High-stiffness reflecting film and manufacturing method thereof

A reflective film and high stiffness technology, applied in the field of reflective film, can solve the problems of reduced film stiffness, decreased reflective film density, and film bending, and achieves the effects of improving stiffness, reducing production costs, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

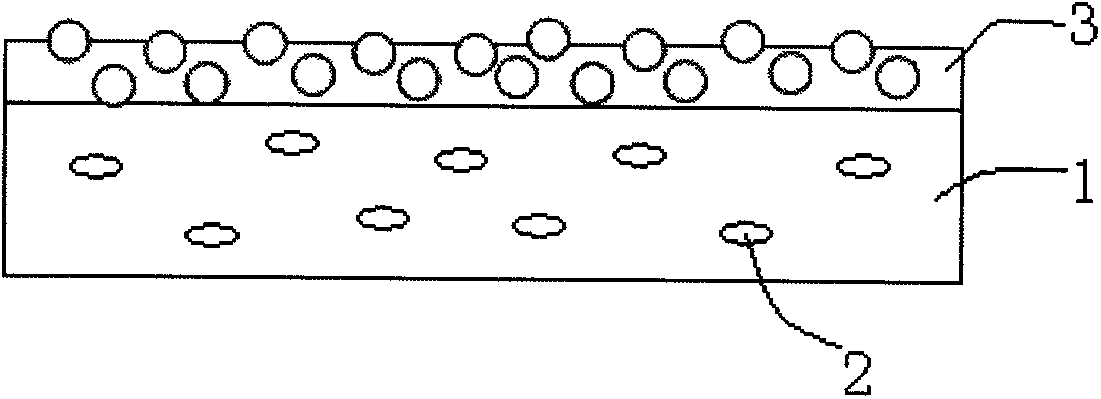

[0020] refer to figure 1 , a high stiffness reflective film, comprising a reflective film base layer 1, microbubbles 2 are provided in the reflective film base layer 1, and the material of the reflective film base layer 1 is PET;

[0021] The reflective film base layer 1 is provided with a diffusion film 3, and the diffusion film 3 is composed of the following components:

[0022] Polymethyl methacrylate: 20 parts by mass

[0023] Polyisocyanate: 15 parts by mass

[0024] Diffusing particles: 1 to 3 parts by mass. The diffusion particles are preferably titanium dioxide particles. Titanium dioxide has two types: rutile type and anatase type. Since the crystal structure of rutile type titanium dioxide is dense, the refractive index is high, and the refractive index difference with polyester resin is large, a highly reflective interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com