Energy-saving method and device of lengthwise graphitization furnace

A graphitization furnace and graphitization technology, used in furnaces, chemical industries, furnace components, etc., can solve the problems of furnace pits being unable to be put into production cyclically, affecting production efficiency, and large thermal energy loss, reducing one-time investment and having a simple structure. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the inventive concept of the present invention, the specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

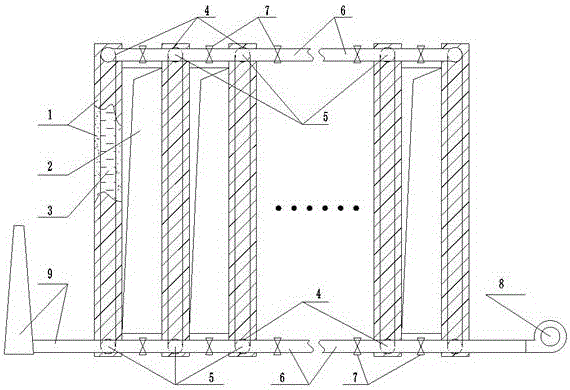

[0024] An energy-saving method for connecting graphitization furnaces in series. The method is to use air as a carrier to blow the heat in the graphitization furnace pit after the graphitization process into normal-temperature air through a blower into the air passage connected to the hollow partition wall and the bottom plate. The air flow will be heated after passing through the tortuous air passage, taking away a large amount of heat energy, so that the material that has completed the graphitization process will be cooled down, and the heated air carrying a large amount of heat energy will be sent to another group of new equipment through the pipeline. In the air channel connected to the furnace pit partition wall and the bottom plate where the material needs to be gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com