Wire drawing equipment and method for large-core-diameter single-polarization optical fiber

A single-polarization fiber, large core diameter technology, used in glass fiber drawing equipment, glass manufacturing equipment, glass fiber products, etc., can solve the problem of easy burnout, excessive fiber warpage end face, waste of energy consumption, optimization of quartz and stress element uniformity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

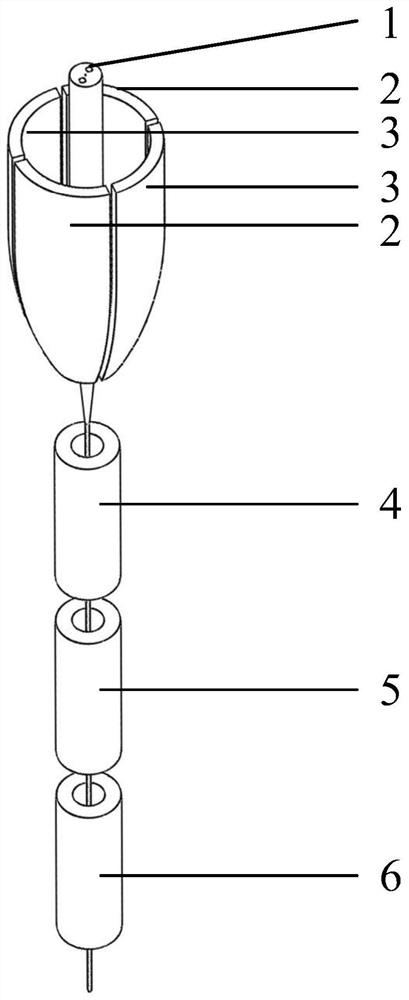

[0044] Embodiment 1: In this embodiment, a preform rod with a rod diameter of 29.6 mm is drawn into a double-clad optical fiber.

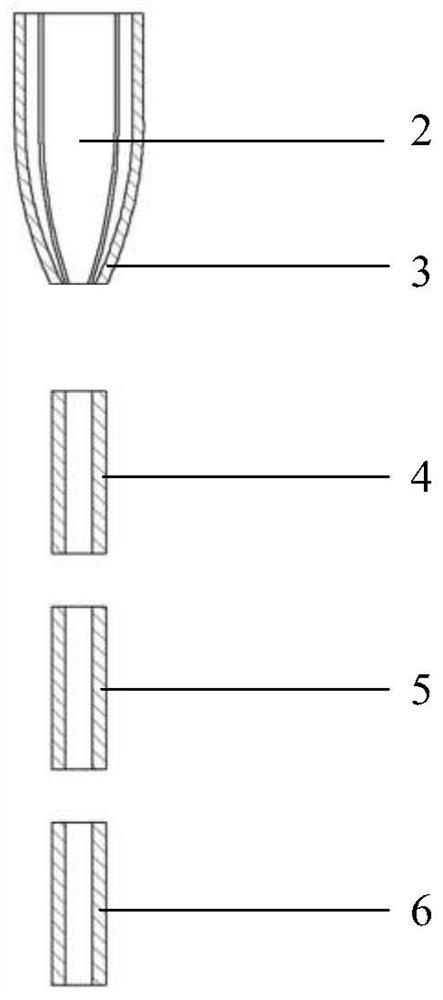

[0045] In this implementation, the arc length ratio of the low temperature zone 2 of the wire drawing furnace to the high temperature zone 3 of the wire drawing furnace is 1:1, both of which are composed of a wire drawing furnace sheet whose temperature can be adjusted. The annealing tube is composed of two pieces, the lengths of the high temperature annealing tube 4 and the low temperature annealing tube 6 are 80 cm and 150 cm respectively, and the temperatures are 800°C and 100°C respectively. See Example 1 in Table 1 for the rest of the parameters.

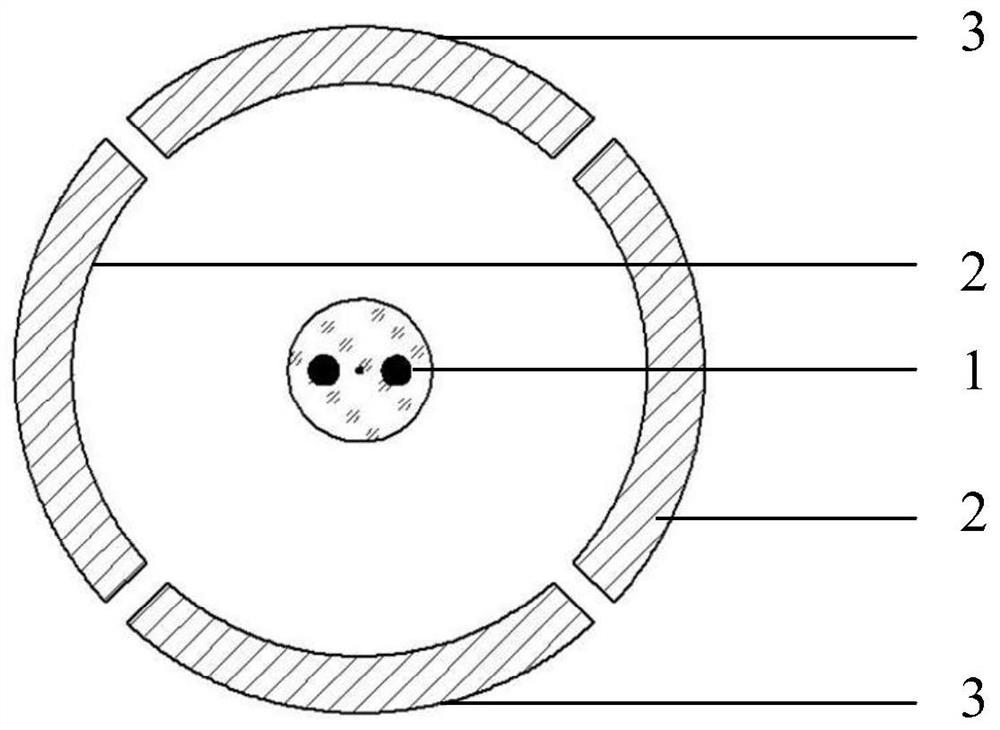

[0046] Step 1. Place the single-polarized optical fiber preform in the drawing furnace by clamping and hoisting. The direction of the line connecting the center of the stress element 1 is aligned with the central axis of the low-temperature zone 2 of the drawing furnace, and the vertical direction i...

Embodiment 2

[0052] Embodiment 2: In this embodiment, a preform rod with a rod diameter of 28.9 mm is drawn into a double-clad optical fiber.

[0053] In this implementation, the arc length ratio between the low-temperature zone 2 of the drawing furnace and the high-temperature zone 3 of the drawing furnace is 1:2, the low-temperature zone 2 of the drawing furnace is composed of one piece of drawing furnace, and the high-temperature zone 3 of the drawing furnace is composed of two pieces of drawing furnace placed side by side. The annealing tube consists of 3 pieces, the lengths of the annealing tube 4, the annealing tube 5 and the annealing tube 6 are 80 cm, 100 cm and 150 cm respectively, and the temperatures are 1000°C, 700°C and 200°C respectively. See Example 2 in Table 1 for the rest of the parameters

[0054] Step 1. Place the single-polarized optical fiber preform in the drawing furnace by clamping and hoisting. The direction of the line connecting the center of the stress element ...

Embodiment 3

[0060] Embodiment 3: In this embodiment, a preform rod with a rod diameter of 30.1 mm is drawn into a single-clad optical fiber.

[0061] In this implementation, the arc length ratio between the low temperature zone 2 of the drawing furnace and the high temperature zone 3 of the drawing furnace is 2:1, the low temperature zone 2 of the drawing furnace is composed of two drawing furnace sheets placed side by side, and the high temperature zone 3 of the drawing furnace is composed of two drawing furnace sheets . The annealing tube is composed of 4 pieces, the lengths of the annealing tube 4, the annealing tube 5, the annealing tube 6 and the annealing tube below the annealing tube 6 are 80cm, 100cm, 150cm and 150cm respectively, and the temperatures are 1000°C, 700°C, 400°C and 100°C respectively. ℃. See Example 3 in Table 1 for the rest of the parameters.

[0062] Step 1. Place the single-polarized optical fiber preform in the drawing furnace by clamping and hoisting. The dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com