Spheroidizing annealing method for medium-and-low-carbon alloy cold forging steel

A low-carbon alloy and spheroidizing annealing technology, which is applied in the field of deep processing of wire rods, can solve the problems of poor diffusion effect and achieve the effect of simple process, good effect and no impact on cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Taking 20Cr cold heading steel as an example, the specific process of the spheroidizing annealing method of low carbon alloy cold heading steel is as follows.

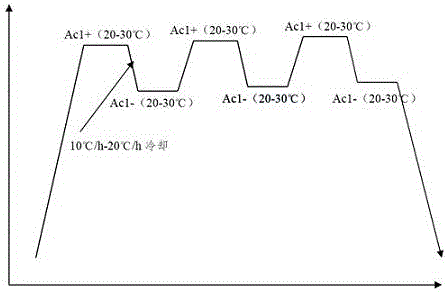

[0030] The Ac1 temperature of 20Cr cold heading steel is 766°C. Since the carbon content of this steel is not high, it can be drawn directly, with a deformation of 25%. Taking a wire rod with a diameter of Φ16mm as an example, after pickling and phosphating, it can be drawn to Φ13.8mm at one time. After that, the spheroidizing annealing process is carried out. First, the temperature is raised to 790°C for 1.5h, and then the temperature is lowered to 740°C at 15°C / h for 1.5h; after 3 cycles, it is slowly cooled to 550°C, and then air-cooled to room temperature.

[0031] Through the 20Cr wire rod of present embodiment spheroidization process, by figure 1 It can be seen that its spheroidized structure level is greater than 5, which can meet the requirements of cold heading with large deformation.

Embodiment 2

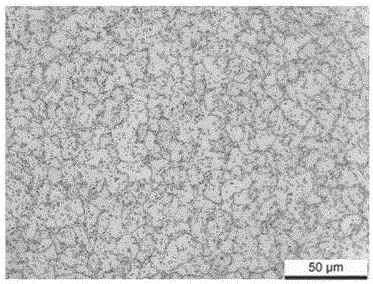

[0032] Example 2: Taking 30CrMnSi cold heading steel as an example, the specific process of the spheroidizing annealing method of low carbon alloy cold heading steel is as follows.

[0033] The Ac1 temperature of 30CrMnSi cold heading steel is 760°C. There are many types of steel alloys, and softening annealing is required before drawing. The annealing temperature is 740 ° C and the temperature is kept for 5 hours. After softening and annealing, pickling and phosphating are carried out, and then 40% cold drawing deformation is carried out; taking the Ф20mm specification as an example, it is drawn twice to Ф16.1mm. Keep at 780°C for 2 hours, then cool at 18°C / h to 730°C and hold for 1.5 hours. After 3 cycles, the furnace is cooled to 500°C and then air-cooled to room temperature.

[0034] The 30CrMnSi wire rod processed by the spheroidization of the present embodiment is made of figure 2 It can be seen that its spheroidized structure level is 6, which can meet the requiremen...

Embodiment 3

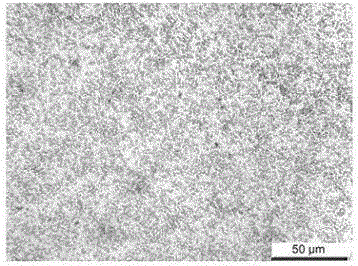

[0035] Example 3: Taking 30CrMo cold heading steel as an example, the specific process of the spheroidizing annealing method of low carbon alloy cold heading steel is as follows.

[0036]The Ac1 temperature of 30CrMo cold heading steel is 757°C. There are many types of steel alloys, and softening annealing is required before drawing. The annealing temperature is 730 ° C and the temperature is kept for 4 hours. After softening and annealing, pickling and phosphating are carried out, and then 30% cold drawing deformation is carried out; taking the Ф14mm specification as an example, it is drawn to Ф11.7mm at one time. Insulate at 785°C for 2.5h, then cool at 10°C / h to 730°C and hold for 1.0h. After 3 cycles, the furnace is cooled to 500°C and then air-cooled to room temperature.

[0037] Through the 30CrMo wire rod of present embodiment spheroidization process, by image 3 It can be seen that its spheroidized structure level is 6, which can meet the requirements of cold heading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com