Concrete wall and bottom plate water seepage crack repair method

A technology for concrete walls and repair methods, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems such as water leakage, and achieve the effect of avoiding water leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] This embodiment provides a method for repairing water seepage cracks in concrete walls and bottom plates;

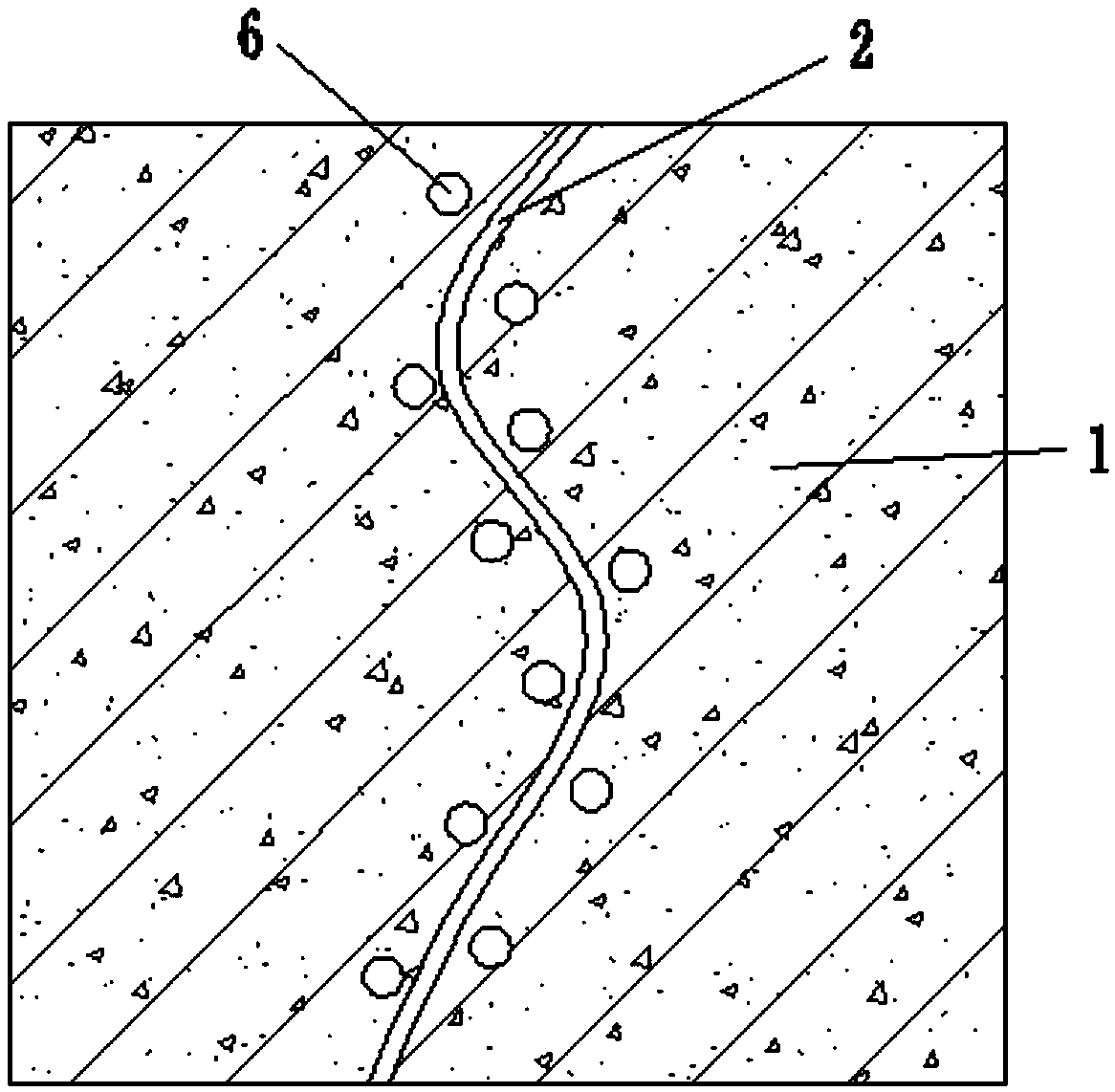

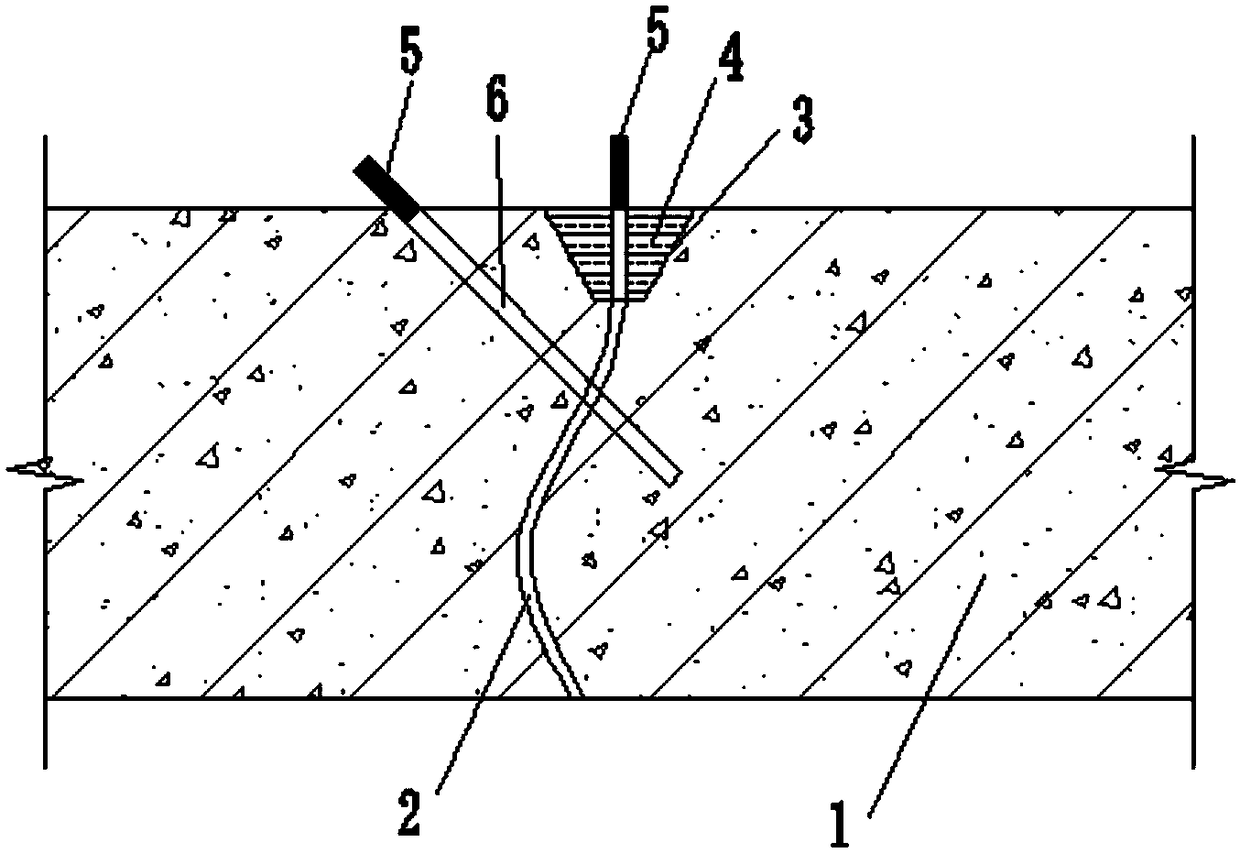

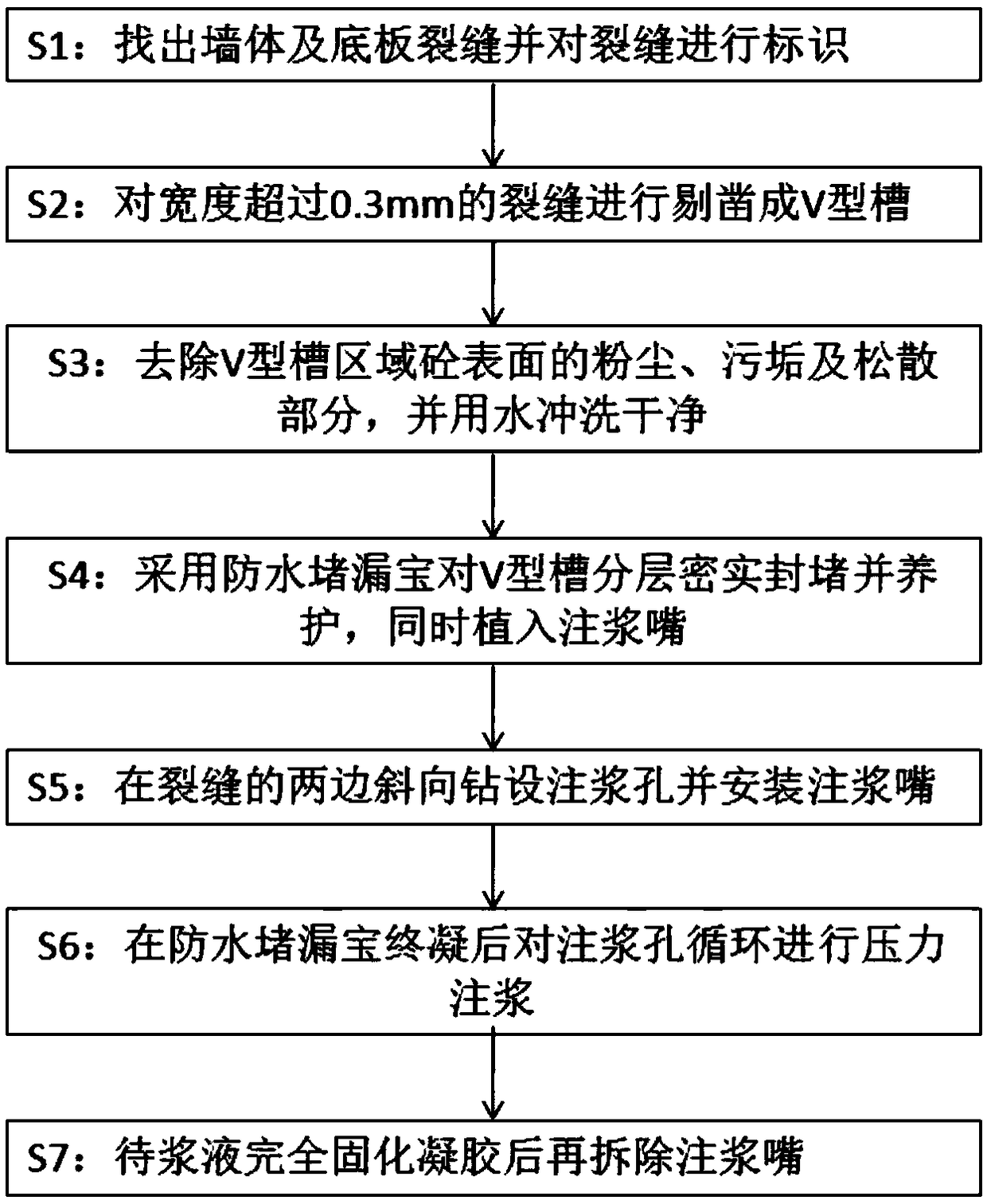

[0036] Such as Figure 1-Figure 3 As shown, the method for repairing water seepage cracks in concrete walls and bottom plates in this embodiment includes the following steps:

[0037] a. First, remove debris, dust, sludge, etc. on the surface of the wall and bottom plate 1, find cracks 2 and use chalk or markers to clearly mark the cracks, and no cracks should be missed;

[0038] b. Pick out cracks with a width of more than 0.3mm to form a V-shaped groove 3. The groove width is 50mm and the groove depth is 50mm. The size of the V-shaped groove can also be determined according to the site conditions. When the crack width is too small, no groove processing is required;

[0039] c. Use a wire brush to remove dust, dirt and loose parts on the surface of the concrete in the V-groove 3 area, and rinse with clean water;

[0040] d. Use waterproof plugging treasure 4 (incorporatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com