Circulating slurry sprinkling device for desulfurization of flue gas

A spray device and slurry technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of wear at the interface between the spray pipe and the absorption tower, insufficient mixing of flue gas and circulating slurry, and desulfurization efficiency. Further improve other issues to achieve the effect that the equipment is not easy to be damaged, prevents wear and leakage, and is convenient for processing, manufacturing and on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

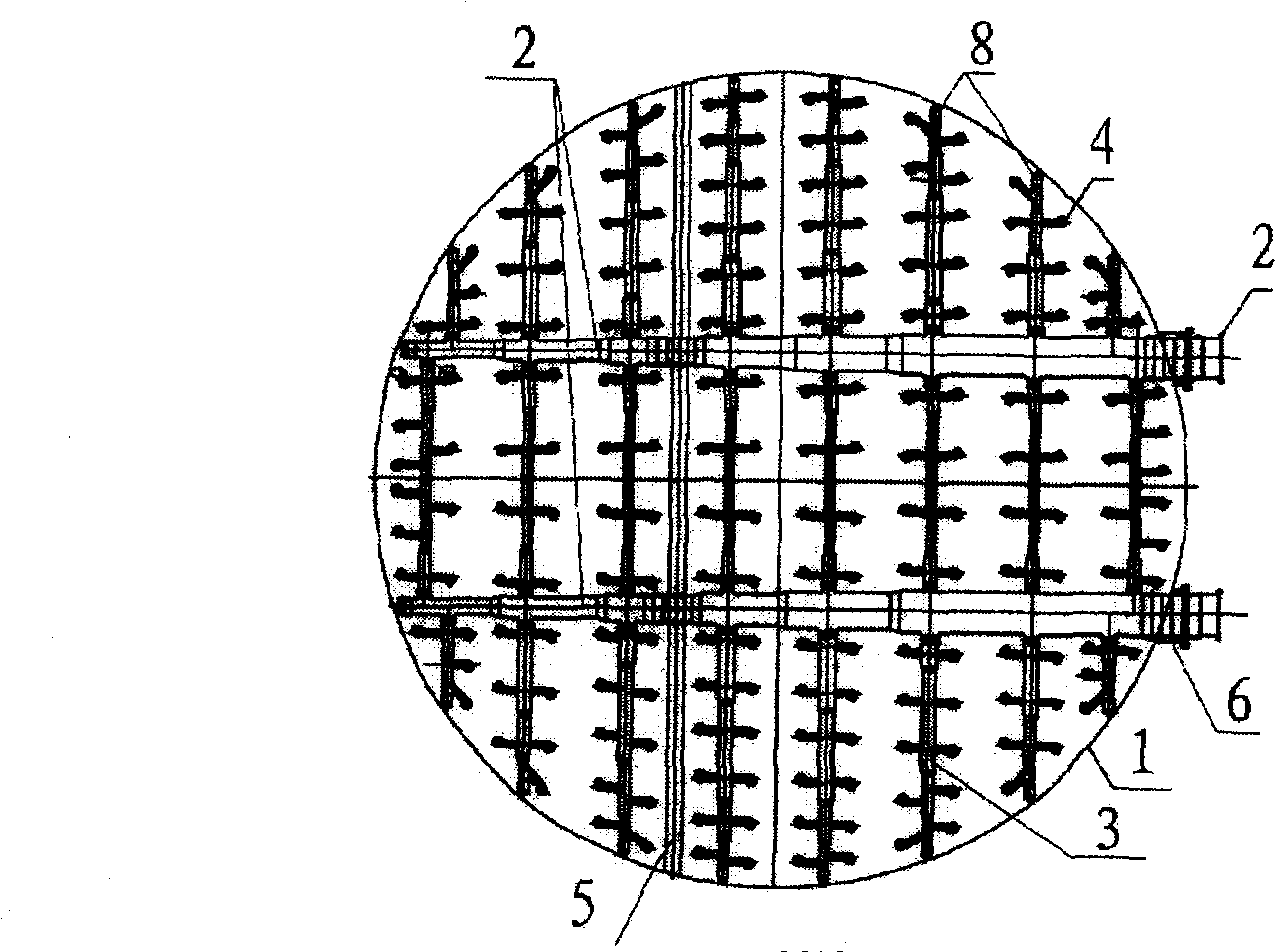

[0026] For implementation examples, see Figure 1-3 , the flue gas desulfurization circulating slurry spraying device is arranged in layers in the absorption tower 1, and each layer of spraying device consists of two parallel spraying main pipes 2, a spraying branch pipe 3 branched from the spraying main pipe, and a spraying branch pipe from the spraying branch pipe Two-way nozzles 4 separated from both sides are interwoven into a net-like spray layer.

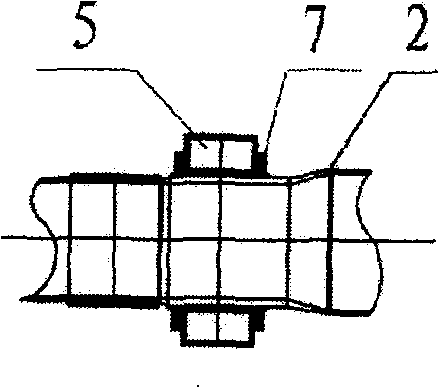

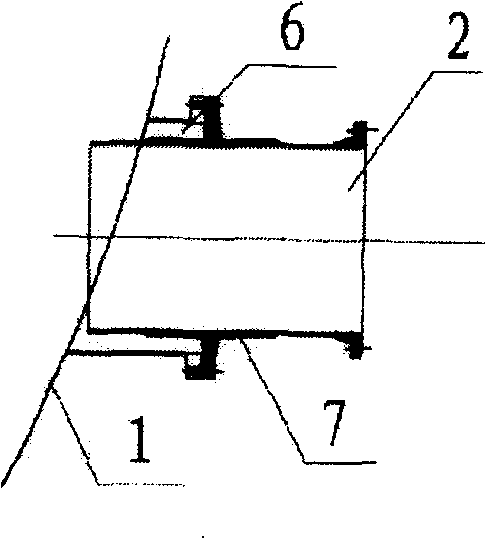

[0027] Two parallel spray main pipes 2 pass through the opening of the support beam 5 in the absorption tower and are supported by a single beam. The above support beam is horizontally fixed in the absorption tower. The part is placed in the sliding support 8 of the absorption tower wall. The support of the spray layer is supported by a single beam, and a hole is opened in the middle of the support beam, and the spray main pipe passes through the opening.

[0028] A pipe joint 6 with a flange is welded on the absorption towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com