Heating furnace supporting beam and heat-resistant bearer fixing structure

A technology for fixing structures and supporting beams, applied in the field of supporting beam structures, can solve problems such as the leakage of cooling bodies of supporting beams that cannot be overcome, and achieve the effects of reducing the number of shutdowns for maintenance, improving service life, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

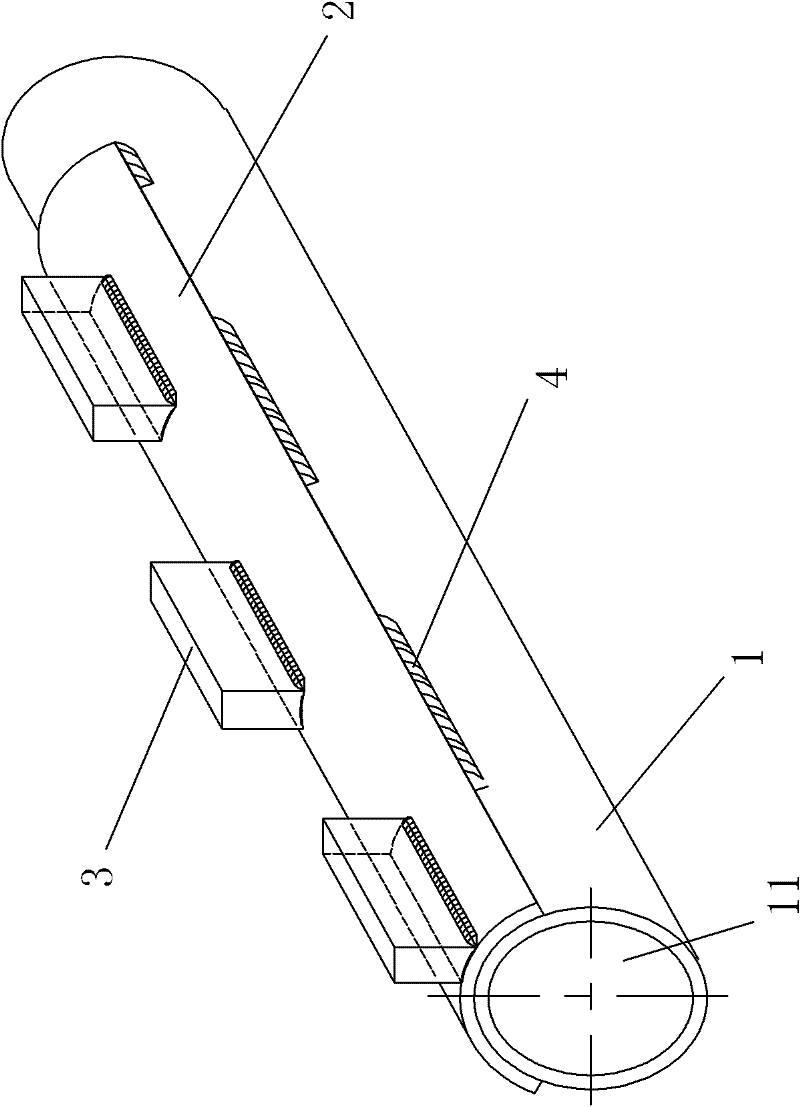

[0029] figure 1 It is a schematic diagram of the first embodiment of the fixing structure of the heating furnace support beam and the heat-resistant pad of the present invention. Such as figure 1 As shown, the fixing structure of the heating furnace support beam and the heat-resistant cushion block proposed by the present invention includes: a horizontal support beam 1, a cooling channel 11 is arranged in the horizontal support beam 1; a backing plate is provided along the length direction of the horizontal support beam 1 2. The backing plate 2 has a radian matching the horizontal support beam 1, forming a long arc backing plate, and is arranged on the upper half of the horizontal support beam 1; the heat-resistant pad 3 is fixed on the backing plate 2 on. The heat-resistant block 3 is used to hold up the steel billet, and the high temperature of the steel billet is directly transmitted to the heat-resistant block 3. Since the average temperature of the backing plate 2 close...

Embodiment 2

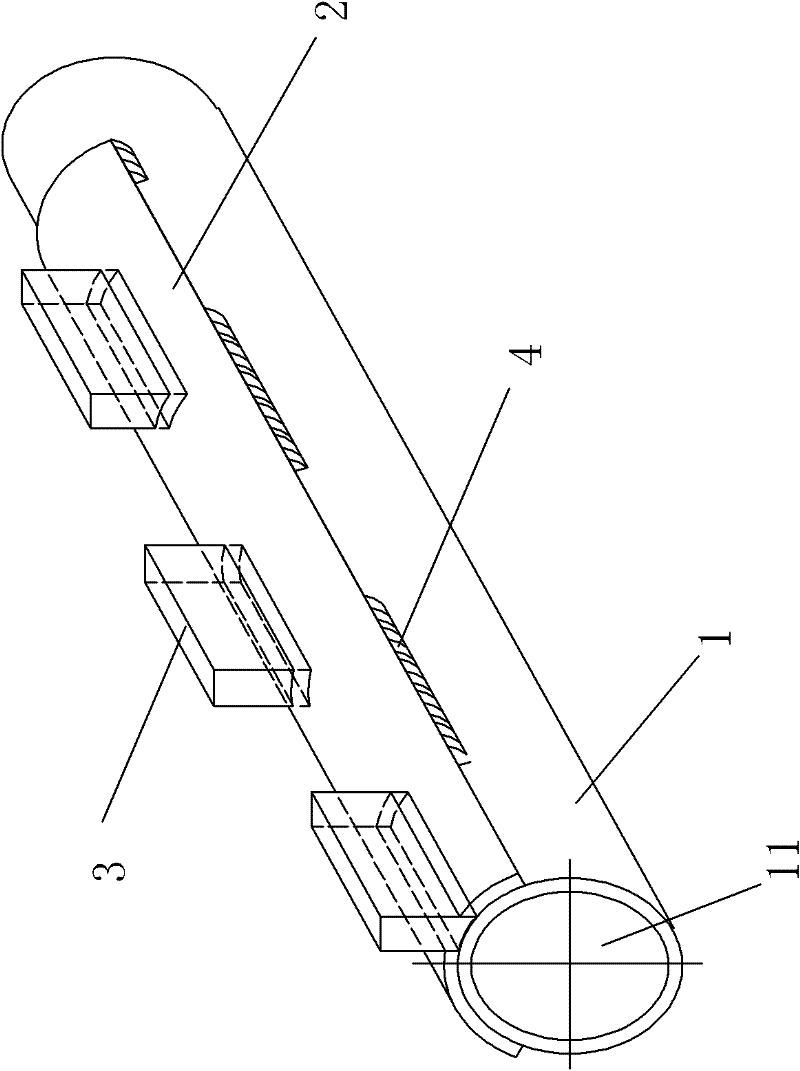

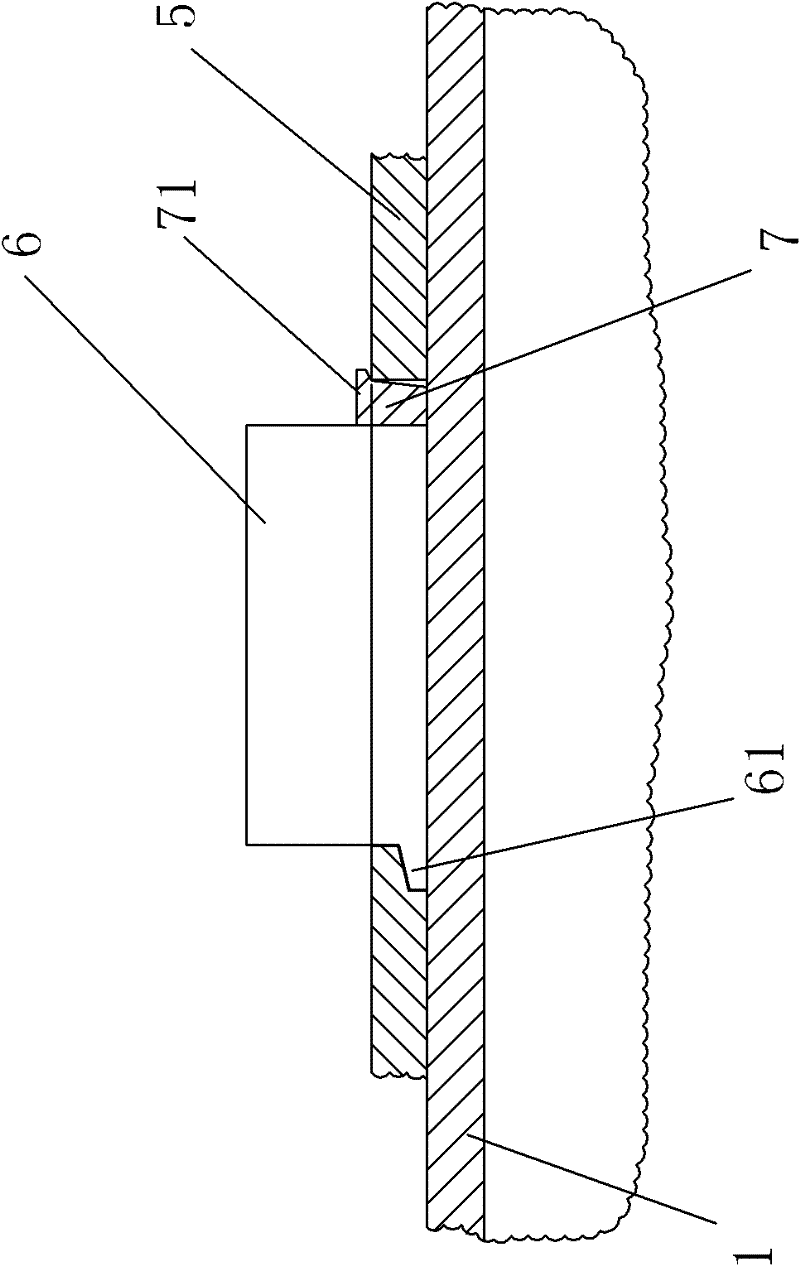

[0033] figure 2 It is a schematic diagram of the second embodiment of the fixing structure of the heating furnace support beam and the heat-resistant pad of the present invention; image 3 It is a partial cross-sectional schematic diagram along the axial direction of the horizontal support beam. Such as figure 2 , 3 As shown, in another embodiment of the present invention, the backing plate 5 is provided with a plurality of through holes, and the heat-resistant spacer 6 is embedded and fixed in the through holes.

[0034] A specific solution is that the periphery of the heat-resistant pad 6 is intermittently welded and fixedly connected to the periphery of the through hole of the backing plate 5 .

[0035] Another feasible solution is that a block 7 is embedded and fixed between the heat-resistant pad 6 and the through hole, and the heat-resistant pad 6 is embedded and fixed in the through hole of the backing plate 5 . In order to ensure the firmness of the connection, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com