Patents

Literature

2693results about How to "Convenient and flexible use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

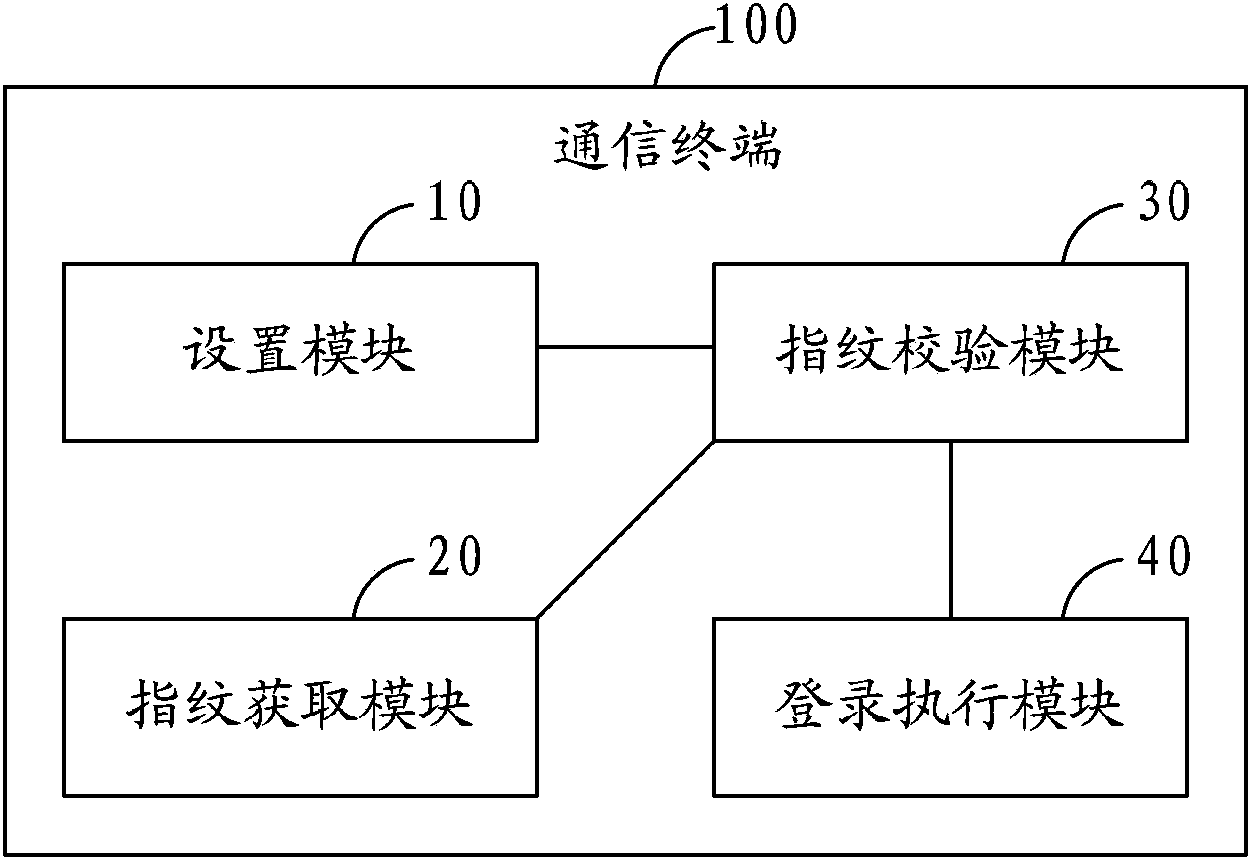

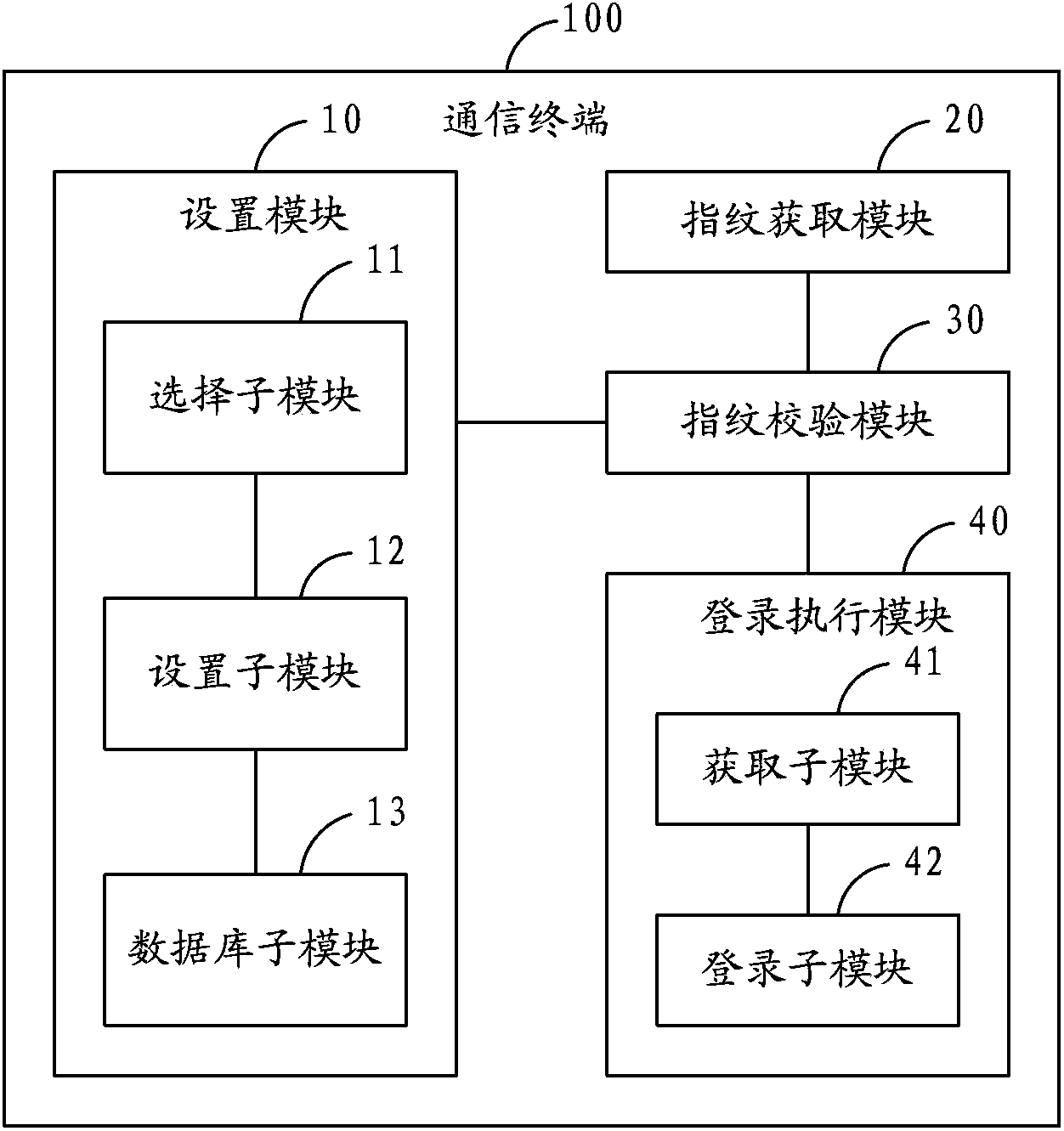

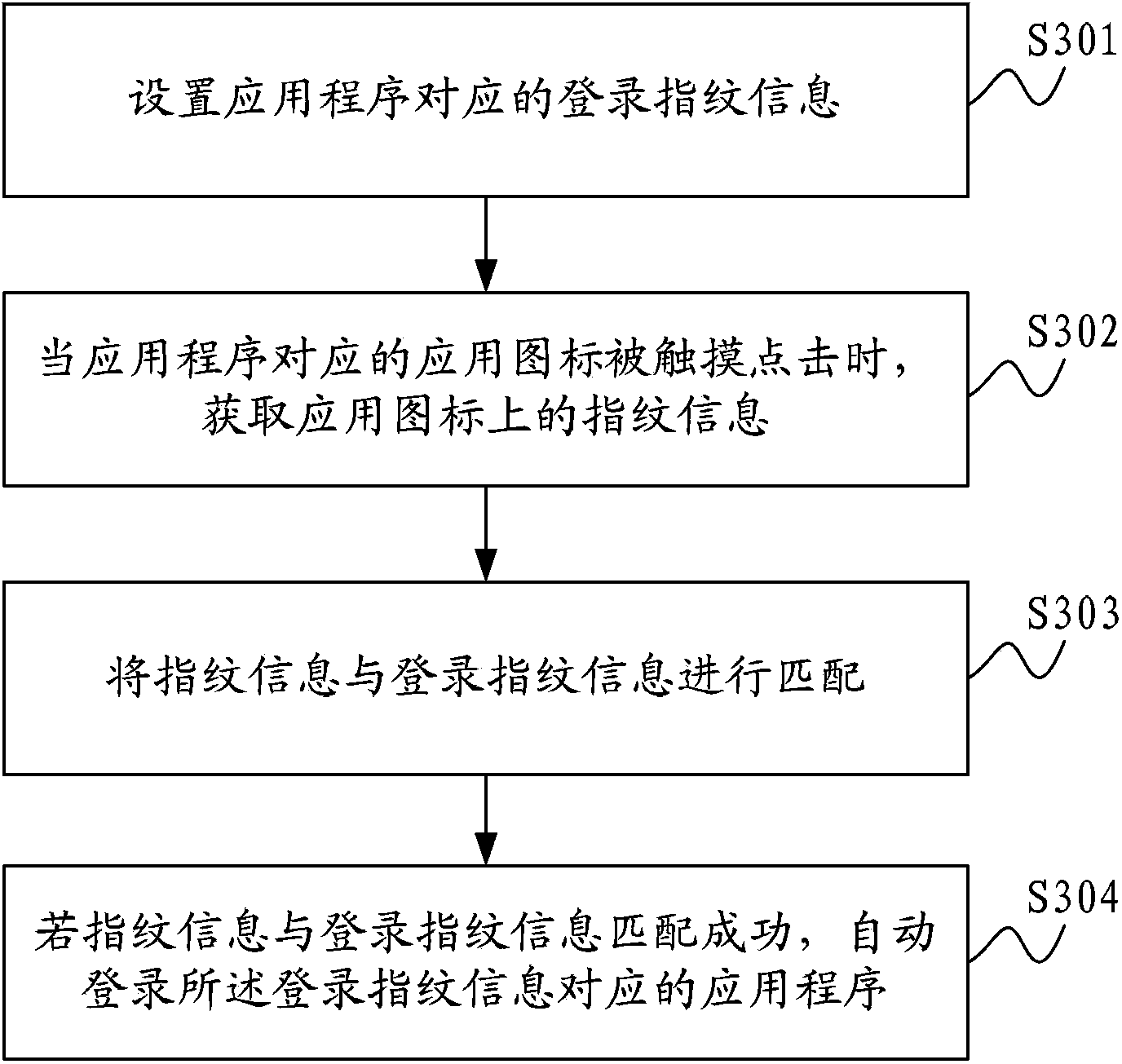

Login method of application program and communication terminal

InactiveCN103425914AEasy loginLog in efficientlyDigital data authenticationSecurity arrangementComputer terminalApplication software

The invention is applicable to the technical field of communication, and provides a login method of an application program. The login method includes the flowing steps: setting login fingerprint information corresponding to the application program; when an application icon corresponding to the application program is touched and clicked, acquiring the fingerprint information on the application icon; matching the fingerprint information with the login fingerprint information; if the fingerprint information is matched with the login fingerprint information, automatically logging in the application program corresponding to the login fingerprint information. Correspondingly, the invention further provides a communication terminal. By the login method and the communication terminal, a user can login the application program conveniently and efficiently through simple fingerprint verification, and the user's using habit is satisfied.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

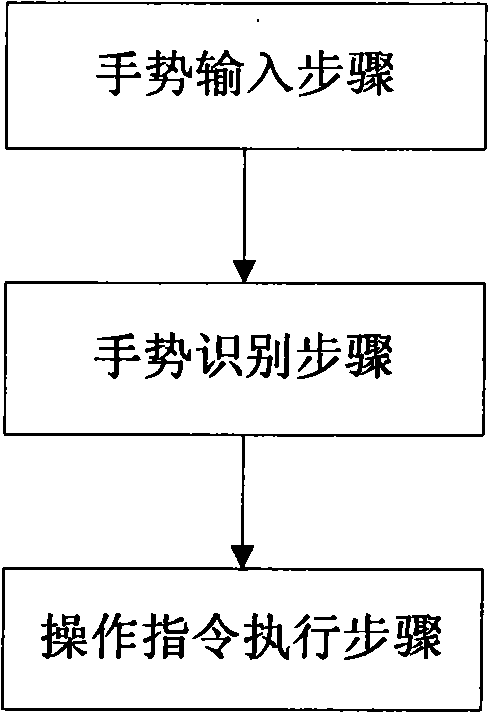

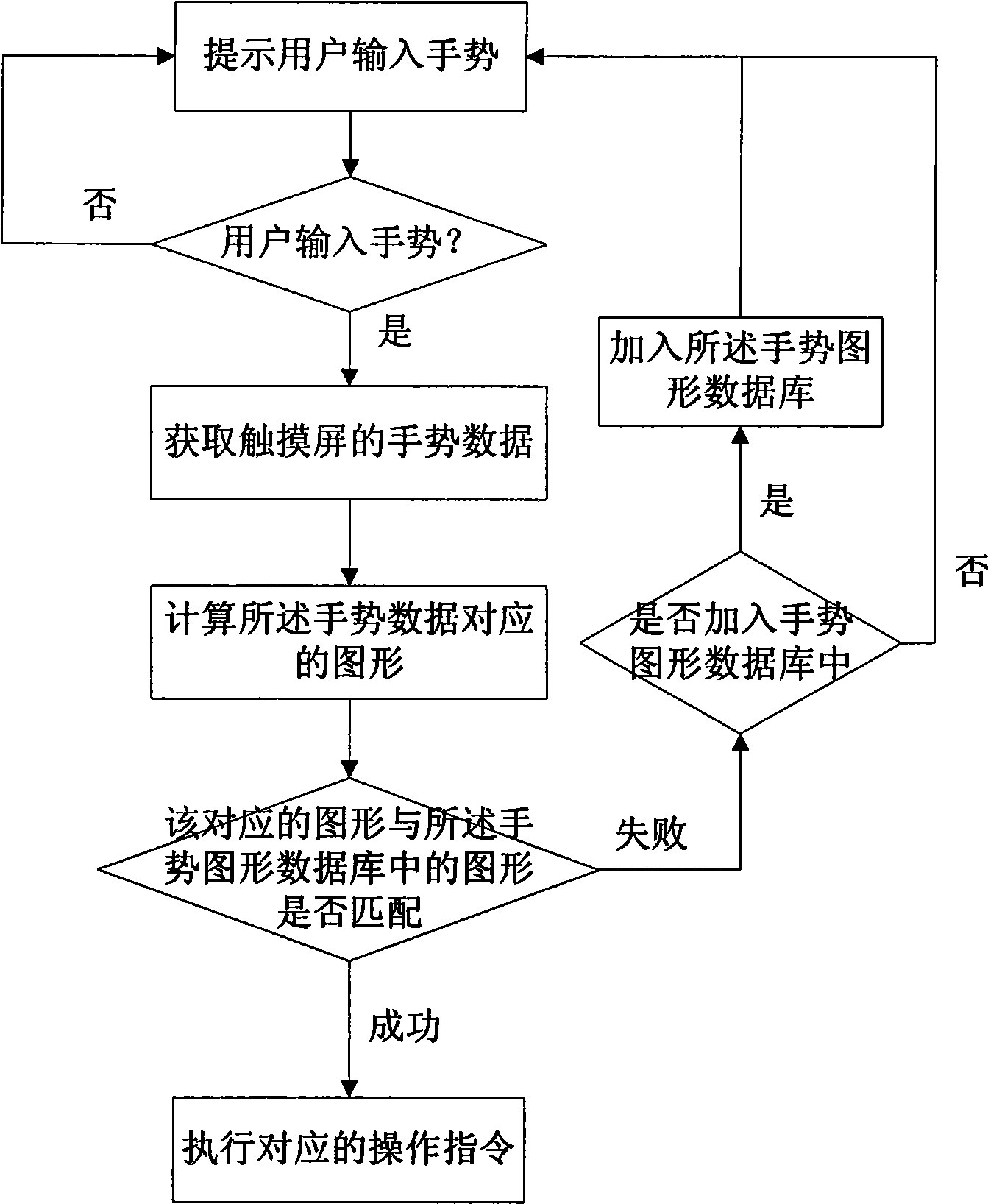

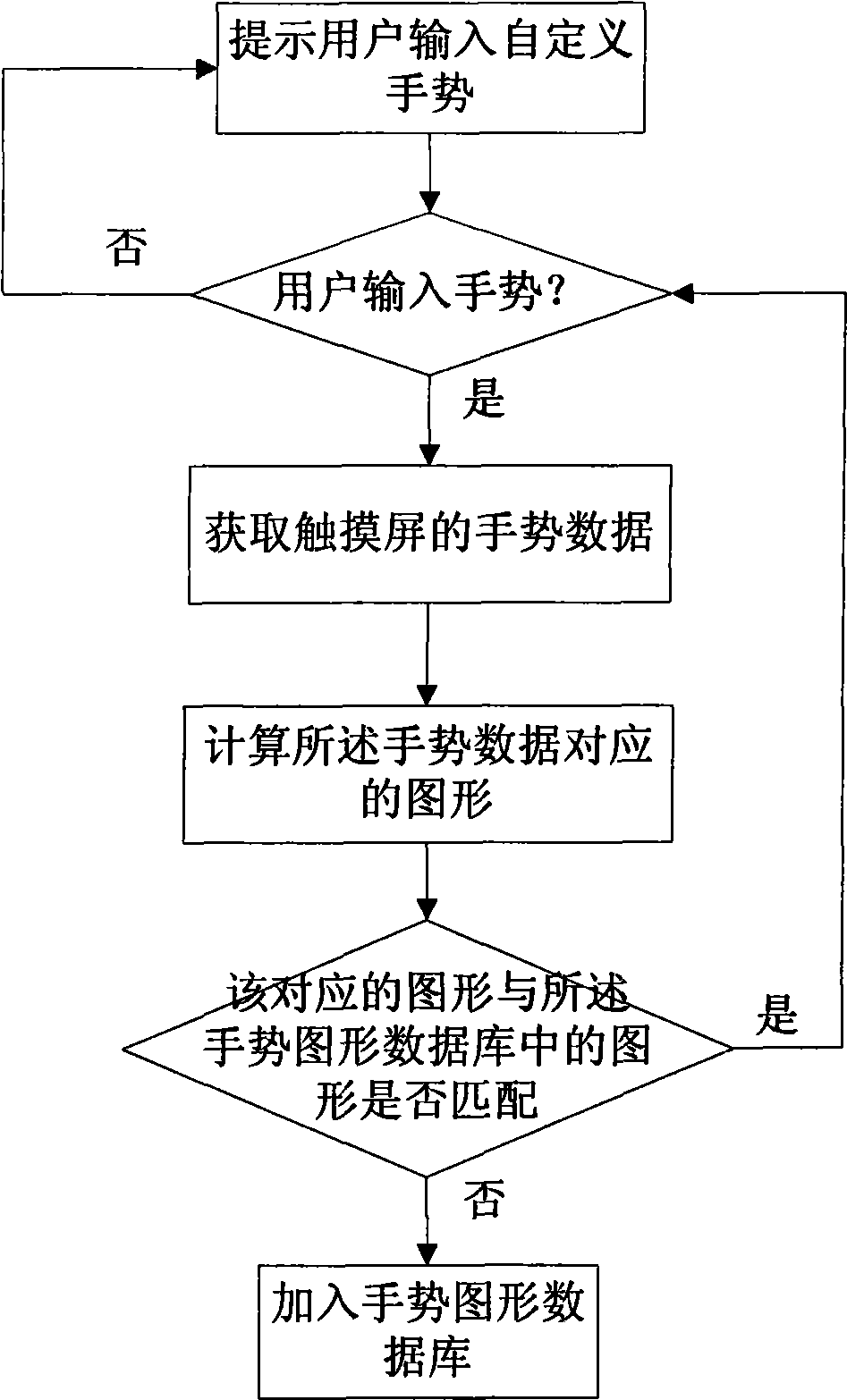

Identification and operation method of touch screen interface gestures

InactiveCN101546233AImprove toleranceImprove usabilityInput/output for user-computer interactionGraph readingGraphicsUser input

An identification and operation method of touch screen interface gestures comprises the following steps: 1) gesture input used for acquiring gesture data input by a user through a touch screen, 2) gesture identification, and 3) operation instruction execution used for executing an operation instruction corresponding to the gesture data, wherein step (1) comprises the following steps: 11) reminding the user to input a gesture; 12) judging whether the user inputs the gesture, and entering step 13) if the user inputs the gesture, otherwise, transferring to step 11); and step 13) acquiring the gesture data of the touch screen. The identification and operation method matches a response action by identifying the features of graphic symbols input by a user instead of clicking on a quite small screen area; therefore, the method has strong tolerance on user input and has no requirements on the specific input position of the user; the method can identify similar graphic symbols input by the user, thereby increasing equipment accessibility; moreover, the method can establish and expand a graphic database by identifying and studying graphics input by the user.

Owner:HUAQIN TECH CO LTD

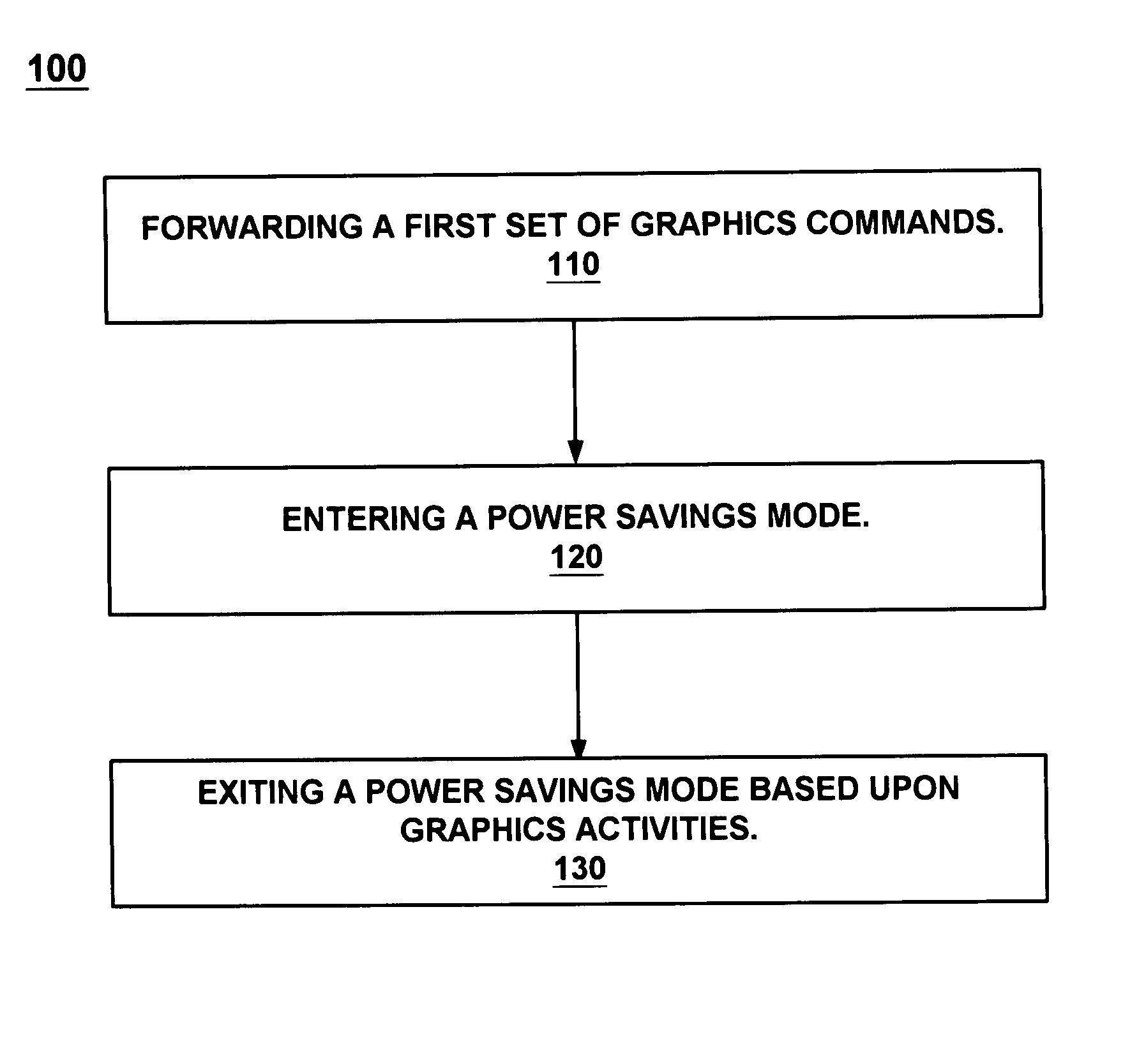

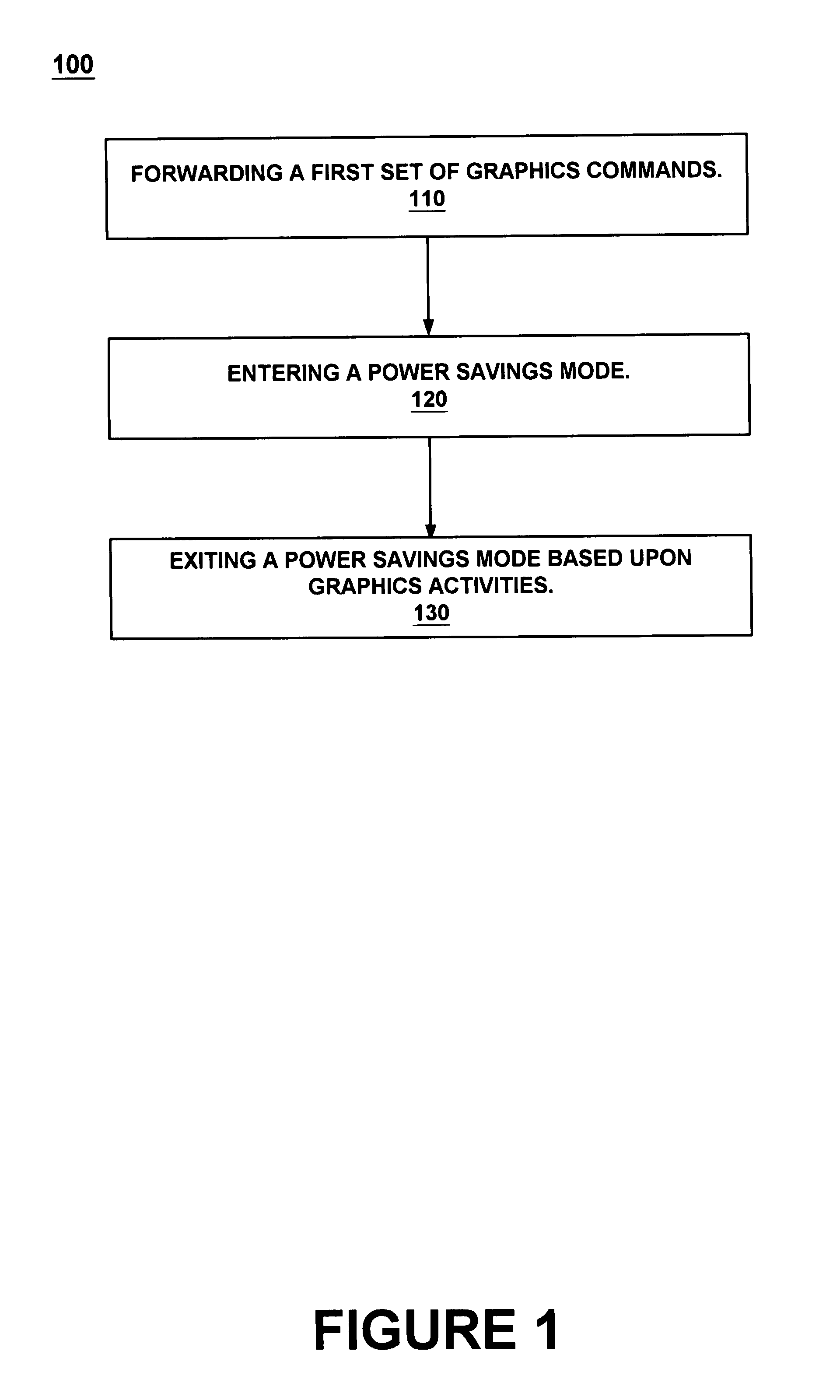

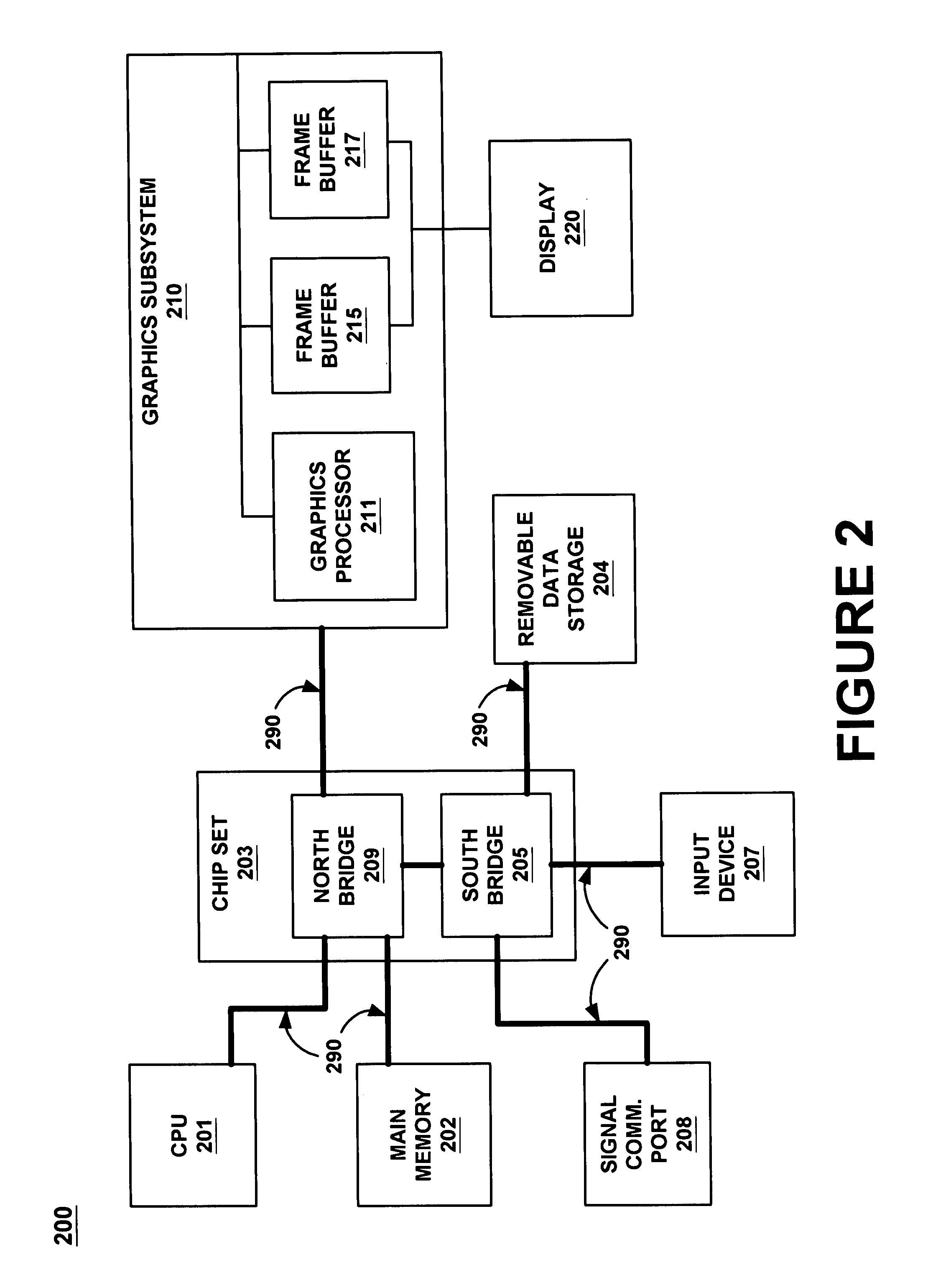

Graphics power savings system and method

InactiveUS7256788B1Efficient power savingConvenient and flexible useEnergy efficient ICTVolume/mass flow measurementComputer hardwareGraphics

The present invention facilitates utilization of flexible and efficient power savings in graphics systems. A graphics power management method loads a first set of graphics commands from a CPU into a GPU at the beginning of a frame cycle. The CPU is put into a power saving mode after the loading is complete. The GPU processes the commands and forwards the results to a graphics buffer. The display begins the presentation of the data at the beginning of the following refresh cycle. The CPU leaves the power savings mode at end of the frame cycle to begin loading a second set of commands. The CPU recognizes the end of the frame cycle by counting a predetermined number of frame flip interrupt requests. After the CPU counts the predetermined number of frame flip interrupt requests the CPU begins to communicate additional graphics commands and then returns to the power savings mode.

Owner:NVIDIA CORP

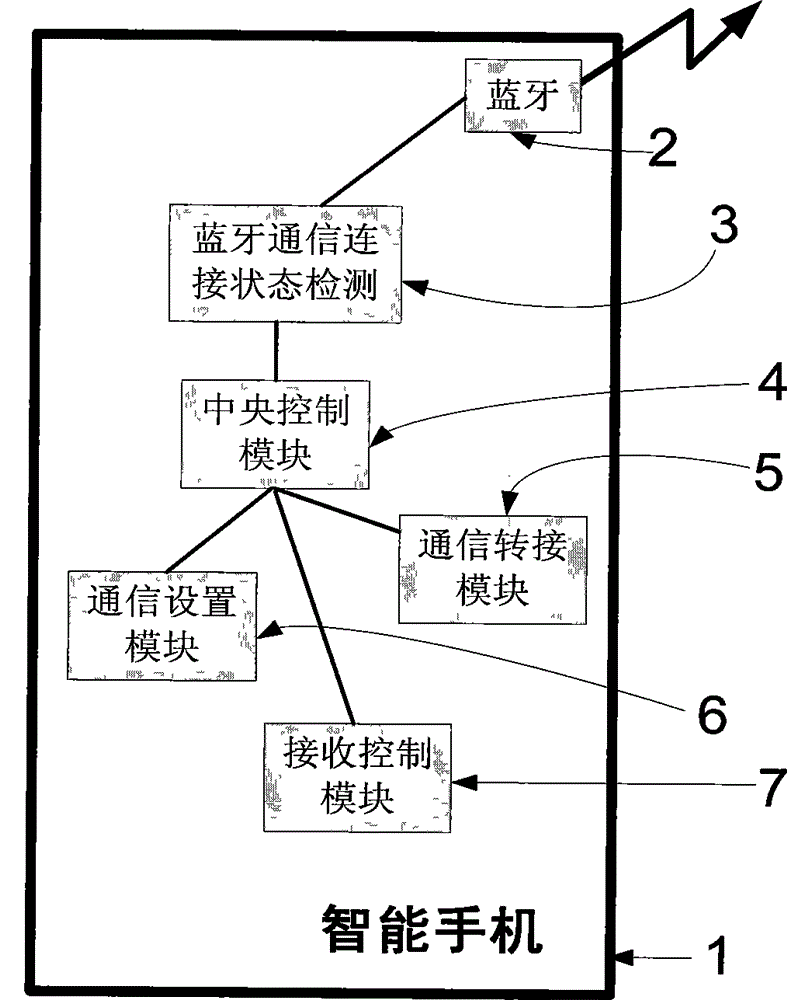

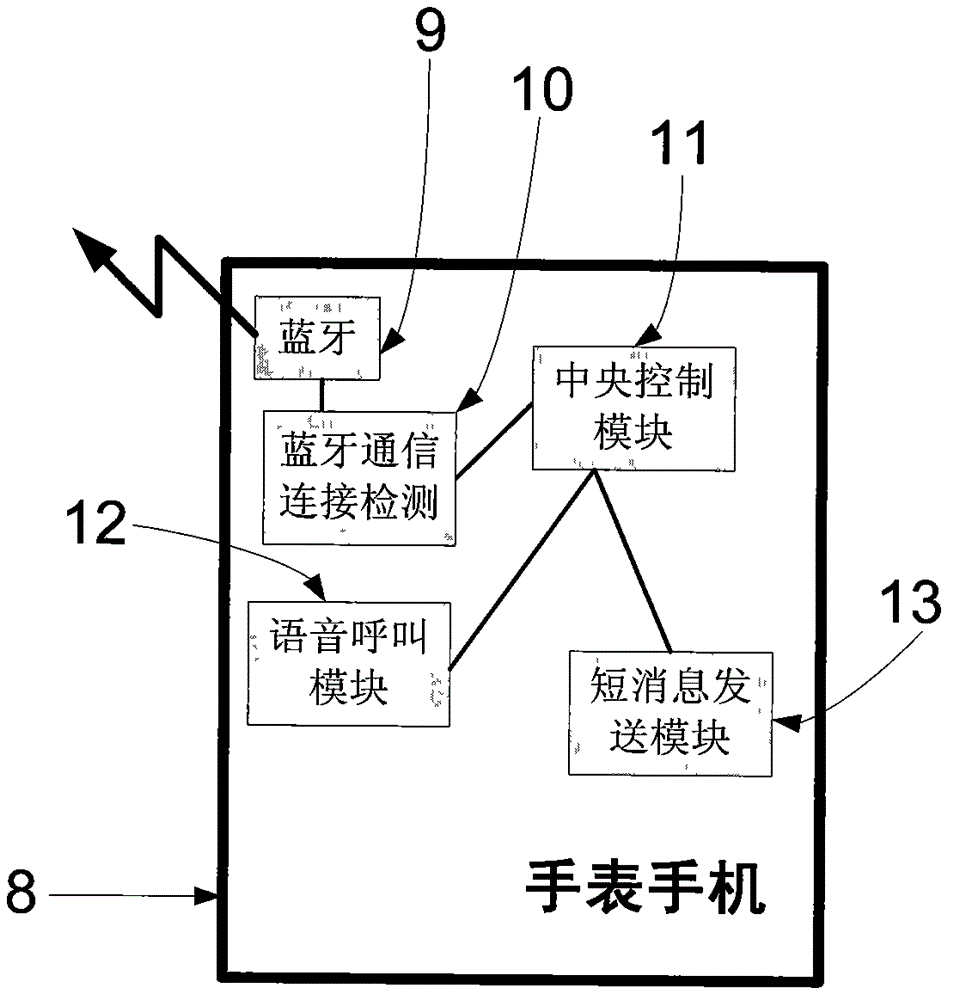

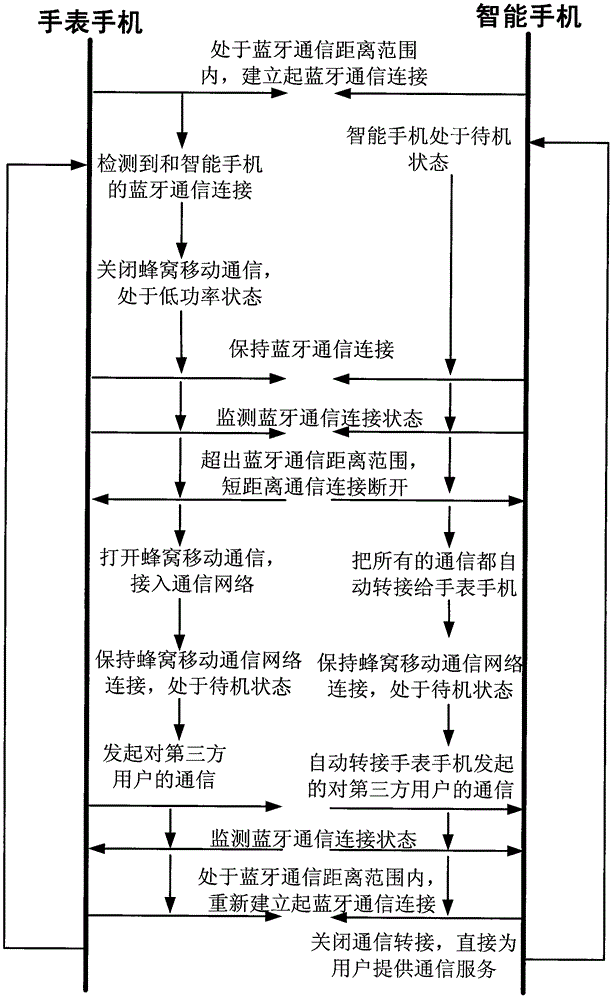

Automated communication switching method and equipment among multiple mobile communication terminals

InactiveCN104469662AConvenient and flexible useImprove user experienceWireless commuication servicesTelecommunicationsDistance detection

The invention belongs to the field of mobile communication terminals and discloses an automated communication switching method and equipment among multiple mobile communication terminals of the same user. The user has portable equipment like a watch phone and further has another large-screen smart phone. When the phones are located remotely and are not located on the same place, the smart phone can automatically switch received communication to the watch phone, and meanwhile calling, launched by the watch phone, on other users is automatically switched. According to the automated communication switching method, automated communication switching can be achieved through the smart phone only through distance detection between the smart phone and the watch phone, and participation of a communication network is not needed. The user can conceal phone numbers of the watch phone and use phone numbers of the smart phone only in the process of communication service, so the user can have unique mobile user identification, and the mobile communication terminals can be used more flexibly and more conveniently.

Owner:王家城

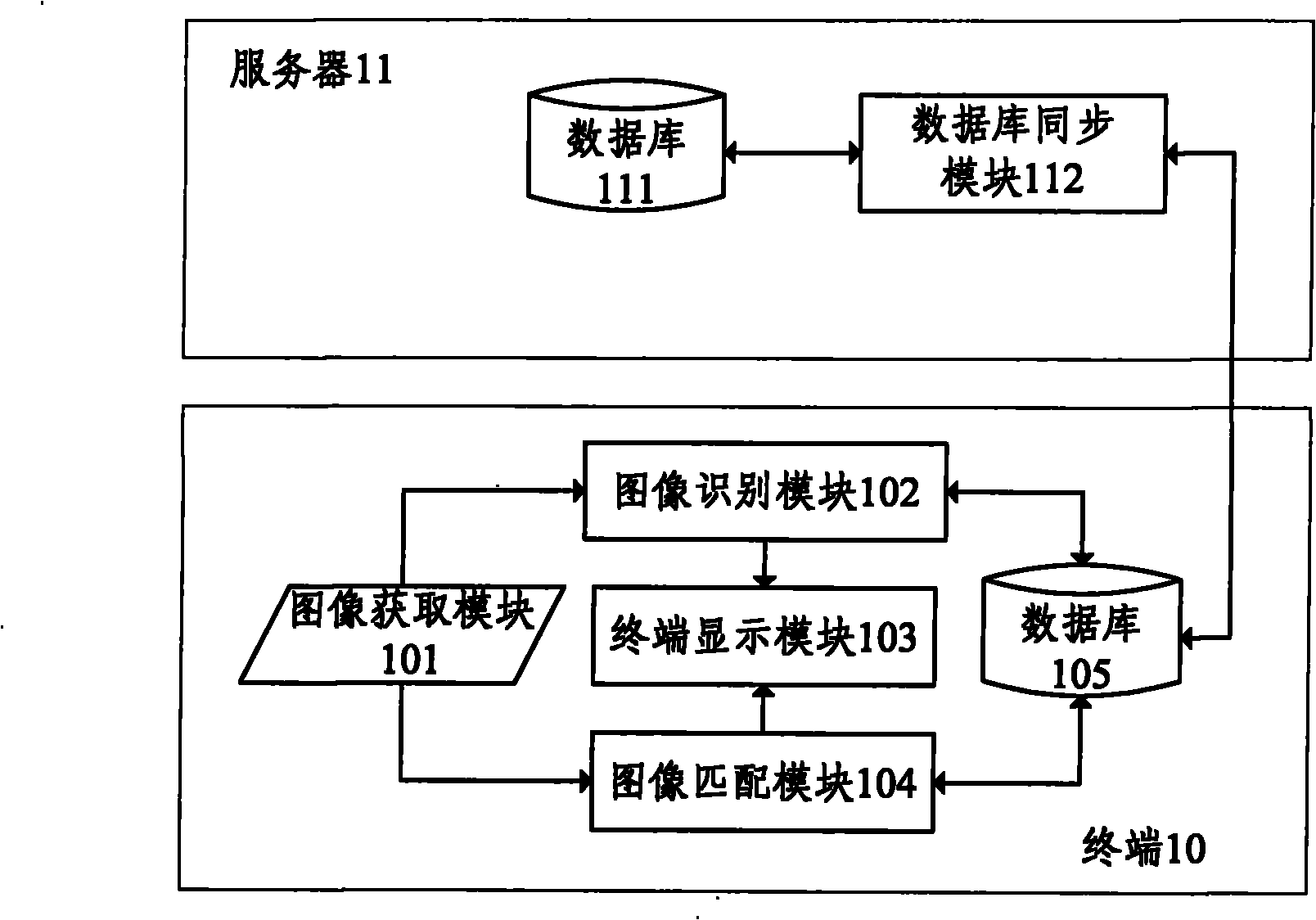

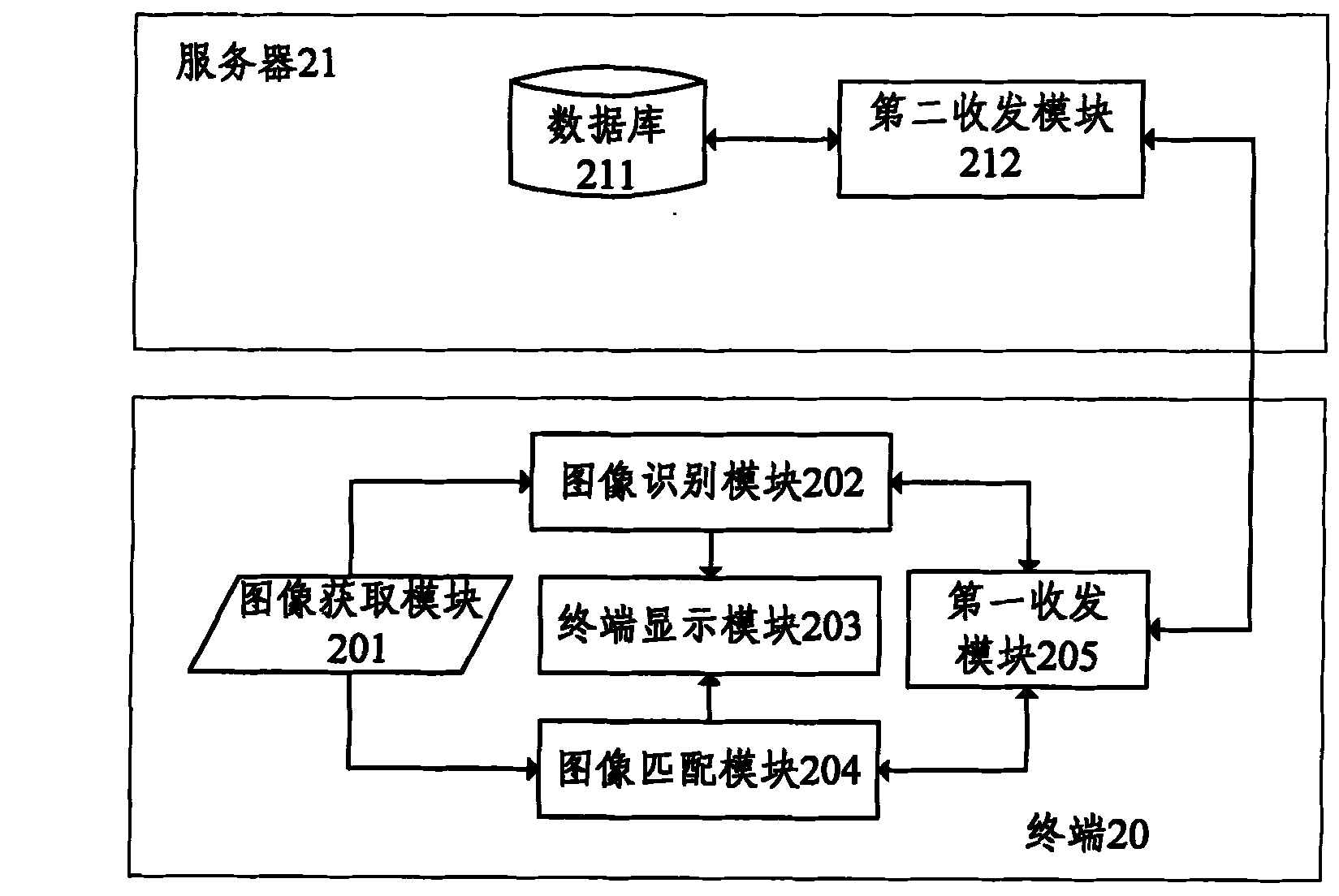

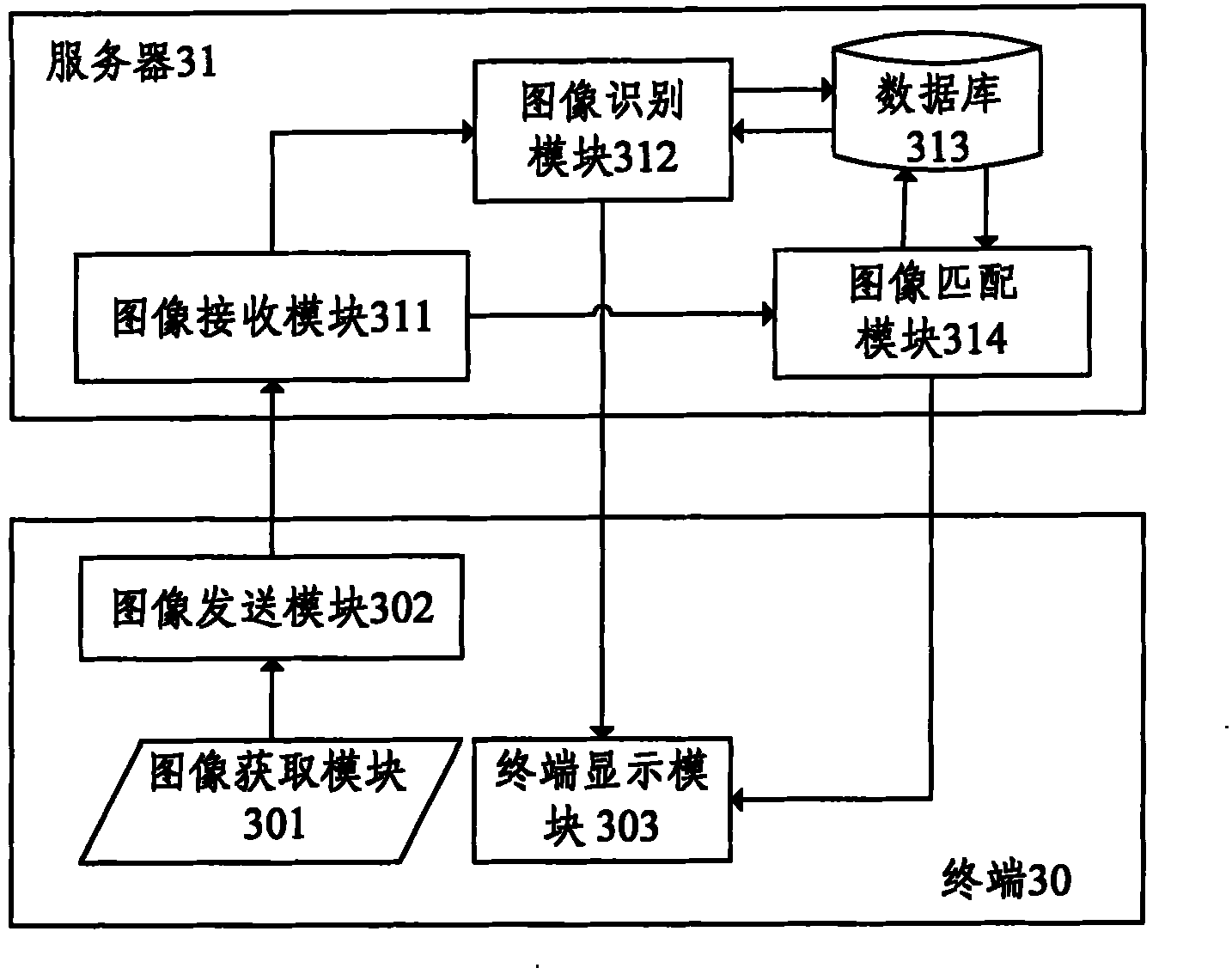

System and method for realizing merchandise information searching by using terminal to acquire images

InactiveCN102063436AEasy accessEasy to purchaseCommerceSpecial data processing applicationsInformation provisionInformation searching

The invention discloses a system and a method for realizing merchandise information searching by using a terminal to acquire images. A user terminal picks up an image of a needed merchandise, performs image recognition and / or image matching on the picked up image of the merchandise, determines the merchandise needed by a user, acquires corresponding merchandise information according to the determined merchandise and provides the acquired corresponding merchandise information for the user. By adoption of the invention, the information of the merchandise needed by the user can be conveniently and fast found out and provided for the user.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Graphene electrothermal film

ActiveCN104219797AWide variety of sourcesLow costOhmic-resistance heatingSatellite antennasFlight vehicle

The invention discloses a graphene electrothermal film which comprises a graphene film radiating layer and an insulating protective layer coated on an upper layer and a lower layer of the graphene film radiating layer. The graphene electrothermal film is simple in structure, can be manufactured in a large-area and mass-production manner, is safe in working voltage, high in thermal conversion efficiency, fine in thermal conductivity, quick in response, fine in tenacity, and can be used in different application environments, and temperature can be controlled accurately. The graphene electrothermal film is used for building heat supply, and can meet the demands of safety and comfort and environmental protection and energy saving. The film is used for snow melt of satellite antenna radars and is small in signal shielding function to the antenna radars. The film is used for deicing of planes and aircrafts, and can bend and combine to meet the demands of deicing in different areas.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

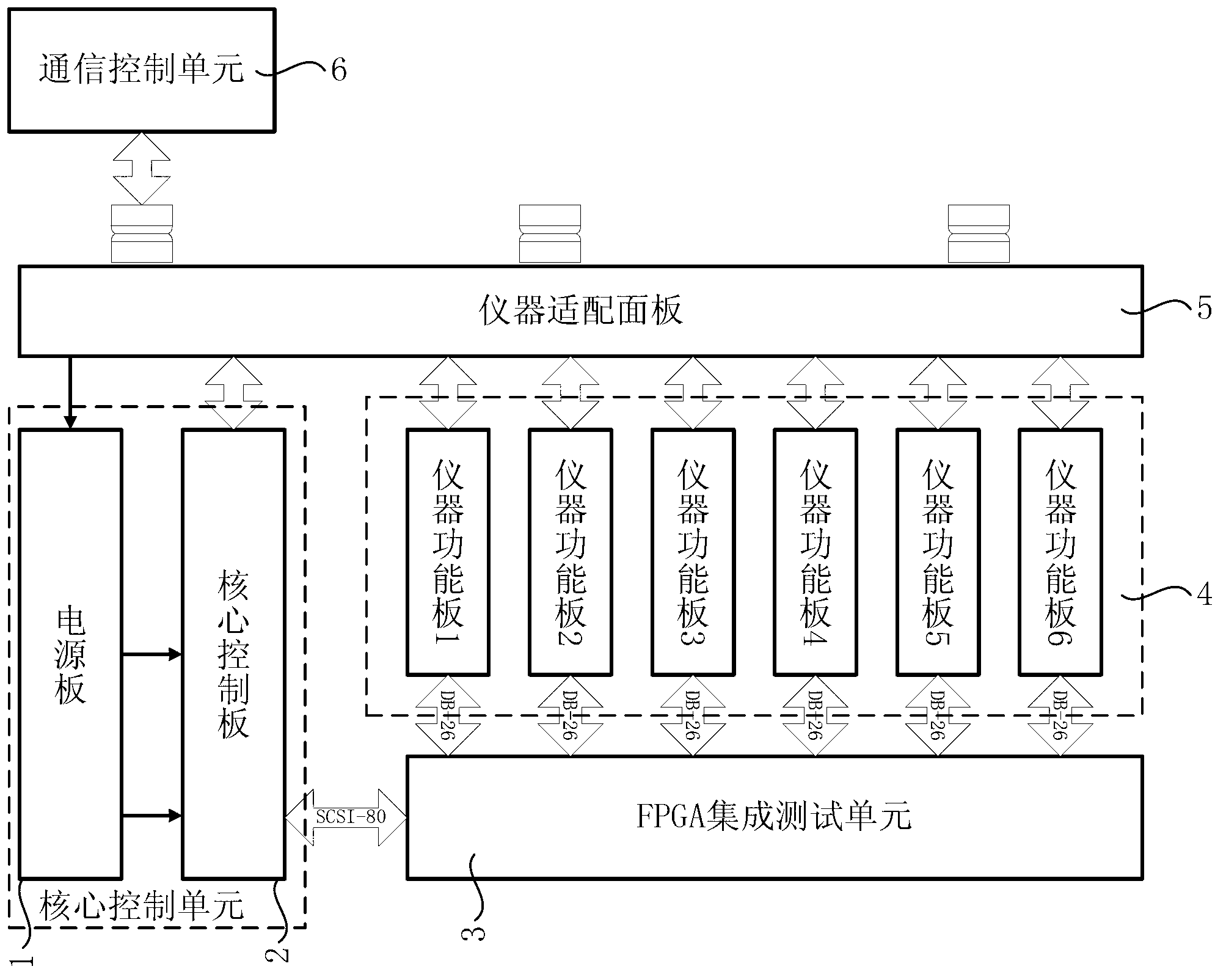

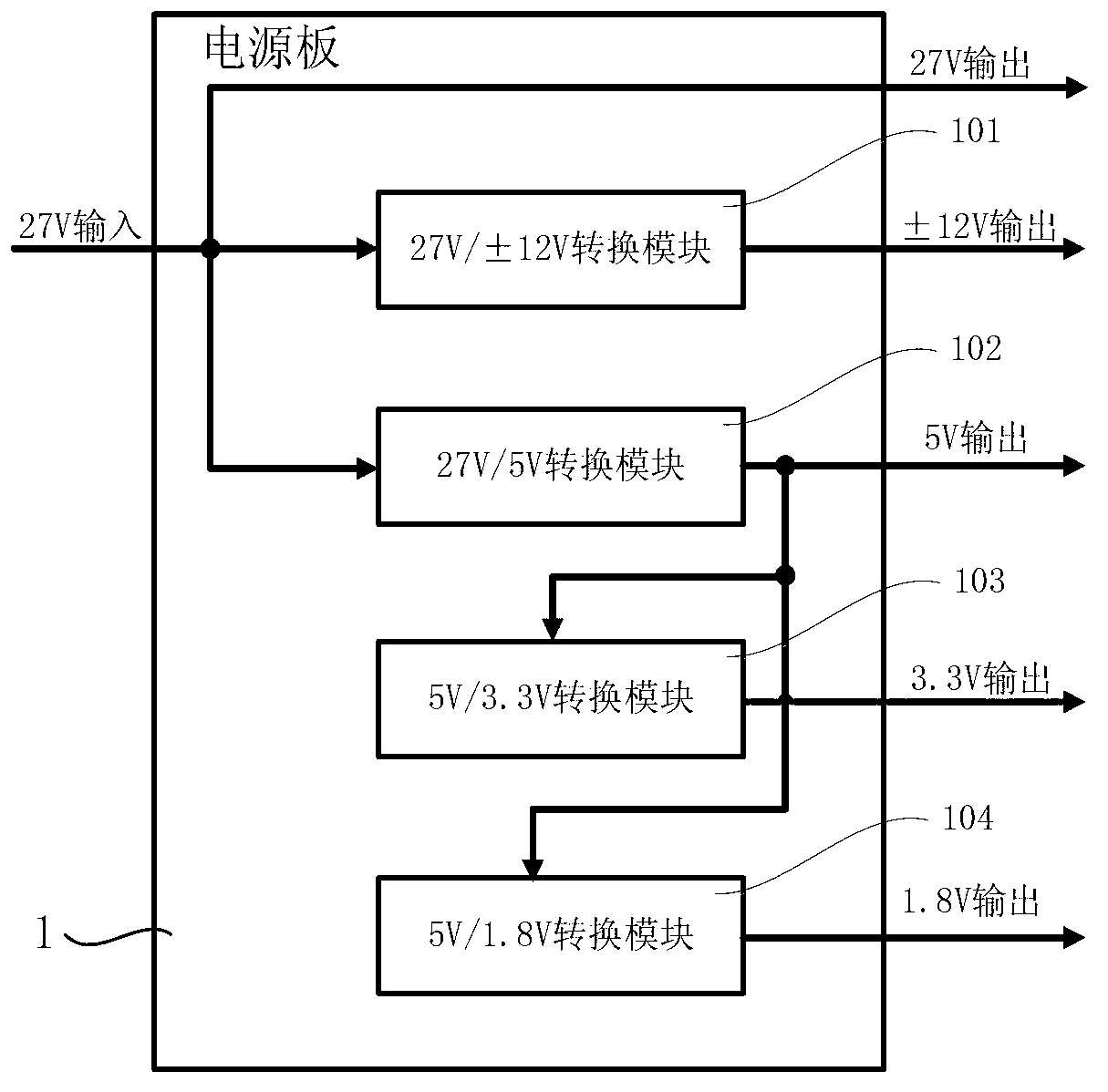

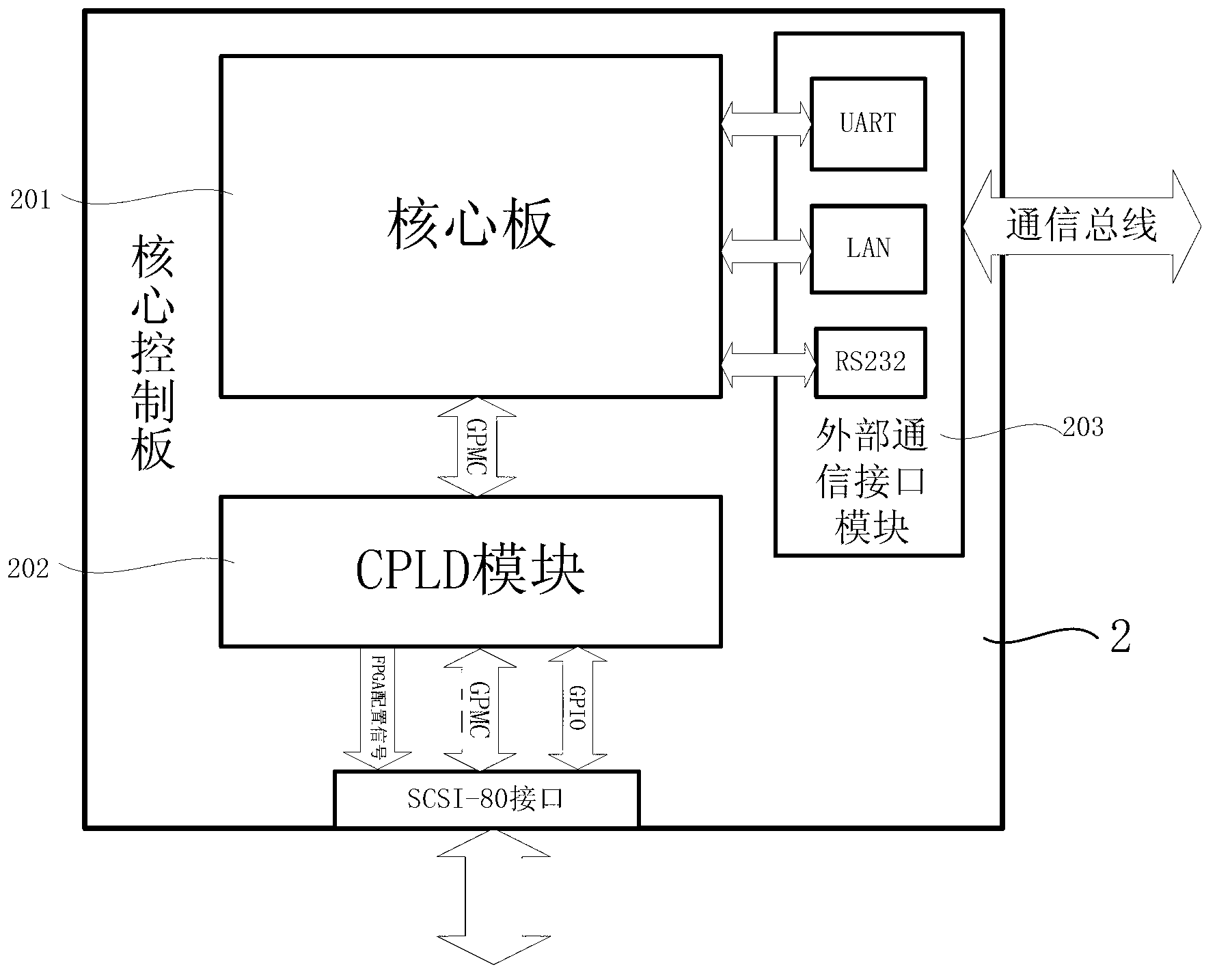

LX I embedded type reconfigurable general test platform capable of being used for on-site test

ActiveCN103257910AEasy for secondary developmentGuaranteed versatilityDetecting faulty computer hardwareInstrument functionWeb service

The invention discloses an LX I embedded type reconfigurable general test platform capable of being used for an on-site test. The test platform mainly comprises a core control unit, an FPGA integrated test unit, an instrument function unit, a test program set, a Web server and the like. Modularized hardware design is reliably and tightly connected with a function module through a compact and firm portable machine box. The core control unit finishes control and communication of a whole system. The integrated test unit mainly completes logic functions of test instruments. The instrument function unit mainly completes conversion of signals. On the basis of LX I standard design, the test platform has multiple communication modes, is suitable for mobile tests, and facilitates secondary development. Hardware is designed in a modularized mode, and is compact in structure, small in size and low in weight. Software meets standards such as IVI, SCPI, ATML and the like, and is strong in generality. The instruments have the strong data processing ability and have functions of multi-channel parallel testing and online reconfiguration of the hardware and the software. What is needed is a browser during use of the instruments, the instruments can be operated remotely and the online reconfiguration of the instruments is achieved.

Owner:BEIHANG UNIV

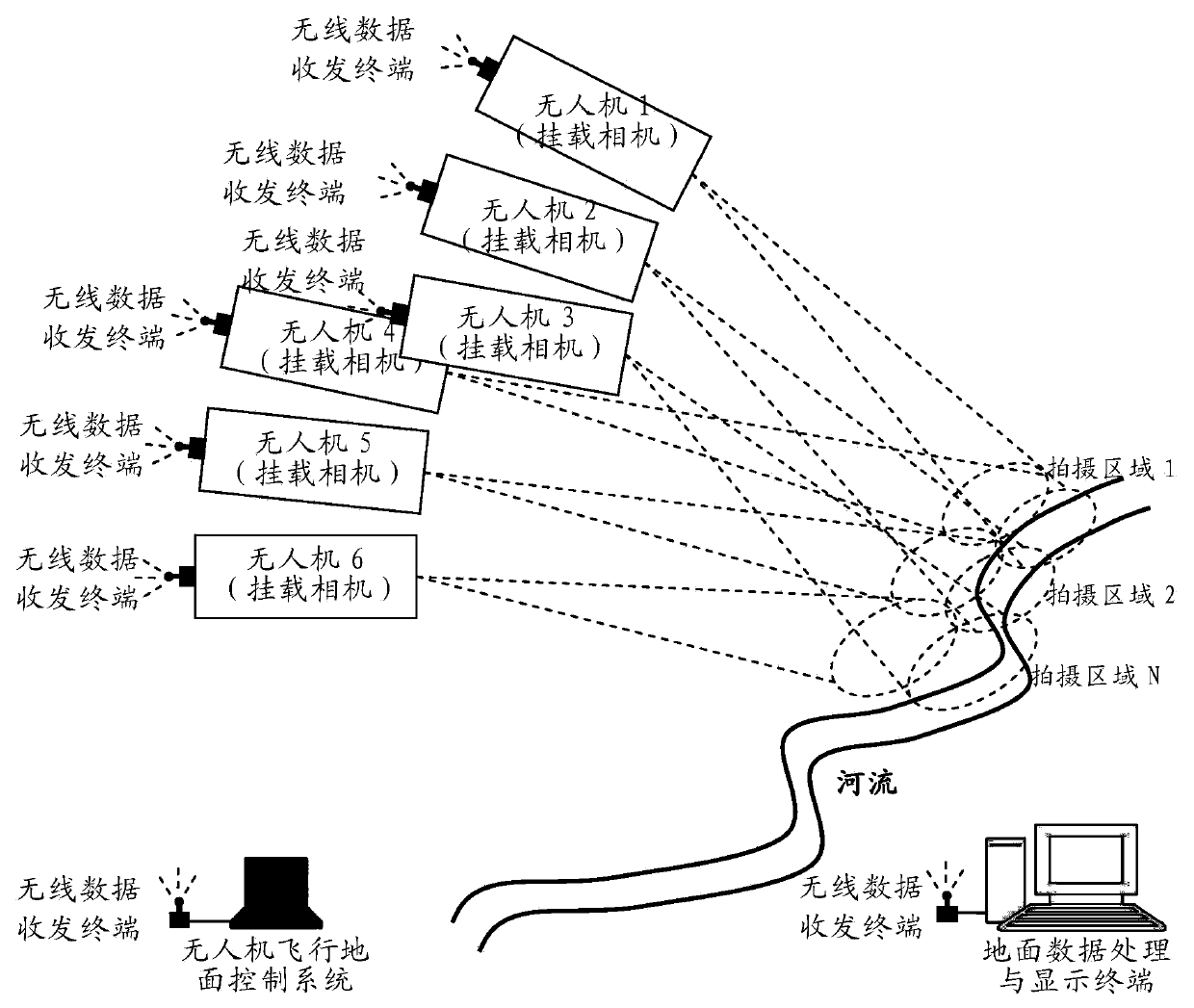

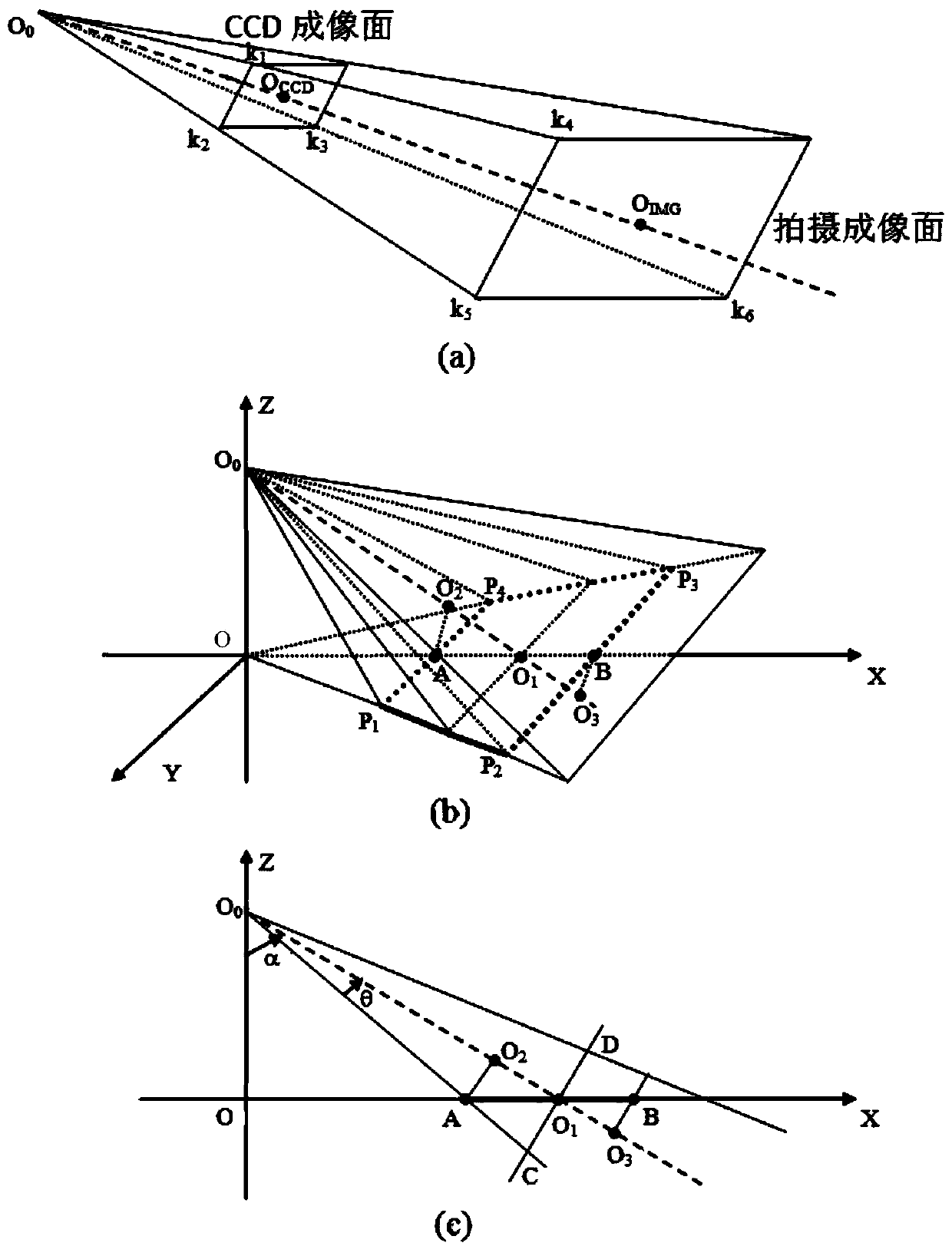

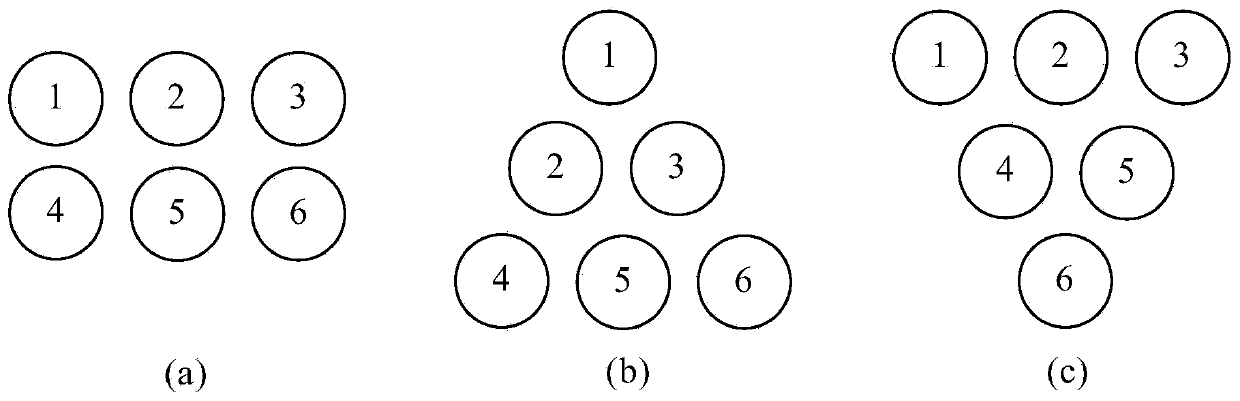

Air-based large-scene photographing system and method

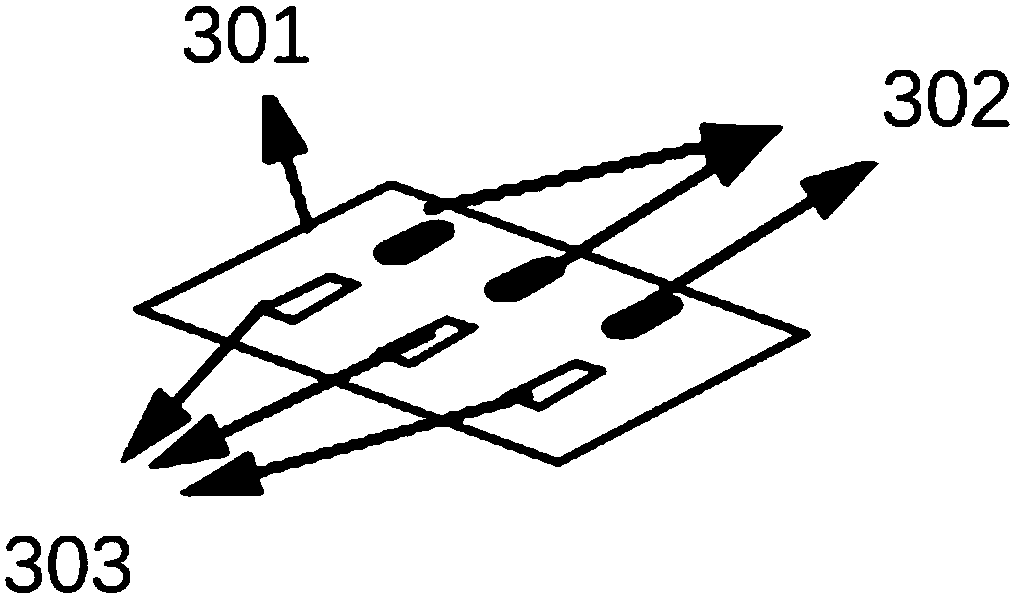

ActiveCN104168455ARealize splicingImprove visual effectsImage enhancementTelevision system detailsMachine visionComputer terminal

The invention discloses an air-based large-scene photographing system and method. The system is composed of a multi-rotor unmanned machine set subsystem, a multi-rotor unmanned machine flight ground control subsystem and a ground image data processing and display terminal subsystem. According to the air-based large-scene photographing system and method, multiple multi-rotor unmanned machines are controlled to conduct the formation flight by additionally hanging cameras below the multi-rotor unmanned machines, the reasonable position layout of multiple aircrafts is achieved in space near the ground, and images photographed by the unmanned machines are sent back to the ground in real time; the ground image data processing and display terminal subsystem receives the image data, projection converting and splicing processing are conducted on the images photographed by the multi-rotor unmanned machines through an image analyzing and machine vision technology, and finally two-dimensional splicing on remote large-scene scenes is formed. The system is suitable for rebuilding of large scenes and observing and measuring of points of impact when various military exercises and target practicing and shooting are conducted.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

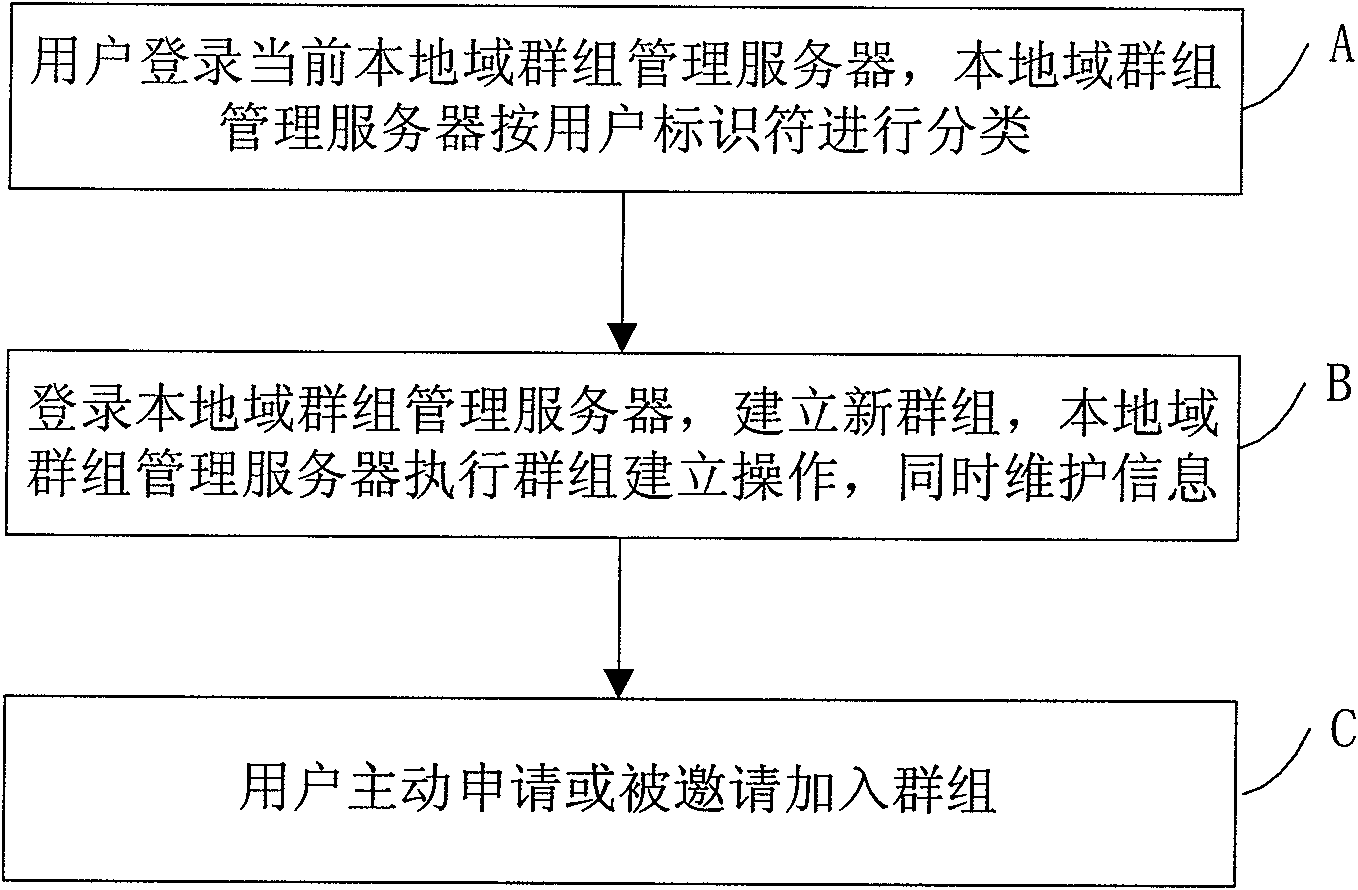

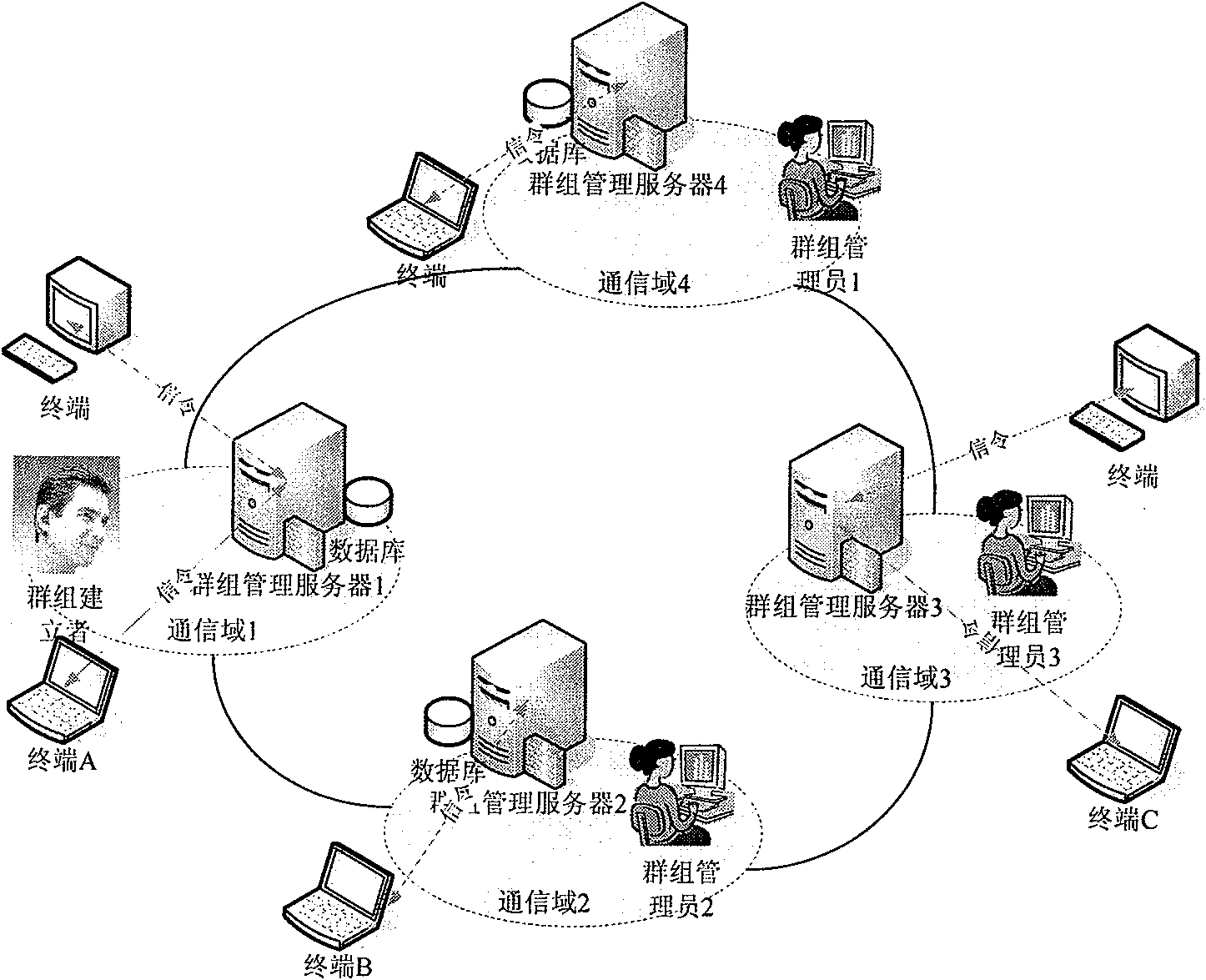

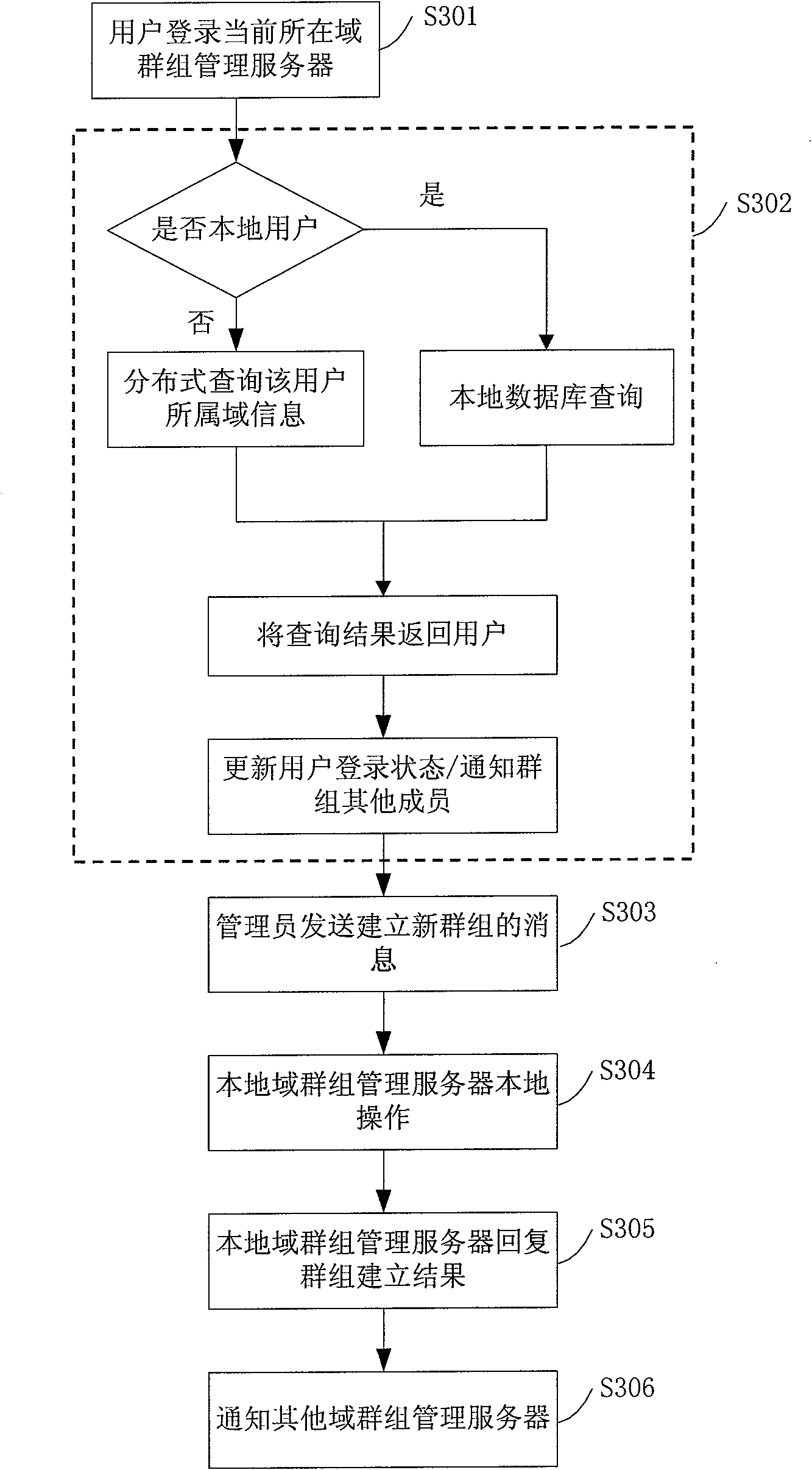

Group creating and member adding method in distributed domain management system

InactiveCN102075456AImprove securityImprove effectivenessData switching networksNon localManagement system

The invention discloses a group creating and member adding method in a distributed domain management system, which is characterized by comprising the following steps: step 1, a user logs in a current local domain group management server, the local domain group management server distinguishes that the user is a local in-domain user or a non-local roaming user, and stores the current user login state; step 2, a group creator logs in the local domain group management server, creates a new group on the local domain group management server, and maintains the locally created groups and group memberinformation of the locally accessed groups; and a step 3, the user applies for joining the group or is invited by a group manager to join the group. The invention implements the group creating and the group member adding in the distributed domain management system.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

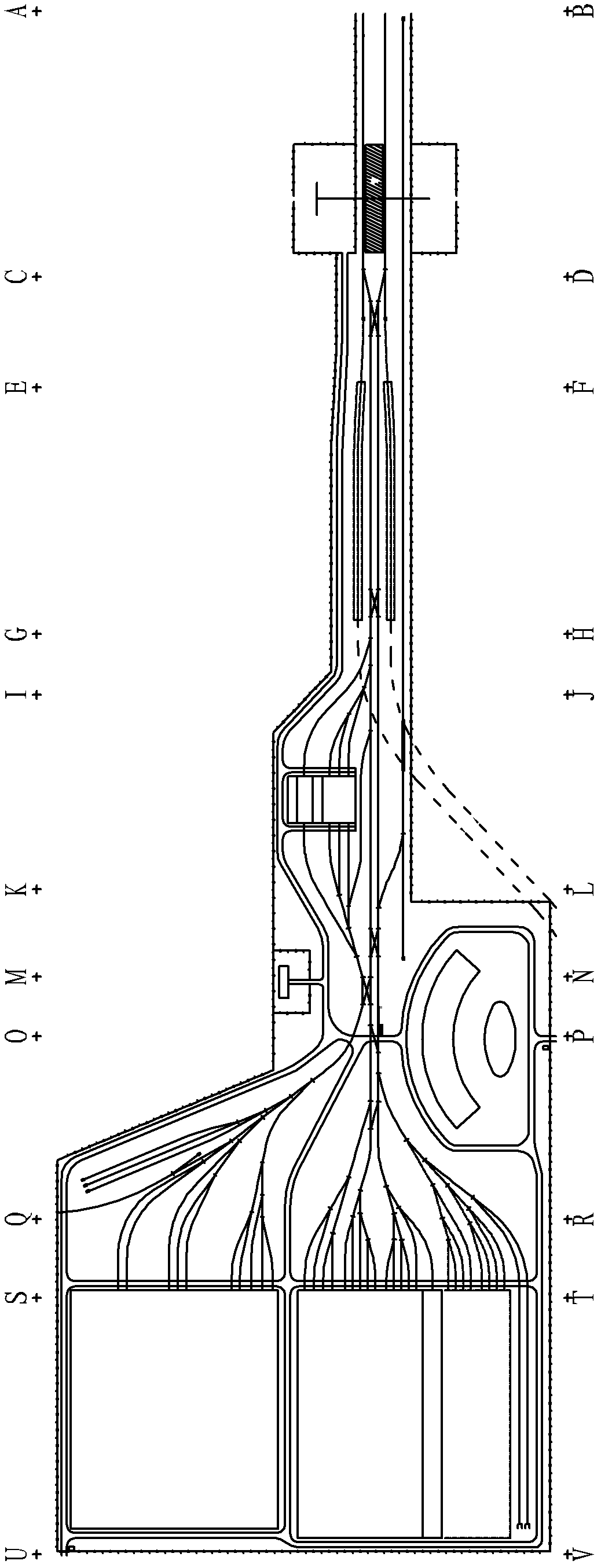

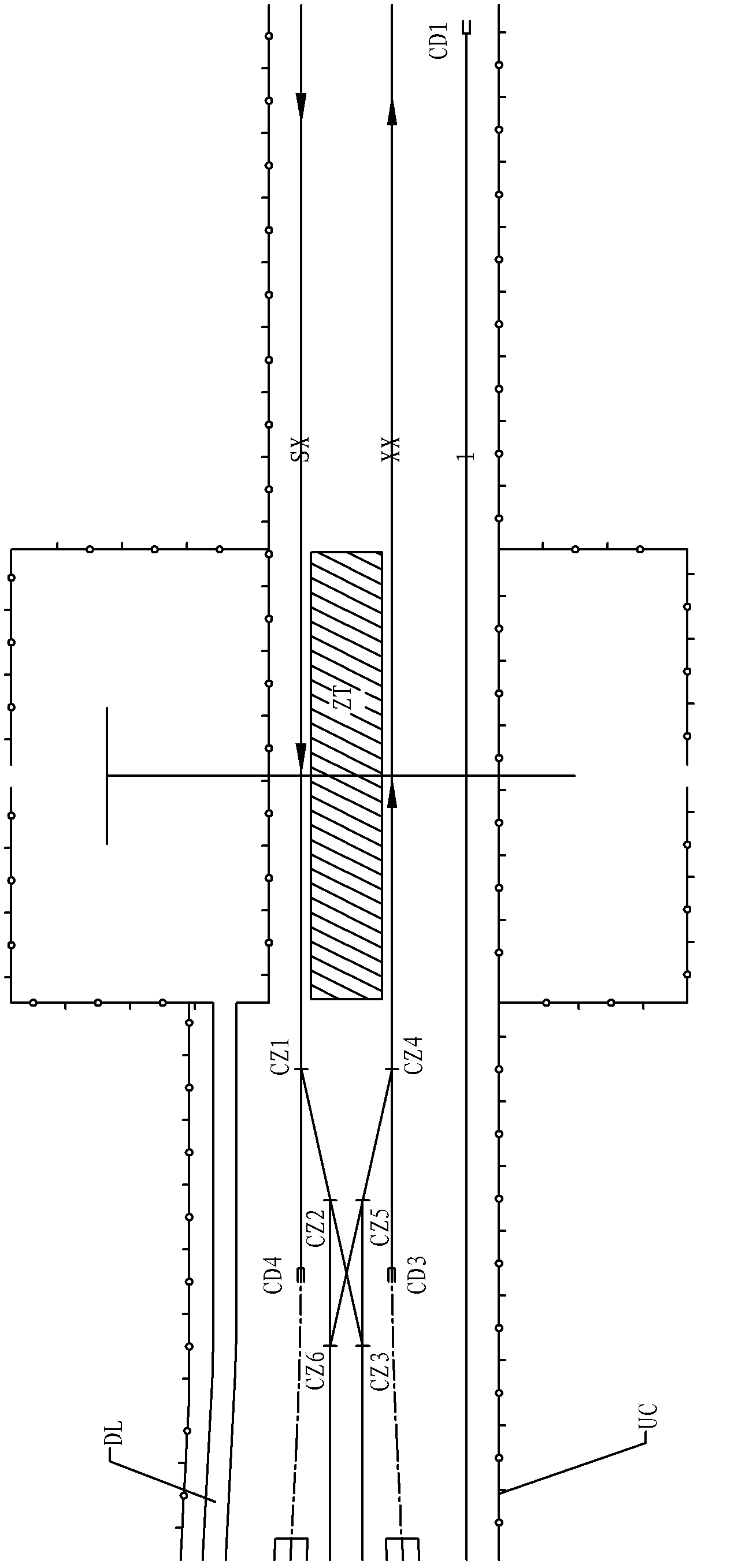

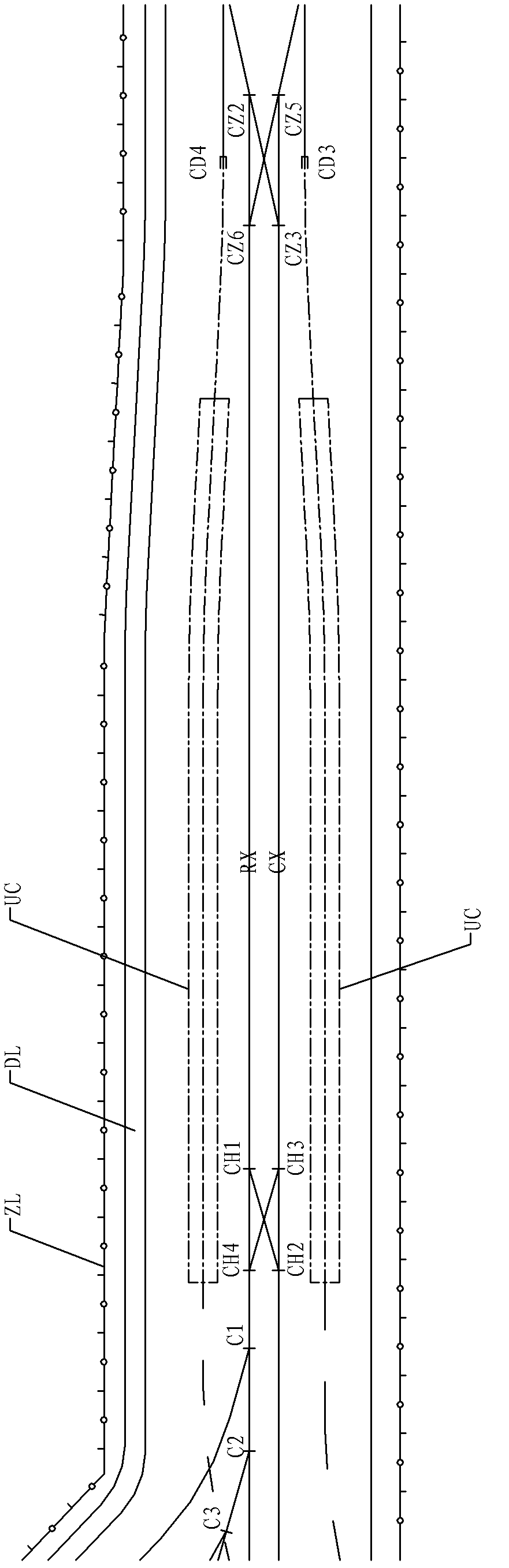

Layout structure for integration of train depot and junction station of urban rail

ActiveCN102501852ASmall working surfaceIncrease profitRailway componentsRailway stationRepair shopCombustion

The invention provides a layout structure for integration of a train depot and a junction station of an urban rail. The layout structure is composed of the junction station, a main line, a turn line, a release line, a lead line, a testing line, a train washing workshop, a parking train examination shop, a plant un-wheeling repair shop, an internal combustion adjustment engine shop, an engineering garage, related lines and turnout junctions, a comprehensive office building, a hazardous material storage and a guardroom erected on the ground. In the structure, the junction station, the turn line, the release line, a train washing line and the parking train examination shop are arranged in a tandem feed-through manner, a return section train starts from a station and enters the train washing workshop for washing through an entry line, and after washing, the return section train can directly enter the parking train examination for storage or enter the plant un-wheeling repair shop for inspection and repair. The lead line, the internal combustion adjustment engine shop, the engineering garage and the train washing workshop are parallel to each other, and the front and the rear of the line are connected with the entry line. The layout structure has the benefits of compactness and high production and operation efficiency. The testing line departs from a main plant area, and passes through the junction station. The door of the main plant area can be directly opened outwards. The layout structure occupies less space, and achieves high land and space utilization.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Temperature responsive intelligent facial mask and method for preparing same

InactiveCN1883438AInhibit high temperature dehydrationAct as a supportCosmetic preparationsToilet preparationsSmart hydrogelsCellulose fiber

A temperature responsive intelligent face mask and preparation method thereof wherein a chitosan modified temperature sensitive isopropyl acryl amide / polyurethane copolymer hydrogel is grafted to a cellulose fiber. The advantages lie in that the intelligent hydrogel can swell and contract reversibly near body temperature, and the high-temperature dehydration phenomenon may be inhibited by the introduction of the polyurethane, the non-woven fabric exerts a supporter function by grafting the isopropyl acryl amide / polyurethane copolymer hydrogel thereto and as a result the strength of the gel is increased, the coupling of the natural chitosan to external surface of the gel film not only improves the face mask comfort, the skin affinity, but also offers the bacteria resistant ability. The gel face mask carries multiple nutrients and the carried nutrient and moisture may release intelligently through gel contraction under body temperature, meanwhile the temperature responsive intelligent face mask can be utilized in a plurality of times to satisfy the personalized requirement.

Owner:THE HONG KONG POLYTECHNIC UNIV

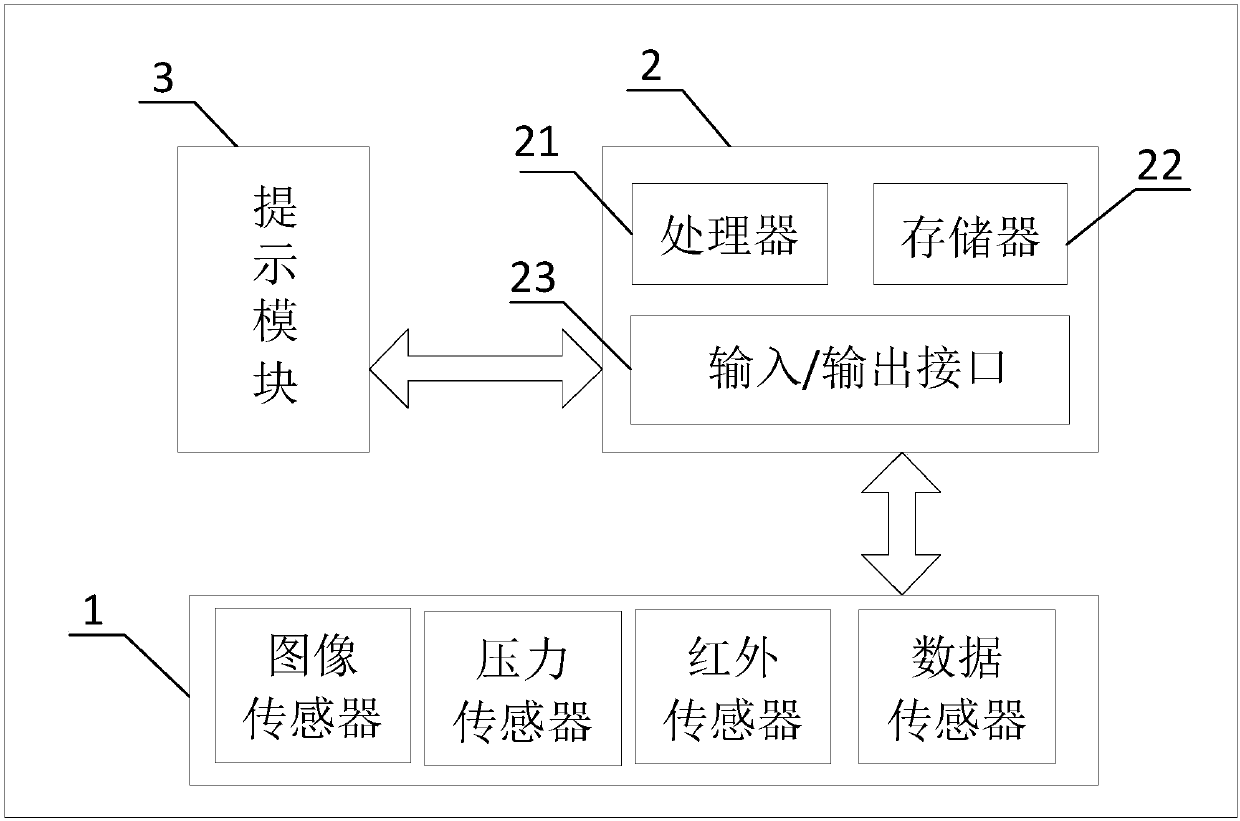

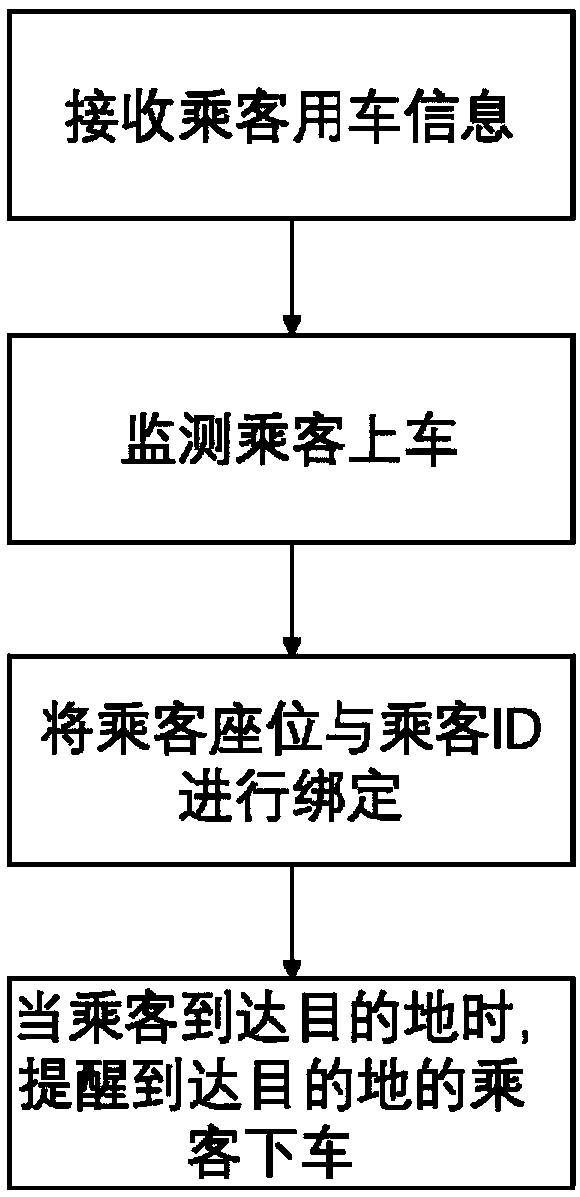

Getting-off targeted reminding method and device

ActiveCN107599971AAvoid missingSave manpower and material resourcesSignalling/lighting devicesAlarmsTransport engineeringOff targets

The embodiment of the present invention provides a getting-off targeted reminding method and device. The method comprises the following steps: receiving at least one piece of vehicle usage informationof a passenger, wherein the vehicle usage information includes identification (ID) information and / or route information of the passenger, and the ID information includes the account, the mobile phonenumber, the photograph and / or the name of the passenger; detecting the vehicle environment and information of the boarding passenger, including detecting the seat position information of the passenger and detecting the luggage position information, and determining whether the passenger carries luggage or not; a calculation processing module receiving the detected data and matching the data with the vehicle usage information to determine whether to remind the passenger or not according to needs; and reminding the passenger getting off, reminding the passenger not getting off, or reminding thepassenger missing the luggage or taking the wrong luggage according to an instruction of the calculation processing module. According to the invention, the seat, the luggage position and the ID of thepassenger are bond, thereby being capable of reminding the passenger getting off when the passenger needs to get off.

Owner:UISEE SHANGHAI AUTOMOTIVE TECH LTD

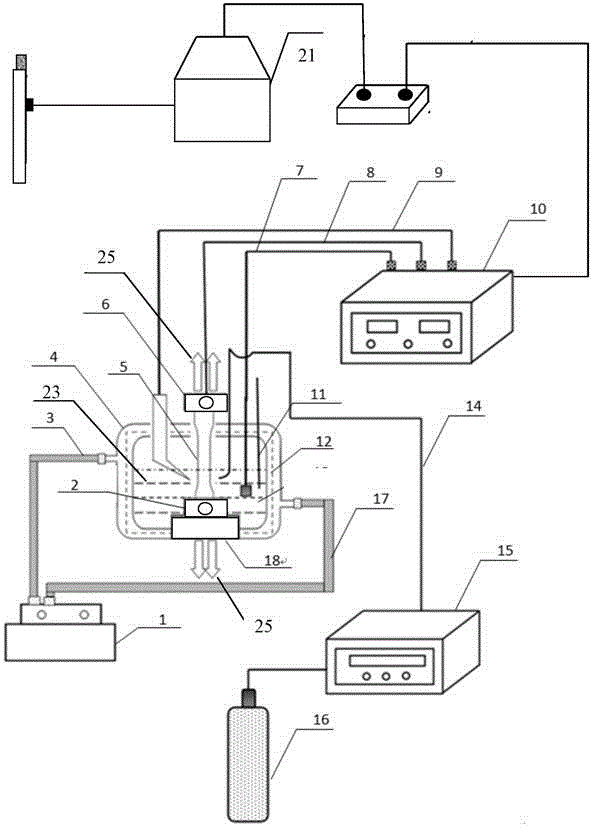

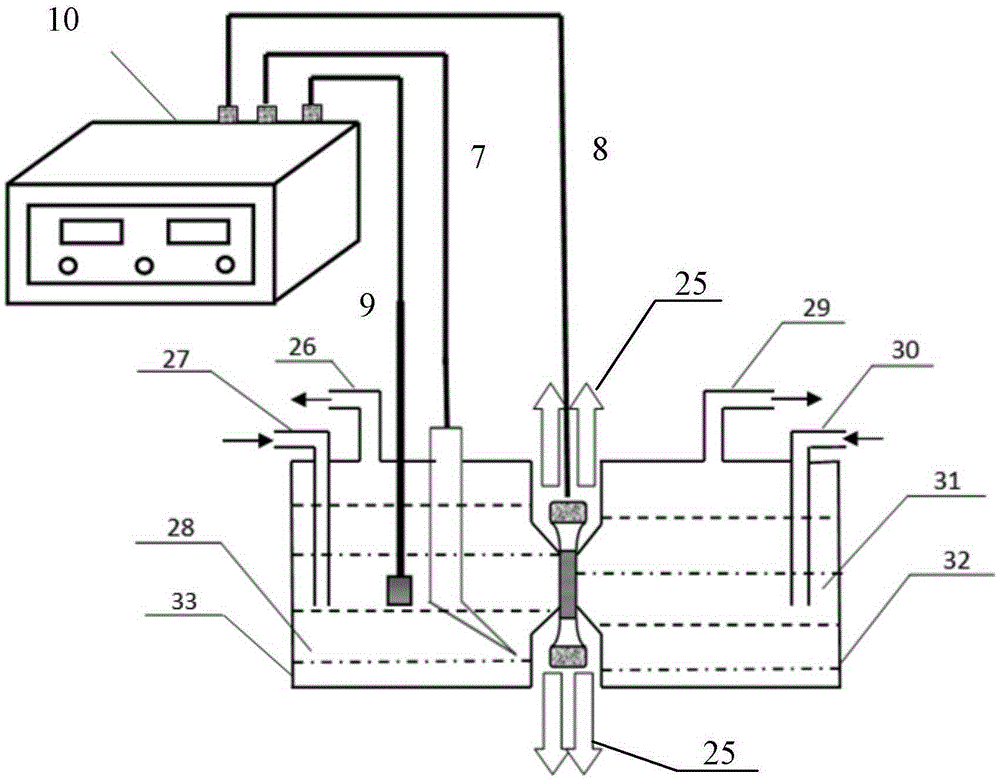

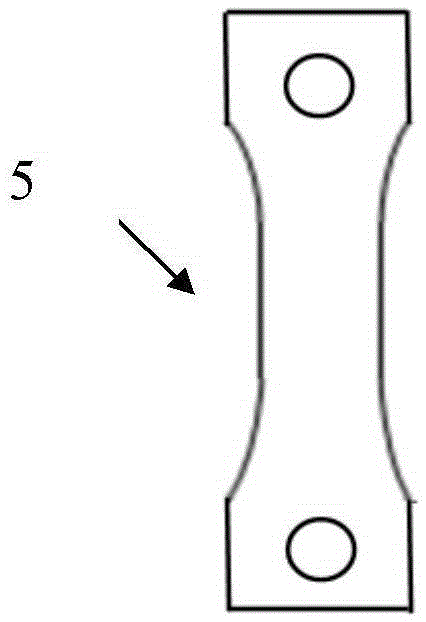

Stress corrosion and hydrogen measuring electrochemical in-situ measurement device under slow strain speed condition

ActiveCN105300874ARealize in situ electrochemical behavior detectionSample size adjustableWeather/light/corrosion resistanceMeasurement deviceMetallic materials

The invention provides a stress corrosion and hydrogen measuring electrochemical in-situ measurement device under a slow strain speed condition. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device comprises an electrochemical work station, an auxiliary electrode, a working electrode, a reference electrode, a stretching test sample, a slow strain stretching machine, a computer, an isolation transformer, a corrosion device and a hydrogen measuring device. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device has the effects that an electrochemical in-situ test can be carried out on stress corrosion and hydrogen permeation respectively under the slow strain speed condition through replacing a corrosion electrolytic tank; the device has the characteristics of adjustable test sample size, in-situ electrochemical measurement, accurate load-displacement readings, simple structure, convenience and flexibility in utilization, simplicity in operation and the like. The device can be used for simultaneously realizing in-situ electrochemical behavior detection of pull stress, corrosive liquid, corrosive gas and temperatures, and can be widely applied to researches of strain speeds, the pull stress, types and concentrations of corrosive media, pH values, temperatures, corrosive gas partial pressure and concentration and influences on corrosion of metal materials by hydrogen brittleness, and a damage evolution rule of materials can be analyzed through electrochemical data.

Owner:CIVIL AVIATION UNIV OF CHINA

Ceiling fan with automatic cleaning function

InactiveCN101435430AEfficient cleaningEasy to usePump componentsPump installationsCeiling fanBristle

The invention discloses a ceiling fan with automatic cleaning function. The ceiling fan comprises a rotating shaft, fan blades, a spring and a cleaning device; one end of the spring is connected with the rotating shaft; the other end of the spring is connected with the cleaning device which is inserted into the fan blades; the cleaning device comprises an upper splint and a lower splint which are connected; a gap is formed between the upper splint and the lower splint; the fan blades run through the gap; and the lower part of the upper splint and the upper part of the lower splint are provided with sponge or bristle. When the ceiling fan is used, a cleaning gear is arranged on a speed governor; when the speed governor is regulated to a normal wind speed gear, an electromagnet operates and has magnetism to restrict the spring in order that the cleaning device can not freely move under the action of centrifugal force; when the speed governor is regulated to the cleaning gear, the electromagnet has no magnetism and does not restrict the free expansion of the spring, and under the action of the centrifugal force and elastic force of the spring, the cleaning device reciprocates along the fan blades, thereby cleaning dust on the fan blades by the sponge or the bristle on the cleaning device.

Owner:万心悦

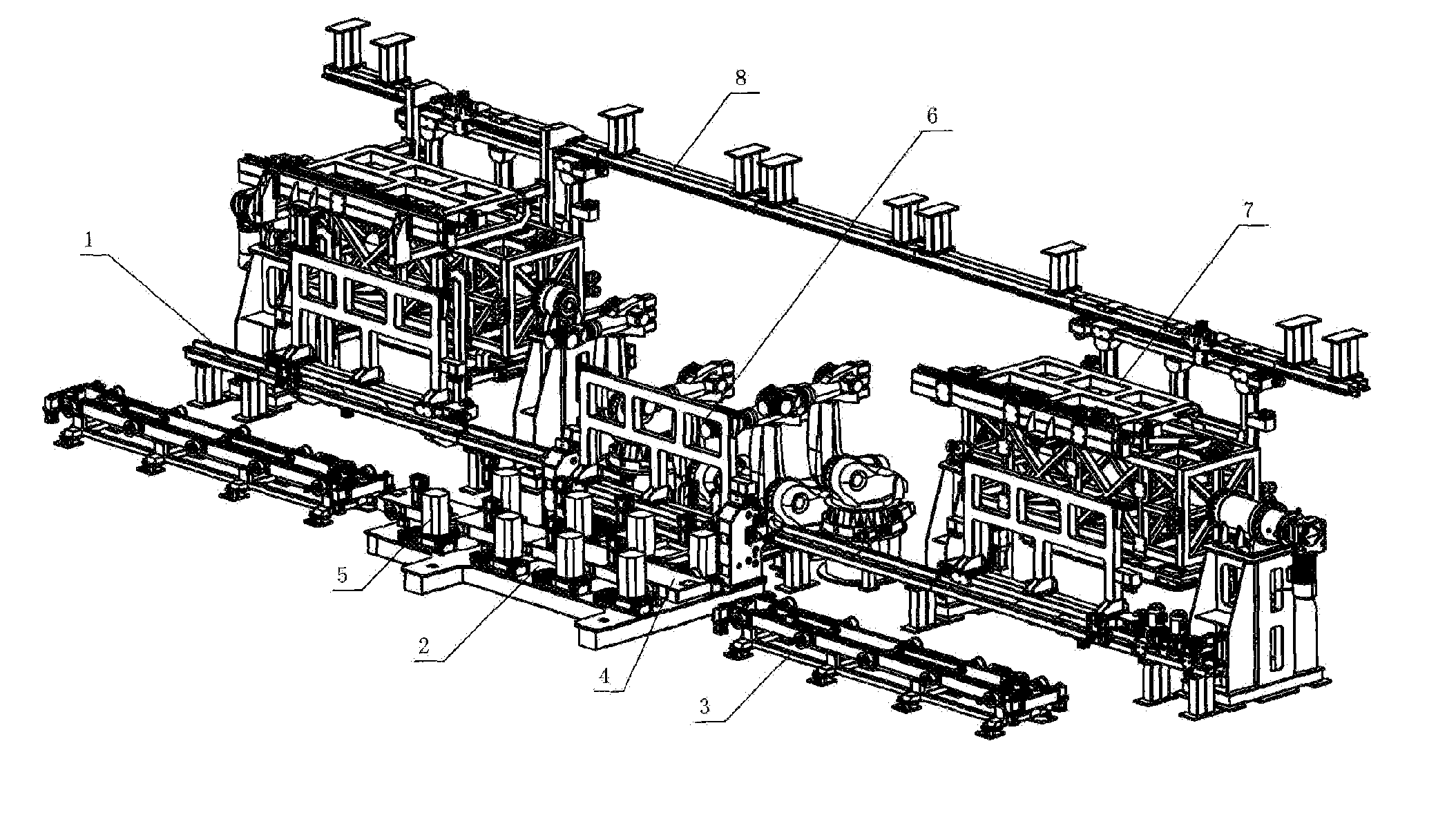

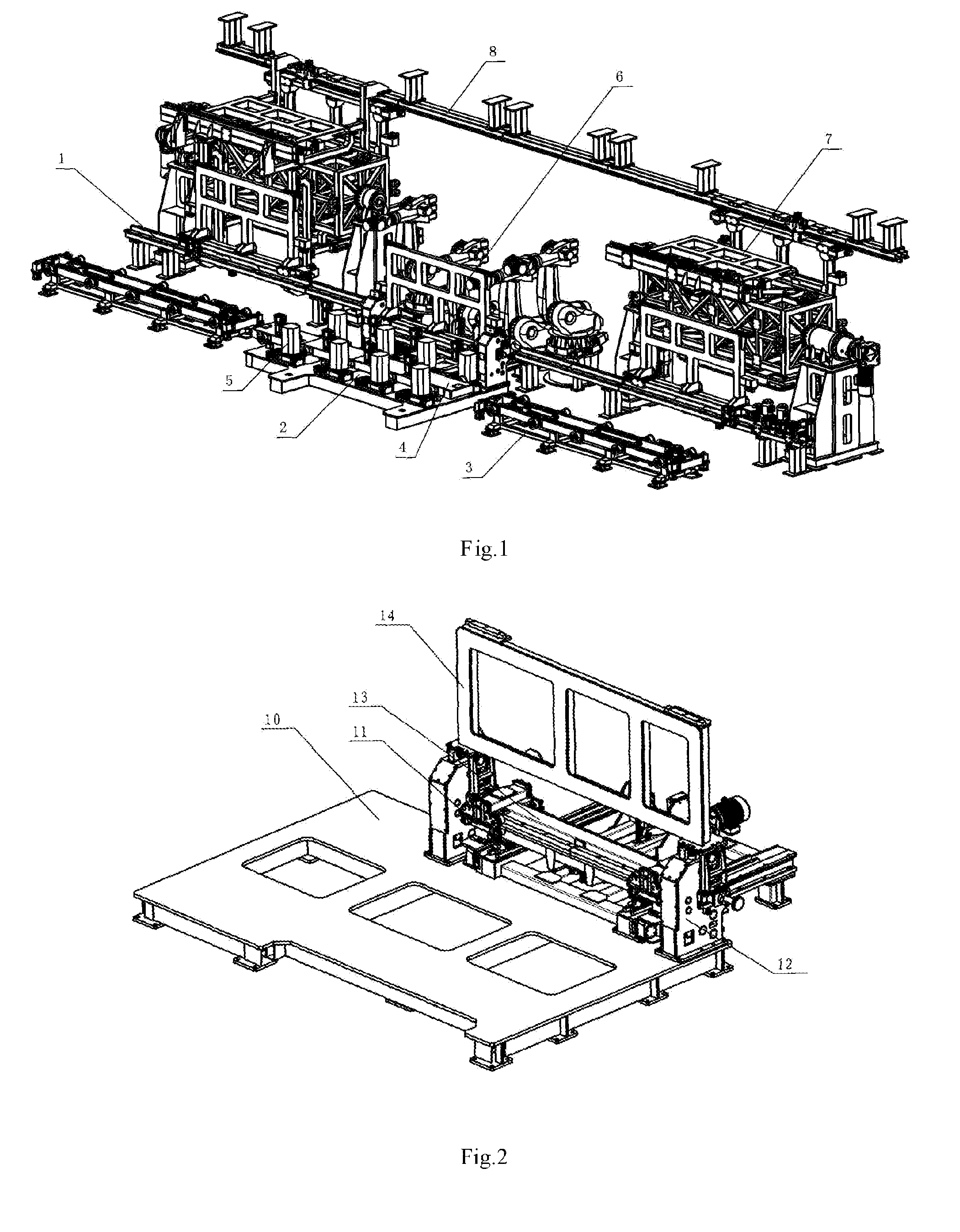

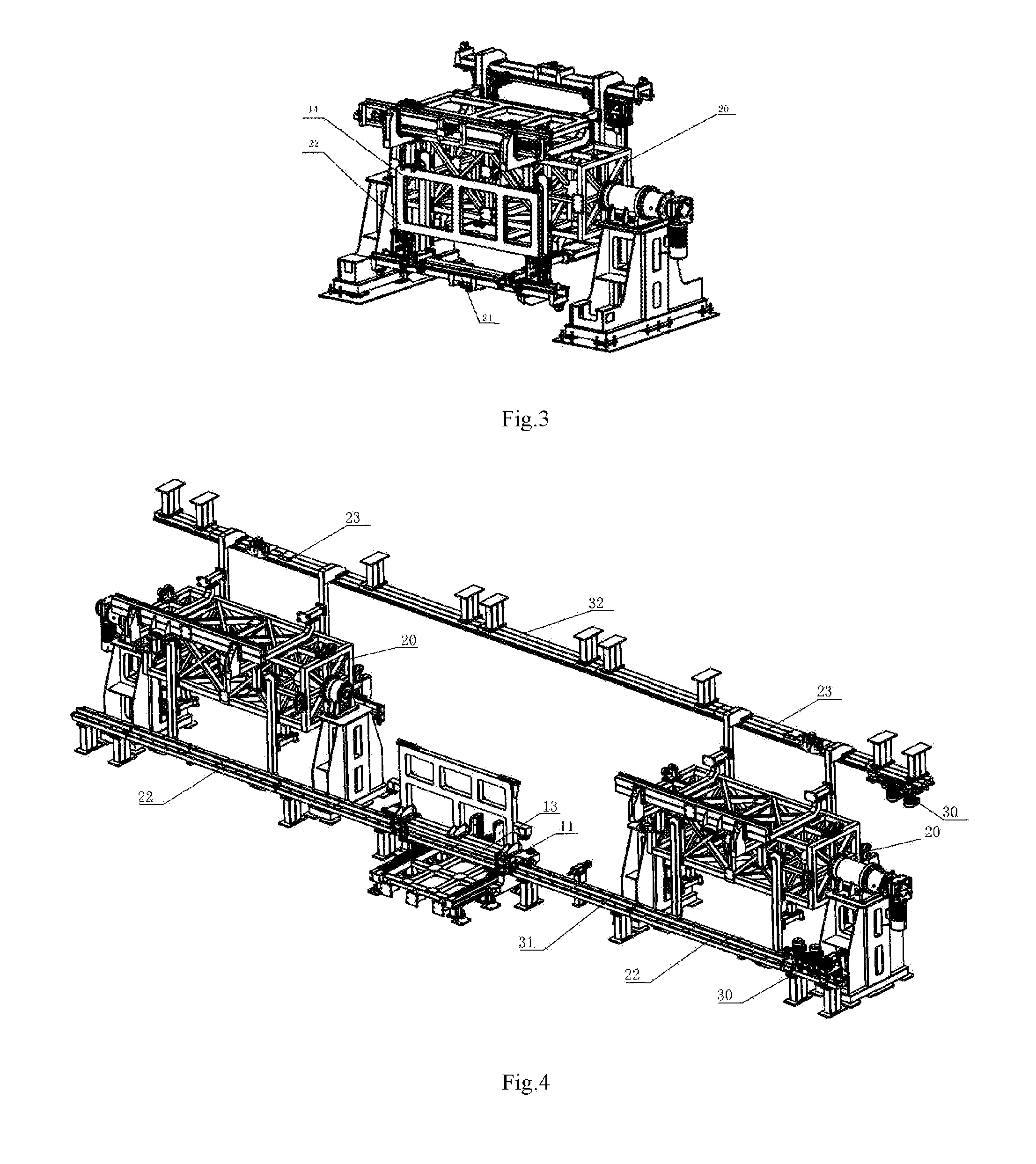

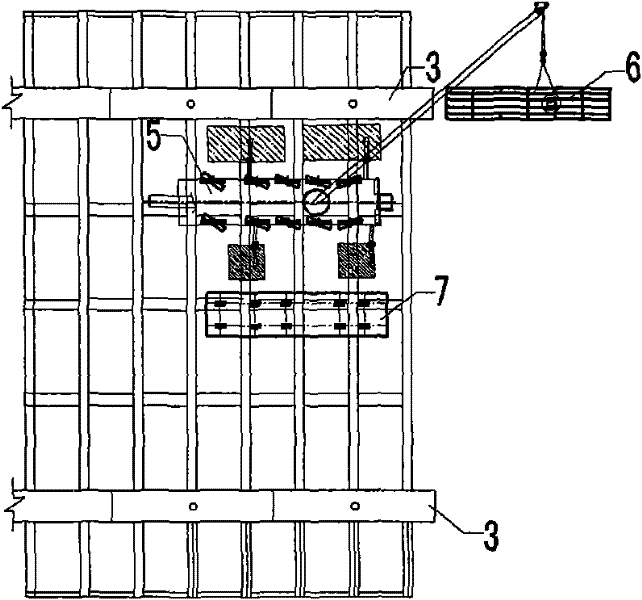

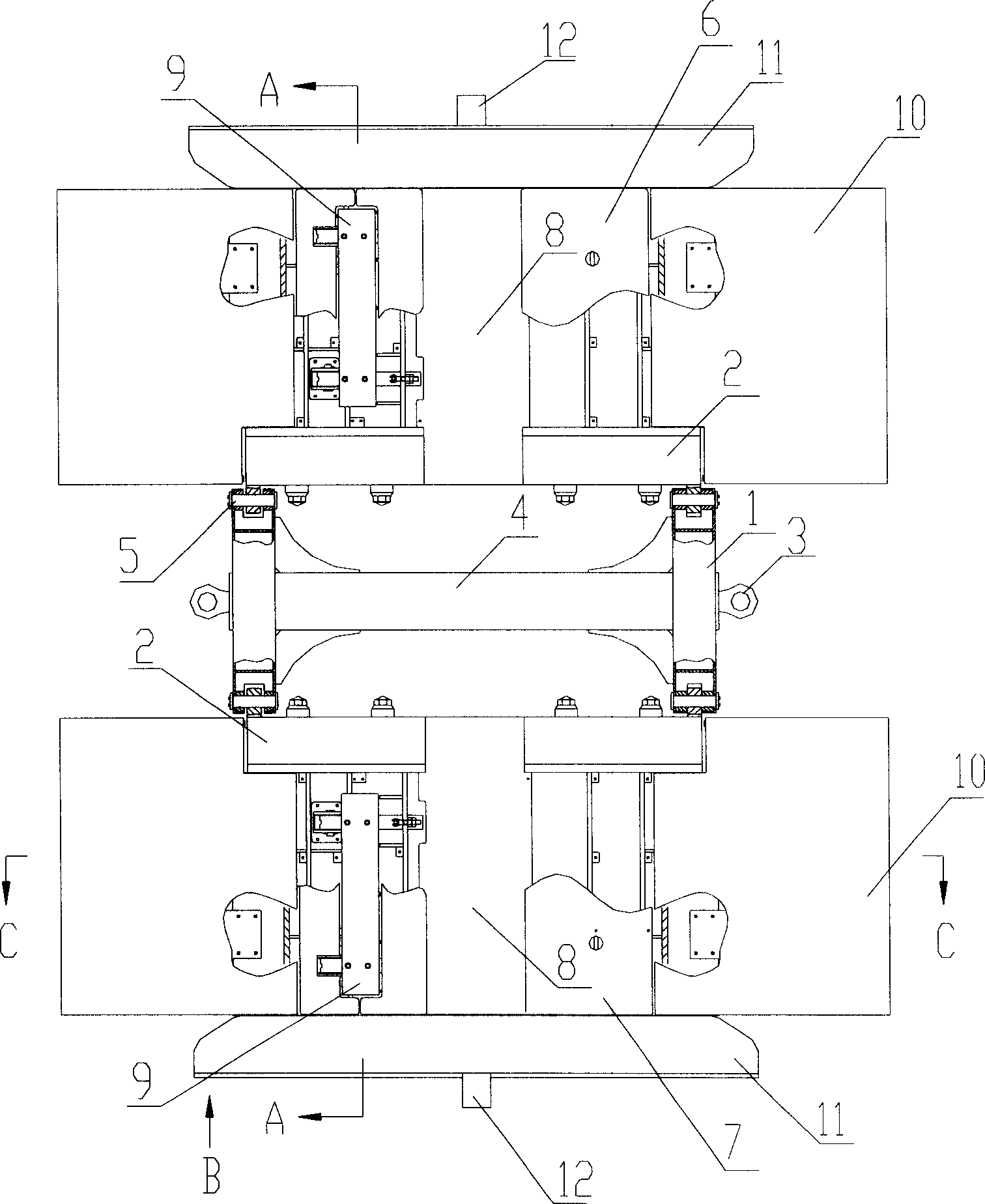

Multi-vehicle model collinear flexible framing system

ActiveUS20150001279A1Improve production efficiencyRapid paceWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTransport system

A multi-vehicle type co-production line flexible framing is disclosed, comprising a robot welding system, a high speed transport system, a floor panel intelligent flexible positioning system, and a side panel flexible positioning and switching system. The floor panel intelligent flexible positioning system is correspondingly connected to a transfer rail of the high speed transport system. The side panel flexible positioning and switching system comprises a side panel fixture consolidation system, a fixture storage system, and a fixture switching and rail system. The side panel fixture consolidation system corresponds to the side of the floor panel intelligent flexible positioning system. The fixture storage system is arranged on two sides of the side panel fixture consolidation system in the transfer direction of the high speed transport system. The fixture switching and rail system is connected between the side panel fixture consolidation system and the fixture storage system. The improved structure is relatively compact and practical, has a short switching time, a high production efficiency, and a small floor area, and may use a large number of welding robots, fully satisfying the capacity requirement of 60JPH of the automobile factory.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

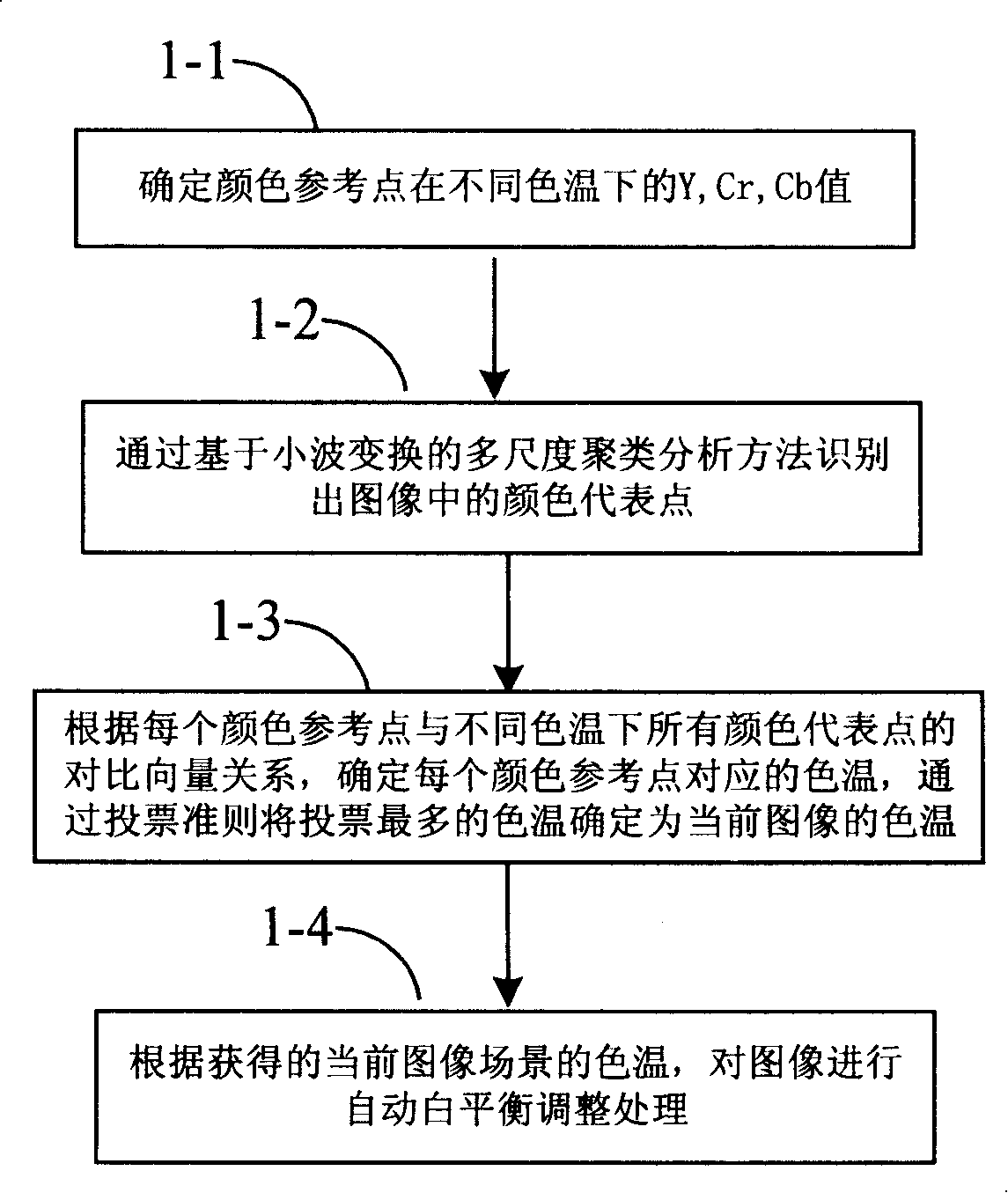

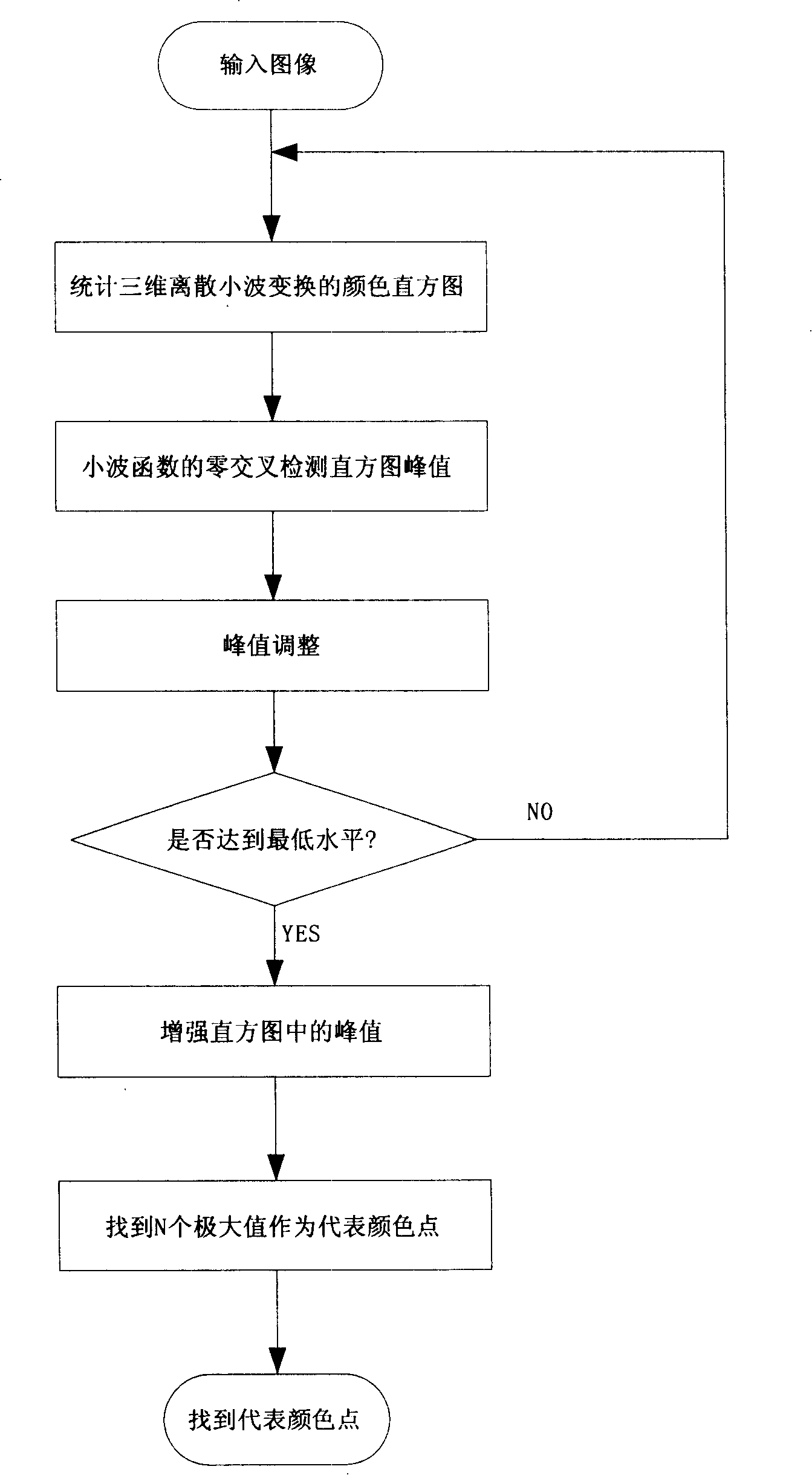

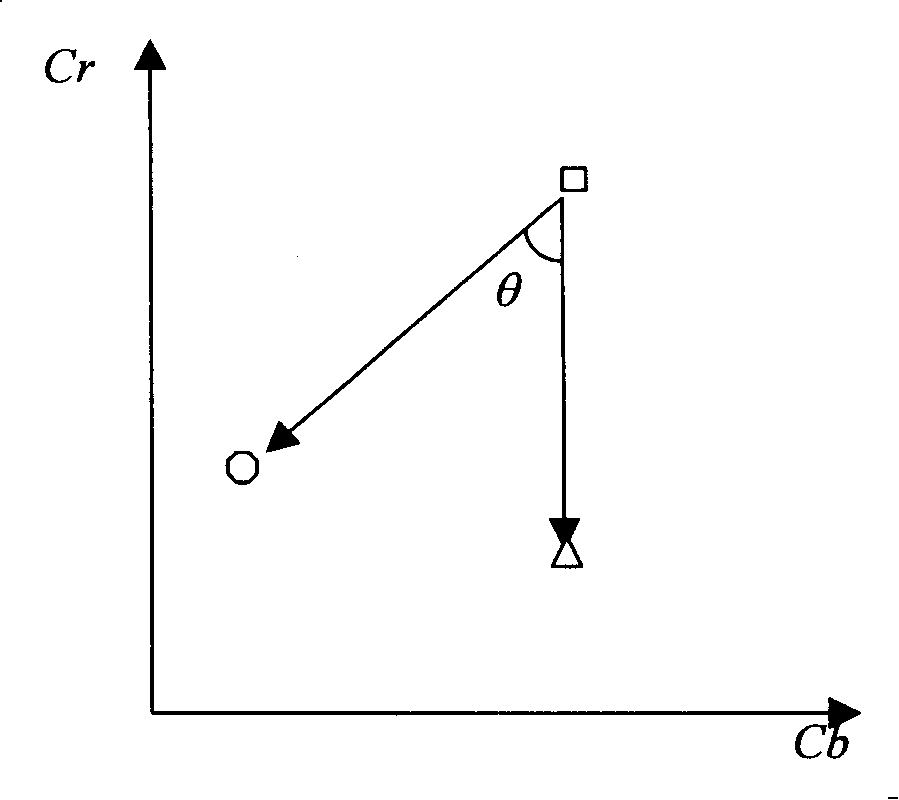

Method and device for automatic white balance processing of the image

InactiveCN101193317AConvenient and flexible useColor signal processing circuitsWhite pointColor temperature

The invention discloses a method for automatically processing white balance of image and a device thereof. The method mainly includes the following steps: a color reference point setting in color space and a color representative point in image are determined; the color representative point and the color reference point are compared in the position information of the setting color space and color temperature of the image is determined according to the result of the comparison; and according to the color temperature, the image is adjusted and processed by the white balance. The device mainly includes a reference point determining module, a representative point determining module, a color temperature determining module and a color component adjusting module. By using the invention, white balance adjustment of image can be automatically performed without depending on a standard white point in the image.

Owner:BEIJING SUPERPIX MICRO TECHNOLOGY CO LTD

Dynamic password authentication method based on digital certificate implement

InactiveCN1477810AGuarantee the legitimacy of identityAchieve convenienceRandom number generatorsMultiple keys/algorithms usagePasswordDigital signature

The present invention relates to a method for implementing dynamic password authentication based on digital certificate, belonging to the field of computer and information safety technology. On the basis of certificate authentication. It adopts the dynamic generation mechanism of password and utilizes the certificate authentication mechanism to acknowledge the user's identity, then utilizes the dynamic password mechanism to implement safe logging of various application systems.

Owner:KOAL SOFTWARE CO LTD

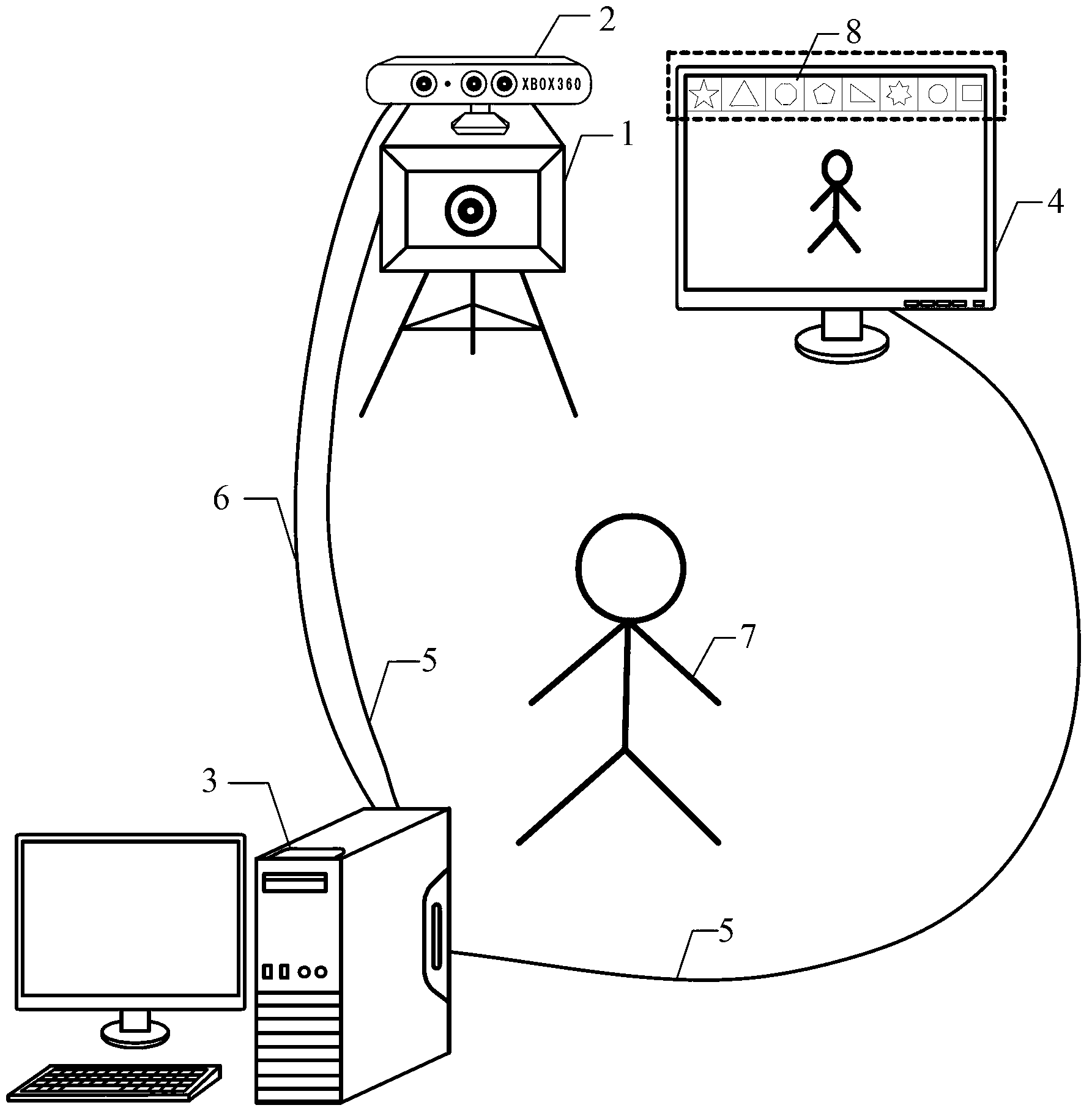

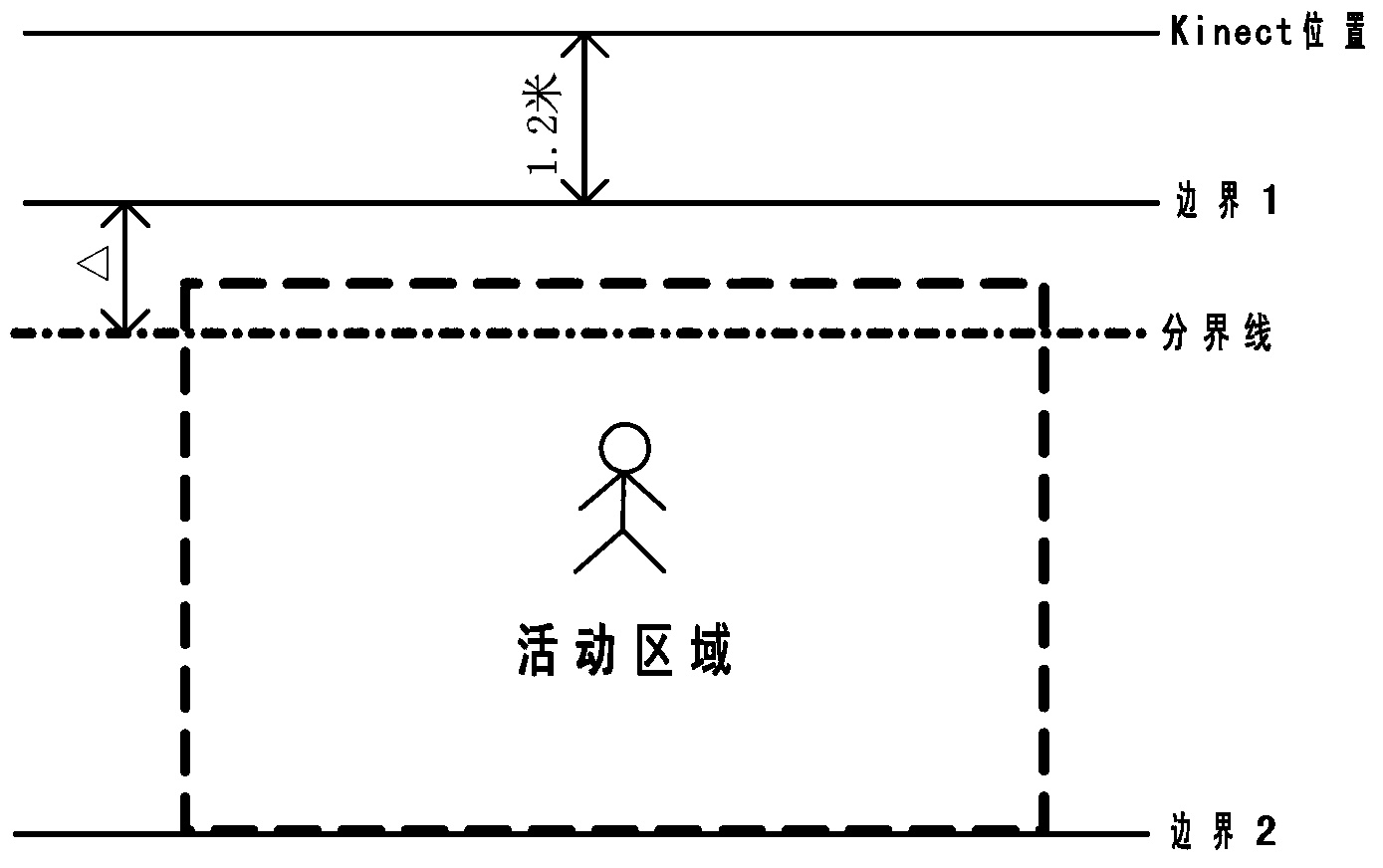

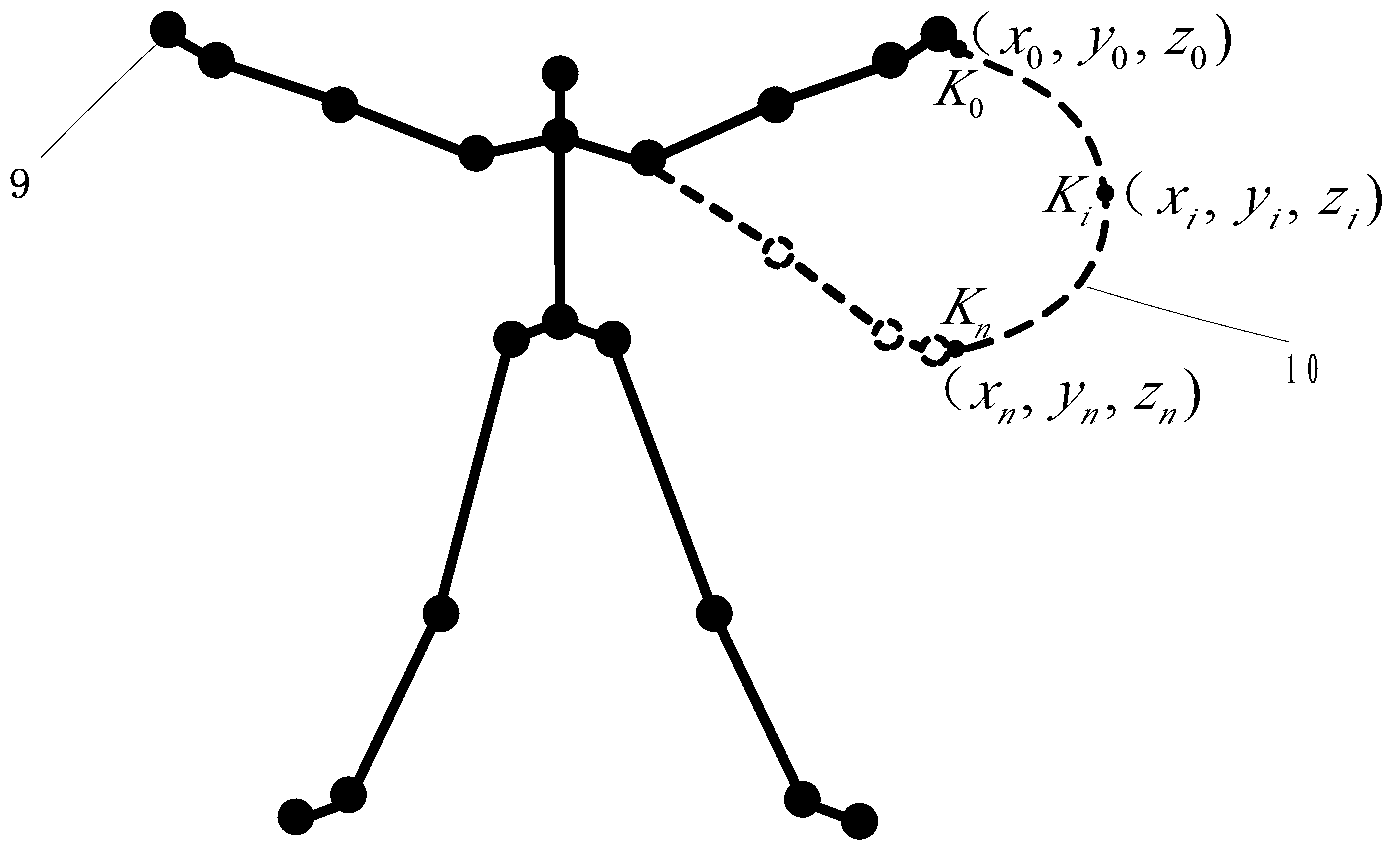

Television program host interaction system based on Kinect

ActiveCN102801924AImprove responsivenessFlexible operationInput/output for user-computer interactionTelevision system detailsInteraction systemsRgb image

The invention discloses a television program host interaction system based on Kinect. The television program host interaction system is characterized in that the system comprises a digital camera, Kinect equipment, a subtitle machine and synchronous display equipment, wherein the digital camera is used for shooting a television program; the Kinect equipment is used for obtaining an RGB (Red, Green and Blue) image and human body skeleton information of a host in the television program; the subtitle machine is used for carrying out image registration on the RGB image and a video image, obtaining hand skeleton information in the human body skeleton information and generating a semantic responding command and a control responding command; and the host can adjust the position of a hand in real time according to the synchronous display equipment. The invention provides a novel non-contact type hoisting way for television hoisting, so that the host can more freely and flexibly control a program playing process on a space; and meanwhile, the investment of labor and equipment cost is reduced.

Owner:HEFEI UNIV OF TECH

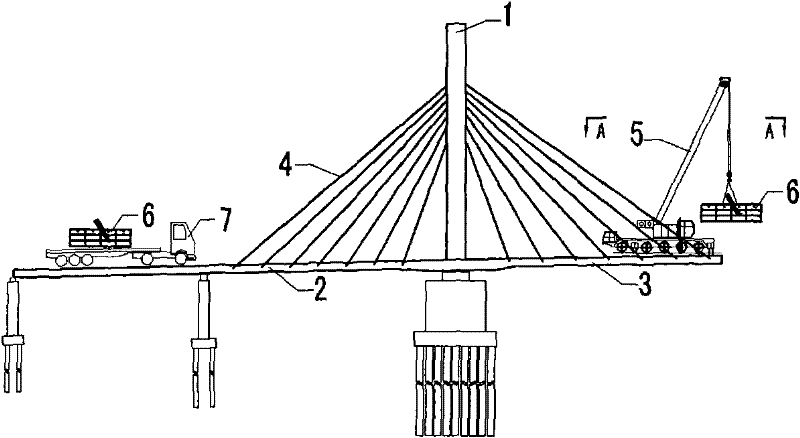

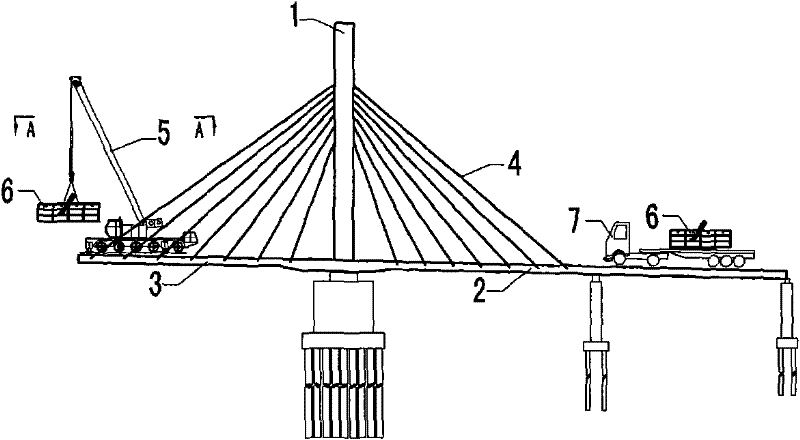

A new construction method of hybrid combined beam cable-stayed bridge

InactiveCN102286935AEliminate assemblyEliminate the hassle of disassemblyBridge erection/assemblyCable stayedBridge deck

The invention relates to a brand-new construction method of a mixed combined girder cable-stayed bridge. After the construction of the main tower, auxiliary piers, side piers, main bridge side span concrete beams and approach bridges, the mid-span steel girder members and prefabricated concrete decks of the cable-stayed bridges are transported from the ground via the approach bridges and main bridge side spans to Midspan. The truck crane also moves from the ground through the approach bridge and the side span of the main bridge to the front end of the completed combined beam in the mid-span, and lifts the components on the girder truck for cantilever construction. The bridge is hung with stay cables and tensioned for the first time. Construct the wet joints of the bridge deck, form the mid-span combined beam of this section, and repeat the construction until the main structure of the cable-stayed bridge is completed, and the bridge deck and the auxiliary structure of the main tower are constructed. The invention adopts the automobile crane, which can adapt to the construction of the wide bridge, and is convenient and flexible in use, and saves labor;

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

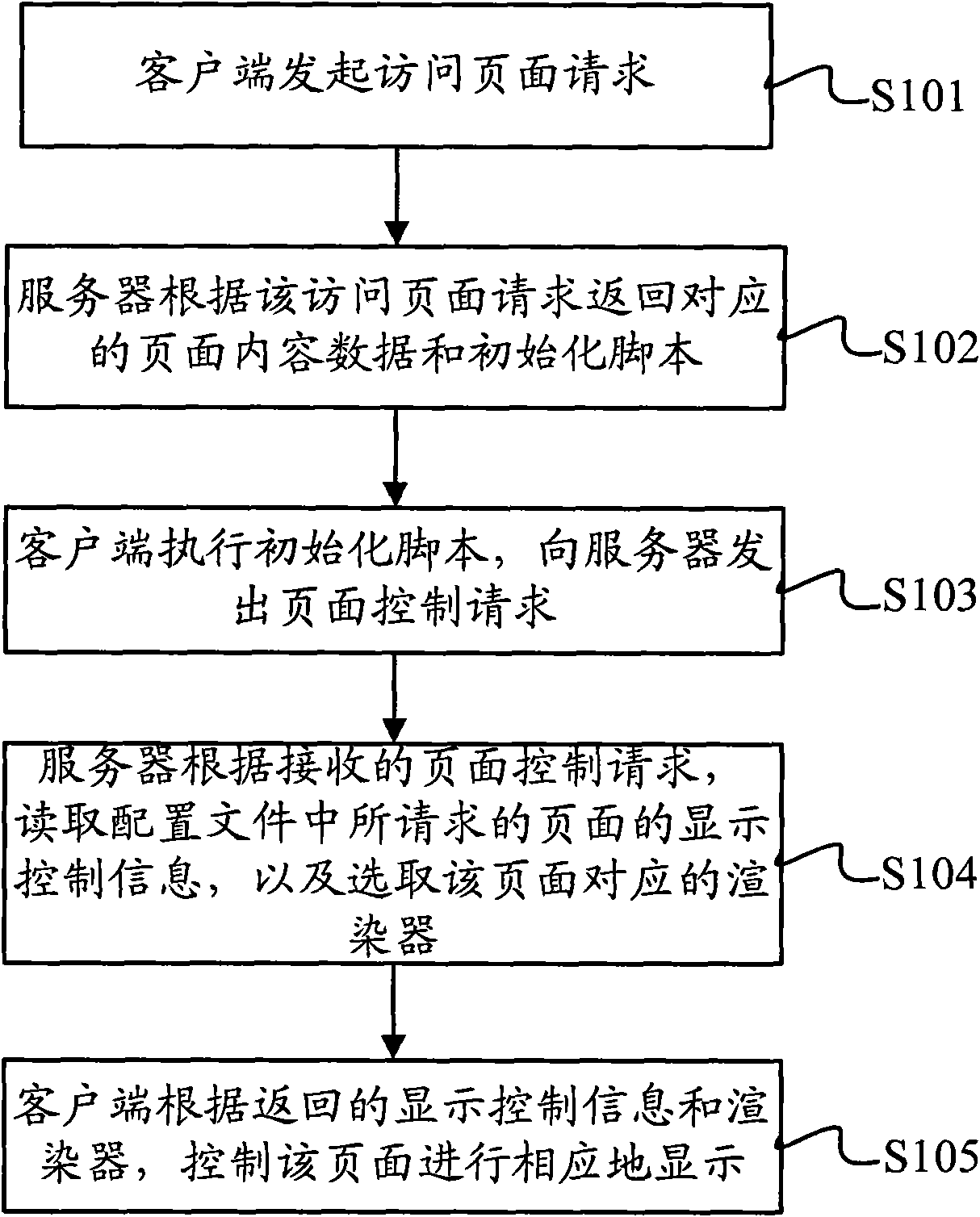

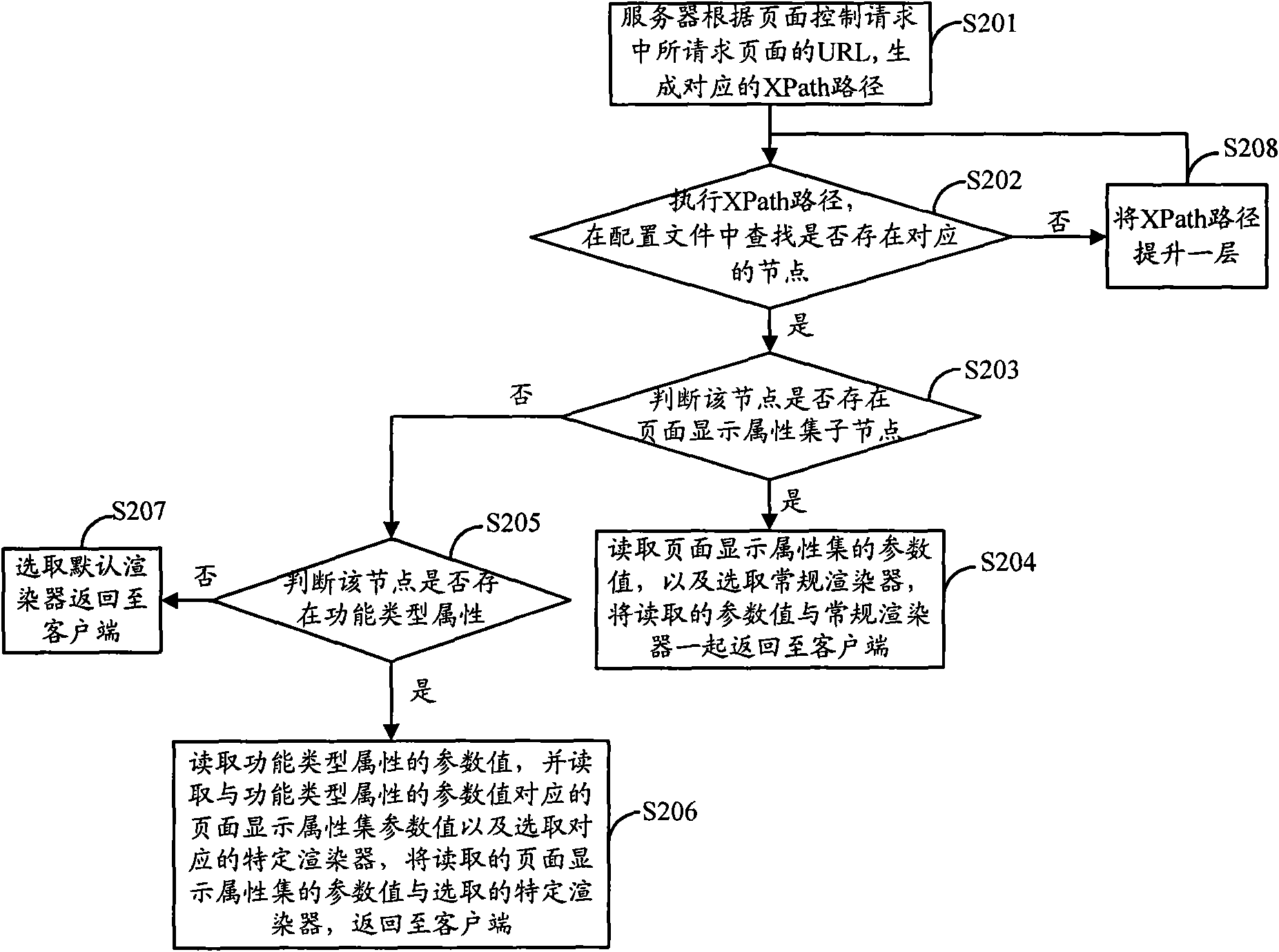

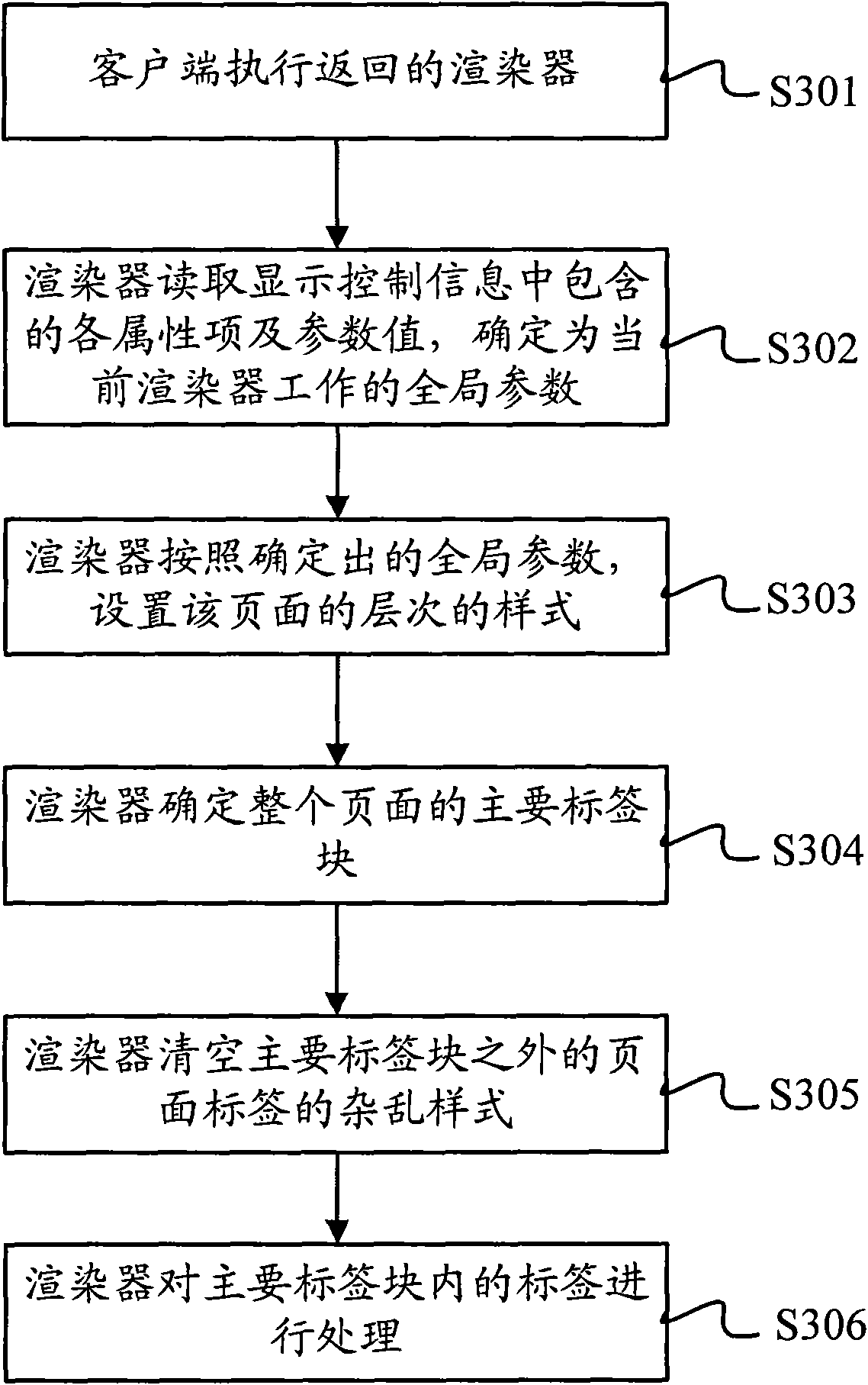

Page display control method, server and system

ActiveCN101771681AFlexible and convenient to useTo achieve the display effectTransmissionSpecial data processing applicationsClient-sideWorkload

The invention discloses a page display control method, a server and a system, relating to the field of information issuing. The page display control method includes the following steps: the server receives a page control request sent by a client, reads display control information of a page requested in a configuration file according to the page control request, and selects a corresponding renderer; the display control information and the renderer are returned to the client; and the client controls the displaying of the page according to the returned display control information and the renderer. The invention realizes automation of page displaying and style controlling, and avoids the problems in the prior art that the manual setting of the page displaying and the style controlling is heavy in workload and low in efficiency.

Owner:NEW FOUNDER HLDG DEV LLC +1

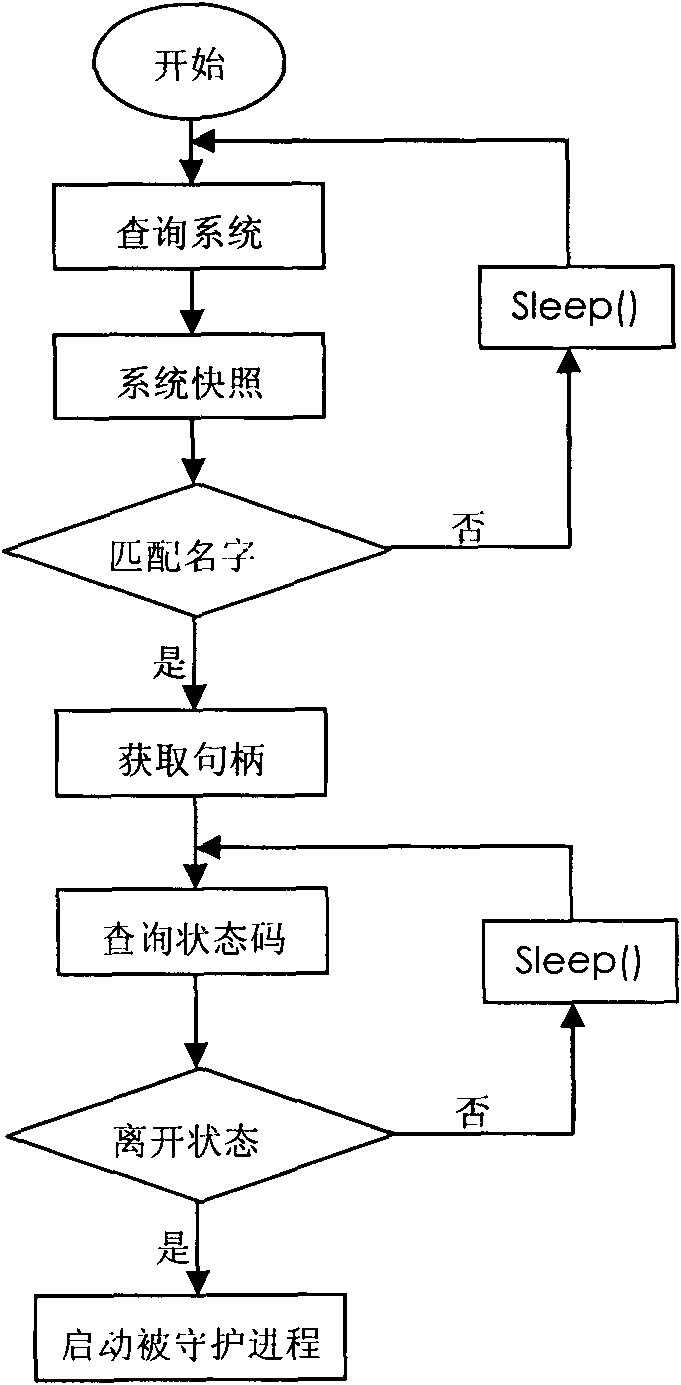

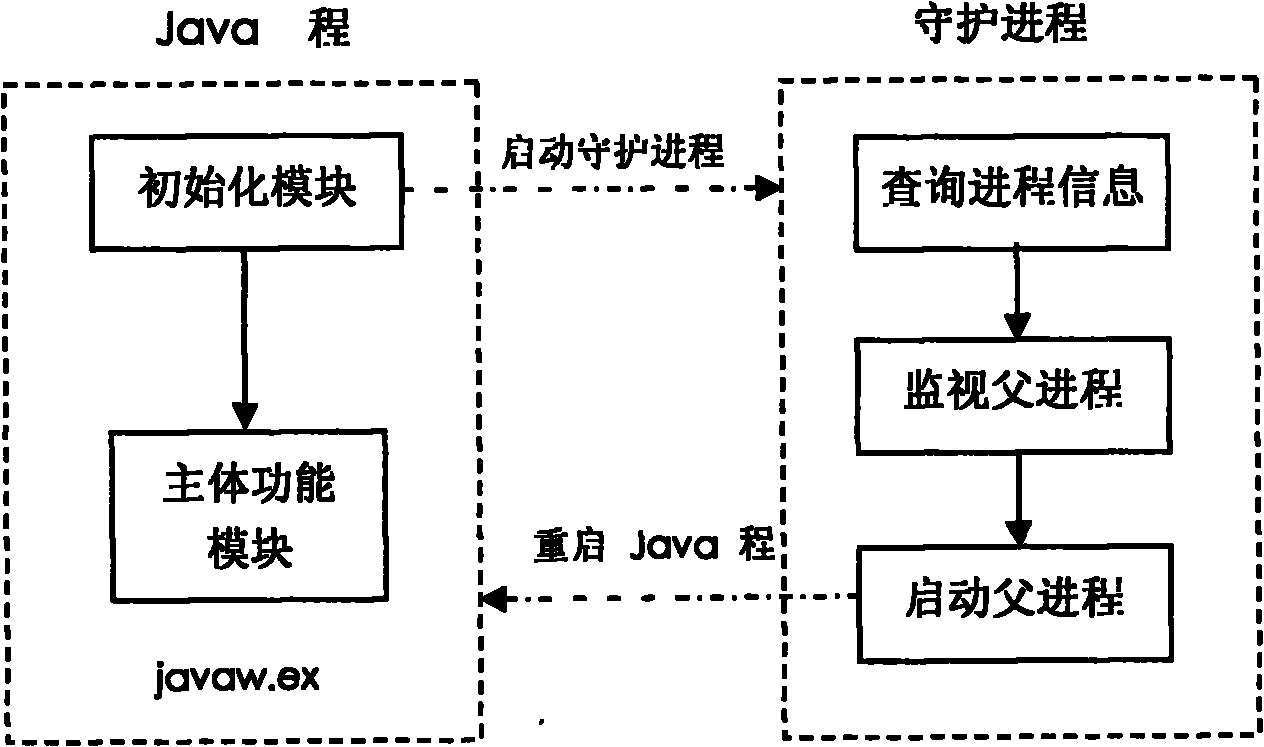

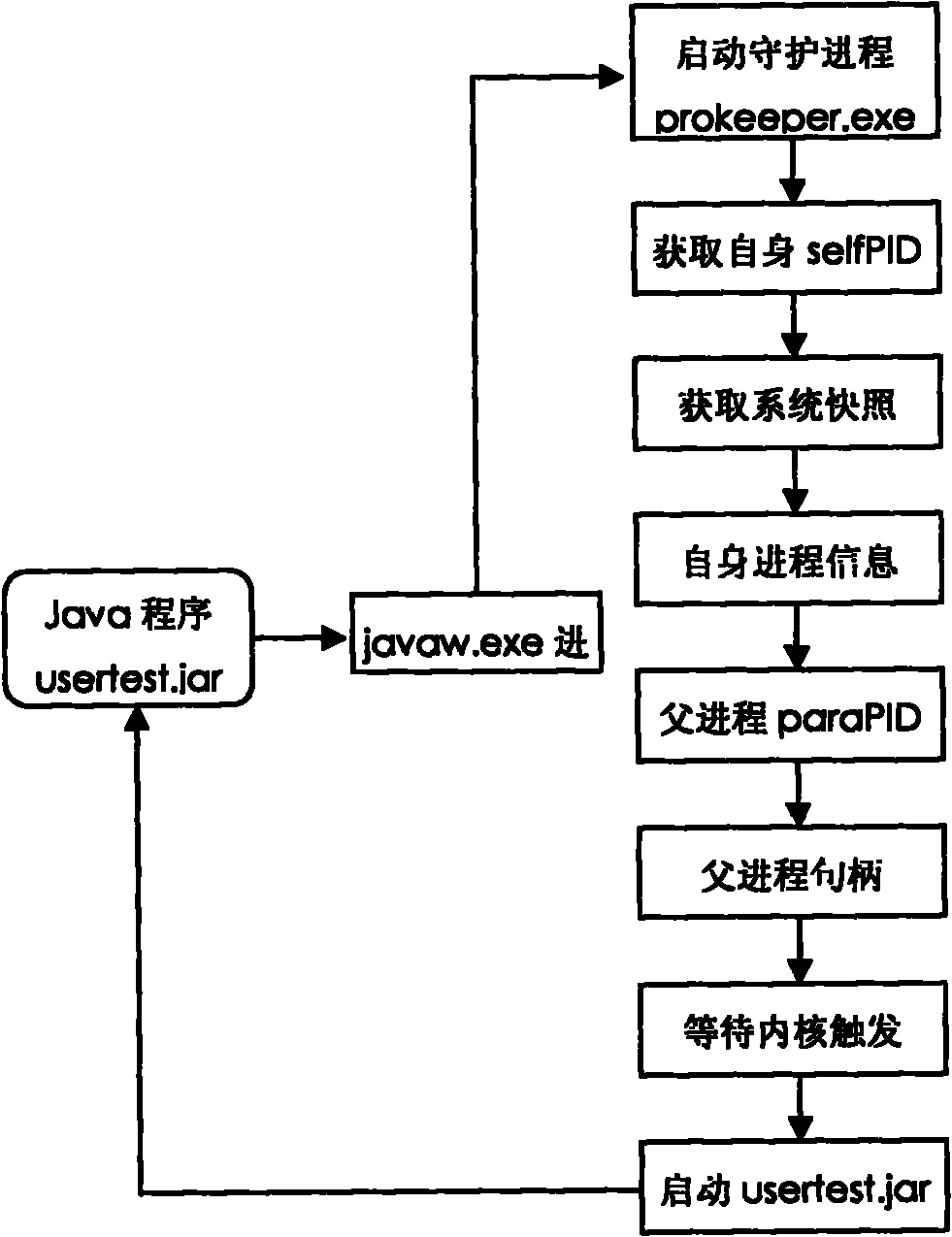

Method for protecting Java program progress based on inheritance relationship among progresses

InactiveCN102103676AOvercoming the drawbacks of matching to determine the daemonized processAccurately determinePlatform integrity maintainanceOperational systemRelationship - Father

The invention provides a method for protecting Java program progress based on an inheritance relationship among the progresses, wherein the method is used for protecting the Java program (the program developed by the Java programming language, hereinafter referred to as Java program) in a windows system (a name of an operating system). The method is mainly used for solving the authentication and determination of the protected Java program progress, monitoring the operating state of the Java program, and preventing the unexpected ending of the operation. The method establishes a father and soninheritance relationship between the protected Java program progress and the protecting program progress, uniquely determines the protected Java program progress by the protecting program progress based on the inheritance relationship and determines the operating state of the protected Java progress based on the inner core object state of the protected Java program progress.

Owner:NANJING UNIV OF POSTS & TELECOMM

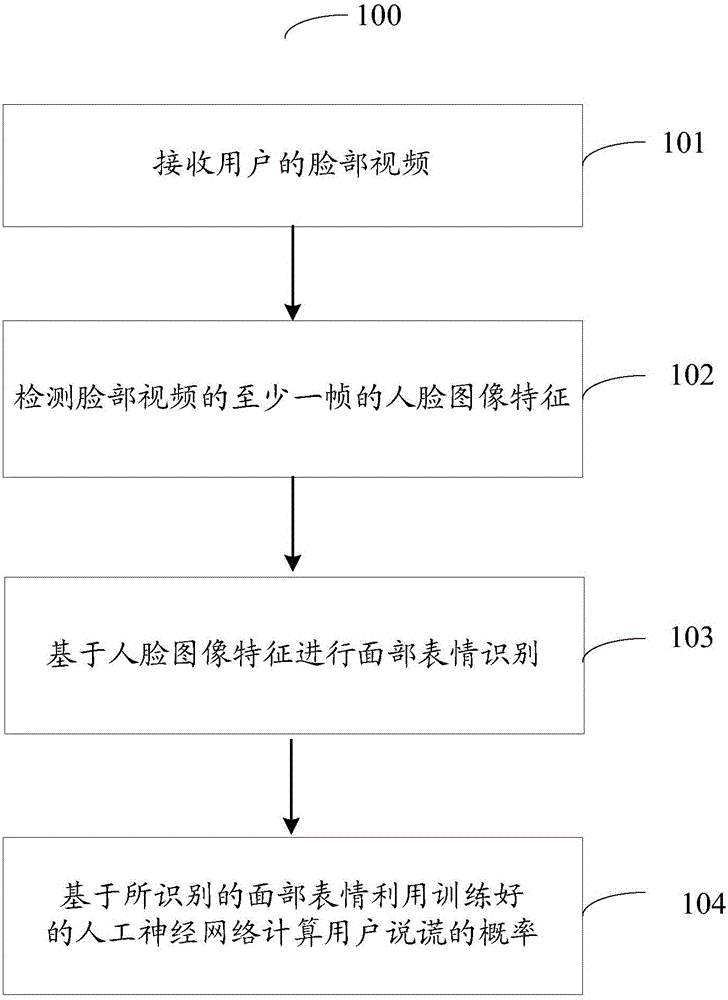

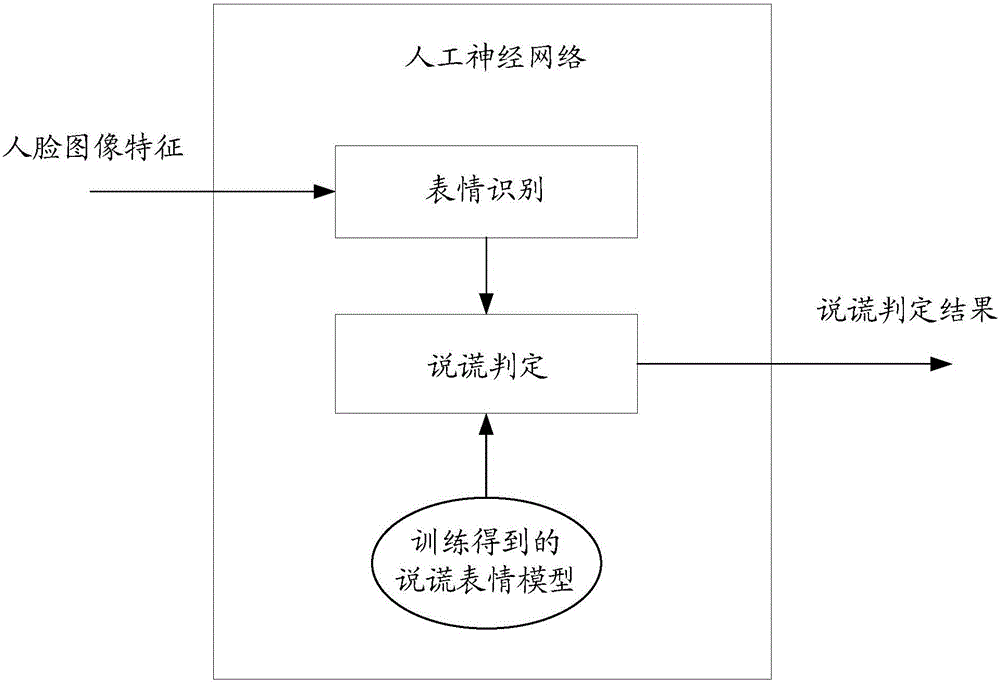

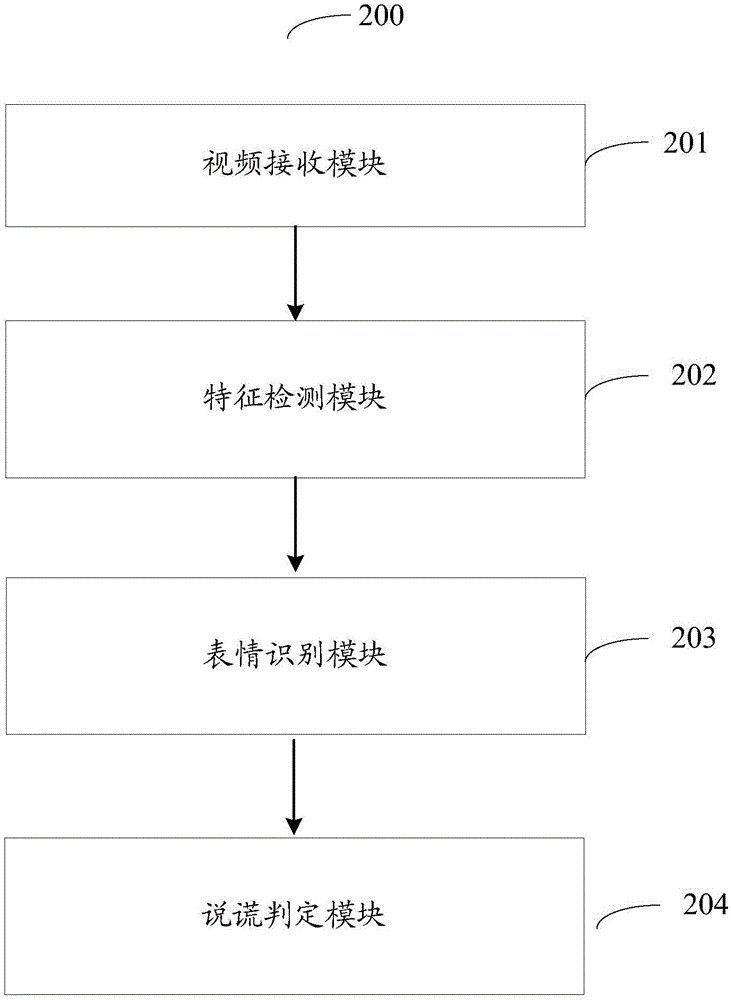

Facial expression based lie detection method and system

ActiveCN105160318AEasy to implementFlexible and convenient to useAcquiring/recognising facial featuresSpoof detectionPattern recognitionImaging Feature

The invention provides a facial expression based lie detection method and system. The method comprises: receiving a facial video of a user; detecting a facial image feature of at least one frame of the face video; identifying facial expression based on the face image feature; and calculating a lying probability of the user by utilizing a trained artificial neural network based on the identified facial expression. According to the facial expression based lie detection method and system, provided by the invention, analysis can be automatically performed in a dialogue process without the need for special cooperation of the user, so that the facial expression based lie detection method and system, provided by the invention, are easy to realize and very flexible and convenient to use.

Owner:BEIJING KUANGSHI TECH +1

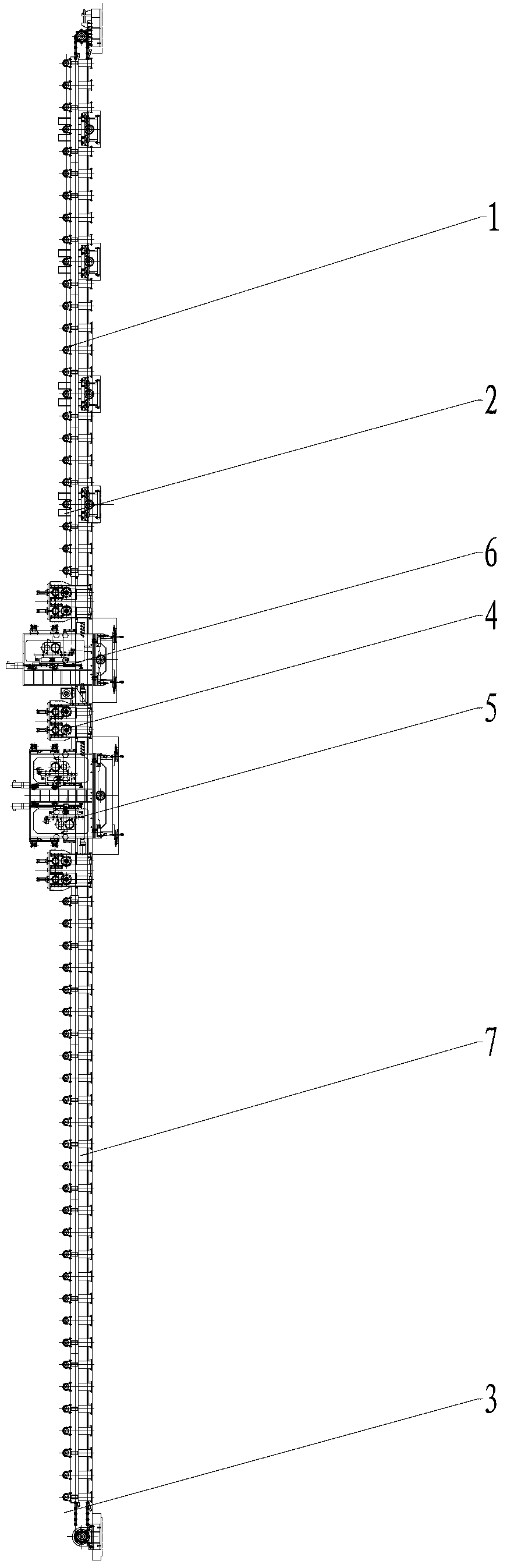

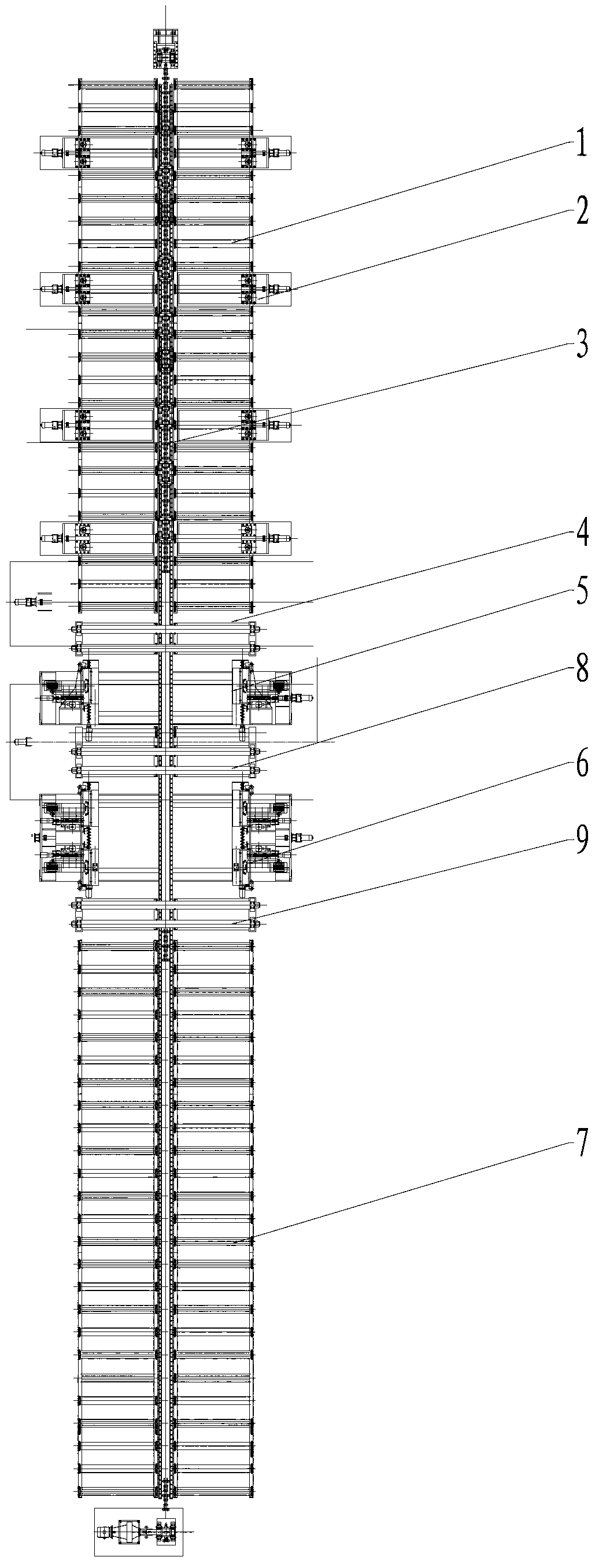

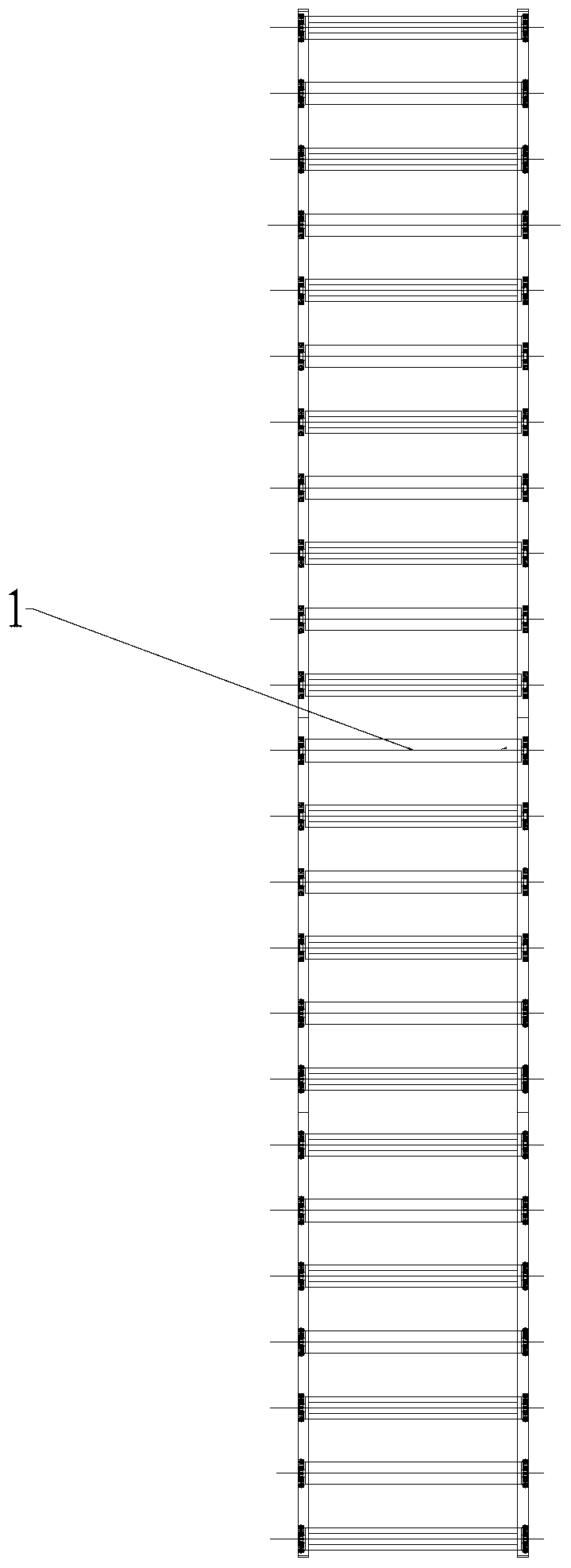

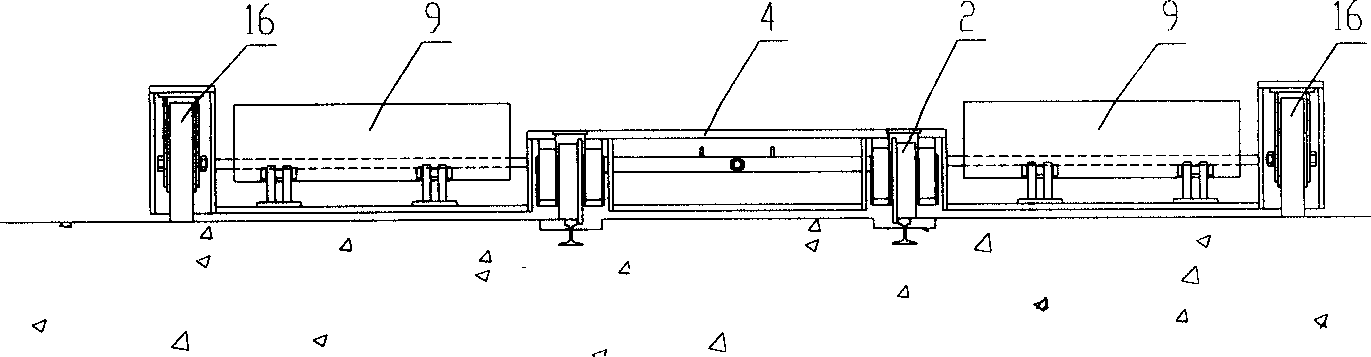

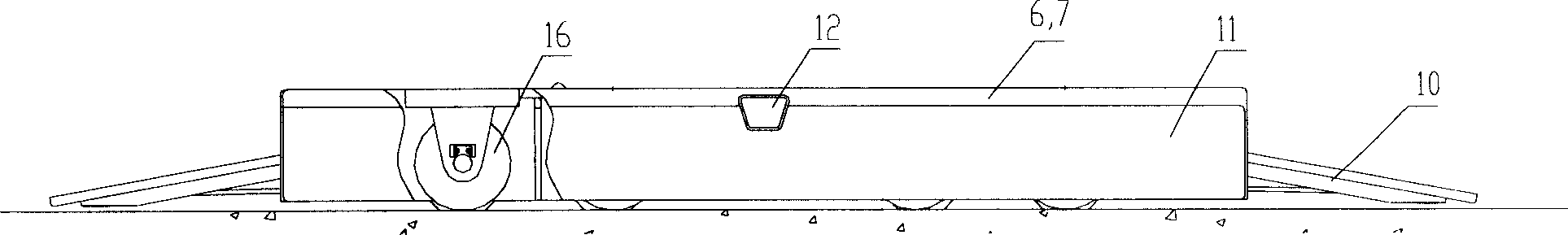

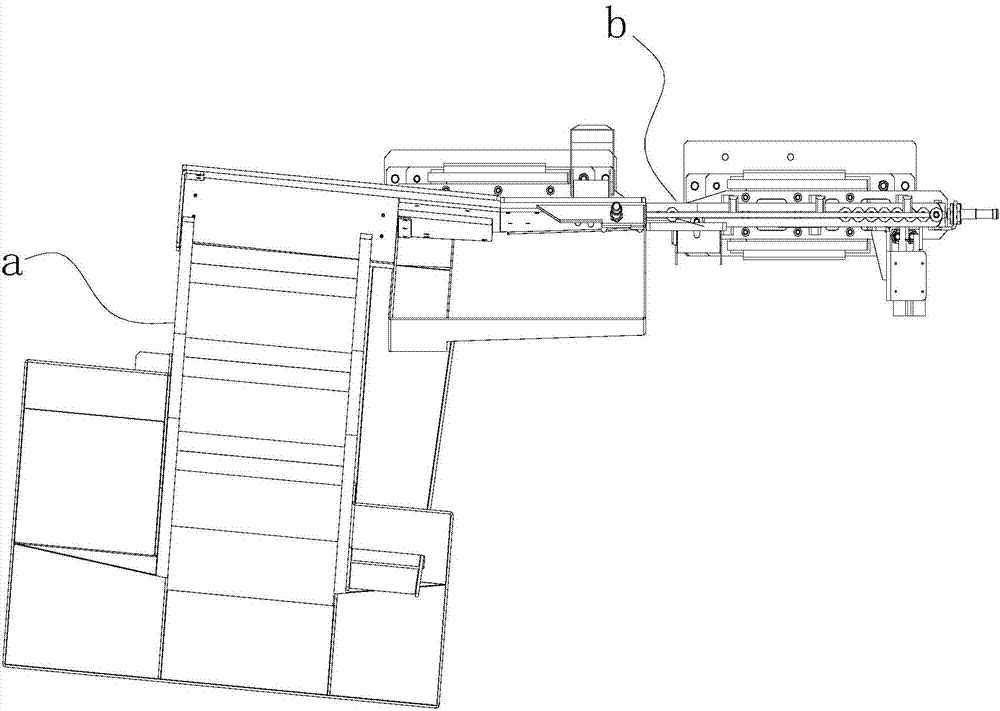

Numerical control steel plate double-side four-surface synchronous groove forming machine production line

ActiveCN103212741AReduce labor intensitySimple structureMilling equipment detailsMetal working apparatusProduction lineNumerical control

The invention relates to a numerical control steel plate double-side four-surface synchronous groove forming machine production line, in particular is used for processing double sides and four surfaces of steel plate welding lines with different plate thicknesses and plate widths synchronously, and belongs to the technical field of mechanical equipment. The numerical control steel plate double-side four-sides synchronous groove forming machine production line comprises a front conveying roller table, a centring device, a conveying power device, first pinch roll devices, double-side straight side miller host machines, double-side upper-lower groove miller host machines, a rear conveying roller table, second pinch roll devices and third pinch roll devices, wherein two first pinch roll devices, two double-side straight side miller host machines, two double-side upper-lower groove miller host machines, two second pinch roll devices and two third pinch roll devices are arranged in the middle of the conveying power device, and the two double-side straight side miller host machines and the two double-side upper-lower groove miller host machines are respectively arranged at two sides of the conveying power device symmetrically. The numerical control steel plate double-side four-surface synchronous groove forming machine production line provided by the invention is simple, compact and reasonable in structure, can process double sides and four surfaces of steel plate welding lines with different plate thicknesses and plate widths synchronously, lowers the labor intensity greatly, is high in automation degree, is high in processing accuracy, is low in cost, and is convenient and flexible to use.

Owner:WUXI HUALIAN SCI & TECH GROUP

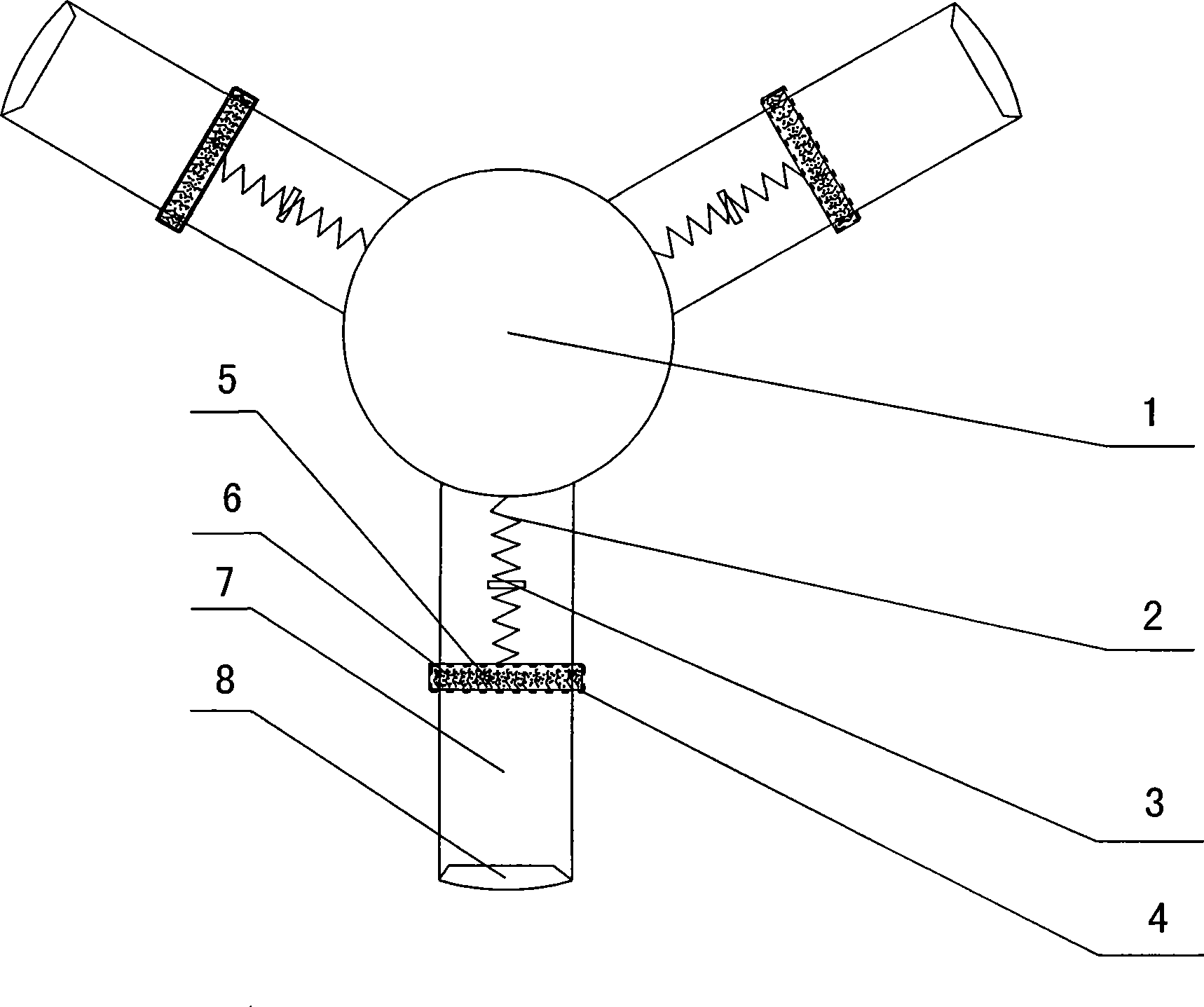

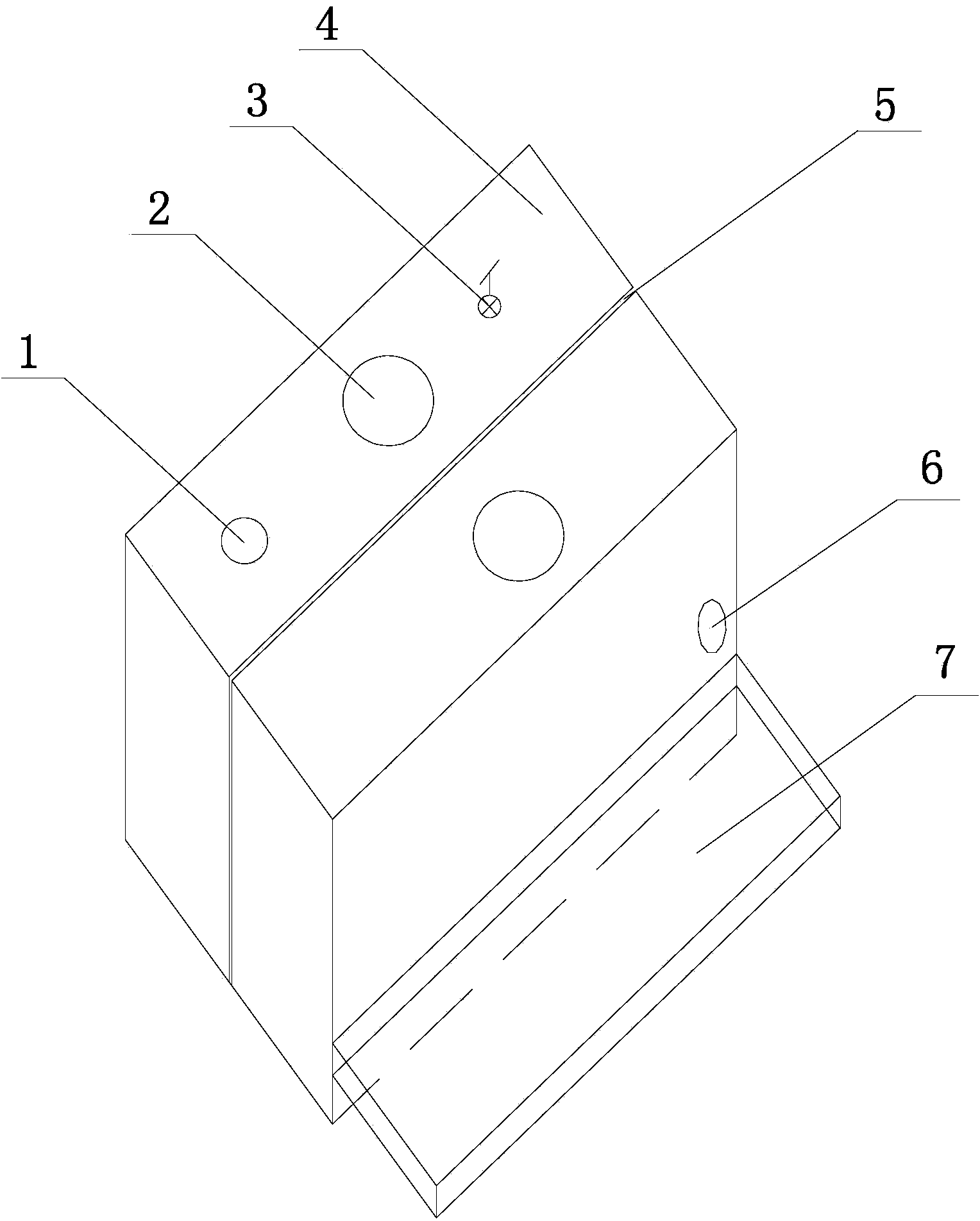

Welding protection tooling

ActiveCN103831553AFlexible and convenient to useConvenient and flexible useWelding/cutting auxillary devicesAuxillary welding devicesCarbon dioxideEngineering

The invention discloses a welding protection tooling. The welding protection tooling is characterized by comprising a protection box, an air outlet and an operating port. An air inlet is arranged in the right side face of the protection box and is connected with an air storage device, and the air storage device fills mixed gas of carbon dioxide and oxygen into the protection box via the air inlet. The air outlet is arranged in the upper side face of the protection box. The operating port is arranged in the upper side face of the protection box. The upper side face is a translucent and anti-glaring structural surface. The protection box is divided into a left part and a right part, and the left and right parts are pivoted on the same shaft and rotate relatively. The welding protection tooling has the advantages that the welding protection tooling is applicable to welding in most environments, quite convenient and flexible to use and capable of easily dividing the protection box into the left part and the right part and pulling the protection box on the ground.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

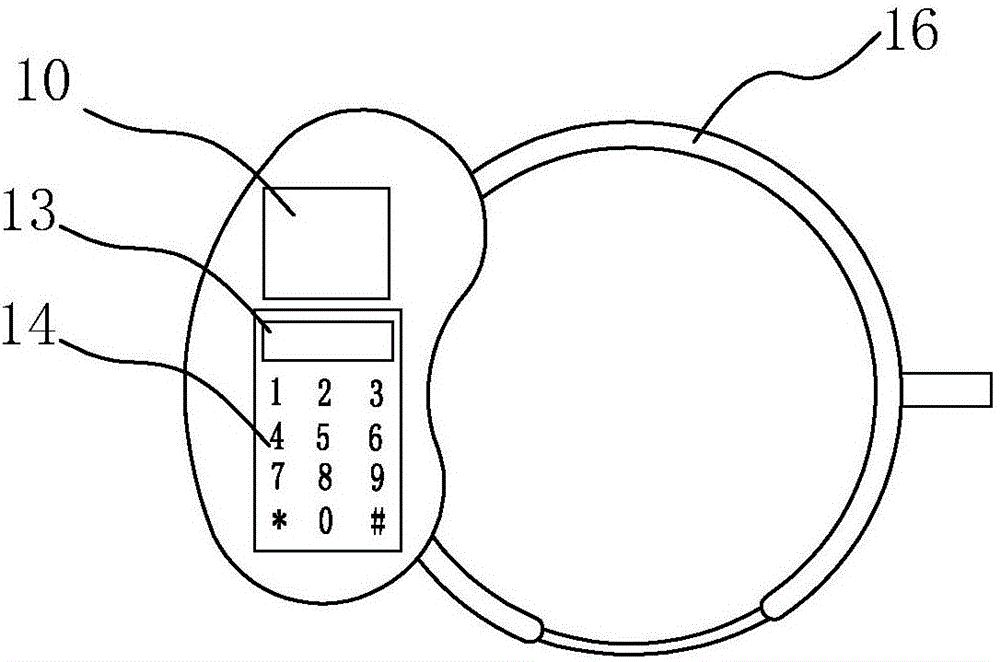

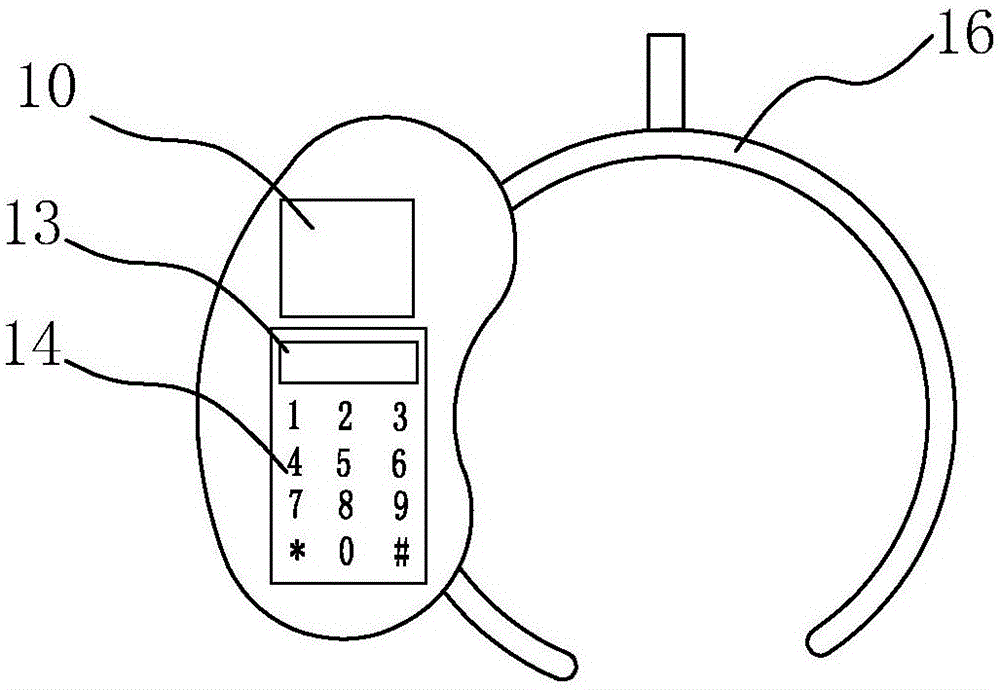

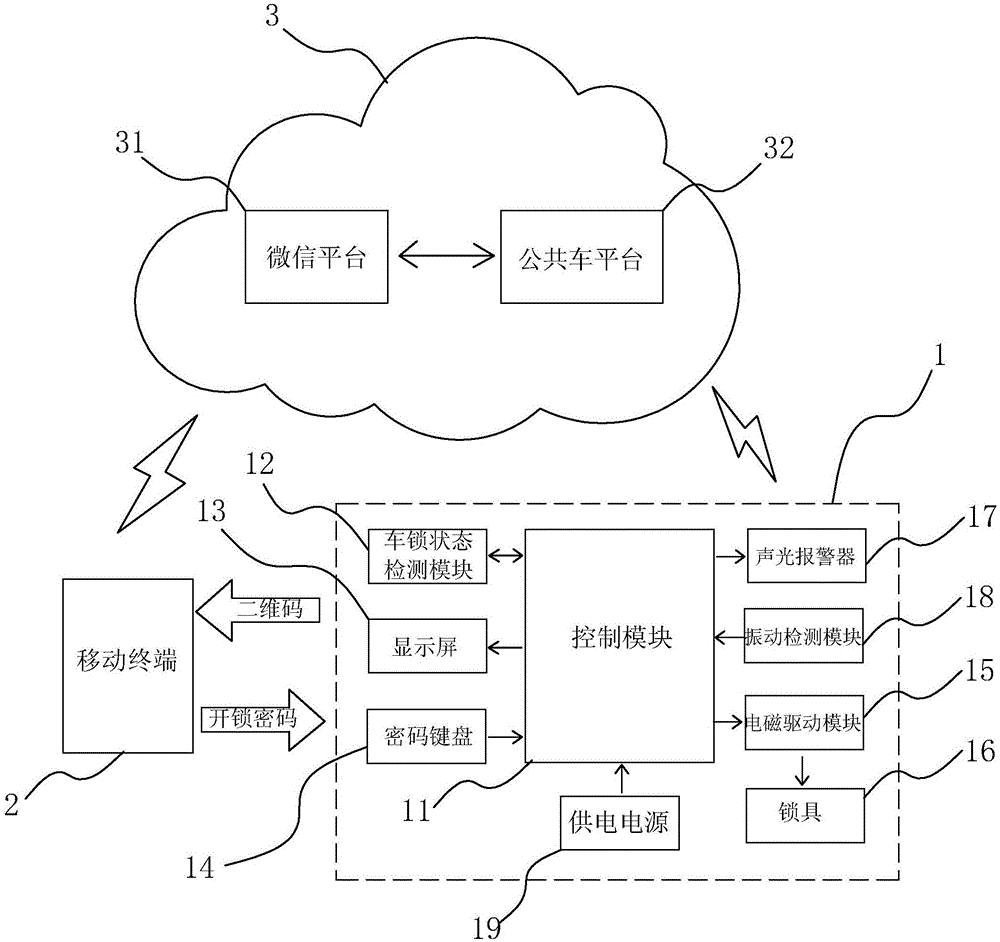

Intelligent password lock, and vehicle renting system and method based on cloud service

InactiveCN106548568APrevent leakageIncrease profitApparatus for meter-controlled dispensingIndividual entry/exit registersPasswordComputer terminal

The invention discloses an intelligent password lock, and a vehicle renting system and a vehicle renting method based on cloud service. The intelligent password lock has a unique two-dimensional code used for identifying identity, a rolling unlocking password generated by identity identification can be acquired by scanning the two-dimensional code by using a mobile terminal, and the intelligent password lock can be unlocked by inputting the unlocking password; the rolling unlocking password is only available currently, so that password leakage can be effectively prevented; the intelligent password is applicable to being installed on a public bicycle in a vehicle renting system, a user does not need to rent or return the bicycle at specified places, after being locked, the intelligent password lock generates a bicycle locking code, a renter can return the bicycle after the current bicycle locking code is input and checked by a cloud platform, so that a fraud problem during a bicycle returning process is completely eradicated; according to the vehicle renting method of the renting system, bicycle renting efficiency and a utilization rate of the public bicycles can be greatly improved.

Owner:江门市雷特诺克物联网科技有限公司

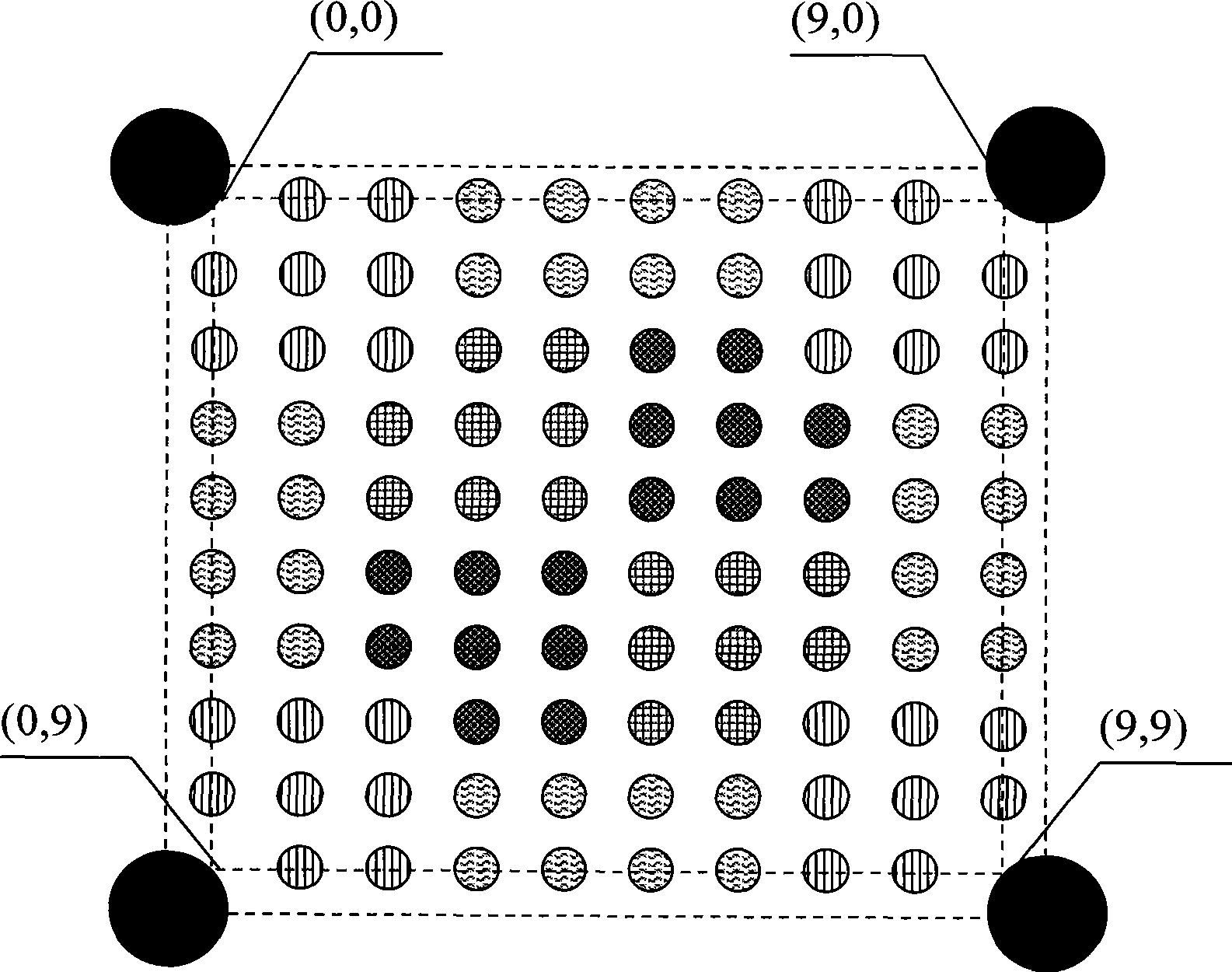

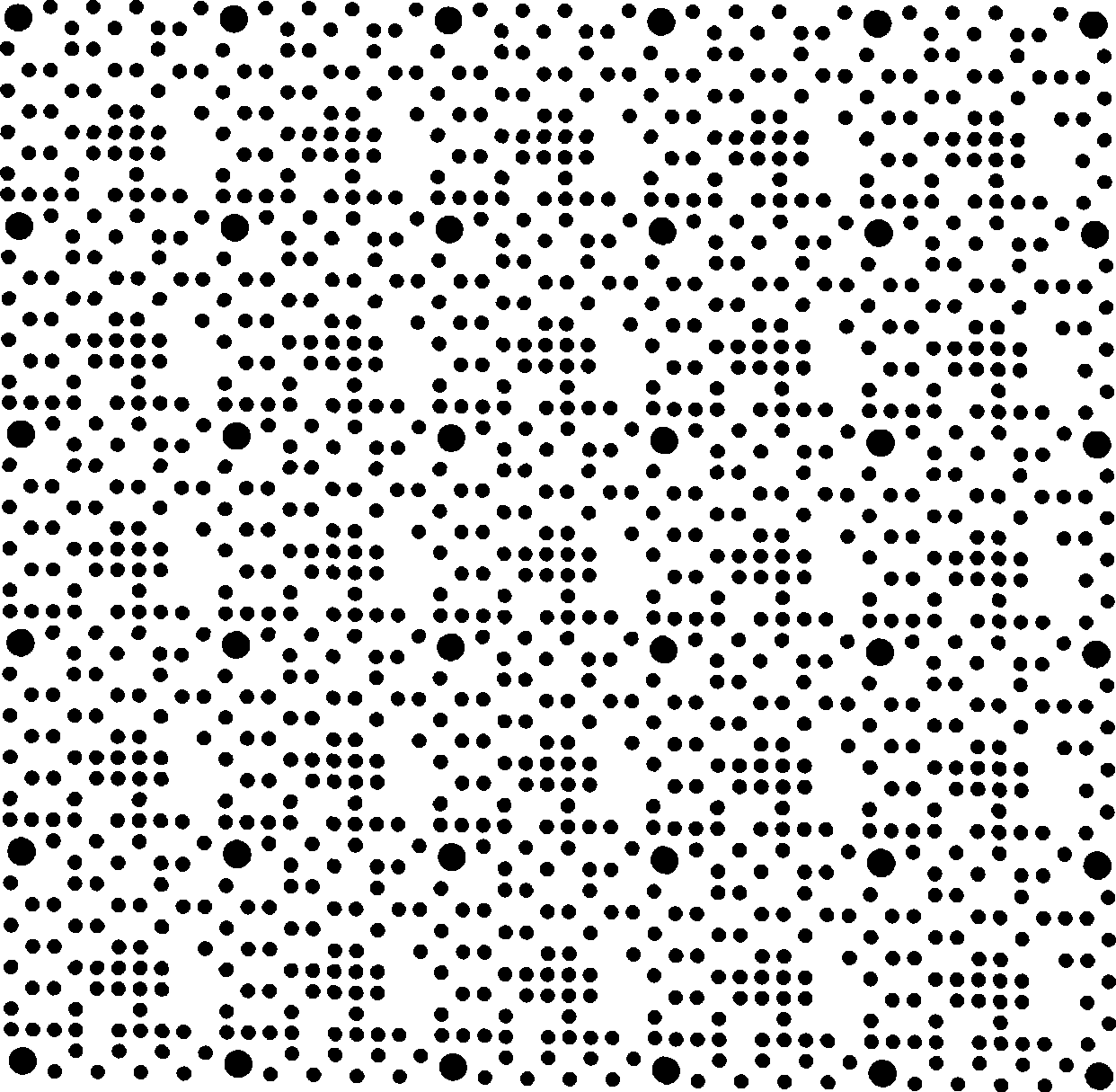

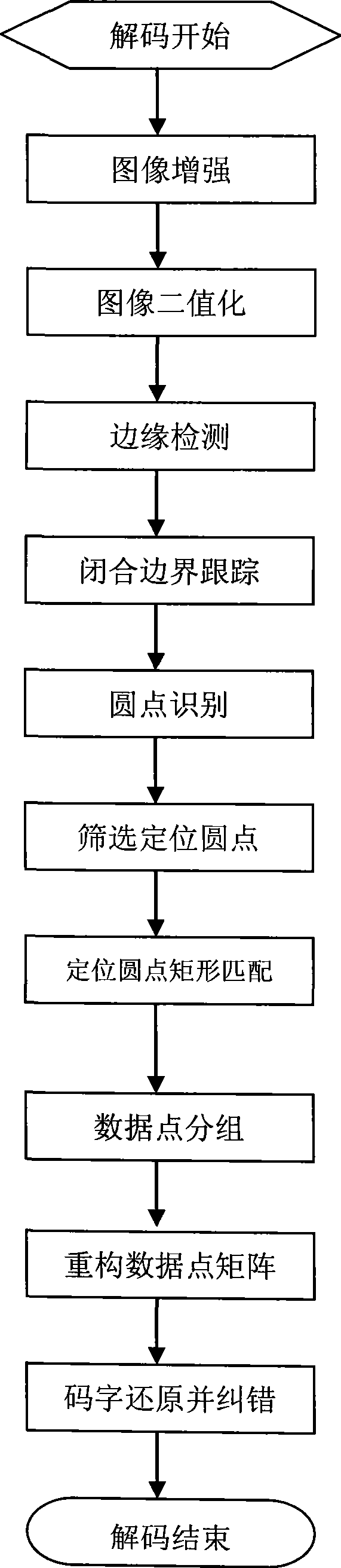

Two-dimensional code, printed publication applying the two-dimensional code and decoding process

ActiveCN101477638AFlexible and convenient to useQuick to useCharacter and pattern recognitionRecord carriers used with machinesQuantum dotOptical reflectance

The invention discloses a two-dimensional code, printed publication using the two-dimensional code and a decoding method. The two-dimensional code is characterized in that rectangular code symbol includes a code unit with different optical reflectivity arranged on a substrate; the code units in the code symbol are solid round dots arranged at equal distance; the units at four corners of the code symbol are location dots for border location and recognition, and the rest units are data dots; and the area of the location dots are larger than that of the data dots. The two-dimensional code can form images under the condition of deep defocusing, and has the advantages of rapid data reading, high reliability, low requirement for reading equipment and wide application.

Owner:SHENZHEN MPR TECH CO LTD

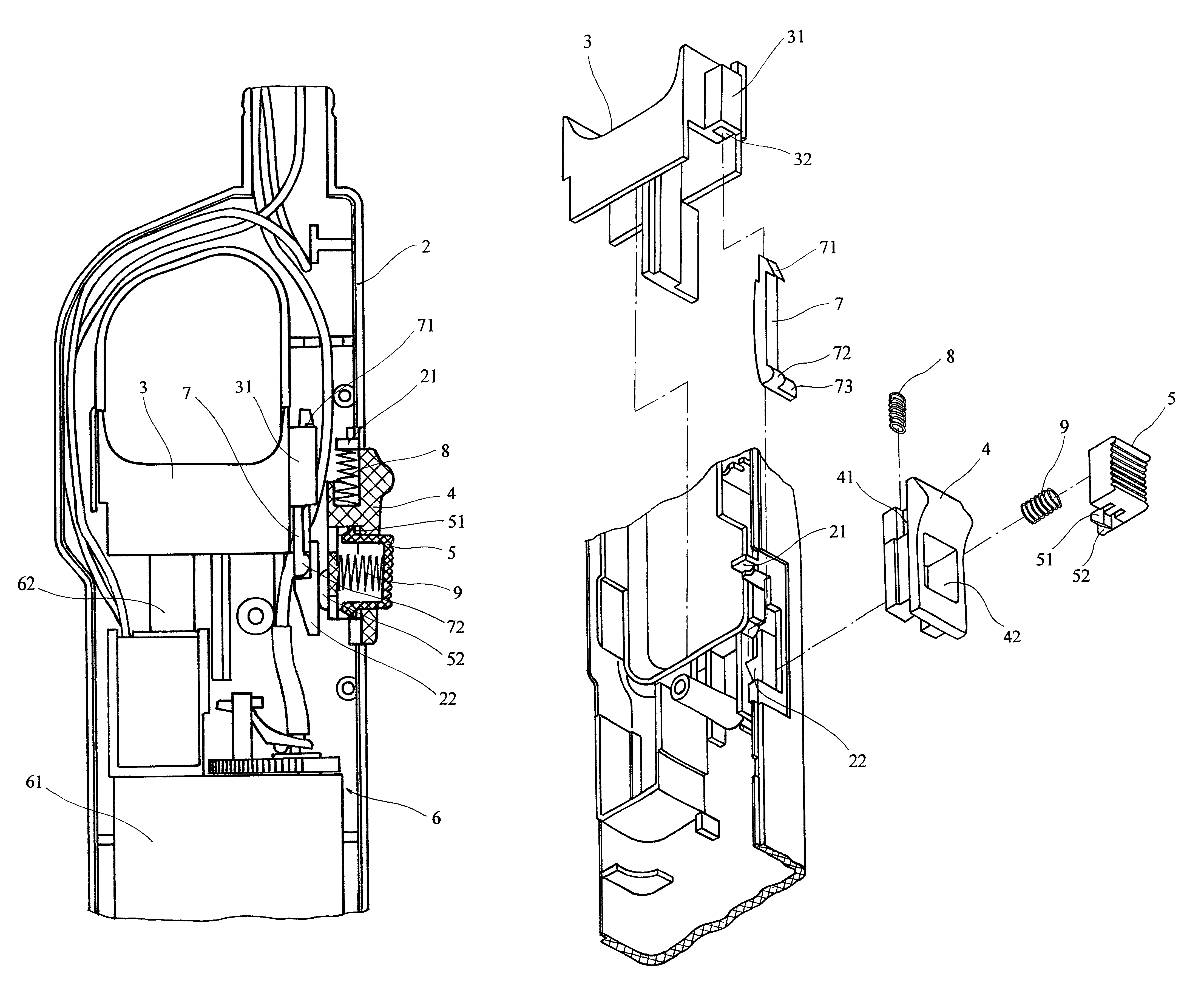

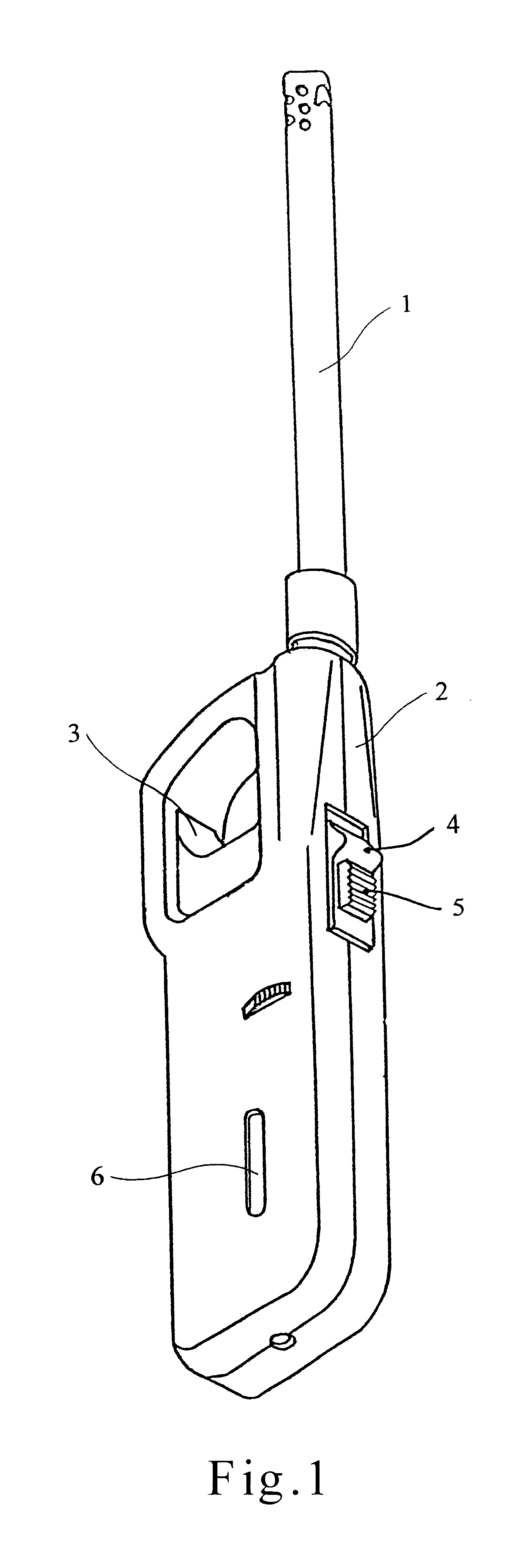

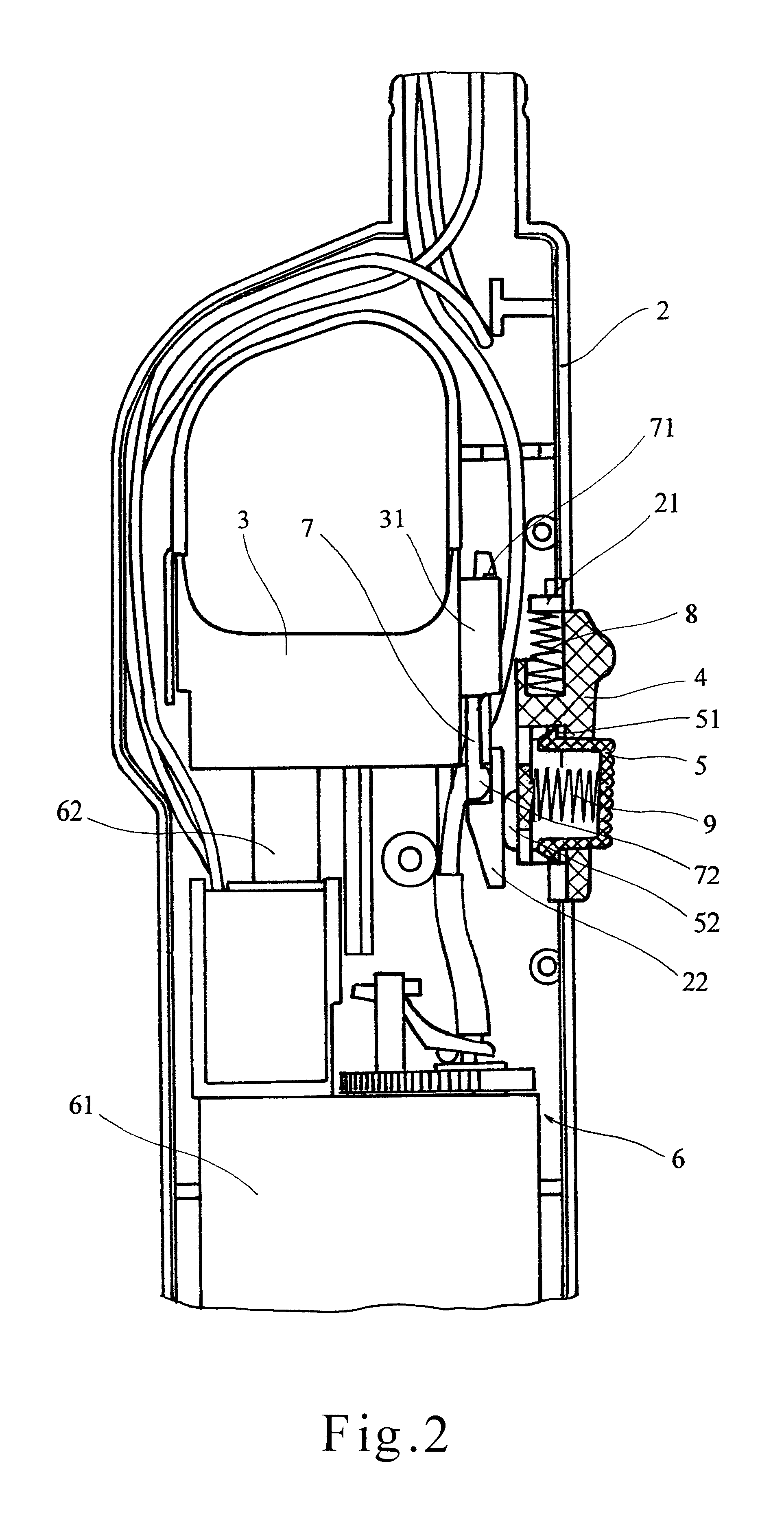

Igniter with a push-button and an elastic bar

InactiveUS6887072B2Promote fireSolve the real problemBranding equipmentIncandescent ignitionNatural statePush ups

Igniter with safety unit, the safety unit comprises a push-button that is arranged at the backside of the gun body and partially protrudes out of the gun body, it can be pushed forward and return relative to the gun body; a elastic limit bar that is arranged at the side of the part of the ignition trigger that is towards the backside of the gun body, in natural condition, its end keeps against a barrier block which is integrated with the inner wall of the gun body; a button that is arranged in the push-button and protrudes out of the push-button, it can be pressed into the gun body and return. A protruding part arranged on the button's inner side protrudes towards a mid-portion of the gun body. In natural condition, the protruding part is towards the blank part, but when the push-button is in pushed up condition, the protruding part is near the end of the elastic limit bar and opposite to it. Thereby, if the button is pressed down, the protruding part of the button pushes the end of the elastic limit bar to make it distort and deflect from the barrier block on the inner wall of the gun body. The locking situation of the ignition trigger can be released. The apparatus can fire the flammable gas only by doing the two compound actions i.e. pressing down the button and pushing up the push-button simultaneously, thus further improving the safety of the ignitor.

Owner:JUDENG ZHANG

Trailer of trailer system used in radiation imaging

ActiveCN1607135ALarge frame clearanceEven by forceCarriagesMaterial analysis by transmitting radiationVehicle frameRadiation imaging

A trailer system for radiation imaging, belonging to radiation imaging check system, consists of trailer and ground anchorage device wherein the trailer consists of frame, multiple pair of guide wheel, rope hanging bolt on frame, H shape beam on meddle of frame, pivot axle on four corners H beam and pivoted with left and right platform of frame, slope platform at front and rear ends of left and right platform of frame and with position dimple, frame board in out side of left and right platform, collision block at middle of outer side of frame boards. Said invention can be used cooperatively with ground anchorage device in large container check system and has advantage of lowering installation accuracy by using moveable slope platform and raising reliability, stability and practicability.

Owner:TSINGHUA UNIV +1

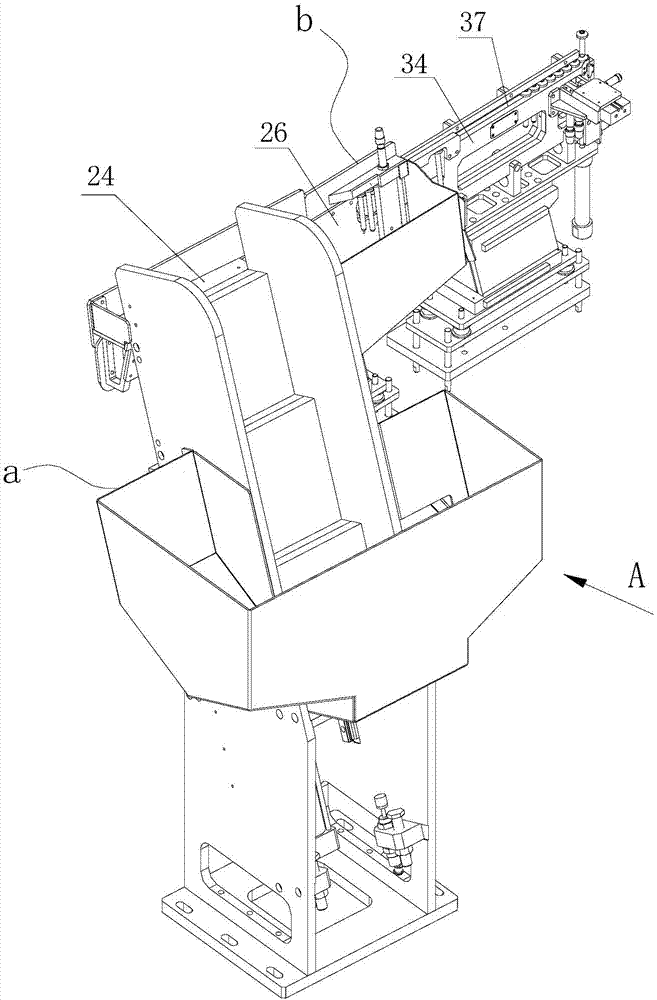

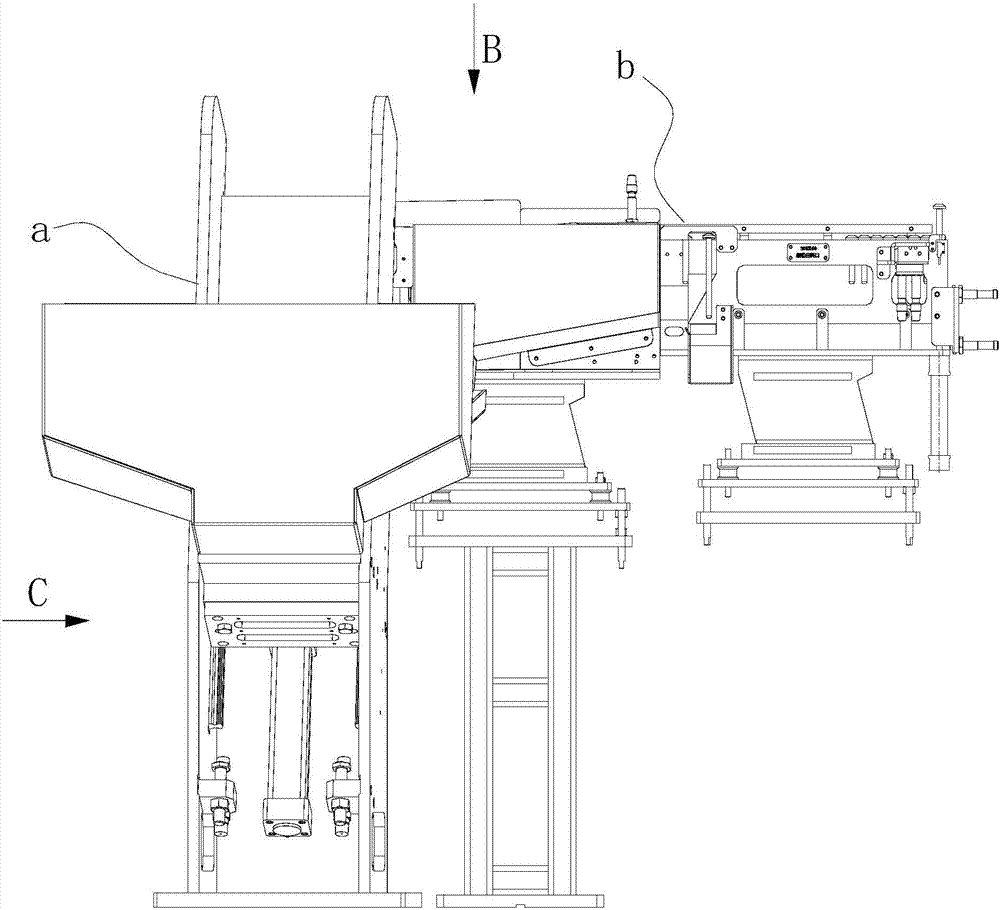

Automatic bolt feeding device

ActiveCN107032095AQuick exclusionRealize automatic feeding processMetal working apparatusConveyor partsLagMechanical engineering

The invention discloses an automatic bolt feeding device which comprises a stepped feeding mechanism and a vibratory screening mechanism which are connected, wherein the vibratory screening mechanism comprises a lag bolt screening component and a stay bolt screening component; the stepped feeding mechanism, the lag bolt screening component and the stay bolt screening component are connected in sequence in the conveying direction of bolts; the stepped feeding mechanism is used for automatically extracting bolts from a feed hopper and conveying the bolts to the follow-up vibratory screening mechanism; the lag bolt screening component is used for screening out and excluding too-short bolts from the bolts; the stay bolt screening component is used for screening out and excluding too-long bolts from the bolts, so as to obtain bolts with qualified specifications. The automatic bolt feeding device completely replaces manual operation, realizes automatic bolt feeding and screening, realizes quick feeding while quickly excluding bolts with unqualified specifications, effectively improves the working efficiency, reduces the production cost of the equipment, and meanwhile meets the requirements of the equipment on high speed assembly.

Owner:广州市嘉特斯机电制造有限公司

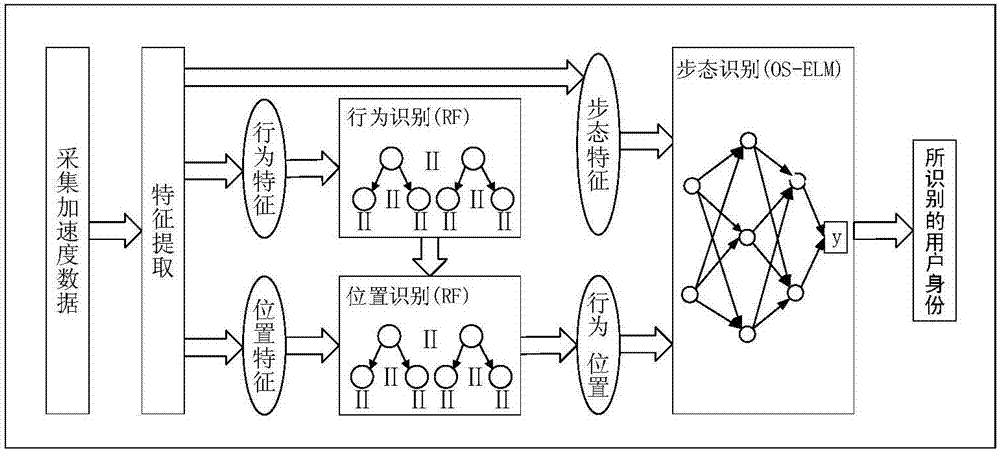

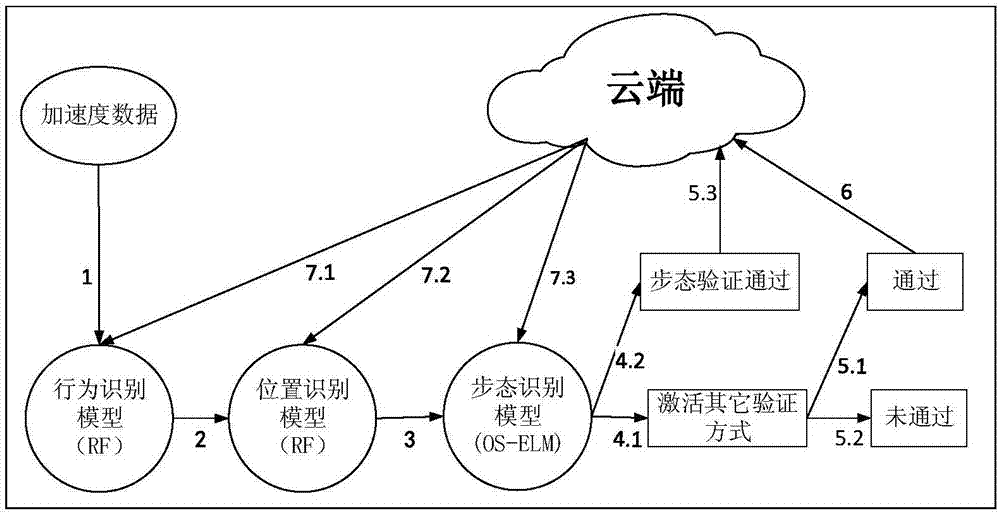

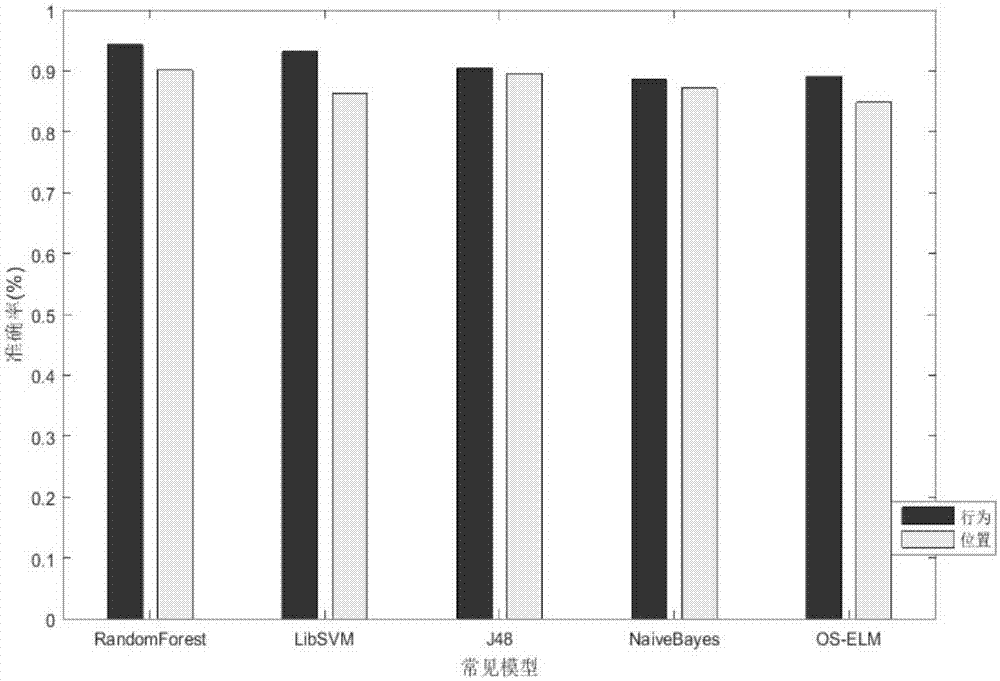

Gait identity identification method and system thereof

InactiveCN107016346AImprove accuracy and robustnessEasy to useCharacter and pattern recognitionDigital data authenticationBehavior recognitionGait

The invention provides a gait identification method and a system thereof. The method is characterized by extracting a behavior characteristic, a position characteristic and a gait characteristic from acceleration data acquired from intelligent terminal carried by a user; using a pre-trained behavior identification model to identify a current user behavior according to the behavior characteristic; using a pre-trained position identification model to identify a current position of the intelligent terminal according to the position characteristic and the identified current user behavior; and using a pre-trained gait identification model to identify a user identity according to the gait characteristic, the identified current user behavior and the current position of the intelligent terminal. In the method, through a layered progressive identification mode, accuracy and robustness of gait identity identification are increased, a correlation sensor placing position and a direction do not need to be limited, and the method and the system are flexible and are convenient to use.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com