Composite automatic aluminum brazing wire used for brazing aluminum alloy automobile frame and skin joints and preparation method

A kind of aluminum alloy and aluminum brazing technology, applied in welding equipment, metal processing equipment, welding medium and other directions, to achieve the effect of improving strength, reducing surface energy, improving processing performance and service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

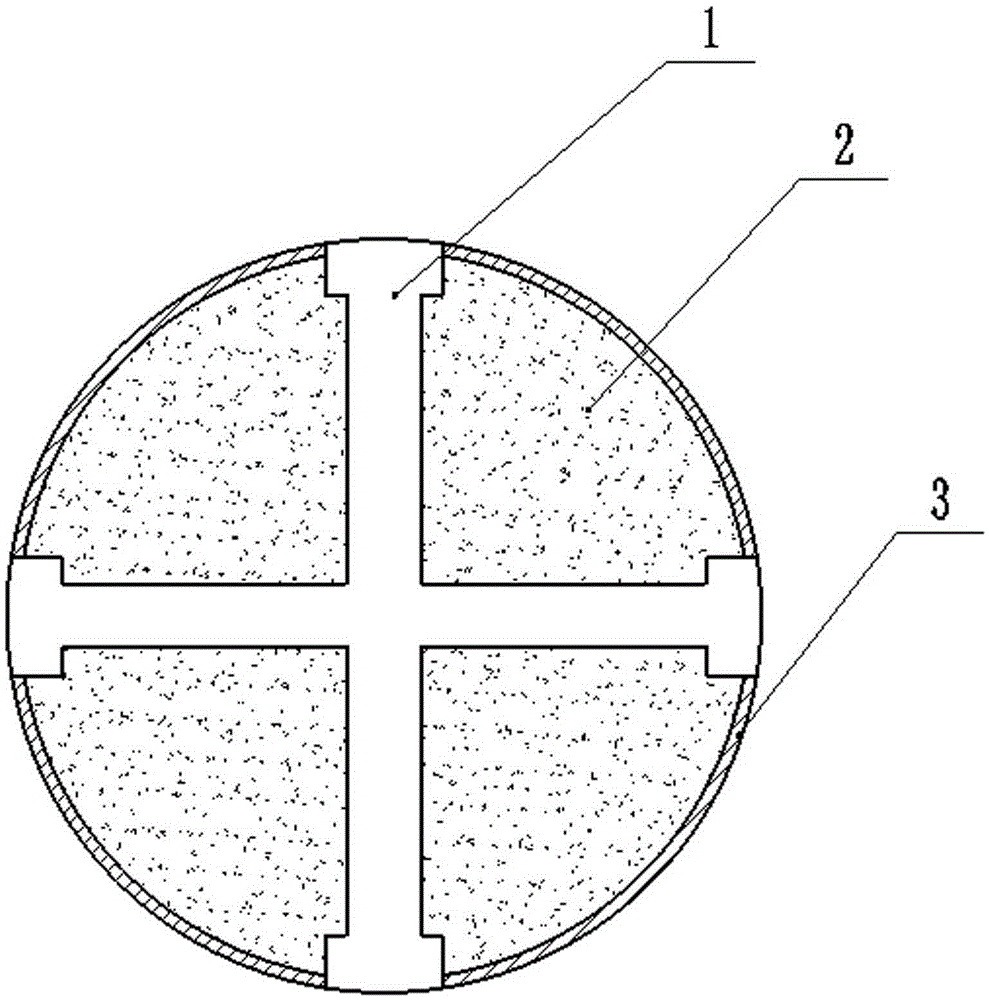

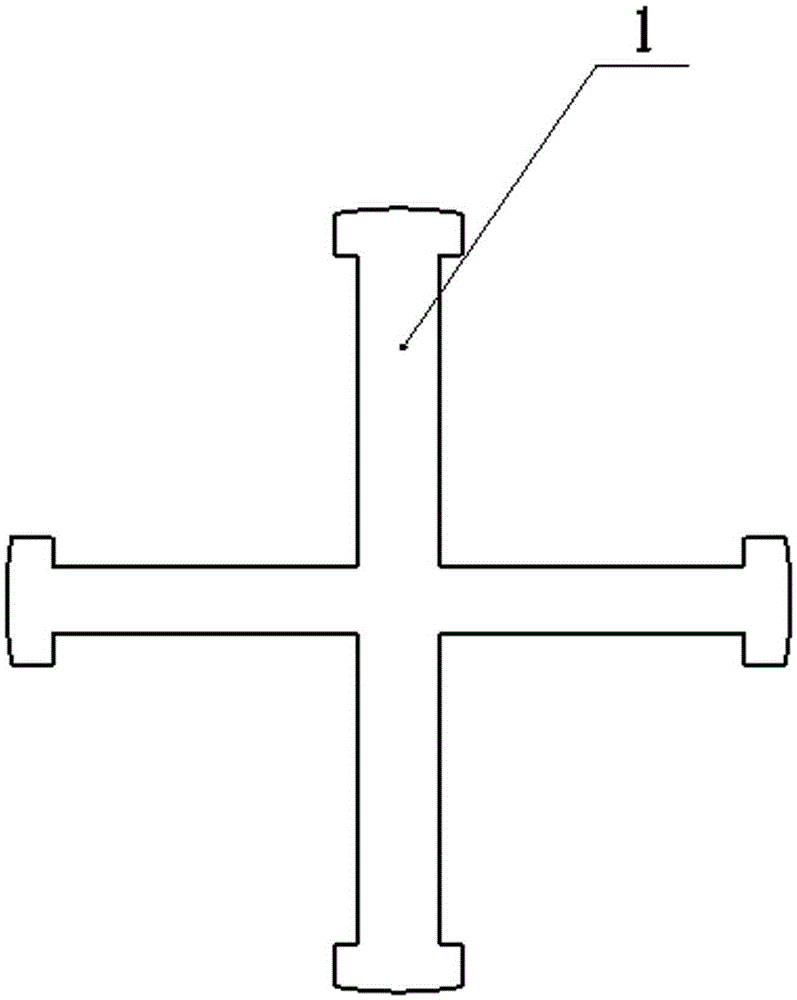

[0030] refer to Figure 1-2 , a composite automatic aluminum brazing wire used for brazing of aluminum alloy automobile frame and skin joints, which consists of an aluminum-based solder core 1, an aluminum flux 2 compounded between the blades of the core 1 and spray coating The aluminum consists of a layer 3 of silicon powder on the surface of flux 2 . The outer diameter of the aluminum-based solder core 1 is 3-4mm, and the thickness T of the core blade is 0.5-0.8mm; the model of the core aluminum-based solder is: BAl86SiZnCuNiMe, and its chemical composition weight ratio is: AL;86 ; Si: 12; Zn: 0.6; Cu: 0.7; Ni: 0.7, Sr: 0.05; Zr: 0.05; Ce: 0.04. The aluminum flux compounded between the core blades is paste flux, which is produced by Nocolok (KAIF 4 +K 3 AlF 6 Eutectic) flux powder, which is uniformly mixed with evaporative polyethylene glycol with a relative molecular mass of 10,000 to 20,000 and synthetic resin in the flux powder, and the flux powder is solidified and f...

Embodiment 2

[0038] The difference from Example 1 is that the weight ratio of each chemical component in the composite aluminum brazing wire core material is: AL; 89; Si: 9; Zn: 1.1; Cu: 0.4; Ni: 0.5, Sr: 0.04; Zr : 0.06; Ce: 0.03. The proportion of polyethylene glycol and synthetic resin in the paste flux mixture, the synthetic resin accounts for 20% of its total weight, and the thickness of silicon powder on the surface layer of the composite solder wire is 50 μm.

[0039] During preparation: In step 1, master alloys such as Al-Si, Al-Cu, Al-Ni, and Al-Zn are added to the molten pure aluminum liquid at 780°C at the same time, all the master alloys are melted and stirred for 2 minutes. into argon (Ar 2 ) and HCH (C 2 Cl 6 ) refining for 10 to 15 minutes, after removing slag, quickly add Al-Sr, Al-Zr and Al-Ce intermediate alloys, and then use argon (Ar 2 ) refining for 3 to 5 minutes, drain the slag, and pour it directly into the mold through the running water tank to make a cast rod....

Embodiment 3

[0041] The difference from Example 1 is that the weight ratio of each chemical component in the composite aluminum brazing wire core material is: AL; 90; Si: 8; Zn: 0.8; Cu: 0.6; Ni: 0.6, Sr: 0.04; Zr :0.05; Ce: 0.02. The ratio of the paste flux mixture polyethylene glycol to the synthetic resin, the synthetic resin accounts for 30% of its total weight. The thickness of the silicon powder on the surface of the composite solder wire is 60 μm.

[0042] During preparation: In step 1, master alloys such as Al-Si, Al-Cu, Al-Ni and Al-Zn are simultaneously added to the molten pure aluminum liquid at 850°C, all master alloys are melted and stirred for 2 minutes, Introduce argon gas (Ar 2 ) and HCH (C 2 Cl 6 ) refining for 10 to 15 minutes, after removing slag, quickly add Al-Sr, Al-Zr and Al-Ce intermediate alloys, and then use argon (Ar 2 ) refining for 3 to 5 minutes, adjust the temperature to 890°C, remove the slag and drain the liquid, pour it directly into the mold through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com