A special waterproof structure for through-wall pipes and its construction method

A waterproof structure and pipeline technology, which is applied to expansion compensation devices for pipelines, pipes, pipe components, etc., can solve problems affecting the power supply and communication of pipe corridors, difficulty in meeting waterproof requirements, and rupture of waterproof structures, so as to improve operational safety performance, enhanced sealing, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

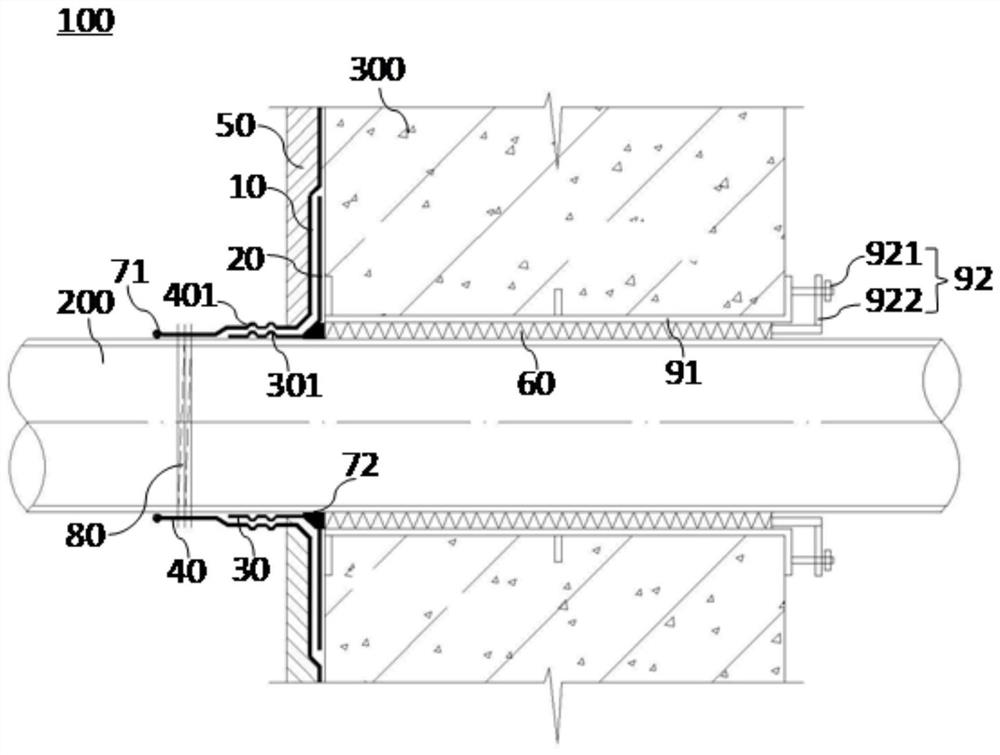

[0020] figure 1 It is a structural schematic diagram of a special waterproof structure for through-wall pipelines according to an embodiment of the present invention. Such as figure 1 As shown, the special waterproof structure 100 for through-wall pipes includes a waterproof layer 30 in the pipe area formed by a first flexible waterproof roll material and a waterproof layer 20 in the wall area formed by a second flexible waterproof roll material. The waterproof layer 30 in the pipe area completely wraps the outer wall of the pipe 200 that runs through the wall 300, and has inner folds 301 that protrude radially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com