Patents

Literature

76results about How to "Guaranteed free expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

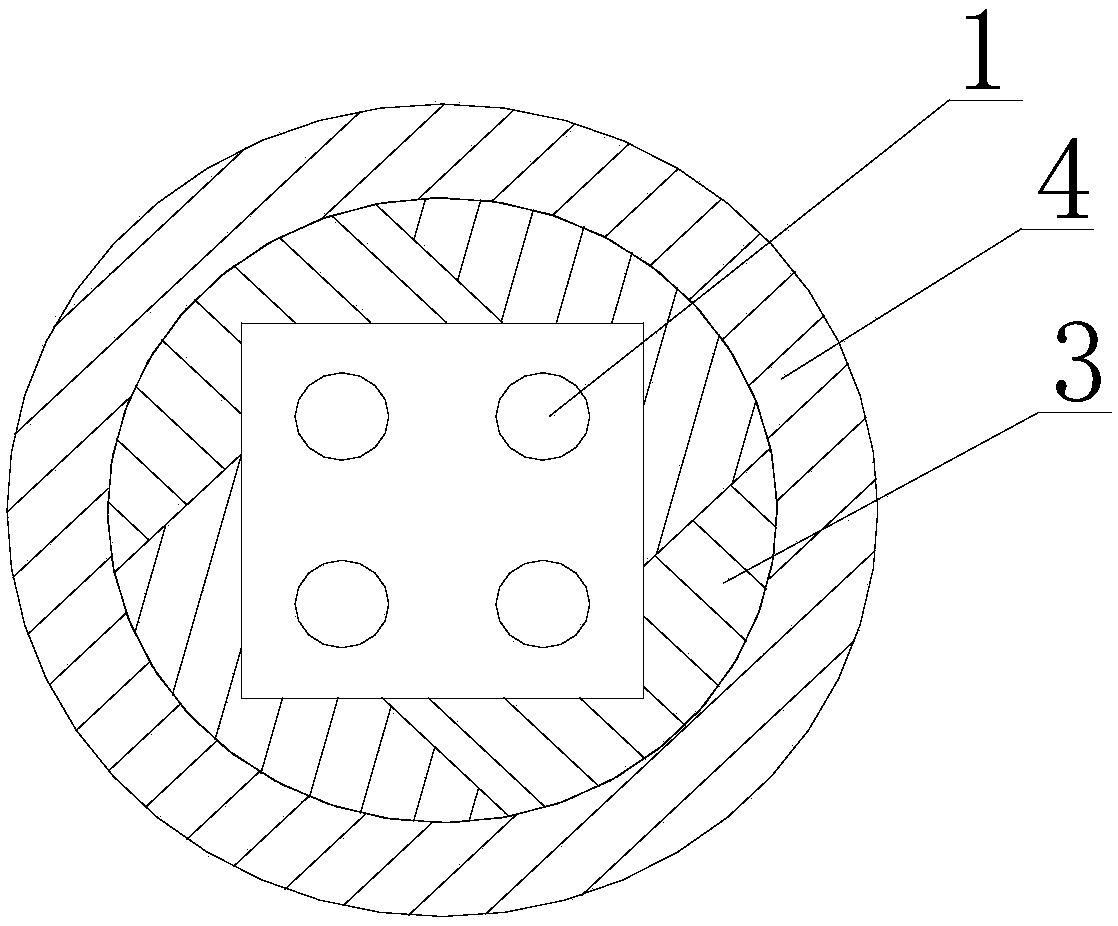

Core-shell structure silicon carbon composite material and preparation method thereof

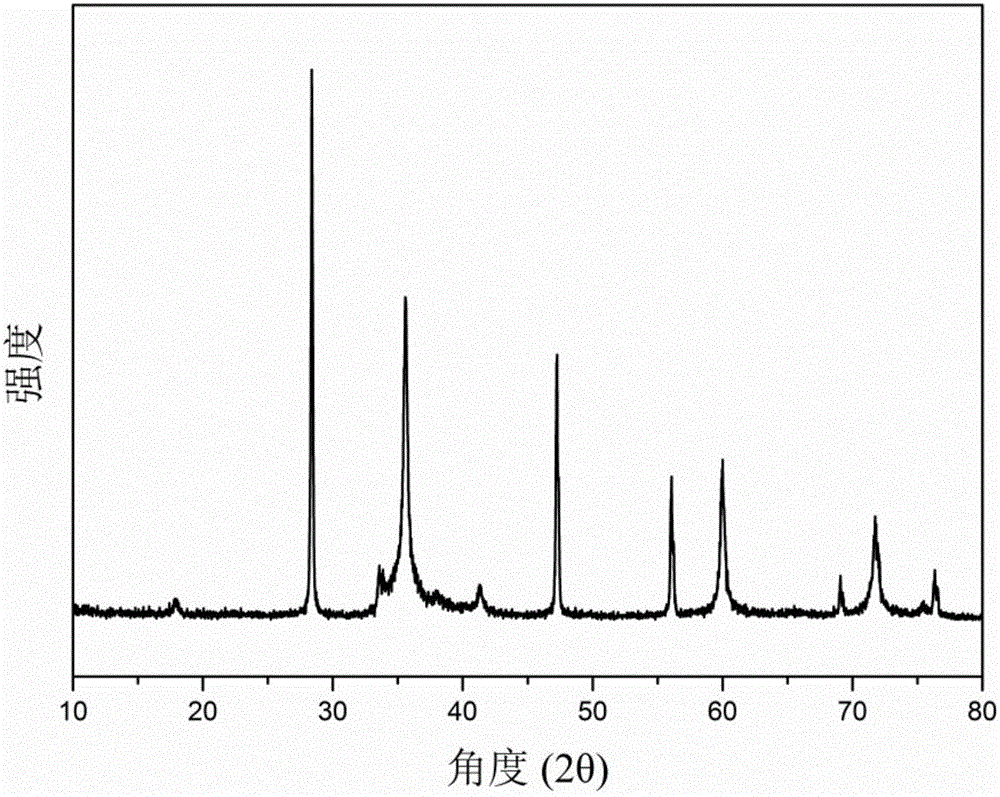

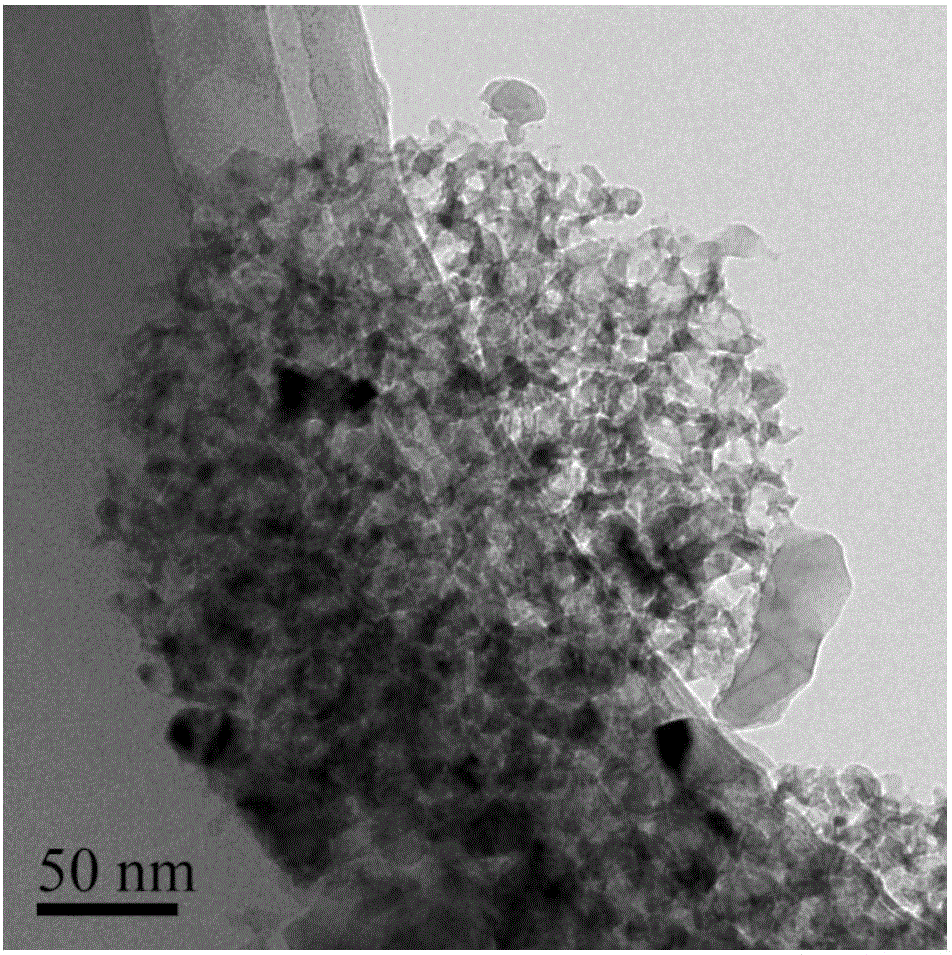

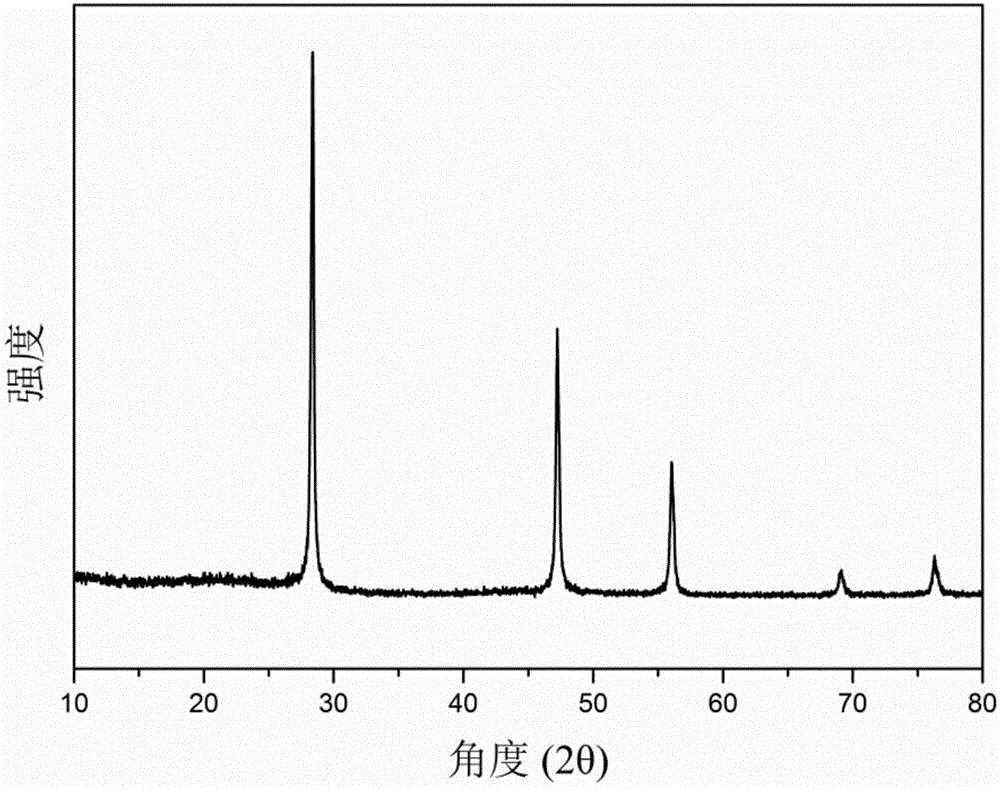

ActiveCN106099113AGuaranteed stabilityAvoid cracking and shatteringCell electrodesCarbon layerCarbon composites

The invention discloses a core-shell structure silicon carbon composite material and a preparation method thereof. The composite material is of a core-shell structure. The core-shell structure includes a shell composed of a carbon layer and a core composed of porous nano silicon. An air gap layer is arranged between the shell and the core. The preparation method comprises the steps that silicon dioxide particles perform magnesiothermic reduction reaction through magnesium powder, a reduction product is subjected to in-situ coating through an organic macromolecular carbon source, then carbonization is performed, and a carbonization product is corroded with hydrofluoric acid to obtain the silicon carbon composite material. The silicon carbon composite material has good stability, can well buffer silicon volume expansion and improve material conductivity, and thus ensures the cycle stability of electrodes. The silicon carbon composite material preparation process is simple and is suitable for industrial production, and the raw materials are wide in source.

Owner:湖南宸宇富基新能源科技有限公司

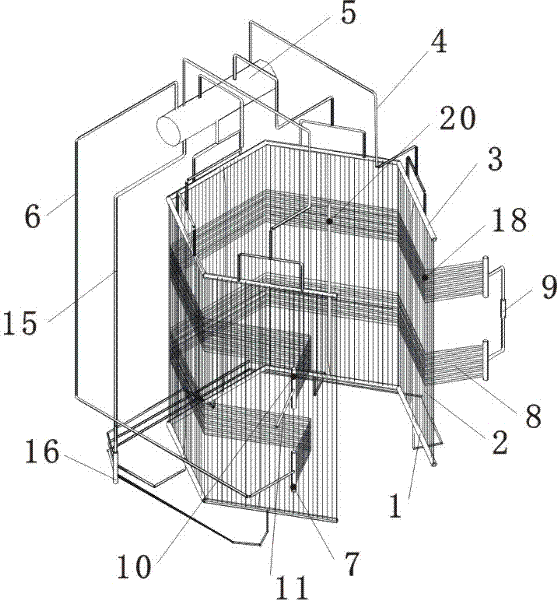

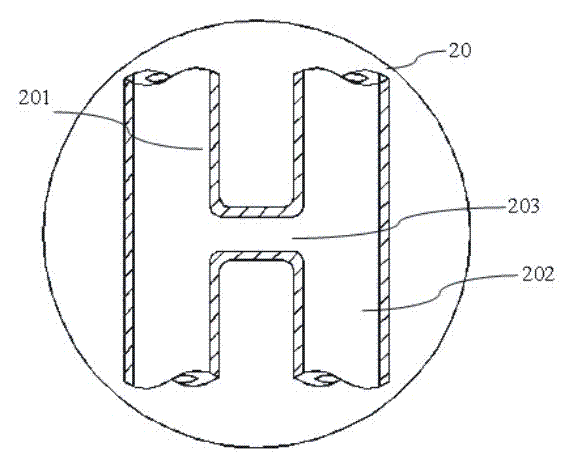

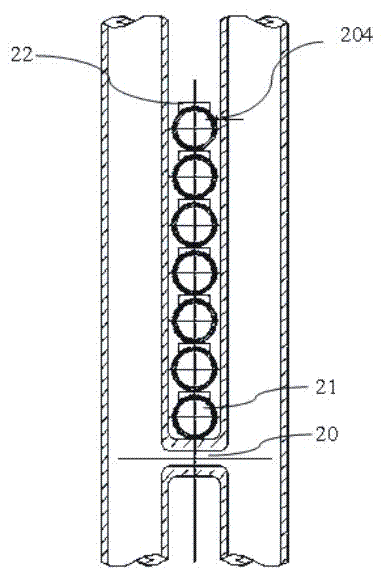

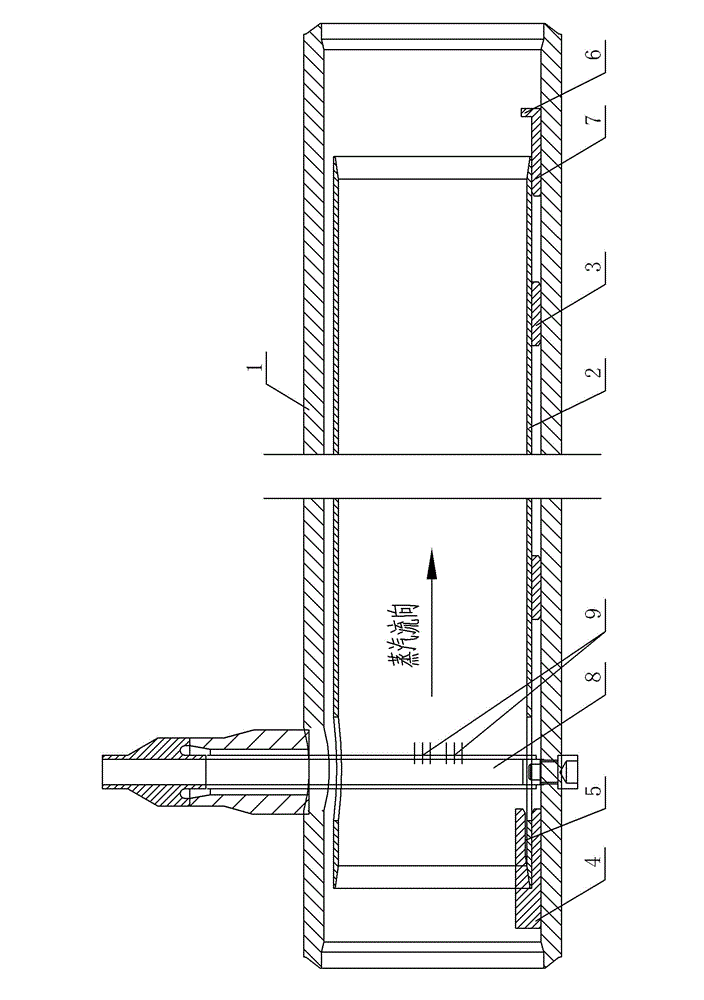

Solar cavity-type heat absorber capable of generating overheated steam

ActiveCN102345858ASolve the heating surface mismatch problemHeat absorption increases or decreasesSolar heat devicesSteam superheatersPower stationEngineering

The invention discloses a solar cavity-type heat absorber capable of generating overheated steam. The heat absorber comprises a water cooling wall and a superheater; the water cooling wall is a cavity which is provided with an opening and defined by a plurality of membrane-type pipe panels, and the water cooling wall is in vertical parallel arrangement; the superheater is positioned at the inner side of the water cooling wall; the pipe panel of the superheater is in horizontal arrangement; the inner side of the water cooling wall is provided with an 'H'-shaped water cooling connection piece which limits and fixes the superheater; and the 'H'-shaped water cooling connection piece consists of a first vertical pipe section, a horizontal pipe section and a second vertical pipe section. The problems of the transient heat match of the water cooling wall with the overheated parameters and the superheater and heat stress of a superheater pipe are solved through the cavity-type heat absorber, thus the heat absorber can adopt the parameters of the superheater, and the power station efficiency is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

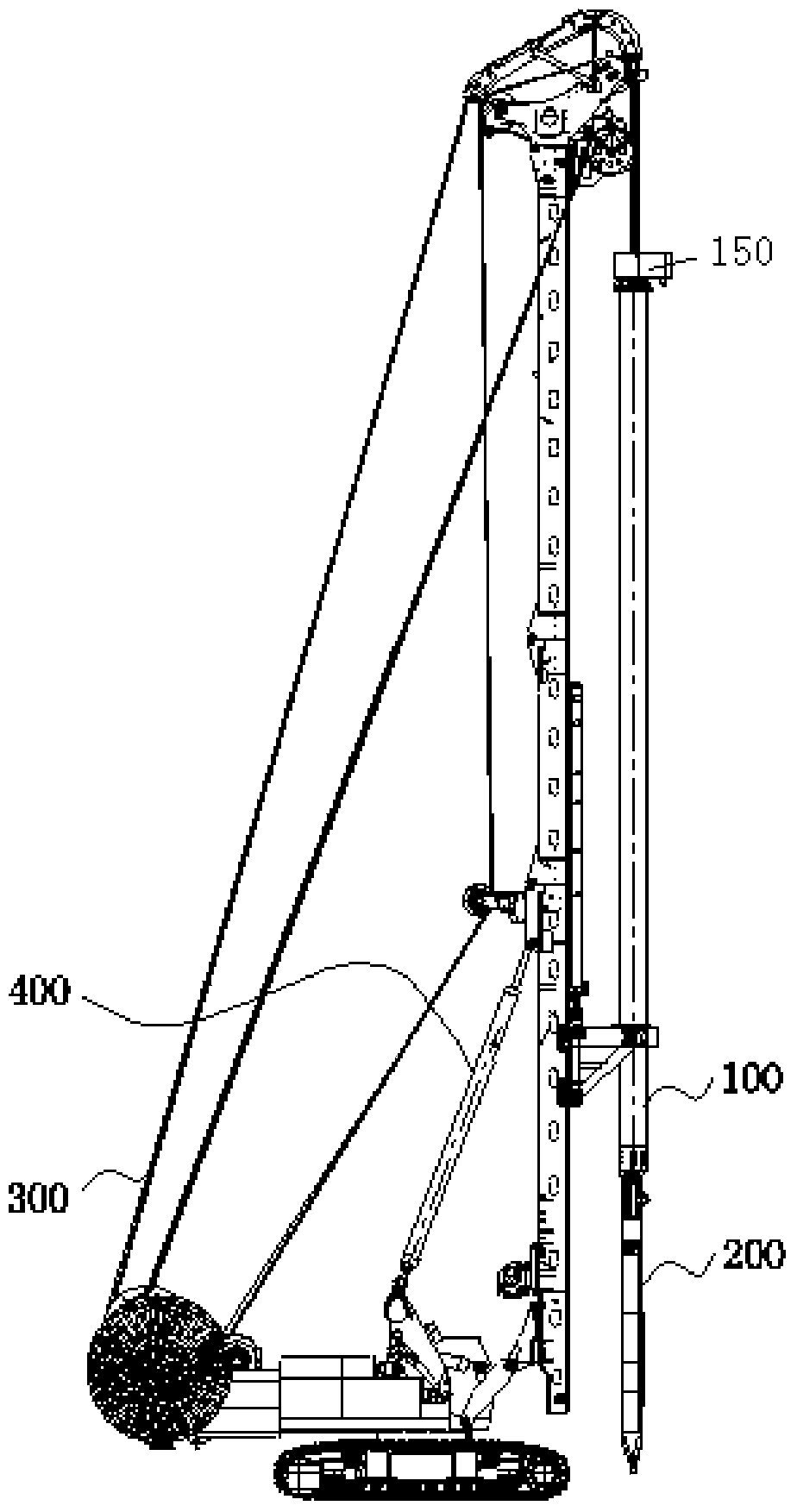

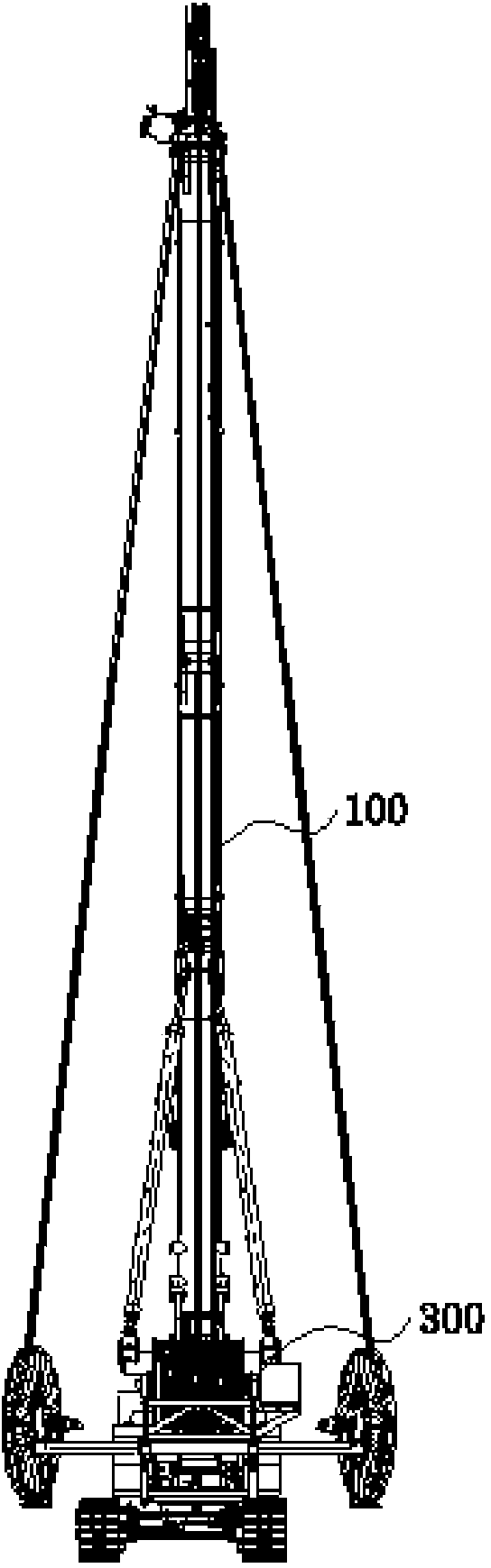

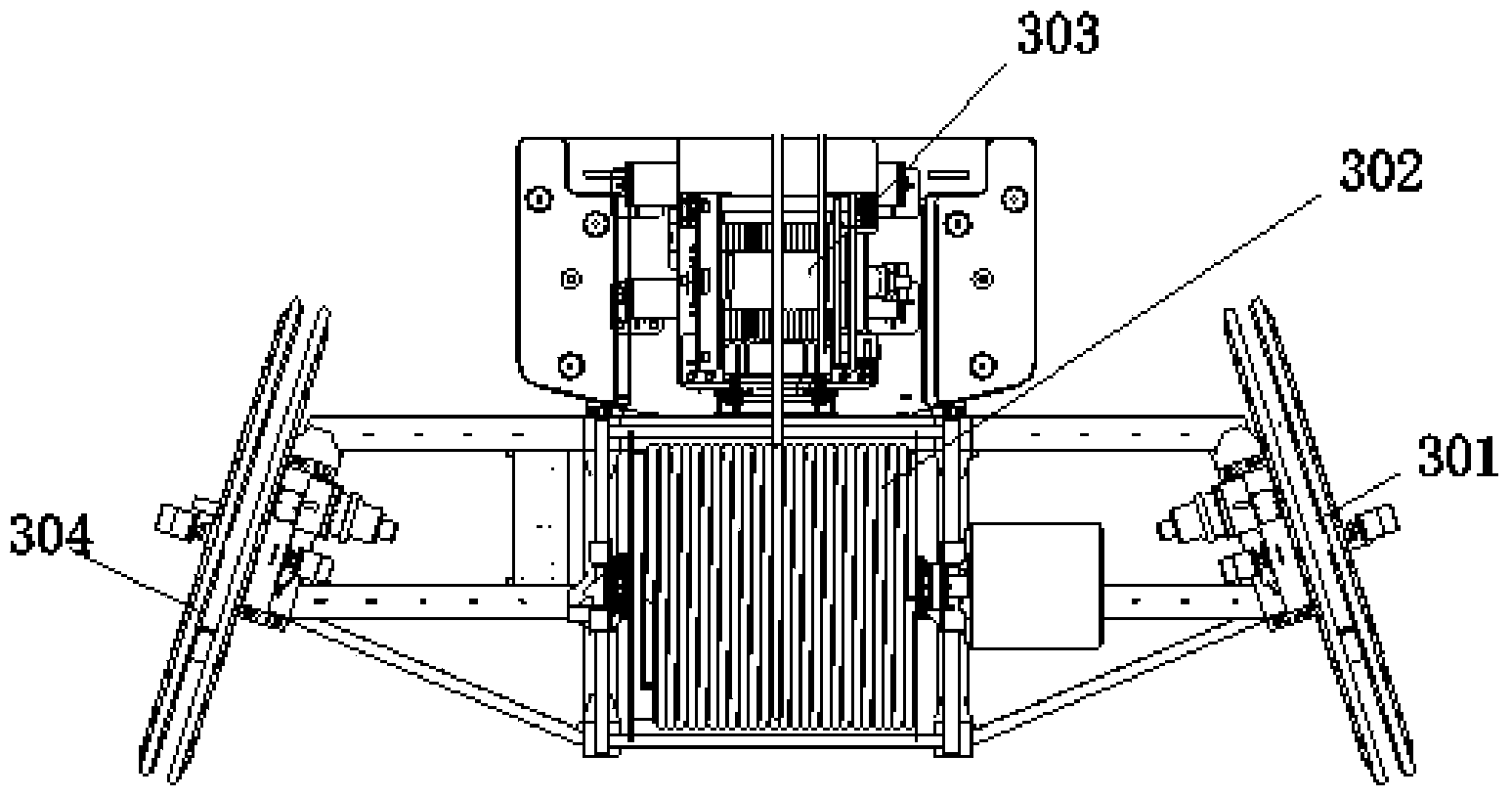

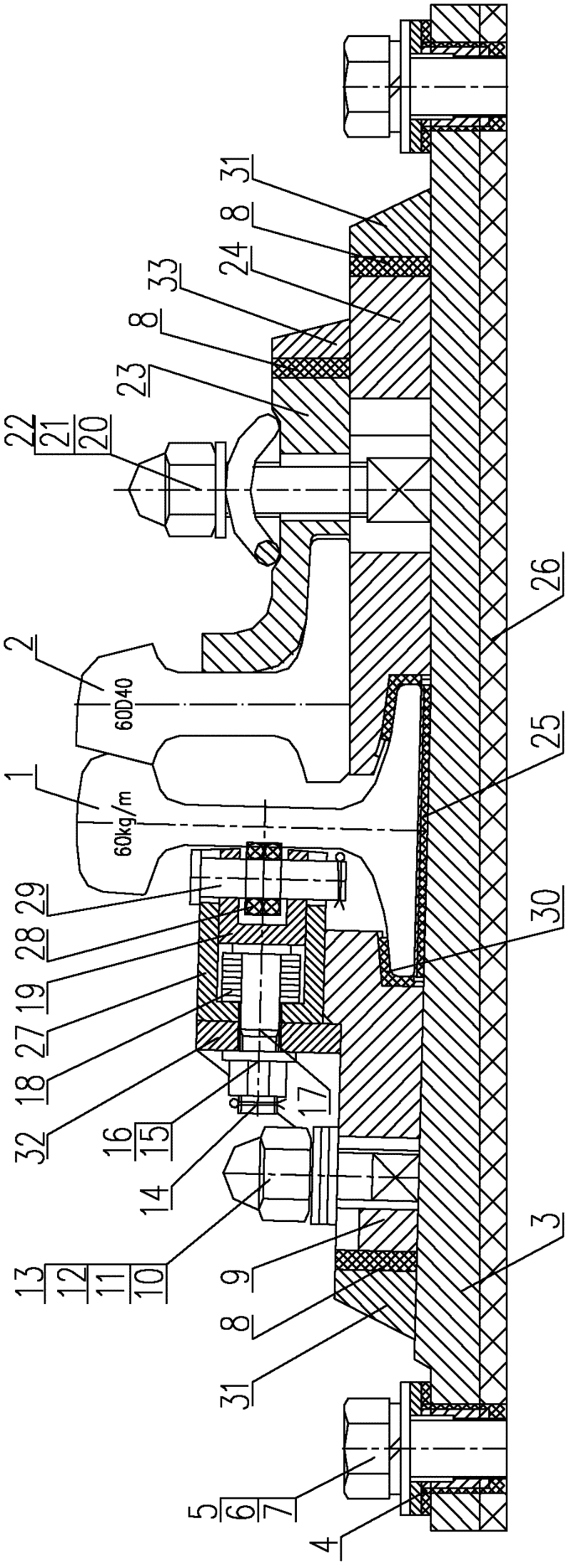

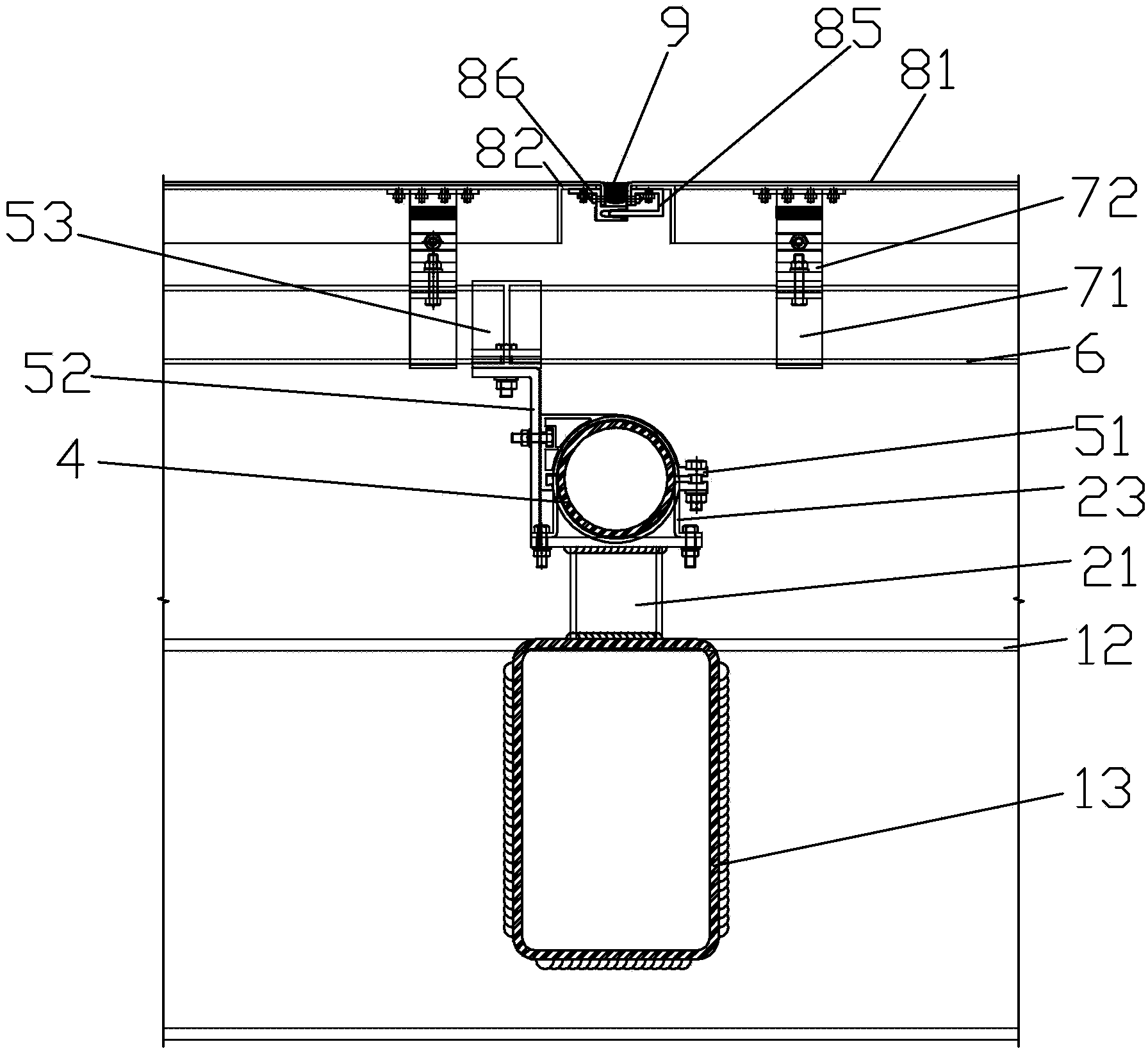

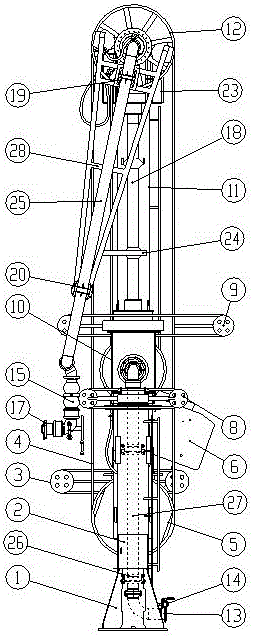

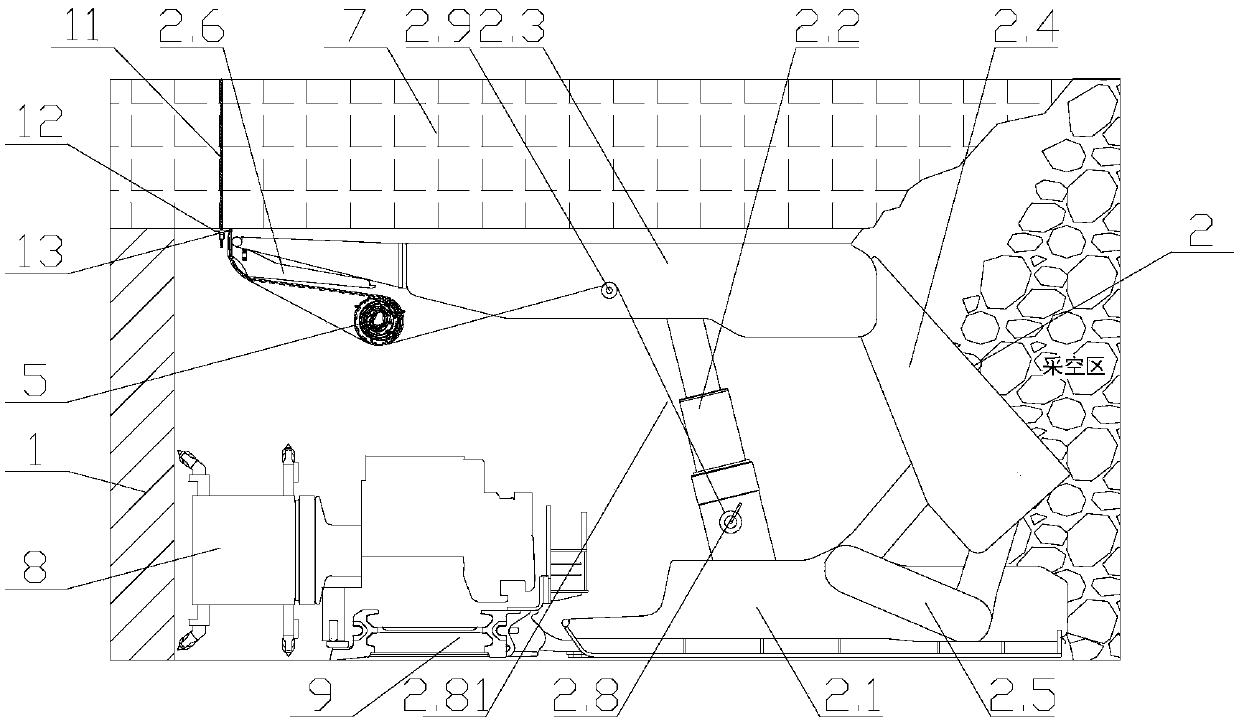

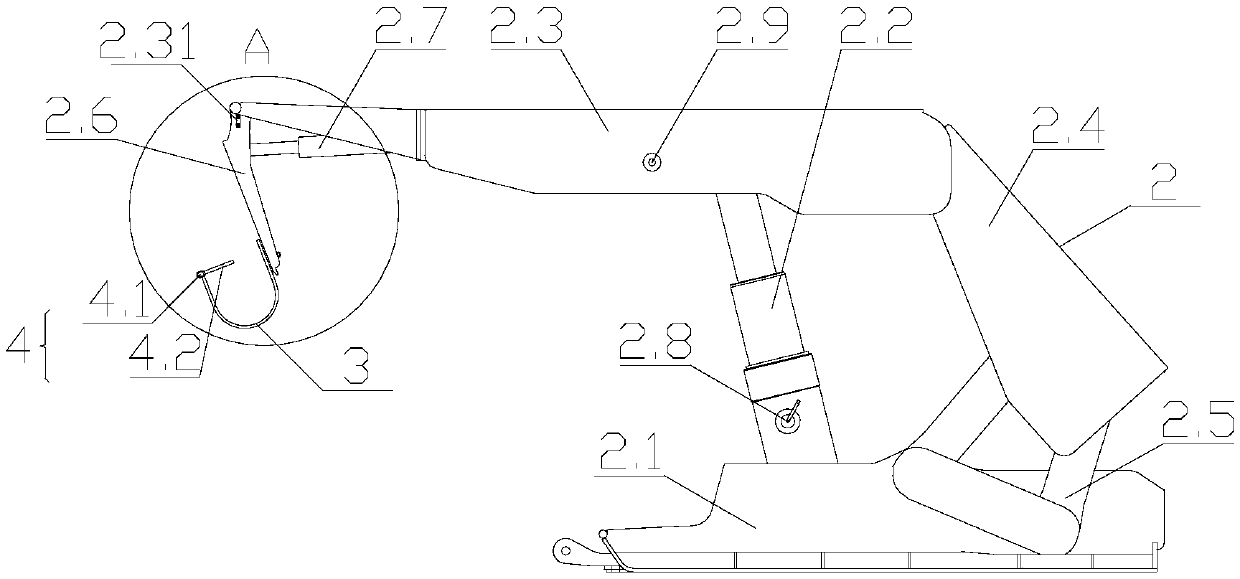

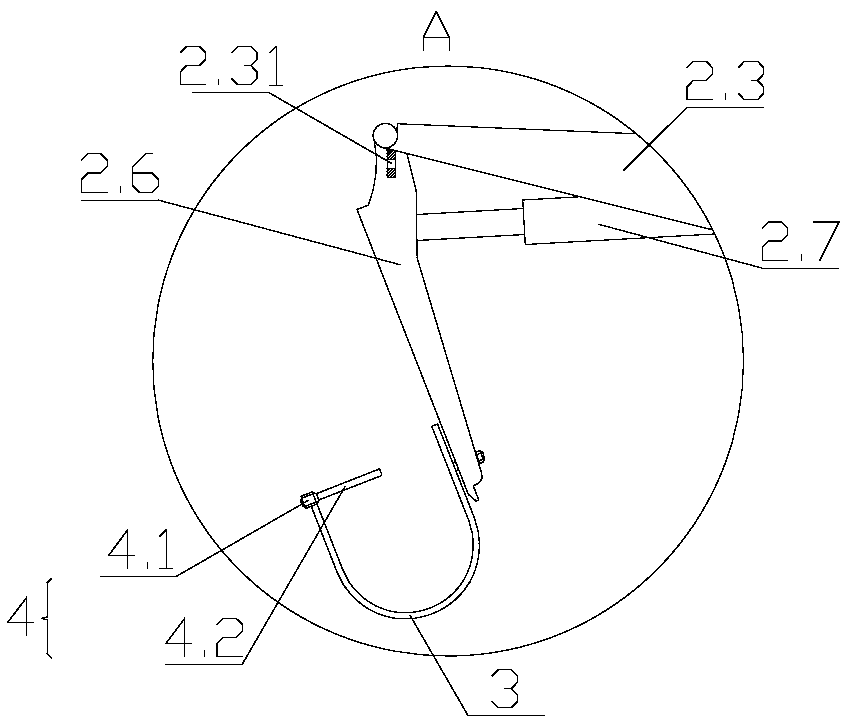

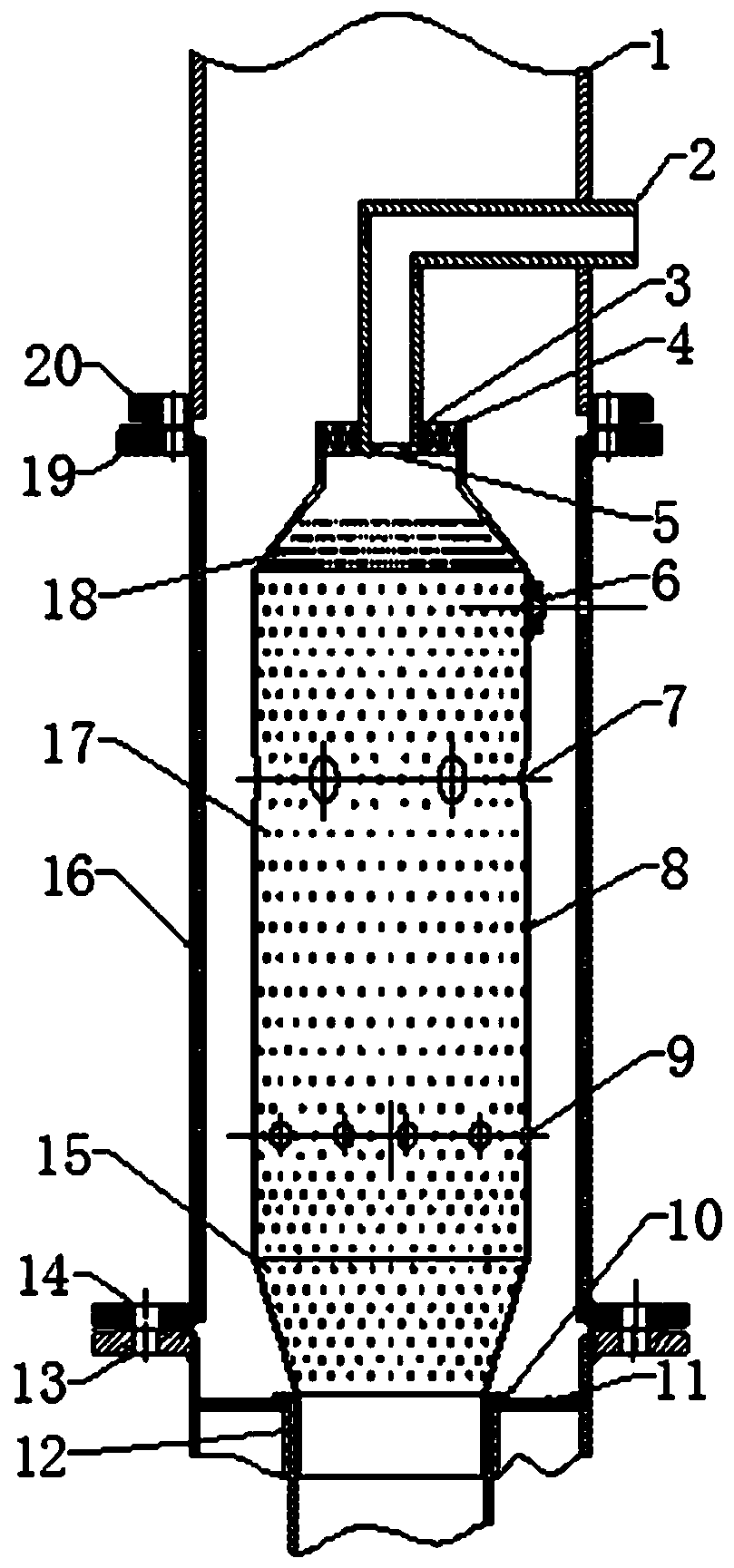

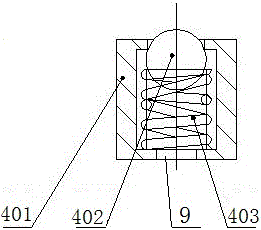

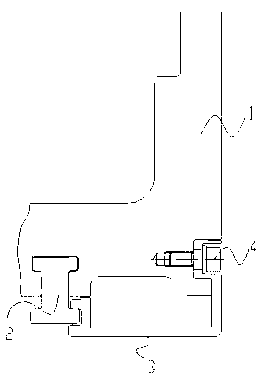

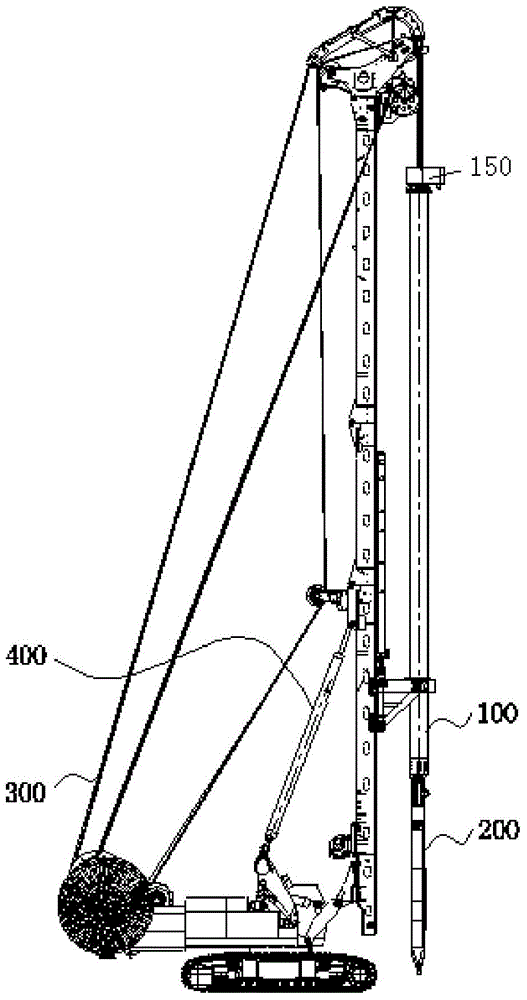

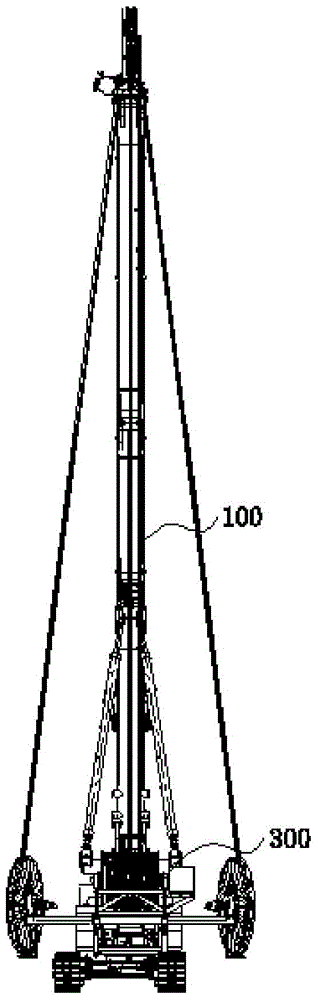

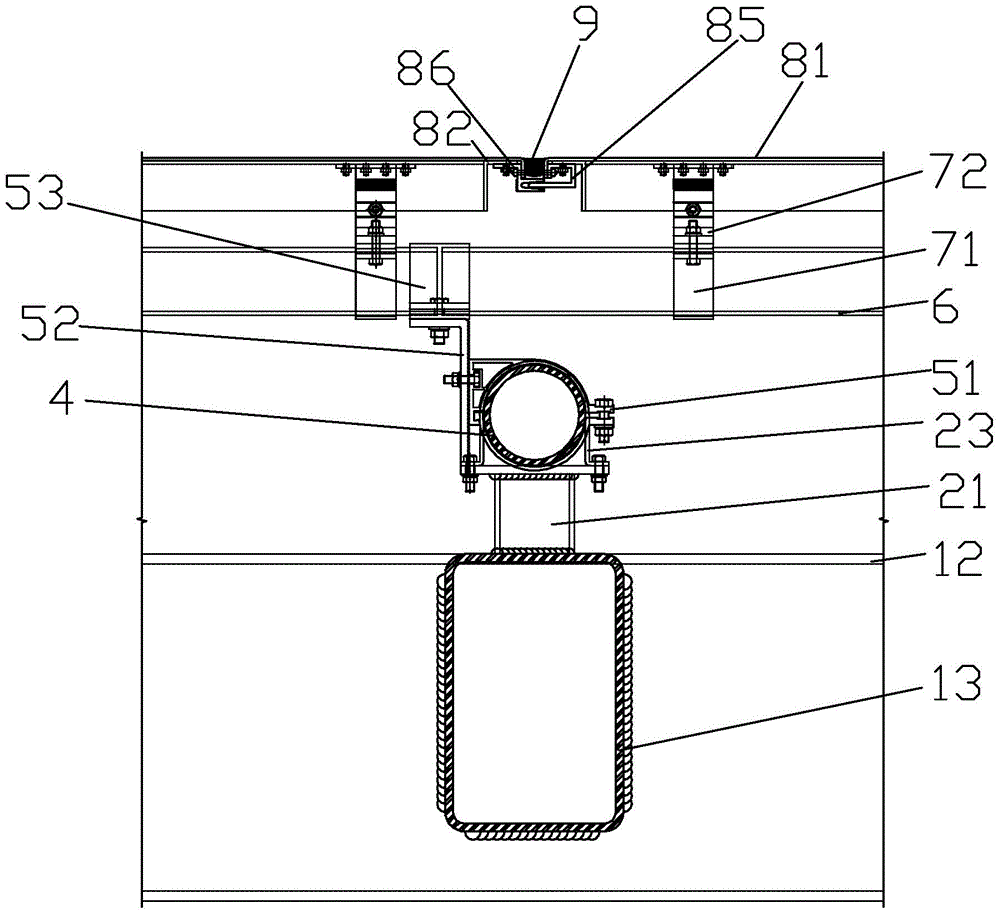

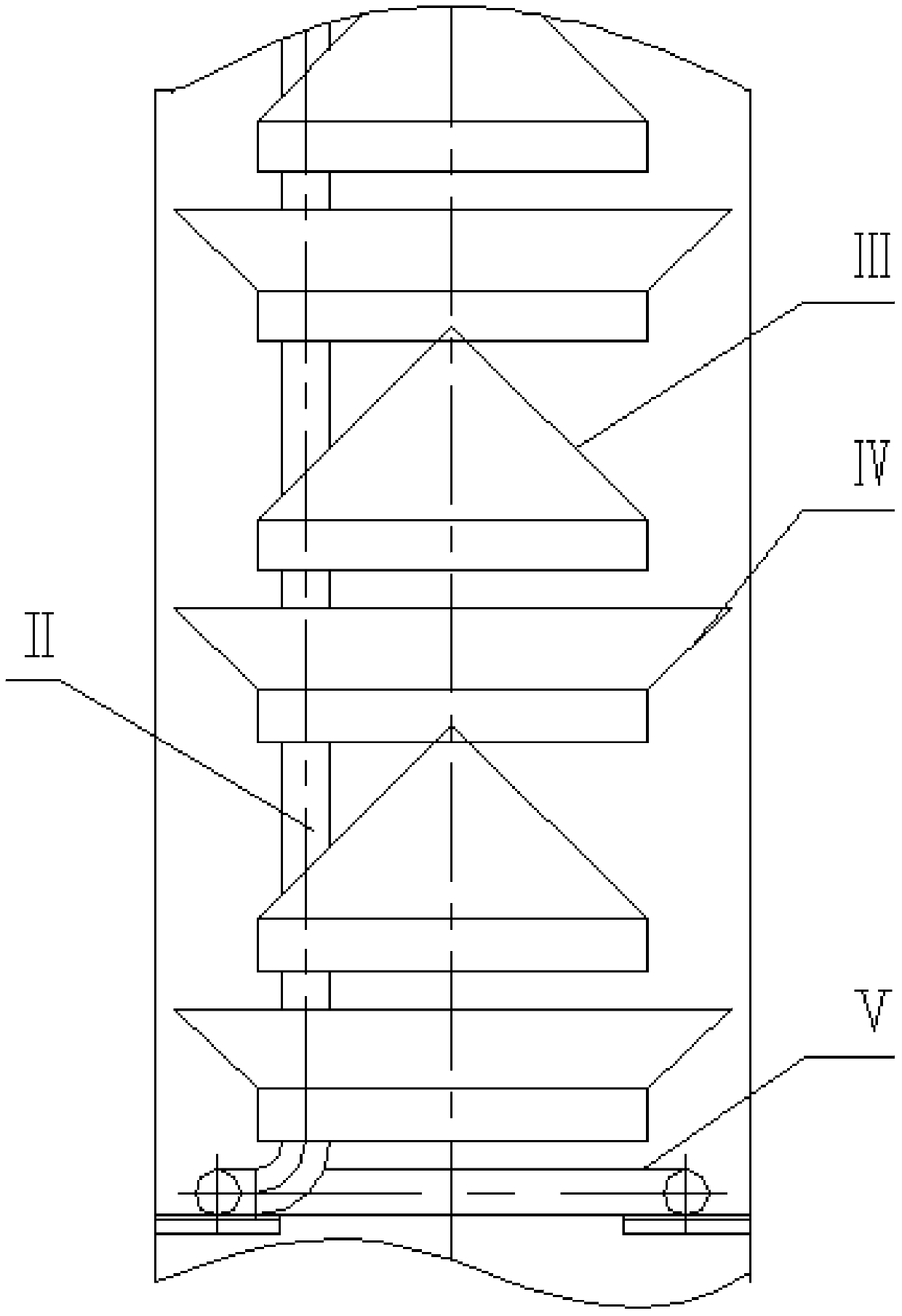

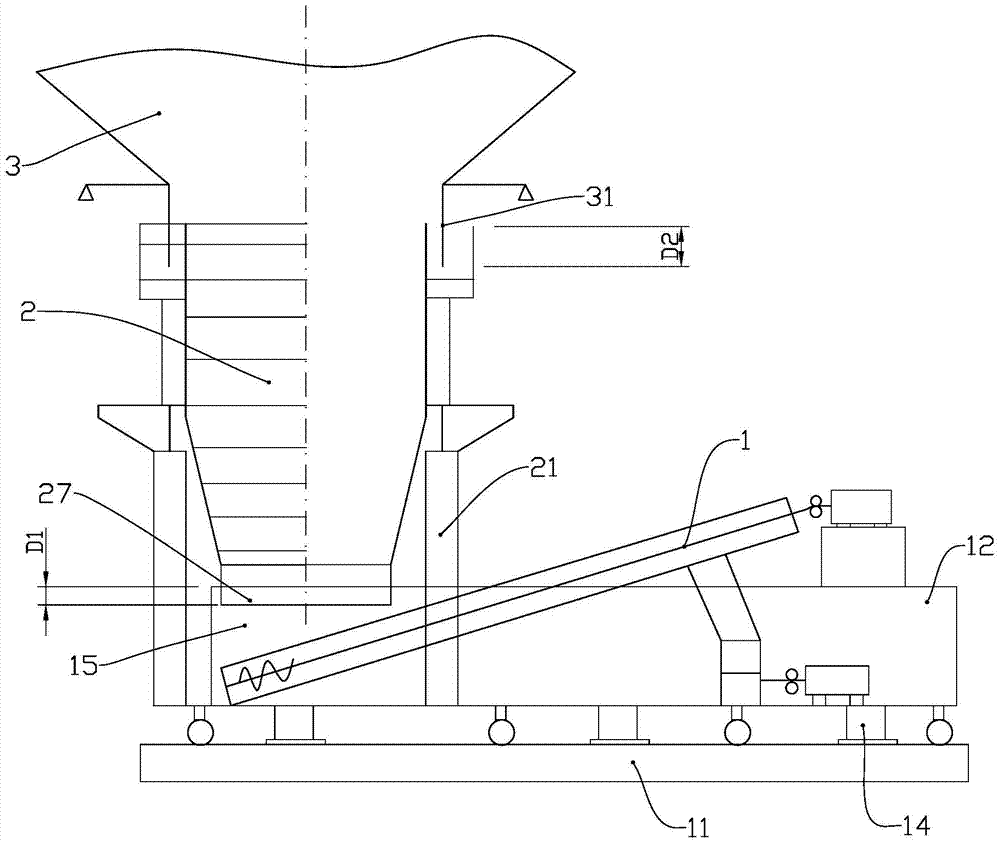

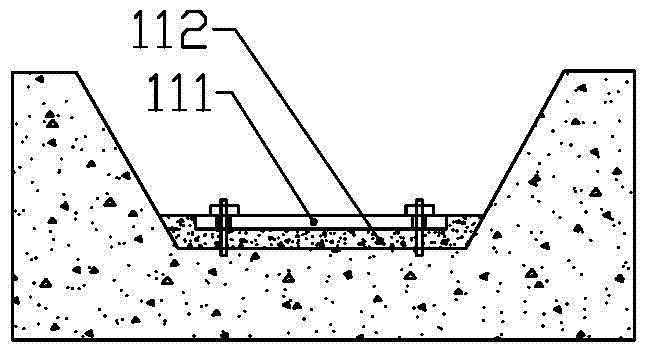

Vibro-replacement stone column machine and construction method thereof

ActiveCN104372788ASolve the hardening problemGuaranteed free expansionSoil preservationEngineeringConductor Coil

The invention discloses a vibro-replacement stone column machine and a construction method thereof. The vibro-replacement stone column machine comprises a crane system, an automatic feeding system, a drill rod system and a vibrator system. The method includes the steps that when the vibro-replacement stone column machine conducts vibrator ultra-deep construction, a steel wire rope winding device enables a vibrator connected below a telescopic guide rod to descend gradually by releasing sleeves in a column hole of the telescopic guide rod layer by layer; while the steel wire rope winding device enables the sleeves in the telescopic guide rod to be released layer by layer, a cable winding device, a water pipe winding device and a gas pipe winding device synchronously release a cable, a water pipe and a gas pipe placed in the telescopic guide rod; the vibrator vibrates downwards continuously through electric power, clear water and gas supplied by the cable, the water pipe and the gas pipe which descend synchronously along with the vibrator, so that an ultra-deep vibro-replacement stone column hole is formed; after the ultra-depth vibro-replacement stone column hole reaches a preset depth, the hole is cleaned up, stone is thrown into the hole, a column can be manufactured in a vibration and compaction mode, and thus an ultra-depth vibro-replacement stone column can be formed.

Owner:SINOHYDRO FOUND ENG

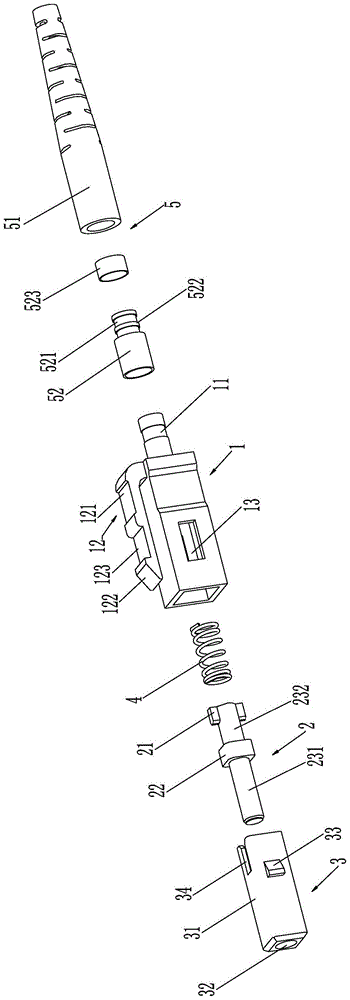

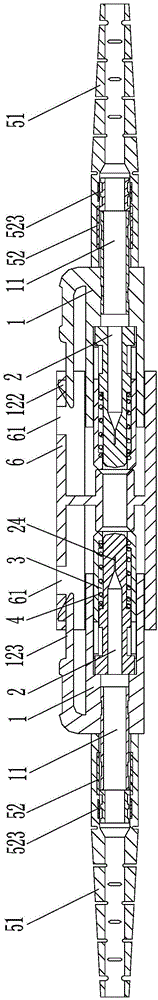

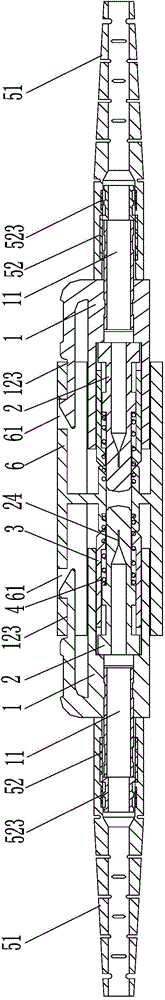

Optical fiber connector and manufacturing method thereof

ActiveCN104965262AReduce assembly requirementsLow matching accuracy requirementsCoupling light guidesFiberElastic component

The invention relates to an optical fiber connector and a manufacturing method thereof. The optical fiber connector comprises a housing and a fiber insertion core arranged in the housing. The end surface of the fiber insertion core is provided with at least one lens. The cavity at one end of the housing is equipped with an insertion core protection structure for protecting the end surface of the insertion core so as to prevent the lens surface at the end surface of the fiber insertion core from being damaged or scraped. The insertion core protection structure is internally provided with the fiber insertion core and an elastic component sleeved on a fiber insertion core tubular body to ensure free telescoping of the insertion core protection structure. The other end of the housing is provided with an extension pipe. The extension pipe is connected with a tail sheath assembly which carries out bending protecting on an optical cable and guarantees that the optical fiber connector can transmit optical signals normally under the bending pressure condition. An elastic buckle structure for enabling the optical fiber connector to be buckled to a corresponding insertion hole of an adapter is integrated to the outer wall of the housing.

Owner:SHENZHEN EPLU SCI TECH

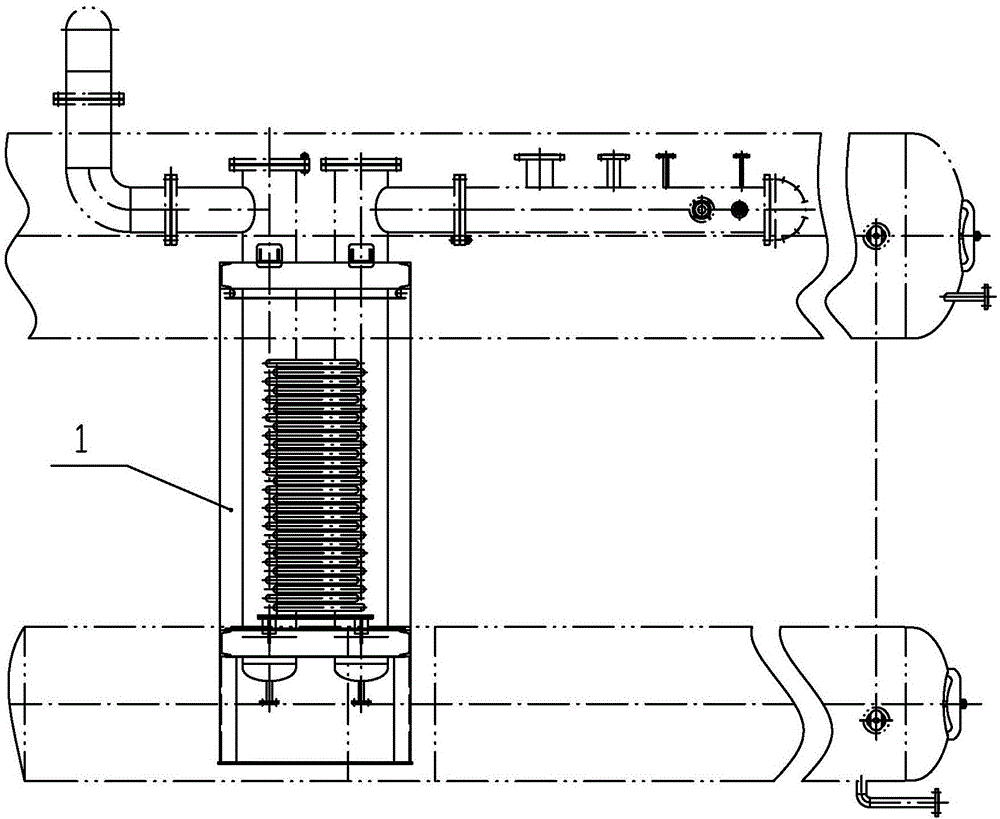

Circulating slurry sprinkling device for desulfurization of flue gas

ActiveCN1843580AReduce power consumptionReduce energy consumptionDispersed particle separationFlue gasSpray nozzle

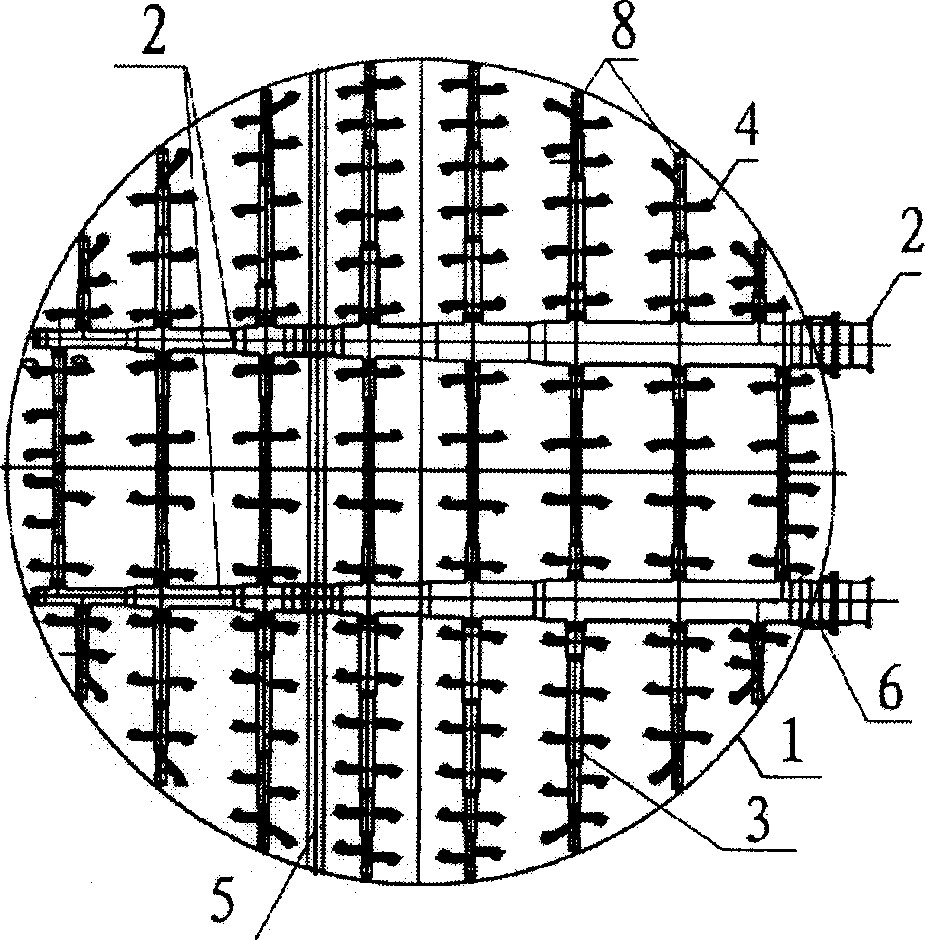

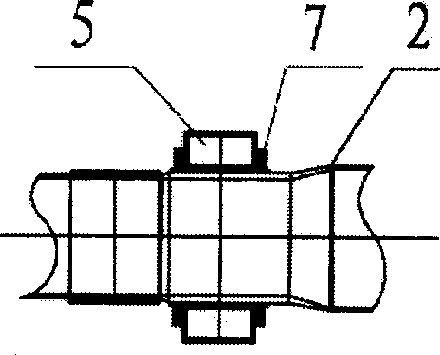

The invention relates to a smoke desulfuration cycle slurry spray device, which are layered in the adsorption tower. Each spray device is formed by at least two parallel spray main tube and the spray sub tubes branched from the spray main tube. The dual-direction ejectors that branched from the spray sub tubes are interlaced into mesh spray layer; two parallel spray main tubes are through the hole of support beam inside the adsorption tower, and horizontally fixed via single-beam support. The invention can solve the problems that not enough mixed between the smoke and cycle slurry; lower desulfuration effect; and easy abrasion and leakage at the interface between the spray tubes and the adsorption tower. The invention can be used in wet smoke desulfuration adsorption tower to utilize the limestone or lime slurry to adsorb the sulfur dioxide and sulfur trioxide.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

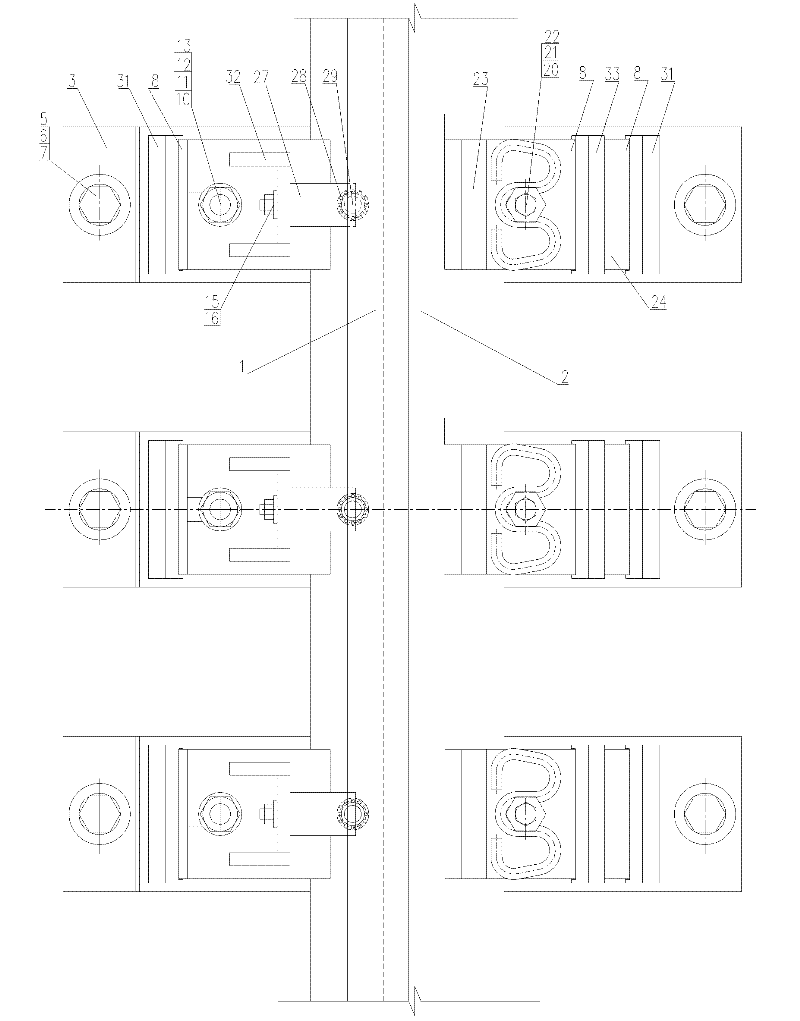

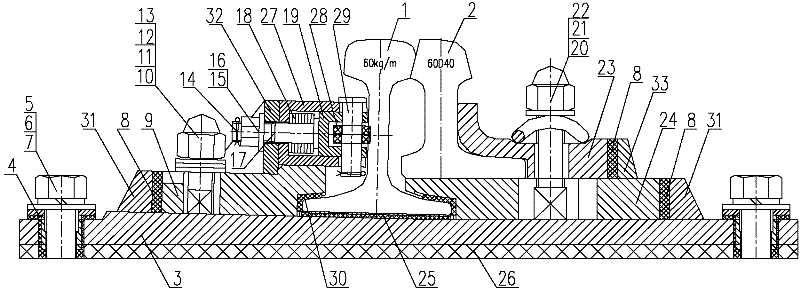

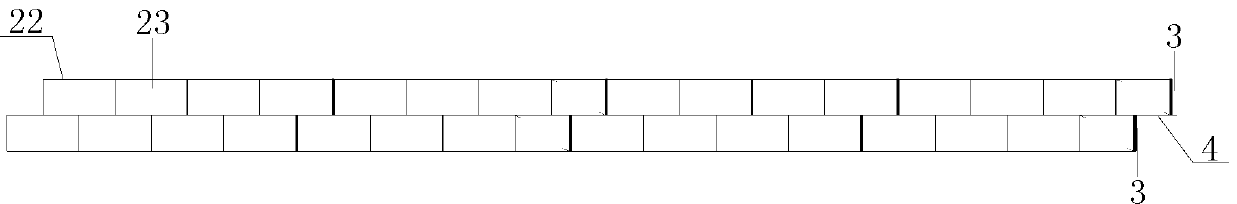

Steel rail expansion adjuster

ActiveCN102518007AReduce productionReduce difficultyRail switchesRail fastenersEngineeringService time

The invention relates to a steel rail expansion adjuster, which comprises a basic rail and a sharp rail arranged on the inner side of the basic rail, wherein the basic rail is arranged on an iron base plate which is fixed on a switch sleeper, the sharp rail is arranged on a bedplate assembly of the sharp rail and the bedplate assembly of the sharp rail is arranged on the iron base plate; the basic rail is fixedly buckled and pressed on the iron base plate through a buckle assembly of the basic rail and the bedplate assembly of the sharp rail, and the sharp rail is fixedly buckled and pressed on the bedplate assembly of the sharp rail through a buckle of the sharp rail; and an external frame internally provided with a horizontal guide rod and an internal frame is fixed in an upper position on the inner side of the buckle assembly of the basic rail, the inner side of the internal frame is horizontally provided with a rolling bearing through a pin shaft, and a spring is sleeved on the guide rod so that the internal end face of the guide rod is propped on the external end face of the internal frame, and accordingly, the rolling bearing is supported on the rail web outside the basic rail. The steel rail expansion adjuster disclosed by the invention has the advantages of a simple structure, convenience in manufacturing and maintenance, and capabilities of minimizing the expansion resistance of the basic rail, optimizing the stiffness of switch zone and prolonging the service time of the adjuster on the steel rail.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

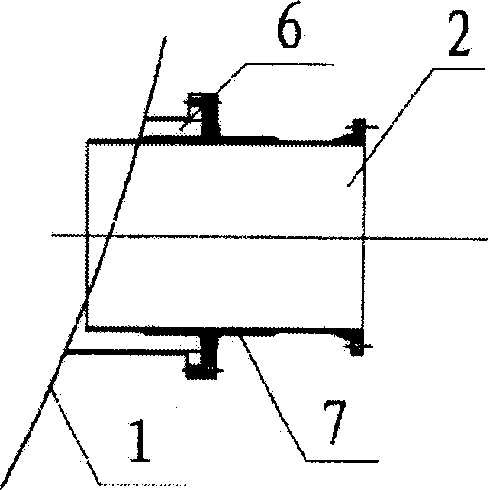

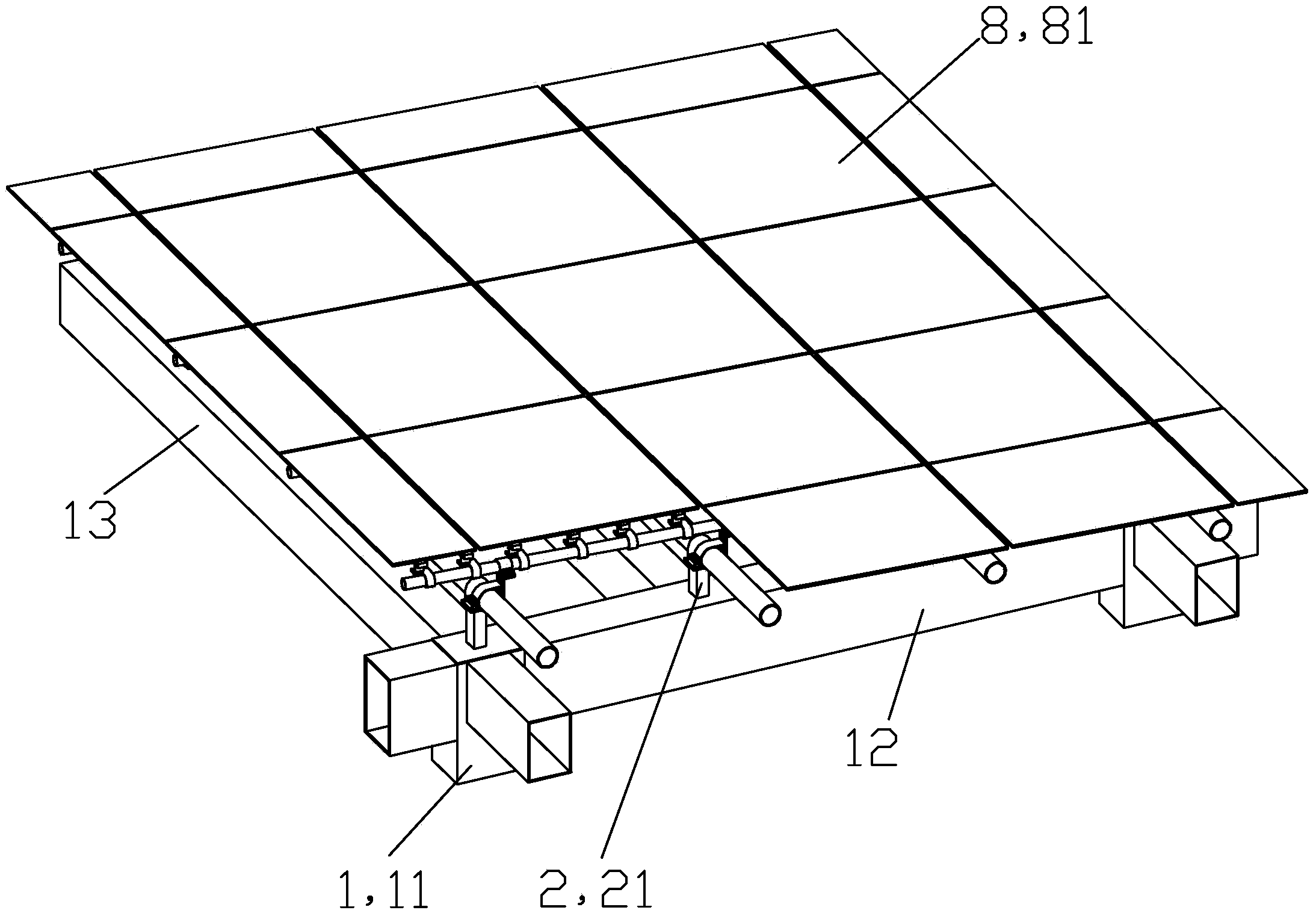

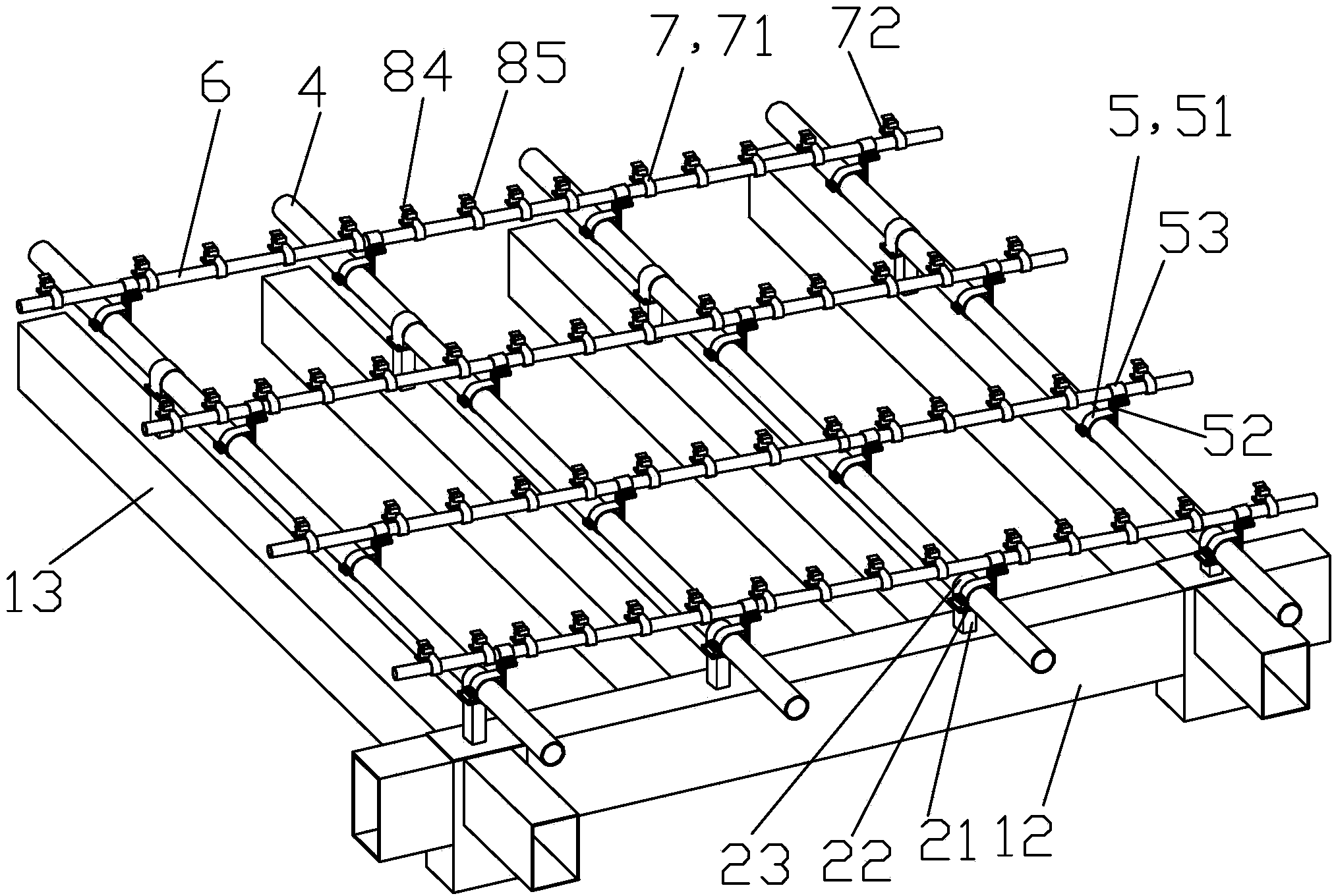

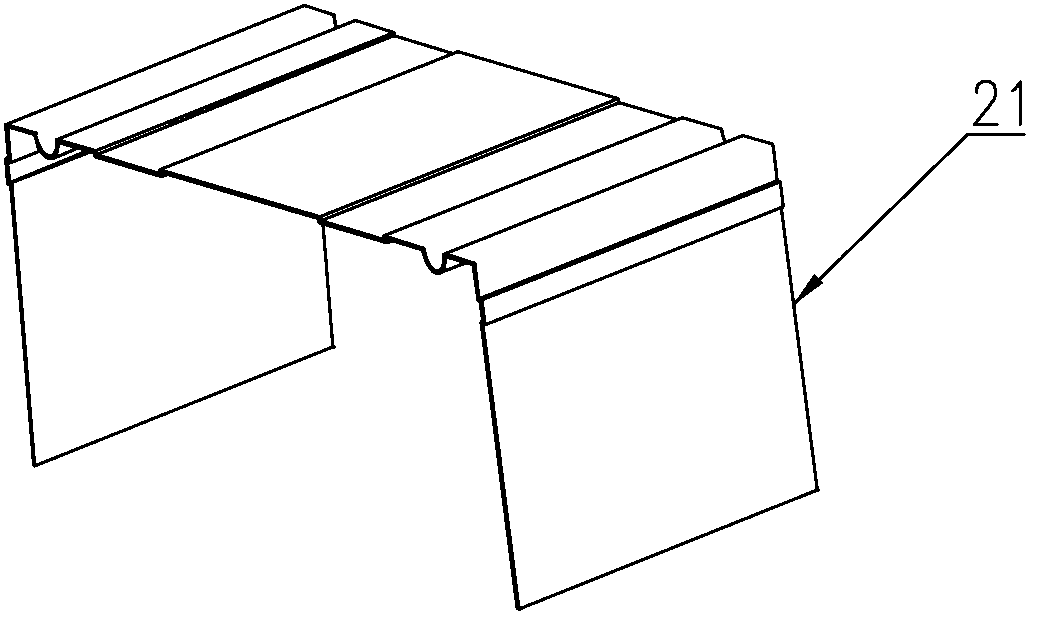

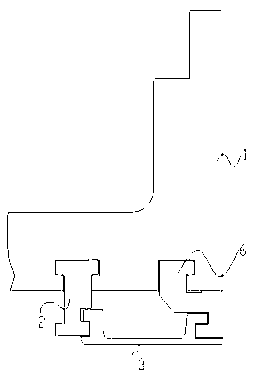

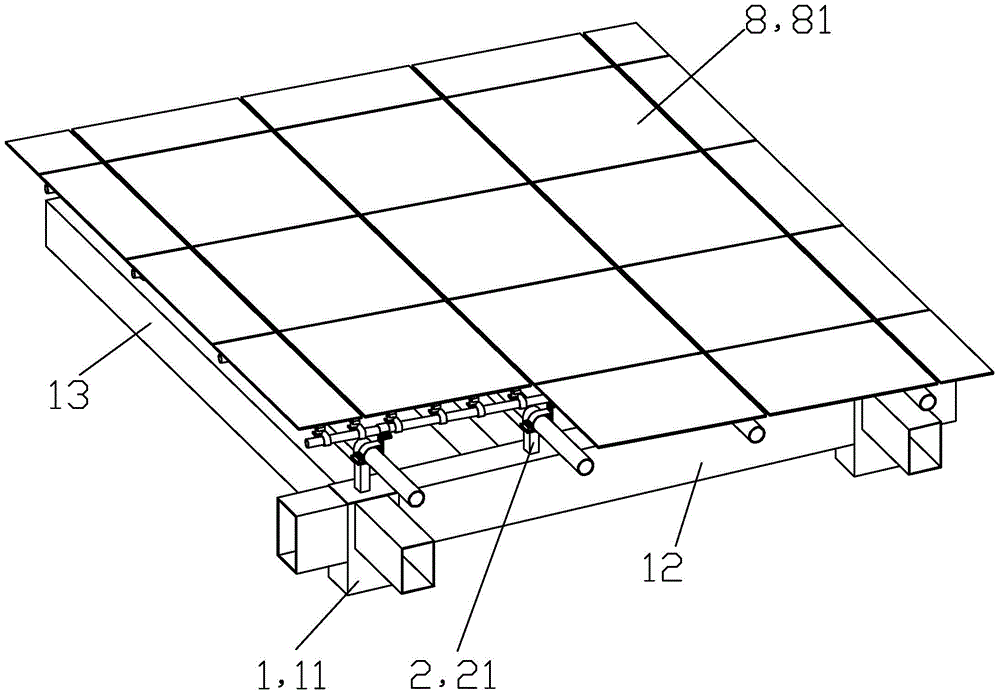

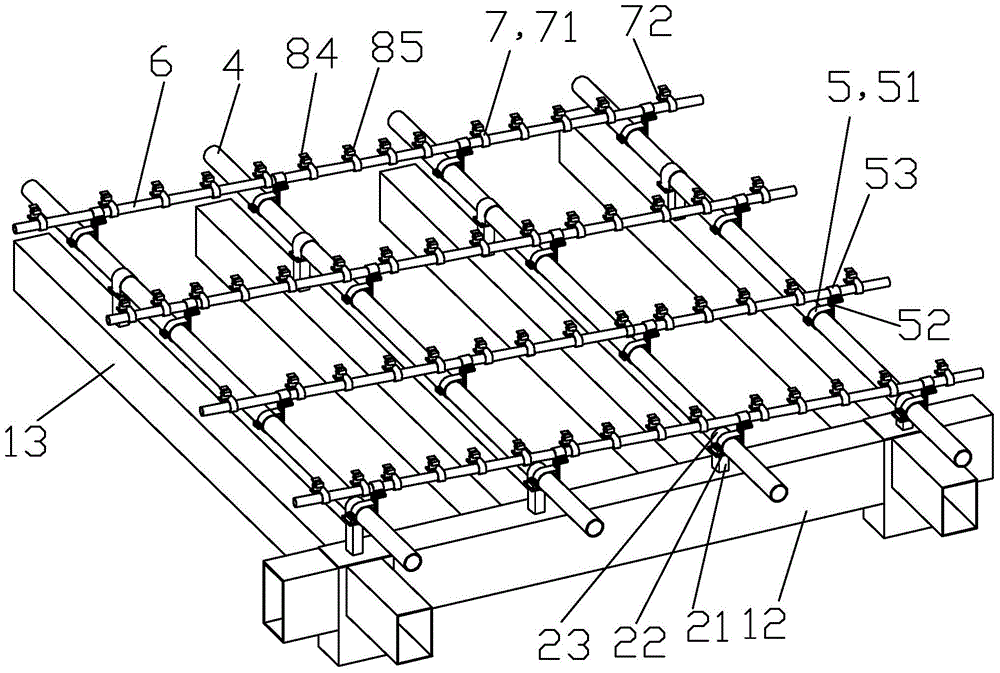

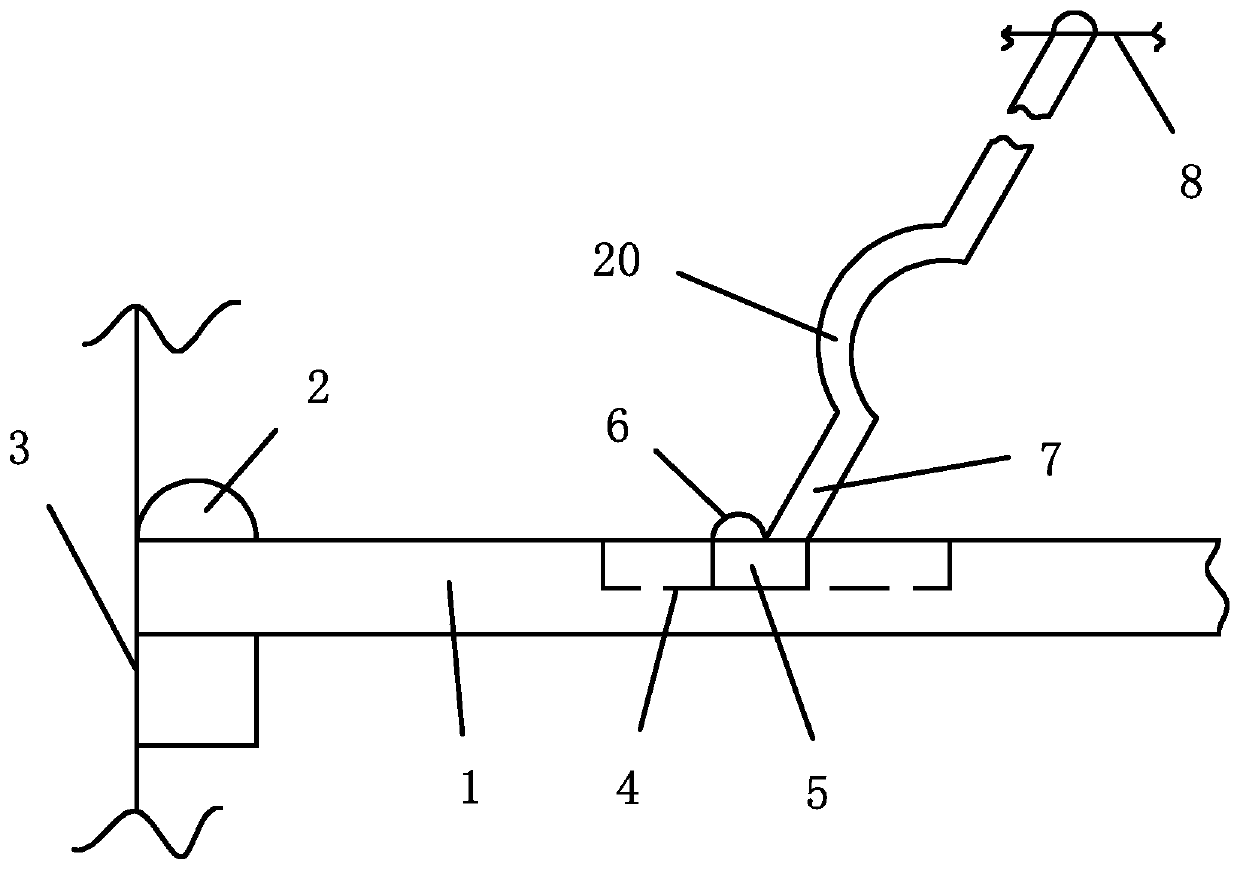

Fastener plug-in type curved surface metal roof and construction method thereof

ActiveCN103711258ASolve the odd-shaped surface problemGuaranteed free expansionRoof covering using slabs/sheetsBuilding material handlingArchitectural engineeringMetal roof

The invention provides a fastener plug-in type curved surface metal roof which comprises a base frame, primary purline supporting components, lengthening connecting fasteners, primary purlines, primary and secondary purline through connection components, secondary purlines, secondary purline panel through connection components, roof panel components and sealing components. The base frame is fixedly mounted on a civil engineering foundation roof face. The primary purlines are fixedly connected with the base frame through the primary purline supporting components. The secondary purlines are connected with the primary purlines through the primary and secondary purline through connection components. The secondary purline panel through connection components are connected with the secondary purlines. The roof panel components are connected with the secondary purline panel through connection components, two adjacent roof panel components are connected in an inserting mode, and the sealing components are arranged in the clearances of the roof panel components. A construction method mainly comprises the step that the base frame, the primary purline supporting components, the primary purlines, the primary and secondary purline through connection components, the secondary purlines, the secondary purline panel through connection components, the roof panel components and the sealing components are mounted in sequence. According to the fastener plug-in type curved surface metal roof and the construction method, steel and manpower cost can be effectively saved, the construction period can be shortened, and the new construction method of the curved surface metal roof is provided.

Owner:CHANGZHOU NO 1 CONSTR GRP

Ground gas turbine single-tube combustion chamber adopting axial gas inflow

InactiveCN106287814AWell mixedFlame stabilizationContinuous combustion chamberRefluxCombustion chamber

The invention discloses a ground gas turbine single-tube combustion chamber adopting axial gas inflow. The ground gas turbine single-tube combustion chamber comprises a combustion chamber gas inlet pipeline, a case and a combustion chamber outlet section. The upper end of the case is connected with the combustion chamber gas inlet pipeline, the lower end of the case is connected with the combustion chamber outlet section, and a flame barrel is mounted on the combustion chamber outlet section. The flame barrel is connected with the combustion chamber gas inlet pipeline through a natural gas inlet pipeline; a natural gas nozzle, a first-level hydrocyclone assembly and a second-level hydrocyclone assembly are mounted at the top end of the head of the flame barrel, and the natural gas nozzle is sleeved with the first-level hydrocyclone assembly and the second-level hydrocyclone assembly. A plurality of natural gas injection holes are formed in the natural gas nozzle; a main combustion hole is formed in the upper side of the middle section of the flame barrel, and an igniter mounting assembly is arranged at the upper end of the main combustion hole; a mixing hole is formed in the lower side of the middle section of the flame barrel. The invention further discloses internal structures of the hydrocyclone assemblies. According to the combustion chamber, fuel and air can be mixed fast and evenly, a stable reflux area is formed at the head of the flame barrel, and the overall service life of the combustion chamber is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

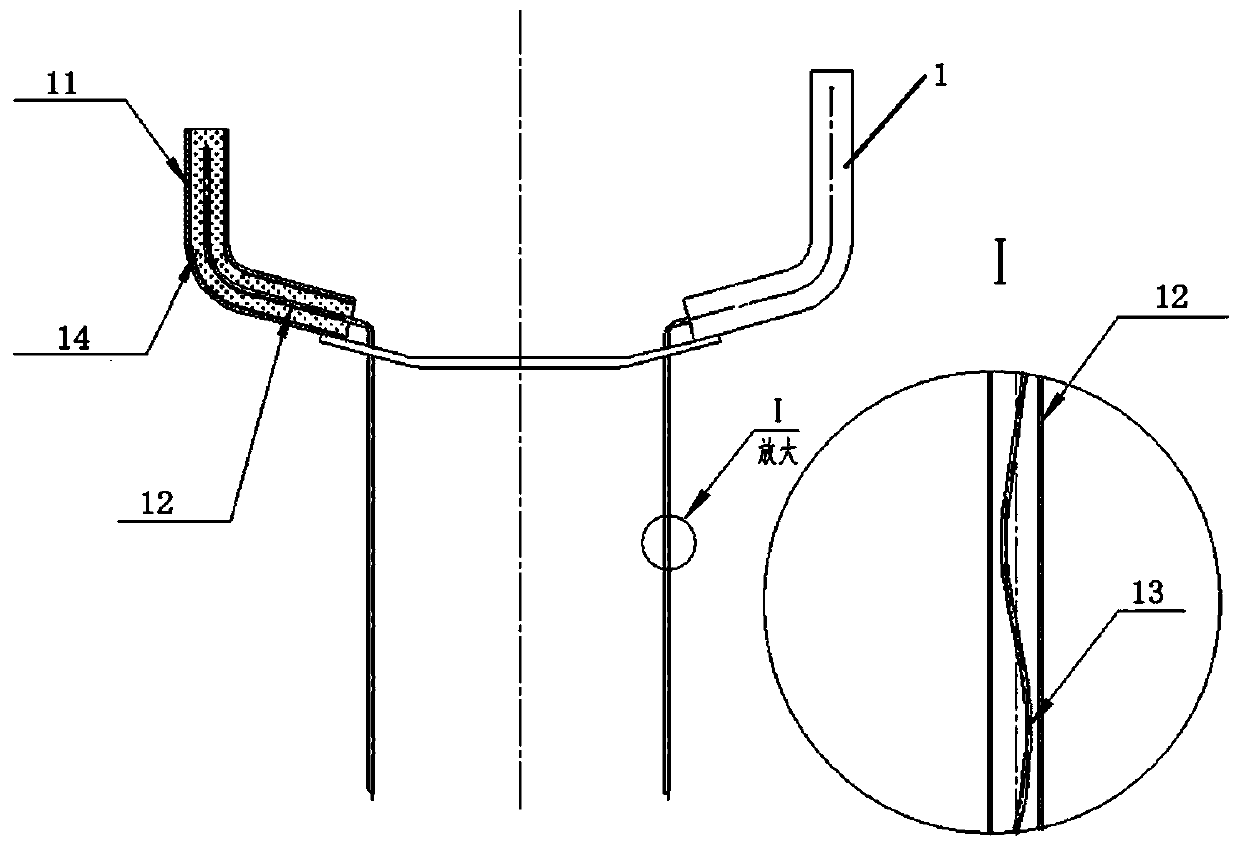

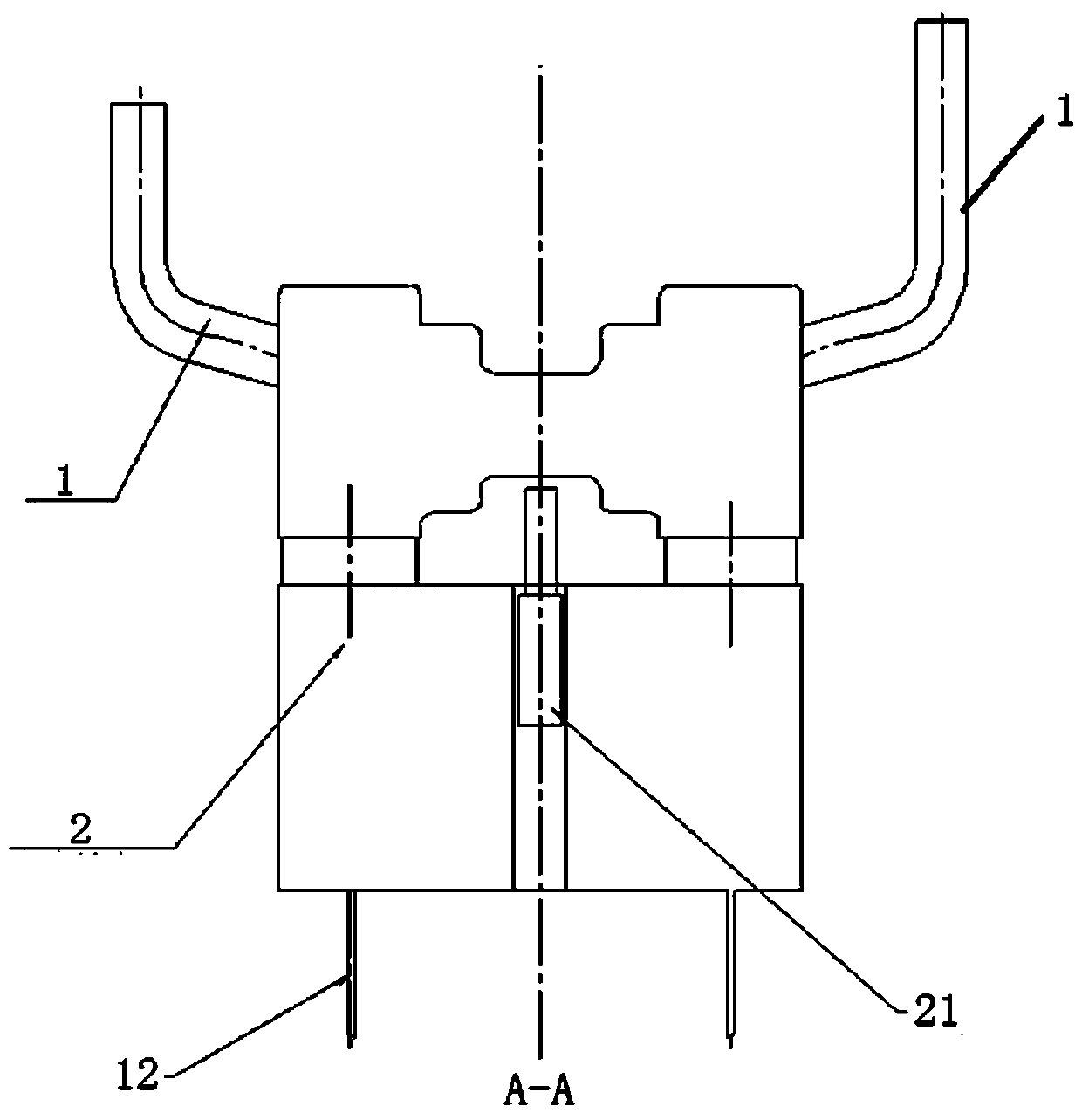

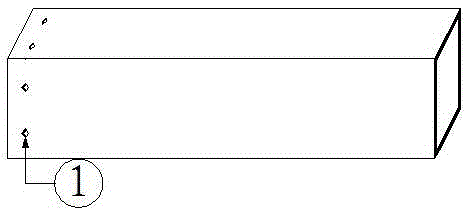

Manufacture method of water-oil pipeline casting mould and water-oil pipeline of diesel engine machine body

ActiveCN107626891AAvoid being unable to cleanIncrease stiffnessFoundry mouldsFoundry coresCooking & bakingFuran

The invention discloses a manufacture method of a water-oil pipeline casting mould and a water-oil pipeline of a diesel engine machine body. The manufacture method includes the following steps that a,a water channel and water cavity combined sand core is manufactured, two L-shaped steel pipes (1) are welded in a positioning mould sample, the two L-shaped steel pipes (1) are filled with first heat-resistant paint coatings (11), flexible exhaust pipes (12) are placed in gaps in the two L-shaped steel pipes (1), blasting fuses (13) are placed in the flexible exhaust pipes (12), then, the L-shaped steel pipes (1) are filled with zircon powder resin sand (14), and a water channel mud core assembly is formed; and b, the water channel mud core assembly is placed in a water cavity core box, the positioning position of the water channel mud core assembly is filled with furan resin sand (2), and the flexible exhaust pipes (12) penetrate out from the furan resin sand (2). By means of design methods such as usage of the water pipe heat-resistant coatings and heat-resistant sand and a certain period time of baking at a certain temperature, the problems that foundry sand in the pipes is sintered and iron burnt-on sand is formed on the inner walls of the pipes and cannot be removed are solved.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

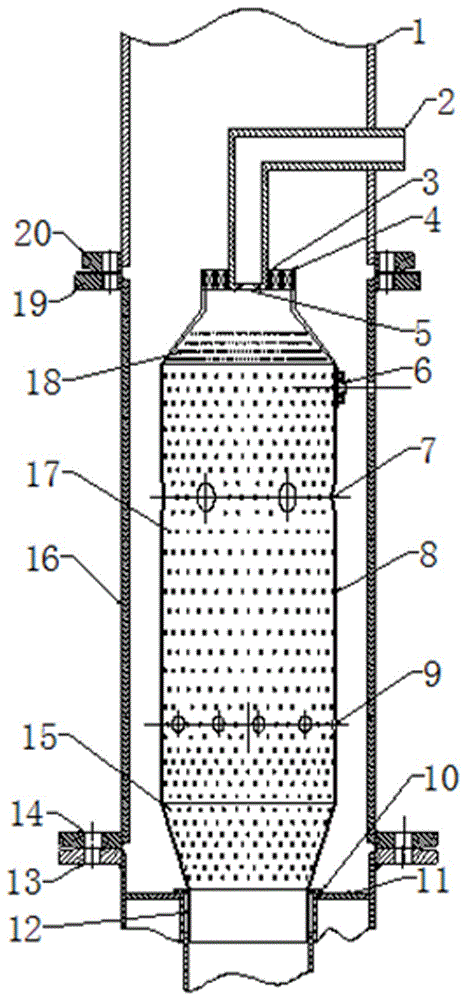

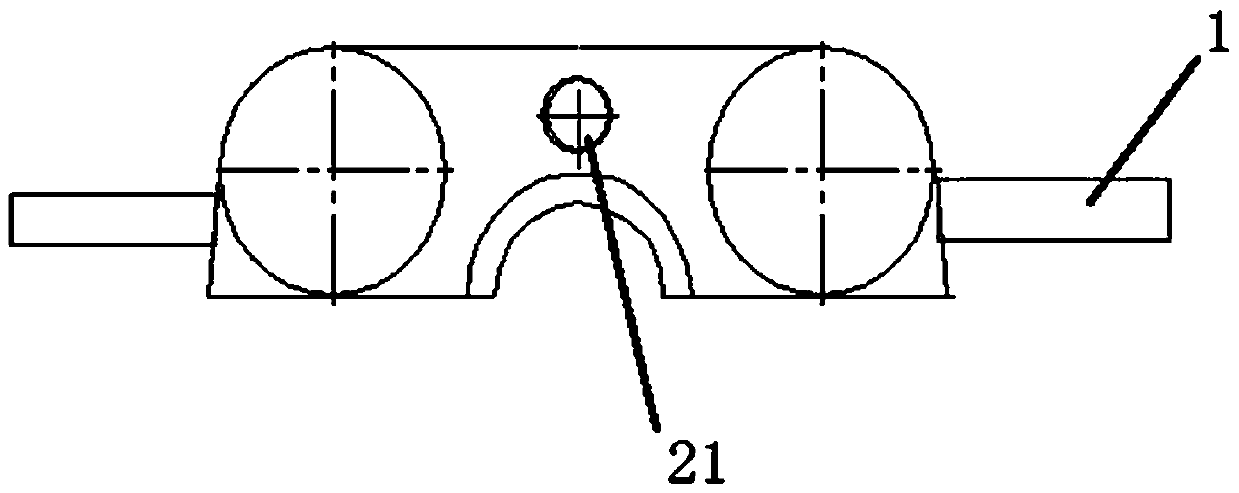

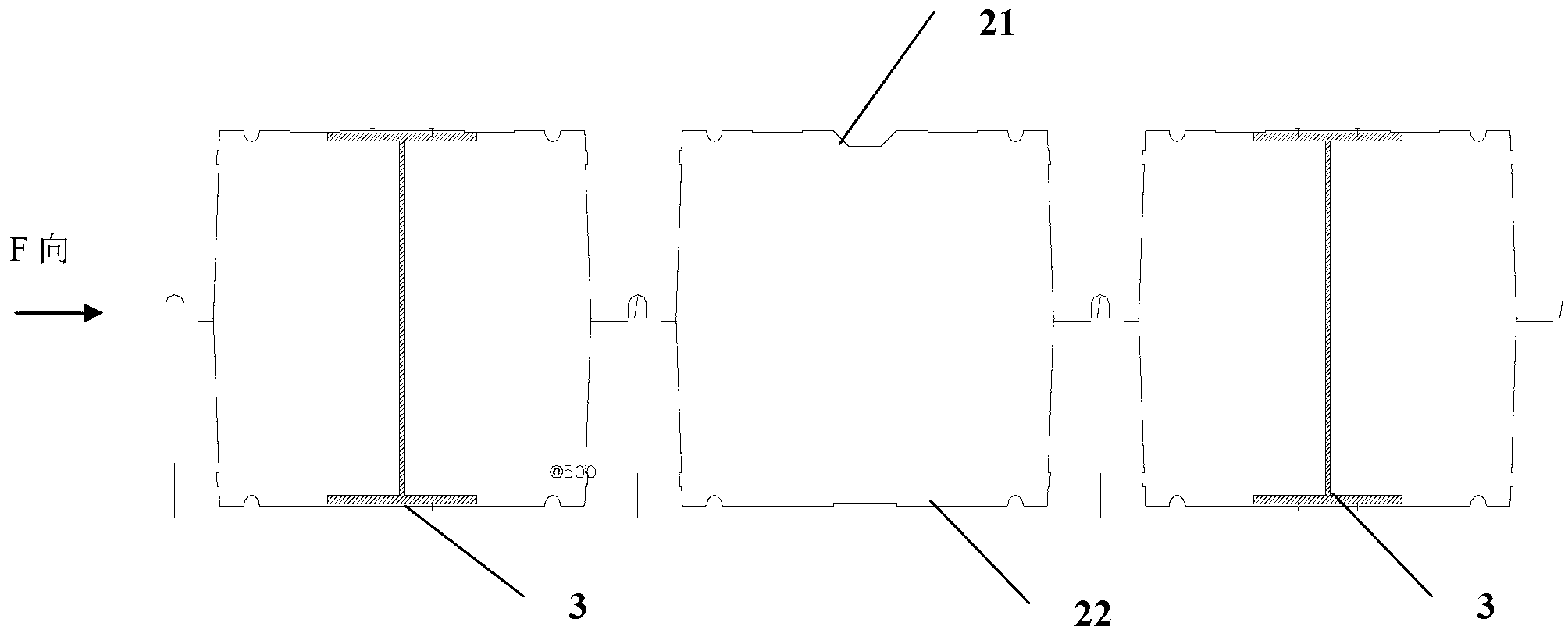

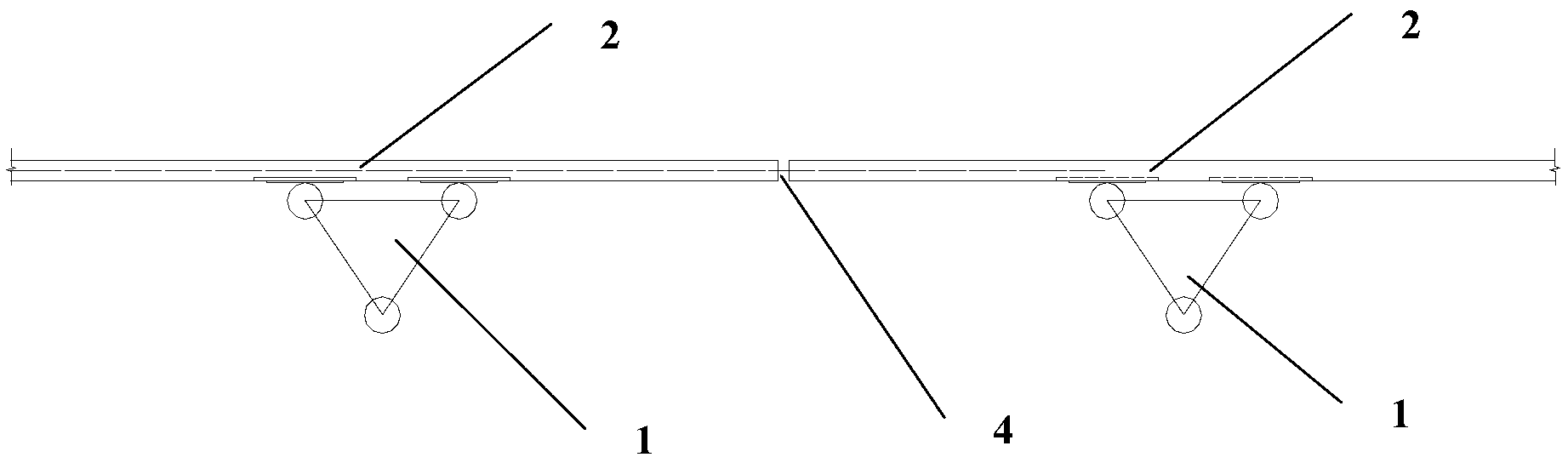

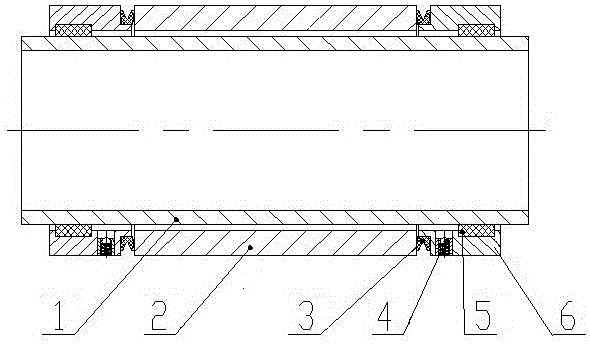

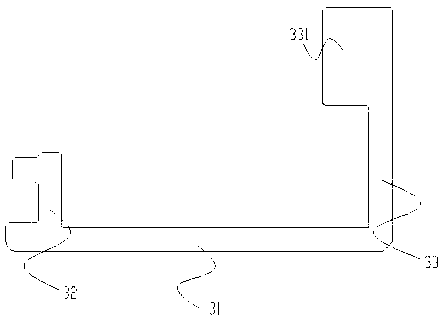

Single-tube beam capable of releasing temperature stress and suitable for transformer substation continuous rigid frame

ActiveCN103938735AGuaranteed free expansionReduce pull-up forceBuilding insulationsTemperature stressTransformer

The invention discloses a single-tube beam capable of releasing temperature stress and suitable for a transformer substation continuous rigid frame. The single-tube beam capable of releasing temperature stress and suitable for the transformer substation continuous rigid frame solves the problem that due to accumulation of stress on a single-tube beam in the length direction, an end supporting foundation cracks. The single-tube beam capable of releasing temperature stress and suitable for the transformer substation continuous rigid frame comprises a single tube (2), an extending single tube (2) and a connecting tube (3), the left end of the connecting tube (3) is connected into a right end tube of the extending single tube (1) in a sleeved mode, the right end of the connecting tube (3) is movably connected into a left end tube of the single tube (2) in a sleeved mode, an lubrication grease layer (11) is arranged between the outer side wall at the right end of the connecting tube (3) and the tube inner side wall at the left end of the single tube (2), single-end bolts (8) are arranged between an extending single tube flange (6) and a single tube flange (7) in a penetrating mode, compression springs are arranged at the two ends of the single-end bolt (8) respectively, and a spacing seam (15) is formed between the side surface of a left end port of the extending single tube (1) and the side surface of a left end port of the single tube (2). The single-tube beam capable of releasing temperature stress and suitable for the transformer substation continuous rigid frame is particularly suitable when the continuous rigid frame needs to be lengthened during expanding of a transformer station.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

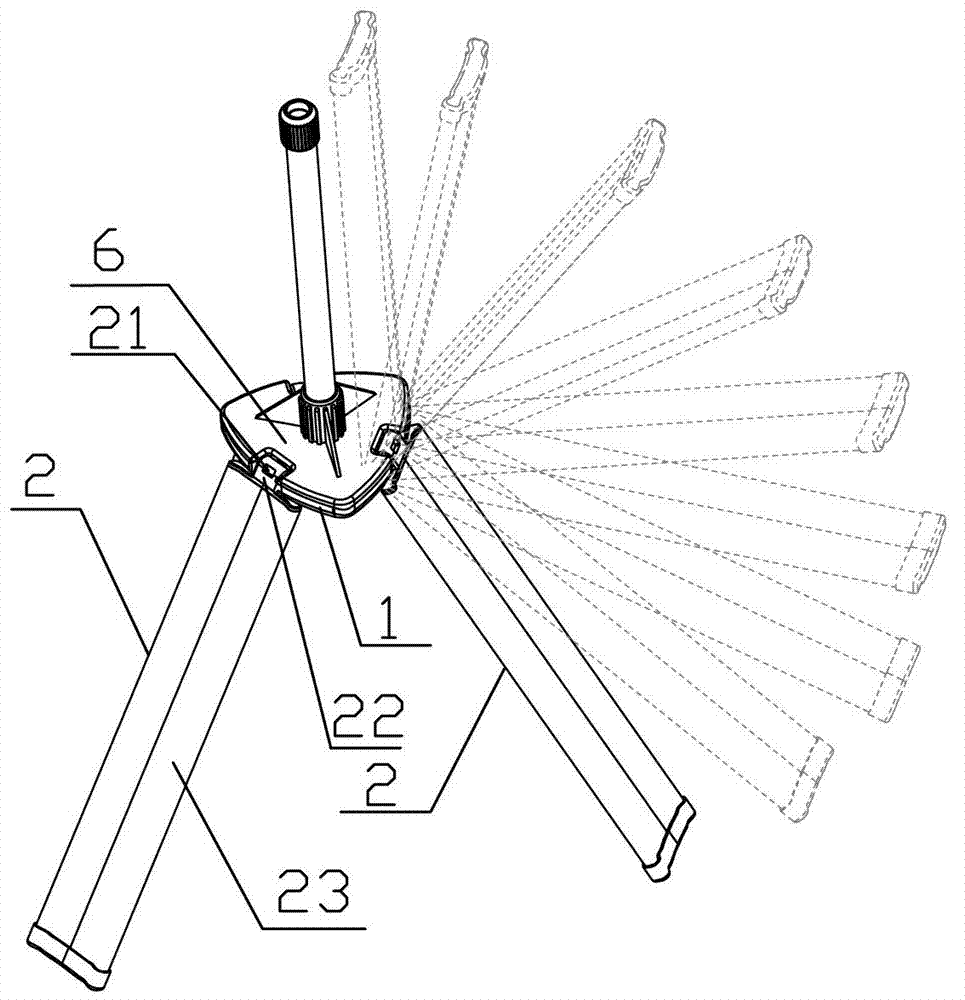

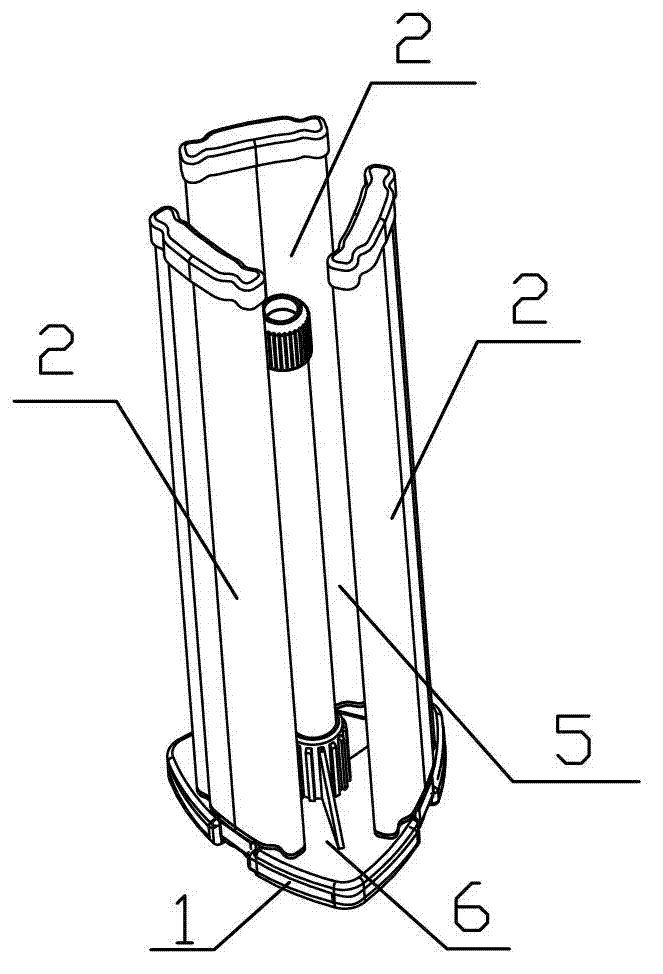

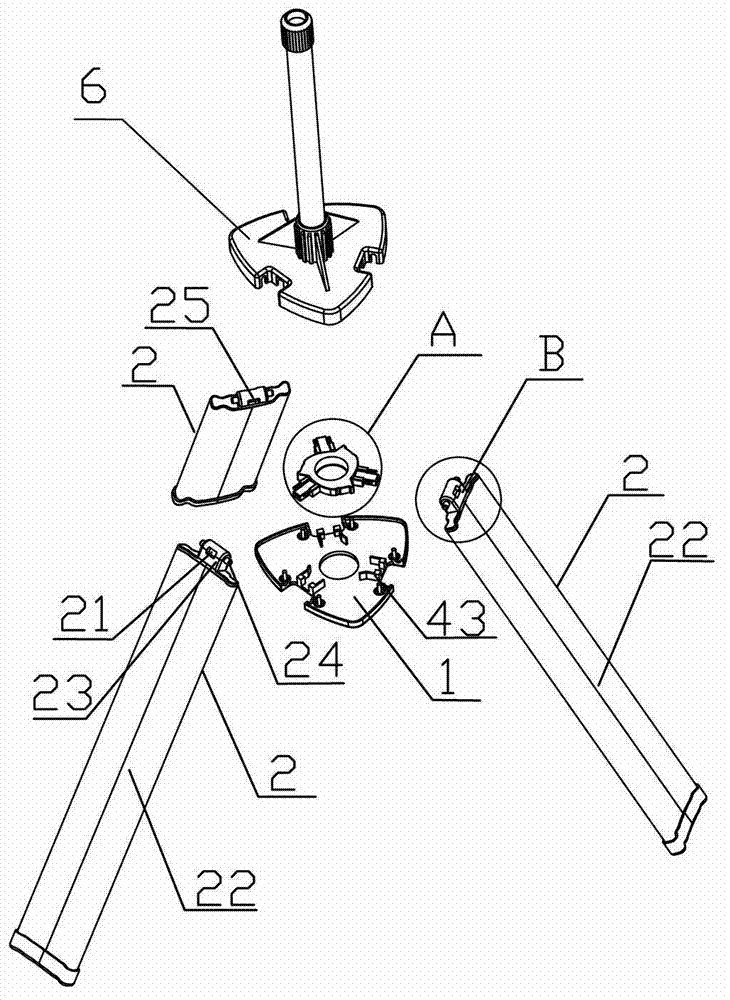

Support component of foldable music score support

The invention discloses a support component of a foldable music score support. The support component comprises a base plate and three support feet which are coupled with the base plate. The three support feet are distributed on the outer side of the base plate. Each support foot is in a flat shape. A first lock hole and a second lock hole are respectively formed in two sides on a coupling end of each support foot. A rotatable drive mechanism is arranged on the base plate. A locking mechanism is arranged between the drive mechanism and the coupling end of each support foot. Each locking mechanism comprises locking dogs. When the locking dogs stretch into the first lock holes, the three support feet are unfolded to support the base plate. When the locking dogs stretch into the second lock holes, the three support feed are folded upwards to a position above the base plate, and a containing space is formed between the support feed and the base plate. The support component of the foldable music score support has the advantages that a placing face plate of the music score support can be placed in the containing space after being folded, the placing face plate of the foldable music score support and the support component can be packaged together, size is small, and carrying is convenient.

Owner:NINGBO SOUNDKING ELECTRONICS

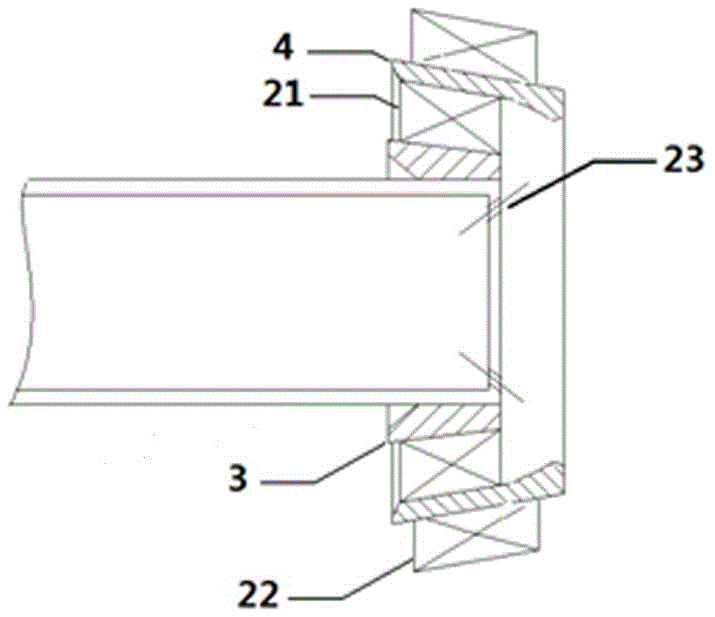

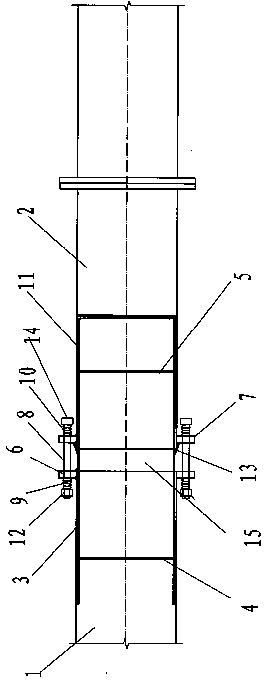

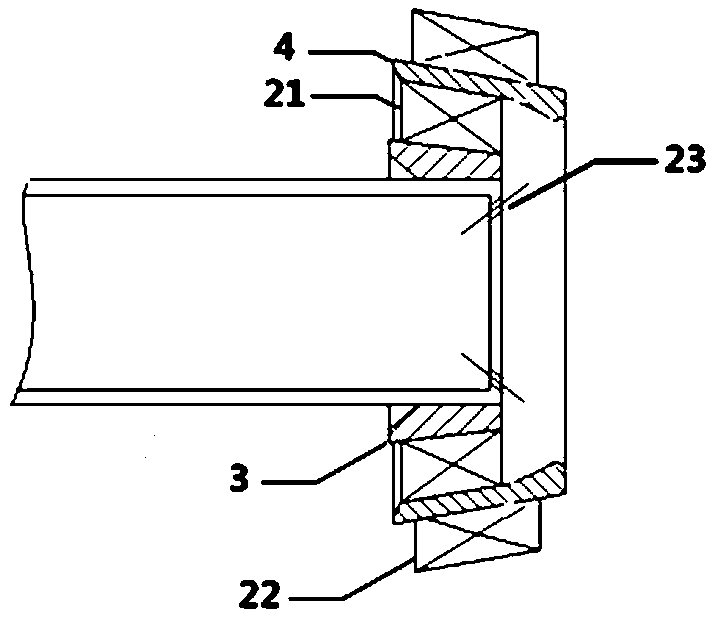

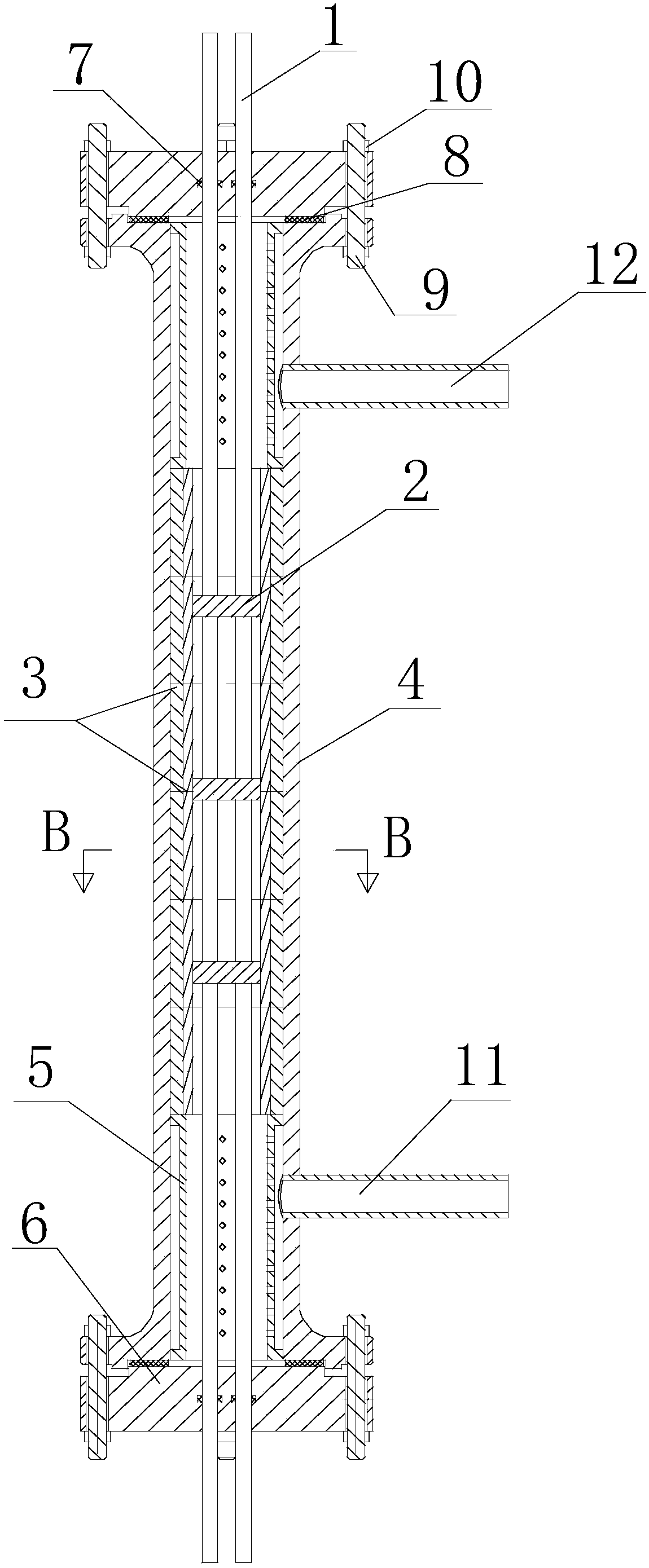

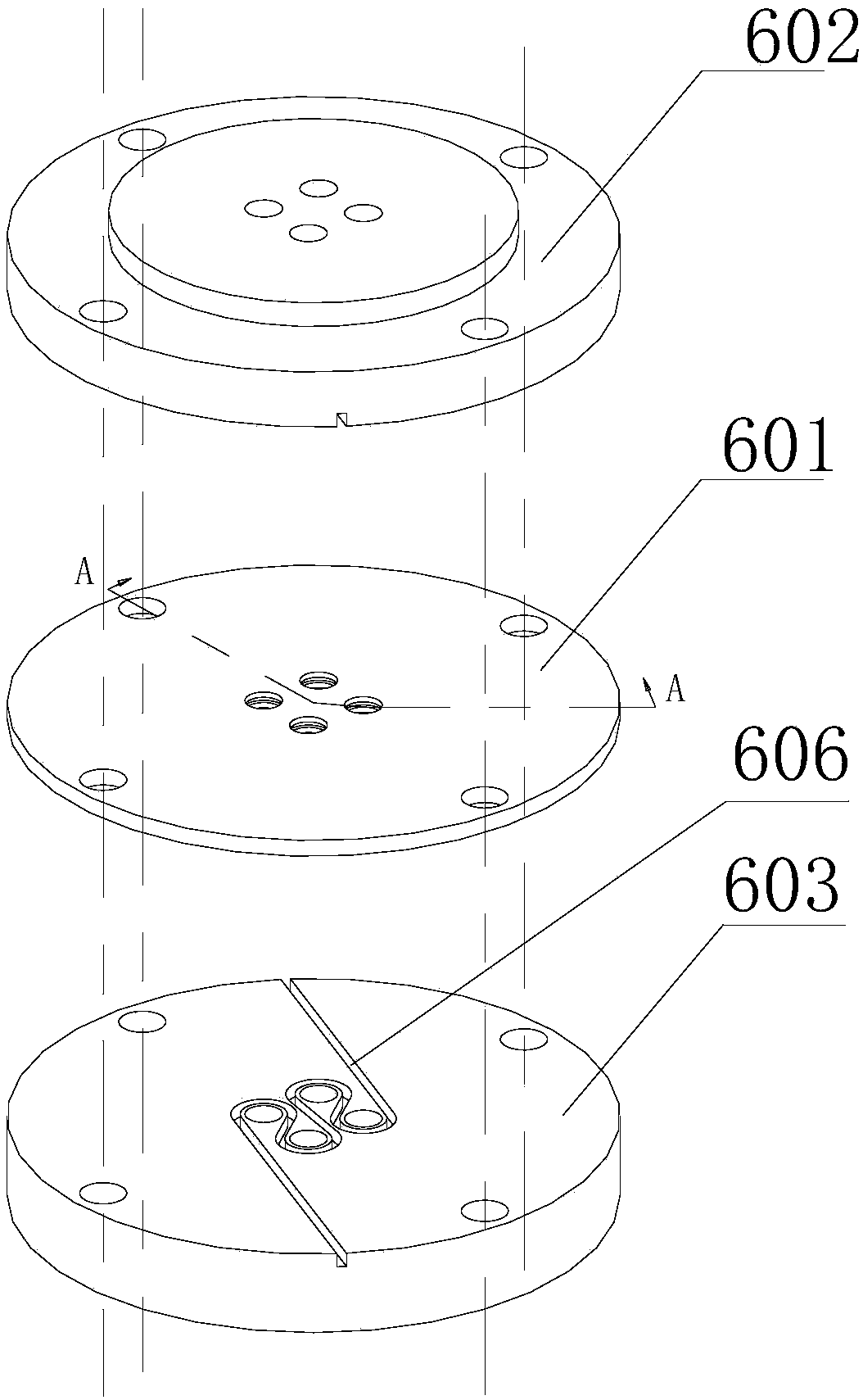

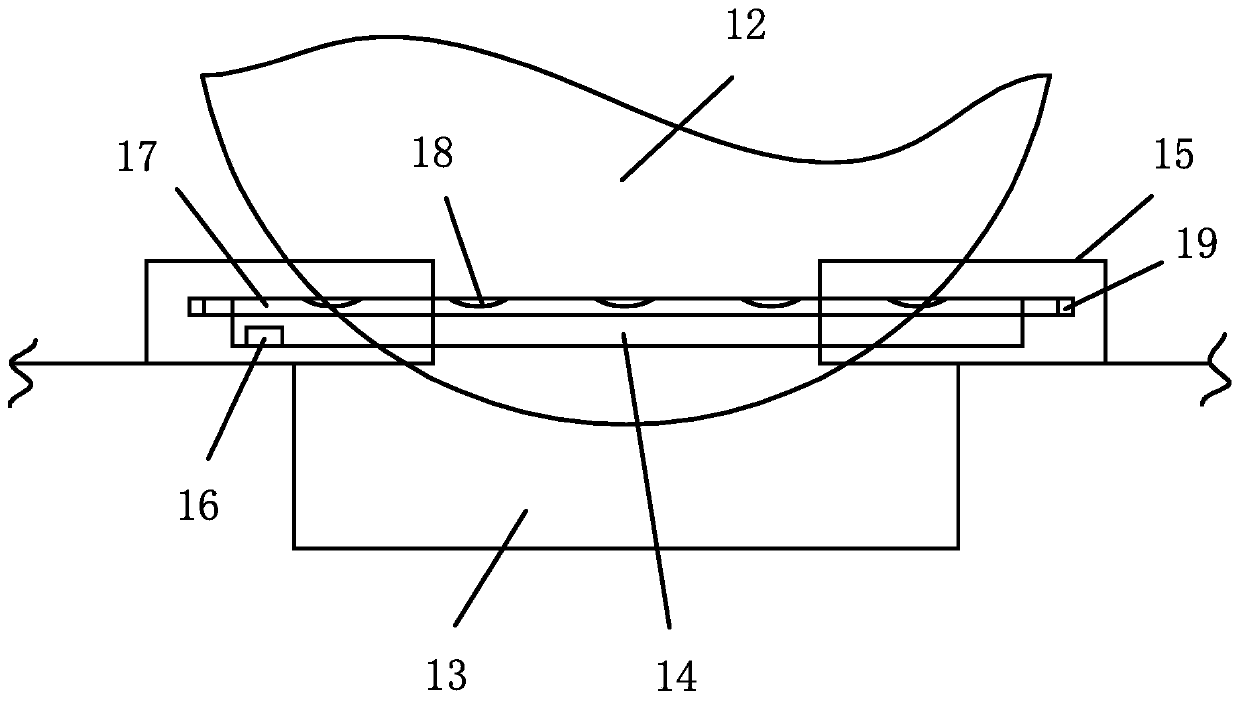

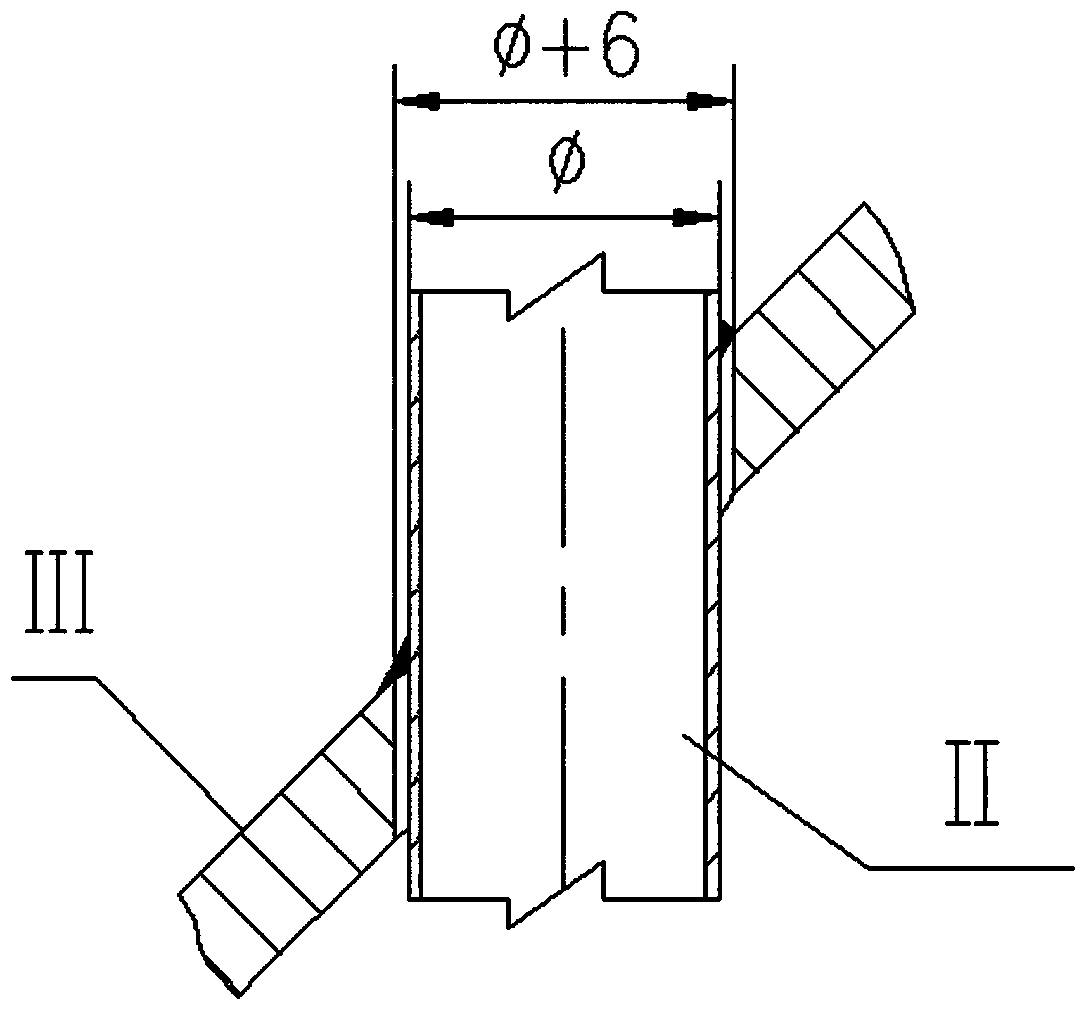

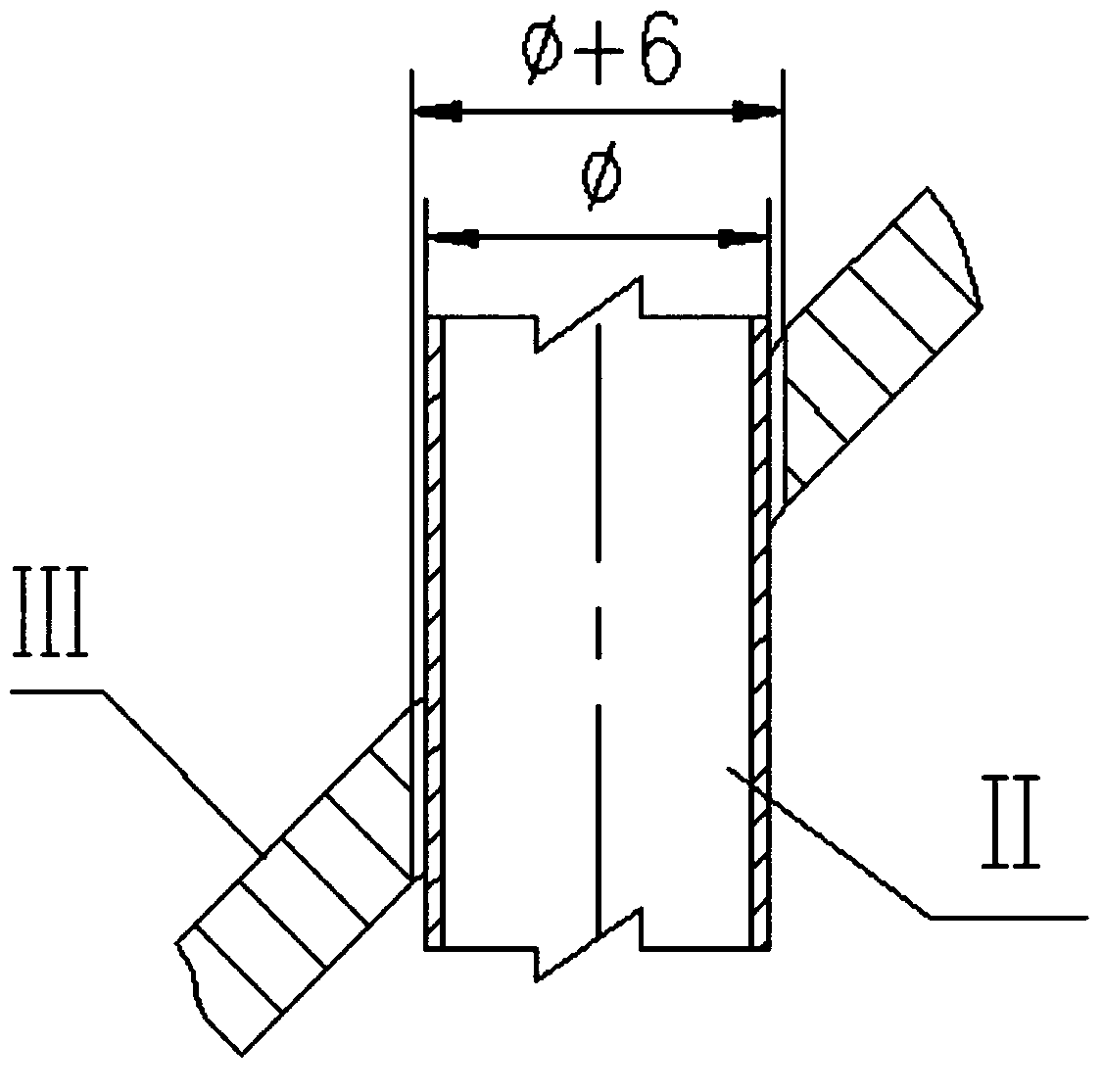

Positioning device for attemperator lining hybrid tube

InactiveCN102748747AGuaranteed free expansionEasy to assembleSuperheating controlEngineeringFree expansion

The invention provides a positioning device for an attemperator lining hybrid tube. The positioning device ensures free expansion of the hybrid tube and is convenient to assemble. The positioning device comprises a thick wall connecting box and the lining hybrid tube, wherein the lining hybrid tube is sleeved in the thick wall connecting box. The positioning device is characterized in that the outer ring surface of the lining hybrid tube is provided with a positioning bump, the positioning bump clings to the inner wall of the thick wall connecting box, a positioning groove is welded on one side of the inner wall of the thick wall connecting box, one end of the lining hybrid tube is abutted into a concave groove of the positioning groove, a limit block is welded on the other side of the inner wall of the thick wall connecting box, the tail end of the limit block is provided with a stopper, and the bottom of the ring surface at the other end of the lining hybrid tube is supported on the upper end surface of the front of the limit block.

Owner:WUXI HUAGUANG BOILER

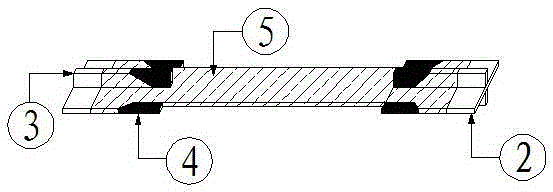

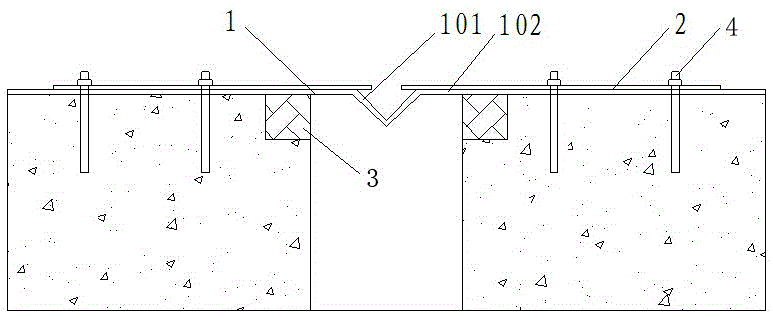

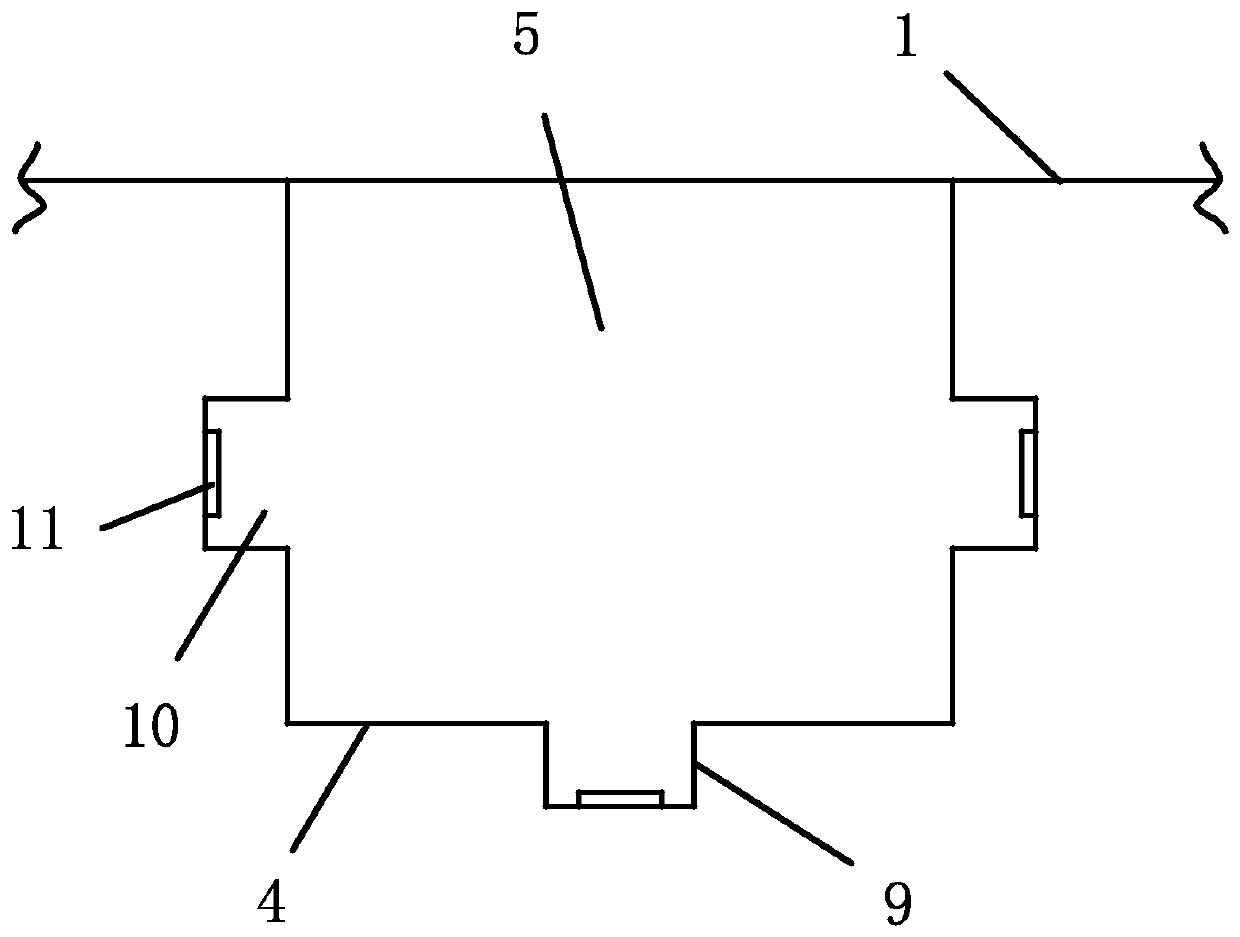

Dislocation-free expansion joint node for box type profiled steel sheets

ActiveCN103015600APrevent leakageEliminate vertical misalignmentBuilding roofsDislocation freeSheet steel

The invention discloses a dislocation-free expansion joint node for box type profiled steel sheets. The dislocation-free expansion joint node comprises a rigid connecting strip and two transitional connecting members, wherein the transitional connecting members are used for the end surfaces of the box type profiled steel sheets respectively arranged at two sides of an expansion joint, one end of the rigid connecting strip is fixed on one transitional connecting member and used as a fixing end, and the other end of the rigid connecting strip horizontally extends out along the longitudinal direction of the box type profiled steel sheets, is used as a free end and extends into a longitudinal sliding chute in the other transitional connecting member, so that the free end of the connecting strip can move along the longitudinal sliding chute. According to the dislocation-free expansion joint node, the vertical dislocation at the expansion joint of the two box type profiled steel sheets can be eliminated, meanwhile, free expansion and withdrawal of the longitudinally adjacent two box type profiled steel sheets can be ensured, and therefore the phenomenon that the two box type profiled steel sheets at two sides of the expansion joint are vertically staggered and pulled apart is effectively avoided on the premise of ensuring that box type profiled steel sheets freely expand and withdraw, and therefore a roof boarding can be effectively prevented from leaking.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

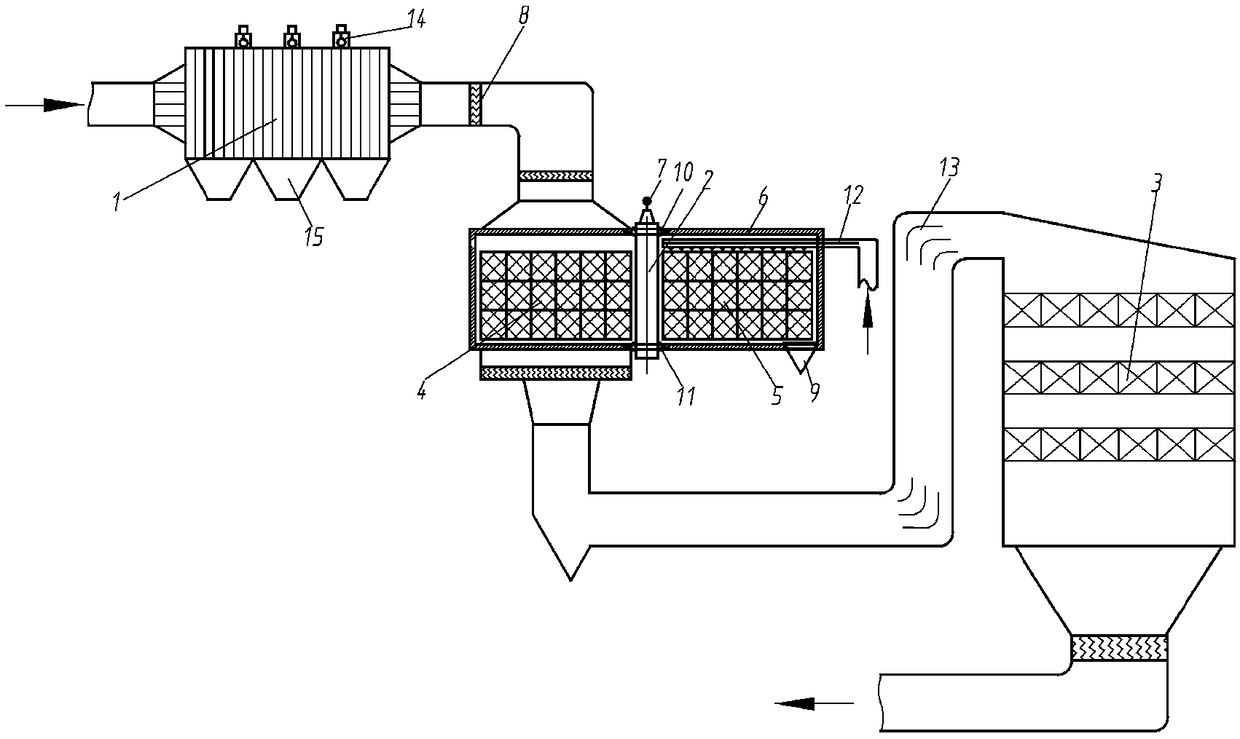

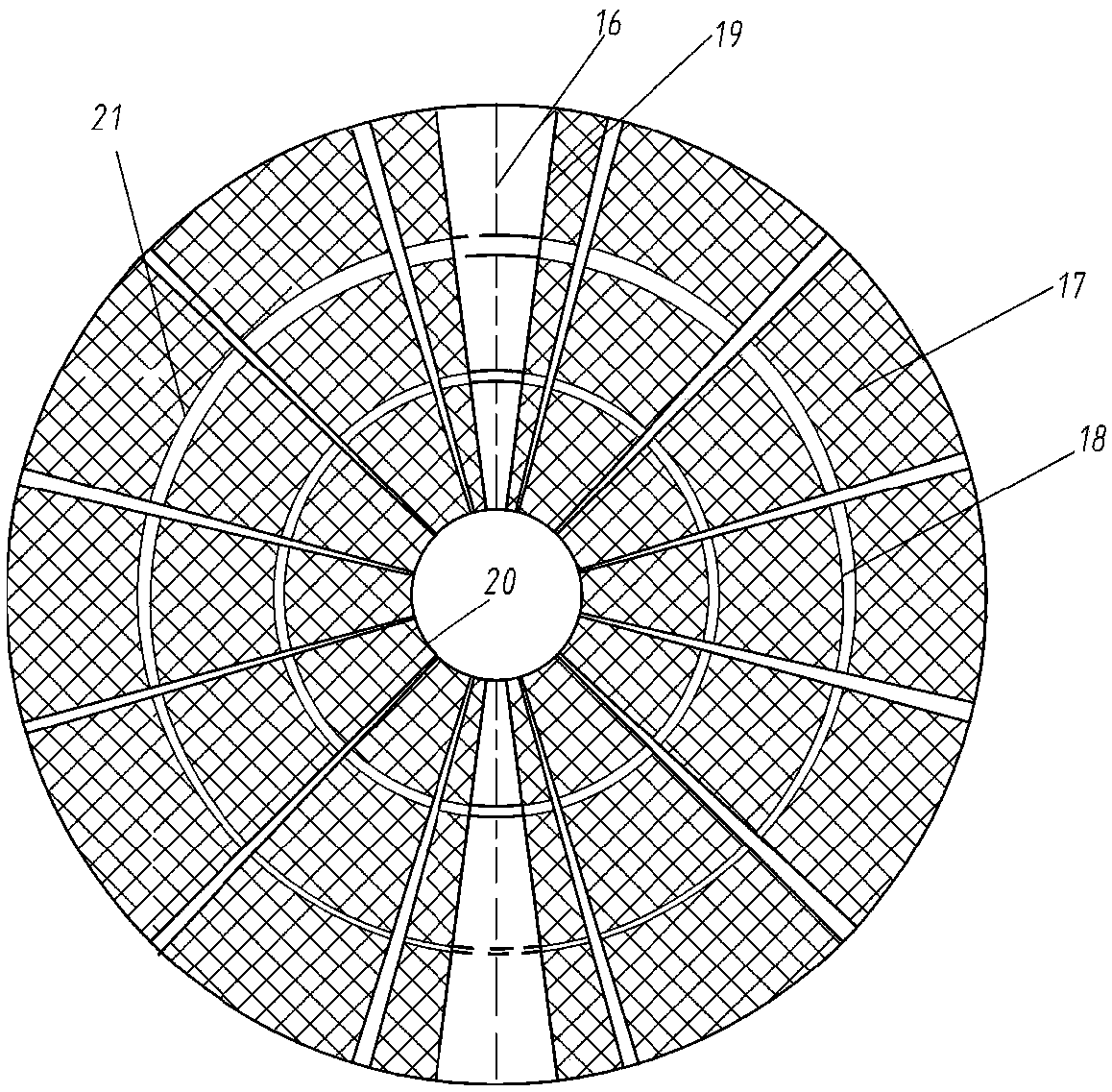

Rotation-based combined desulfurization and denitrification distribution system

PendingCN108939912ASolve corrosiveSolve the cloggingGas treatmentDispersed particle separationHydrogen SulfateDistribution system

The invention relates to a rotation-based combined desulfurization and denitrification distribution system. The system comprises a rotation type dry desulfurization and adsorbent regeneration device,wherein the rotation type dry desulfurization and adsorbent regeneration device comprises a shell, an adsorption bin and a regeneration bin are formed in the shell, a first rotation bin box containingan absorbent is mounted in the adsorption bin, a second rotation bin box containing an absorbent is mounted in the regeneration bin, a hollow rotating shaft is arranged between the first rotation binbox and the second rotation bin box, and the first rotation bin box and the second rotation bin box can rotate along the hollow rotating shaft; and a high-temperature electric dust remover is connected with the adsorption bin, and the adsorption bin is connected with a selective catalytic reduction denitrification device. The high-temperature electric dust remover and the denitrification device are distributed in front of an SCR device, so that the content of dust in the dust entering the SCR device is effectively controlled, SO2 in the smoke is completely removed, and ammonium hydrogen sulfate is not generated even when the escape amount of ammonia at an outlet of an SCR system is great.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for manufacturing buckling restrained braces

InactiveCN105350676AConvenient groutingGuaranteed free expansionShock proofingBuckling-restrained braceEngineering

The invention relates to a method for manufacturing buckling restrained braces. The method comprises following specific steps that: sleeves are vertically placed into an iron stand; the side, of each sleeve, welded to a lower sealing plate is downwardly arranged; the gap between each sleeve and the corresponding lower sealing plate is sealed with silica rubber, so that grout leakage can be prevented; grouting materials are poured into the sleeves in batch; and then the upper sealing plates are installed after the strength of the grouting materials meets requirements. By employing the method, the production efficiency of the buckling restrained braces is improved, the buckling restrained braces can be produced in batch; the production cost is greatly reduced; the supporting appearance is more beautiful; energy dissipating and damping effects can be achieved; the buckling restrained braces are convenient to disassemble and check; and a foundation of the further promotion and application of the buckling restrained braces is laid.

Owner:上海史狄尔建筑减震科技有限公司 +1

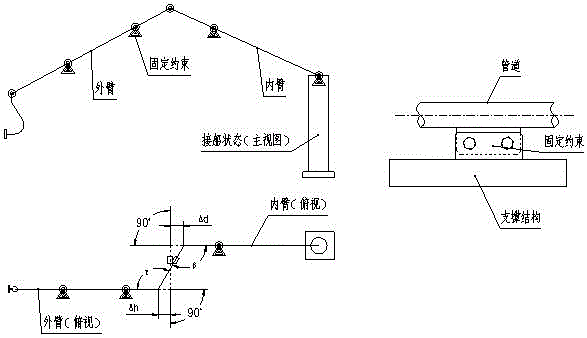

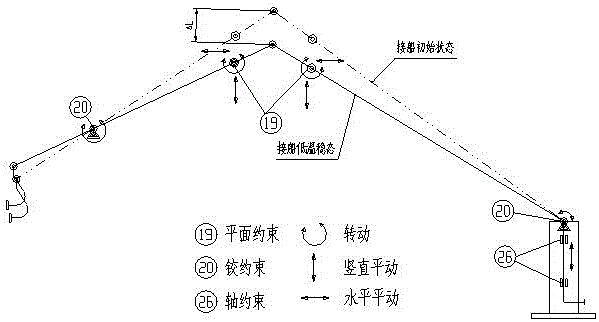

Single pipe loading and unloading arm for low-temperature ship

ActiveCN105858584ASolving resonance problemsIngenious designLiquid transferring devicesNitrogen gasInternal stress

The invention relates to a single pipe loading and unloading arm for a low-temperature ship. The single pipe loading and unloading arm comprises a supporting structure, a pipe system, a hydraulic drive system, a maintenance platform, a nitrogen gas blowing and sweeping system, an emergency escaping system, a hydraulic substation, an upper rope pulley, a steel wire rope and a lower rope wheel; the steel wire rope is arranged between the upper rope wheel and the lower rope wheel, the maintenance platform is arranged on the upper portion of the loading and unloading arm, the nitrogen gas blowing, sweeping and distributing system is arranged near an inlet flange of the loading and unloading arm, and the hydraulic substation is arranged on the side face of a stand column. The pipe system comprises a stand column pipe, an inner arm pipe and an outer arm pipe, the upper end and the lower end of the stand column pipe are constrained with a shaft, and it is guaranteed that the stand column pipe stretches out and contracts back freely in the axial direction and rotates freely in the axial direction; one end of the inner arm pipe is constrained with a hinge, and the other end of the inner arm pipe is constrained with a plane; one end of the outer arm pipe is constrained with a hinge, and the other end of the outer arm pipe is constrained with a plane. By means of the single pipe loading and unloading arm, the pipe system can stretch and contract freely under an environmental temperature as well as an ultra-low temperature working condition, and thus internal stress generated by temperature deformation is eliminated.

Owner:优必得流体科技设备(江苏)有限公司

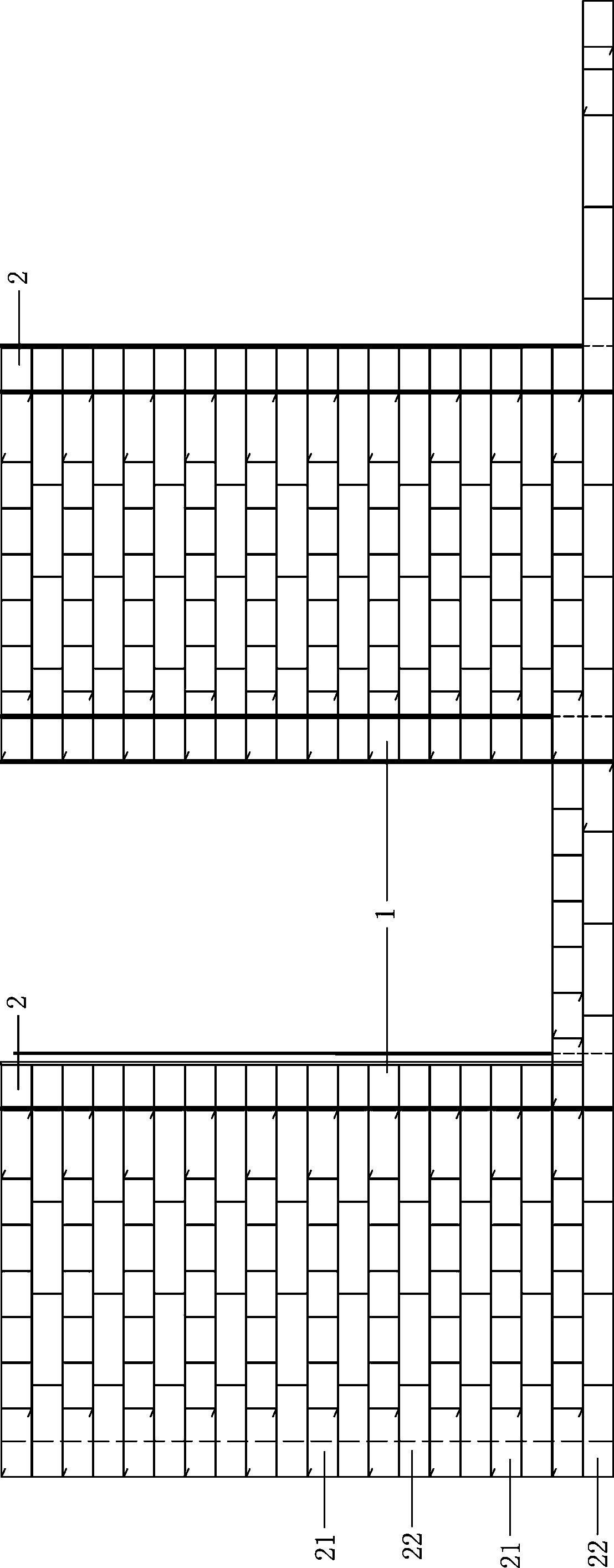

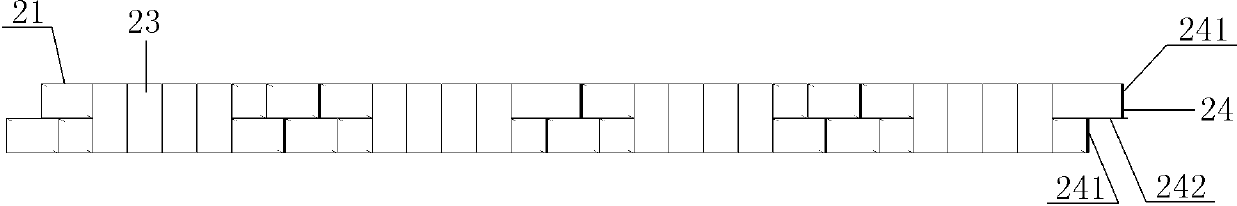

Jumping bin bricklaying method of light-weight brick furnace wall of annealing furnace

The invention relates to the field of bricklaying of a light-weight brick structure furnace wall lining of an industrial furnace, in particular to a jumping bin bricklaying method of a light-weight brick furnace wall of an annealing furnace. The jumping bin bricklaying method of the light-weight brick furnace wall of the annealing furnace is characterized in that the method is carried out according to the following steps of (1) preparation; (2) assembly and bricklaying of wall plates; (3) laying and adhesion; (4) jumping bin bricklaying; and (5) bricklaying of an upper layer in sequence. The jumping bin bricklaying method of the light-weight brick furnace wall of the annealing furnace is high in bricklaying quality, high in bricklaying speed, low in cost, little in environmental pollutionand long in service life.

Owner:CHINA MCC20 GRP CORP

Net laying device and method for fully-mechanized coal mining face

ActiveCN110056382ASmall expansion rangeIncrease job securityMine roof supportsClimate change adaptationWork periodFree expansion

The invention discloses a net laying device and method for a fully-mechanized coal mining face. The net laying device comprises a plurality of hydraulic supports arranged along the fully-mechanized coal mining face and net storage hooks, and the net storage hooks are fixed to the bottoms of side protection plates of the hydraulic supports; and the net laying method comprises the steps of (1) net roll erecting, (2) automatic net laying and (3) net fixing. The net laying device and method have the beneficial effects that operation is easy, the number of operators is decreased, and the working time is shortened; the working safety factor of the operators is increased; the effect of the side protection plates is fully exerted; the labor intensity is reduced, and the work efficiency of coal mining is ensured; and the free expansion and contraction quantity of a laid net is ensured, the possibility that the net is torn is decreased, and the safety of a retracement operation environment is guaranteed.

Owner:国电建投内蒙古能源有限公司

A single-tube combustor of a ground gas turbine with axial intake

InactiveCN106287814BWell mixedFlame stabilizationContinuous combustion chamberCombustion chamberEngineering

The invention discloses a ground gas turbine single-tube combustion chamber adopting axial gas inflow. The ground gas turbine single-tube combustion chamber comprises a combustion chamber gas inlet pipeline, a case and a combustion chamber outlet section. The upper end of the case is connected with the combustion chamber gas inlet pipeline, the lower end of the case is connected with the combustion chamber outlet section, and a flame barrel is mounted on the combustion chamber outlet section. The flame barrel is connected with the combustion chamber gas inlet pipeline through a natural gas inlet pipeline; a natural gas nozzle, a first-level hydrocyclone assembly and a second-level hydrocyclone assembly are mounted at the top end of the head of the flame barrel, and the natural gas nozzle is sleeved with the first-level hydrocyclone assembly and the second-level hydrocyclone assembly. A plurality of natural gas injection holes are formed in the natural gas nozzle; a main combustion hole is formed in the upper side of the middle section of the flame barrel, and an igniter mounting assembly is arranged at the upper end of the main combustion hole; a mixing hole is formed in the lower side of the middle section of the flame barrel. The invention further discloses internal structures of the hydrocyclone assemblies. According to the combustion chamber, fuel and air can be mixed fast and evenly, a stable reflux area is formed at the head of the flame barrel, and the overall service life of the combustion chamber is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

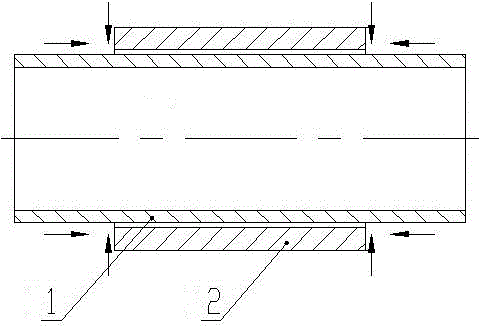

Bimetal-composite-pipe liquid expansion forming base-pipe and liner-pipe gap waterproof device

ActiveCN105134947AOptimize the waterproofing processImprove forming qualityEngine sealsCheck valvesEngineeringStructural engineering

The invention provides a bimetal-composite-pipe liquid expansion forming base-pipe and liner-pipe gap waterproof device. The bimetal-composite-pipe liquid expansion forming base-pipe and liner-pipe gap waterproof device comprises a base pipe and a liner pipe which is located in the base pipe and is coaxial with the base pipe. Sealing pressing rings arranged on the liner pipe in a sleeving manner are arranged at the two ends of the base pipe respectively. Waterproof sealing rings arranged on the liner pipe in a sleeving manner are arranged between the sealing pressing rings and the liner pipe. First through holes are formed in the sealing pressing rings in the radial direction, and air exhausting valves used for exhausting air between the inner wall of the base pipe and the outer wall of the liner pipe are arranged in the first through holes. By means of the bimetal-composite-pipe liquid expansion forming base-pipe and liner-pipe gap waterproof device, the air between the base pipe and the liner pipe can be easily exhausted, water can be prevented from entering the portion between the base pipe and the liner pipe, it can be guaranteed that the liner pipe can freely stretch out and draw back in the axial direction, the bimetal-composite-pipe liquid expansion forming waterproof technology is optimized, and the forming quality of a composite pipe is greatly improved while the manufacturing cost is reduced. The device has the beneficial effects of being simple in structure, convenient to install, high in reliability and low in cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO +1

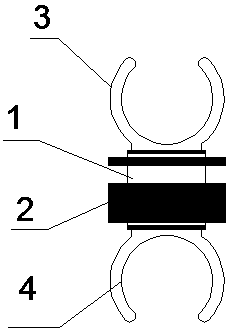

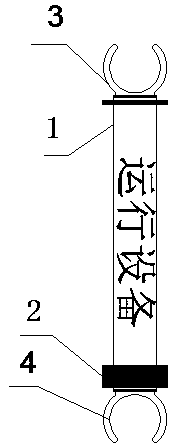

Relay protection secondary operation isolation device

PendingCN111029912AEasy to installNot easy to fall offSubstation/switching arrangement detailsWarning signsOperation safety

The invention relates to a relay protection secondary operation isolation device. At present, in order to prevent a worker from mistakenly contacting and mistakenly touching the wiring terminal of anoperation terminal strip and mistakenly touching and mistakenly operating the operation terminal in operating, the operating terminals and devices in the working protection screen cabinet strip need to be obviously isolated, striking warning signs need to be arranged, and operation safety is guaranteed. The relay protection secondary operation isolation device comprises a stretchable red warning strip cloth (1) and a cylindrical warning strip cloth storage box (2). The stretchable red warning strip cloth is connected with the cylindrical warning strip cloth storage box, the cylindrical warningstrip cloth storage box is made of PVC materials, the reel spring is fixed in the cylindrical warning strip cloth storage box, free stretching and retracting of the warning strip cloth are guaranteedthrough the reel spring, and white characters of operation equipment are printed on the stretchable red warning strip cloth. The relay protection secondary operation isolation device is applied to the relay protection device.

Owner:SUIHUA POWER SUPPLY COMPANY OF STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +1

Fixing structure of gas turbine splitting ring

ActiveCN109578091ASimple structureEasy to installStatorsMachines/enginesEngineeringThermal expansion

The invention discloses a fixing structure of a gas turbine splitting ring. The fixing structure of the gas turbine splitting ring comprises a blade carrier, a heat insulating ring, and a splitting ring, a clamping part and a pothook part are arranged on the splitting ring, so that the splitting ring is connected with the heat insulating ring and the blade carrier, the splitting ring is divided evenly into a plurality of segmental arcs, a plurality of heat expansion gaps are arranged, and thus the free expansion at a high temperature of the splitting ring is guaranteed. The fixing structure ofthe gas turbine splitting ring has the characteristics that the structure is simple, installation is convenient, and mutual effects caused by interference between parts due to heat expansion are prevented.

Owner:DONGFANG TURBINE CO LTD

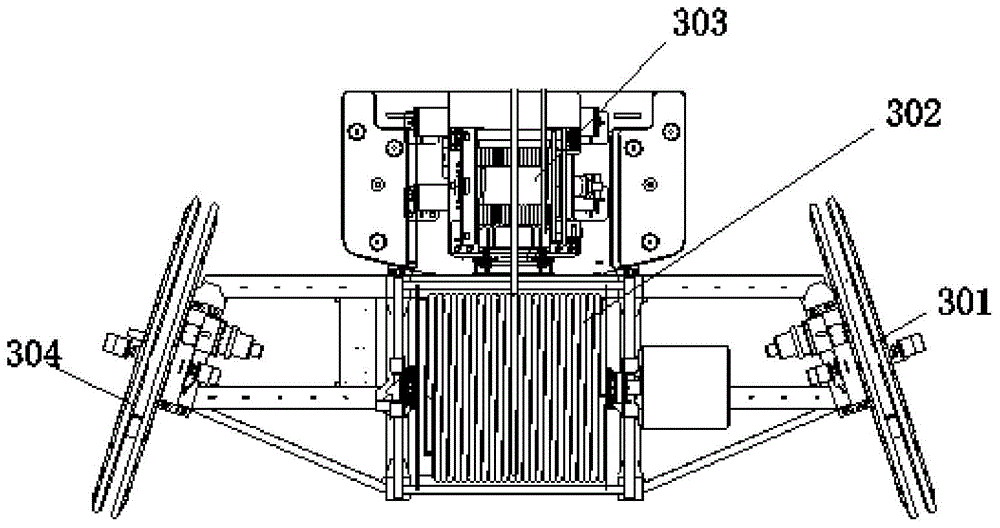

Method and system for water and gas combined sand settling prevention for vibroflotation gravel

ActiveCN104358249ASolve the hardening problemGuaranteed free expansionSoil preservationCrushed stoneArchitectural engineering

The invention discloses a method and a system for water and gas combined sand settling prevention for a vibroflotation gravel pile machine. A guide rod of a drill rod system of the vibroflotation gravel pile machine is a telescopic guide rod. The method comprises the following steps of when the vibroflotation gravel pile machine performs the ultra-deep construction of a vibroflotation device, gradually extending or retracting the telescopic guide rod in a pile hole along with the increase or decrease of the vibroflotation depth, so as to enable the vibroflotation device under the telescopic guide rod to perform upward vibroflotation for hole forming or upward densification for pile manufacturing; when the telescopic guide rod is retracted or extended, continuously filling water into the telescopic guide rod, and filling pressure water into the telescopic guide rod; enabling the water pressure in the telescopic guide rod to be always higher than the water pressure of the pile hole, and then enabling the pressure water in the telescopic guide rod to flow to mud in the pile hole through a sleeve pipe gap of the telescopic guide rod, so as to prevent the sand in the mud from entering and clamping in the sleeve pipe gap; continuously injecting air into the telescopic guide rod, blowing the sand in the telescopic guide rod from bottom to top, and enabling the sand to btar in the pipe, so as to prevent the sand settling in the pipe.

Owner:SINOHYDRO FOUND ENG

Detachable settlement joint high-waterproofing structure and construction method thereof

InactiveCN106088366AGood waterproof effectNot easy to leakBuilding constructionsSteel platesWaterproofing

Owner:周忠

Simulation device for high temperature resistant rod bundle fuel assembly based on diffusion welding

ActiveCN107240427BAvoid failureAvoid damageNuclear energy generationNuclear monitoringNuclear reactorDesign standard

The invention discloses a high-temperature-resistant rod bundle fuel assembly simulation device based on diffusion welding. The heating rod bundle simulation body is fixed by the fuel assembly positioning grid simulation body arranged in sequence along the axial direction, and placed in the ceramic flow according to the arrangement of the core rod bundle. In the channel chamber, the outer side of the ceramic flow channel chamber is a pressure-bearing sleeve, and the two ends of the cylinder wall are respectively arranged with an inlet joint and an outlet joint. Connect with the external power supply after bundle sealing the end cap. The diffusion welding method of the present invention enables the temperature of the wall surface of the heating rod bundle simulation body to exceed the melting point of silver brazing, and maintains the temperature of the high-temperature sealing ring below the design standard through the cooling flow channel formed in the rod bundle sealing end cap by diffusion welding, so that The operating condition of the rod bundle fuel assembly simulation body can reach the actual temperature and pressure level of the nuclear reactor, and can be used to accurately simulate the high temperature and high pressure flow and heat transfer state in the rod bundle channel under any axial power distribution during the life of the nuclear reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Fastener plug-in curved metal roof and its construction method

ActiveCN103711258BSolve the odd-shaped surface problemGuaranteed free expansionRoof covering using slabs/sheetsBuilding material handlingArchitectural engineeringMetal

The invention provides a fastener plug-in type curved surface metal roof which comprises a base frame, primary purline supporting components, lengthening connecting fasteners, primary purlines, primary and secondary purline through connection components, secondary purlines, secondary purline panel through connection components, roof panel components and sealing components. The base frame is fixedly mounted on a civil engineering foundation roof face. The primary purlines are fixedly connected with the base frame through the primary purline supporting components. The secondary purlines are connected with the primary purlines through the primary and secondary purline through connection components. The secondary purline panel through connection components are connected with the secondary purlines. The roof panel components are connected with the secondary purline panel through connection components, two adjacent roof panel components are connected in an inserting mode, and the sealing components are arranged in the clearances of the roof panel components. A construction method mainly comprises the step that the base frame, the primary purline supporting components, the primary purlines, the primary and secondary purline through connection components, the secondary purlines, the secondary purline panel through connection components, the roof panel components and the sealing components are mounted in sequence. According to the fastener plug-in type curved surface metal roof and the construction method, steel and manpower cost can be effectively saved, the construction period can be shortened, and the new construction method of the curved surface metal roof is provided.

Owner:CHANGZHOU NO 1 CONSTR GRP

Steering link of vehicle

InactiveCN110203282AGuaranteed free expansionImprove support strengthSteering linkagesVehicle frameEngineering

Owner:保定卓沐园林绿化工程有限公司

Novel stripping element tight connecting device

The invention relates to a novel stripping element tight connecting device. A stripping steam vertical pipe passes through a cone-shaped baffle plate, and the stripping element tight connecting device is tightly connected with the stripping steam vertical pipe and the cone-shaped baffle plate. The stripping element tight connecting device comprises a compressing baffle plate, a connecting plate, a compressing ring, a silk screen, a sleeve and ceramic fibers, wherein the inner side face of the compressing baffle plate is fixedly connected with the stripping steam vertical pipe, the upper end of the connecting plate is fixedly connected with the compressing baffle plate, the lower end of the connecting plate is fixedly connected with the compressing ring, the compressing ring extends into the sleeve, the silk screen is located below the compressing ring and meanwhile is arranged on the top of a circular gap between the sleeve and the stripping steam vertical pipe, the ceramic fibers are filled in the circular gap below the silk screen, the sleeve is fixedly connected with the cone-shaped baffle plate, and the circular gap is formed between the lower end opening of the sleeve and the stripping steam vertical pipe. According to the technical scheme, not only can the free swelling deformation between the cone-shaped baffle plate and the stripping steam vertical pipe be ensured, but also the device has the sealing effect and can be used for effectively preventing the stripping steam vertical pipe from being worn through.

Owner:LUOYANG ZHIDA PETROCHEM ENG

Superheater protecting device with thermal expansion eliminating function

ActiveCN106765051AEliminate disturbanceGuaranteed free expansionSteam superheatersEngineeringThermal expansion

The invention relates to a superheater protecting device, in particular to a superheater protecting device with a thermal expansion eliminating function, and belongs to the technical field of boiler structures. The problem that when a superheater serpentine pipe in an existing boiler is arranged in a convection pipe bundle zone, a welding line at the connecting position of a header and the serpentine pipe is prone to cracking is solved through the superheater protecting device with the thermal expansion eliminating function. The superheater protecting device with the thermal expansion eliminating function comprises a vertical support, a transverse support set and a pipe bundle fixing device. The pipe bundle fixing device is supported and positioned through the transverse support set fixedly connected to a lower boiler barrel. The vertical support is of a sealed cubic structure. The header and the connecting position of the header and the serpentine pipe are located in the vertical support and sealed through the vertical support. The serpentine pipe is fixed through the pipe bundle fixing device. The superheater protecting device with the thermal expansion eliminating function is used for protecting a superheater.

Owner:哈尔滨红光锅炉总厂有限责任公司

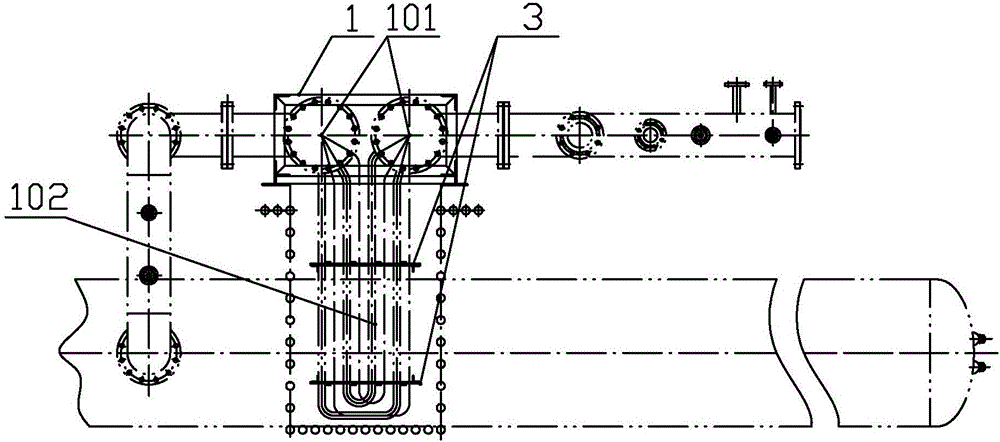

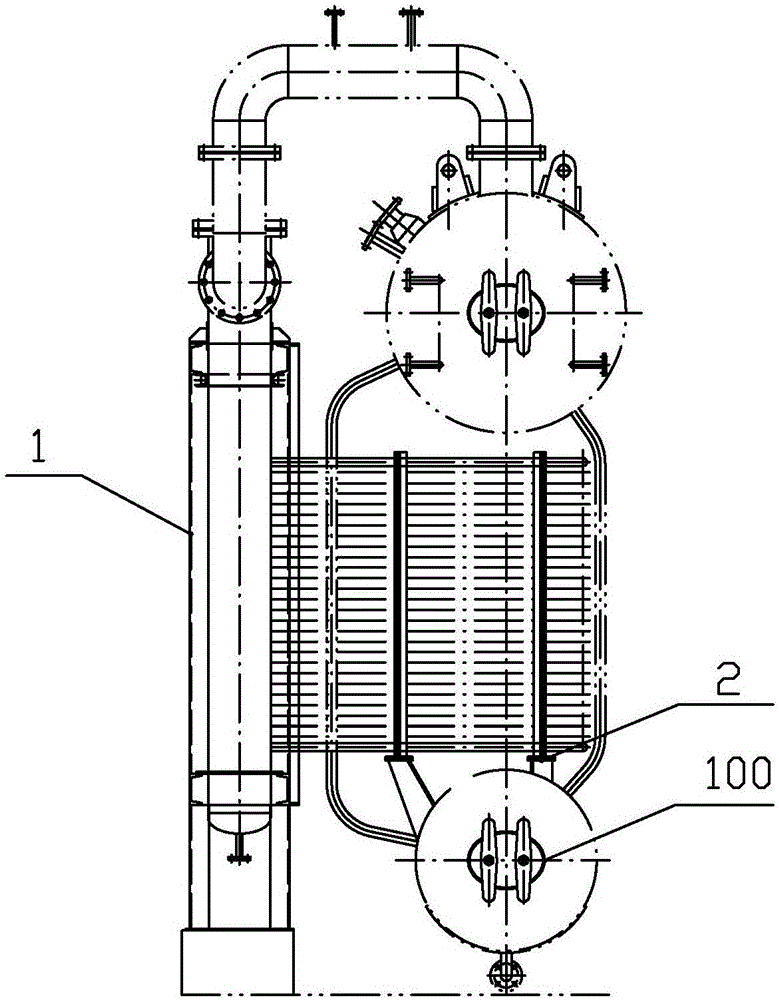

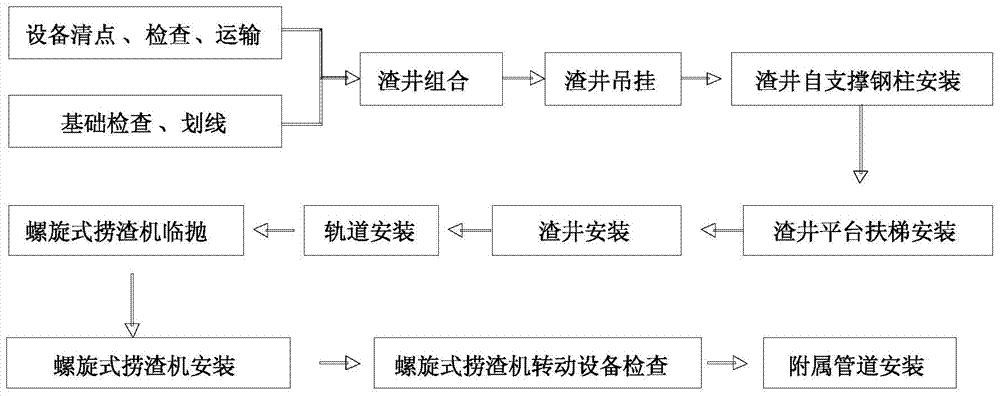

Power plant boiler spiral slag removal device and installation method

ActiveCN104949140BIncrease flexibilityImprove convenienceLighting and heating apparatusPower stationBoiler slag

The invention discloses a power station boiler screw deslagging device and a mounting method. The power station boiler screw deslagging device and the mounting method are used for solving the problems of air leakage and mounting difficulty. The device comprises a slag well, a slag well self-supporting steel column, a screw slag conveyor and a slag crusher. The screw slag conveyor is located underthe slag well, and the slag crusher is mounted at the position of a slag outlet of the screw slag conveyor. The device is characterized in that the slag well is mounted between a dry bottom hopper and the screw slag conveyor, the slag well is mounted on a foundation through the slag well self-supporting steel column, an annular water seal is utilized between the dry bottom hopper and the slag well to achieve sealing connection, and a water seal is adopted between the slag well and a water trough of the screw slag conveyor for connection. The invention also discloses an inverted order overlapped mounting method, the influence of errors accumulated to the dry bottom hopper after a heated surface is mounted on the deslagging device is avoided, and the device has the advantages of being good in sealing effect and convenient and fast to mount.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com