Installation support structure for theater main stage steel beam and construction method of structure

A supporting structure and construction method technology, applied in the field of building construction, can solve the problems of high risk of safety management, long construction period, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

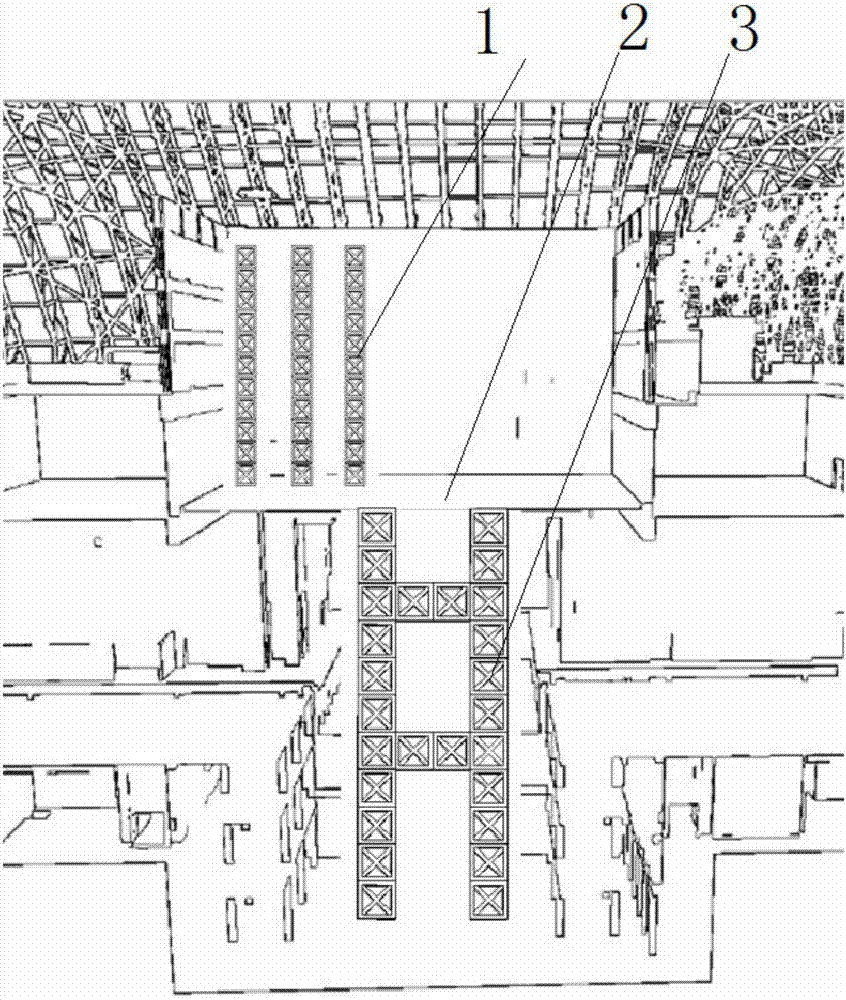

[0043] Embodiment 1: An installation support structure for steel beams on the main stage of a theater, including: a first support system, a conversion platform 2, and a second support system;

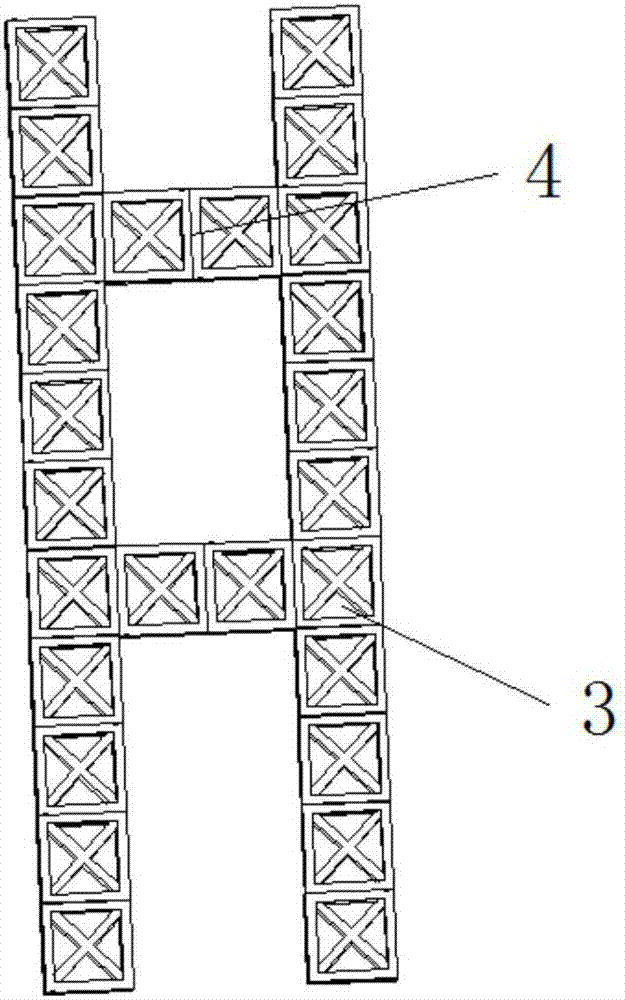

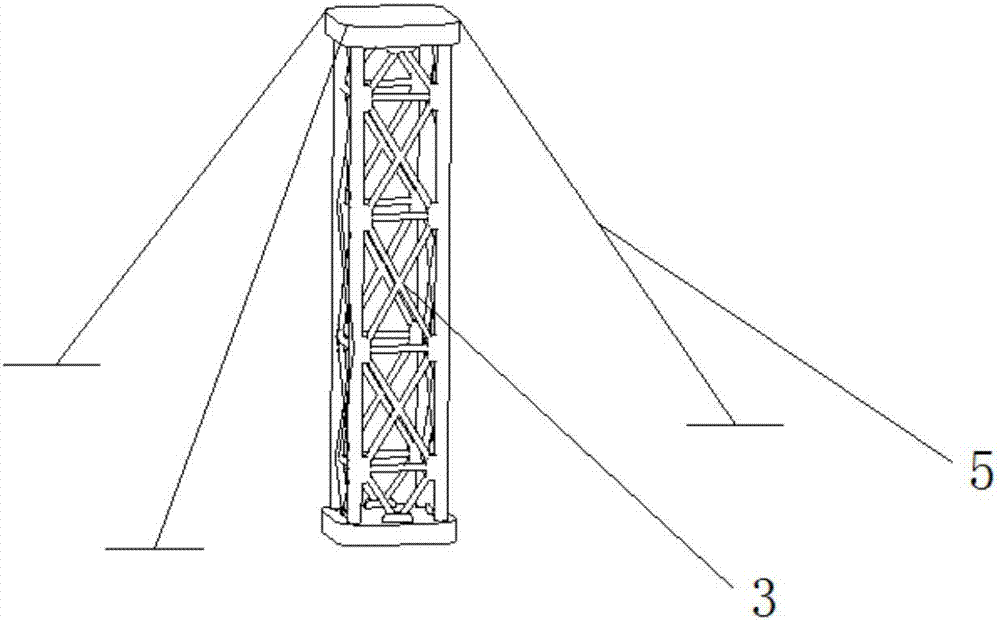

[0044] The first support system includes: two first lattice columns 3 and lateral support beams 6, the first lattice columns 3 are vertically fixed on the ground as ground support, and the first lattice columns 3 are erected There are two parallel trusses 4 as lateral supports; the first lattice column 3 is also provided with a wind rope 5 for traction, one end of the wind rope 5 is fixed on the top of the first lattice column 3, and the other fixed at one end to the beam;

[0045] The transverse support beam 6 is supported by two first lattice columns 3, and is horizontally fixed on the top surfaces of the two first lattice columns 3. Preferably, the transverse support beam 6 is a box beam;

[0046] The conversion platform 2 is laid and fixed on the support platform formed by the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com