace. According to the method, air is used as a carrier, normal temperature air is blown into air channels through an air blower and is heated after passing through the air channels to take away a large amount of heat energy generated after the graphitization process is finished, thereby cooling materials which is already subjected to the graphitization process; and heated air which carries a large amount of heat energy is fed into furnace pit air channels of new materials needing to be graphitized and preheats the low-temperature materials needing to be heated, and power consumption needed by powering on and temperature rise of the low-temperature materials is reduced. By means of the device implementing the energy-saving method, waste heat energy is reused for the technological process, the cooling speed of the high-temperature materials is increased, therefore, the number of constructed furnace pits is reduced, and the initial temperature of the new materials can be rapidly raised. The energy-saving method and device of the lengthwise graphitization furnace have the advantages that the structure is simple; heating power consumption is reduced; the floor space is small; the equipment and civil engineering investment is reduced; cooling of the high-temperature materials and reutilization of heat of the lengthwise graphitization furnace are achieved; and energy is saved, and the production efficiency is improved.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

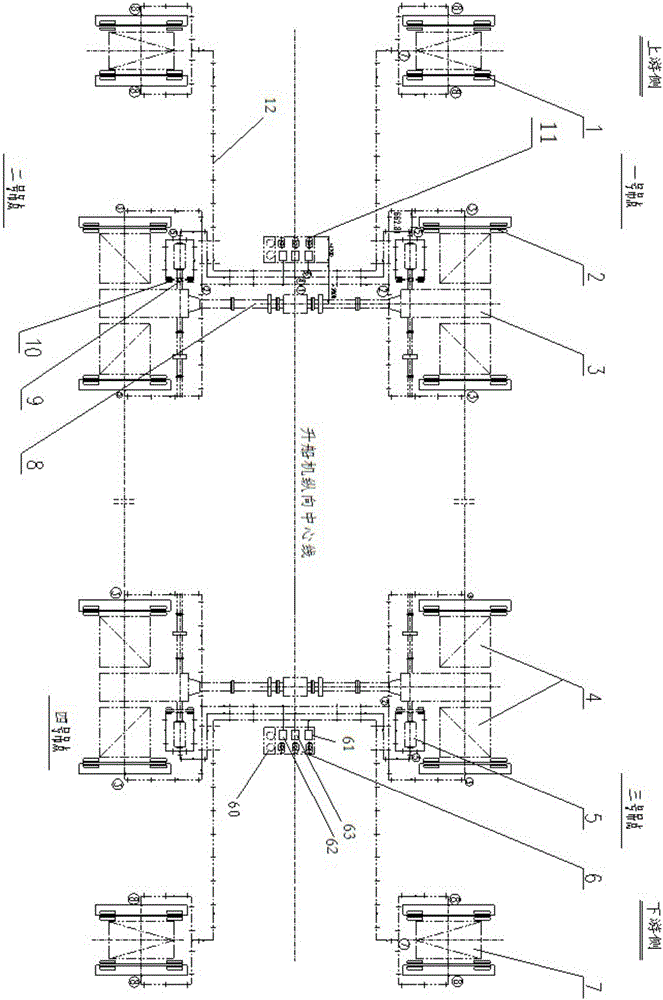

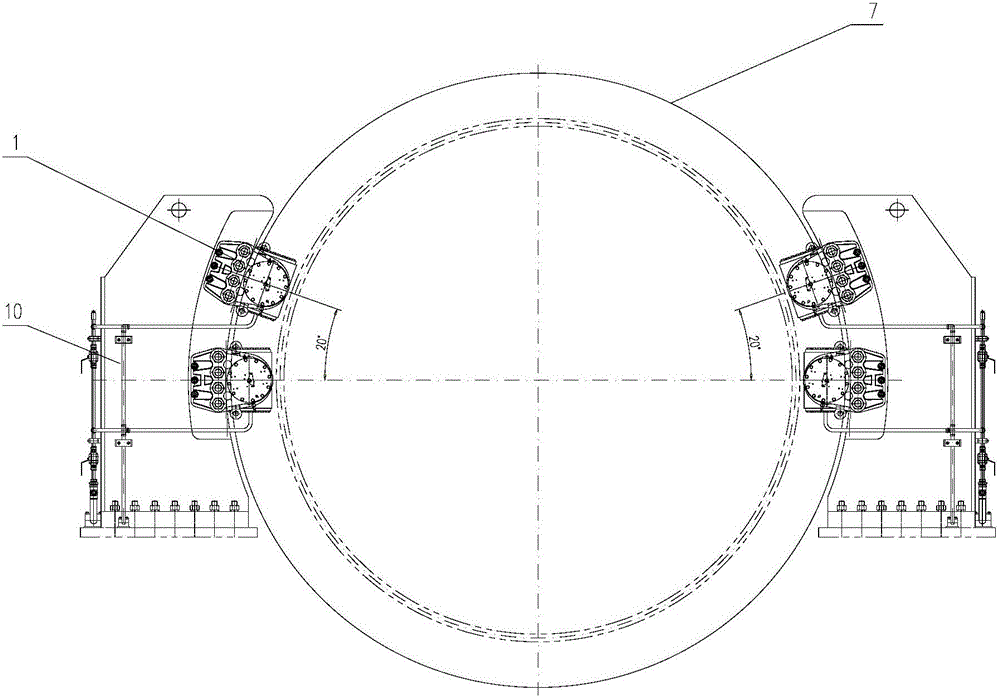

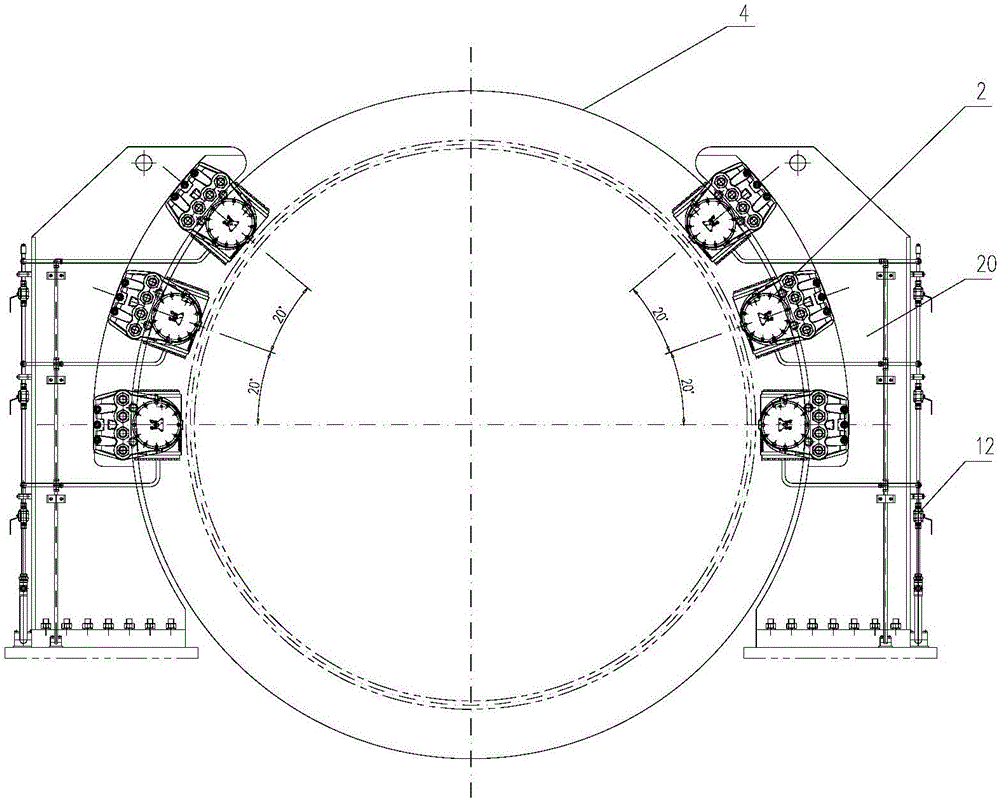

Main lifting brake system of windlass full-balance vertical ship lift

ActiveCN106542456ALarge capacityGuaranteed uptimeServomotor componentsAccumulator installationsReduction driveCoupling

The invention relates to a main lifting brake system of a windlass full-balance vertical ship lift. The system comprises a multi-steel wire rope windlass with counterweights in four lifting pints; two main lifting drums with brake discs and a controllable balance weight drum are respectively arranged in each lifting point; the two main lifting drums in each lifting point are coaxially connected, and are driven by a speed reducer; the speed reducer is connected with a synchronous shaft device; the four lifting points are annularly spaced by the synchronous shaft devices, and are synchronously connected; the speed reducer in each lifting point is electrically connected with a motor by a coupling; each controllable balance weight drum is provided with four pairs of first safety brakes; each main lifting drum is provided with six pairs of second safety brakes; an output shaft of the motor in each lifting point is provided with two pairs of working brakes; and the first safety brakes, the second safety brakes and the working brakes are driven by a hydraulic pump station. The main lifting control system improves the working stability.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

Device for separating electro-adsorption water-based solution ions

InactiveCN102211803BLower performance requirementsEasy to separateDispersed particle separationWater basedElectricity

The invention discloses a device for separating electro-adsorption water-based solution ions. The device is provided with a direct current power supply and one or more compound adsorption units, wherein each compound adsorption unit is provided with an electrode plate which is respectively connected with the direct current power supply to form a positive electrode plate and a negative electrode plate; an anion exchange resin layer and a cation exchange resin layer are respectively arranged on the inner side of the positive electrode plate and the inner side of the negative electrode plate; ananion exchange membrane and a cation exchange membrane are respectively arranged on the inner side of the anion exchange resin layer and the inner side of the cation exchange resin layer; a channel for accommodating a treated water-based solution is arranged between the anion exchange membrane and the cation exchange membrane; two ends of the channel are respectively communicated with an inlet pipe and an outlet pipe; the outlet pipe is respectively communicated with a concentrated liquid outlet pipe and a weak liquid outlet pipe through two electrical control valves; and the inlet pipe is communicated with an inlet pipe of a water-based solution to be treated through the electrical control valves. The device can be further provided with a PLC (Programmable Logic Controller) for automatically controlling. The device disclosed by the invention is suitable for desalting sea water and brackish water and separating ions in the water-based solutions as well as has the advantages of complete structure, flexibility in control, high efficiency, energy saving and environment friendliness.

Owner:苏润西

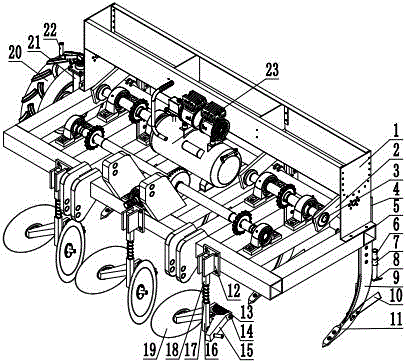

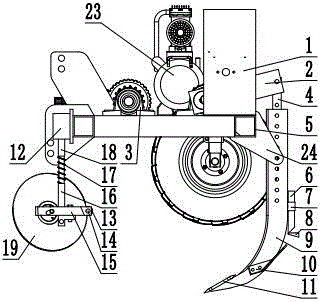

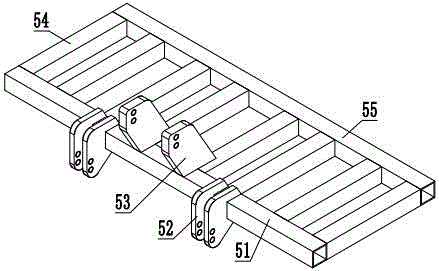

Forced vibrating, air-pressure deep loosening, weeding and fertilizing machine

InactiveCN105900546ARealize vibration subsoiling operationAchieve the effect of reducing drag and reducing consumptionSoil lifting machinesSpadesAgricultural engineeringAtmospheric pressure

The invention relates to a forced vibrating, air-pressure deep loosening, weeding and fertilizing machine which is characterized by comprising a machine frame, a weeding device, a forced vibrating device, a deep loosening device, a high-pressure air pump, a fertilizing device and deep control devices; the weeding device is arranged under a front beam; the forced vibrating device, the high-pressure air pump and the fertilizing device are arranged on a cross beam; the deep loosening device is arranged under a rear beam; one deep control device is arranged on each of the two sides of the cross beam. According to the forced vibrating, air-pressure deep loosening, weeding and fertilizing machine provided by the invention, firstly, a deep loosening shovel is forced to vibrate through the forced vibrating device so as to realize deep loosening operation of soil; on the other hand, high-pressure air is injected into the deep loosening shovel through the high-pressure air pump, so that soil can be broken through air pressure, and meanwhile, an air film is formed on a shovel tip and jointly plays a role of resistance reduction with the vibration. In a word, the invention provides the forced vibrating, air-pressure deep loosening, weeding and fertilizing machine which can reduce the traction resistance, reduce the energy consumption and finish weeding, deep loosening, fertilization and other operations at a time and of which parts are convenient to disassemble, and the tilling width is adjustable.

Owner:SHIHEZI UNIVERSITY

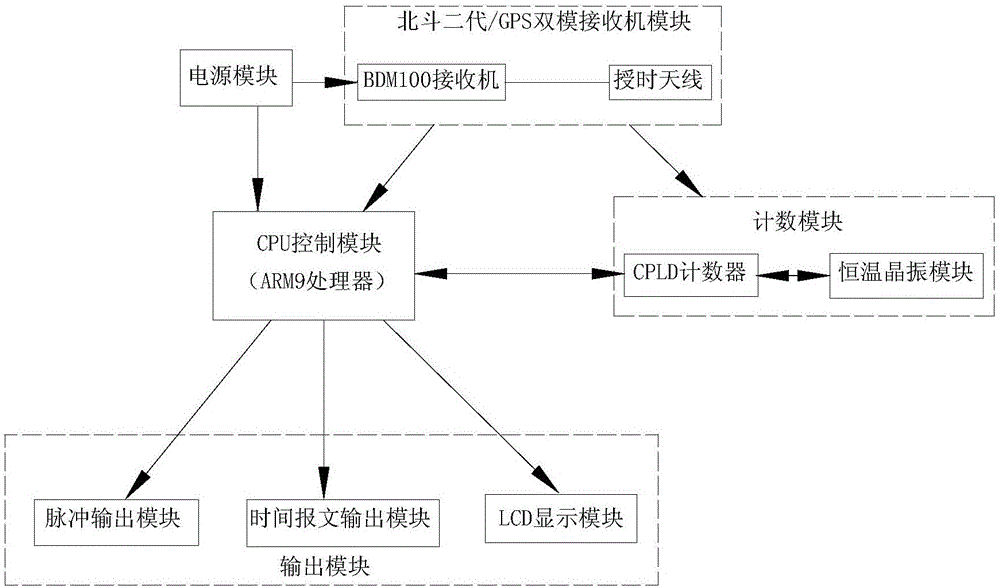

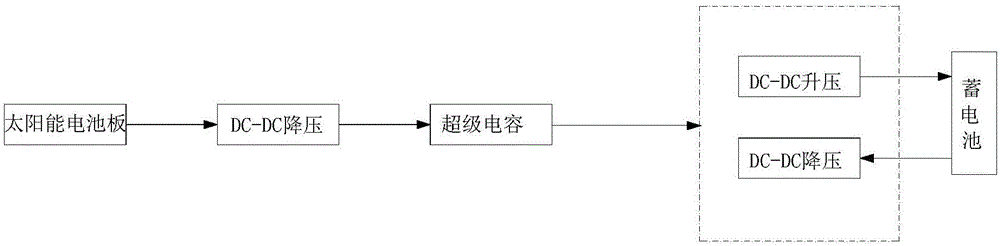

Dual-mode time service machine

InactiveCN106502088AImprove efficiencySmall kernelRadio-controlled time-piecesDual modeComputer module

The invention relates to the field of electronic product production testing, and particularly relates to a dual-mode time service machine. The time service machine comprises a Beidou 2nd generation / GPS dual-mode receiver module, a power supply module, a counting module, a CPU control module and an output module. According to the invention, satellite signals are received by using a Beidou 2nd generation / GPS dual-mode receiver, dual-channel running of a Beidou 2nd satellite and a GPS satellite is ensured, the stability of a signal source is ensured, the counting module selects a constant temperature crystal oscillator module, a Beidou 1pps random error mathematic model is built, and a Beidou 1pps random error is corrected online, so that a random error of Beidou second pulse signals can be effectively eliminated, and the time precision is improved. Meanwhile, the power supply module of the dual-mode time service machine utilizes a photovoltaic effect of solar cells, thereby achieving effects of energy conservation, stable power supply and convenient installation.

Owner:GUANGXI UNIV

Heat-insulation magnesium casting material and preparation method thereof

The invention relates to a heat-insulation magnesium casting material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: evenly mixing 20-50 wt% of magnesite, 33-63 wt% of mesitite, 0.9-7 wt% of silicon dioxide fine powder, 0.1-2 wt% of sodium polyphosphate and 3-8 wt% of water, thereby obtaining the heat-insulation magnesium casting material. The magnesite is more than one of fused magnesite grains, sintered magnesite grains, fused magnesite fine powder and sintered magnesite fine powder. The invention has the advantages of abundant raw material storage and simple preparation technique; and the prepared heat-insulation magnesium casting material basically has no crack or peel phenomenon, has the advantages of low heat conductivity, high strength, strong alkaline dust and slag corrosion resistance, high melting point and strong alkaline solid and gas slag corrosion resistance, and is beneficial to energy saving and consumption reduction. The heat-insulation magnesium casting material provided by the invention is suitable for liners of high-temperature industrial kilns and containers.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com