Production method of colored tape with long printing service life

A production method and ribbon technology, applied in printing, ink ribbon, fiber type, etc., can solve problems such as insufficient ink content, incomplete use, and inability to continue using the ribbon, and achieve the effect of increasing the absorption speed and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the production method of the color ribbon of high printing life, is made up of the following steps:

[0026] A, choose the nylon 66 yarn of high breaking strength to make and produce ribbon gray cloth 5;

[0027] b. Carry out pre-shrinkage and new process scouring treatment on the ribbon gray cloth 5;

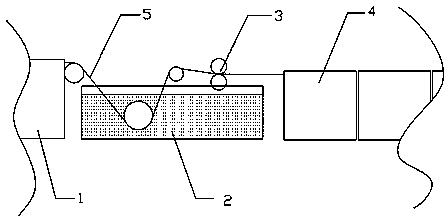

[0028] c. Pass the scoured ribbon fabric 5 through the ink adsorption accelerator solution pool 2 and squeeze it through the pressure roller 3 to make the ribbon fabric 5 fully absorb the accelerator solution;

[0029] d. Dry and shape the ribbon gray cloth 5 according to the new process standard;

[0030] e, using a hot-melt slitting machine to fuse and cut the ribbon gray cloth 5 to form a ribbon base;

[0031] f. Use the ribbon ink coater to coat the ribbon base with ink.

[0032] After the ribbon gray cloth 5 comes out from the washing pool 1, it passes through the ink absorption accelerator solution pool 2, so that the ribbon fabric 5 fully absorbs ...

Embodiment 2

[0037] Embodiment 2: the production method of the color ribbon of high printing life, is made up of the following steps:

[0038] A, choose the nylon 66 yarn of high breaking strength to make and produce ribbon gray cloth 5;

[0039]b. Carry out pre-shrinkage and new process scouring treatment on the ribbon gray cloth 5;

[0040] c. Pass the scoured ribbon gray cloth 5 through the ink adsorption accelerator solution pool and squeeze it through the pressure roller to make the ribbon gray cloth 5 fully absorb the accelerator solution;

[0041] d. Dry and shape the ribbon gray cloth 5 according to the new process standard;

[0042] e. Use a professional melting and cutting machine to melt and cut the ribbon fabric 5 to form the ribbon base;

[0043] f. Use a professional inking machine to apply ink to the ribbon base.

[0044] After the ribbon gray cloth 5 comes out of the washing pool 1, it passes through the ink absorption accelerator solution pool 2, so that the ribbon fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com