Scaling inhibitor applied to industry cooling water systems, and preparation method thereof

A technology of cooling water system and scale inhibitor, which is applied in the field of new scale inhibitor and its preparation, can solve environmental pollution and other problems, and achieve the effects of improving thermal conductivity, improving operating efficiency, and improving heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First prepare graphene oxide: add 10.0g graphite, 10.0g potassium persulfate, and 10.0 phosphorus pentoxide to a three-necked round-bottomed flask, slowly pour 100ml of concentrated sulfuric acid and stir, and after stirring evenly, slowly raise the temperature to 80°C React for 5 hours, pour the reacted liquid into the ice-water mixture until the solution is completely exothermic, filter, wash with deionized water, put it in a vacuum oven at 80°C for 12 hours, and the product is pre-oxidized graphite . Pre-oxidized graphite was further treated with 300ml of concentrated sulfuric acid, 60.0g of potassium permanganate and 50ml of hydrogen peroxide, and the precipitate was collected, washed with (10%, v / v) dilute hydrochloric acid for 10 times to obtain graphite oxide, and the graphite oxide was ultrasonically treated for 10~ After 180 minutes, graphene oxide with a particle size of 15-800nm was obtained.

Embodiment 2

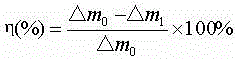

[0026] In simulated water containing 0, 10, 50, 100, and 200 mg / L antiscalant (graphene oxide), the weight gain of stainless steel coupons after the scaling test was 32.0, 11.5, 3.1, 4.2, and 6.8 mg, respectively , so the scale inhibition rates of graphene oxide scale inhibitors with concentrations of 10, 50, 100, and 200 mg / L can be calculated to be 64.1%, 90.3%, 86.9%, and 78.8%.

[0027] Through the above examples, the results show that using graphene oxide as the scale inhibitor, the scale inhibition rate first increases and then decreases with the increase of the concentration, and the scale inhibition rate reaches 90.3% when the graphene oxide concentration is 50 mg / L .

[0028] To sum up, the present invention is a novel scale inhibitor that can be used in industrial cooling water systems, that is, adding a certain concentration of graphene oxide in the cooling water can inhibit the adhesion of scaling particles on the metal surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com