Main lifting brake system of windlass full-balance vertical ship lift

A technology of vertical ship lift and braking system, which is applied in the direction of vertical lifting of ship machinery, hoisting devices, mechanical equipment, etc. It can solve problems such as inability to control separately, wear of brake pads, and rough manufacturing, so as to improve work efficiency, The effect of increasing the accumulator capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

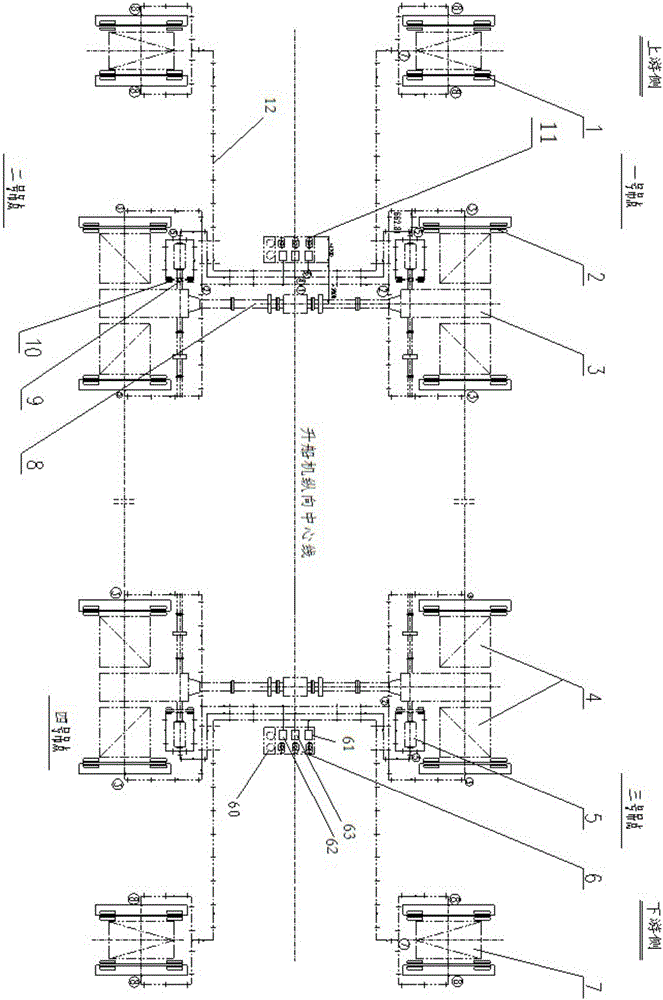

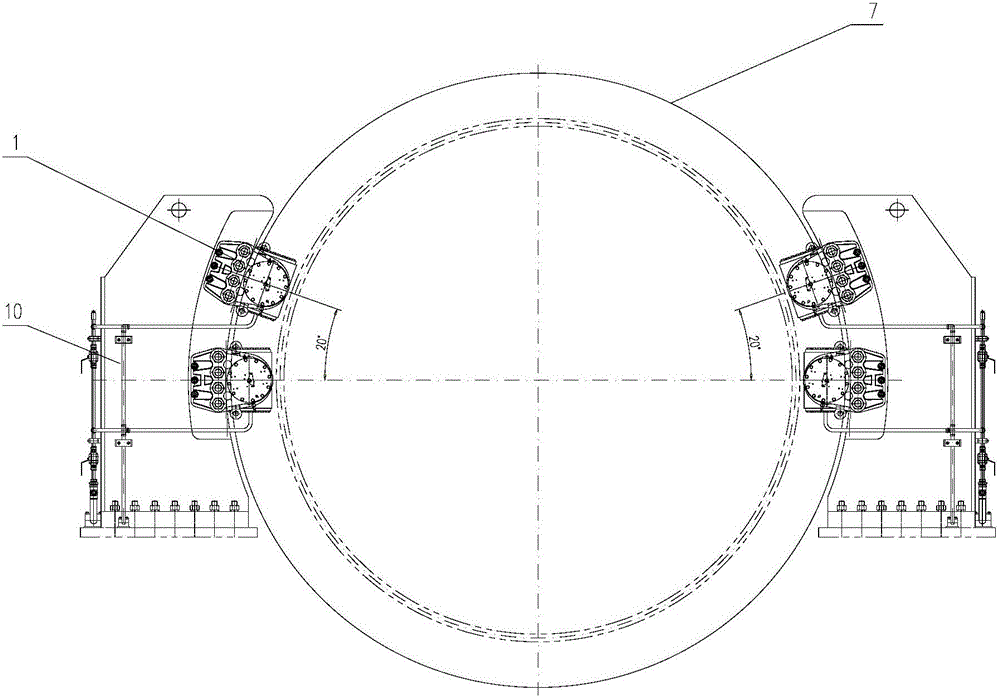

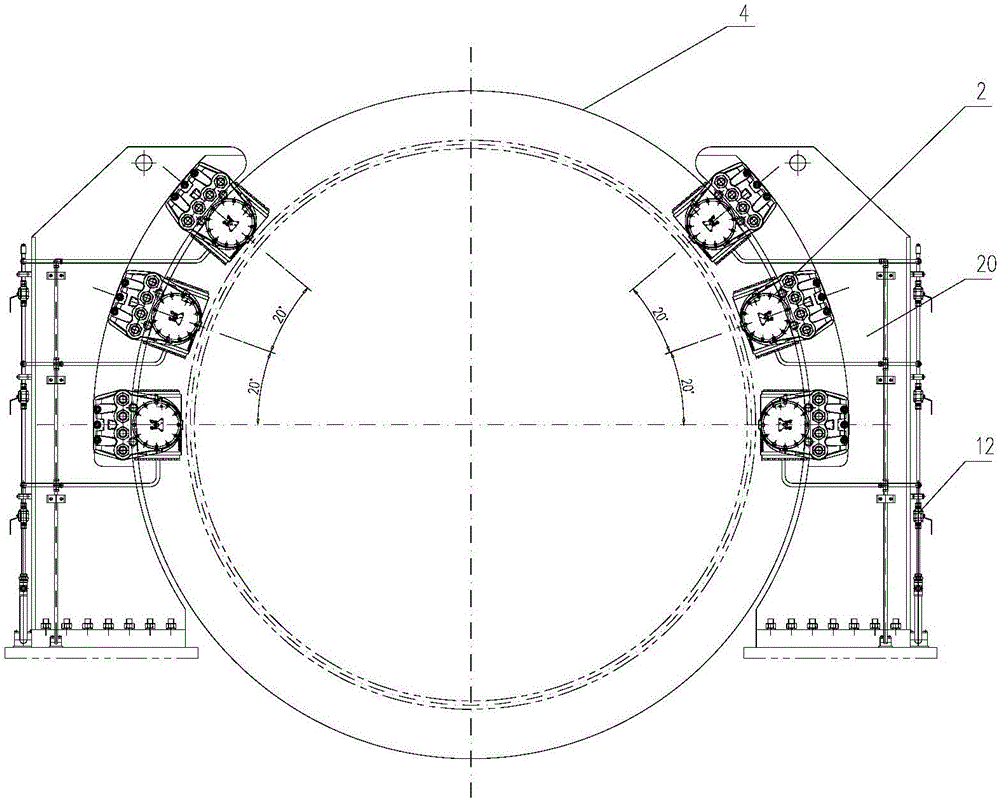

[0021] Such as Figure 1~4 As shown, the main hoisting brake system of a winch-type full-balanced vertical ship lift in this embodiment includes a multi-wire rope winch with four lifting points and counterweights, which is used to drive the ship cabin to lift vertically along the tower column; each There are two main hoisting drums 4 with brake discs and a controllable counterweight drum 7 respectively on the lifting point, and the two main hoisting drums 4 on each hoisting point are connected coaxially and passed through a reducer 3 Drive, the reducer 3 is connected with a synchronous shaft device 8, and the four lifting points are arranged at equal intervals in a ring through the synchronous shaft device 8 and connected synchronously; the reducer 3 of each lifting point is connected to a shaft coupling 9 respectively. The electric motor 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com