Light weight microporous corundum aggregate and preparation method thereof

A lightweight corundum bone technology, which is applied in the field of lightweight microporous corundum aggregates and its preparation, can solve the problems of uncontrollable pore size and quantity inside the material, poor resistance to molten steel and steel slag erosion and permeability, and large amount of water added in the wet grinding process and other problems, to achieve the effect of improving thermal shock stability, good thermal shock stability, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22

[0041] After the components in the raw materials are mixed evenly, the pellets are formed into balls with a diameter of 20 mm, and then kept at a certain temperature for a period of time to obtain lightweight microporous corundum aggregates.

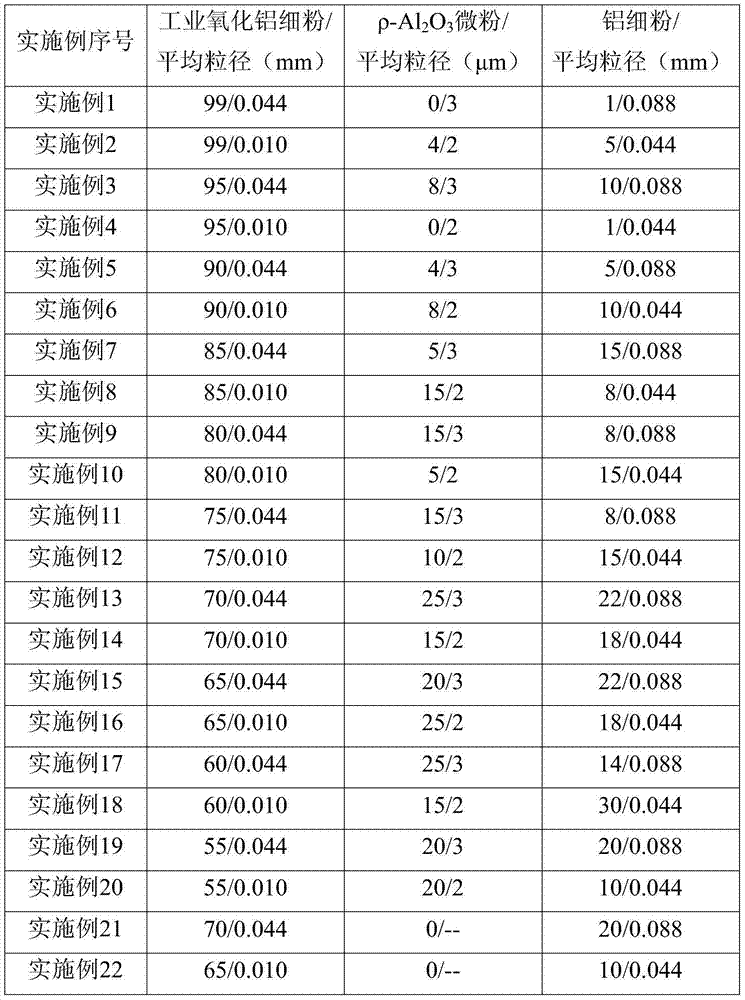

[0042] The proportion by weight of each component in the raw material and the average particle size of each raw material are shown in Table 1, wherein, the Al in the industrial alumina fine powder used 2 O 3 The weight percentage of aluminum fine powder is ≥99%, and the aluminum fine powder is stirred in the air for 24h before use. The amount of water added into the ball, the holding temperature and the holding time are shown in Table 2. The performance of the prepared lightweight microporous corundum aggregate is shown in the table. 3 shown.

[0043] Table 1

[0044]

[0045] Table 2

[0046] Example serial number

[0047] table 3

[0048] Example serial number

[0049] Example 3

[0050] As can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com