Patents

Literature

37results about How to "Extended annealing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

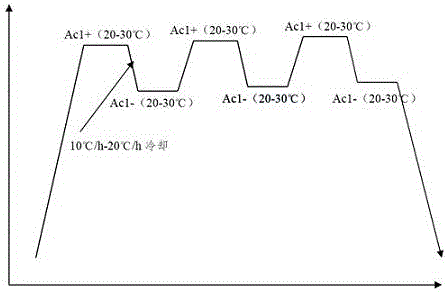

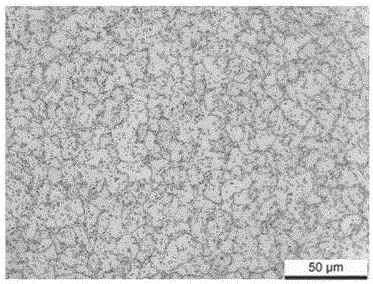

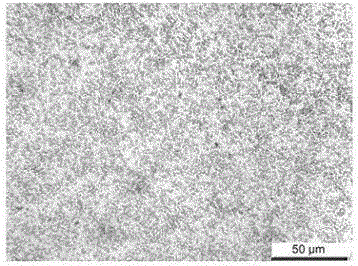

Spheroidizing annealing method for medium-and-low-carbon alloy cold forging steel

InactiveCN106011404AGood ball organizationGood effectFurnace typesHeat treatment furnacesSingle passCarbon alloy

The invention discloses a spheroidizing annealing method for medium-and-low-carbon alloy cold forging steel. The method technology includes the steps that firstly, cold drawing deforming is conducted, wherein cold drawing deforming with the deformation ranging from 25% to 40% is conducted on an alloy steel wire of the medium-and-low-carbon alloy cold forging steel; secondly, spheroidizing is conducted, wherein the temperature of the alloy steel wire obtained after cold drawing deforming is increased to Ac1+20 DEG C to Ac1+30 DEG C, heat insulation is conducted, then the temperature is reduced to Ac1-20 DEG C to Ac1-30 DEG C, and heat insulation is conducted; and thirdly, discharging is conducted, wherein the alloy steel wire obtained after spheroidizing is slowly cooled and discharged. By means of the method, an adjusting drawing and spheroidizing technology is combined with a spheroidizing annealing technology with the single-pass deformation larger than 25% so that the spheroidizing effect of medium-and-low-carbon alloy cold forging steel can reach the fifth level or higher, and the spheroidizing structure is good and cannot crack in the subsequent cold forging process; and the beneficial effects that the technology is simple and effects are good are achieved. When multiple times of repeated spheroidizing annealing periods are adopted in the method, although several times of cooling is added, the total annealing time is not prolonged, the cost is not affected, and the beneficial effects that effects are good and cost is low are achieved.

Owner:XINGTAI IRON & STEEL

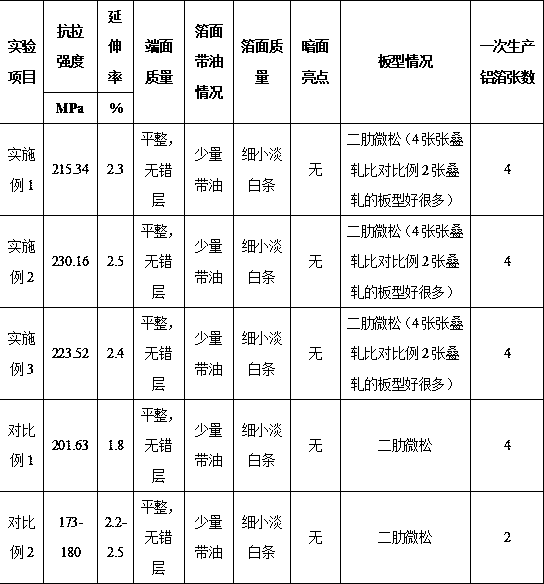

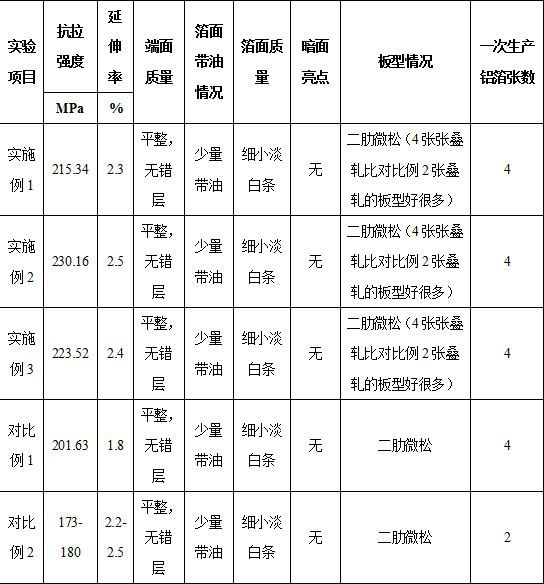

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

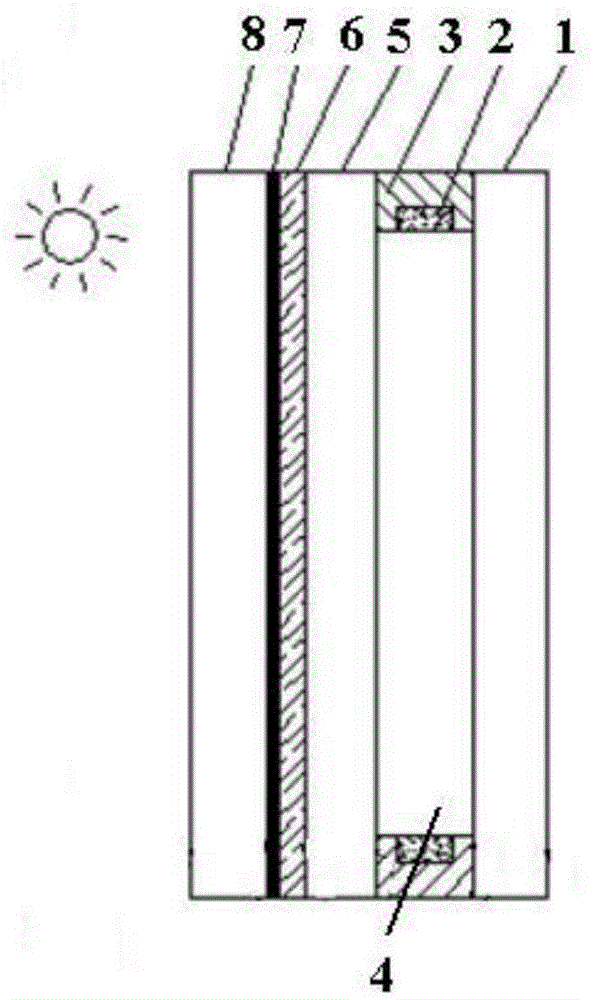

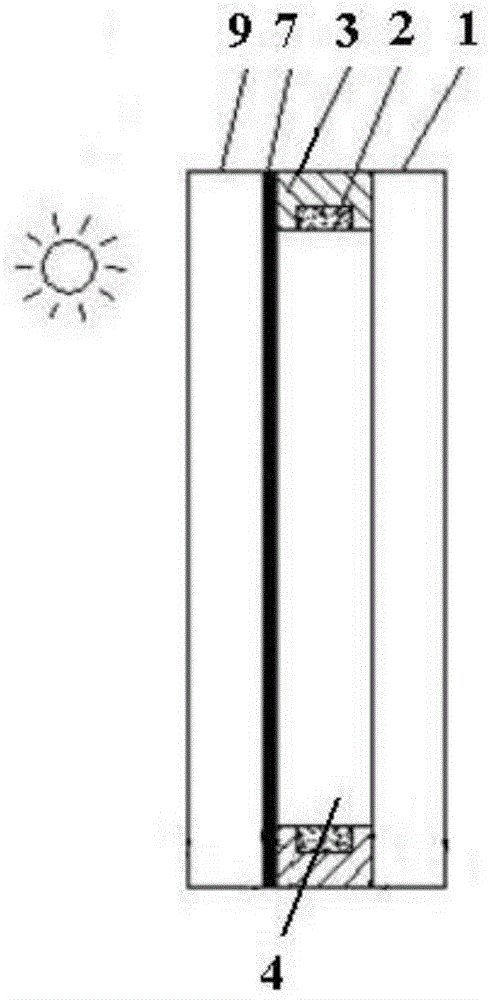

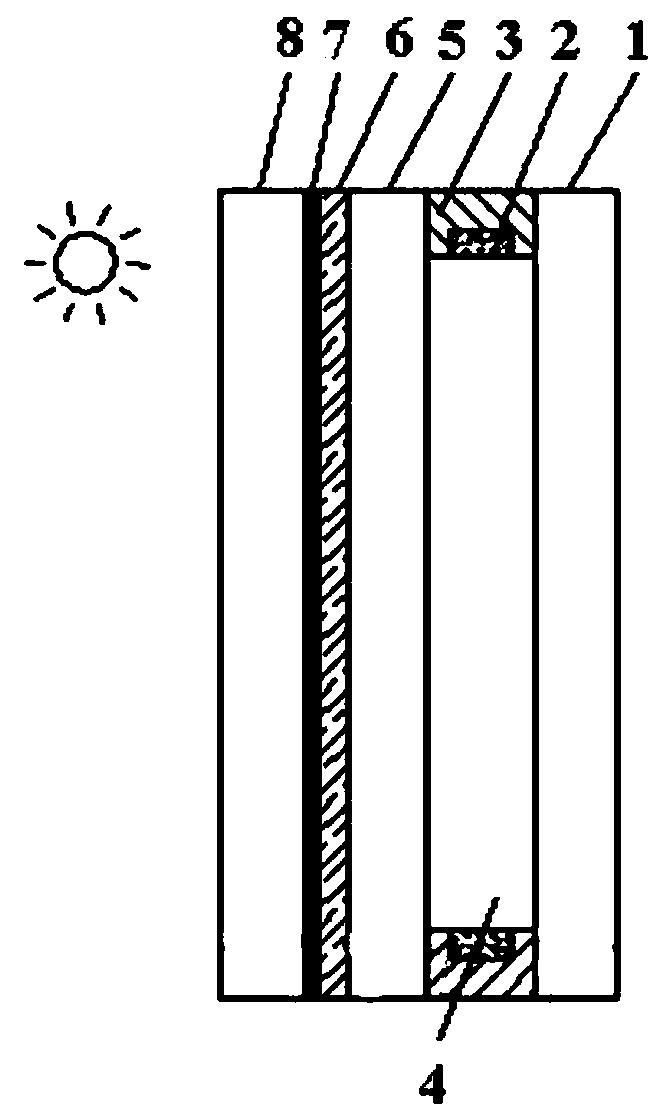

Intelligent heat-color light-dimming energy-saving glass and manufacturing method thereof

ActiveCN106150290ADelay agingExtended service lifeUnits with parallel planesNon-linear opticsComposite filmBuilding energy

The invention relates to intelligent heat-color light-dimming energy-saving glass. The intelligent heat-color light-dimming energy-saving glass is characterized by comprising a first glass layer, a frame and a glass complex which are adhered in sequence, wherein the first glass layer is boned with the glass complex through the frame to form a hollow glass structure. The glass complex is selected from single-layer glass or interlayer glass structures. The glass complex comprises an intelligent heat-color film layer having a phase-change function. The intelligent heat-color light-dimming energy-saving glass achieves heat adjustment with environment temperature change and can be widely applied to the field of building energy-saving door windows and vehicle and ship windows. By the adoption of the structure, impact resistance and other safety properties of the glass can be improved, the service life of a vanadium oxide composite film layer can be prolonged, and the demands for different environmental glass strength can be met by selecting multiple substrate materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

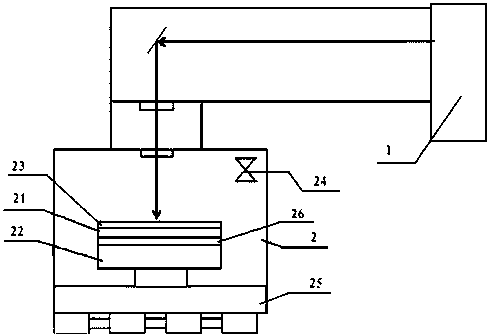

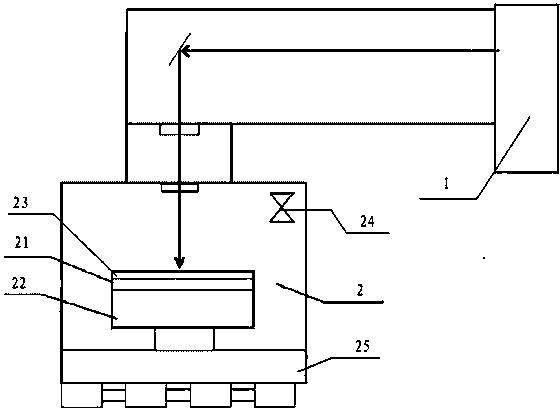

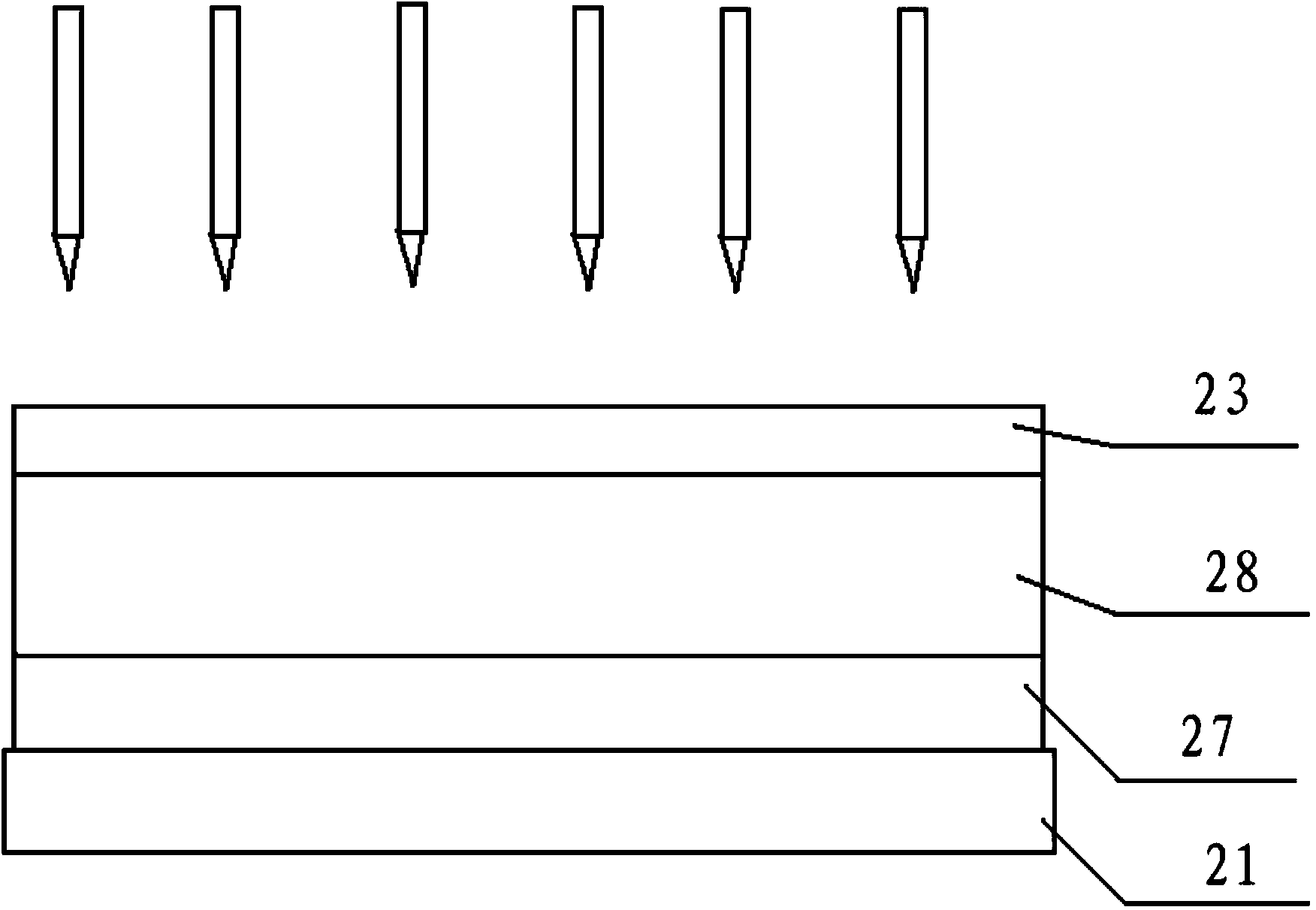

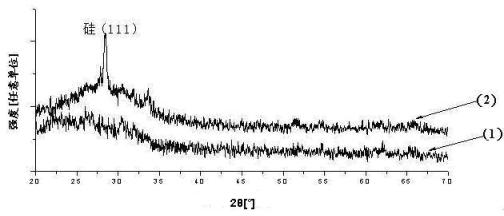

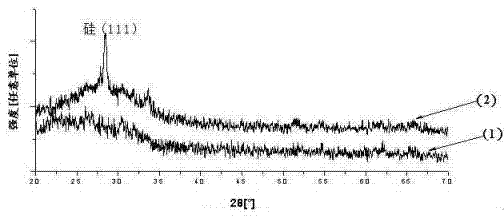

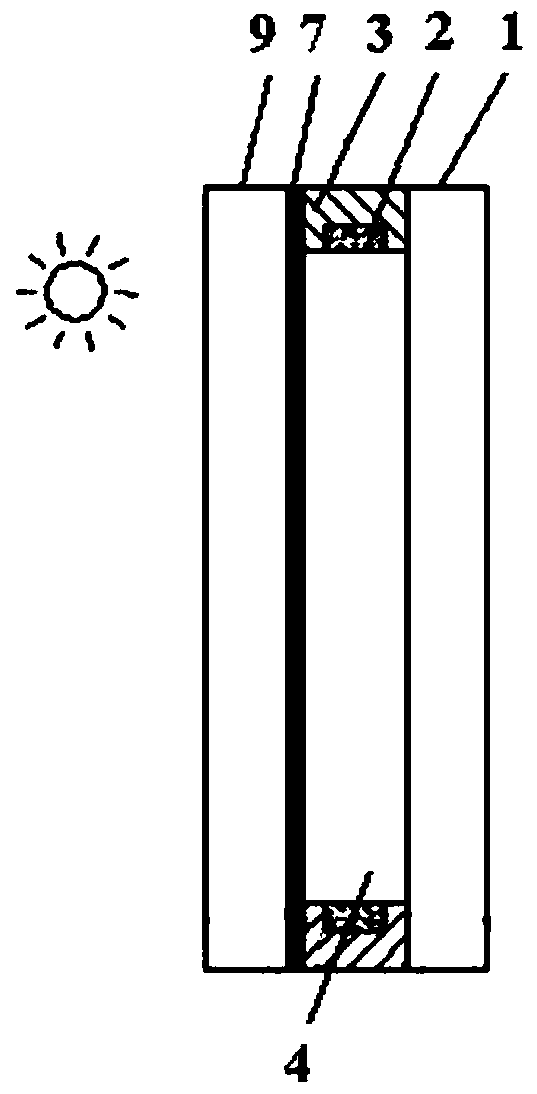

Quasi molecule laser annealing apparatus and preparation method of low-temperature polysilicon thin film

ActiveCN104392913AReduce temperature differenceReduce the rate at which the temperature decreasesSemiconductor/solid-state device manufacturingState of artOptoelectronics

The invention provides a quasi molecule laser annealing apparatus and a preparation method of a low-temperature polysilicon thin film, for solving the problems of short effective annealing time and quite small crystal grains during annealing of a conventional low-temperature polysilicon thin film in the prior art. In the quasi molecule laser annealing apparatus, a heating unit is arranged at one side, which is far away from an amorphous silicon thin film, at a substrate to be processed, for heating the substrate to the processed. The heating unit heats the substrate during the annealing process of the substrate to be processed, such that the temperature difference between the substrate to the processed and the amorphous silicon thin film is reduced, heat generated when laser is irradiated on the amorphous silicon thin film is not rapidly conducted to the substrate, the temperature reduction speed of the amorphous silicon thin film is slowed down, the annealing time is prolonged, and fused amorphous silicon can be conveniently annealed to form the large-crystal-grain polysilicon thin film. Since the preparation method of the low-temperature polysilicon thin film employs the quasi molecule laser annealing apparatus, the large-crystal-grain polysilicon thin film can be obtained, and a polysilicon thin film transistor with higher mobility can be obtained.

Owner:BOE TECH GRP CO LTD

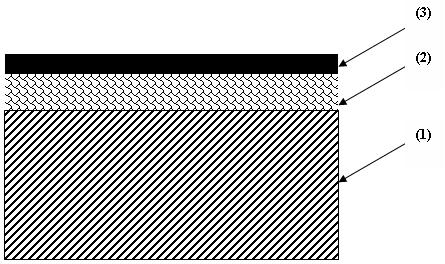

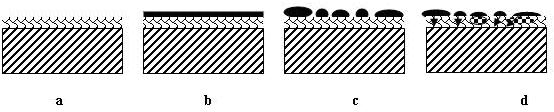

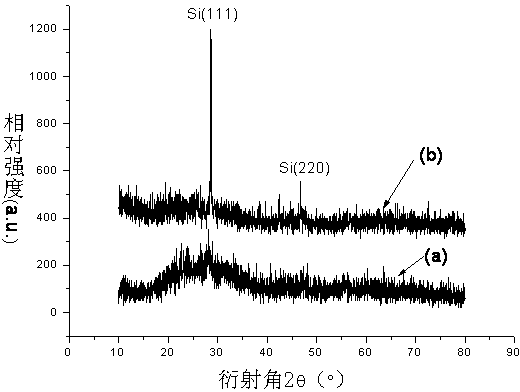

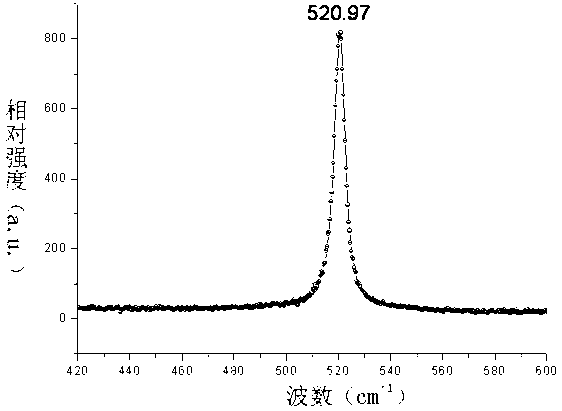

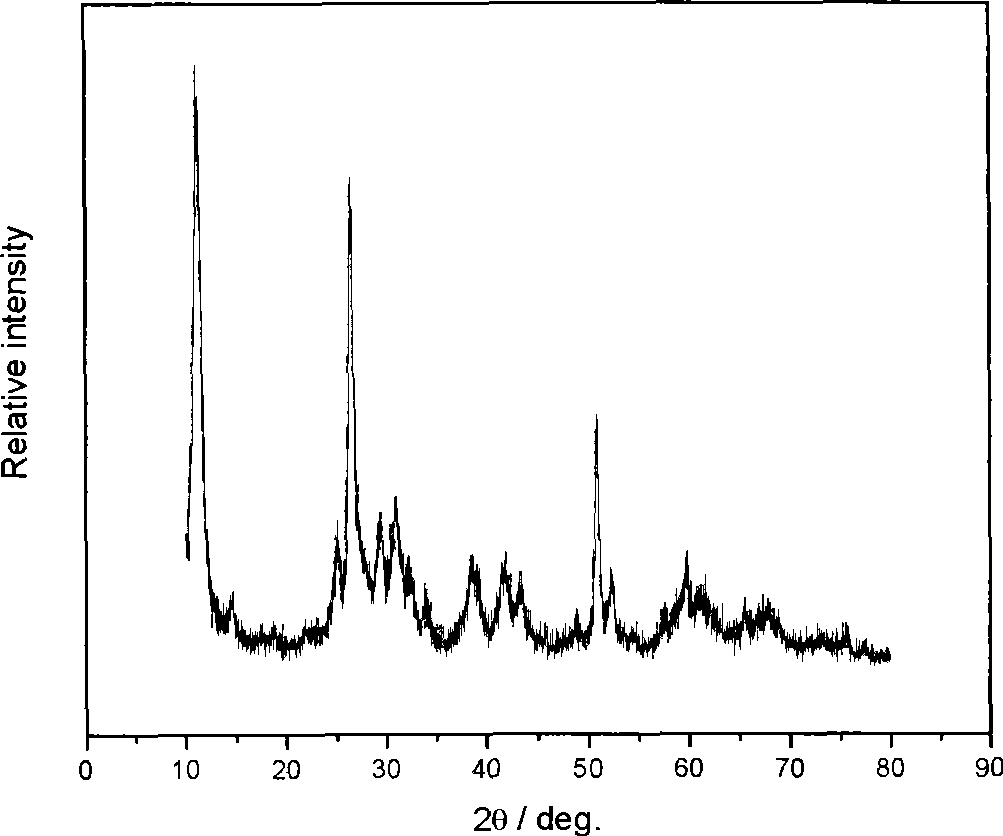

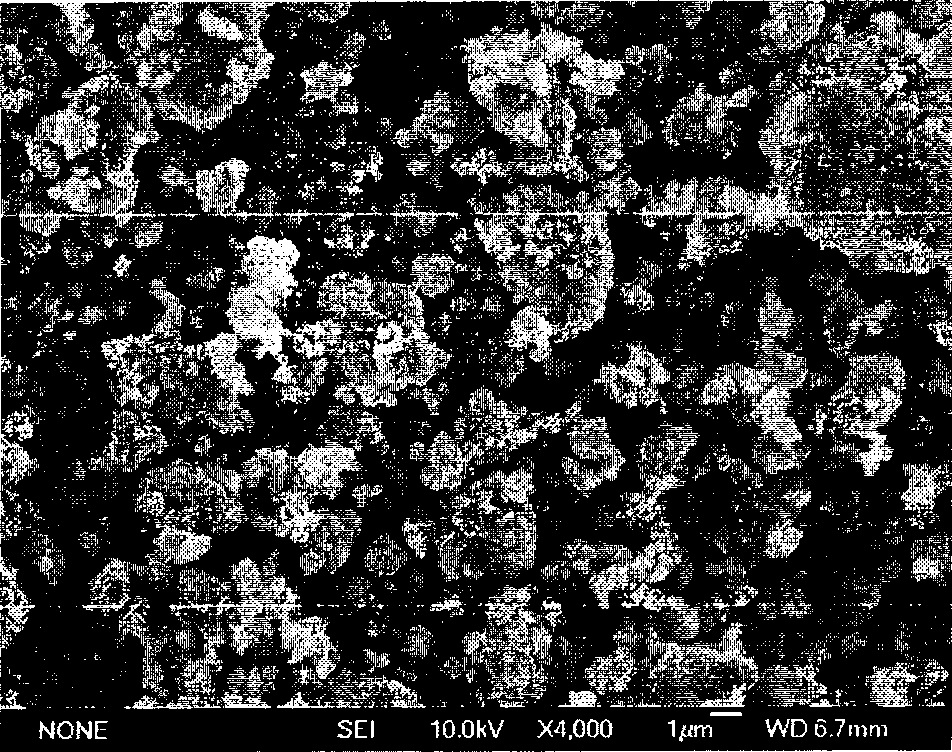

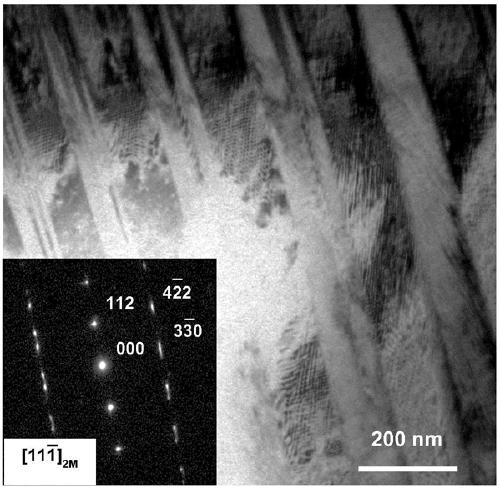

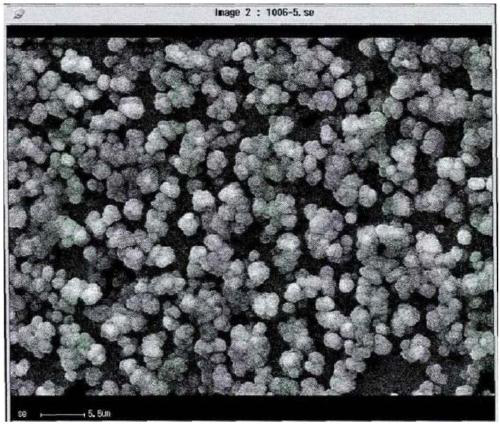

Method for inducing amorphous silicon film with tin to be crystallized into polycrystalline silicon film

InactiveCN102243991ASimple process structureEasy to operateSemiconductor/solid-state device manufacturingField-effect transistorNitrogen gas

The invention relates to a method for preparing a polycrystalline silicon thin film, in particular to a method for inducing an amorphous silicon thin film with tin to be crystallized into a polycrystalline silicon thin film at a low temperature. according to the main technical scheme of the invention, the method comprises the following steps of: 1, carrying out ultrasonic cleaning on a glass substrate by using acetone and deionized water respectively to clean the glass substrate; 2, growing a layer of amorphous silicon (a-Si:H) thin film on the glass substrate by using a plasma enhanced chemical vapor deposition method (PECVD), wherein the temperature of the substrate is about 200 DEG C, and the thickness of the thin film is 200nm-300nm during deposition; 3, growing a layer of metal tin (Sn) thin film with the thickness of 10nm-20nm on the amorphous silicon thin film by using a physical vapor deposition method so as to obtain a substrate / (a-Si:H) / Sn structure; 4, arranging the substrate / (a-Si:H) / Sn in a heat treatment furnace in a laminated manner, and carrying out heat treatment for more than 1 hour at the temperature of 450 DEG C, then cooling naturally, where nitrogen (N2) is introduced and used as a protection gas during the whole annealing process; and 5, removing the remained metal tin on the surface with concentrated hydrochloric acid with the concentration of 37.5% to finally obtain the polycrystalline silicon thin film which is crystallized under the induction of tin, wherein the particle size is about 70-200nm. The method is applicable to the fields of thin-film field effect transistors and solar cells.

Owner:SHANGHAI UNIV

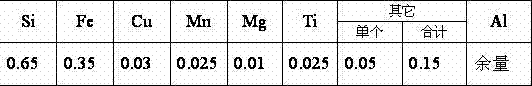

Aluminum alloy cable strap material and production method thereof

InactiveCN102191414ALow tensile strengthHigh tensile strengthSingle bars/rods/wires/strips conductorsProcess efficiency improvementSocial benefitsUltimate tensile strength

The invention relates to an aluminum alloy cable strap material and a production method thereof. The aluminum alloy cable strap comprises the following components in percentage by weight: 0.60 to 0.80 percent of Si, 0.20 to 0.40 percent of Fe, less than or equal to 0.05 percent of Cu, less than or equal to 0.03 percent of Mn, less than or equal to 0.03 percent of Mg, 0.02 to 0.03 percent of Ti and the balance of Al and inevitable impurities. The production method comprises the following steps of: smelting, refining in a standing furnace, refining crystalline grains, online degassing, filtering, continuous casting rolling, cold rolling, foil rolling, slitting and annealing. The tensile strength of the aluminum alloy cable strap is 90 to 105MPa and the percentage elongation is more than or equal to 23 percent. When the aluminum alloy cable strap is compared with the traditional product, the tensile strength is reduced, the percentage elongation is improved and requirements of clients are met to a greater extent. The production process is simplified; annealing for one time is required in the production process; and the product with low tensile strength and high percentage elongation can be obtained without adding any process in the subsequent processing process. By the method, the production cost can be saved, and the production efficiency and the yield are improved. The method is easy to popularize and has obvious economic and social benefits.

Owner:河南顺源宇祥铝业科技有限公司

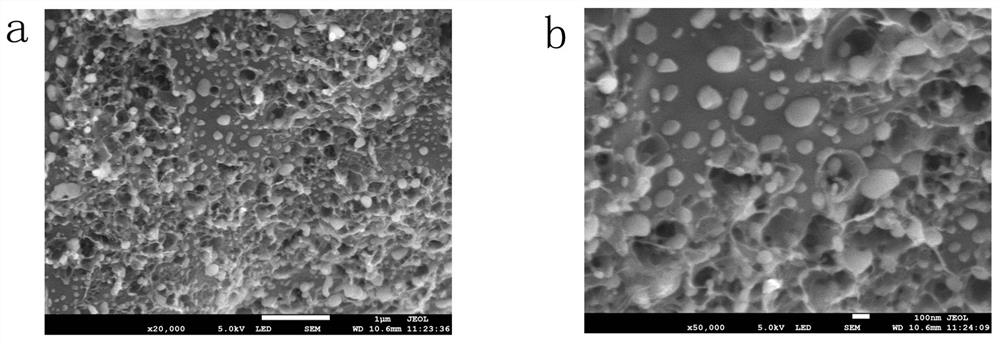

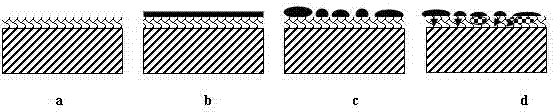

Method for preparing polycrystalline silicon film by carrying out induced crystallization on amorphous silicon film by using metallic copper under low temperature

InactiveCN102709404AReduce pollutionImprove compatibilityFinal product manufactureChemical vapor deposition coatingOptoelectronicsField-effect transistor

The invention relates to a preparation method of a polycrystalline silicon film, in particular to a method for preparing a polycrystalline silicon film by carrying out induced crystallization on an amorphous silicon film by cycle annealing under low temperature by using catalytic action of metallic copper. The main technical scheme of the invention is as follows: the method comprises the following steps of: growing a substrate / amorphous silicon / silicon dioxide / copper film structure on a glass substrate, then carrying out cycle annealing, putting a sample in corrosive liquid for corroding after first annealing is finished, and carrying out cycle annealing and corroding again, and drying the sample with nitrogen; and finally preparing the polycrystalline silicon film prepared by induced crystallization by copper, wherein the grain size is about 50-200nm. The method disclosed by the invention can ease the problem of serious metal pollution in the traditional MIC (Metal Induced Crystallization) technology and is suitable for the field of thin film field effect transistors and thin-film solar cells.

Owner:SHANGHAI UNIV

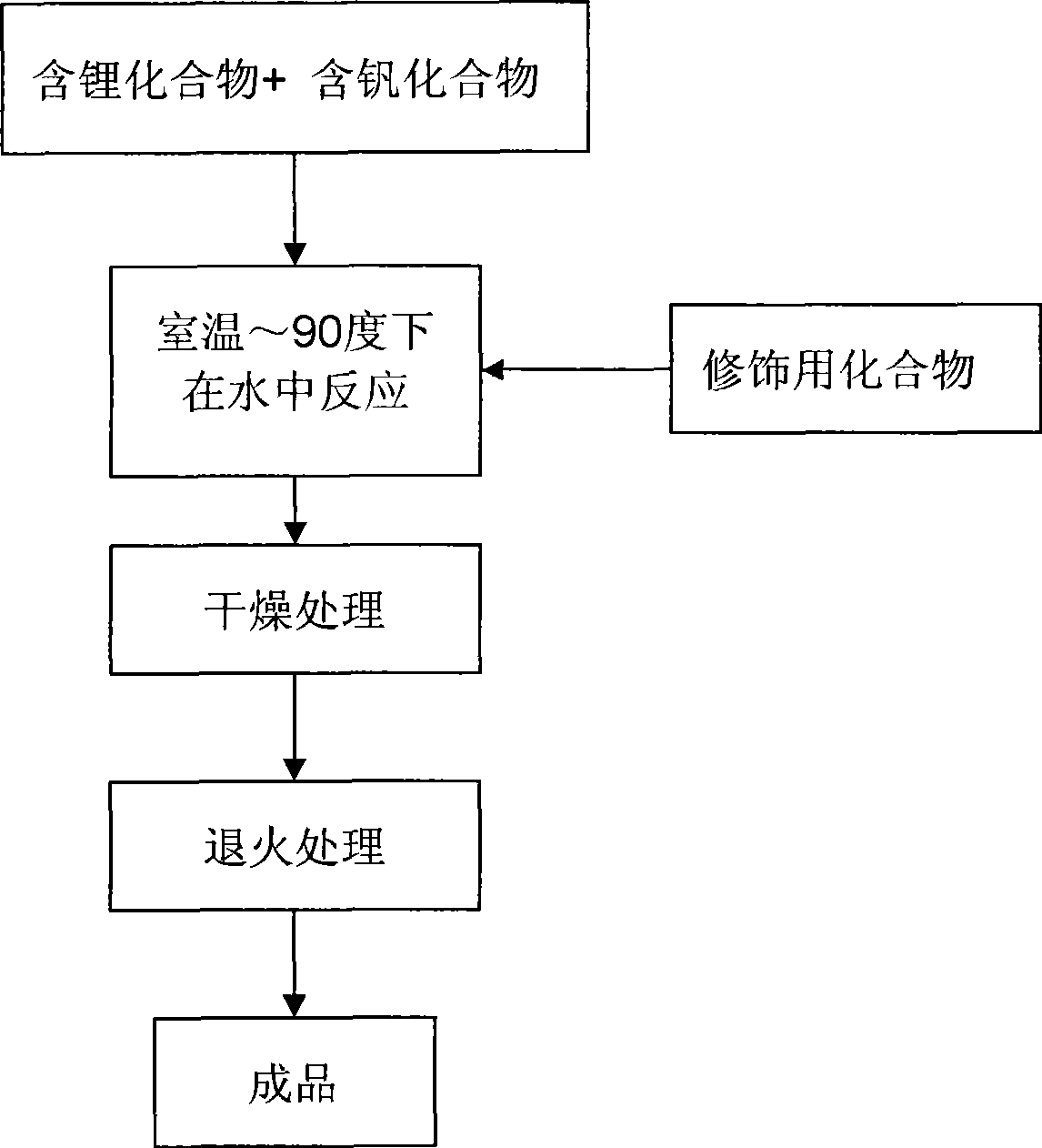

Low temperature synthesizing method of long life lithium vanadate

InactiveCN101503213AComposition is easy to controlSolve the problem that the stoichiometric ratio cannot be accurately controlledElectrode manufacturing processesVanadium compoundsVanadium CompoundsRoom temperature

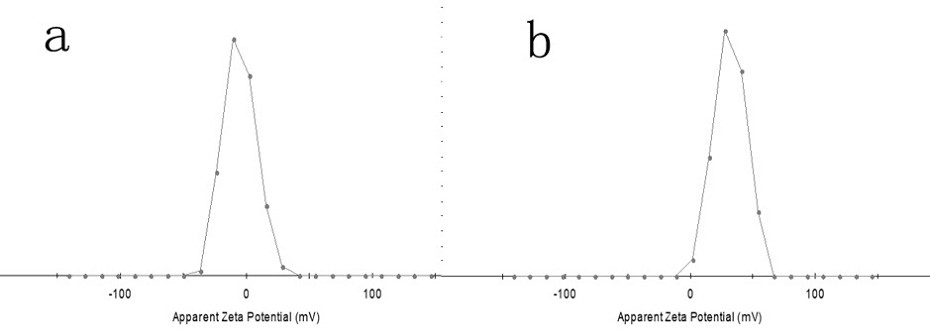

The invention discloses a low temperature synthetic method for lithium vanadate with long service life, which comprises the following steps: firstly, reacting a lithium compound and a vanadium compound in water for 0.5 to 10 h at the temperature of room temperature to 90 DEG C according to the molar ratio (0.9 to 1.1) of a lithium ion and a vanadium ion, wherein the weight ratio of the water and a solid mixture is (1 to 10):1; secondly, drying the product prepared in the step 1 at the temperature of room temperature to 120 DEG C, wherein the drying time is 1 to 24h; and thirdly, annealing for 0.5 to 5h at the temperature of 100 to 400 DEG C. The invention has the advantages of accurate composition, long cycle life, controllable electrochemical performance, easy adulteration, cladding and other decorations, simple preparation method and low flow energy consumption.

Owner:TIANJIN B&M SCI & TECH

Composite aluminum alloy foil used for radiator and production process thereof

InactiveCN107855361AGood anti-sag performanceUniform thickness acrossMetal rolling arrangementsReduction rateAlloy

The invention discloses a composite aluminum alloy foil used for a radiator and a production process thereof. The composite aluminum alloy foil comprises an A3003 core material and an A4045 coating layer, wherein the A3003 core material and the A4045 coating layer are composited by adopting a double-sided coating method. According to the composite aluminum alloy foil used for the radiator and theproduction process thereof: during cold-rolling bonding, the skin material A4045 and the core material A3003 are initially bonded firmly according to the first-pass reduction rate of 30%-50%; comparedwith the hot-rolling composite foil, the cold-rolling composite foil has the advantages as follows: the transversal thickness of the coating layer is more uniform, and the thicknesses of the upper and lower coating layers tends to be the same; when the precision rolling reduction rate is 25%-35%, the sagging resistance ability of the composite foil is the best; besides, the annealing temperatureof the composite foil before finished product is controlled to be 320-400 DEG C, the sagging resistance ability of the composite foil is improved when the annealing is performed at 400 DEG C and the annealing time is prolonged, and the sagging resistance ability is poorer when the annealing time exceeds 80 min.

Owner:ANHUI TIANLI CENT ALUMINUM CO LTD

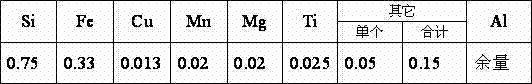

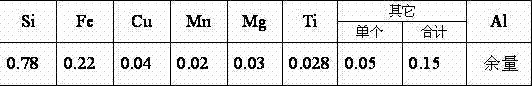

Double-sided dark battery foil and preparation method thereof

ActiveCN109402456AEasy to useQuality improvementJackets/cases materialsMetal rolling arrangementsRoom temperatureRaw material

The invention discloses double-sided dark battery foil and a preparation method thereof. The double-sided dark battery foil is prepared from the following component raw materials: Si, Fe, Cu, Mn, Mg,Ti and Al. The preparation method of the double-sided dark battery foil comprises the following steps: (1) the raw materials are added into a smelting furnace to be smelted, and molten liquid is obtained; (2) the molten liquid is input into a cast-rolling machine to be cast-rolled into a blank; (3) the cast-rolled blank is cold-rolled by a cold-rolling machine, and homogenizing annealing treatmentis conducted; and (4) after an aluminum coil subjected to homogenizing annealing is cooled to the room temperature, cold rolling in passes is conducted; (5) rerolling and edge cutting are conducted;(6) intermediate annealing treatment is conducted; (7) the aluminum coil subjected to intermediate annealing treatment is cold-rolled; and (8) the cold-rolled aluminum coil is rerolled, then foil rolling is conducted, and thus the double-sided dark battery foil is prepared. Aluminum powder on the dark side of the double-sided dark battery foil produced by the invention is effectively controlled,corrugated edges are avoided, the using performance and surface quality of a finished product are high, and the double-sided dark battery foil can be applied to most batteries.

Owner:GUANGXI BAISE XINGHE ALUMINUM

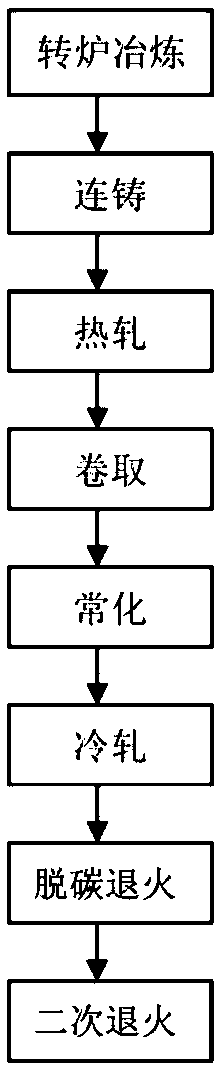

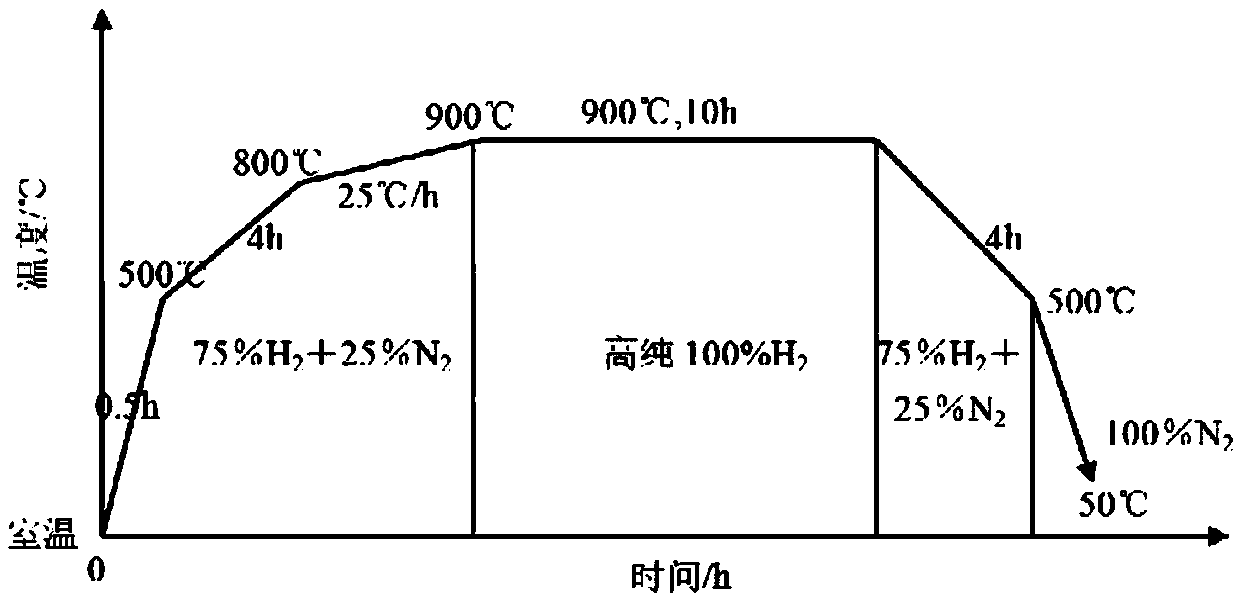

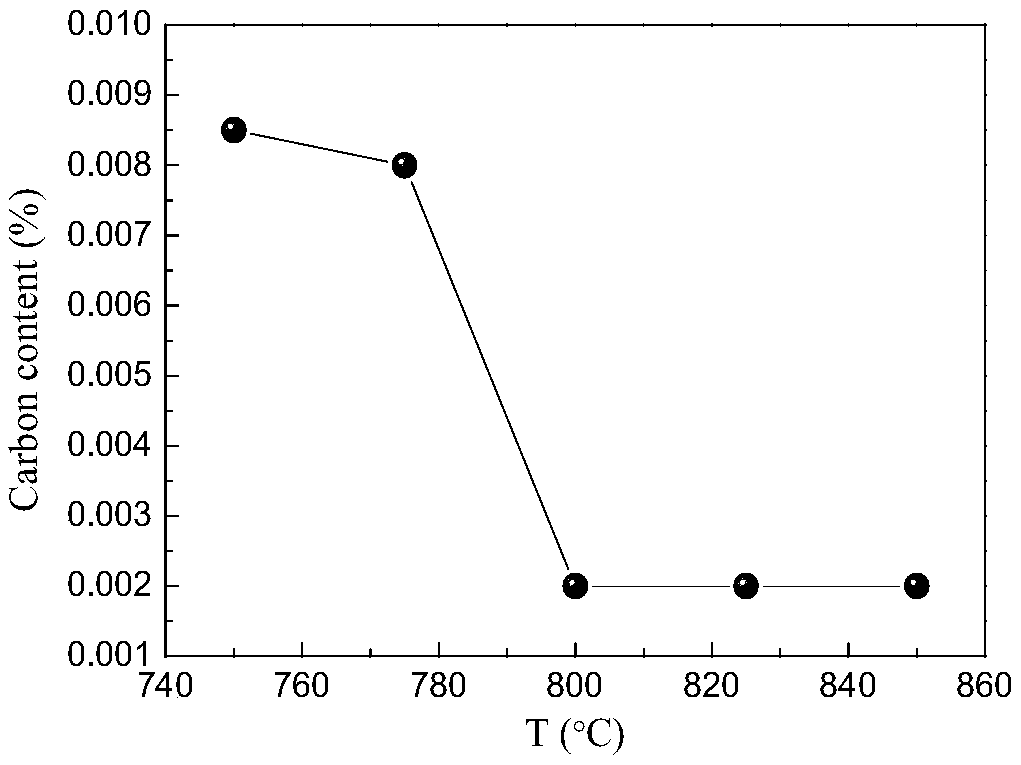

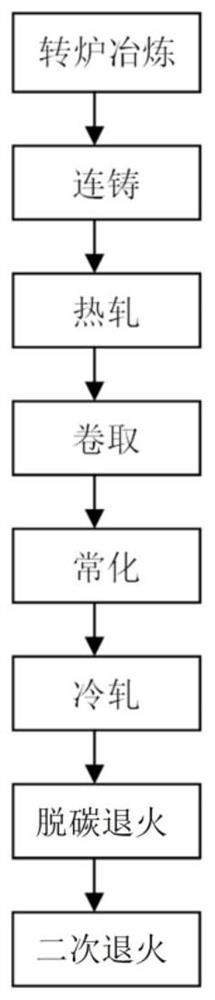

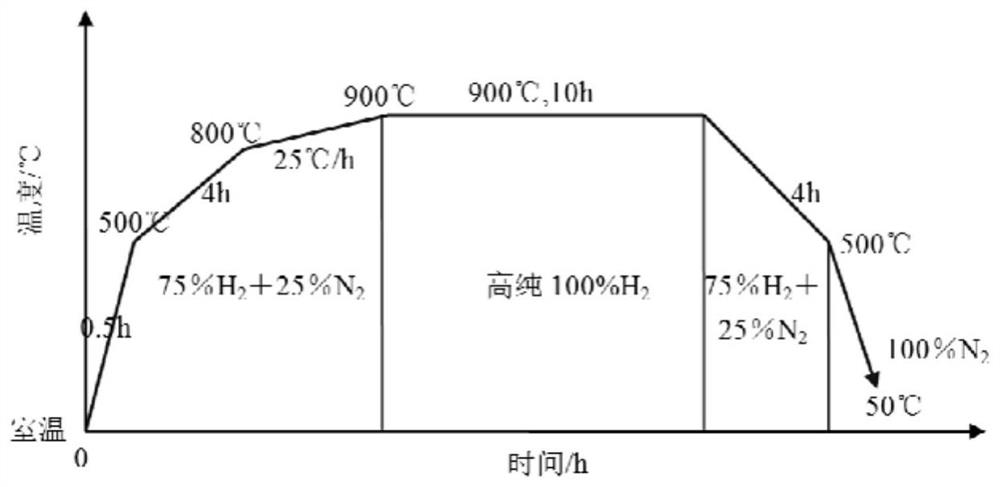

Method for producing grain oriented pure iron through secondary annealing

ActiveCN109593927AIncrease magnetic inductionExtended annealing timeHeat treatment process controlHydrogenShielding gas

The invention discloses a method for producing grain oriented pure iron through secondary annealing, and belongs to the technical field of electrotechnical soft magnetic materials. According to the method for producing the grain oriented pure iron through secondary annealing, a plate blank is subjected to secondary annealing treatment which includes a heating section, a high-temperature purifyingsection and a cooling section; and mixed gas composed of hydrogen and nitrogen serves as protective gas of the heating section, and the volume ratio of the hydrogen to the nitrogen in the mixed gas is3:1; and hydrogen serves as protective gas in the high-temperature purifying section. The temperature T<high net > of the high-temperature purifying section is 880-900 DEG C, the magnetic induction intensity B<800> of the oriented pure iron produced through secondary annealing is larger than 1.90T, and B<10000> is 2.12-2.15T. The method aims to overcome the defect that in the prior art, the high-temperature purifying section in a grain oriented pure iron producing method is poor in purifying effect, the method for producing the grain oriented pure iron through secondary annealing is providedand can achieve the good purifying effect, and by means of other technology steps, the magnetic induction intensity of the grain oriented pure iron can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

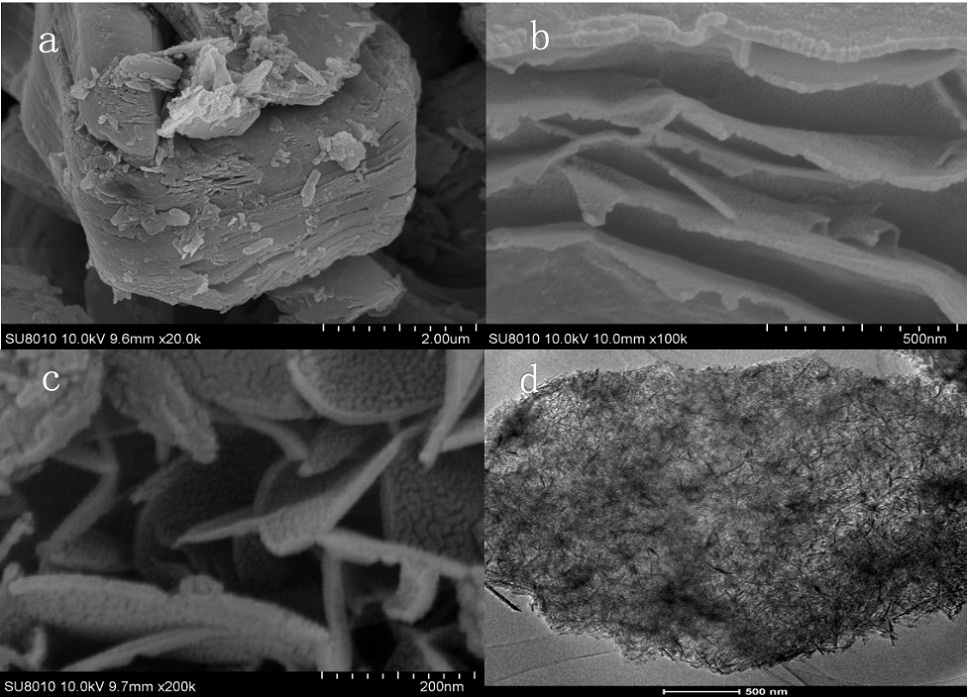

Si@ MXene nano composite material and preparation method thereof

ActiveCN111969193AOptimal Control StructureShape is easy to controlSecondary cellsNegative electrodesNano siliconSodium-ion battery

The invention discloses a Si@ MXene nano composite material and a preparation method thereof. The Si@ MXene nano composite material is composed of MXenes, nano silicon loaded on the MXenes and a hardcarbon layer coated on the surface of the MXenes. The Si@ MXene is a composite material obtained by mixing three-dimensional MXene with a modified nano-silicon solution, dropwise adding the mixture into an organic polymer solution, separating out a solid product and carrying out annealing treatment in an inert atmosphere. According to the method, MXene can be changed into a three-dimensional structure and then compounded with modified silicon, the nano composite material with larger nanosheet pores and channels, larger interlayer spacing and more active sites is prepared, and the capacity andmultiplying power of the battery can be further improved when the composite material is used as a lithium / sodium ion battery anode material.

Owner:ZHONGBEI UNIV

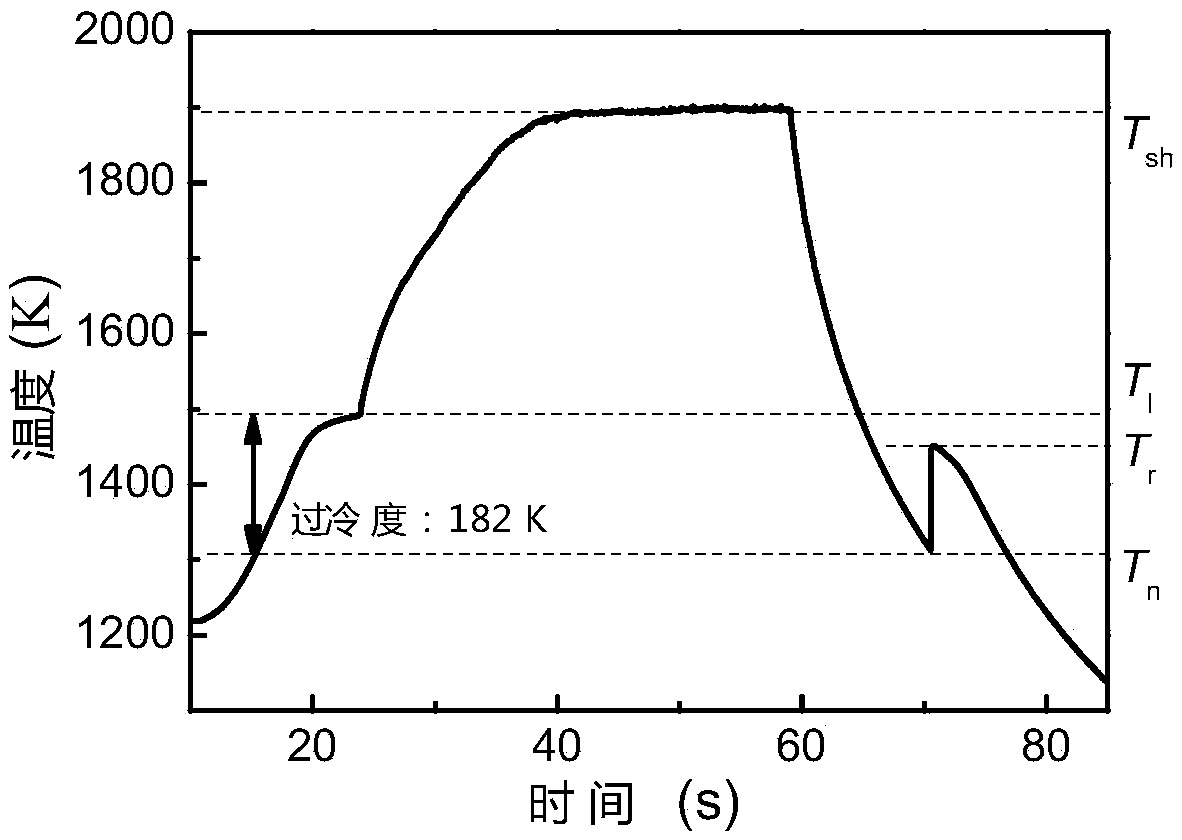

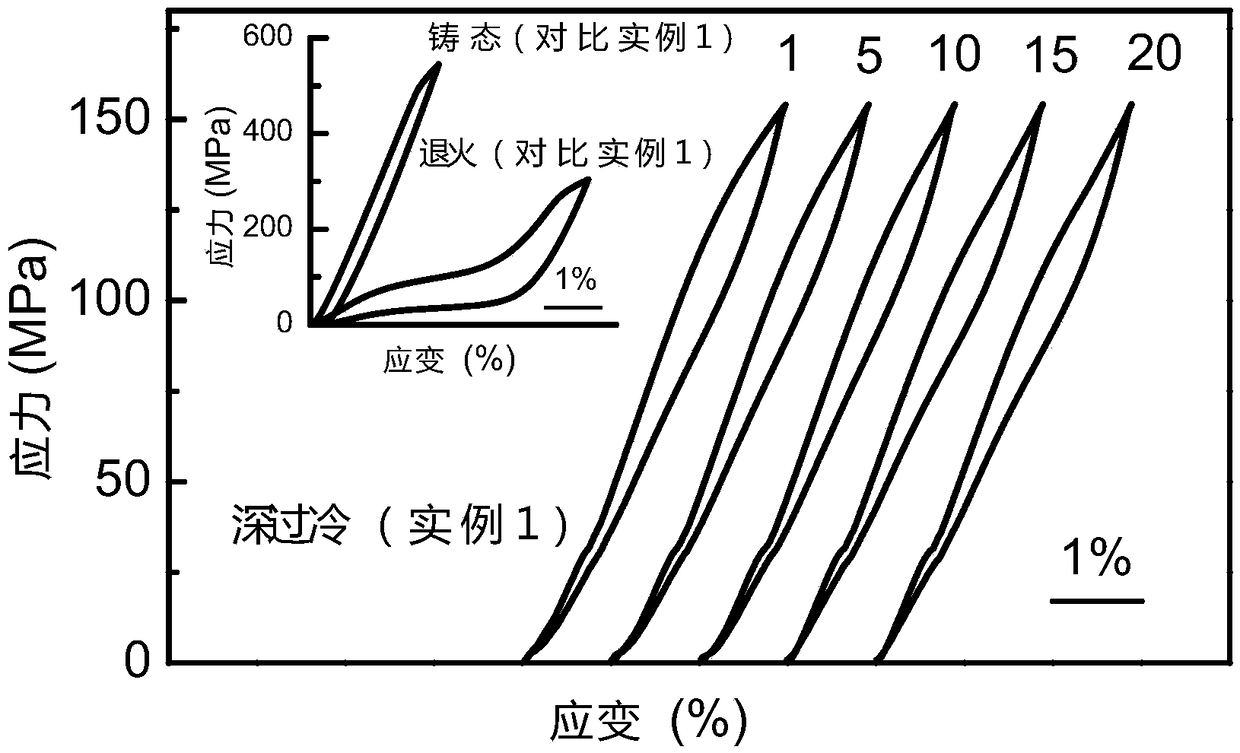

Preparation method of Pd-In-Fe elastic-thermal refrigerating material with linear superelasticity

The invention provides a preparation method of a Pd-In-Fe elastic-thermal refrigerating material with linear superelasticity. The method comprises the following steps: smelting an alloy raw material to form alloy ingots, and obtaining a Pd-In-Fe elastic-thermal refrigerating material by adopting molten glass and a circular overheat treatment deep supercooling technology. A superelasticity curve ofthe obtained Pd-In-Fe elastic-thermal refrigerating material has linear characteristics; and moreover, by virtue of multiple circulations, the shape of the curve is unchanged, the superelasticity isstable, and the obtained Pd-In-Fe elastic-thermal refrigerating material has a potential application prospect in the field of elastic-thermal refrigeration.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

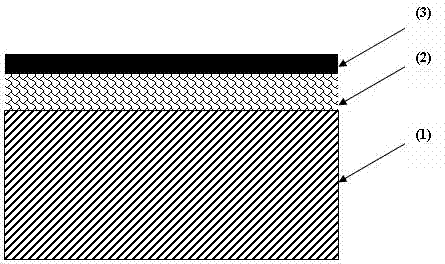

Method for preparing lanthanum titanate thin film through sol coating method

InactiveCN106868477AExtended annealing timeLiquid/solution decomposition chemical coatingPre treatmentSilicon

The invention discloses a method for preparing lanthanum titanate film by sol coating method. The invention can well improve its affinity for conductive sol by pretreating the surface of the silicon substrate, so that the conductive sol is more uniform during the spraying process. are distributed on the surface of the silicon substrate, and the lanthanum titanate conductive thin film material prepared by the chemical solution deposition method in the present invention effectively improves the conductivity of the lanthanum titanate conductive thin film material, and has the advantages of simple process.

Owner:SUZHOU NANER MATERIAL TECH CO LTD

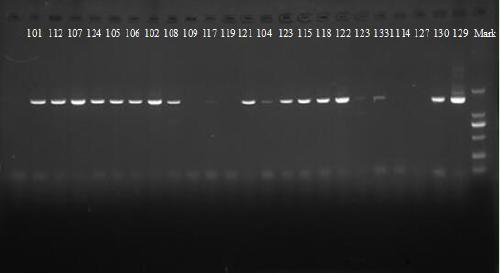

PCR rapid detection method for marine culturable bacteria, and kit

InactiveCN109234415AIncrease productionRaise the annealing temperatureMicrobiological testing/measurementMicroorganismA-DNA

The invention discloses a PCR rapid detection method for marine culturable bacteria, and a kit, belonging to the technical field of microorganism detection. The kit comprises a DNA extraction reagent,a PCR reaction reagent and an electrophoretic reagent. Among them, DNA extraction reagent is Chelex- 100; The PCR reaction reagents included two universal 16S rRNA primers (27F and 1492R) and 2 x TaqPCR Mastermix solution. Electrophoretic reagents included agarose, 50 x TBE, Goldview II nucleic acid dye, DNA Marker. The kit can be used for DNA amplification of marine culturable bacteria in a short time, and has the advantages of simple procedure, safety, economy, high efficiency and small bacterial requirement.

Owner:HEZHOU UNIV

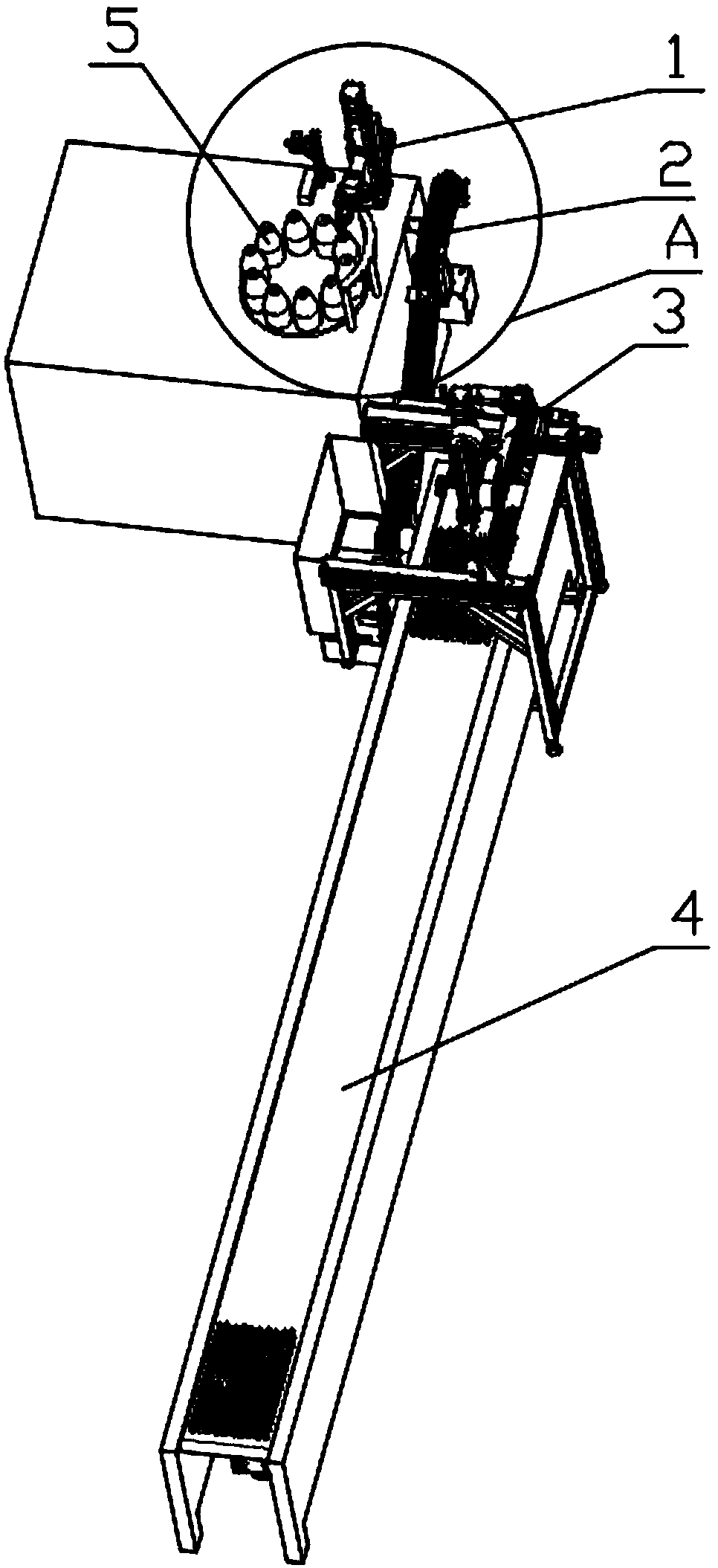

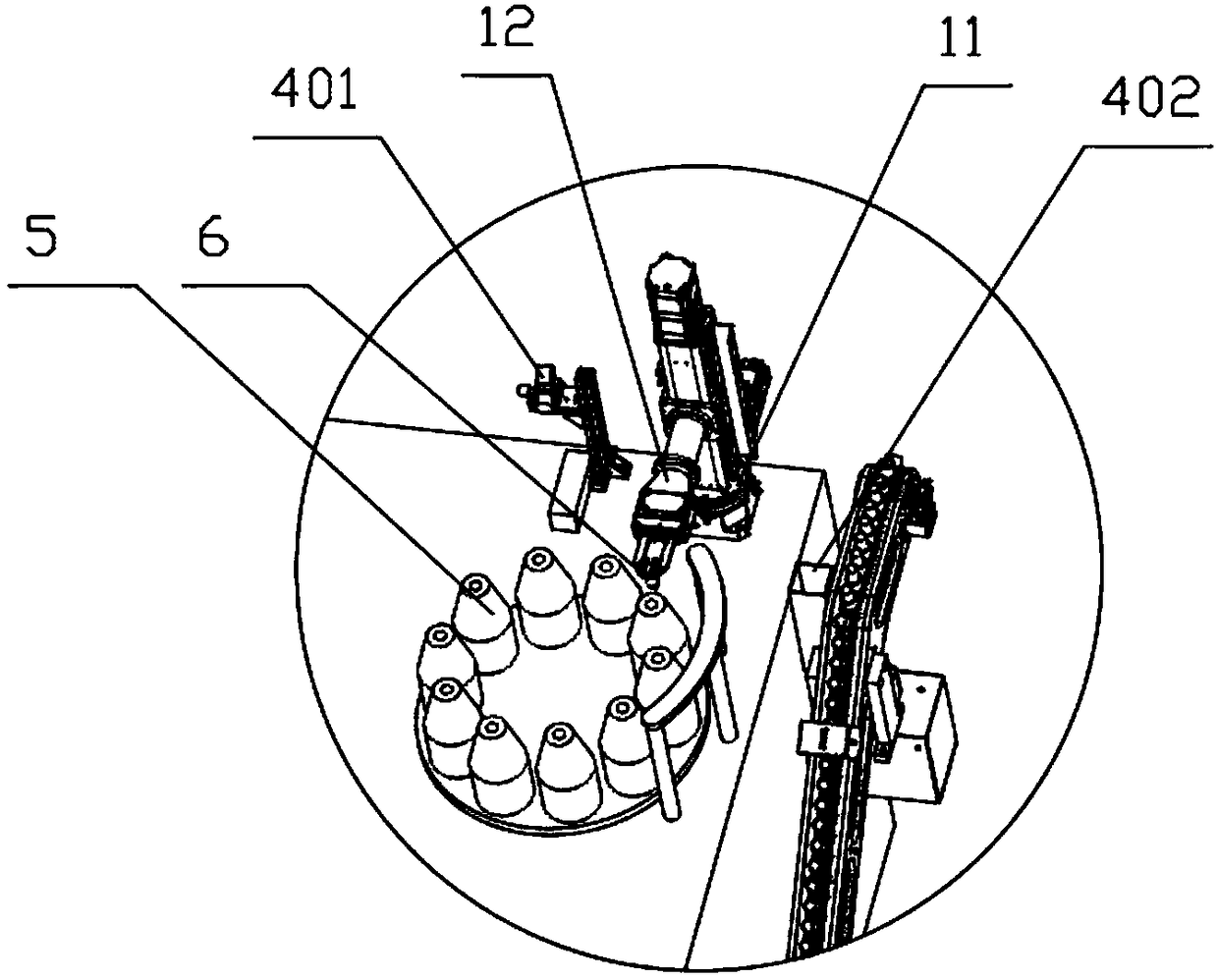

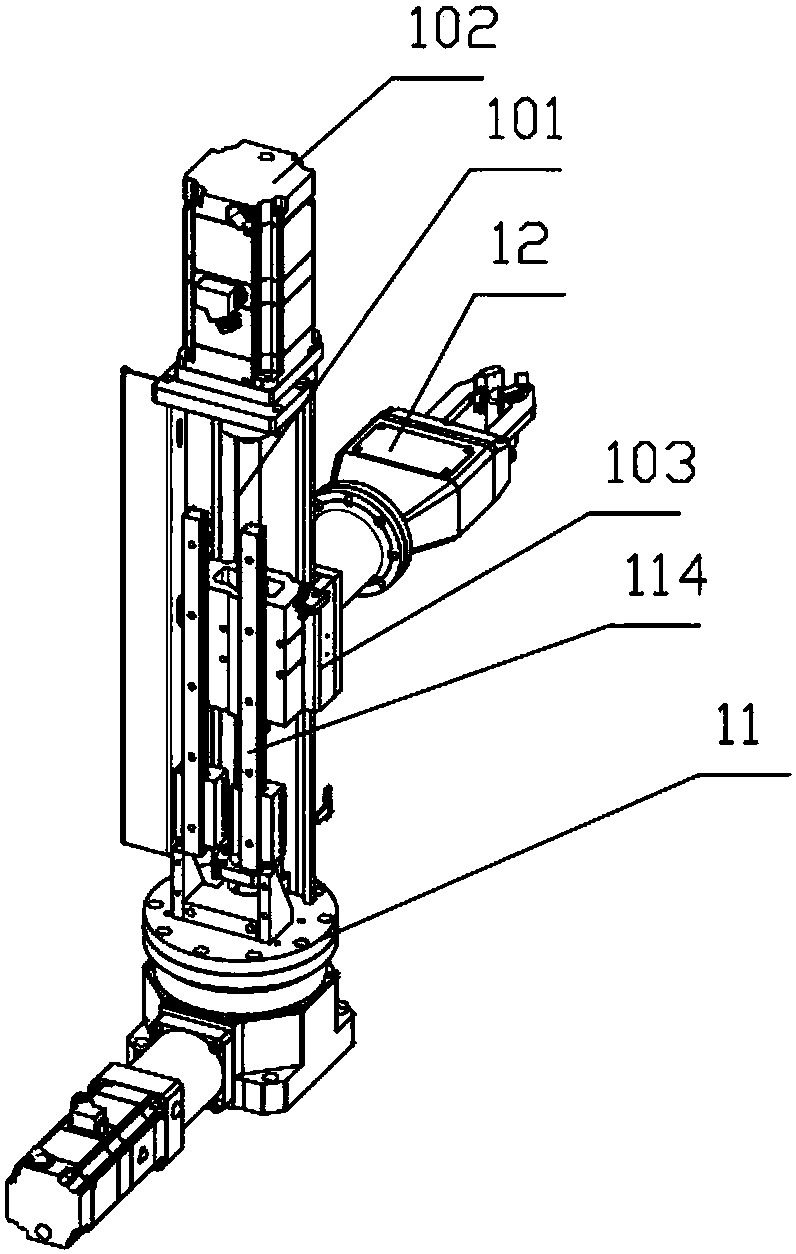

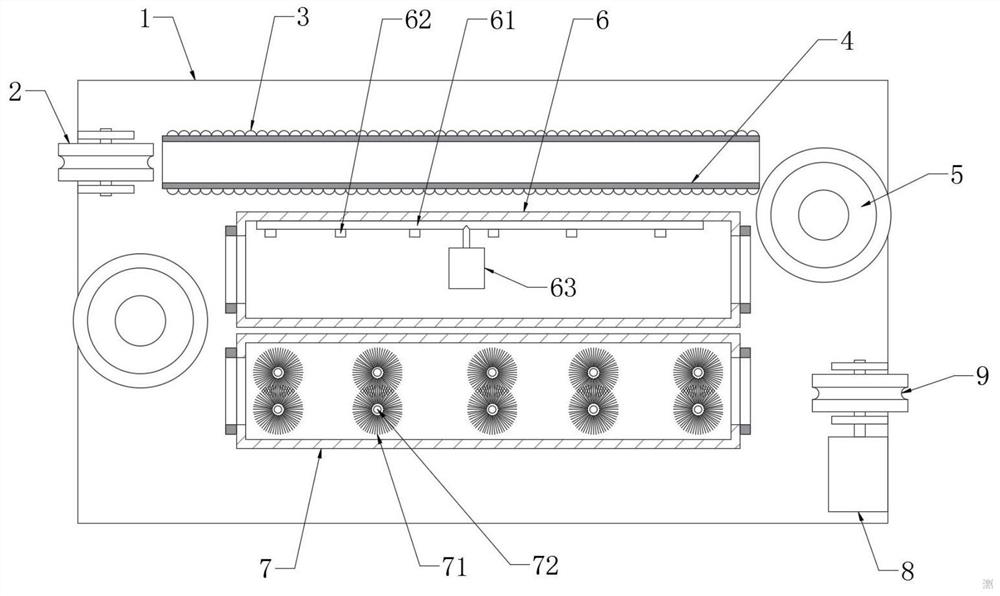

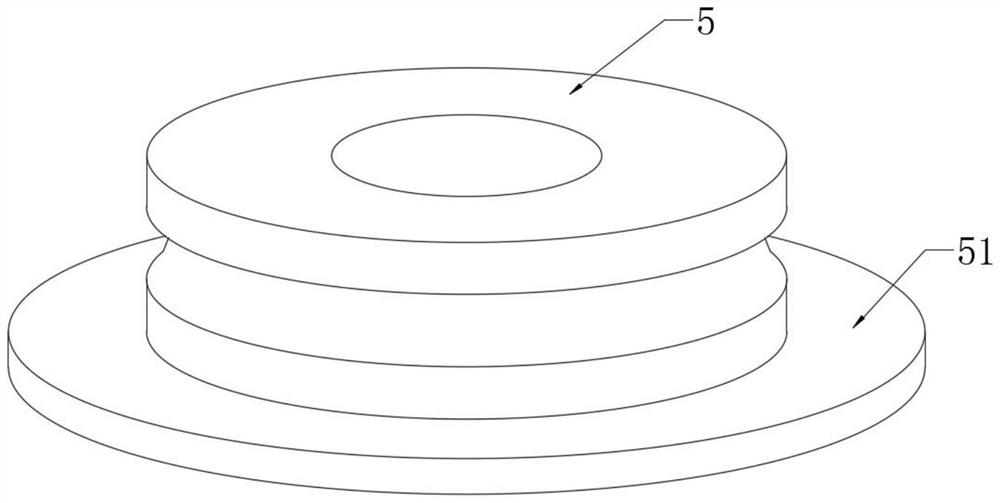

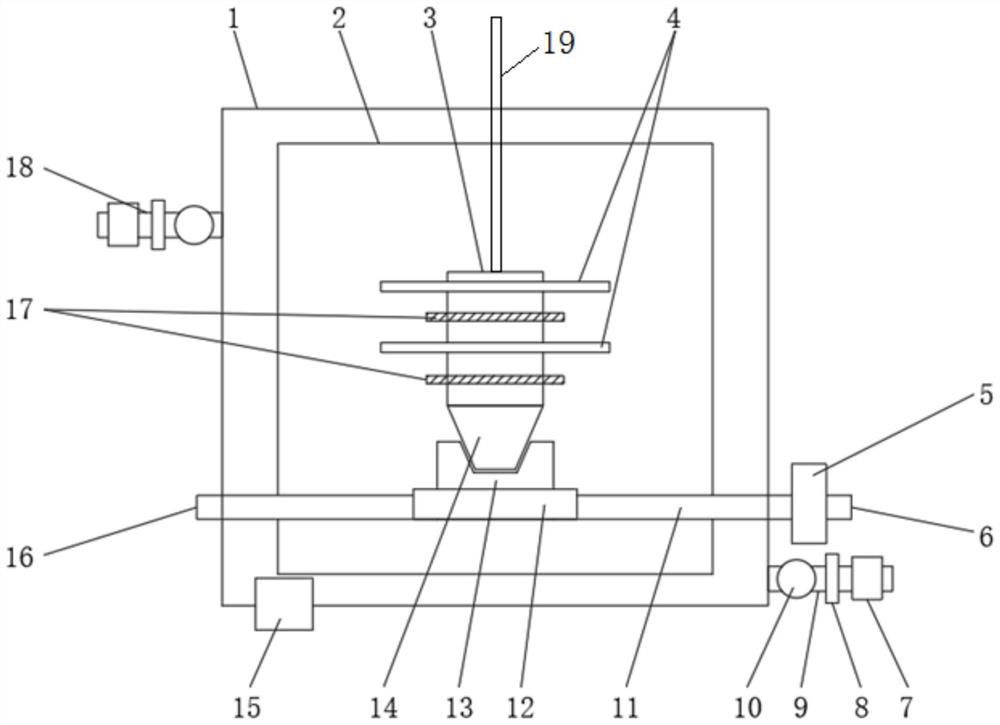

Medicine bottle transfer system

PendingCN108423408AExtended annealing timeReduce damage rateConveyorsConveyor partsDynamic annealingTransfer system

The invention discloses a medicine bottle transfer system, comprising a first grasping device, a first conveying device and a second grasping device which are sequentially mounted, wherein the first grasping device comprises a rotating platform, the upper end of the rotating platform is fixedly connected with a screw rod, and a screw rod sliding block of the screw rod is fixedly connected with a first clamp. The medicine bottle transfer system provided by the invention has the beneficial effects of prolonging annealing time after medicine bottle preparation, realizing dynamic annealing and reducing the medicine bottle damage rate.

Owner:重庆环视高科技有限公司

Method for growing CdS film or CdS nano-structure on CdTe film

ActiveCN104810249ASimple preparation processExtended annealing timeMaterial nanotechnologySemiconductor/solid-state device manufacturingHeterojunctionNano structuring

The invention relates to a method for growing a CdS film or CdS nano-structure on a CdTe film. The method comprises the following steps of 1) filling the CdTe film into a quartz tube, and then placing the quartz tube into a sintering furnace to eliminate superfluous gas inside the quartz tube; 2) inletting mixed gas containing hydrogen sulfide, increasing the temperature of the sintering furnace to anneal the CdTe film; 3) performing cooling after the annealing step, discharging the film to obtain a finished product. According to the method for growing the CdS film or CdS nano-structure on the CdTe film, the CdTe film is placed inside the sintering furnace, the sintering furnace is filled with the hydrogen sulfide, then the temperature of the sintering furnace is increased, and lastly, the CdS film or CdS nano-structure can be formed in situ on the surface of the CdTe film. The method for growing the CdS film or CdS nano-structure on the CdTe film has the advantages of being simple in equipment and low in cost, and during a growing process, being low in temperature, saving catalyst and formworks and the like, and meanwhile, is a novel heterojunction preparing method and can be applied to preparation of heterostructural photovoltaic batteries such as CIGS, CZTS and CdTe.

Owner:NANJING UNIV

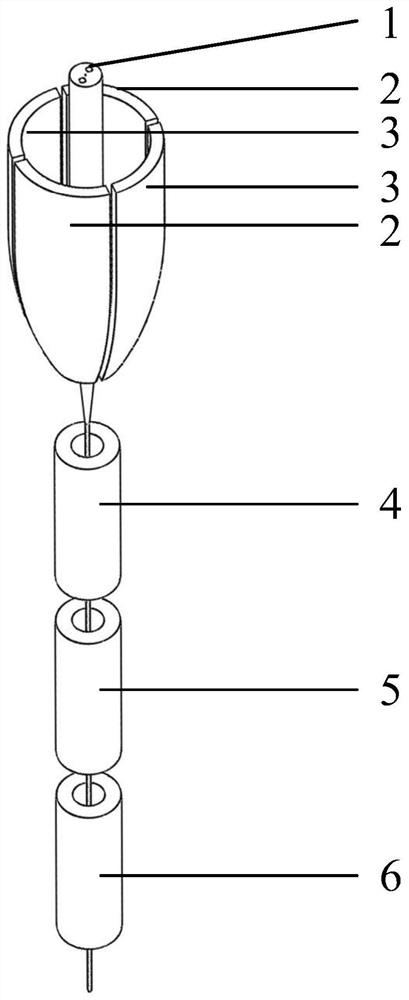

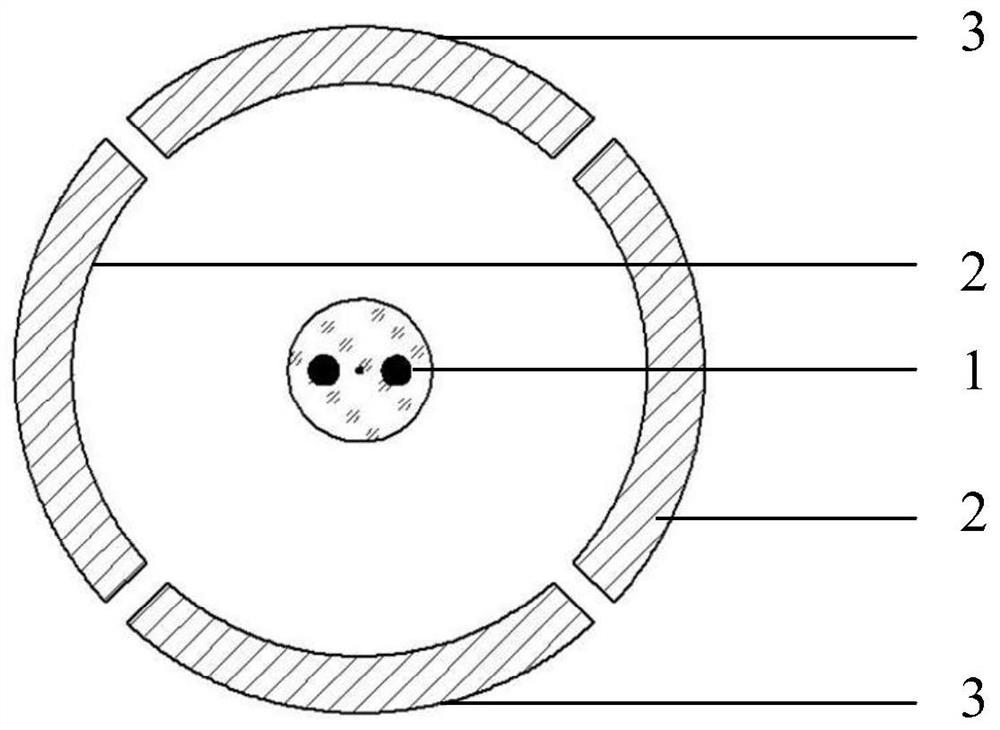

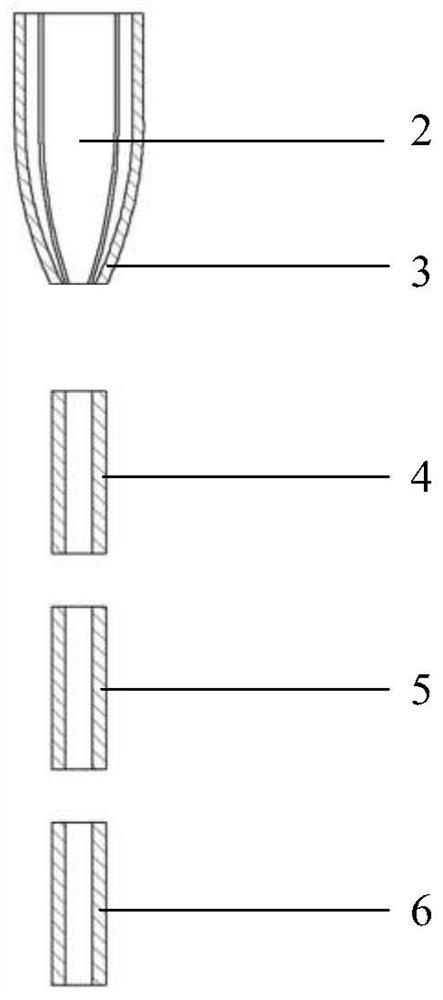

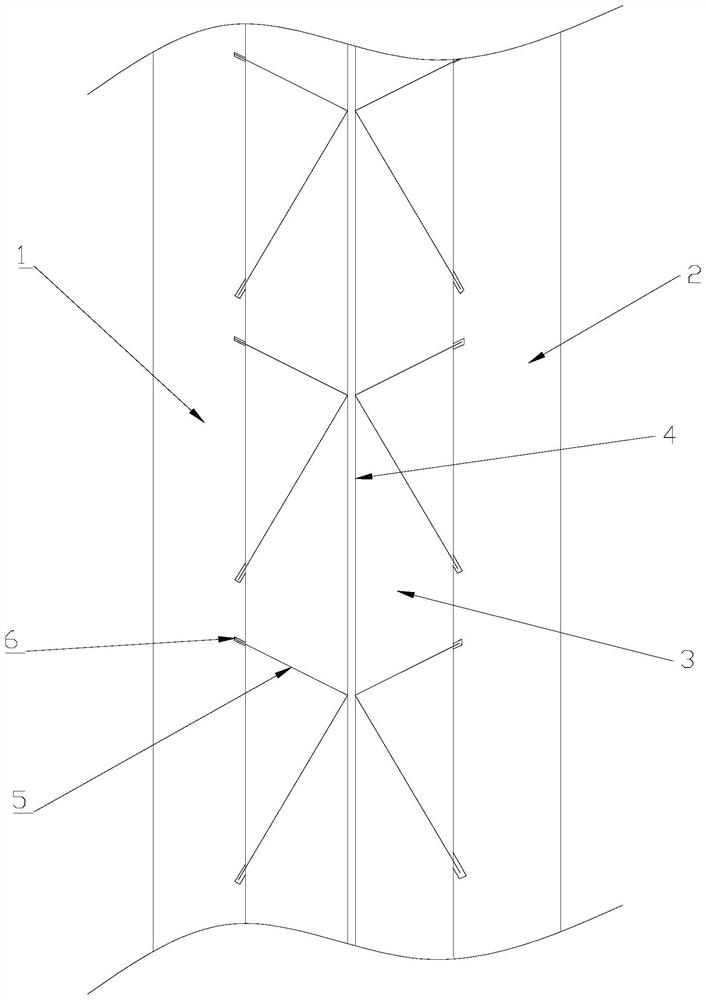

Wire drawing equipment and method for large-core-diameter single-polarization optical fiber

PendingCN111704357AEasy to adjust viscosityEasy to adjust speedGlass fibre drawing apparatusGlass fibre productsHeating furnaceOptical polarization

The invention relates to a wire drawing device and method for a large-core-diameter single-polarization optical fiber. The equipment is characterized by comprising wire drawing furnace low-temperatureareas, wire drawing furnace high-temperature areas and an annealing pipe, wherein the wire drawing furnace low-temperature areas and the wire drawing furnace high-temperature areas are alternately and sequentially arranged to form a heating furnace area, the center lines of the two wire drawing furnace high-temperature areas are perpendicular to the center connecting line of stress elements of the optical fiber, the center lines of the two wire drawing furnace low-temperature areas are consistent with the center connecting line of the stress elements, and the annealing pipe is placed under the center line of the furnace area. The method is characterized by comprising the following steps: 1, clamping a preform in the wire drawing furnace; 2, heating the wire drawing furnace; 3, loading thepreform on a disc, and setting the temperature of the annealing pipe; 4, subjecting the preform to vacuumizing treatment; step 5, carrying out wire drawing; and 6, cutting off the optical fiber. Non-uniform internal stress generated in the wire drawing process of the large-core-diameter single-polarization optical fiber can be eliminated, so the optical fiber has the characteristic of complete welding after being cut, and the usability of the optical fiber is thus realized.

Owner:上海传输线研究所

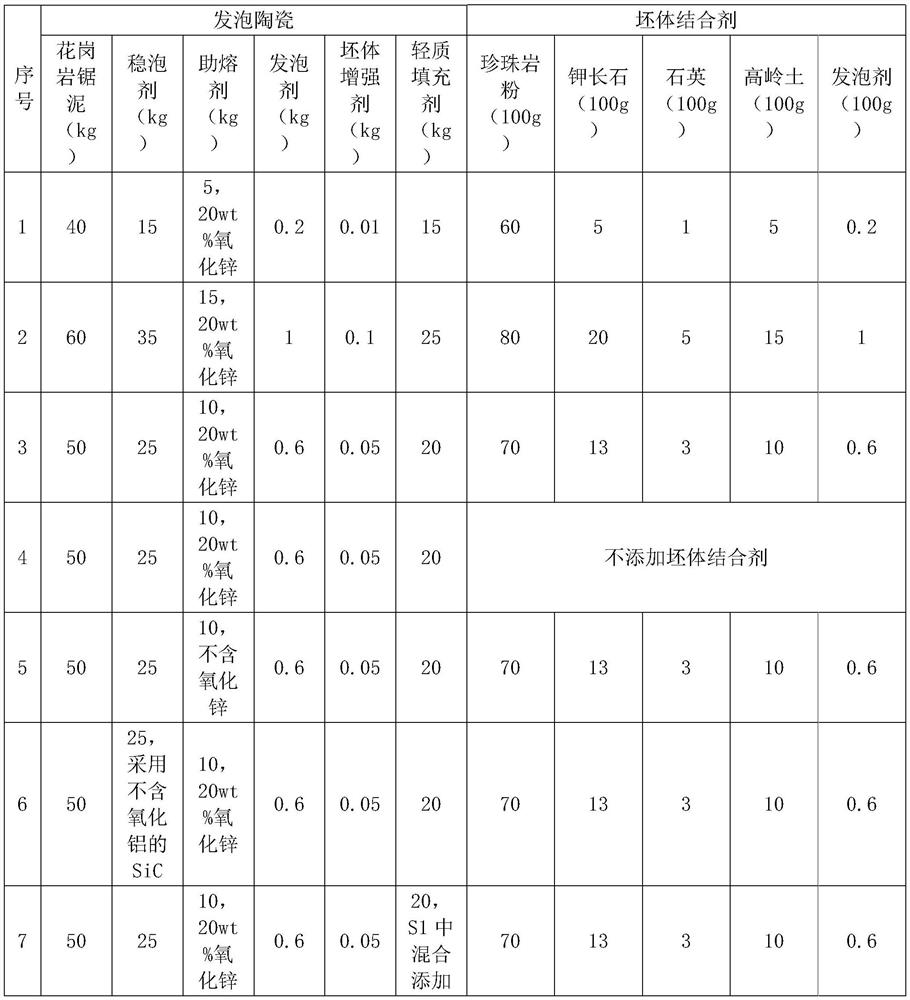

Foamed ceramic and high-strength foamed cement composite board and preparation method thereof

PendingCN113152816AReduce foam expansionShorten the annealing timeCovering/liningsCeramic materials productionCeramic compositeCement composites

The invention relates to a foamed ceramic and high-strength foamed cement composite board and a preparation method thereof. The foamed ceramic and high-strength foamed cement composite board comprises a first foamed ceramic board and a second foamed ceramic board, a foamed cement board is arranged between the first foamed ceramic board and the second foamed ceramic board, and a structural reinforcer is arranged in the foamed cement board. According to the foamed ceramic blank and high-strength foamed cement composite board and the preparation method thereof, the foamed ceramic composite board can effectively reduce the production cost of a foamed ceramic partition board; and meanwhile, the used foamed ceramic board is formed by dry pressing of a blank and firing of foamed ceramic through a die-free naked firing process, the upper and lower surfaces of the blank are relatively smooth, the blank can be used for the composite board without surface cutting, the finished product utilization rate of the foamed ceramic material can be improved, and the cost of the foamed ceramic composite board can be reduced.

Owner:山东晟世达科技有限公司

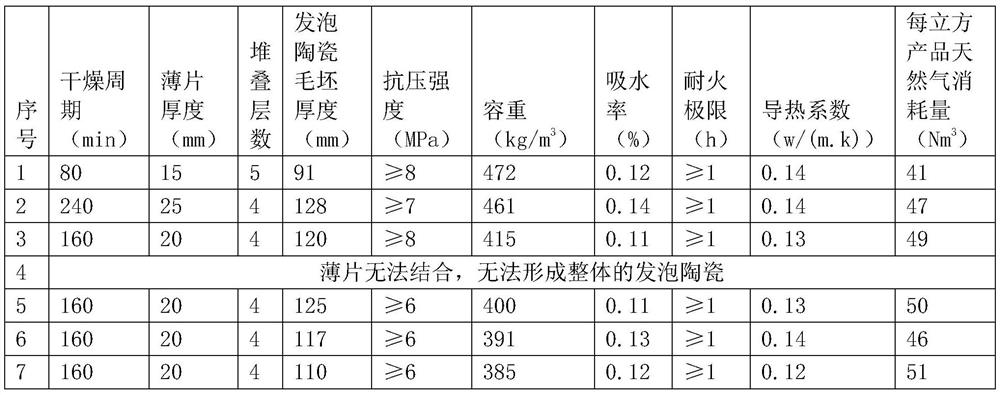

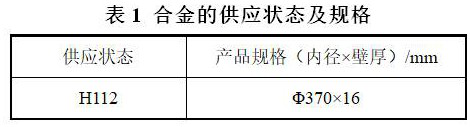

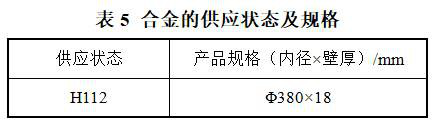

Preparation method of large-diameter 6061 aluminum alloy extruded pipe for hydrogen storage of new energy automobile

The invention discloses a preparation method of a large-diameter 6061 aluminum alloy extruded pipe for a new energy automobile. The preparation method sequentially comprises the working procedures of alloy component optimization, smelting, melt purification, standing, degassing and deslagging, casting, homogenizing annealing, machining and extrusion. The alloy comprises the following elements in percentage by weight: 0.6%-0.70% of Si, 0.15%-0.20% of Fe, 0.28%-0.35% of Cu, 0.15%-0.20% of Mn, 0.85%-1.1% of Mg, 0.18%-0.25% of Zn, 0.14%-0.15% of Ti, 0.1%-0.3% of Cr, 0.05% of Ni and the balance of Al, the ratio of Mg to Si is adjusted to be 1.40%-1.53, and a heat treatment process of a cast ingot is optimized. Meanwhile, in order to ensure that the pipe meets the precision requirement and the surface quality requirement, a tool, a mold and extrusion parameters are designed, the aluminum alloy extruded pipe with good plasticity, toughness and rigidity, uniform component distribution and fine crystal grains is obtained, and therefore the use requirement of a hydrogen storage pipe of a new energy automobile is met.

Owner:西北铝业有限责任公司

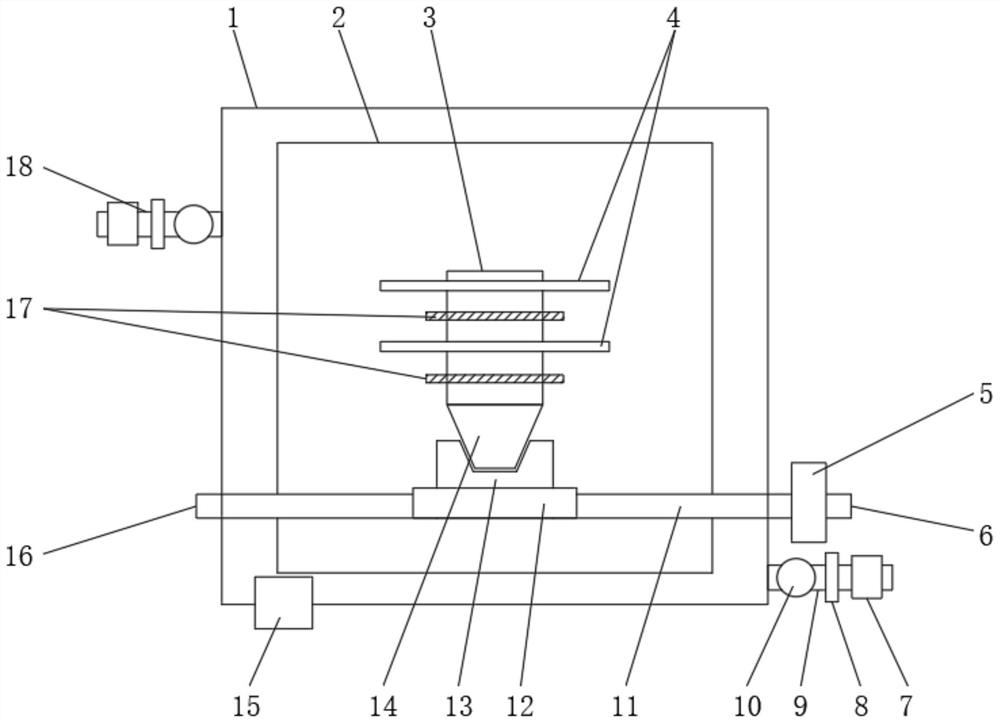

Annealing treatment device for enameled wire processing and using method

PendingCN114058795AExtended annealing timeFully annealedApparatus for heat treatmentFurnace typesSteering wheelCopper wire

The invention provides an annealing treatment device for enameled wire processing and a using method, the device comprises a heating mechanism, awind-heat annealing mechanism, a surface cleaning mechanism, a driving mechanism and a sealing cover which are arranged on a support, the heating mechanism is a spiral copper pipe, and an iron copper wire is subjected to electromagnetic heating treatment through an external radio frequency power supply of the spiral copper pipe; and the wind-heat annealing mechanism is a wind-heat box with a heating function and is used for prolonging the annealing time of the copper wire and fully annealing the copper wire, the surface cleaning mechanism is a cleaning box and is used for timely treating a surface oxide film of the quenched copper wire, the driving mechanism comprises a leading-in wheel, a steering wheel, a leading-out wheel and a gear motor, and a power shaft of the gear motor is connected with the leading-out wheel. The gear motor provides single drive to pull the copper wire, looseness between the leading-in wheel and the leading-out wheel is prevented, the structure is reasonable, the enameled wire is fully and uniformly annealed, high temperature and air contact oxidation is prevented, and stains on the surface of the enameled wire are cleaned in time.

Owner:江苏龙创新材料科技有限公司

Preparation method of magnesium diboride superconducting thin film used for superconducting cables

ActiveCN108930027AHigh purityImprove compactnessChemical vapor deposition coatingHydrogenThermal insulation

The invention discloses a preparation method of magnesium diboride superconducting thin film used for superconducting cables. The preparation method comprises following steps: a substrate is selected,washed, and is introduced into a deposition chamber; the deposition chamber is vacuumized, the substrate is heated, a mixed gas of argon and hydrogen is introduced into the deposition chamber, diborane is introduced into the deposition chamber, the substrate is heated to a temperature higher than 400 DEG C so as to realize deposition of elementary B onto the substrate and generation of an amorphous B film; the amorphous B film is cooled to room temperature, the amorphous B film and high purity magnesium particles are introduced into a sealed crucible; annealing is carried out in high purity argon for 10min, wherein in the annealing process, the temperature is increased to 800 to 1000 DEG C at a temperature increasing speed of 20 DEG C / min, thermal insulation treatment is carried out for 30 to 40min, natural cooling to room temperature is carried out. The MgB2 superconductor prepared through the preparation method is high in density and purity; the steps are simple; operation is convenient; cost is low; no environment pollution is caused; and the practical value is high.

Owner:无锡众创未来科技应用有限公司

Method for inducing amorphous silicon film with tin to be crystallized into polycrystalline silicon film

InactiveCN102243991BSimple process structureEasy to operateSemiconductor/solid-state device manufacturingField-effect transistorNitrogen gas

The invention relates to a method for preparing a polycrystalline silicon thin film, in particular to a method for inducing an amorphous silicon thin film with tin to be crystallized into a polycrystalline silicon thin film at a low temperature. according to the main technical scheme of the invention, the method comprises the following steps of: 1, carrying out ultrasonic cleaning on a glass substrate by using acetone and deionized water respectively to clean the glass substrate; 2, growing a layer of amorphous silicon (a-Si:H) thin film on the glass substrate by using a plasma enhanced chemical vapor deposition method (PECVD), wherein the temperature of the substrate is about 200 DEG C, and the thickness of the thin film is 200nm-300nm during deposition; 3, growing a layer of metal tin (Sn) thin film with the thickness of 10nm-20nm on the amorphous silicon thin film by using a physical vapor deposition method so as to obtain a substrate / (a-Si:H) / Sn structure; 4, arranging the substrate / (a-Si:H) / Sn in a heat treatment furnace in a laminated manner, and carrying out heat treatment for more than 1 hour at the temperature of 450 DEG C, then cooling naturally, where nitrogen (N2) is introduced and used as a protection gas during the whole annealing process; and 5, removing the remained metal tin on the surface with concentrated hydrochloric acid with the concentration of 37.5% to finally obtain the polycrystalline silicon thin film which is crystallized under the induction of tin, wherein the particle size is about 70-200nm. The method is applicable to the fields of thin-film field effect transistors and solar cells.

Owner:SHANGHAI UNIV

Double-sided dark battery foil and preparation method thereof

ActiveCN109402456BQuality improvementIncrease productivityJackets/cases materialsMetal rolling arrangementsElectrical batteryAluminium powder

The invention discloses a double-sided dark battery foil and a preparation method thereof. The double-sided dark battery foil comprises the following component raw materials: Si, Fe, Cu, Mn, Mg, Ti, Al; the double-sided dark battery foil The preparation method comprises the following steps: (1) adding raw materials into a smelting furnace for smelting to obtain a molten liquid; (2) inputting the molten liquid into a casting-rolling machine, and casting and rolling a billet; (3) cooling the cast-rolling billet Cold rolling in the rolling mill, performing homogenization annealing treatment; (4) After the aluminum coil after homogenization annealing is cooled to room temperature, cold rolling in separate passes; (5) Recoil trimming; (6) Intermediate annealing treatment; ( 7) Cold-rolling the intermediate annealed aluminum coil; (8) Recoiling the cold-rolled aluminum coil, followed by foil rolling, to obtain a double-sided dark battery foil. The aluminum powder on the dark side of the double-sided dark battery foil produced by the invention is effectively controlled, has no ruffles, has high usability and surface quality of the finished product, and is applicable to most batteries.

Owner:GUANGXI BAISE XINGHE ALUMINUM

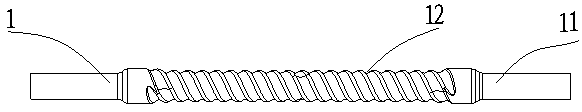

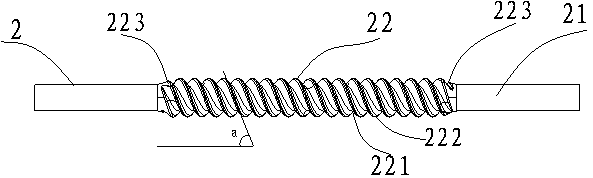

A kind of air conditioner bellows and its manufacturing method

ActiveCN104976447BNot easy to cause deformationSimple preparation processFlexible pipesEngineeringWave crest

The invention relates to the field of air conditioner pipelines, in particular to an air conditioner bellows and a manufacturing method thereof. The air conditioner bellows comprises a bellows body, wherein the bellows body comprises a bellows section and polished rod sections; corrugated protrusions are arranged on the outer side of the bellows section and raised from the outer wall of the bellows section, wave crests of the corrugated protrusions are higher than the outer wall of the polished rod sections, and the diameters of circles on which wave troughs of the corrugated protrusions are positioned are the same as the diameters of the polished rod sections; the bellows section and the polished rod sections on the bellows body are manufactured into the bellows body in an integrated manner. According to the air conditioner bellows disclosed by the invention, defects that corrugations in a traditional bellows are concave inwards and the production technology of the traditional bellows is complex are overcome, and the air conditioner bellows provided by the invention is high in production efficiency and good in flow guiding effect. Besides the invention further provides the manufacturing method of the bellows, the manufacturing method comprises three steps of discharging and straightening, annealing and spreading, so that processing procedures are reduced, and the annealing time is shortened.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

A kind of temperature control system and method for sapphire crystal annealing

ActiveCN109338476BGuaranteed temperatureSave materialPolycrystalline material growthAfter-treatment detailsTemperature controlCrucible

The invention discloses a temperature control system for sapphire crystal annealing. The temperature control system comprises a growth furnace body, wherein a heat transfer rod transversely runs through the interior of the growth furnace body; a water outlet is formed in the outer side of the growth furnace body; a water inlet is formed in the right end of the heat transfer rod; a flow controlleris mounted on the left side of the water inlet; the middle part of the heat transfer rod runs through a base and is in close contact with an inner hole in the base; the upper side of the base is connected with a crucible support; a seed crystal trough is formed in the bottom of the crucible; rack-type temperature measuring thermocouple sets are mounted on the periphery of the crucible; a heat-insulating hood is mounted between the growth furnace body and the crucible; a vacuum system is mounted on the left side of the lower side of the growth furnace body; a gas inlet pipe and a gas outlet pipe are mounted on the upper side of the left side and the lower side of the right side of the growth furnace body respectively. The invention further discloses a method for annealing by using the temperature control system.

Owner:国宏中晶集团有限公司

A kind of thermochromic intelligent dimming energy-saving glass and its preparation method

ActiveCN106150290BDelay agingExtended service lifeUnits with parallel planesNon-linear opticsGlass compositesComposite film

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A method for producing grain-oriented pure iron by secondary annealing

ActiveCN109593927BIncrease magnetic inductionExtended annealing timeHeat treatment process controlMetallurgyNitrogen gas

The invention discloses a method for producing grain oriented pure iron through secondary annealing, and belongs to the technical field of electrotechnical soft magnetic materials. According to the method for producing the grain oriented pure iron through secondary annealing, a plate blank is subjected to secondary annealing treatment which includes a heating section, a high-temperature purifyingsection and a cooling section; and mixed gas composed of hydrogen and nitrogen serves as protective gas of the heating section, and the volume ratio of the hydrogen to the nitrogen in the mixed gas is3:1; and hydrogen serves as protective gas in the high-temperature purifying section. The temperature T<high net > of the high-temperature purifying section is 880-900 DEG C, the magnetic induction intensity B<800> of the oriented pure iron produced through secondary annealing is larger than 1.90T, and B<10000> is 2.12-2.15T. The method aims to overcome the defect that in the prior art, the high-temperature purifying section in a grain oriented pure iron producing method is poor in purifying effect, the method for producing the grain oriented pure iron through secondary annealing is providedand can achieve the good purifying effect, and by means of other technology steps, the magnetic induction intensity of the grain oriented pure iron can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

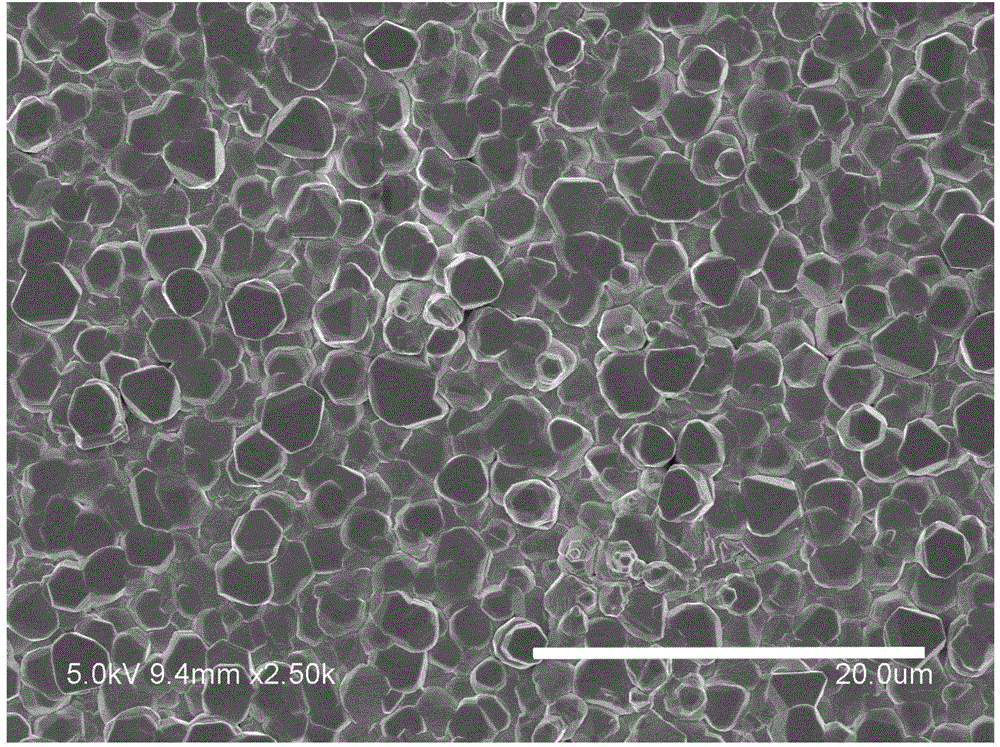

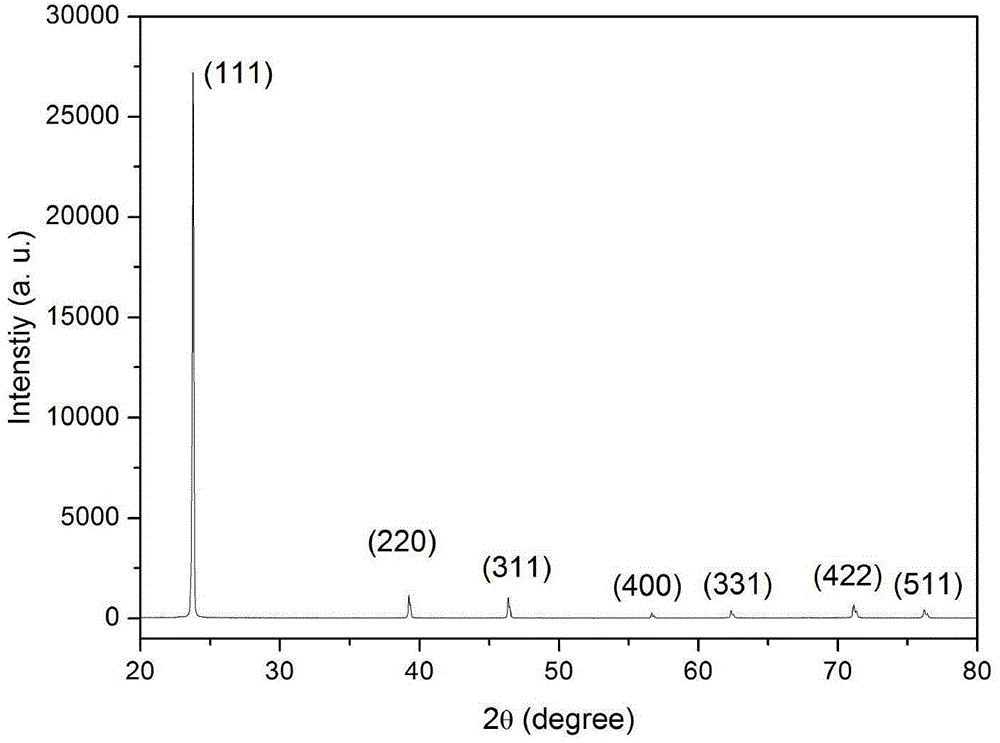

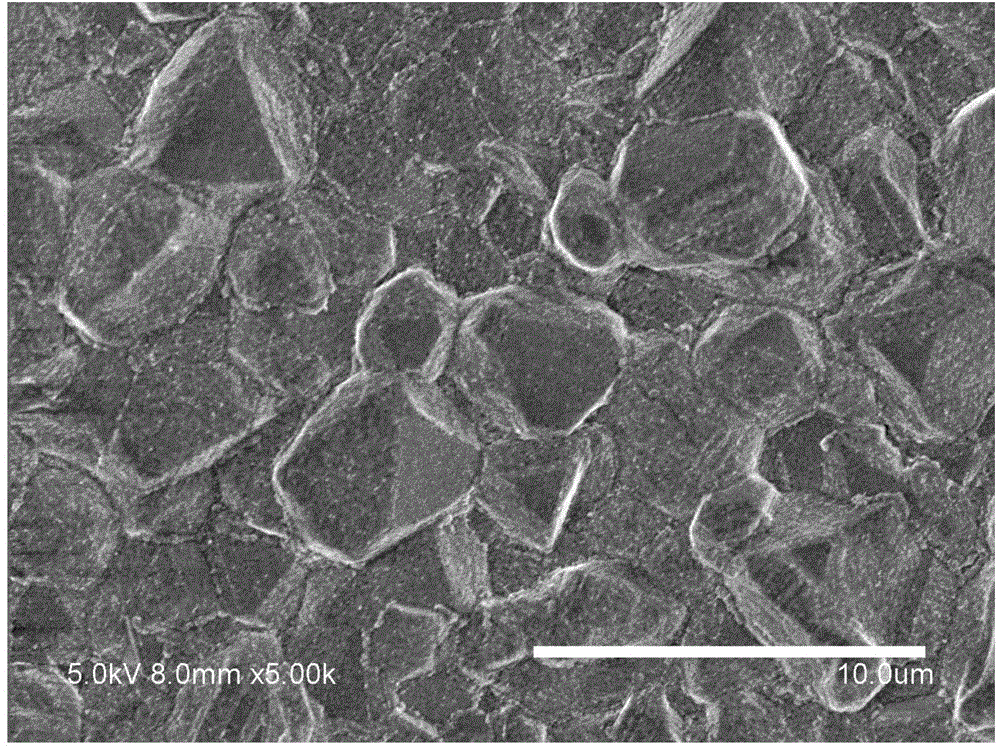

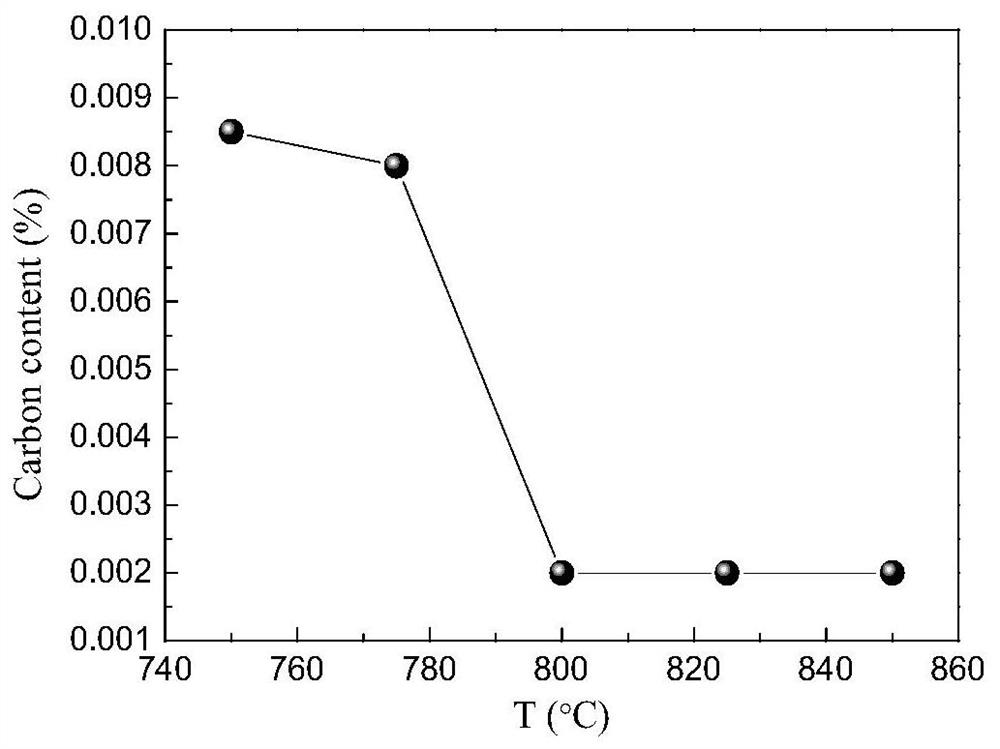

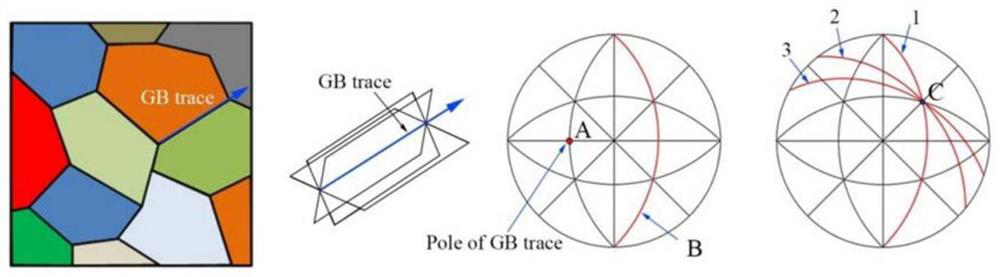

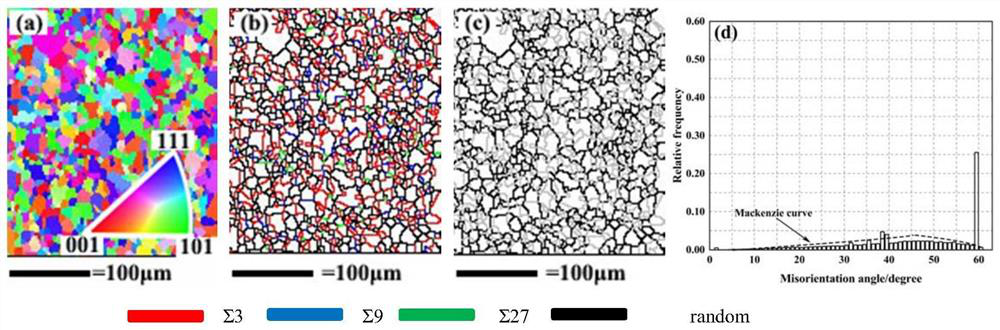

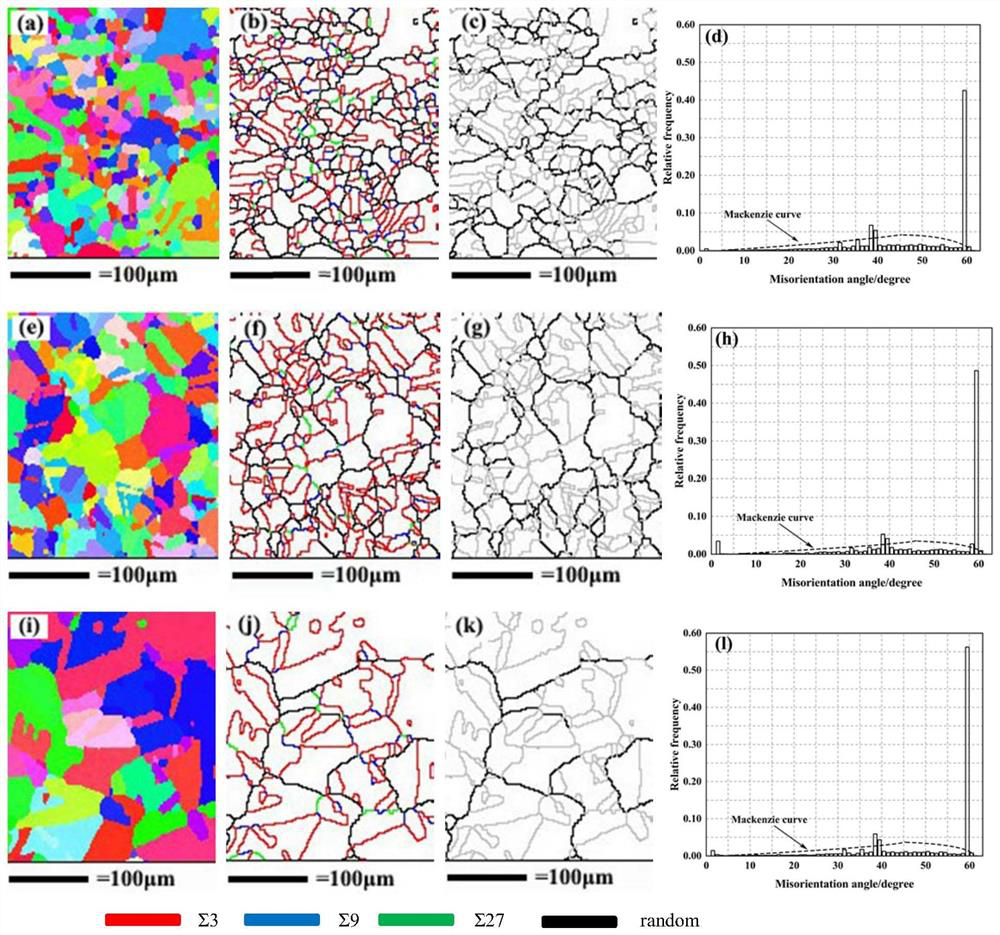

Method for improving pure copper grain boundary corrosion resistance by increasing coherent twin grain boundary proportion

ActiveCN114686789AImprove grain boundary corrosion resistanceExtended annealing timeProcess efficiency improvementCopperVacuum annealing

The invention belongs to the field of batteries, and discloses a method for improving pure copper grain boundary corrosion resistance by increasing coherent twin grain boundary proportion, which comprises the following steps: performing repeated room-temperature multidirectional forging on pure copper, and then recrystallizing and annealing for 10 minutes at 600 DEG C to homogenize the structure of the pure copper; and the pure copper with the homogenized structure is subjected to small-deformation cold rolling, the rolling deformation is 5%, and then vacuum annealing is conducted at the temperature of 650 DEG C for 5-15 min. Pure copper is subjected to small-deformation high-temperature short-time annealing to obtain a primary recrystallization structure, although the grain boundary characteristic distribution of the primary recrystallization structure has a certain proportion of sigma 3 special grain boundaries, the proportion of coherent twin boundaries is not high, and a considerable number of non-coherent twin boundaries exist; according to the method, the annealing time is prolonged on the basis of primary recrystallization, the crystal grains are further made to grow, the result shows that the proportion of coherent twin boundaries is monotonically increased along with the growth of the crystal grains and finally exceeds 50%, and the crystal boundary corrosion resistance of pure copper is greatly improved.

Owner:FUJIAN UNIV OF TECH

Forging method for R6-grade mooring chain riveting swivel

InactiveCN111014535AGuaranteed plasticityExtended annealing timeMetal-working apparatusFurnace typesStructural engineeringManufacturing engineering

The invention relates to a forging method for a R6-grade mooring chain riveting swivel. The swivel comprises a swivel body and a swivel bolt. The method comprises the following steps: 1) performing feeding; 2) forming a blank of the riveting swivel body; 3) molding the riveting swivel body; (4) forming a blank of the riveting swivel bolt; 5) molding the riveting swivel bolt; 6) performing edge trimming and polishing. The forged swivel product has good mechanical properties and meets size and shape requirements. The forging method is applicable to the processing field of the R6-grade mooring chain riveting swivel.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com