Patents

Literature

259results about How to "Convenient grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

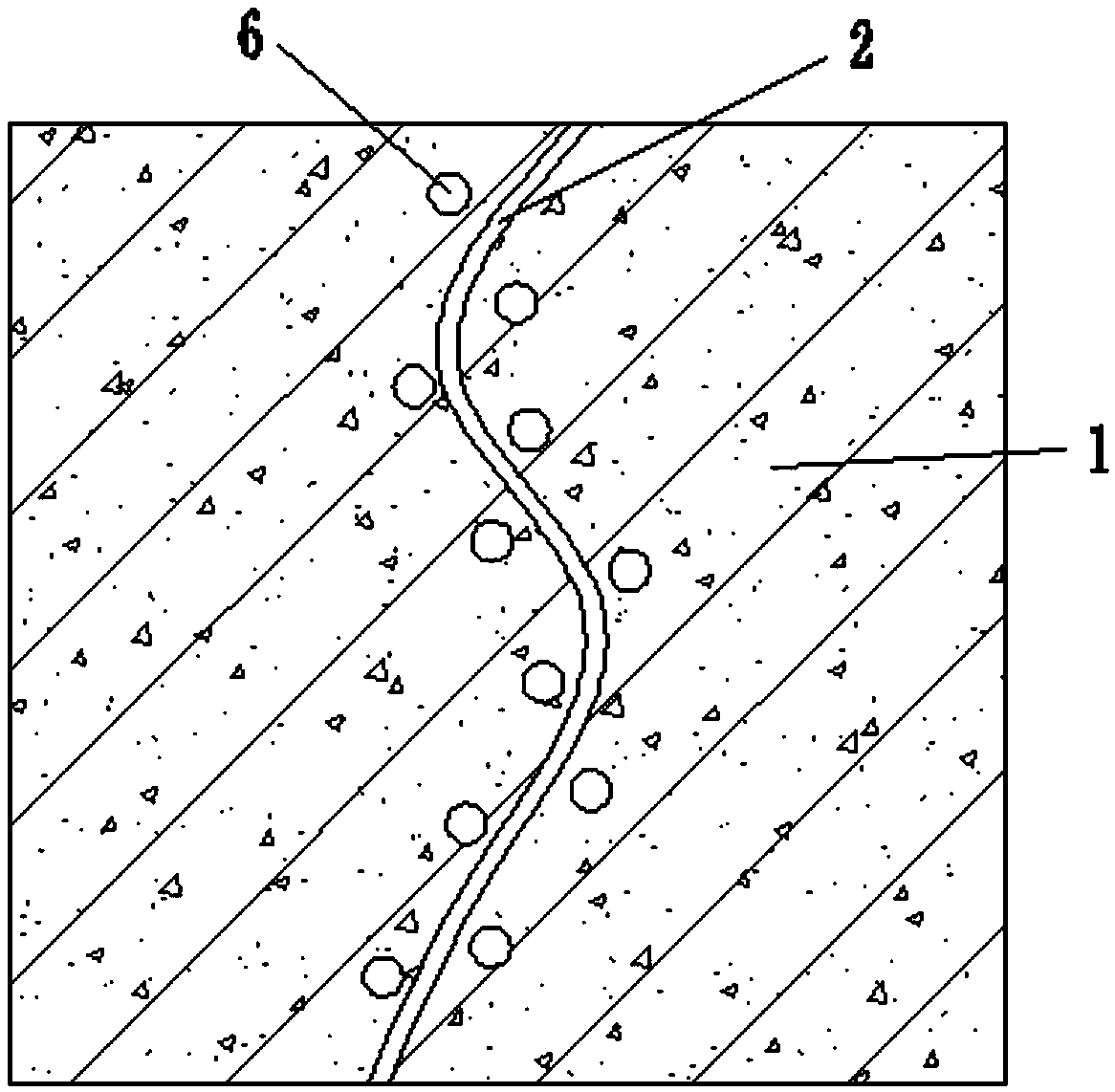

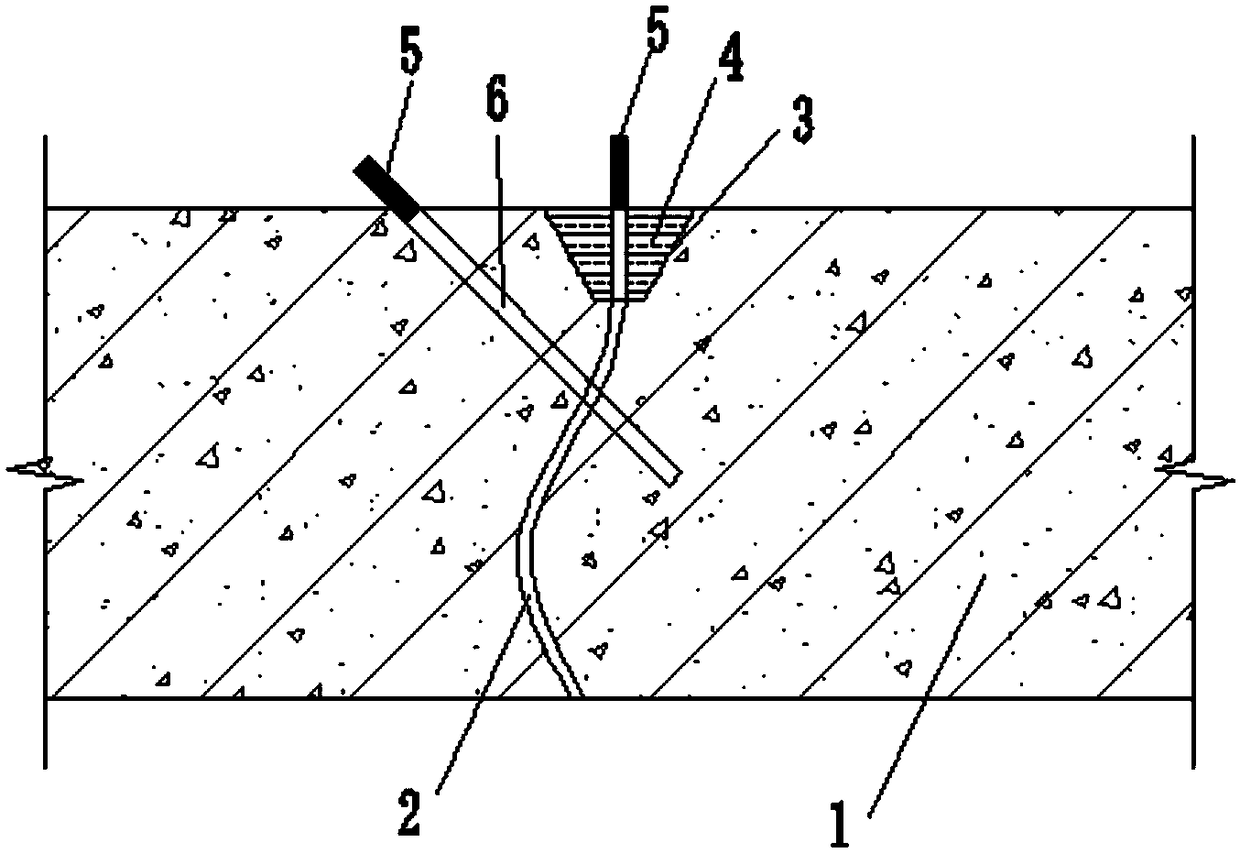

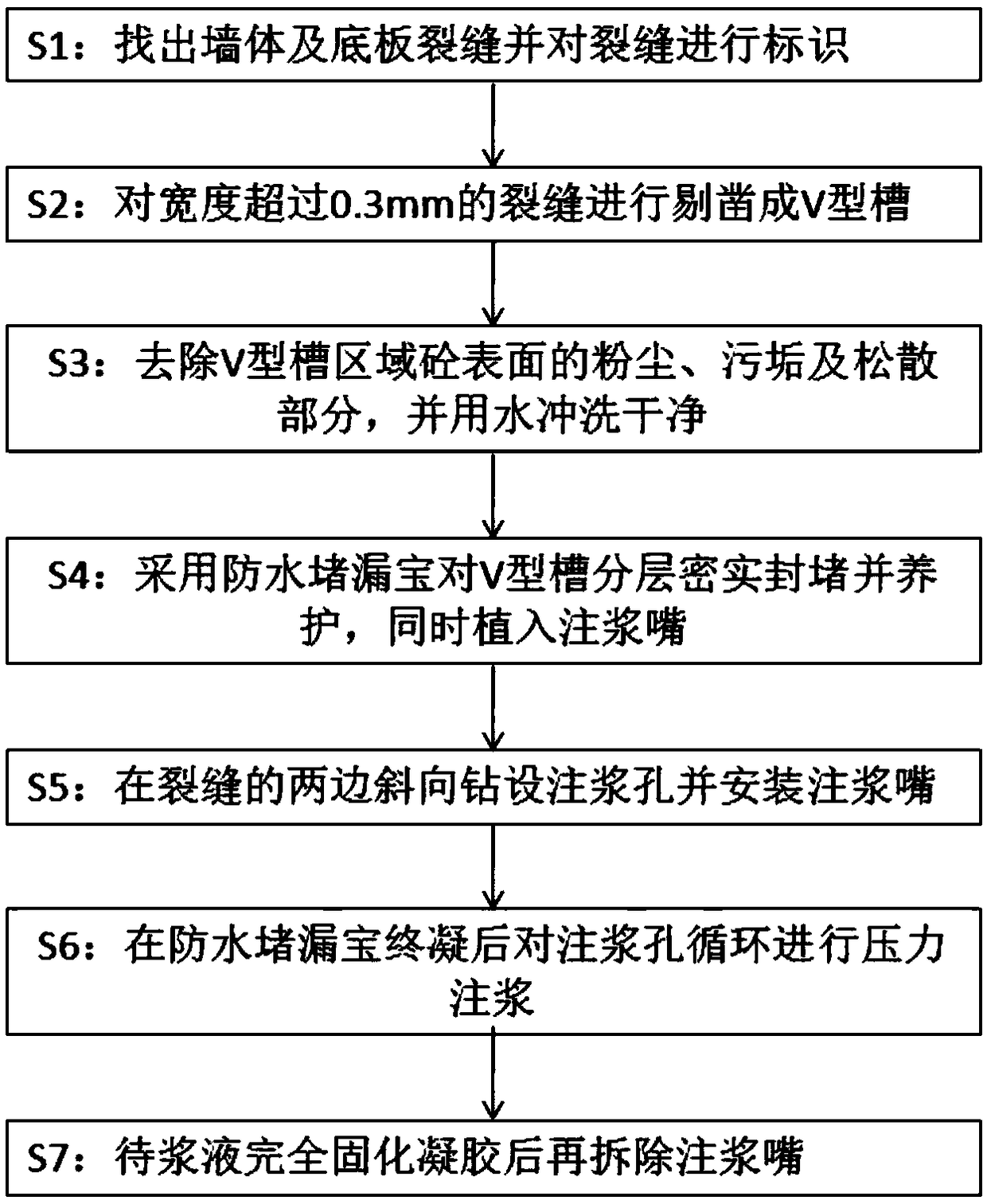

Concrete wall and bottom plate water seepage crack repair method

ActiveCN109457735AAvoid water leakage accidentsReduce water pressureArtificial islandsProtective foundationSlurryPressure grouting

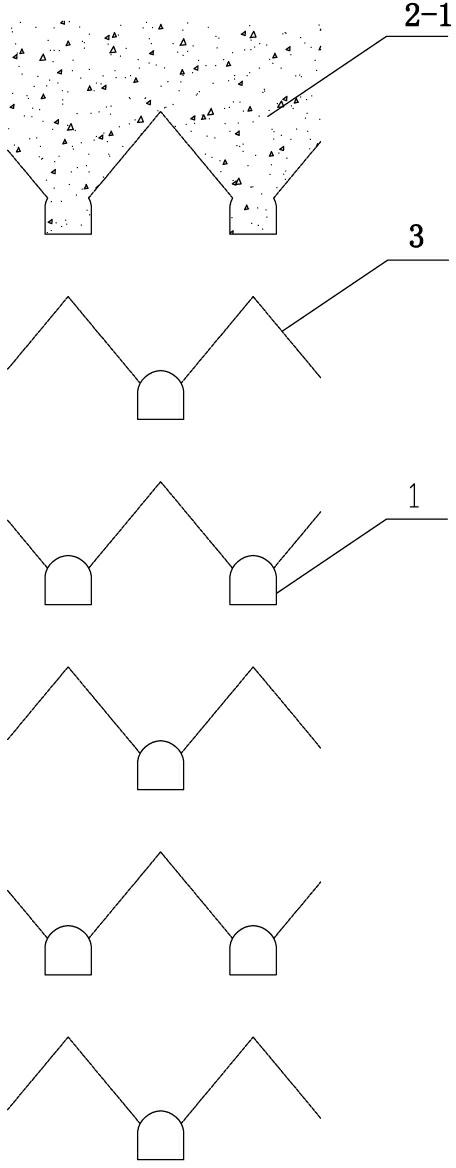

The invention discloses a concrete wall and bottom plate water seepage crack repair method. The method comprises the following steps that wall and bottom plate cracks are found out and marked; the crack of which the width is larger than 0.3 mm is subjected to digging into a V-shaped groove; dust, dirt and loose parts of the surface of concrete in the V-shaped groove area are removed and washed with water; layered dense blocking and maintenance are conducted on the V-shaped groove through a waterproof leaking stoppage part, and meanwhile, a grouting nozzle is implanted; grouting holes are obliquely drilled in the two sides of the crack, and a grouting nozzle is installed; and after final set of the waterproof leaking stoppage part, the grouting holes are circularly subjected to pressure grouting; and after grout is completed solidified, the grouting nozzles are disassembled. According to the method, by obliquely drilling the grouting holes in the two sides of the crack and installing the grouting nozzle, a plurality of channels communicating with the interior of the crack are formed, the water pressure of the interior of the crack can be reduced, grout can be injected into the crackconveniently in the later period, through permeation of the grout, the water seepage crack is sealed after the grout is solidified, and accordingly, the water seepage crack leaking stoppage effect isachieved so that underground construction water seepage accidents can be avoided.

Owner:中铁二十三局集团第四工程有限公司

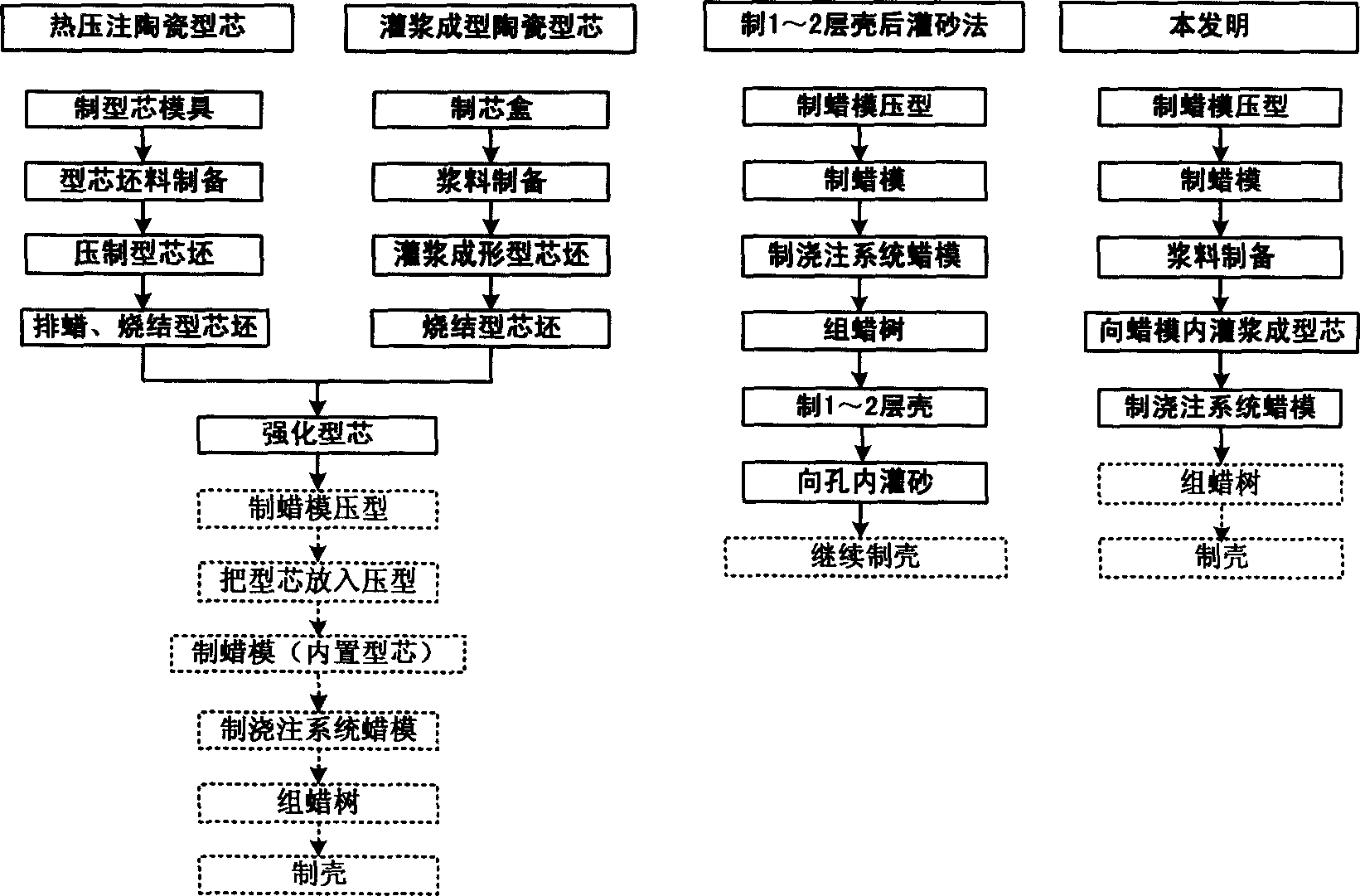

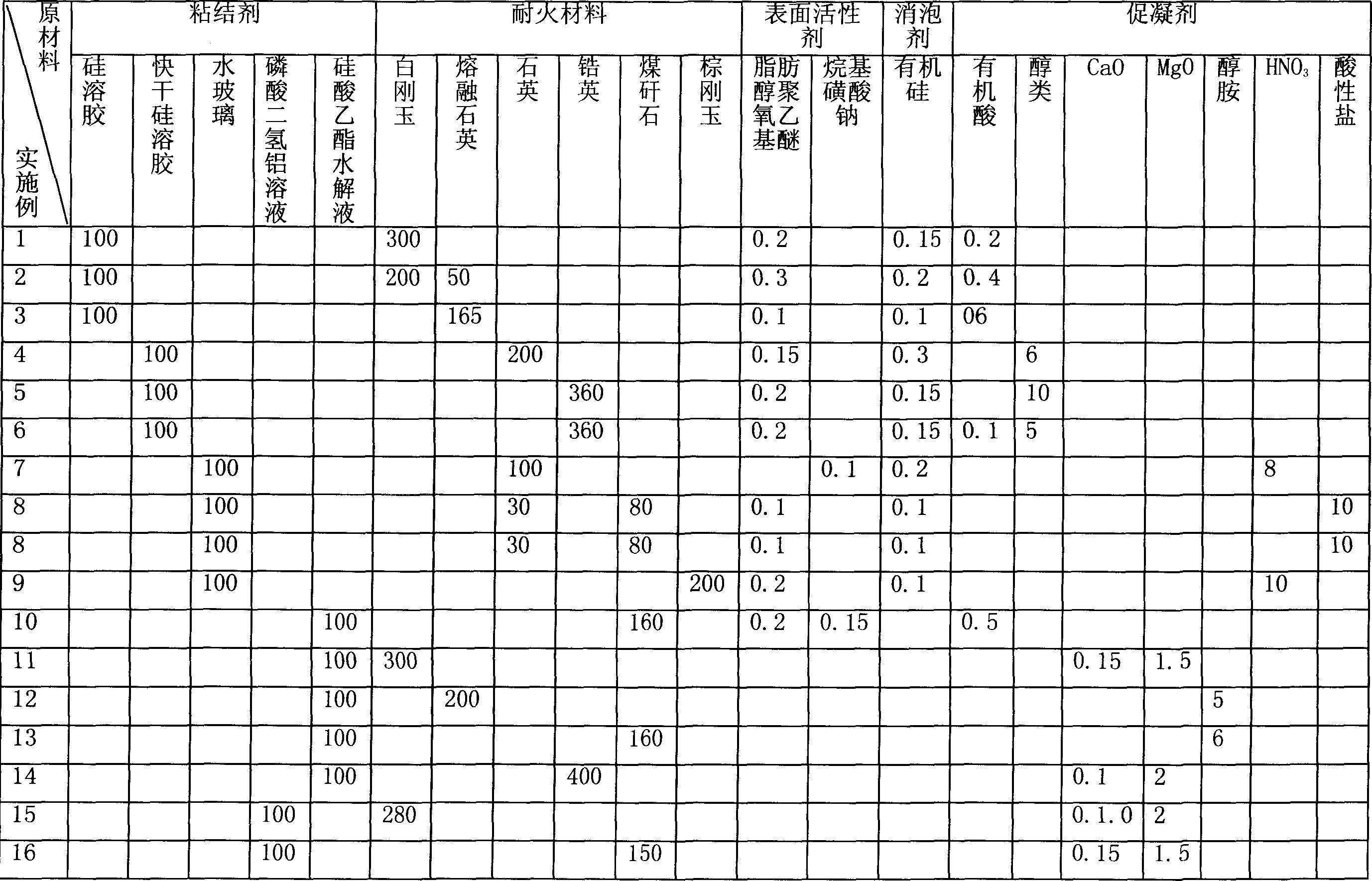

Method for direct production of core in narrow groove and blind hole of wax mould

The invention relates to a method for directly producing core inside the narrow groove and blind hole of wax hole, which provides a method that casting core with simple molding pattern. Said method fills the slurry with accelerant into the forward groove and blind hole before assembling the wax mold to prepare the core, which comprises: preparing wax mold to be compressed; preparing wax mold; adding raw materials at the mass percentages as: fireproof material : accelerant : surface active agent : defoaming agent as 100 : (100-40) : (0.1-10) : (0.1-0.3) : (0.1-0.3) to prepare the slurry; then filling into the wax mold to be shaped; being solidified to attain the core inside the narrow groove and blind hole. The inventive method is simple without special device and it can save energy, reduce cost, with shorten producing period.

Owner:TSINGHUA UNIV

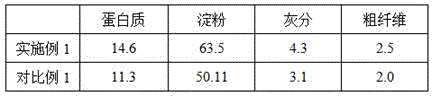

Self-heat-insulation light weight wallboard containing hollow ceramsites and preparation method thereof

ActiveCN104129959AUniform porous structureReduce voidsSolid waste managementCeramicwareFiberFoaming agent

The invention discloses a self-heat-insulation light weight wallboard containing hollow ceramsites and a preparation method thereof, and belongs to the technical field of building materials. The self-heat-insulation light weight wallboard comprises the following components by mass: 20-60 parts of a cementitious material, 5-30 parts of a lightweight aggregate, 0.05-0.5 part of a composite early strength agent, 2-8 parts of a foaming agent, 0.02-0.14 part of a foam stabilizing agent, 0.1-0.8 part of a catalyst, 0.05-0.6 part of a binder, 0.05-0.6 part of straw fiber and 15-30 parts of water. The preparation method is as follows: putting the cementitious materials, the straw fiber and the binder together, then mixing, then orderly adding the water, the foaming agent, the stabilizer and the catalyst, stirring to obtain a slurry mixture, adding hollow ceramsites, obturator perlite and expanded vermiculite in saturated surface-dry condition, stirring, then using an injection pump to inject into a wallboard forming machine for molding, and 3-5 hours after the concrete is solidified and hardened, demoulding to obtain the self-heat-insulation light weight wallboard containing the hollow ceramsites. The self-heat-insulation light weight wallboard containing the hollow ceramsites has energy saving, environmentally-friendly, fire insulating, sound-insulation, high-strength, lightweight, waterproof, thermal-insulation, corrosion-resistant, durable and other characteristics.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

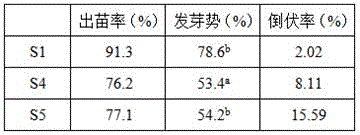

High-yield cultivation method for winter wheat in Huanghuaihai region

ActiveCN104663239AIncrease productionImprove survival ratePlant cultivationCultivating equipmentsDiseasePotassium

The invention relates to a high-yield cultivation method for winter wheat in the Huanghuaihai region. The high-yield cultivation method comprises the following five main steps: (1) performing soil preparation and sowing; (2) managing before winter; (3) managing in spring; (4) managing in middle and later stages; and (5) harvesting. According to the technical mode of selecting a winter variety, returning straw to the field, applying fertilizers, performing deep loosening and deep digging, performing rotary tillage and soil preparation, performing broad accurate sowing, mechanically pressing, watering in winter, backwards shifting nitrogen fertilizers, spraying once to prevent pests and diseases, dry and hot wind and lodging, and mechanically harvesting, the high-quality wheat variety which is high in yield, stable in yield and strong in lodging resistance is selected, the soil fertility is raised, seeds are sowed at proper time, the proper pre-winter management is performed, the survival rate of the wheat seedlings is increased, and the uneven growth is prevented; organic fertilizers and inorganic fertilizers are reasonably combined, the technology of backwards shifting the nitrogen fertilizers and applying potassium in stages is applied, the nutrient needs of the wheat at different stages are sufficiently guaranteed, a reasonable group structure is established, the spikelet floret degeneration is reduced, the kernels per spike are increased, the functional period of green leaves is prolonged, the grain filling is promoted, the thousand seed weight is increased and the high-yield breakthrough is realized.

Owner:SHANDONG AGRI SUSTAINABLE DEV INST

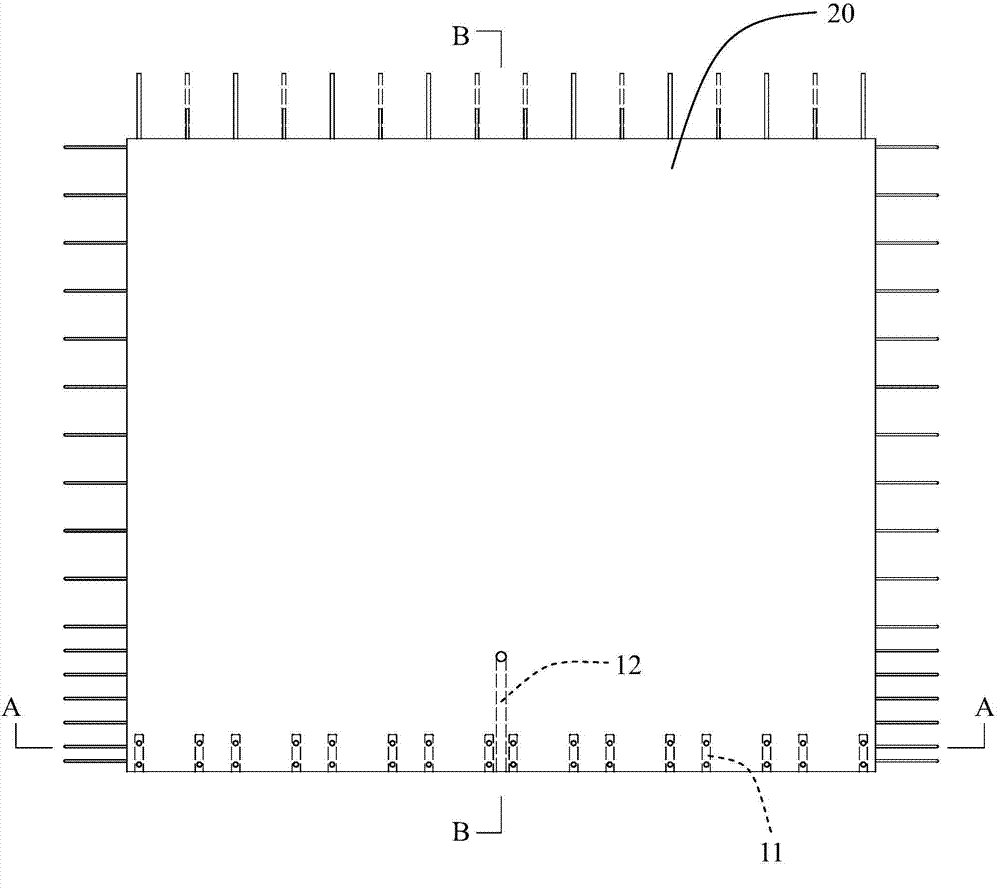

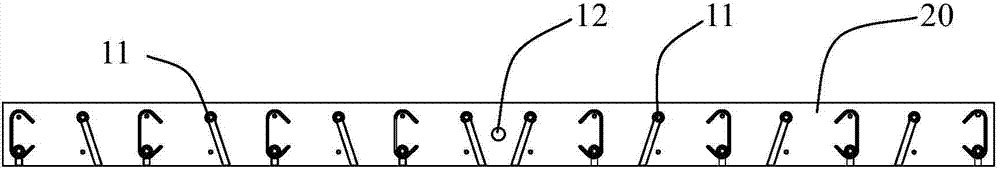

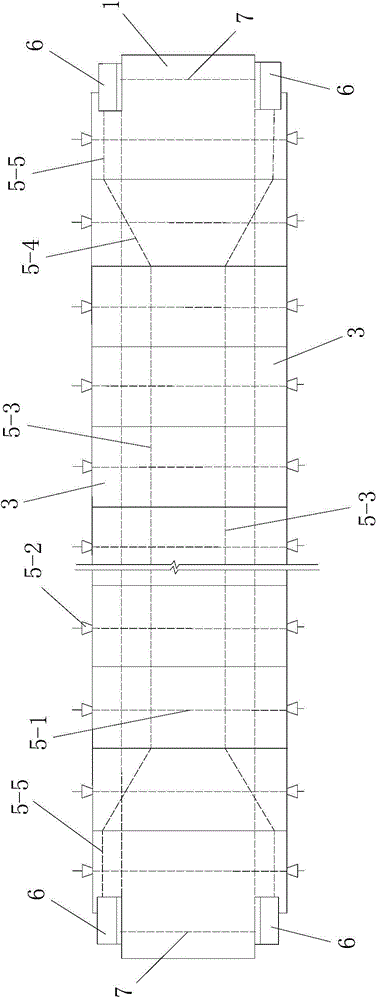

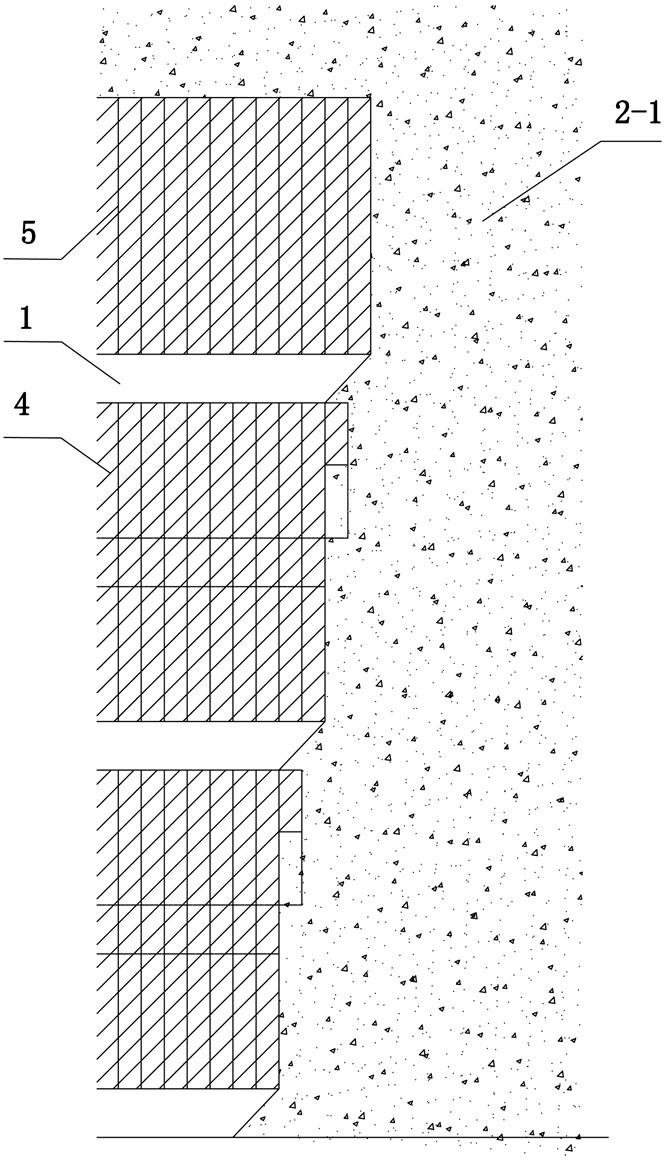

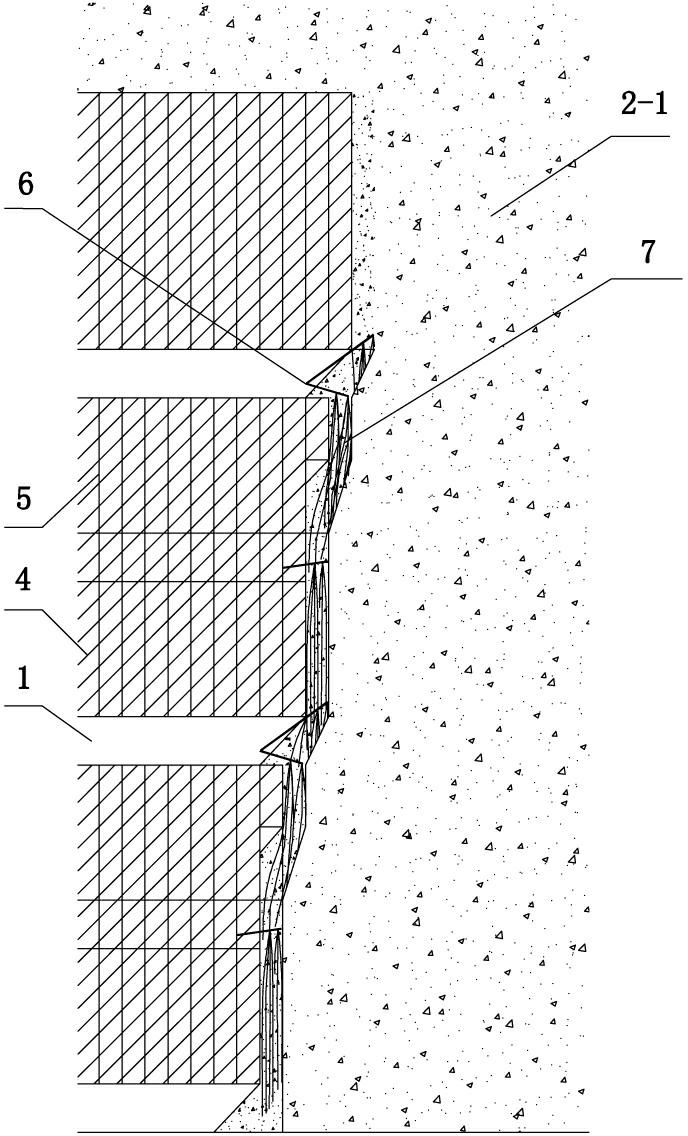

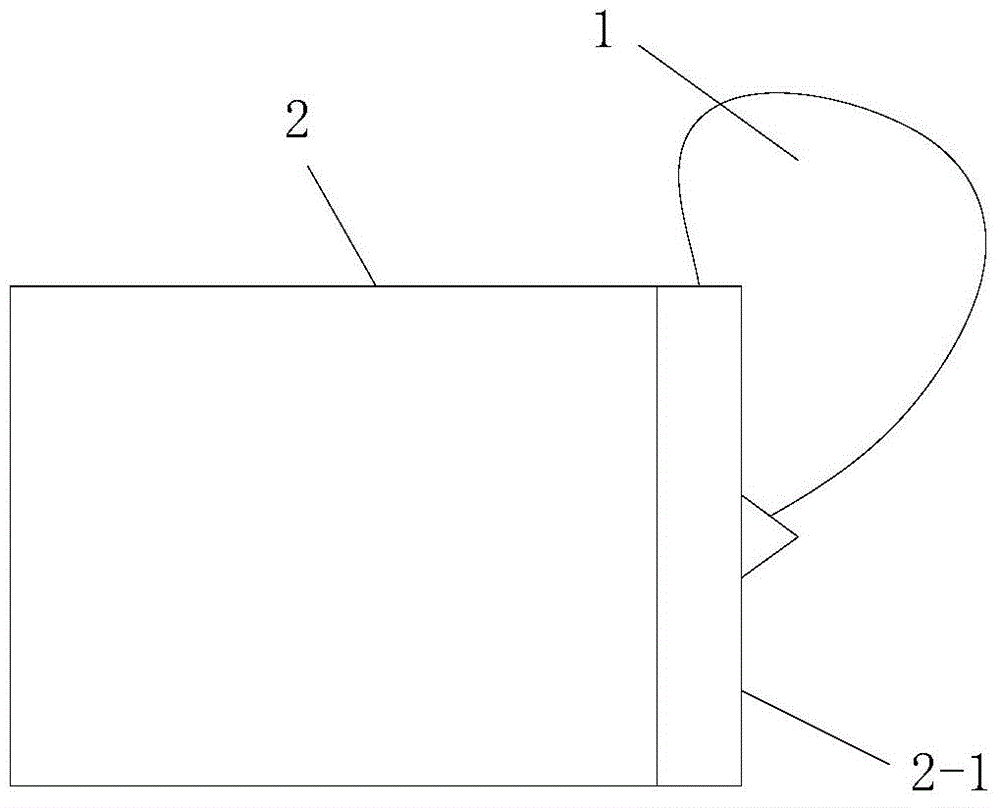

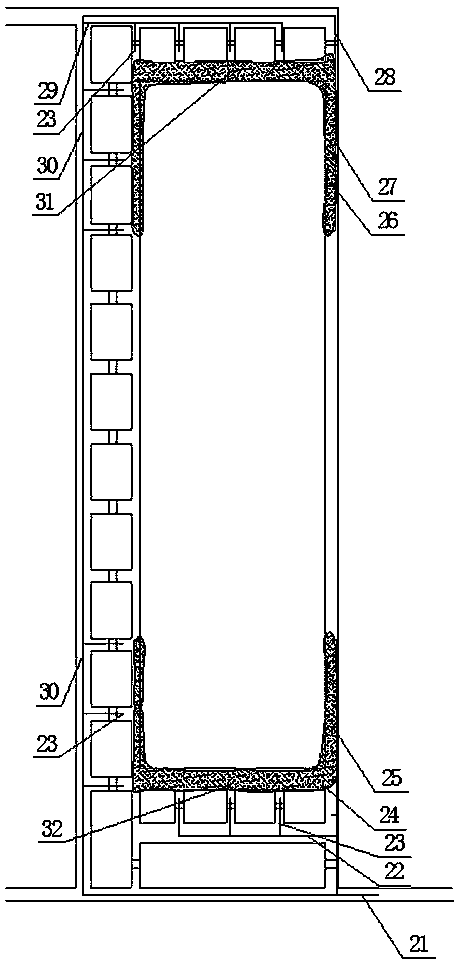

Grouting connecting structure of prefabricated part and construction method thereof

The invention discloses a grouting connecting structure of a prefabricated part and a construction method thereof. The grouting connecting structure comprises grouting sleeves and an observation pipe, wherein the grouting sleeves are arranged at the bottom of the prefabricated part in an embedded mode and serve for insertion of butt-joint reinforcing steel bars, a grouting port is formed in the lower portion of the sleeve wall of each grouting sleeve, a grout discharge port is formed in the upper portion of the sleeve wall of each grouting sleeve, and grouting holes and grout discharge holes corresponding to the grouting ports and the grout discharge ports are formed in the prefabricated part; the observation pipe is arranged at the bottom of the prefabricated part in an embedded mode, a pipe port at a first end of the observation pipe is formed in the end face of the bottom of the prefabricated part, a pipe port at a second end of the observation pipe is formed in the surface of the side wall of the prefabricated part, and the arrangement location of the pipe port located at the second end of the observation pipe is higher than the top positions of the grouting sleeves. According to the grouting connecting structure of the prefabricated part and the construction method thereof, by pre-embedding the observation pipe at the lower end of the prefabricated part, the grouting sleeves and the observation pipe are filled with grout, by means of the intrinsic pressure of the filling grout, automatic grout replenishment is completed when the liquid level at the tops of the grouting sleeves declines, and the observation pipe is utilized for raising the grout liquid level, so that it is convenient for workers to make observation, the grout is replenished in time, and the grout compactness is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Dedicated fertilizer for promoting grain-filling in rice and preparation method therefor

InactiveCN104987251AAlleviate supply shortagesConvenient groutingFertilizer mixturesSodium BentonitePhosphoric acid

A dedicated fertilizer for promoting grain-filling in rice and a preparation method therefor, belonging to the technical field of fertilizers for agricultural production. The fertilizer is prepared by using the following raw materials in parts by weight: 40-50 parts of urea, 18-30 parts of superphosphate, 12-27 parts of potassium chloride, 7-15 parts of potassium silicate, 3-5 parts of bentonite, 4-11 parts of sodium tetraborate decahydrate, 0.1-0.3 parts of N-(N-butyl)thiophosphoric triamide, 0.2-0.8 parts of matrine extract, 0.5-1.1 parts of kudzu extract and 0.5-1.0 parts of aloe extract. A product of the present invention can remarkably promote yield when applied to rice, the production cost is reduced, and the utilization rate of nitrogen fertilizer is improved.

Owner:CHINA NAT RICE RES INST

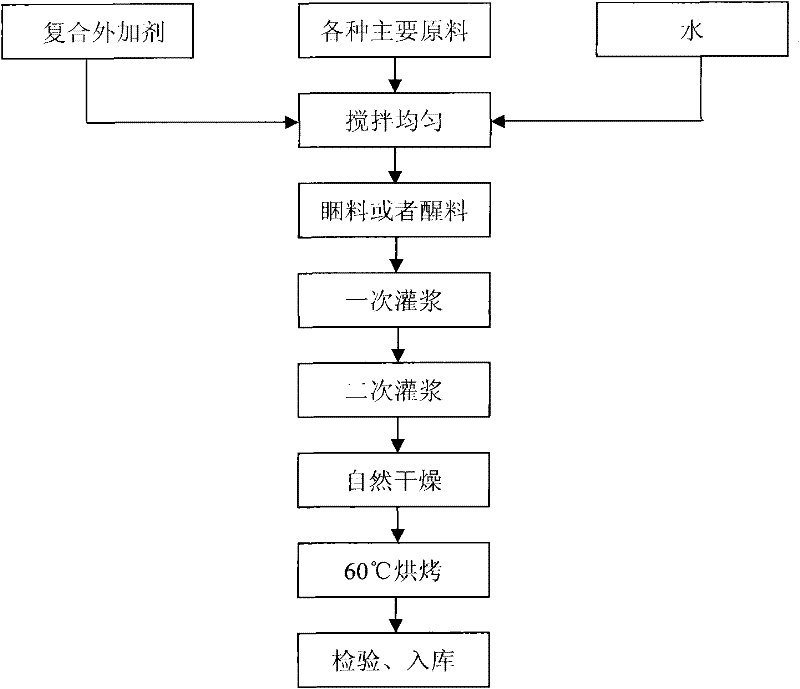

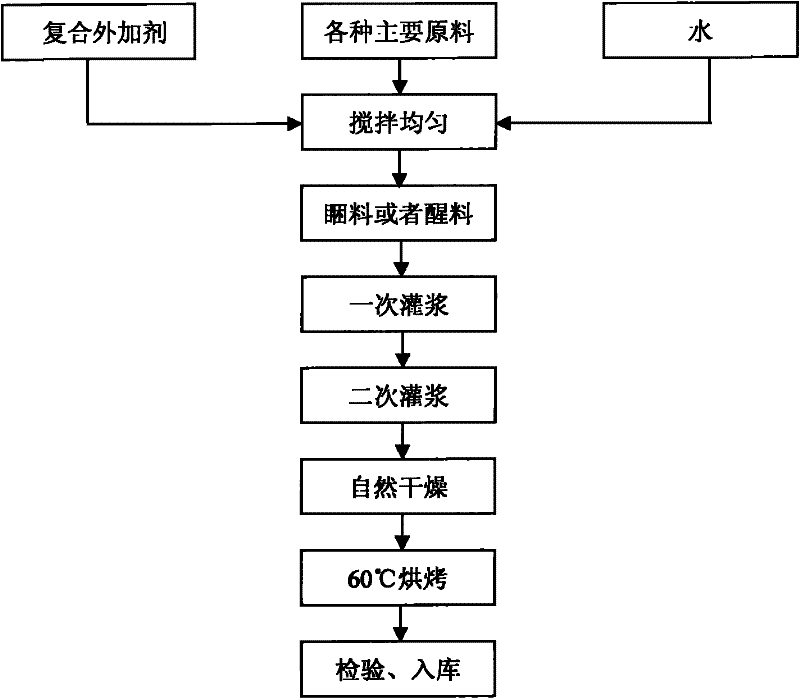

Early-strength quick-drying refractory mud filling material with good insulativity

The invention discloses an early-strength quick-drying refractory mud filling material with a good insulativity. The filling material is prepared through the following steps: adding water in 100 parts of main raw material and 1-10 parts of composite additives, mixing, ageing mixture or fermenting, grouting, naturally drying and baking, wherein the main raw material is a mixture of sintered mullite, quartz sand powder, alumina micropowder and pure calcium aluminate cement; and the composite additives are lignosulfonate, sodium carboxymethylcellulose and one substance or a mixture of two substances selected from subnano alumina micropowder with a grain size of 0.25-0.50 mu m, silicon micropowder with a grain size of 1-2 mu m, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyphosphate. The filling material has good properties such as good early strength, rapid consolidation speed, no moisture regain and good insulativity, dose not corrode metals, can be widely applied to a metallurgy smelting high temperature sensor and a rapid temperature-measuring element to be used as an insulation material.

Owner:马鞍山江润冶金有限责任公司

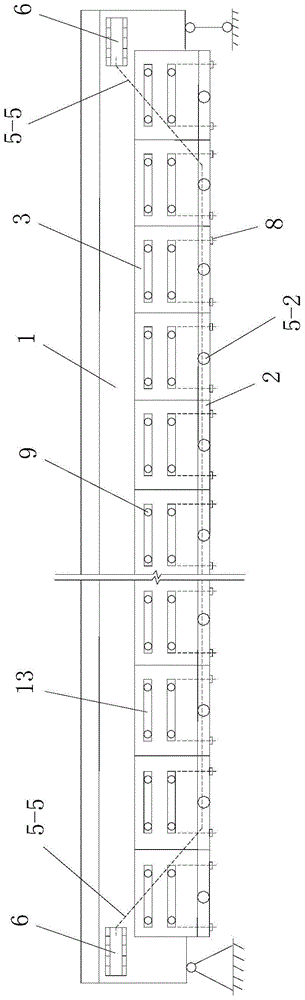

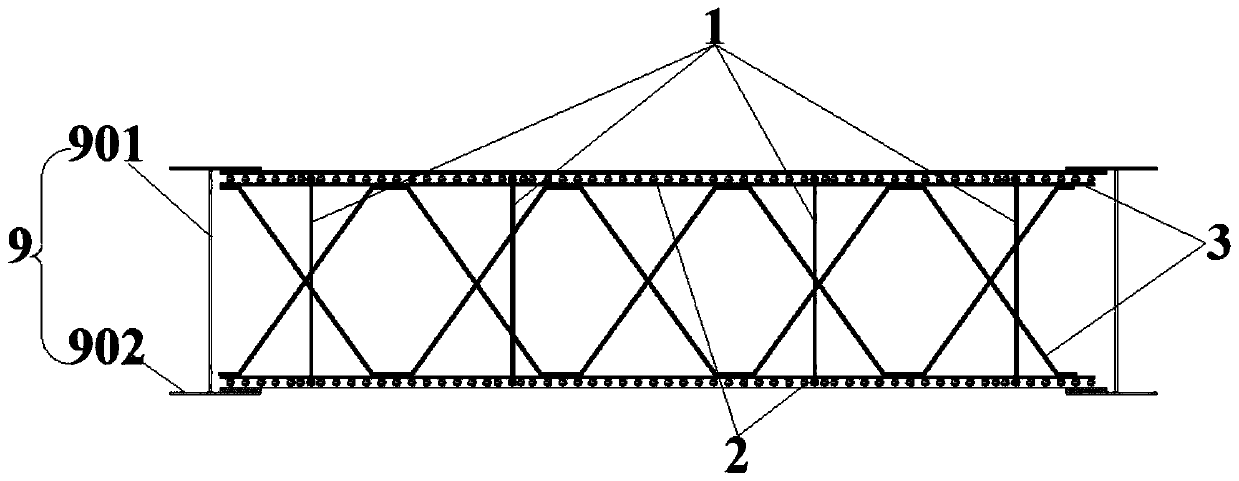

Reinforced concrete girder bridge girder reinforcing structure and method

ActiveCN104947603ASimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:XIAN UNIV OF SCI & TECH

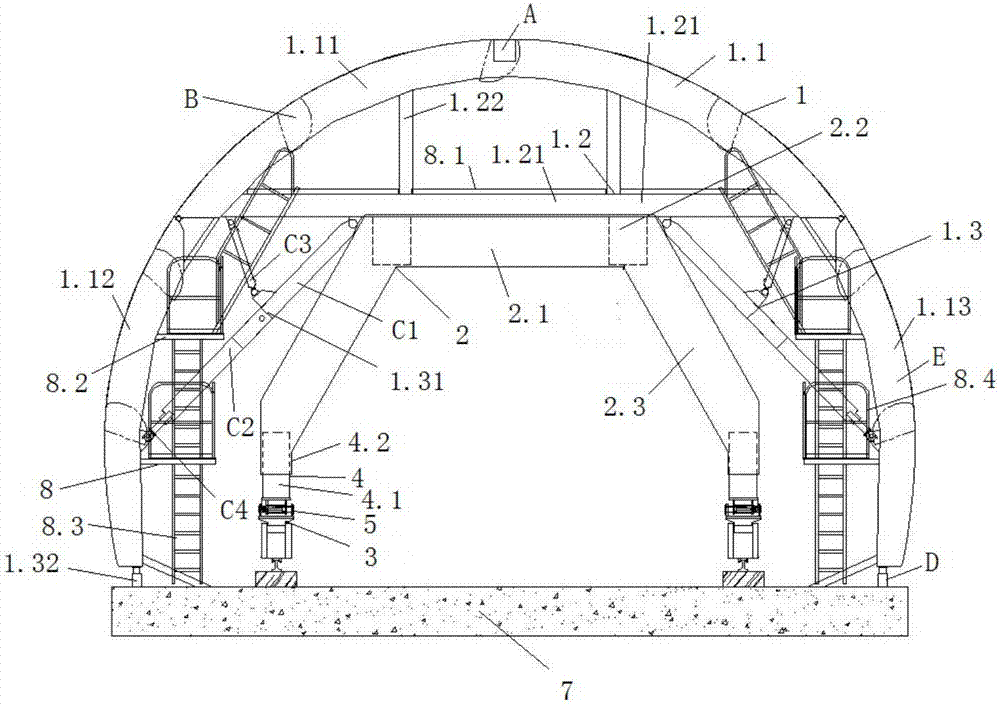

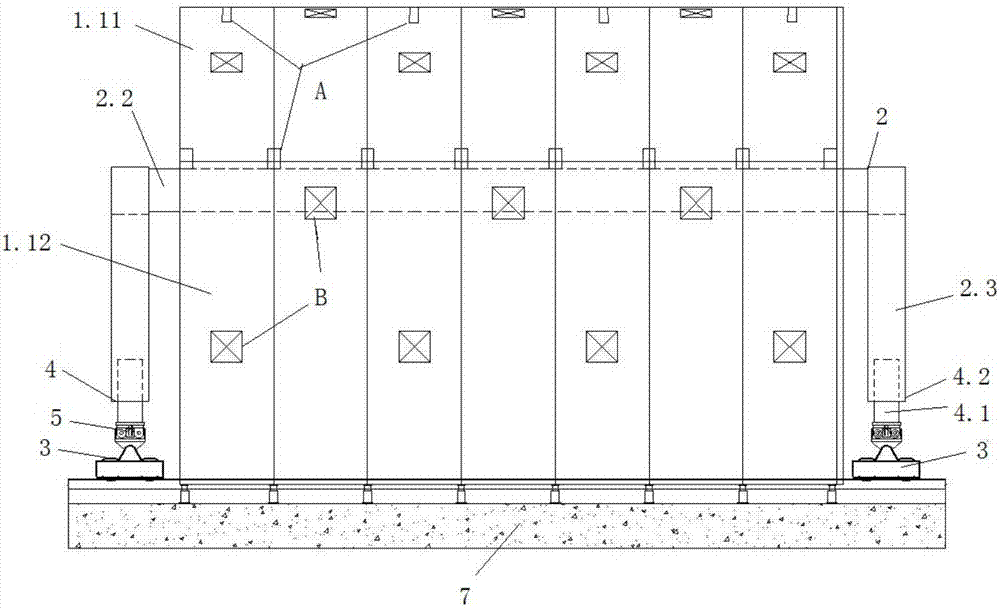

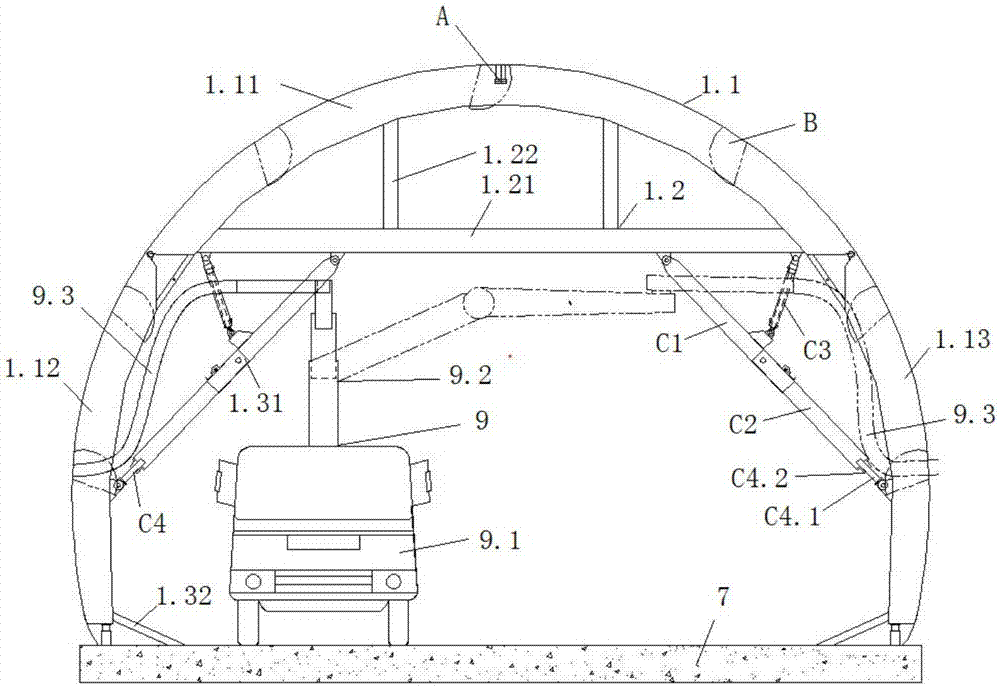

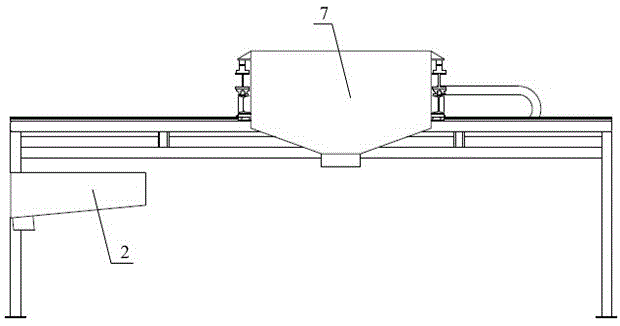

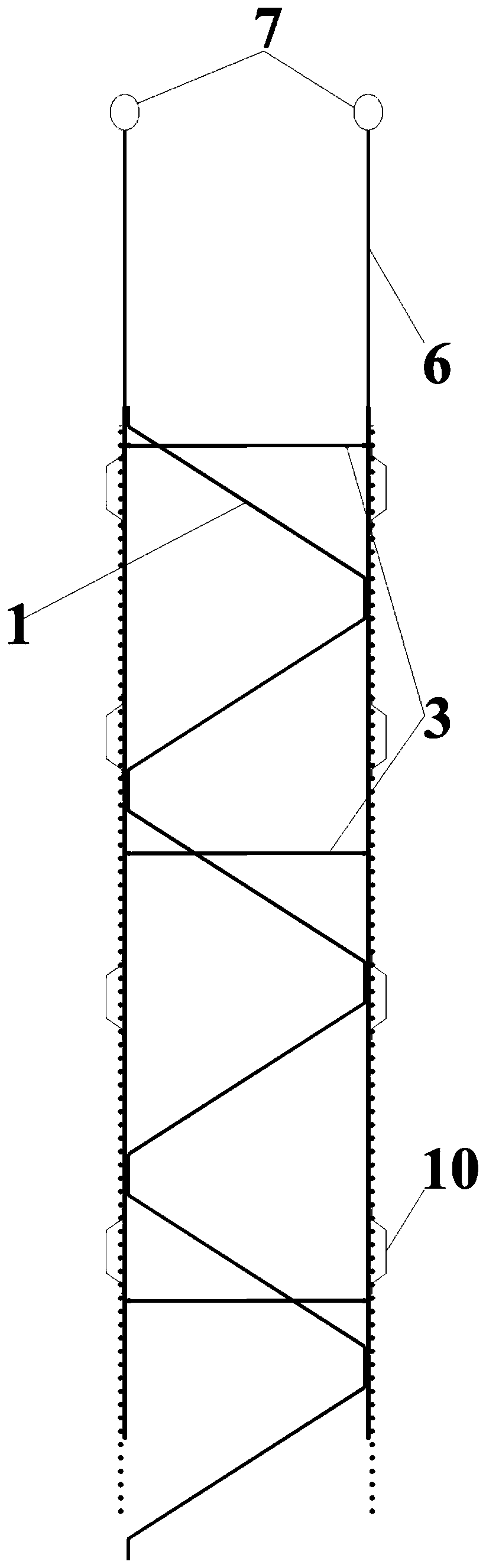

Lining construction method and lining trolley thereof

PendingCN107965337AReduce typesReduce in quantityUnderground chambersTunnel liningArchitectural engineeringPortal frame

The invention provides a lining construction method. The lining construction method includes equipment of a lining trolley and a concrete pumping mechanism, wherein the lining trolley comprises a formwork system, a portal frame system and a walking mechanism. The lining construction method comprise the following steps that the walking mechanism drives the portal frame system to convey formwork system single pieces to a construction site; the portal frame system splits the formwork system single pieces; the concrete pumping mechanism conveys concrete into pouring gates or working windows of theformwork system single pieces for lining construction; after lining construction of the construction site is completed, the walking mechanism drives the portal frame system to convey the formwork system single pieces to a next construction site. During application of the lining construction method, the combination of the portal frame system and the walking mechanism can serve as a standard component, which can be combined with a number of sets of formwork systems simultaneously to achieve simultaneous construction of multiple sets of formwork system single pieces, thereby greatly improving the construction efficiency. The invention also provides the lining trolley. The lining trolley is concise in structure and small in the number of parts; the formwork system single pieces serve as majorload bearing parts and accordingly are less prone to deformation and shifting during a pouring process.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

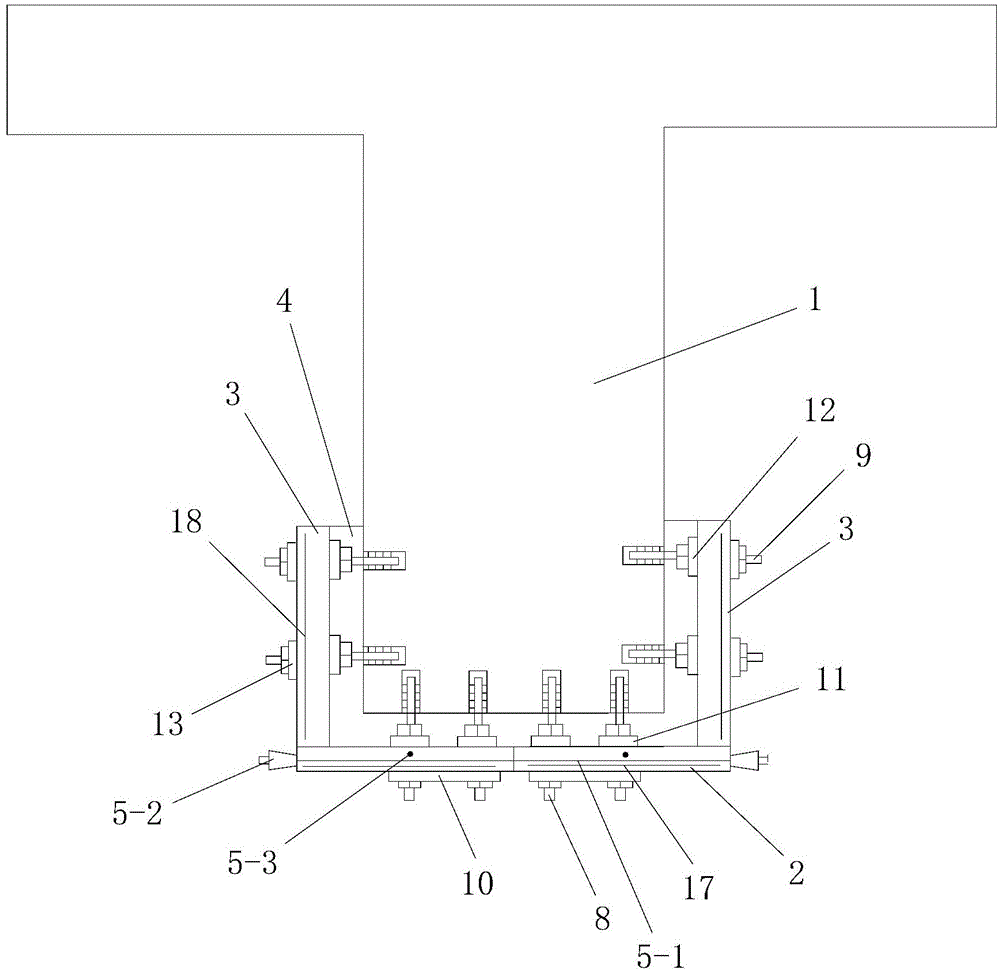

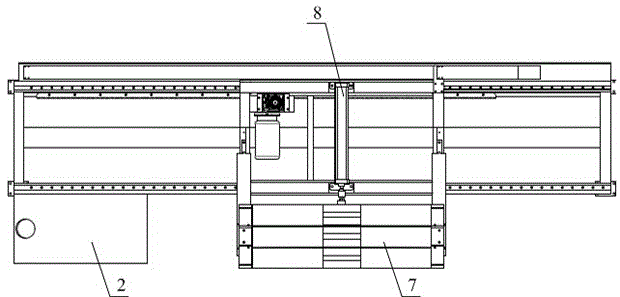

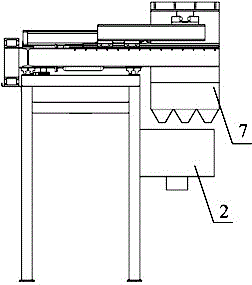

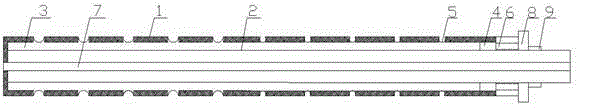

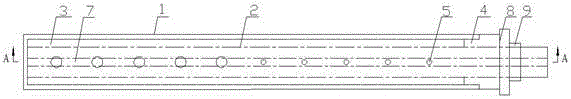

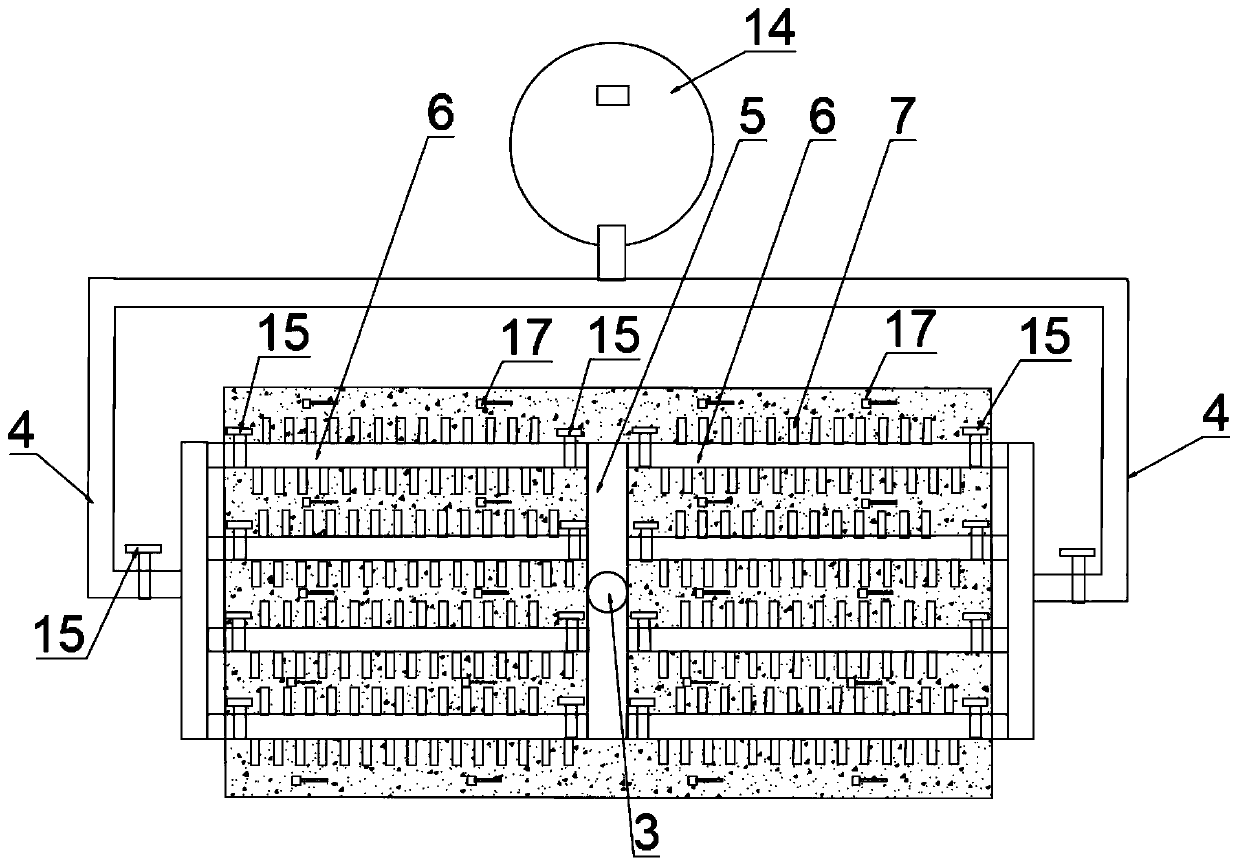

Quantitative uniform grouting machine

The invention discloses a quantitative uniform grouting machine. The quantitative uniform grouting machine comprises a rack component, a water collecting tank, first linear guide rails, a translation rack, a motor assembly, second linear guide rails, an equivalent grouting barrel and an air cylinder, wherein the motor assembly is used for driving the translation rack, and the air cylinder is used for driving the equivalent grouting barrel; the water collecting tank is arranged on the lower part of the rack component, and the translation rack is fixed to the top of the rack component by virtue of the first linear guide rails and can slide back and forth along the first linear guide rails; the motor assembly, the air cylinder and the second linear guide rails are arranged on the translation rack, and the equivalent grouting barrel is fixed to the translation rack by virtue of the second linear guide rails and can slide back and forth along the second linear guide rails; the first linear guide railsare perpendicular to the second linear guide rails. According to the quantitative uniform grouting machine, the first linear guide railsare perpendicular to the second linear guide rails, so that the equivalent grouting barrel flexibly moves, the quantitative uniform grouting machine has the advantages of simple structure, convenience in operation and strong flexibility, and a plurality of mold cavities in a mold can be quantitatively and uniformly grouted.

Owner:南通舜腾纺织品有限公司

Top-filled pillarless cornice end-wall sublevel caving method extraction technique

ActiveCN102619514APrevent collapseControl liquidityUnderground miningSurface miningLiquid mediumCrushed stone

The invention relates to a top-filled pillarless cornice end-wall sublevel caving method extraction technique. The pillarless cornice end-wall sublevel caving method is characterized by comprising the following steps of: (1) after ore drawing is completed, stretching a grouting tube deep into overlaying rocks by using a grouting device at both sides and front part of the end part of a mining roadway besides the lowest sublevel roadway, injecting and permeating one liquid medium into overlaying rocks surrounding the ore drawing port and the end wall, laying aside for 1-3 days, eliminating excessive water in the overlaying rocks, and performing blasting and actual mining in the next ore caving step; and (2) filling tailings and broken stone into the top of a gob so as to prevent surface subsidence. Compared with the traditional underground extraction method, the pillarless cornice end-wall sublevel caving method solves the problems of great loss dilution and surface subsidence of the caving method, has lower loss dilution index than the open-stope method and the filling method and also has the advantages of simple structure, large production capacity and high production efficiency.

Owner:ANSTEEL GRP MINING CO LTD

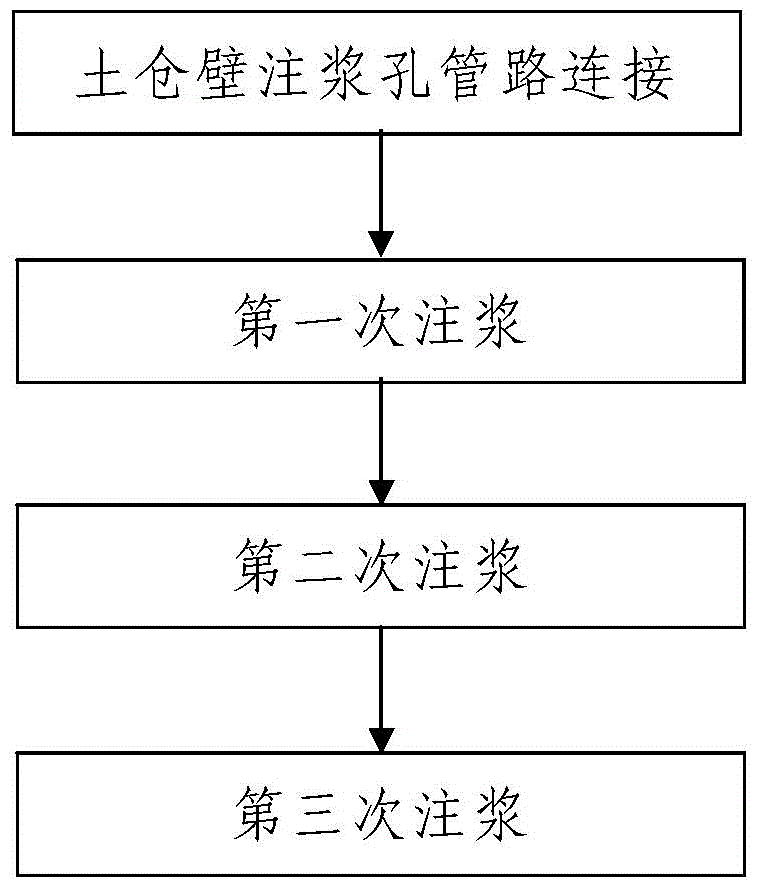

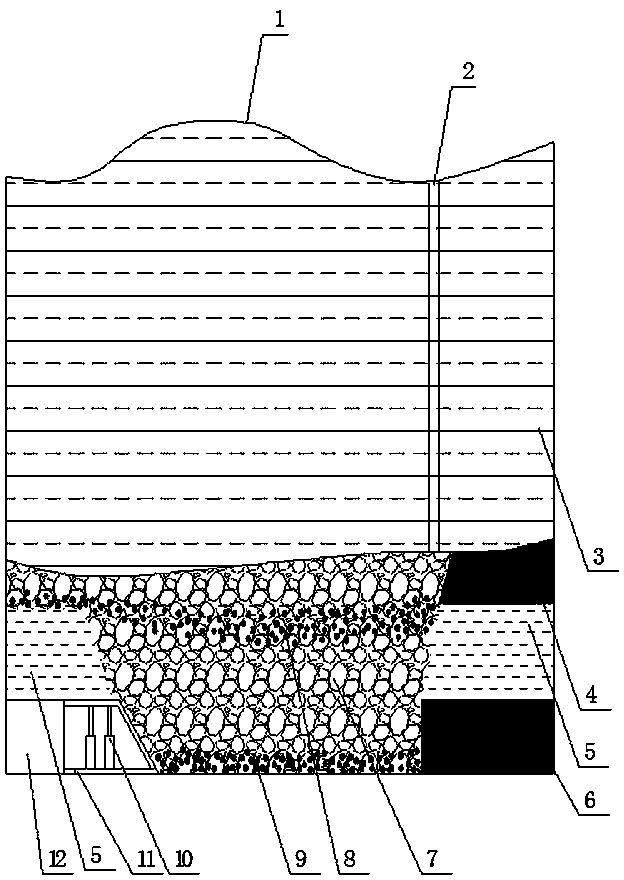

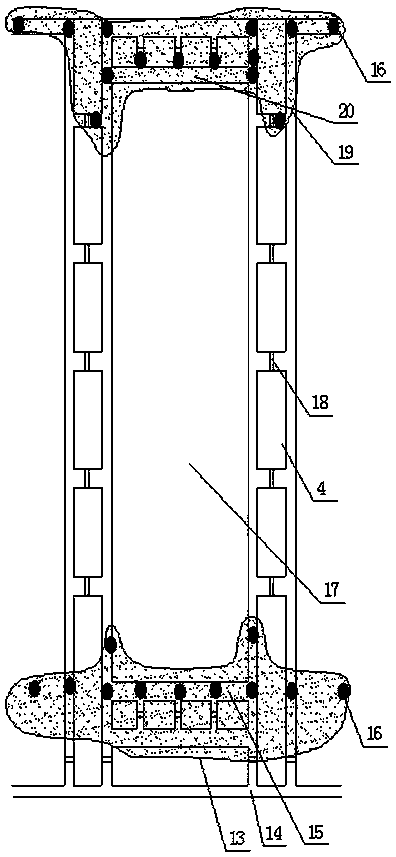

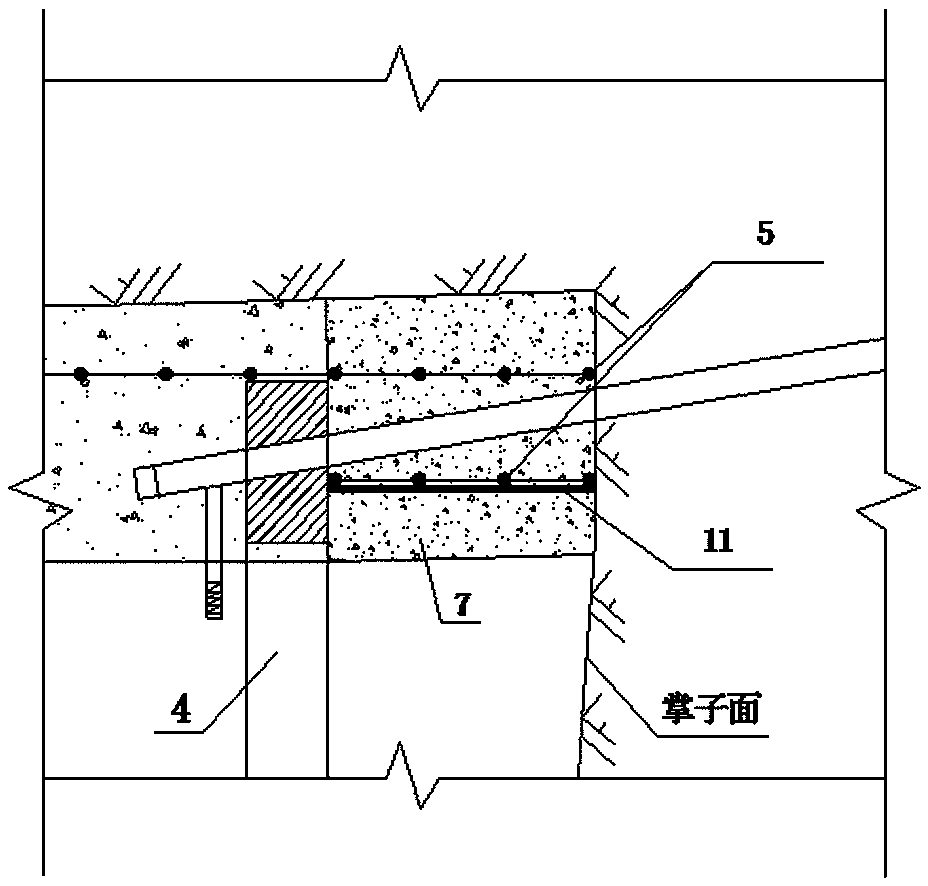

Tunnel face cavity processing method for shield tunnel construction

ActiveCN104481548AThe method steps are simpleLow input costUnderground chambersTunnel liningCement slurryShield tunnelling

The invention discloses a tunnel face cavity processing method for shield tunnel construction. The tunnel face cavity processing method for the shield tunnel construction includes steps that 1, primary grouting, to be specific, using a grouting system to fill first cement mortar to the lower part of the cavity from the top to bottom through a soil warehouse, wherein the first grouting size is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 45-55: 45-55: 180-220: 540-660: 360-440; 2, secondary grouting, to be specific, using the grouting system to fill second cement mortar to the middle of the cavity, wherein the second cement mortar is composed of cement, bentonite, coal ash, sand and water according to the weight ratio of 90-110: 68-82: 200-280: 540-660: 420-500; 3, tertiary grouting, to be specific, using the grouting system to fill cement slurry to the upper part of the cavity. The tunnel face cavity processing method for the shield tunnel construction is simple in steps, reasonable in design, easy and convenient to operate, low in invested cost, good in use effect and capable of solving the problems of a traditional grouting strengthening method.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

Method for preventing spontaneous combustion of coal in upper and lower levels of goafs in contiguous coal seam groups

InactiveCN107642375AAvoid the disadvantages of conventional groutingIncreased grout flowDust removalFire preventionCoal spontaneous combustionEngineering

The invention relates to the field of coal mine fire prevention, in particular to a method for preventing spontaneous combustion of coal in upper and lower levels of goafs in contiguous coal seam groups in lower layer of coal seam of low seam thickness and small coal seam spacing, in the mining and recovery process. The method for preventing spontaneous combustion of coal in the upper and lower levels of goafs in the contiguous coal seam groups includes the following steps: determining coal spontaneous combustion prevention and control key areas in the upper and lower goafs of the contiguous coal seam groups; carrying out surface drilling and grouting processes in the coal spontaneous combustion prevention and control key areas before mining the lower layer coal seam in the contiguous coalseam groups so as to completely cover the coal left in the upper goafs; after 500m below the lower layer of the contiguous coal seam groups is mined, and 15 days after the completion of mining, connection roadway closed grouting hole grouting and return airway embedded grouting pipe grouting are carried out in the coal spontaneous combustion prevention and control key areas in the upper and lowergoafs of the contiguous coal seam groups.

Owner:TAIYUAN UNIV OF TECH

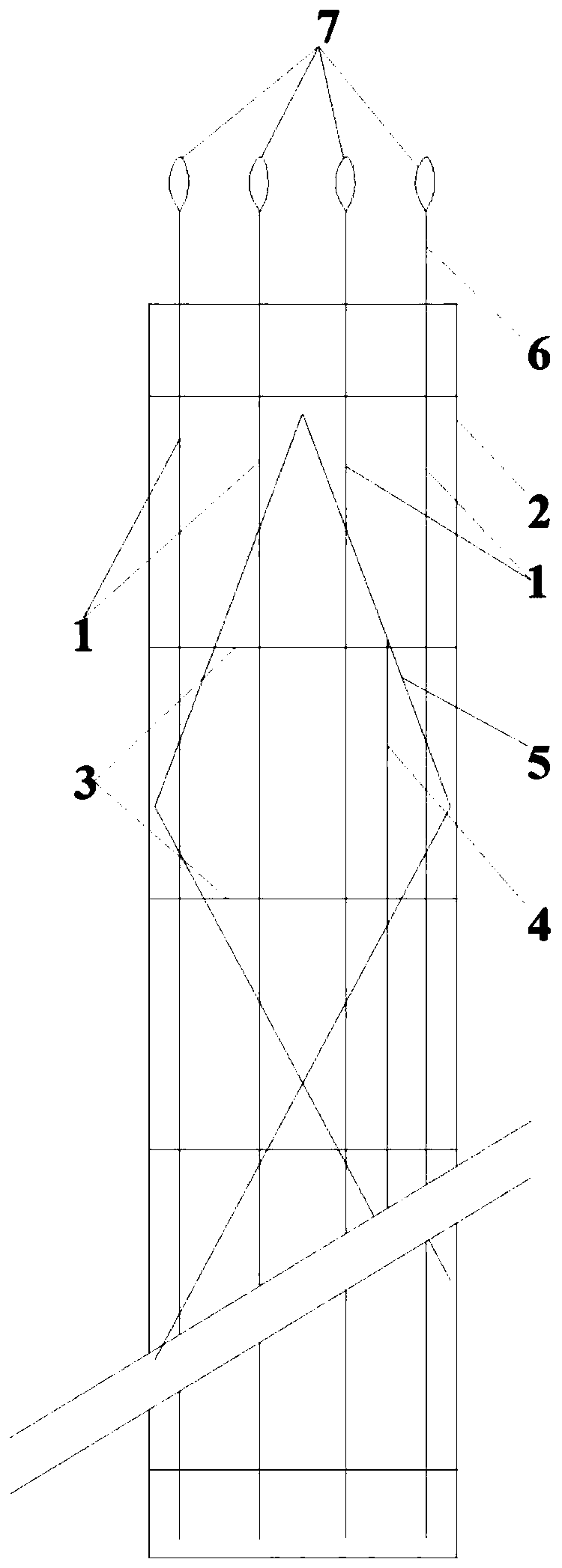

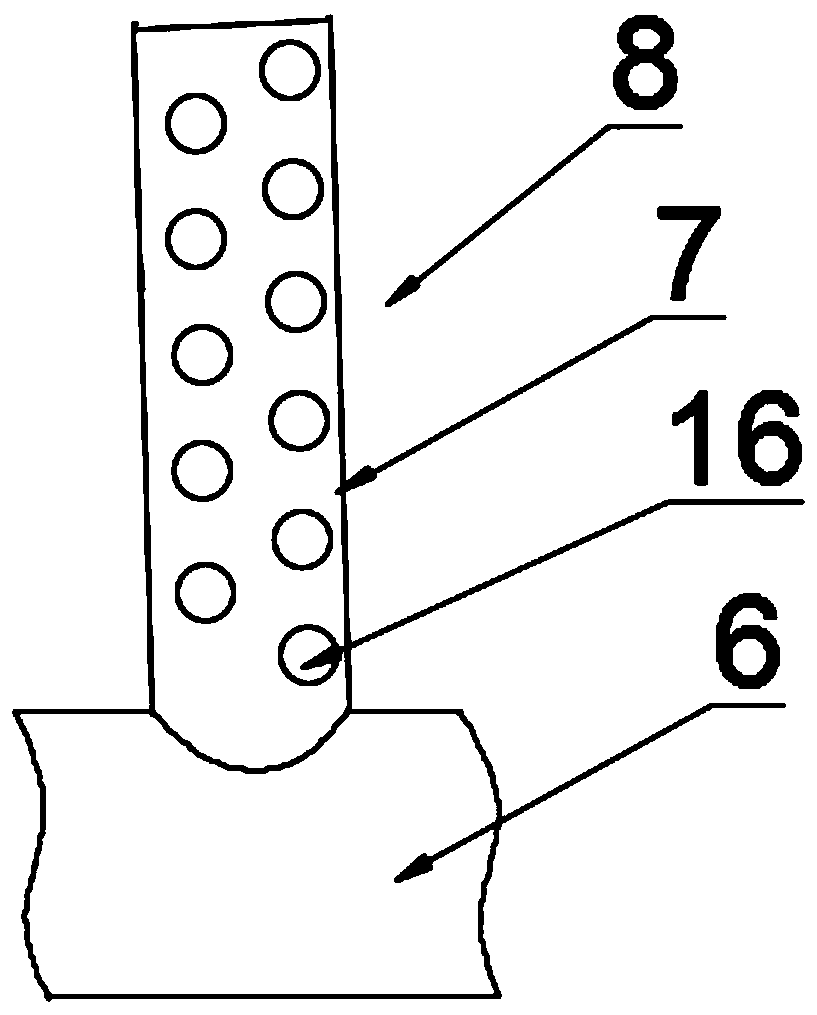

Steel reinforced cage applicable to air shaft underground continuous wall and using method thereof

PendingCN110847156AGood effectIncrease stiffnessBuilding reinforcementsBulkheads/pilesCross connectionMesh reinforcement

The invention provides a steel reinforced cage applicable to an air shaft underground continuous wall and a using method thereof. The steel reinforced cage comprises two layers of steel reinforced meshes; the two layers of steel reinforced meshes are connected to each other through truss ribs; the truss ribs comprise longitudinal truss ribs and horizontal truss ribs; main ribs are arranged in thelength direction of the steel reinforced cage; the longitudinal truss ribs are arranged parallel to the main ribs at intervals; one end of each longitudinal truss rib is connected to a hanging rib; the horizontal truss ribs are perpendicularly and fixedly connected to the longitudinal truss ribs; the longitudinal truss ribs intersect and are connected to the horizontal truss ribs; a shearing support is arranged on the horizontal truss ribs on the inner sides of the steel reinforced cage, and is used for fixing and moulding the longitudinal truss ribs and the horizontal truss ribs. According tothe steel reinforced cage, the sizes of components can be compatible; the phenomenon of twisting, deforming and shattering during conveying is avoided; hoisting and positioning are convenient; the size of each steel reinforced cage is uniform; the integral rigidity of the steel reinforced cage is large; and meanwhile, twisting and deforming can be well avoided during conveying and hoisting.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY NO 9 GRP

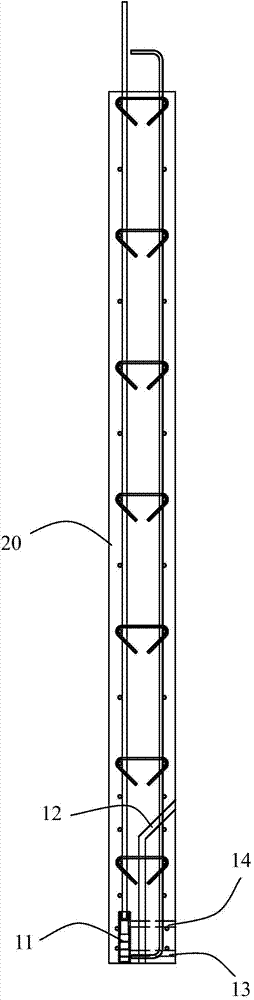

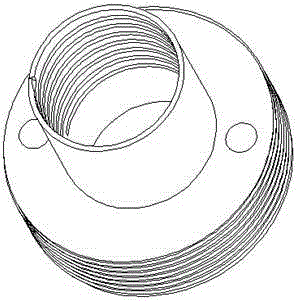

Novel composite type groutable anchor rod

The invention discloses a novel composite type groutable anchor rod and belongs to the technical field of mineral engineering anchorage supporting. The anchor rod comprises an outer sleeve, an inner rod body of which the middle is provided with a backflow cavity, a base plate, a nut and a check ring, and grouting holes are formed in the check ring. Grout is poured into a grouting cavity between the outer sleeve and the inner rod body through the grouting holes in the check ring and then is poured into a rock stratum through holes formed in the outer sleeve, after drilling holes are filled with the grout fully, the grout flows back through the backflow cavity, and accordingly grouting is completed. By adopting the anchor rod to conduct supporting, the problems that traditional grouting anchor rods are not high in supporting force and limited in grouting range, and whether drilling holes are filled with grout completely cannot be effectively judged can be solved; grouting is conducted on the deep soft rock stratum, a plastic zone can be decreased, the anchorage force of the anchor rod is increased, and accidents are decreased.

Owner:SHANDONG UNIV OF SCI & TECH

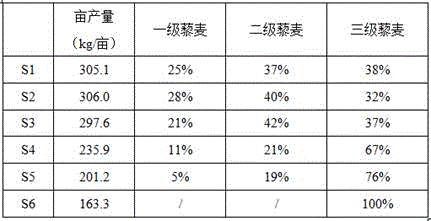

Chenopodium quinoa planting method suitable for Huang-Huai-Hai region

InactiveCN106234021AGrowth inhibitionPromote germinationPlant cultivationCultivating equipmentsPhacusCrop cultivation

The invention belongs to the technical field of crop cultivation, and particularly relates to a chenopodium quinoa planting method suitable for Huang-Huai-Hai region. The method includes following steps: preparing land before sowing; applying acetochlor mixing liquid and base fertilizer; performing seed screening and treating; ditching and sowing; performing field management. By the planting method, chenopodium quinoa in the Huang-Huai-Hai region is enabled to be high in seedling emergence rate, good in growing trend and high in yield and quality; ditching is conducted during a branching period, so that root system development in a vigorous growing period can be promoted, growing of base nodes can be controlled, and stems are enabled to be thick and strong; earth-up treatment is combined, so that growing of neck nodes is promoted, supporting capability of plants is enhanced, and later lodging can be prevented.

Owner:德州市农业科学研究院

Polyurethane compound suitable for grouting and preparation method thereof

The invention discloses a polyurethane compound suitable for grouting. The polyurethane compound comprises the following raw materials by weight: 30-60 parts of polyether, 3-12 parts of methyl silicone oil, 3-15 parts of a plasticizer, 10-25 parts of a flame retardant, 25-50 parts of polypropylene glycol, 1-7 parts of dihydromethyl propionic acid, 2-10 parts of a chain extender, 2-10 parts of a catalyst, 20-35 parts of polyisocyanate, 10-25 parts of polyether polyol, 20-60 parts of isophorone diisocyanate, 10-25 parts of glycerol, 2-15 parts of pentaerythritol, 2-8 parts of a defoaming agent, and 3-7 parts of a diluents. The preparation method provided by the invention is simple, and the prepared grouting composition can be used in a high-pressure environment, and can maintain the high strength characteristic for a long time, thus being suitable for popularization.

Owner:江苏卓美聚氨酯科技有限公司

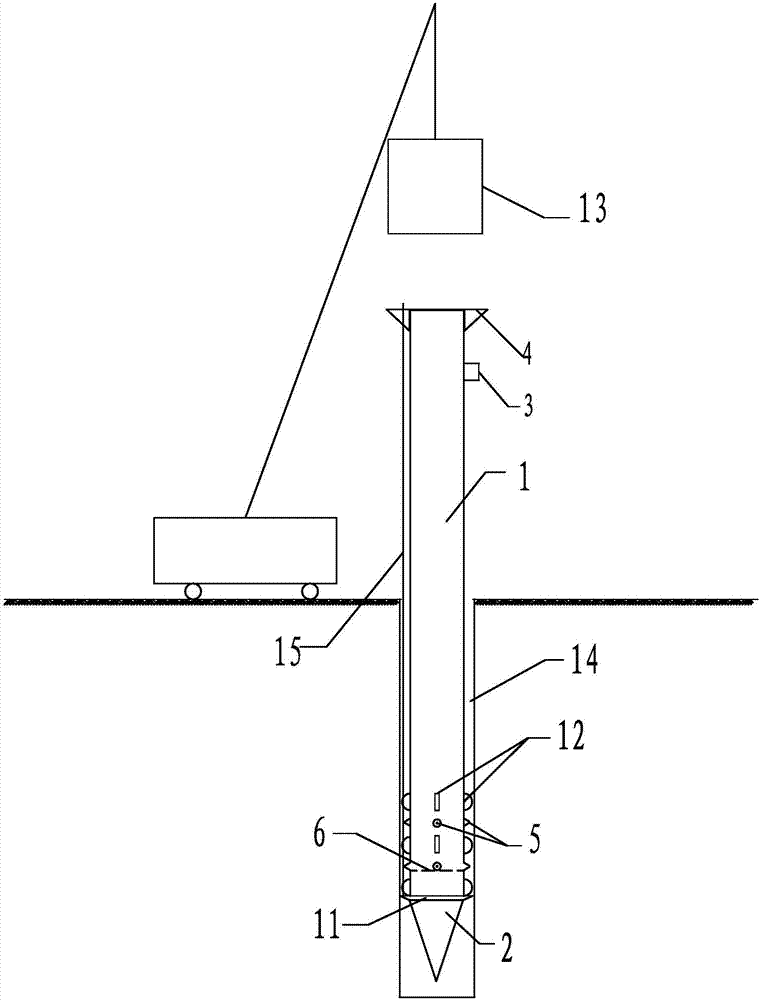

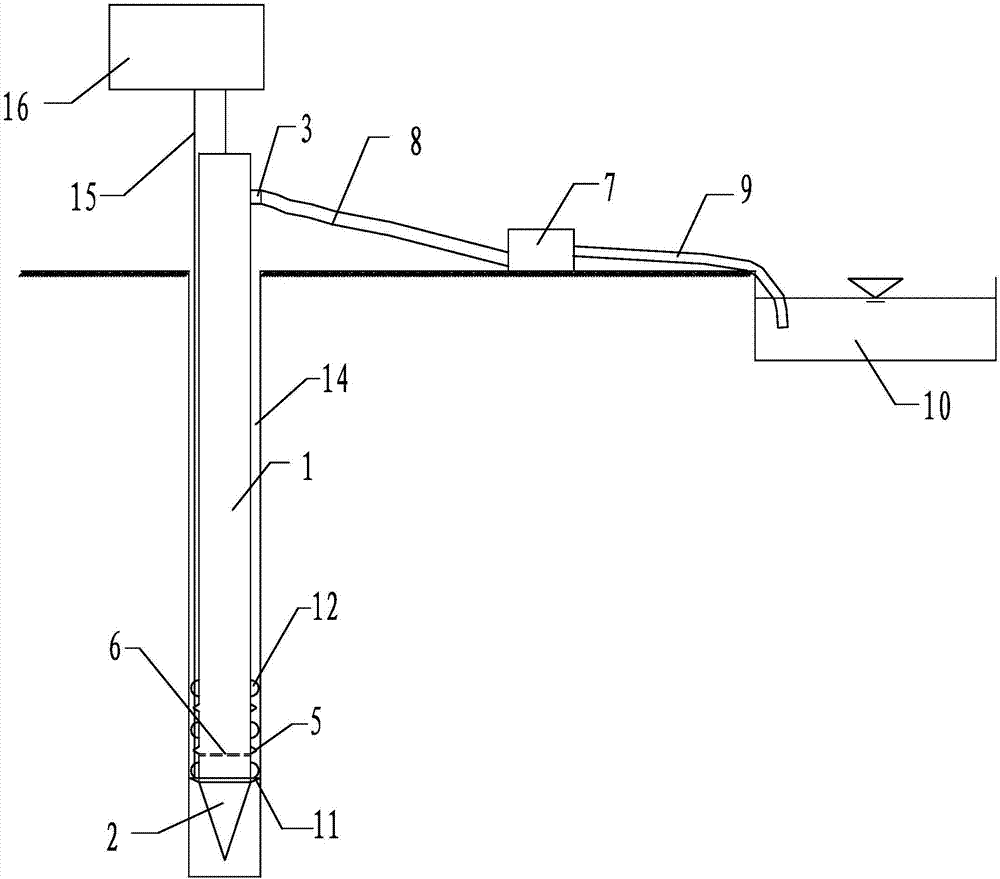

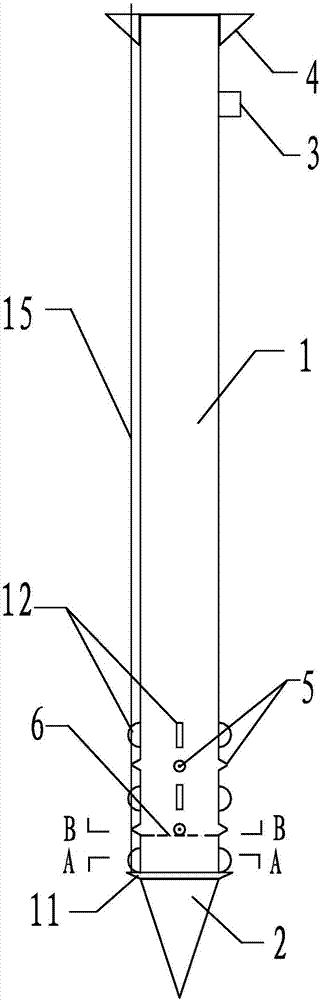

Collapsible loess compaction pile construction device and method capable of reducing thickness of falling soil

The invention provides a collapsible loess compaction pile construction device and method capable of reducing the thickness of falling soil. The collapsible loess compaction pile construction device comprises a hammering device and a hole forming pile pipe. A grouting hole is formed in the position, lower than a hammering protective sleeve, of the upper end of the hole forming pile pipe, and the length of a pipe body below the grouting hole is equal to or larger than the depth of pile holes. A plurality of grout spraying holes are formed in the positions, higher than an expansion ring, of the lower end of the hole forming pile pipe. The construction process of a compaction pile comprises the steps that after pile hole construction is completed by hammering the sinking pipe, the grouting hole is connected with a grouting pump, grout spraying operation is uniformly conducted on the walls of the pile holes through the grout spraying holes in the wall of the hole forming pile pipe in the pipe pulling process, the inner wall surfaces of the pile holes are cured, and filling work is conducted after curing. According to the collapsible loess compaction pile construction device and method capable of reducing the thickness of the falling soil, construction is easy, the quantity of the falling soil on the hole walls is decreased through curing of the hole wall surfaces, the situation that layered compaction of plain soil / lime soil subsequently is affected due to the fact that the falling soil is thick in the hole forming process is avoided, the pile hole depth is also ensured, and the construction progress and the construction quality are improved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

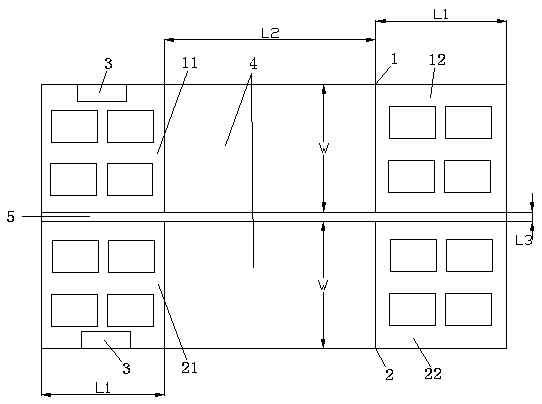

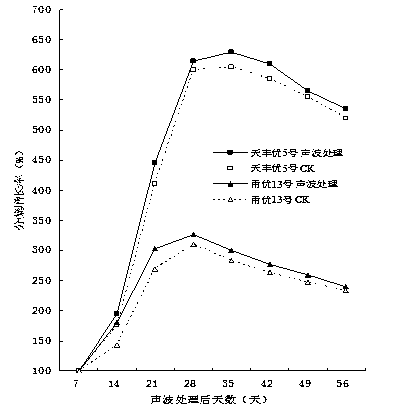

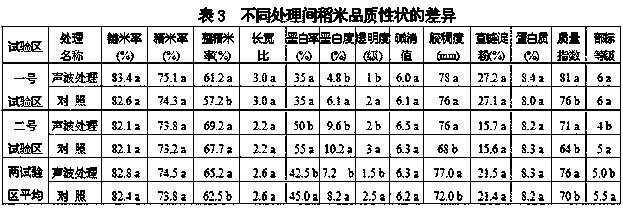

Paddy yield increasing cultivation method using acoustic wave treatment

InactiveCN103348891AImprove photosynthetic efficiencyIncrease chlorophyll contentHorticulture methodsRice cultivationSoil scienceAcoustic wave

The invention relates to a paddy yield increasing cultivation method using acoustic wave treatment. The paddy yield increasing cultivation method is characterized by comprising the following steps: (1) finely preparing a paddy field, uniformly and sparsely sowing seeds and cultivating strong seedlings with tillers; (2) finely preparing the soil before transplantation, applying sufficient basal fertilizer, rationally performing thick planting and timely transplanting; (3) playing acoustic wave with frequency of 300-6,000 Hz for 3 hours to treat each day after transplantation and 5 days before harvesting; (4) performing nutrient and water management according to local conditions in the field phase; and (5) timely preventing the disease pests and weeds according to prediction and forecast and the practical situation in the field and timely harvesting the paddy when 95 percent of grains in the whole field are yellow ripe. The paddy yield increasing cultivation method using acoustic wave treatment has the advantages of simple and rational design, capabilities of promoting growth and development of paddy and achieving yield increasing, high grade and anti-disease effects, excellent operability and better practicability, and can be widely applied to paddy production.

Owner:CHINA NAT RICE RES INST

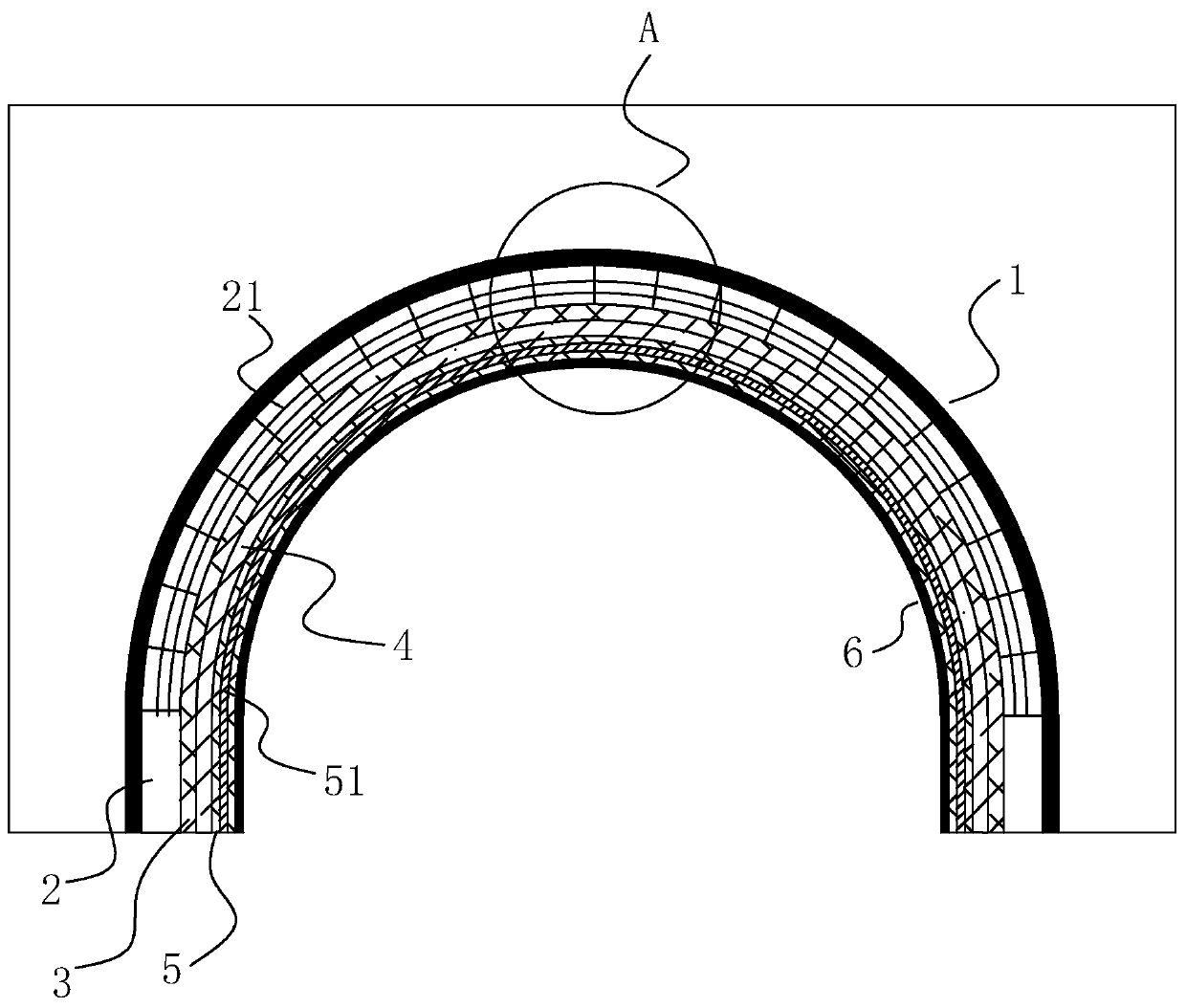

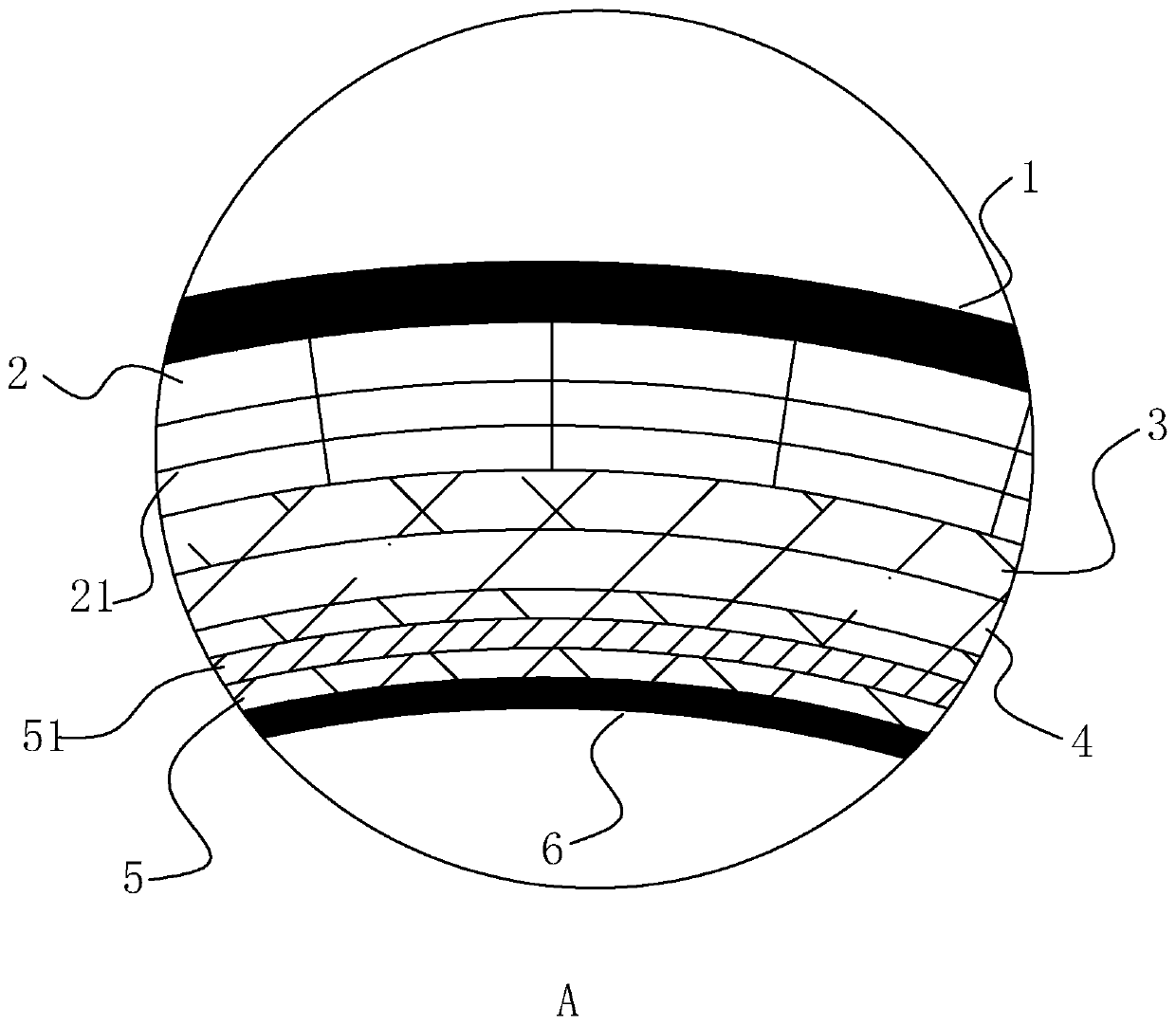

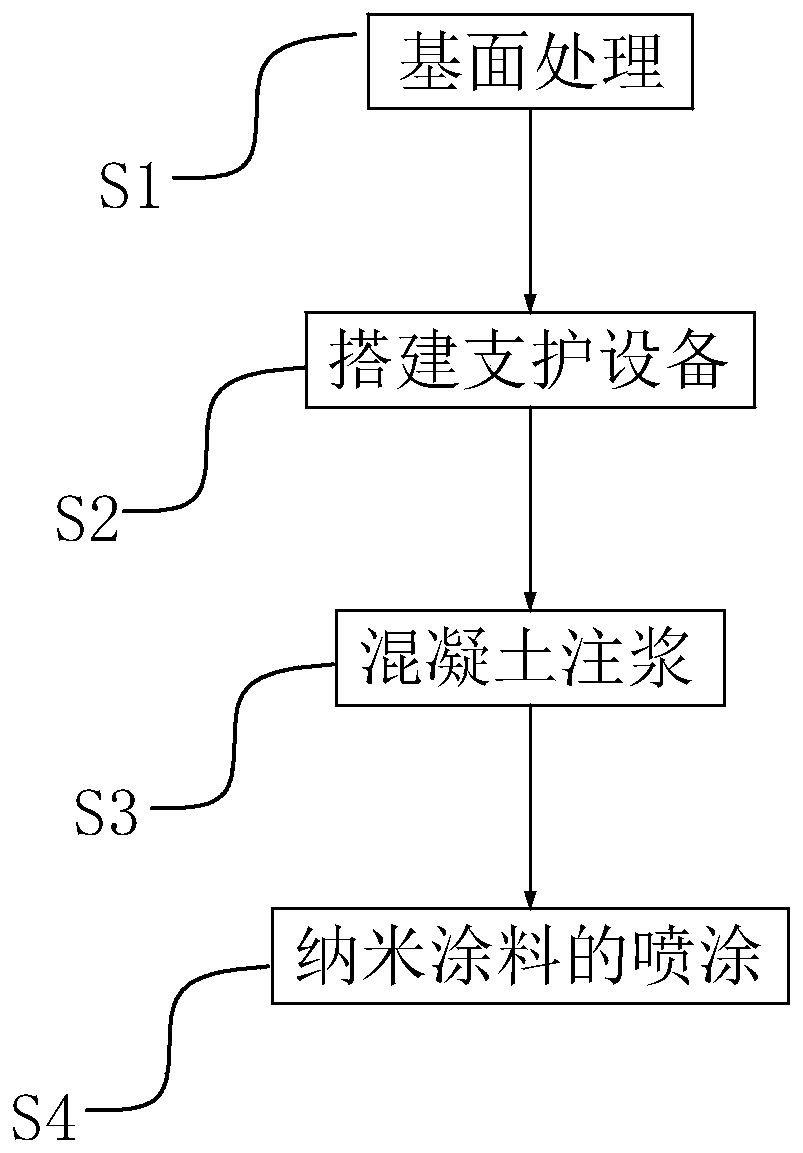

Waterproof single-layer lining structure and construction technology thereof

InactiveCN110284901AGood waterproof and anti-seepage effectMeet the waterproof requirements of constructionUnderground chambersTunnel liningReinforced concreteIsolation layer

The invention relates to a waterproof single-layer lining structure and construction technology thereof, and belongs to the technical field of subway construction. According to the main points of the technical scheme, the waterproof single-layer lining structure includes a base concrete layer, a supporting concrete layer, a waterproof isolation layer, a reinforced concrete layer, a waterproof concrete layer, and a nanometer coating layer, wherein the base concrete layer, the supporting concrete layer, the waterproof isolation layer, the reinforced concrete layer, the waterproof concrete layer and the nanometer coating layer are arranged successively from an arch structure close to a tunnel main body to one side of the earth surface; the supporting concrete layer is provided with a steel bar skeleton; and the waterproof isolation layer is made of corrosion-resistant metal, and the waterproof concrete layer is grouted by waterproof concrete mud and internally provided with a waterproof cloth. The problem of poor waterproof effect when the single-layer lining structure is constructed in the place with abundant groundwater is solved, and when subway construction is at the location where groundwater is abundant, the main structure of the tunnel can be well supported, water-proofed and anti-permeated.

Owner:THE 5TH ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

Special foliar fertilizer for rice

InactiveCN106007976AIncrease productionPromote absorptionBio-organic fraction processingAlkali orthophosphate fertiliserSucroseFilling rate

The invention belongs to the technical field of agricultural fertilizer and relates to a special foliar fertilizer for rice. The special foliar fertilizer comprises a first-stage fertilizer for the vegetative stage of rice and a second-stage fertilizer for the reproductive stage of rice, wherein the second-stage fertilizer comprises a flowering-stage fertilizer applied in the flowering stage and a filling fertilizer applied in the filling stage; and the flowering-stage fertilizer comprises the following components in parts by weight: 35-50 parts of biogas slurry, 10-22 parts of microcrystalline cellulose, 7-12 parts of aloe extract, 1-5 parts of sucrose, 16-25 parts of chitin and 1-2 parts of auxiliary. In the invention, different foliar fertilizers are prepared for the vegetative growth and reproductive growth of rice, and each stage in the rice growth can be fully utilized to increase the rice yield; particularly by utilizing the flowering stage and the filling stage, the flowering period is prolonged, the pollination success rate is increased, the filling is accelerated, the filling rate is increased, and the particle fullness is remarkably improved; and moreover, the absorption effect of the foliar fertilizer is good, the dosage is small, and the cost is saved.

Owner:广德县新农民水稻种植专业合作社

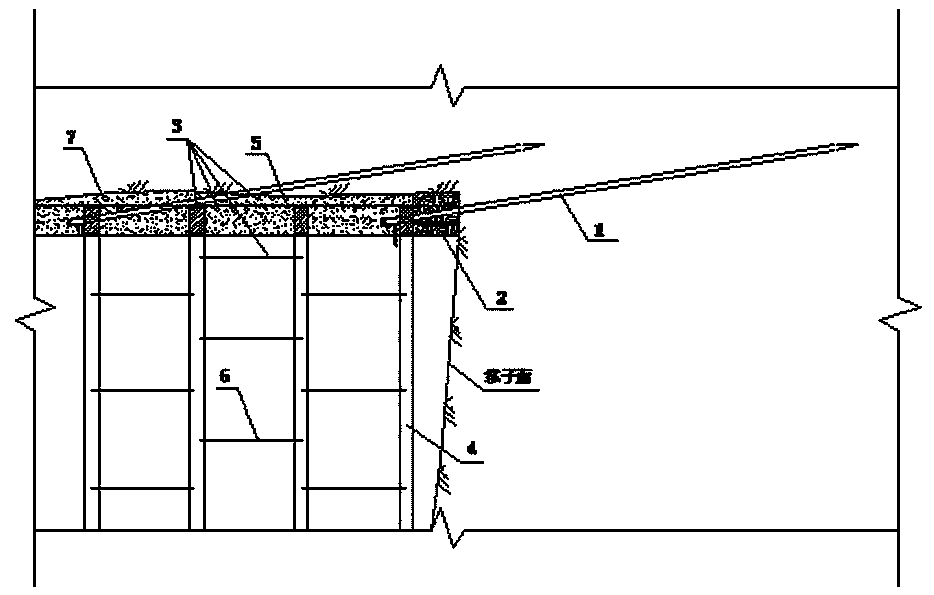

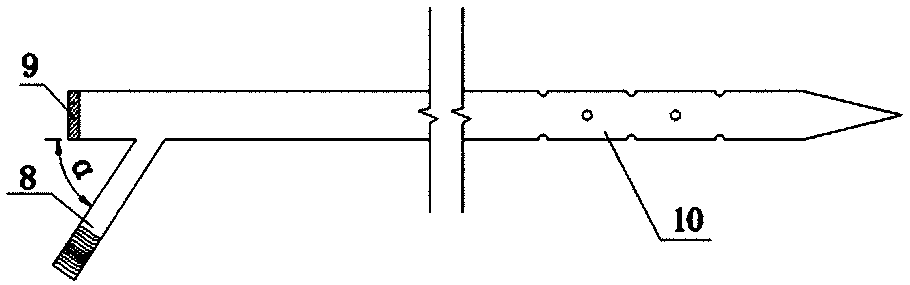

Advanced small pipe grouting structure and construction method thereof

ActiveCN109139048AGood slurry effectQuick closureUnderground chambersTunnel liningRock tunnelApplication time

The invention relates to the technical field of tunnel construction, in particular to an advanced small pipe grouting structure and a construction method thereof. According to an advanced small pipe,quick closure of a primary support can be ensured, a grout stopping wall and the primary support form an integral stress structure and are tightly attached to a tunnel face, so that the stability of the tunnel face is increased, the safety risk of the tunnel face is greatly reduced, and soft rock tunnels and special geological tunnels excavated by blasting are facilitated; and the grouting structure is simple, the application of the grout stopping wall basically does not occupy the application time of the primary support, the grout stopping wall can be applied synchronously with the primary support, the construction speed is high, rapid grouting can be realized, a great deal of time is saved and the construction progress is speeded up compared with the set of the grout stopping wall alone,and grout stopping wall can be used as a part of the primary support without dismantling after the grouting of the advanced small pipe is finished. The advanced small pipe is factory processed, and has convenient and quick installation and grouting. The grout stopping wall is of an integral structure, has good grout stopping effect, can bear large grouting pressure, and greatly ensures the grouting effect of the advanced small pipe.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Foliar fertilizer for wheat

PendingCN106045659AImprove efficacyHigh activityCalcareous fertilisersBio-organic fraction processingAgricultural scienceBetaine

The invention belongs to the technical field of agricultural fertilizers and relates to a foliar fertilizer for wheat. The foliar fertilizer comprises a first-stage fertilizer for a vegetative growth stage of the wheat and a second-stage fertilizer for a reproductive growth stage of the wheat, wherein the second-stage fertilizer contains a flowering stage fertilizer sprayed at a flowering stage and a grain filling fertilizer sprayed at a grain filling stage, and the grain filling fertilizer contains 20-40 parts (by weight) of biogas slurry, 6-12 parts (by weight) of borax, 2-5 parts (by weight) of betaine, 15-20 parts (by weight) of seaweed powder and 1-3 parts (by weight) of glycerine. According to the foliar fertilizer for the wheat, different foliar fertilizers are prepared in view of the vegetative growth and reproductive growth of the wheat, so that the yield of the wheat can be increased by making full use of every stage of growth of the wheat; and particularly, by the use of the flowering stage and the grain filling stage, the flowering stage is prolonged, the success rate of pollination is increased, the grain filling is accelerated, the grain filling rate is increased, the plumpness of grains is greatly improved, the absorption effect of the foliar fertilizer is good, the consumption is low, and the cultivation cost is reduced.

Owner:广德县新农民水稻种植专业合作社

Anti-static ceramic

The invention is an antistatic ceramic, which is made of the following raw materials in parts by weight: silicon nitride 60-75, kaolin 10-16, aluminum oxide 2-8, silicon dioxide 2-5, tin oxide 3‑9, zirconia 1‑5, molybdenum disilicide 1‑3, antimony powder 10‑15, titanium dioxide 1‑3, conductive graphite 5‑6, silicon carbide 1‑5, boron carbide 1‑2, aluminum nitride 1 ‑2, thorium oxide 2‑4, appropriate amount of deionized water. The ceramic prepared by the present invention has certain electrical and thermal conductivity, prevents the generation of static electricity, prevents frictional overheating, prolongs the service time of pipelines and channels, and the ceramic of the present invention also has certain corrosion resistance and oxidation resistance, and has Good toughness.

Owner:苏州志英明建信息科技有限公司

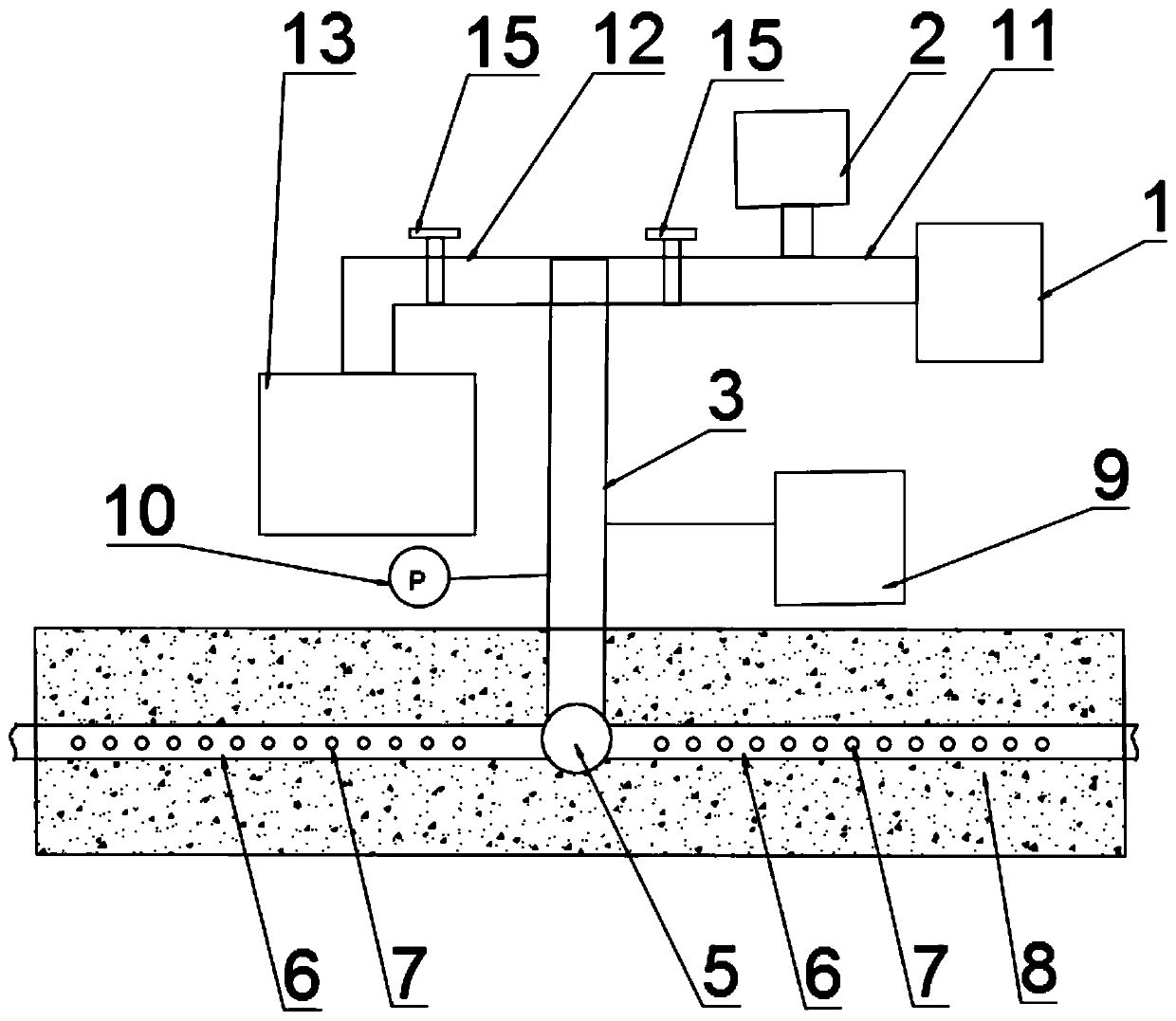

Cooling, moisturizing and grouting integrated device and method for mass concrete

The invention relates to a cooling, moisturizing and grouting integrated device and method for mass concrete. The device comprises an air refrigerator, an atomizer and a cold air pipeline. The cold air pipeline comprises an air inlet pipe, an air outlet pipe and a cold air buried pipe pre-buried in concrete. The cold air buried pipe comprises a cold air main pipe, cold air branch pipes and cold air branch pipes. A pressurizing device and a pressure gauge are arranged on the air inlet pipe, and the air inlet pipe is connected with the low-temperature atomization channel and the superfine cementpaste grouting channel through a three-way pipe; the air outlet pipe is connected with the recovery tank; the two sides of the pipeline of each cold air branch pipe are connected with a plurality ofcold air branch pipes, and a plurality of vent holes are formed in the cold air branch pipes. According to the integrated device, the interior of concrete can be subjected to cooling and moisturizingmaintenance at the same time, the internal stress is greatly reduced, temperature shrinkage and drying shrinkage are reduced, and cracks are reduced; and grouting treatment can be performed to repaircracks in concrete.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

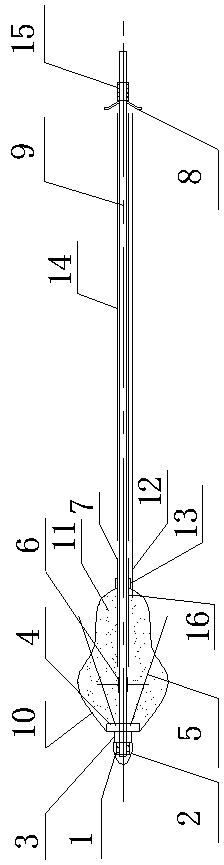

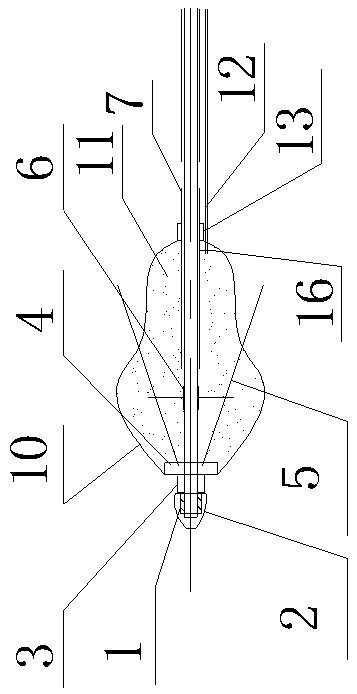

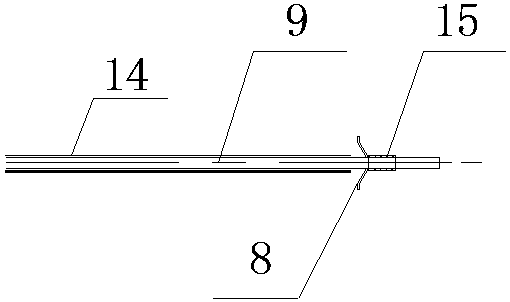

Reinforced concrete two-ended anchor cable and construction method thereof

ActiveCN109441512AReinforcement is fast and effectiveTo achieve reinforcementAnchoring boltsReinforced concreteRebar

The invention discloses a reinforced concrete two-ended anchor cable and a construction method thereof. The two-ended anchor cable comprises an anchor cable front fixed end and a main body anchor cable, wherein the anchor cable front fixed end is composed of a front lockset, a guide head, a front locking ring, a clamping ring, short reinforcing steel bars, a pushing device, a short pushing rod, acapsular bag, a grouting pipe, a grouting pipe clamping device and a rear locking ring; and the main body anchor cable is composed of an anchor cable body, a rear lockset, a tray and a long pushing rod. According to the reinforced concrete two-ended anchor cable and the construction method thereof, a novel bidirectional reinforcing technology for a deep thick coal seam small coal pillar for roadway driving along a goaf is provided, coal pillar bidirectional reinforcing can be rapidly and effectively completed on one side of a newly excavated roadway, the action that the lateral confining pressure of the coal pillar is reinforced and thus the coal pillar bearing capacity is improved can be realized, the problem that a traditional roadway driving along the goaf technology cannot realize one-way construction and bidirectional reinforcing is solved, the problem that the capsular bag cannot be fully distended when the two-ended anchor cable is grouted is solved, and meanwhile, grouting pipes with lager inner diameters can be assembled to better complete the grouting.

Owner:NORTH CHINA INST OF SCI & TECH

Paddy rice hybridization method

InactiveCN105123496ARaw materials are easy to obtainOvercome expensivePlant genotype modificationPollinationKraft paper

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Prestressed prefabricated concrete shear wall system and construction method thereof

InactiveCN111779160AImprove reliabilityClear forceWallsBuilding reinforcementsRebarTongue and groove

The invention provides a prestressed prefabricated concrete shear wall system and a construction method thereof. The prestressed prefabricated concrete shear wall system comprises prefabricated shearwalls and prestressed reinforcements; the transversely adjacent prefabricated shear walls are connected with each other through tongues and grooves; reinforcement through passages are formed in the prefabricated shear walls; anchor bearing plates are buried in positions, corresponding to the reinforcement through passages, at the tops of the prefabricated shear walls; through holes and grout outlets are formed in the anchor bearing plates; gaps are reserved in the bottoms of the prefabricated shear walls; the gaps communicate with the reinforcement through passages; the prestressed reinforcements penetrate through the reinforcement through passages; a first reinforcement connector at the top of the prefabricated shear wall in the lower layer is correspondingly inserted in the gap of the prefabricated shear wall in the upper layer and is connected with the gap through the first reinforcement connector; the gap is filled with a filling material; a grouting pipeline is buried in the filling material; and passage grouting materials are poured in the reinforcement through passages. According to the prestressed prefabricated concrete shear wall system and the construction method thereof,the technical problems of high making accuracy requirement, high quality control difficulty, lack of effective grouting quality detection means, difficult member transportation, multiple site wet operations and longer construction period of a traditional prefabricated shear wall are solved.

Owner:CHINA BUILDING TECHN GROUP

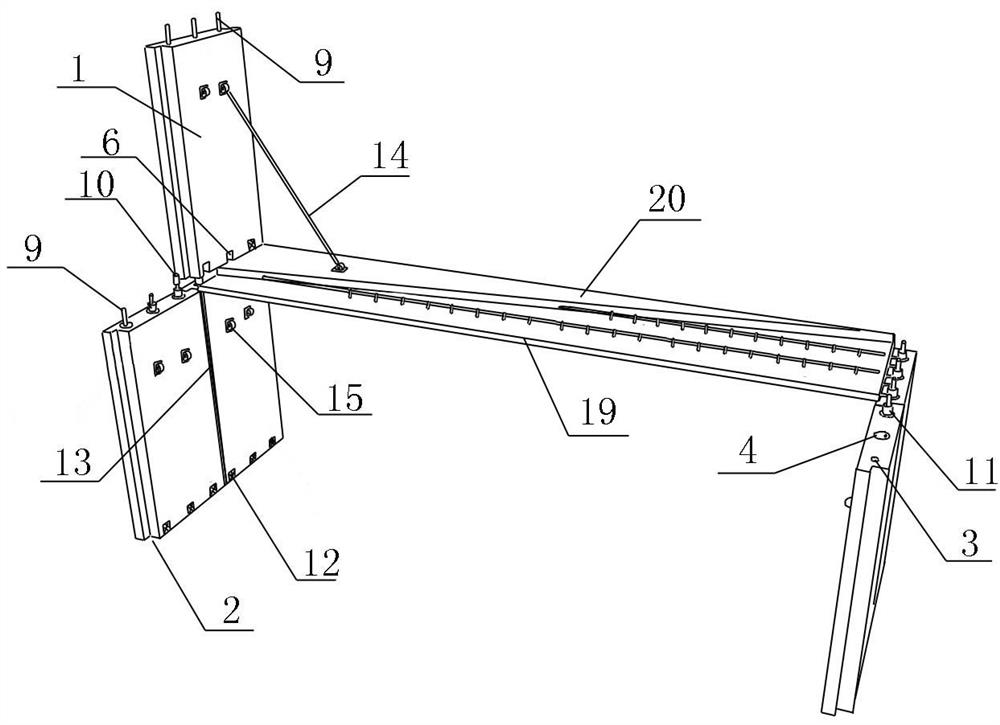

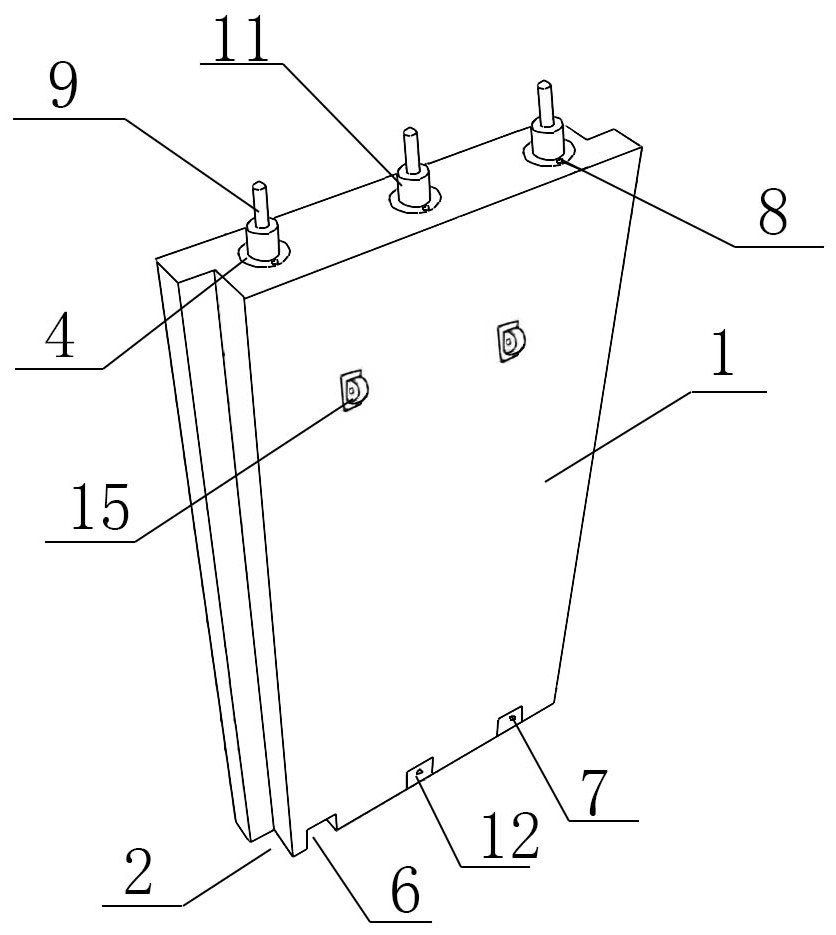

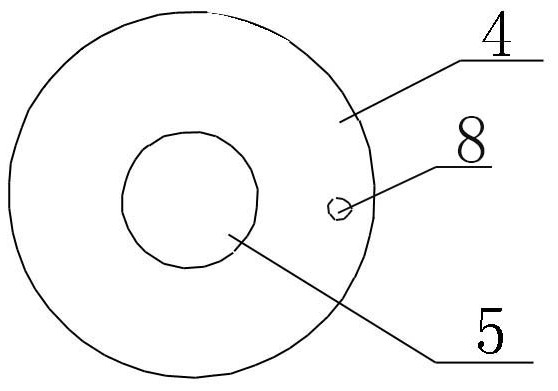

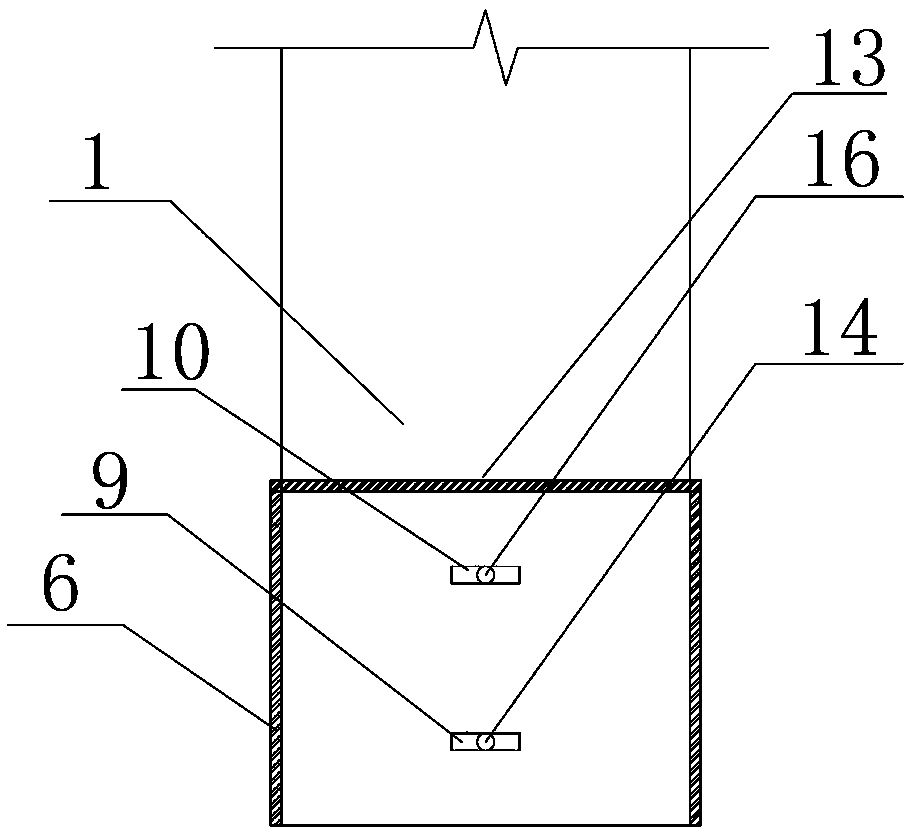

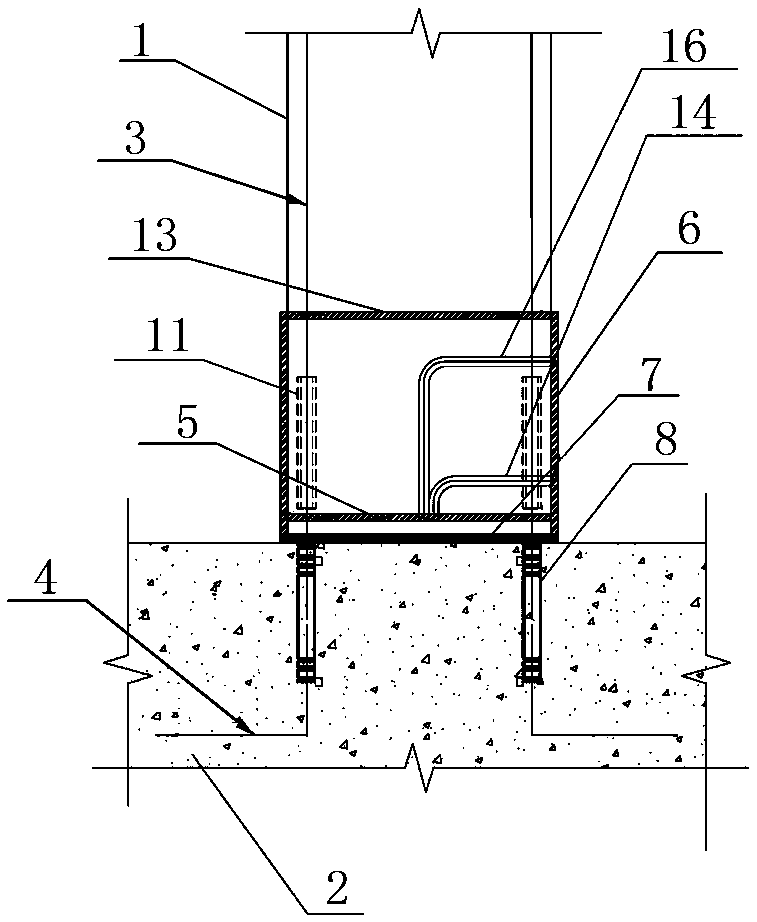

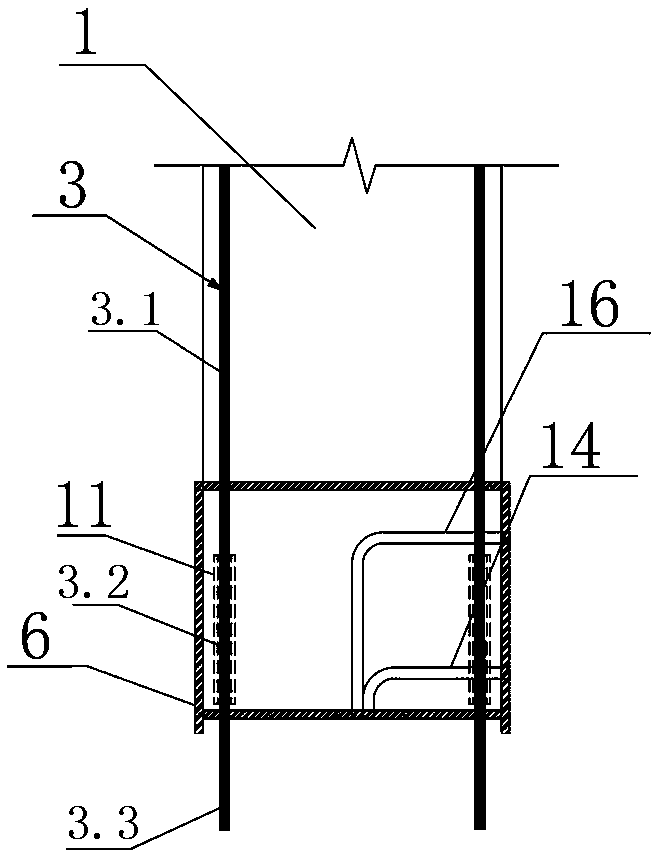

Assembling type concrete column base node structure and construction method thereof

ActiveCN108374489AReduce damageIncreased ductility levelBuilding constructionsReinforced concrete columnRough surface

The invention discloses an assembling type concrete column base node structure and a construction method thereof. The assembling type concrete column base node structure comprises a reinforced concrete foundation and a prefabricated reinforced concrete column, wherein the part of the top surface of the reinforced concrete foundation, corresponding to the connection of the prefabricated reinforcedconcrete column, is provided with a rough surface; the parts in the reinforced concrete foundation, corresponding to vertical reinforcements in the prefabricated reinforced concrete column, are provided with foundation anchoring reinforcements; vertical grouting sleeves sheath the upper parts of the foundation anchoring reinforcements; the top parts of the grouting sleeves are level to the top part of the reinforced concrete foundation; a circle of externally-wrapping steel plates are arranged at the lower part of the prefabricated reinforced concrete column; exhausting holes and grouting holes are formed in the externally-wrapping steel plates; corresponding to the externally-wrapping steel plates in position, a top plate, cross partitioning plates, vertical partitioning plates, groutingpipes and exhausting pipes are also embedded in the prefabricated reinforced concrete column. The assembling type concrete column base node structure and the construction method disclosed by the invention have the beneficial effect that the technical problem of damage of the column base due to poor deformation capability and mechanical property of the column base node with the assembling type structure is solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Water burst blast hole plugging method

ActiveCN104265229ASolve the problem of water blockingConvenient groutingSealing/packingSlurryCement mortar

A water burst blast hole plugging method comprises the steps of (1) stopping drilling instantly and withdrawing a drill rod when water burst occurs during blast hole drilling; (2) ejecting a high-pressure rubber expansion rubber hose into the bottom of a hole with a drilling machine, wherein the two ends of the high-pressure rubber expansion rubber hose are sealed, and a check valve and a water injection rubber hose are installed at one end of the high-pressure rubber expansion rubber hose; (3) injecting pressure water into the high-pressure rubber expansion rubber hose with a high-pressure pump by means of the water injection rubber hose to enable the high-pressure rubber expansion rubber hose to be large enough to abut against the blast hole; (4) withdrawing the drilling rod; (5) conducting grout sealing on the blast hole; (6) stop grouting after the blast hole is filled with grout. The method well achieves hole plugging when water burst occurs during blast hole drilling which is conducted in an area with abundant underground water and is highly targeted, the high-pressure rubber expansion rubber hose is expanded after reaching the bottom of the hole, water burst is prevented from being continued through the blast hole, the portion, between the high-pressure rubber expansion rubber hose and the opening of the blast hole, of the blast hole does not contain gush water any more, cement mortar grout sealing can be conducted on the blast hole conveniently, sealing is easy and convenient, construction speed is high, quality is high, grout loss is avoided, plugging effect is good, and cost is low.

Owner:SINOHYDRO BUREAU 6 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com