Double-row radiator for environment-friendly device

A technology of environmental protection equipment and radiator, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of large amount of consumables, difficult assembly, and inability to achieve heat removal, and achieve low production cost, high electrical conductivity, and high heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

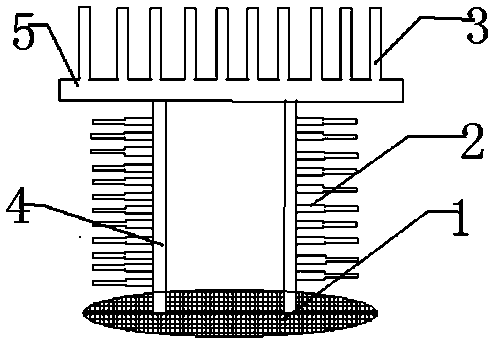

[0016] Such as figure 1 As shown, a double-row heat sink for environmental protection equipment mainly includes a base 1, a support 4 and a heat sink 2 connected to the support 4. The cross section of the base is circular, and the two sides of the base are symmetrical respectively. A bracket 4 is connected, and a heat sink 2 extending to the outside of the base 1 is arranged on one side of the bracket 4, and a horizontal extension frame 5 is arranged above the bracket 4, and the upper end of the extension frame 5 is arranged There are sheets 3 arranged parallel to each other on top of the base 1 .

[0017] The heat sink 2 is arranged in a tapered structure with a large bottom end and a small top end.

[0018] The top radius of the heat sink 2 is 0.8mm, and the bottom radius is 1.6mm.

[0019] The radius of the base 1 is 160mm, and the material is carbonized steel coated with anti-oxidation paint.

[0020] The above are the embodiments of the present invention, so all equiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com