Layout structure for integration of train depot and junction station of urban rail

A layout structure and urban track technology, applied in the direction of stations, tracks, railway car body parts, etc., can solve the problems of low production efficiency, inability to extend lines, and scattered and disordered layout structures, so as to reduce employees and equipment and reduce detours distance, reducing the effect of direct production land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The integrated layout structure of the urban rail vehicle depot and the rail connection station of the present invention will be described in conjunction with the accompanying drawings and embodiments.

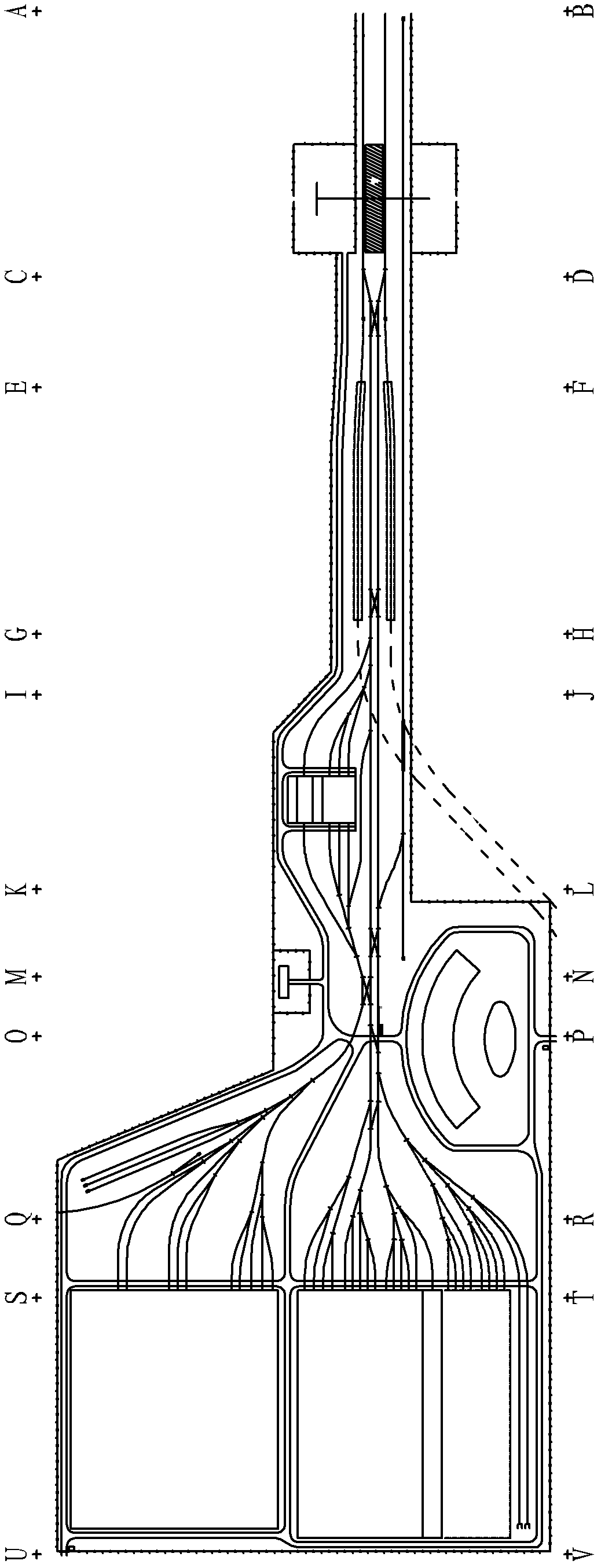

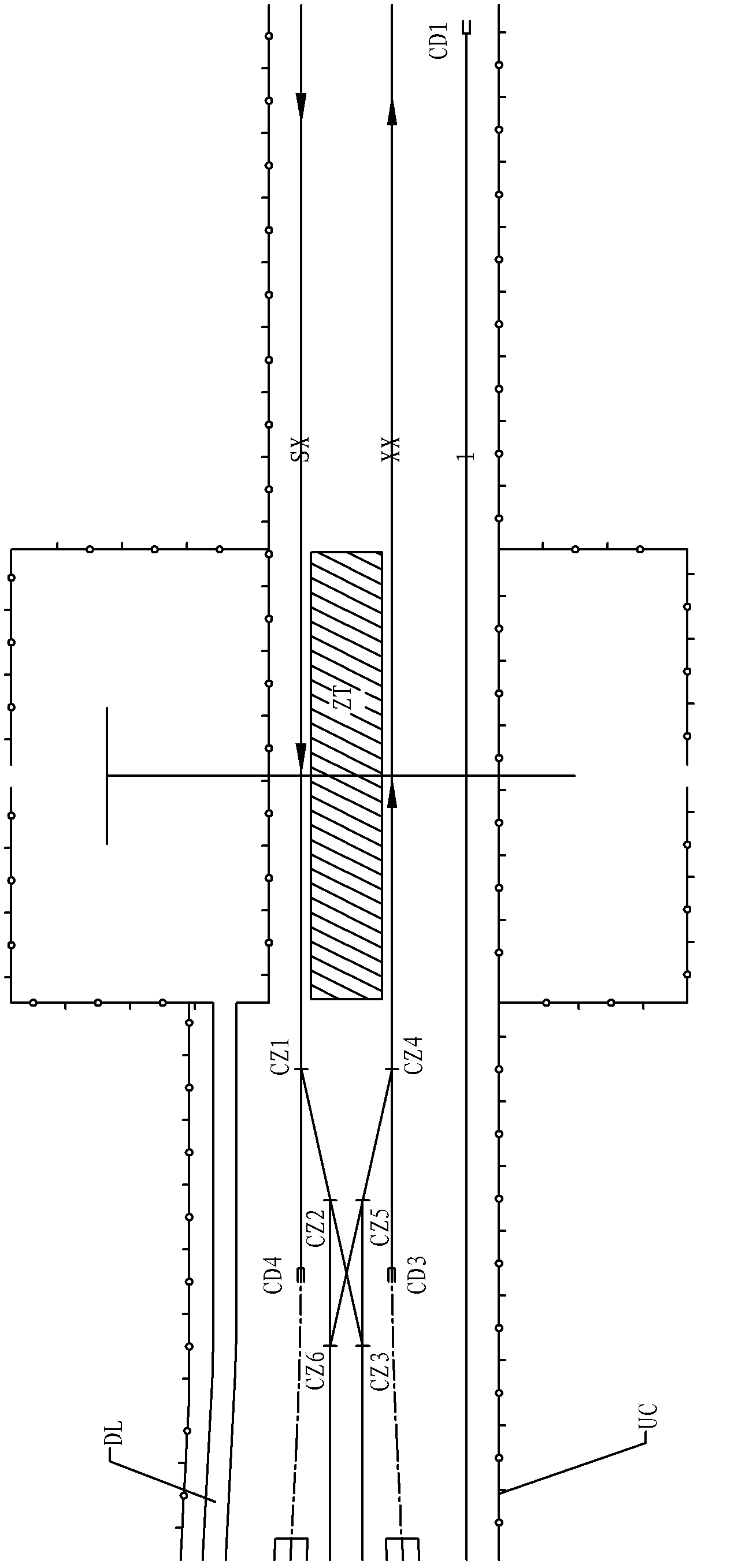

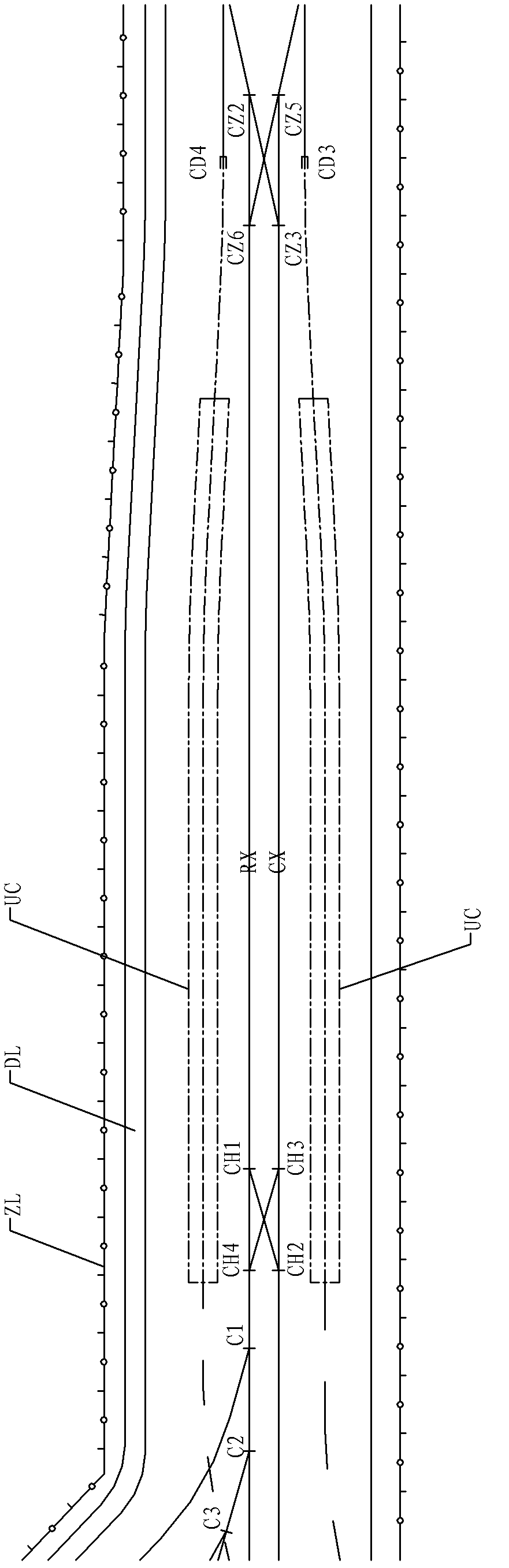

[0090] The integrated layout structure of the urban rail vehicle depot and the rail connection station of the present invention faces the municipal road, and includes a rail connection station built on the ground, a vehicle depot and connected tracks and switches; the rail connection station includes the main line SX and main line XX, turnback line, entry line RX, and exit line CX; vehicle depot includes parking line, maintenance line, car washing line, pull-out line, test run line, material line and turnout, as well as parking train inspection warehouse and factory frame repair warehouse , Washing garage, internal combustion engine storage, engineering garage, flammable product storage, comprehensive office building, guard room. Since the station building is not the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com