Patents

Literature

278results about How to "Weld smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

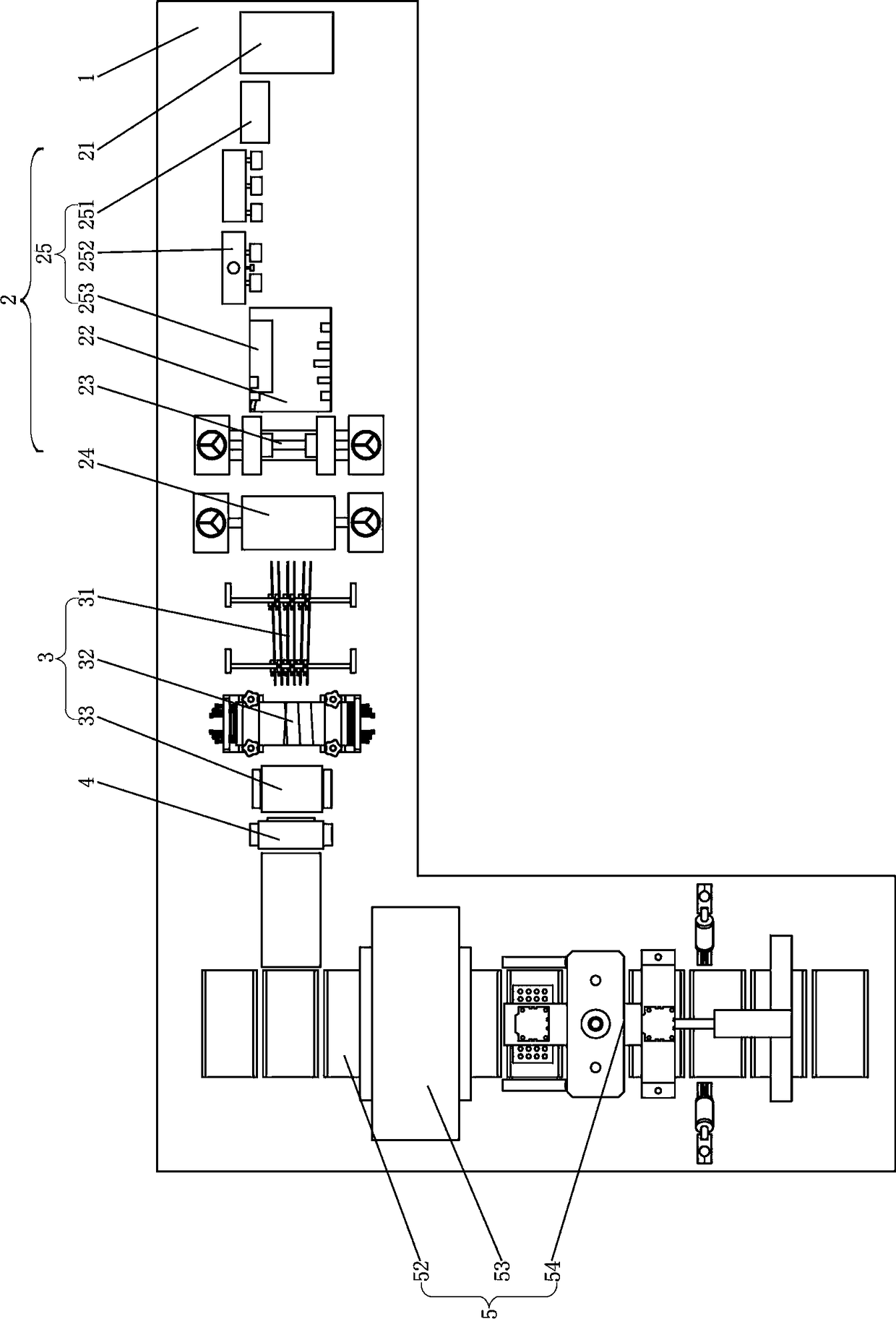

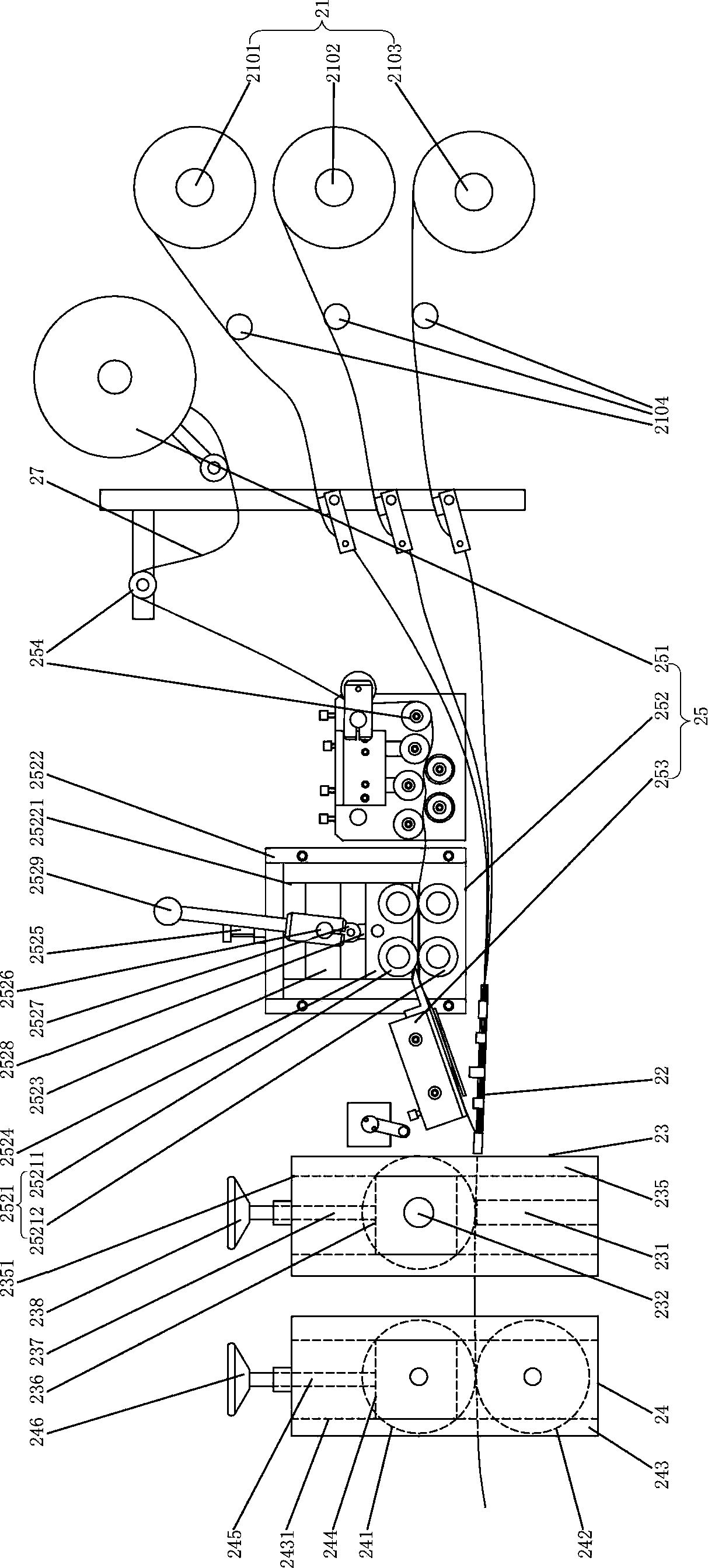

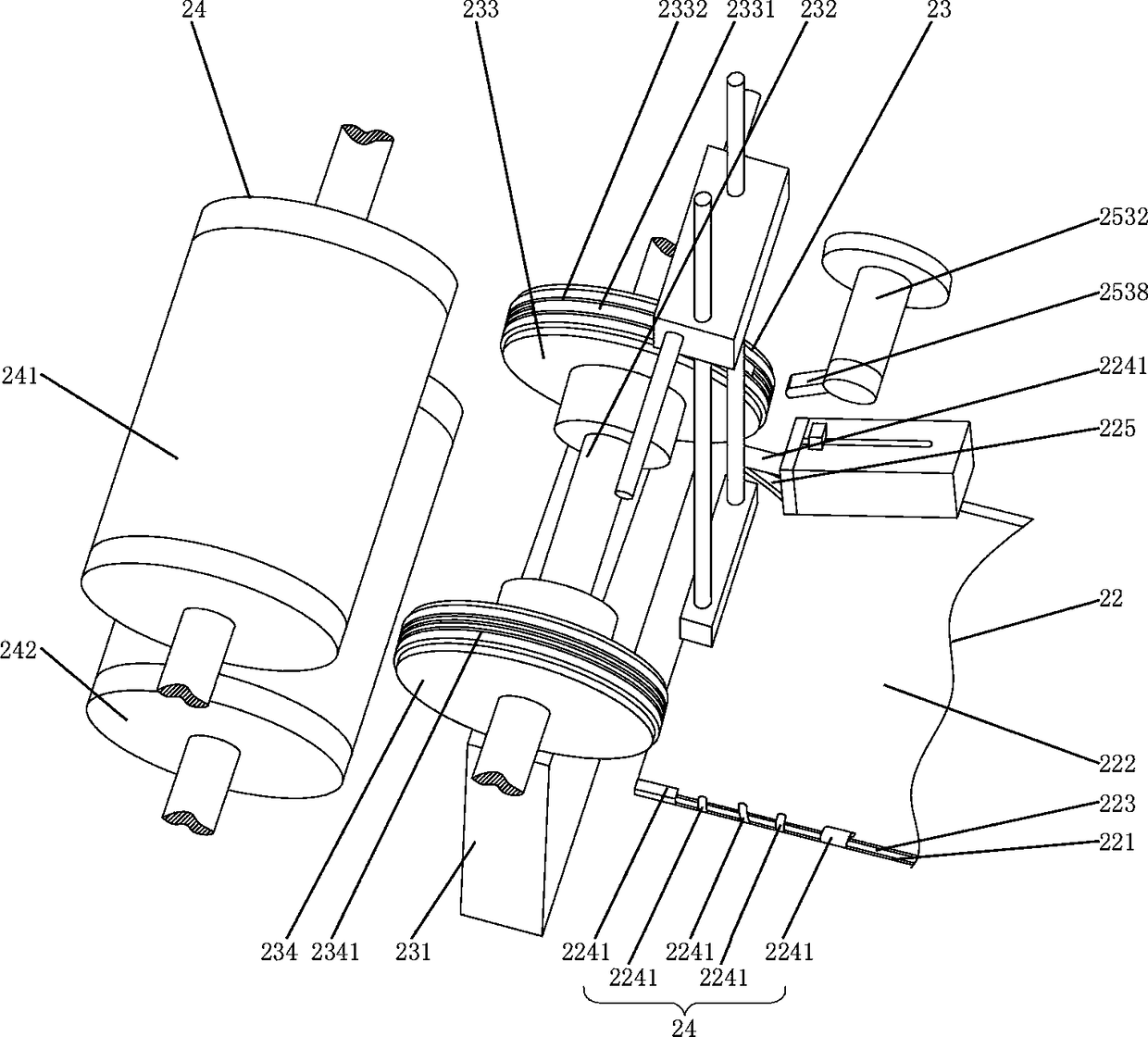

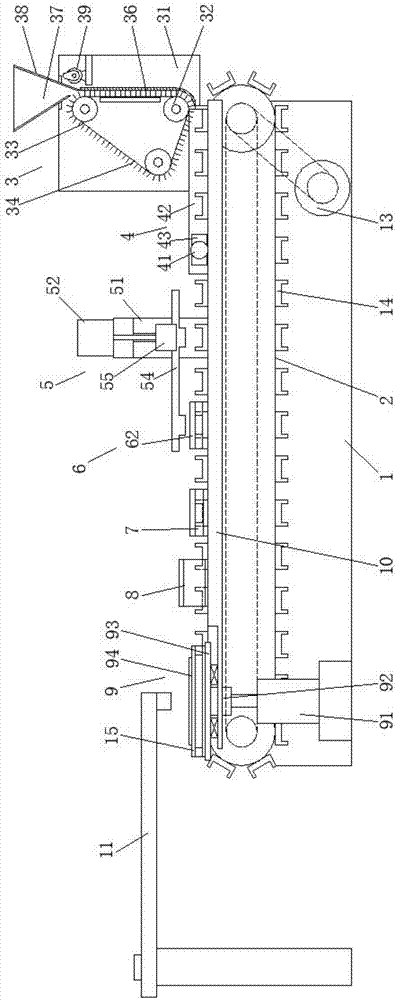

Full-automatic mask production line

The invention discloses a full-automatic mask production line. The production line comprises a machine frame, a mask fabric edge banding device, a mask surface folding device, a mask transverse sealing cutting device and an ear strip welding device; the mask fabric edge banding device comprises a fabric feeding device, a fabric edge folding device, a fabric splicing device, a fabric drawing mechanism and a nose bridge strip feeding device, the fabric edge folding device comprises a lower supporting plate and an upper pressing plate, the upper pressing plate is arranged above the lower supporting plate, two side edges of the lower supporting plate are provided with multiple edge folding side plates which are sequentially arranged from front to back, a nose bridge strip flowing pipe is arranged between the backmost edge folding side plate and the upper pressing plate, and the discharging port of the nose bridge strip feeding device faces the front end of the nose bridge strip flowing pipe; the fabric splicing device comprises a splicing motor, a first ultrasound mold, a rotary shaft, a first splicing wheel and a second splicing wheel, a strip-shaped groove is formed in the circumferential surface of the first splicing wheel, and the strip-shaped groove faces the rear end of the nose bridge strip flowing pipe. By means of the mask production line, edge banding process of fabrics can be automatically completed, and the nose bridge strip is accurately added into the edge banding parts of the fabrics.

Owner:汕头市泰恩康医用器材厂有限公司

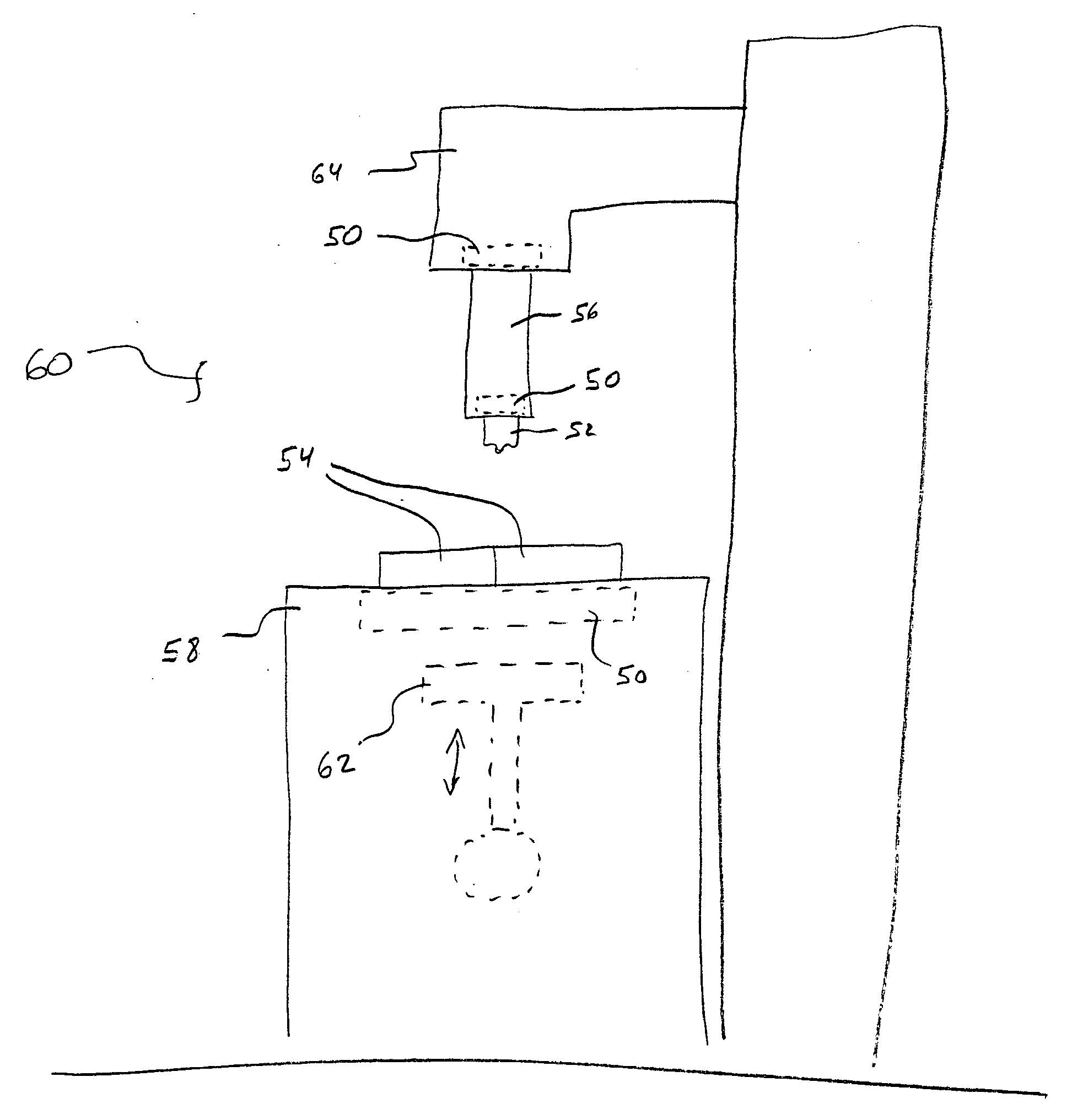

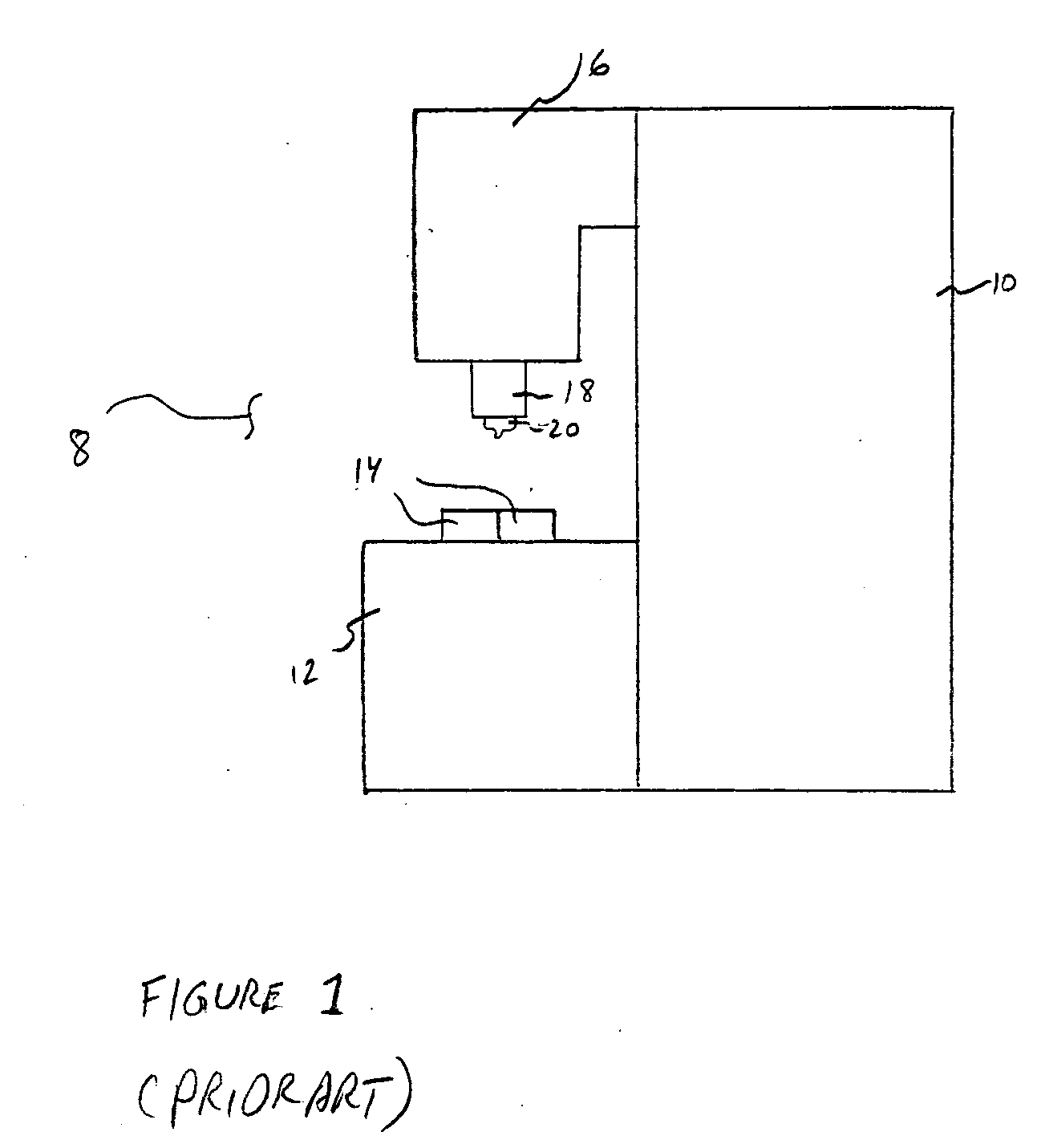

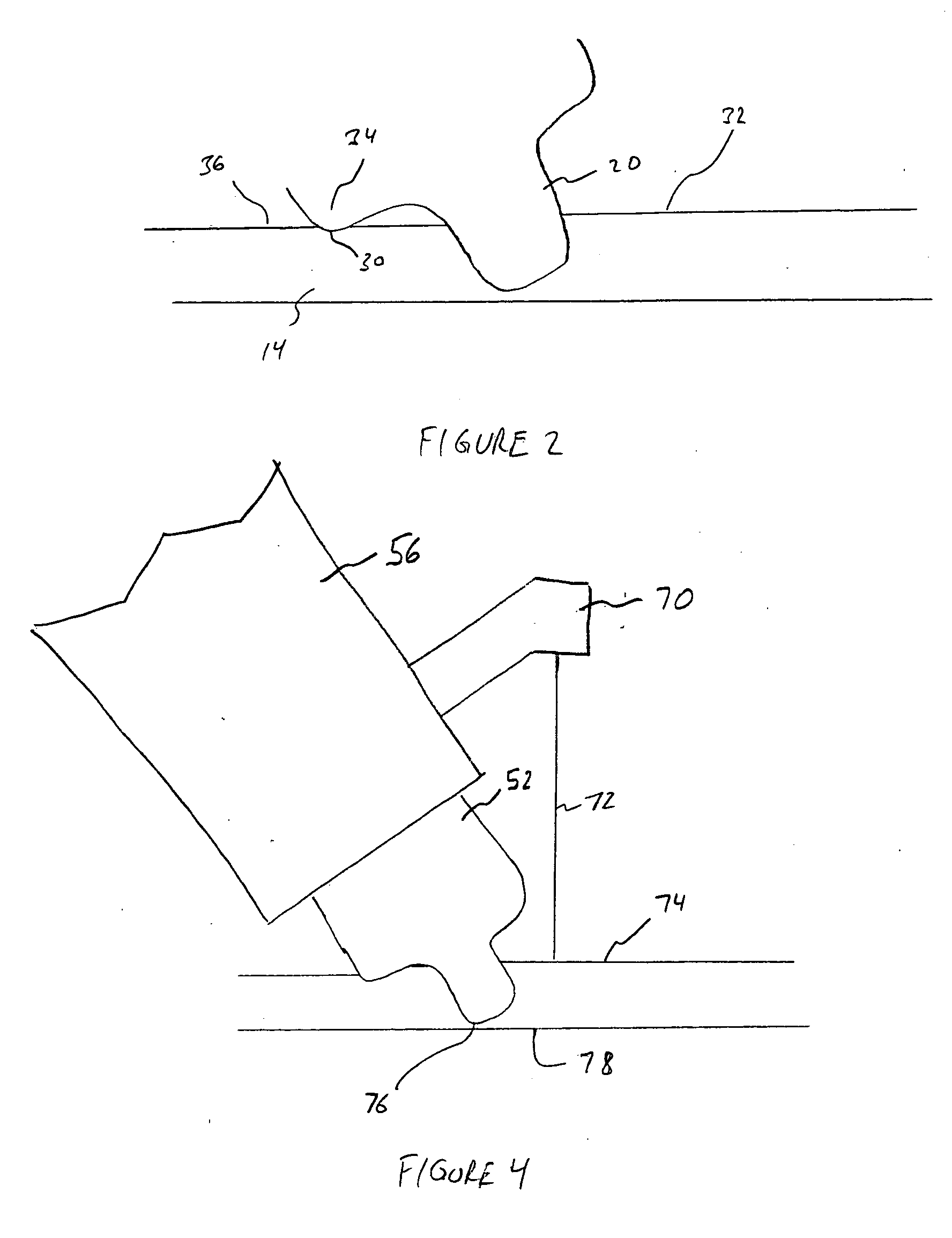

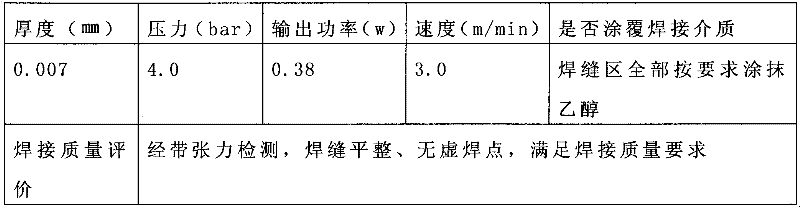

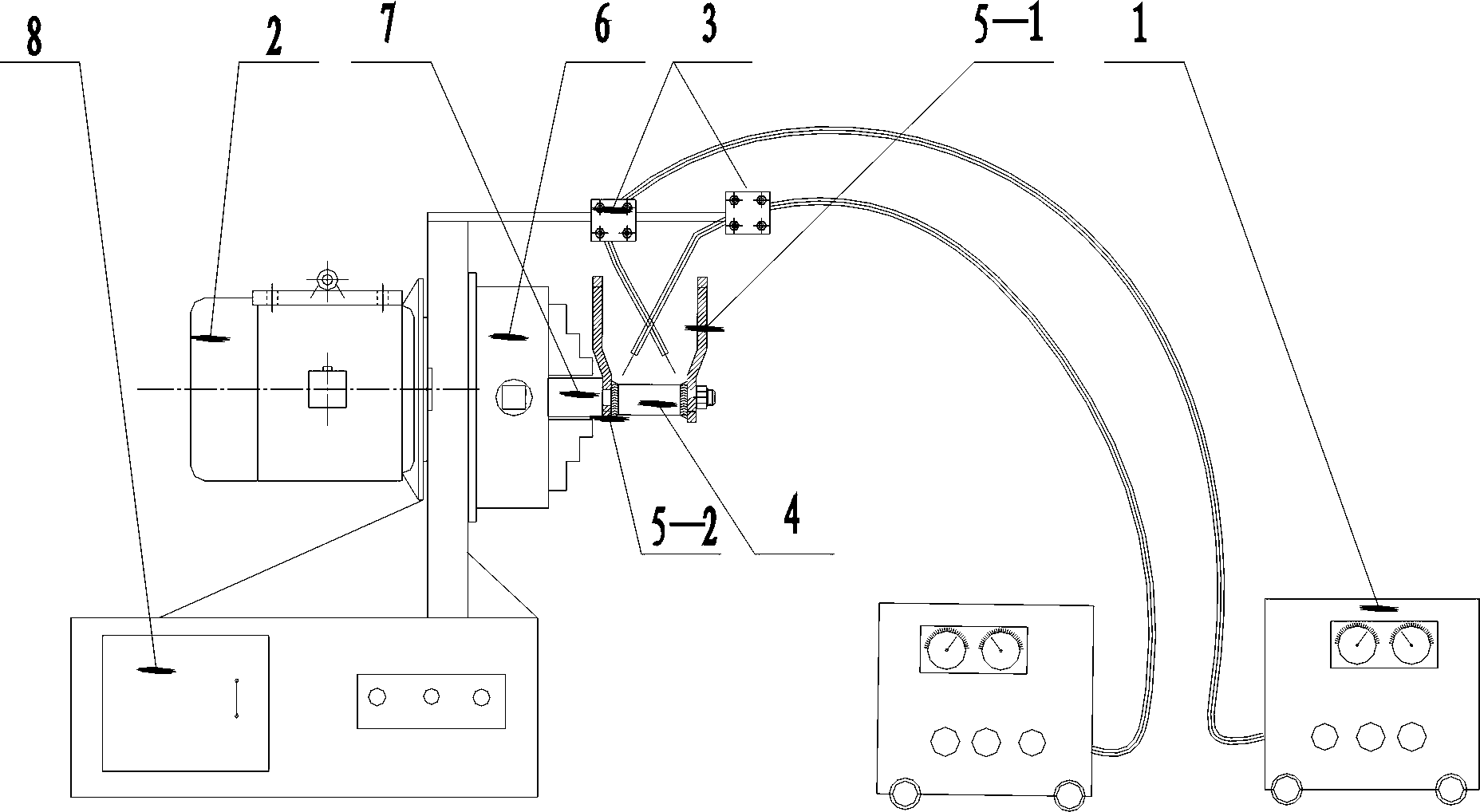

Control system for friction stir welding of metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys

InactiveUS20050051602A1Precise speed controlEasy to controlWelding/cutting auxillary devicesAuxillary welding devicesControl systemSuperalloy

A control system and method of use that enables friction stir welding of metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys when using a superabrasive tool, wherein the control system and method enables control of various operational aspects of a friction stir welding mill in order to make it possible to perform friction stir welding that is repeatable, reliable, and results in a superior finished workpiece.

Owner:SII MEGADIAMOND +3

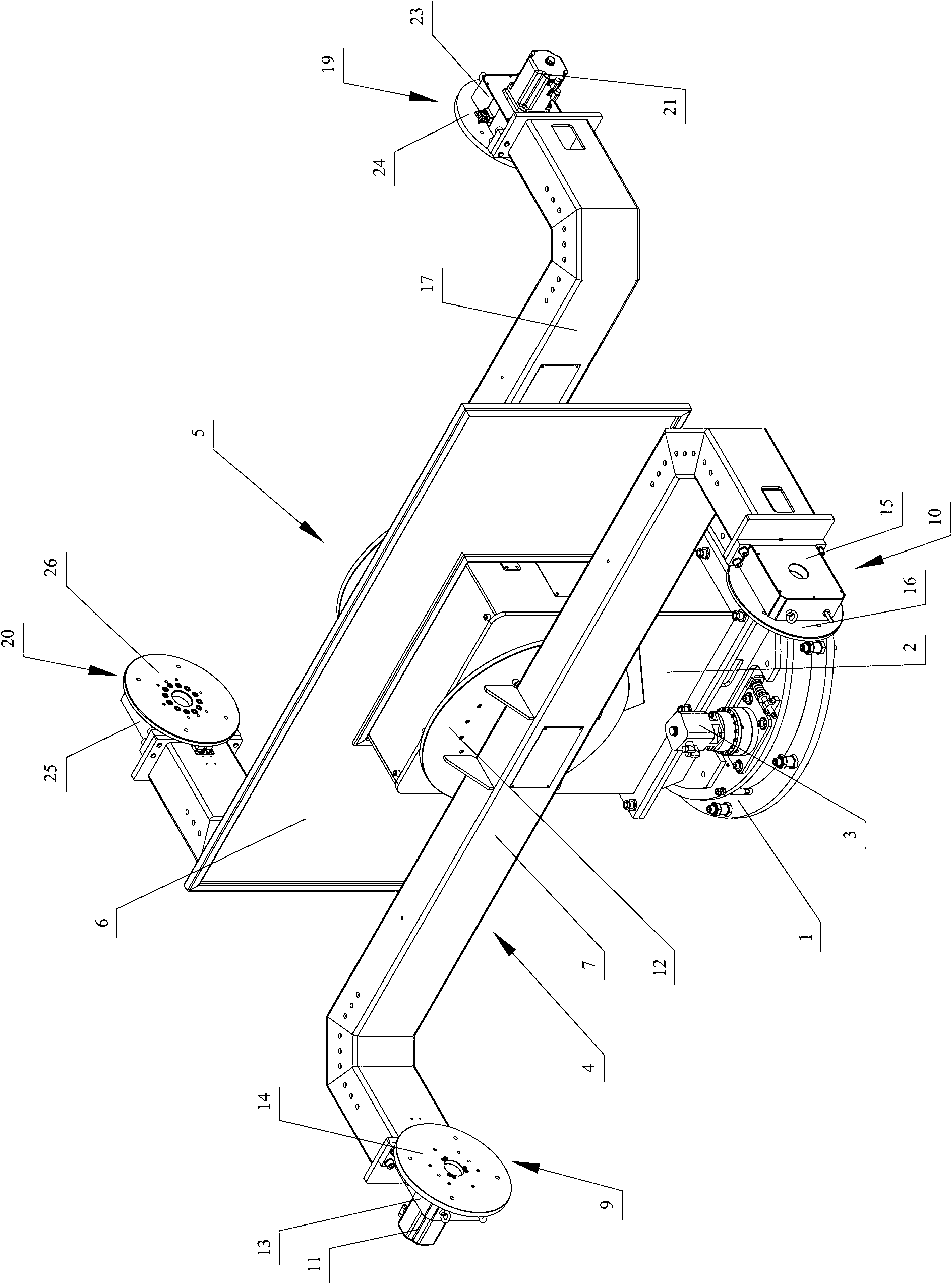

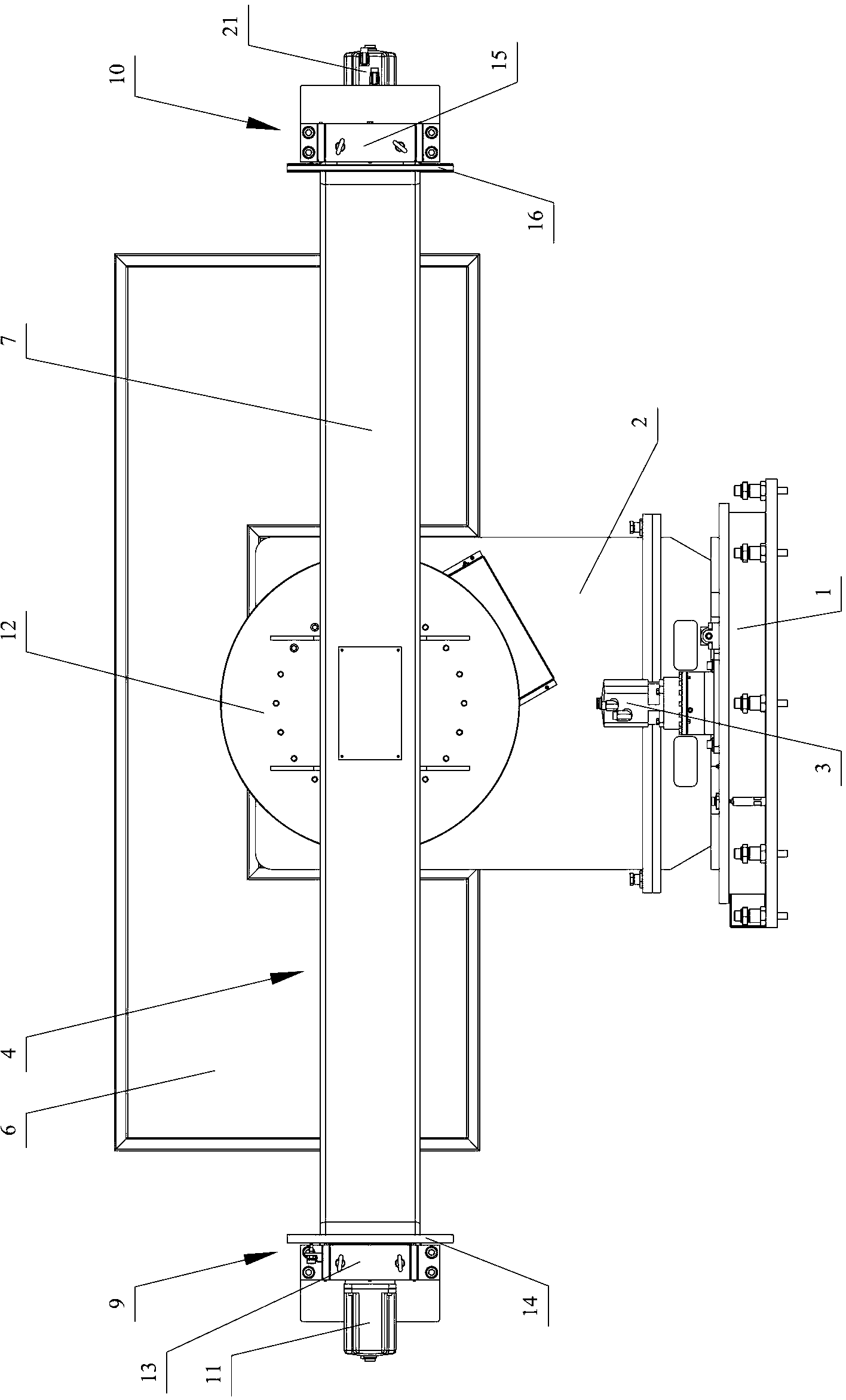

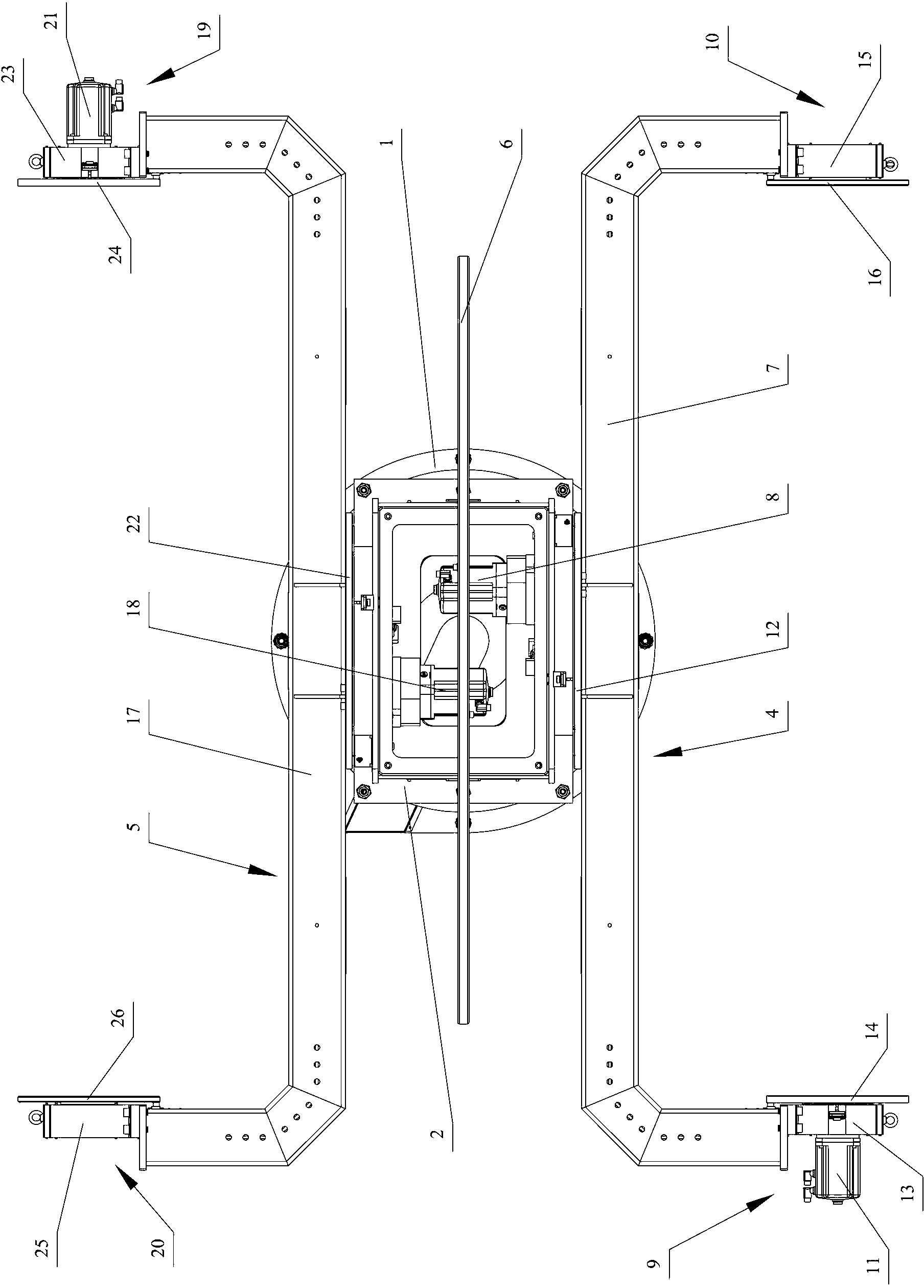

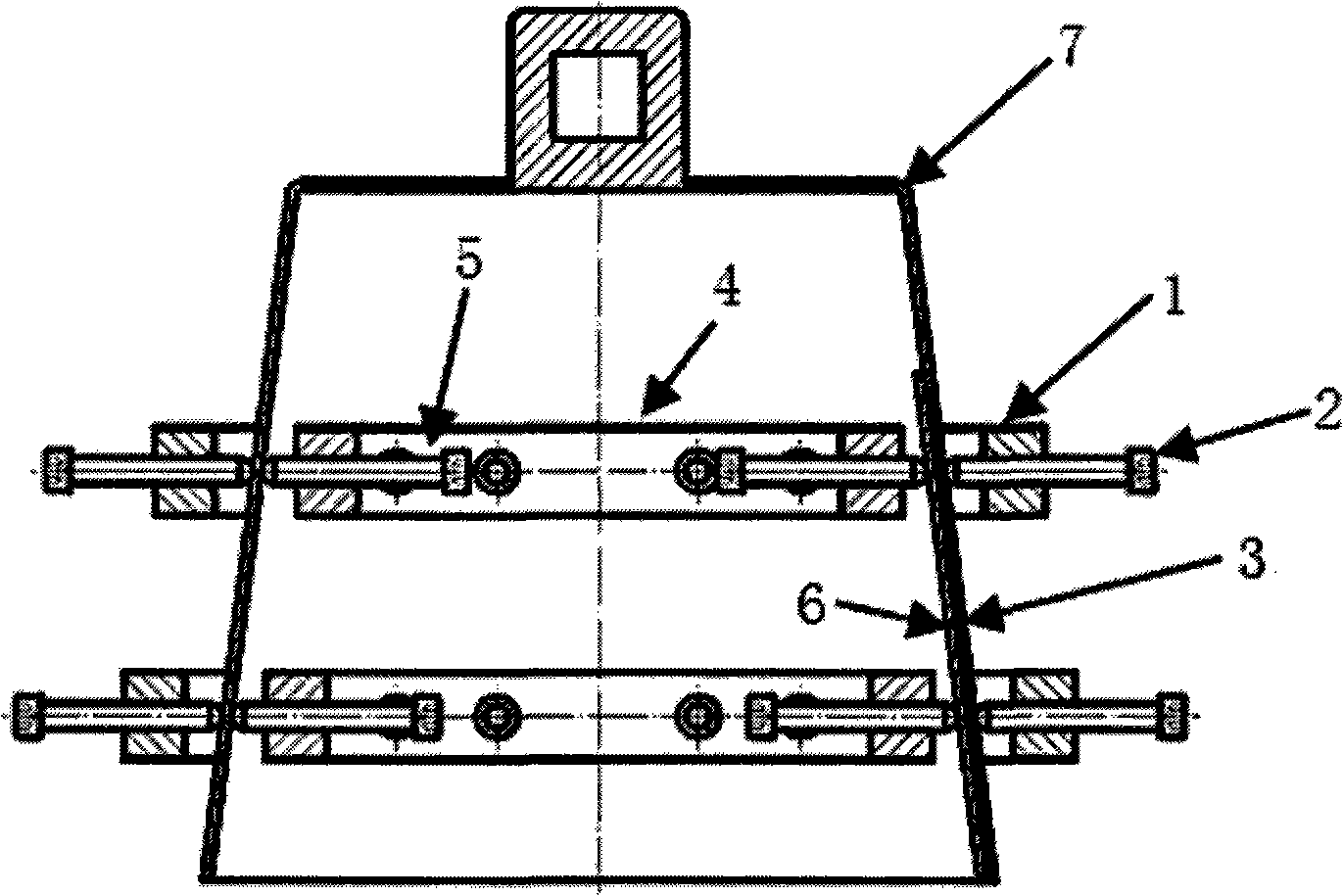

Precision five-axis double-station position changing machine

ActiveCN102699612AReduce production timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesRocker armEngineering

The invention relates to a precision five-axis double-station position changing machine. The machine comprises a rotating base, an upright post box arranged on the rotating base in a horizontal rotating mode, a first servo motor for driving the upright post box to rotate, and a first clamping device and a second clamping device which are respectively arranged on the two sides of the upright post box, wherein the first clamping device comprises a first rocker arm, a second servo motor for connecting the upright post box and the first rocker arm and driving the first rocker arm to vertically rotate, a first headstock and a first tailstock which are arranged on the first rocker arm, and a third servo motor for driving the first headstock to rotate; and the second clamping device comprises a second rocker arm, a fourth servo motor for connecting the upright post box and the second rocker arm and driving the second rocker arm to vertically rotate, a second headstock and a second tailstock which are arranged on the second rocker arm, and a fifth servo motor for driving the second headstock to rotate. Double position-changeable stations are arranged, so that a welding robot can continuously work, time consumption during production is reduced, production efficiency is improved, and rotating accuracy and repositioning accuracy are high.

Owner:XUZHOU HUAHENG ROBOT SYST

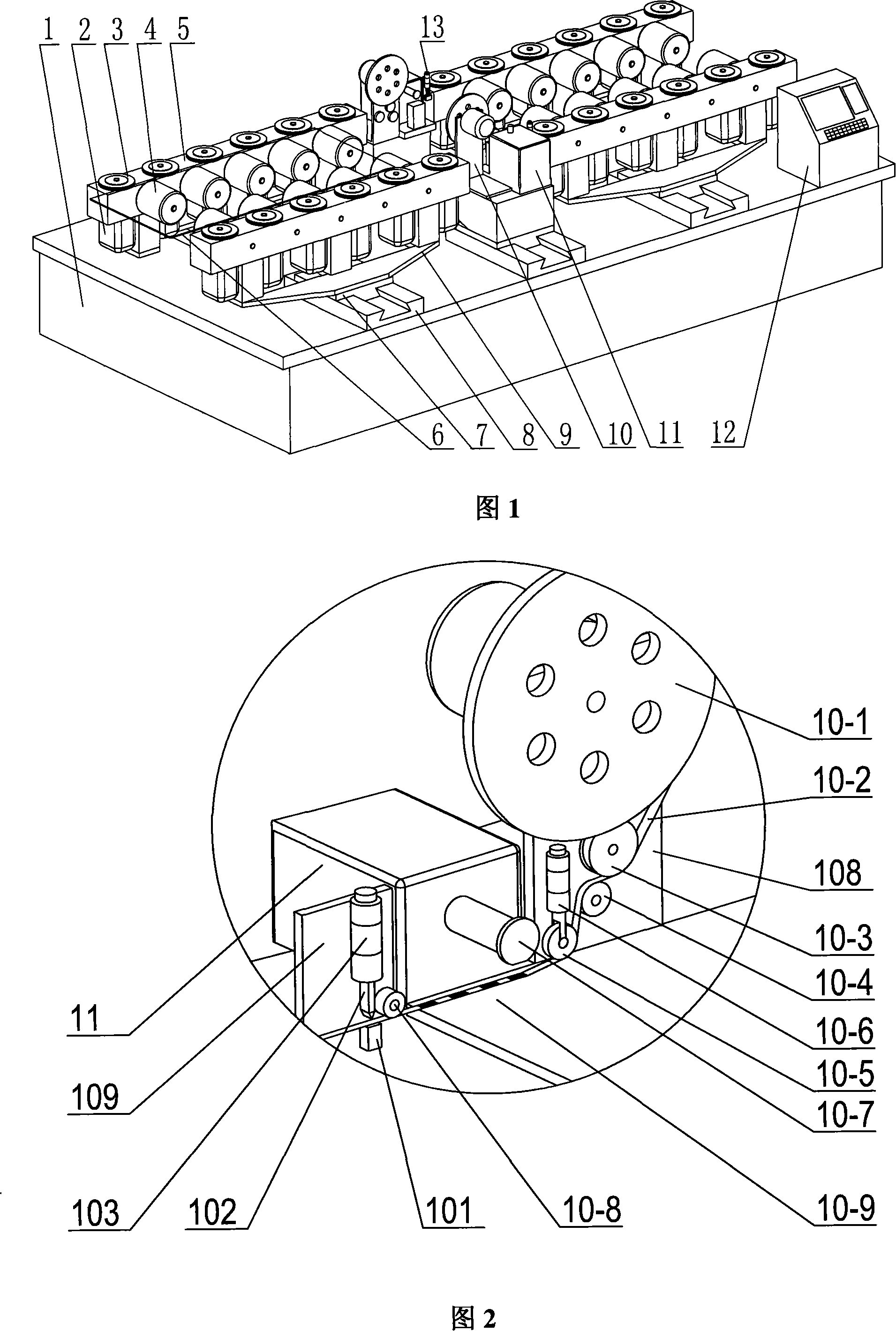

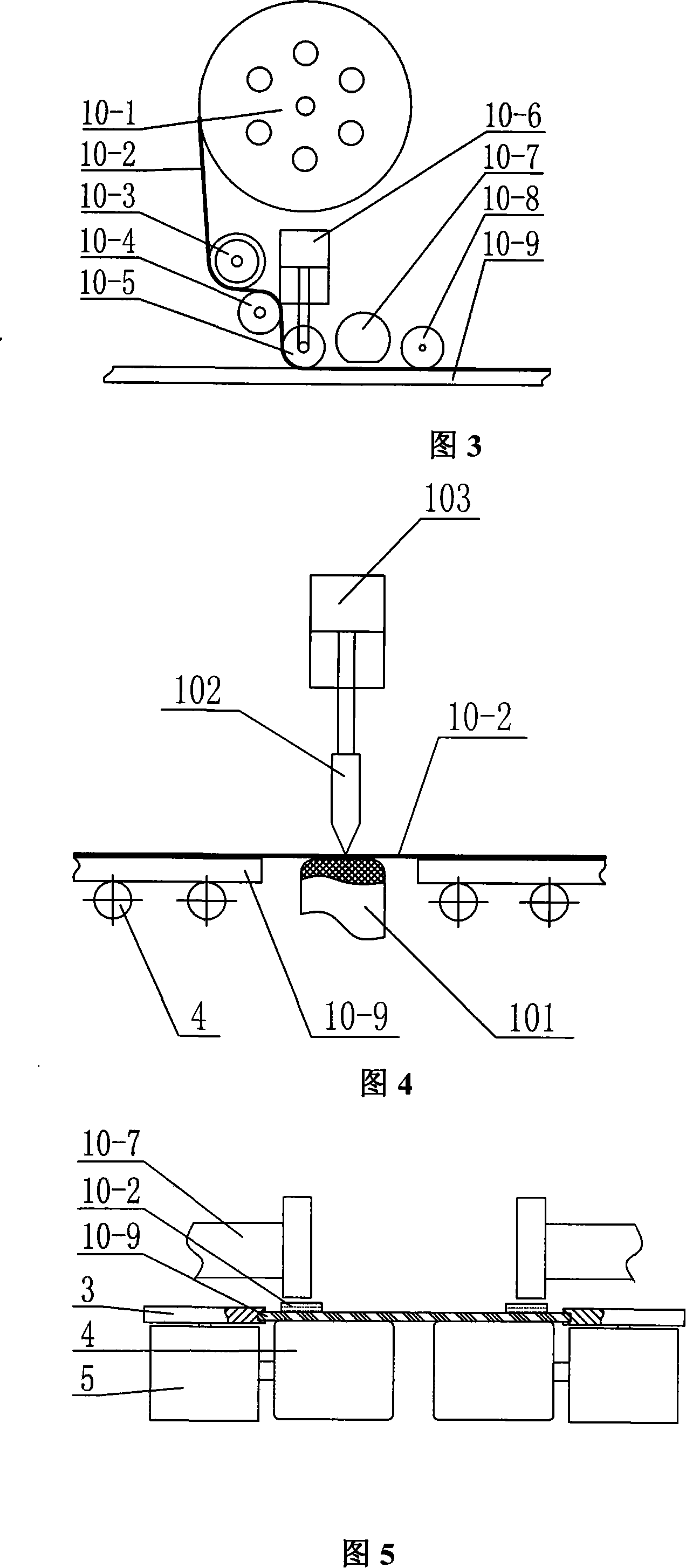

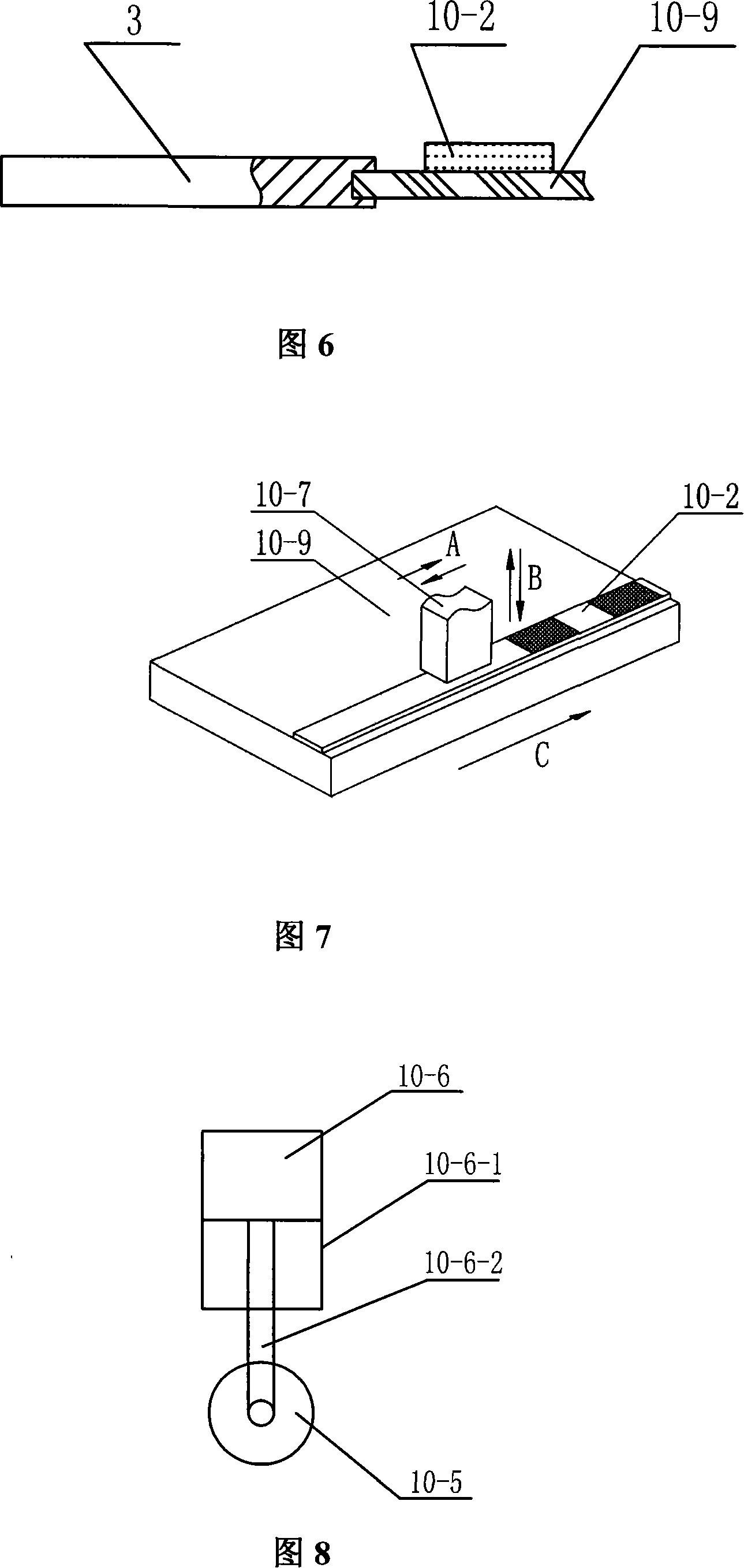

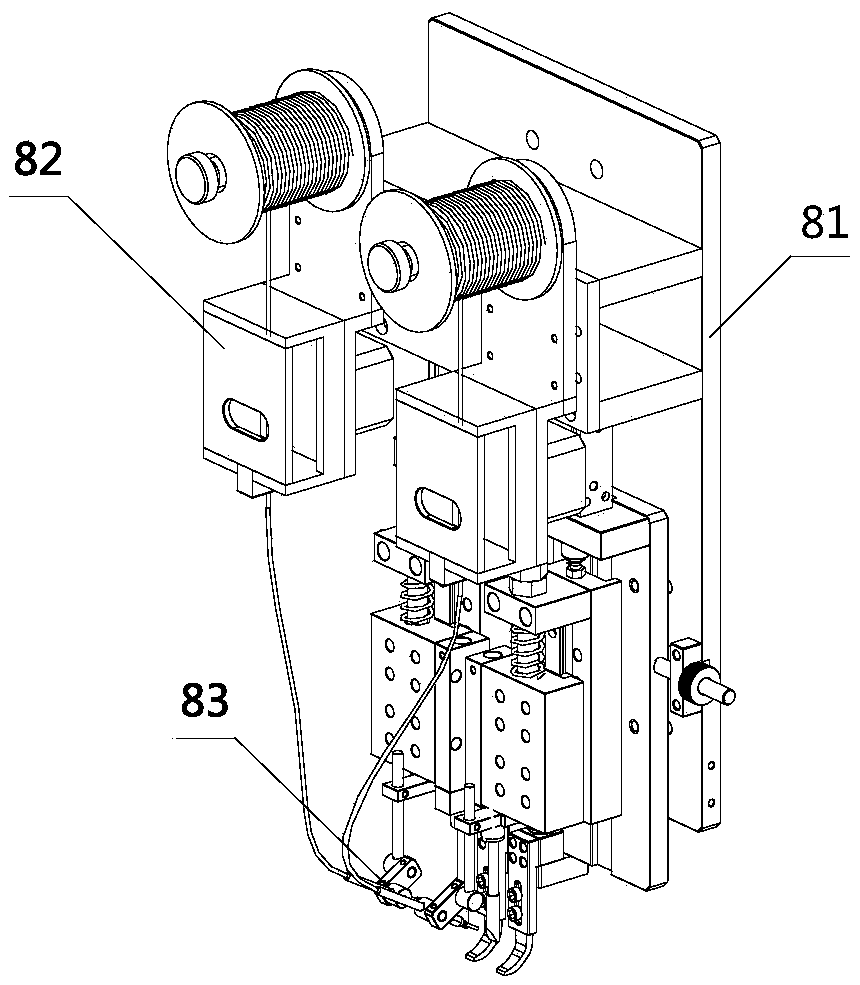

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

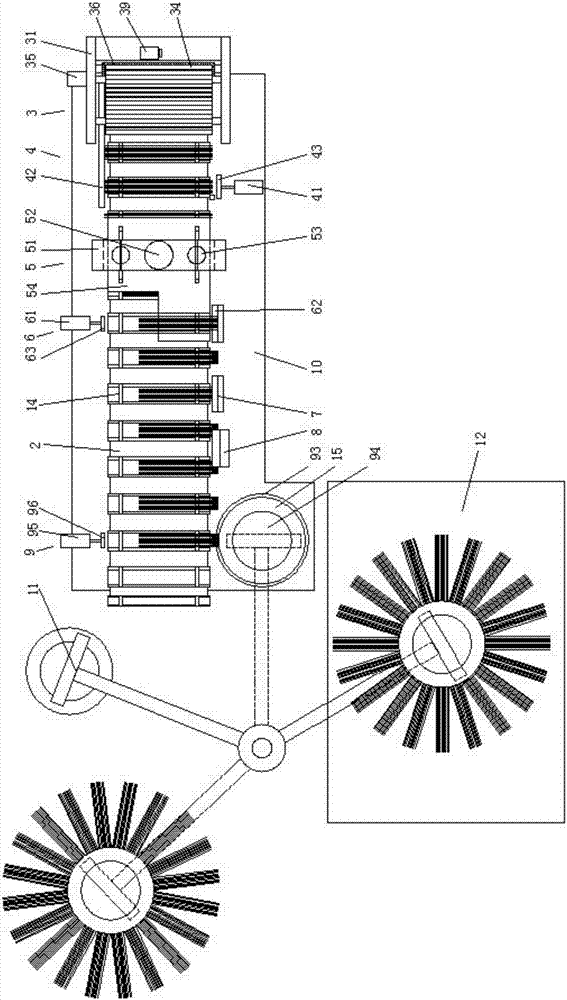

Full-automatic production equipment for brushes

The invention discloses full-automatic production equipment for brushes. The full-automatic production equipment for brushes comprises a rack, a conveying belt, a base plate, a manipulator and punch forming equipment, wherein the outer surface of the conveying belt is fixedly connected with a plurality of fixing grooves which are arranged equidistantly; a feeding device, a positioning device, a clipping device, a hot melting device, a gluing device, a cooling device and an insertion device are successively arranged on the base plate; the feeding device comprises a supporting plate, a feeding wheel set, a synchronous belt, a shifting plate, a feeding motor, a guiding groove and a feeding hopper; the clipping device comprises a support, a pressing air cylinder, a clipping air cylinder, a pressure plate and a blade; the insertion device comprises an insertion motor, a rotating shaft, a rotating plate, a fixed shaft and an insertion air cylinder. The full-automatic production equipment has the advantages that by automatic feeding, aligning, punching, hot melting, gluing and insertion, automation of the whole production process of the brushes is realized; production efficiency is greatly improved; the quality of products is improved; resource waste is avoided; the full-automatic production equipment is efficient and practical.

Owner:ANHUI ZHEN DA BRUSH IND

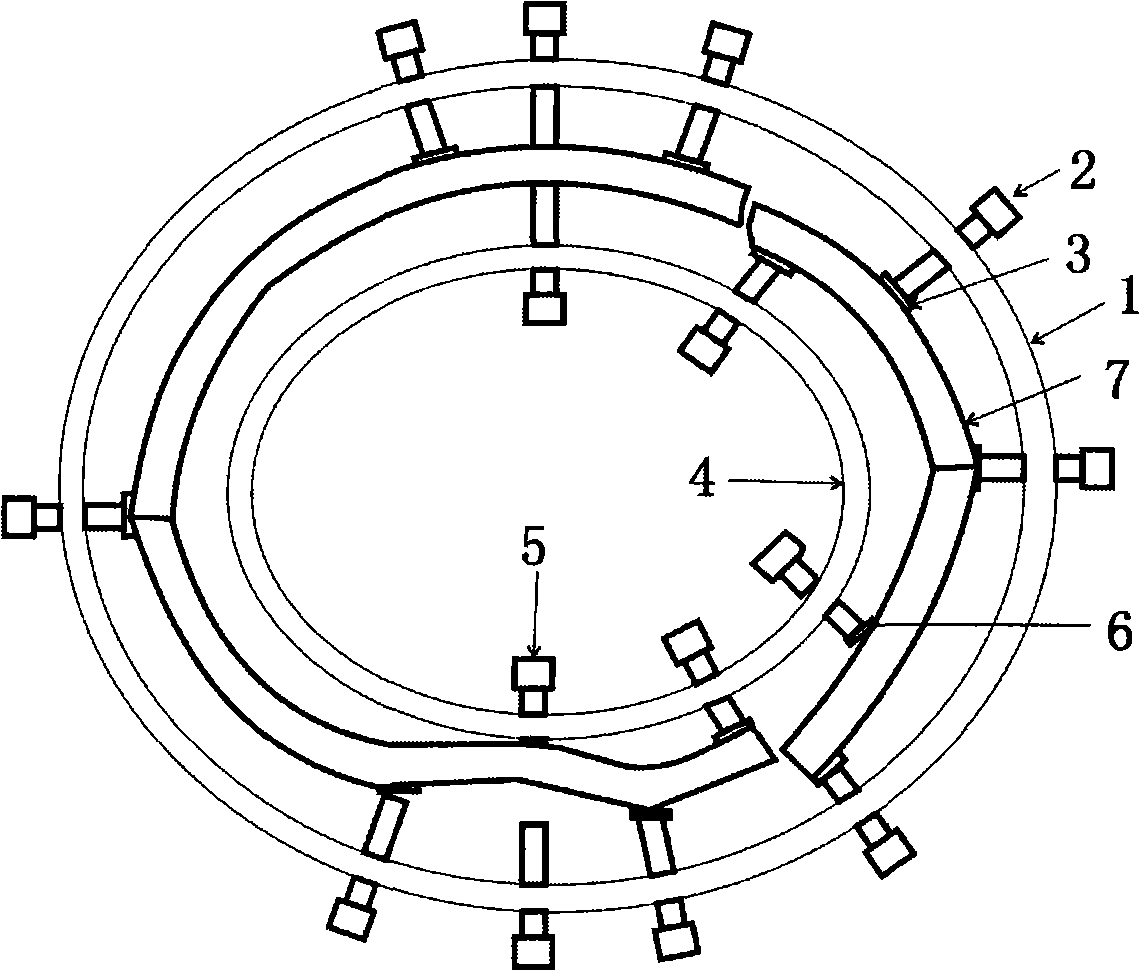

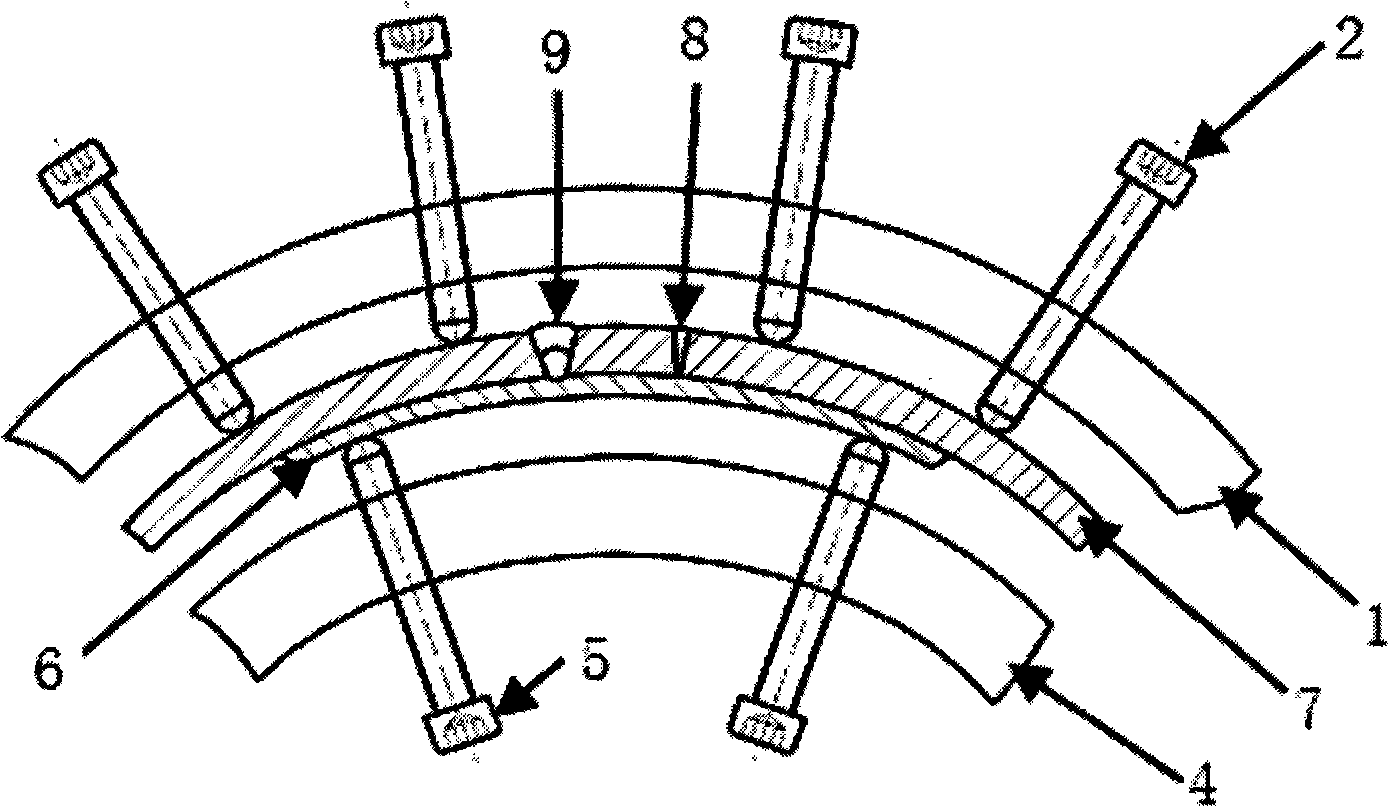

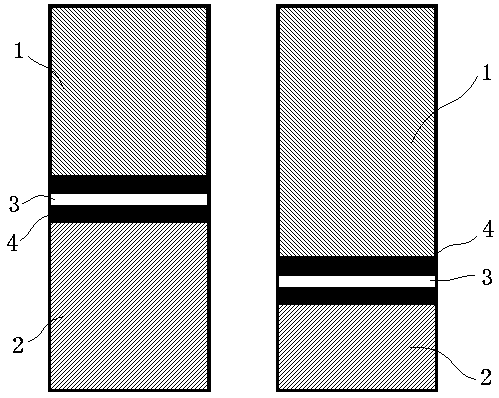

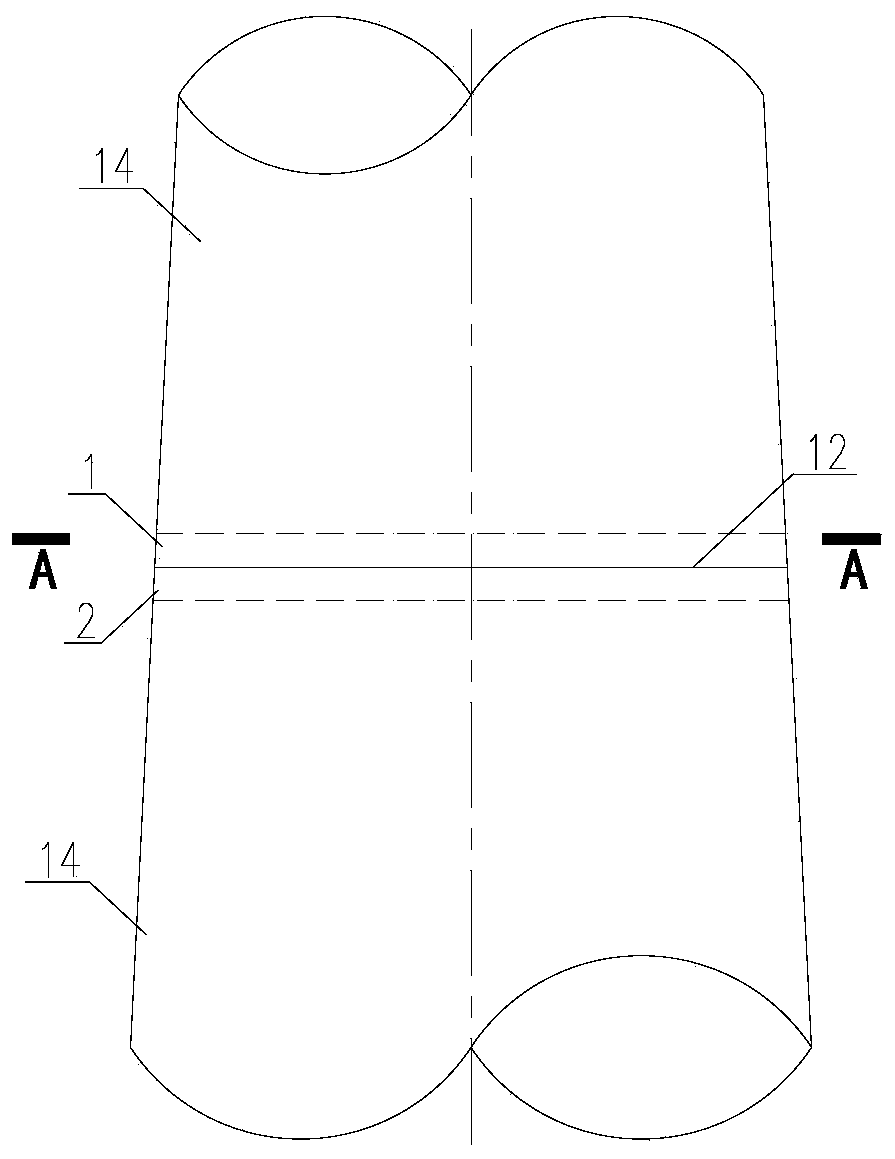

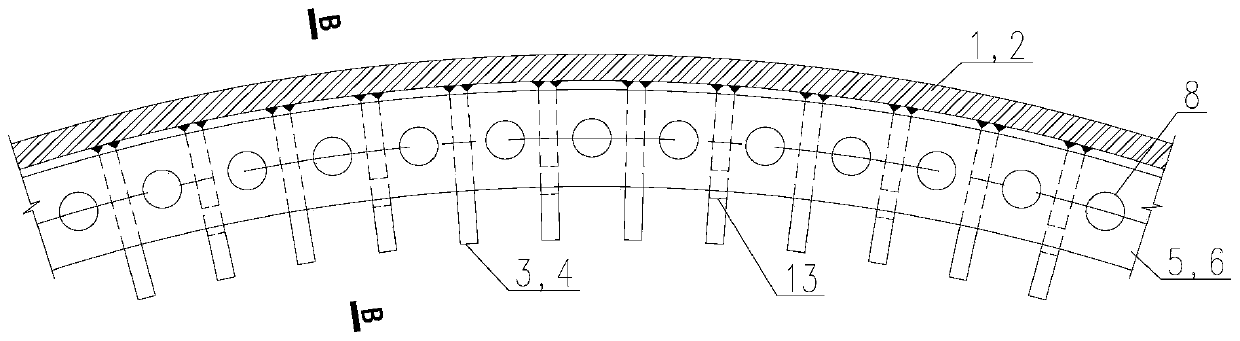

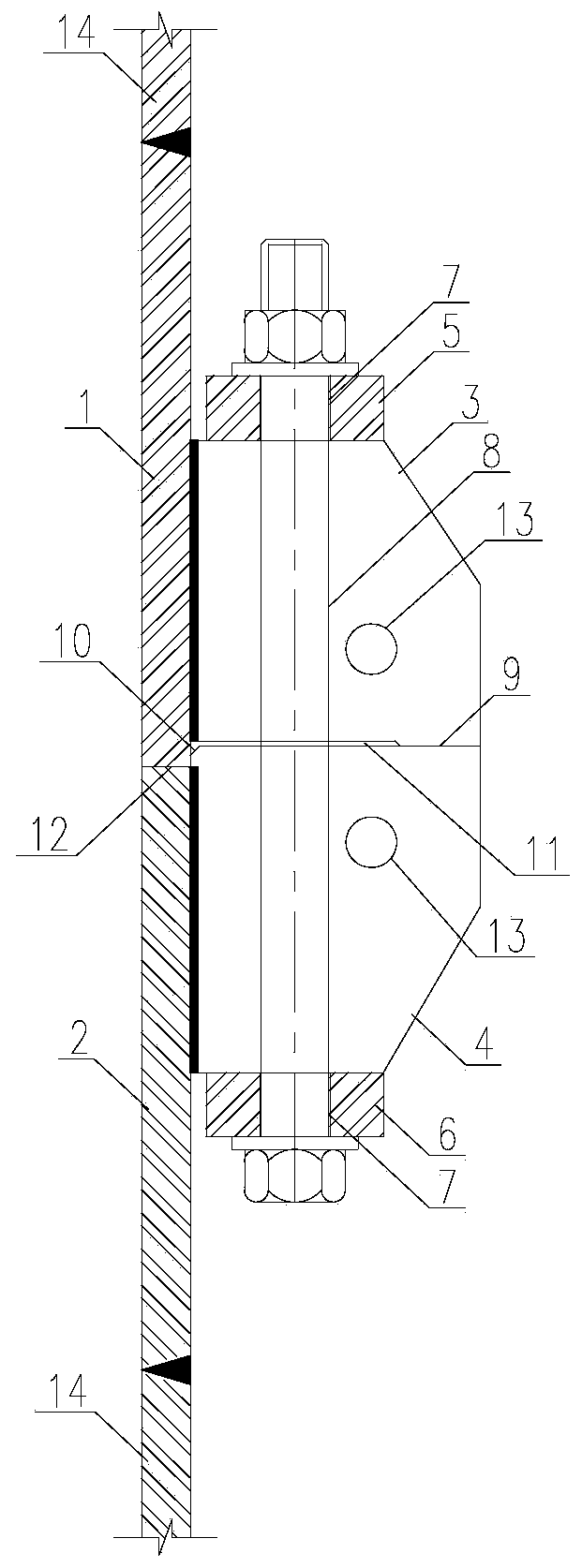

Damaged deformation bronze ware correcting locating and repairing device and method thereby

InactiveCN101264562ASimultaneous recoveryGuarantee smooth implementationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBronze

The invention discloses a reparation device and a method thereof for the shape-righting and positioning of damaged and distorted bronze ware, belonging to the technical field of relic restoration, which is characterized in that an inner ring (4) is arranged in a damaged and distorted bronze ware (7); an inner adjusting bolt is connected with an inner gasket (6) on the inner wall of the damaged and distorted bronze through a plurality of screw holes on the inner ring (4); an outer ring (1) is arranged outside the damaged and distorted bronze ware (7); an outer adjusting bolt is connected with an outer gasket (3) on the outer wall of the damaged and distorted bronze through a plurality of screw holes on the outer ring (1); the screw holes on the outer ring (1) and the inner ring (4) are evenly distributed. The reparation device and method for the shape-righting and positioning of damaged and distorted bronze ware has an advantage that shape-righting and positioning of seriously damaged and distorted bronze ware are realized to ensure successful laser welding reparation.

Owner:湖北省博物馆

Method for manufacturing X100 pipeline steel submerged arc straight weld pipe

ActiveCN101205597AIncrease productivityImprove molding qualityArc welding apparatusWelding/cutting media/materialsSteel tubeSteel plates

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

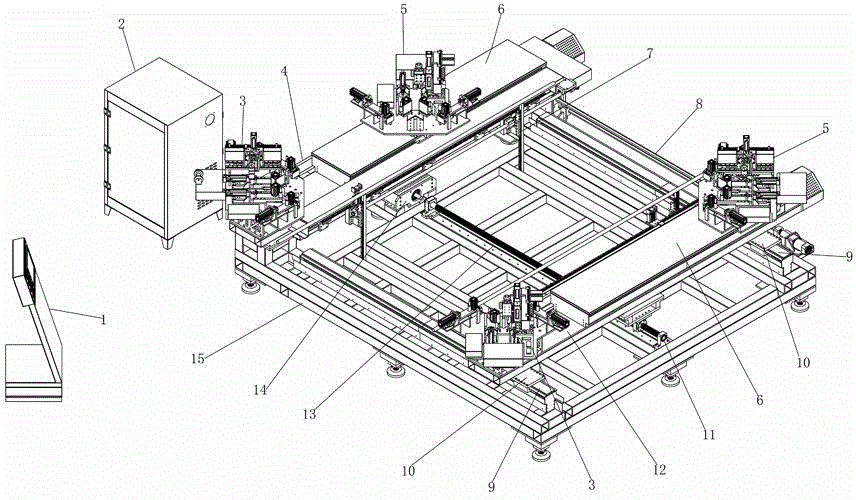

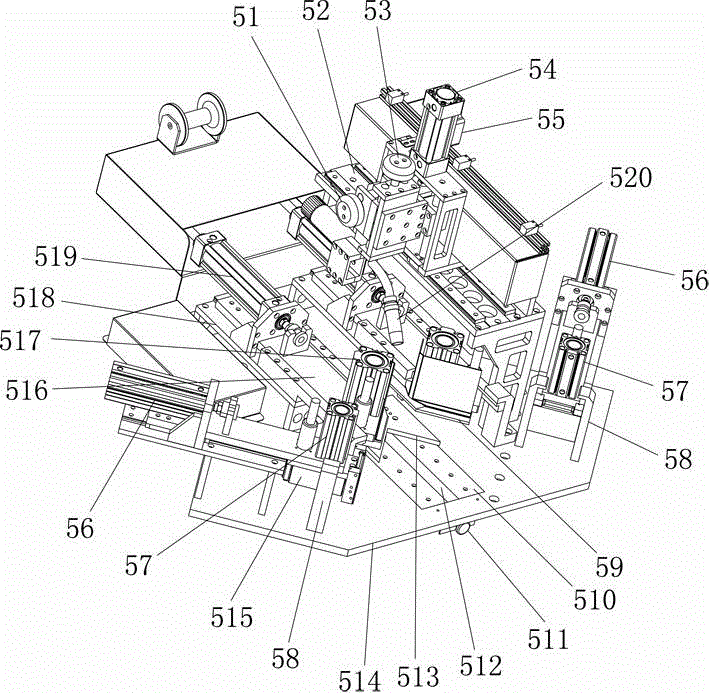

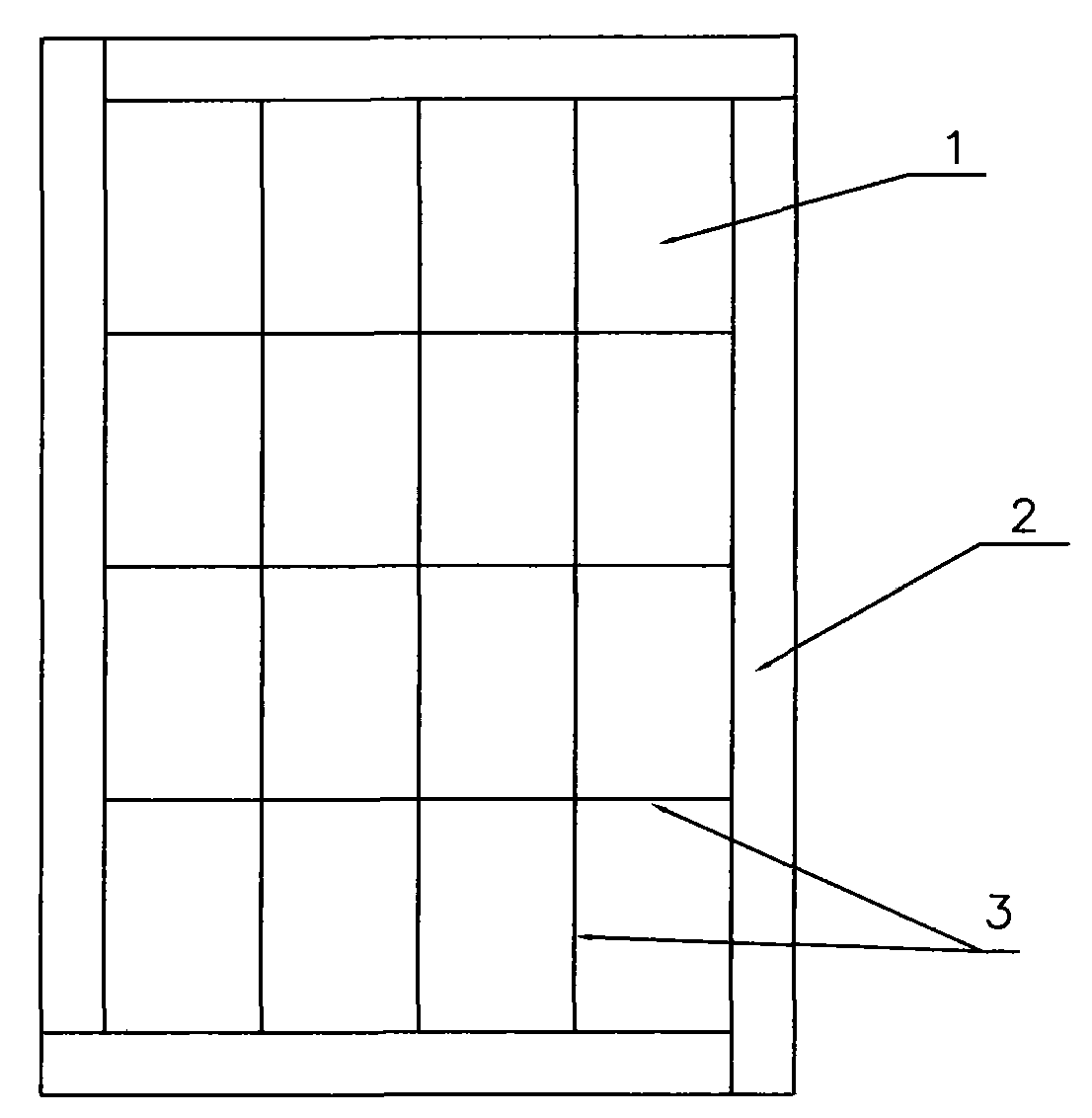

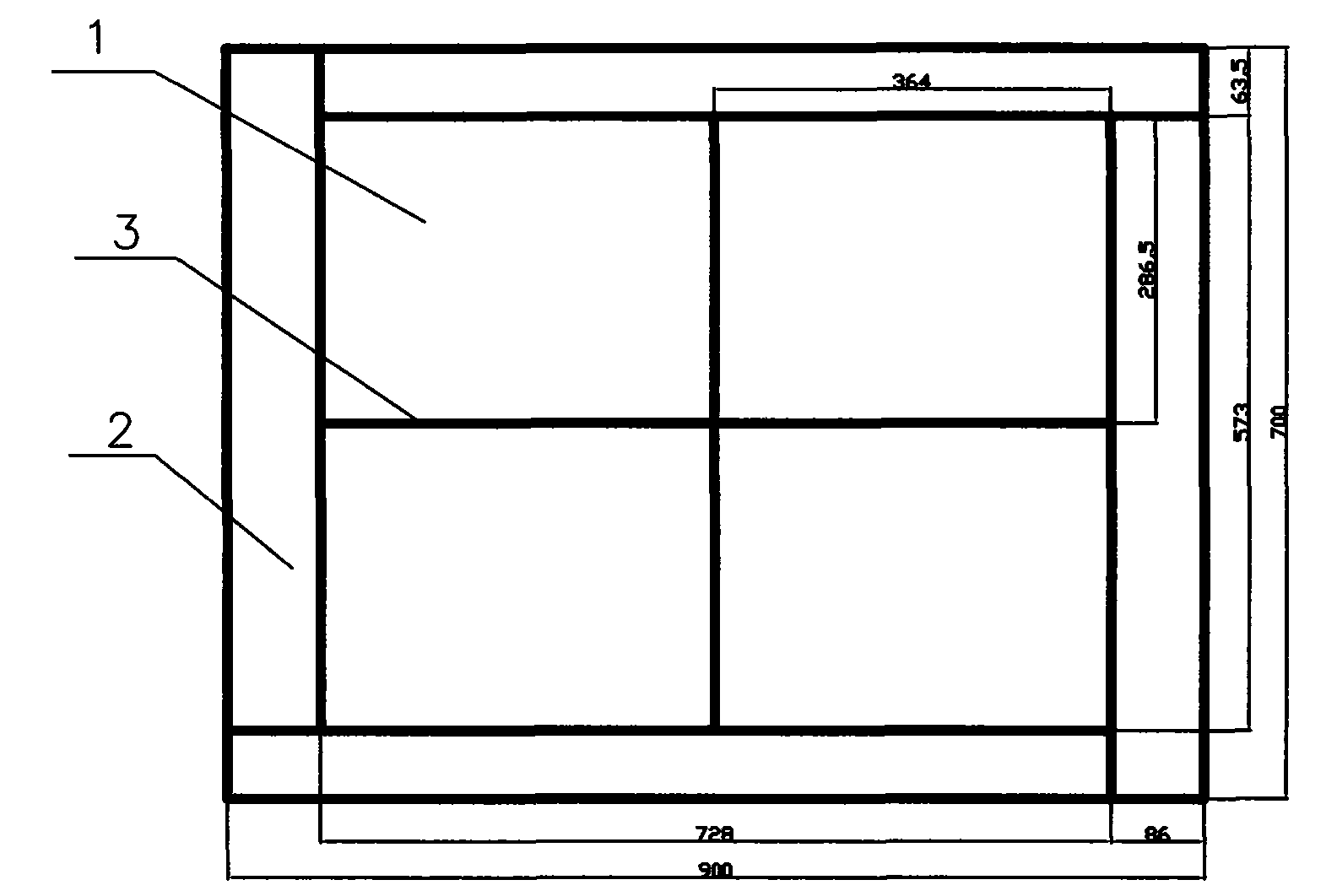

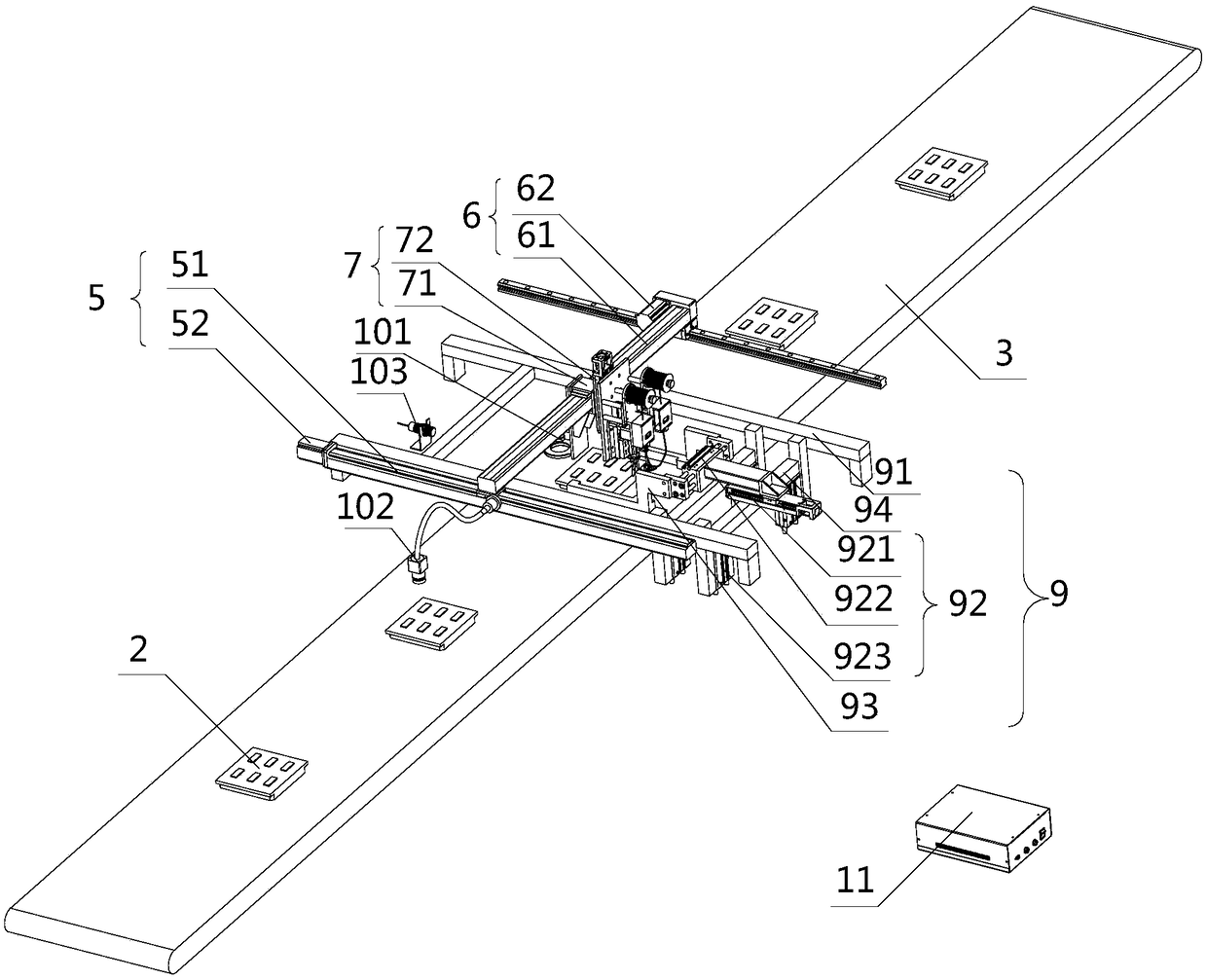

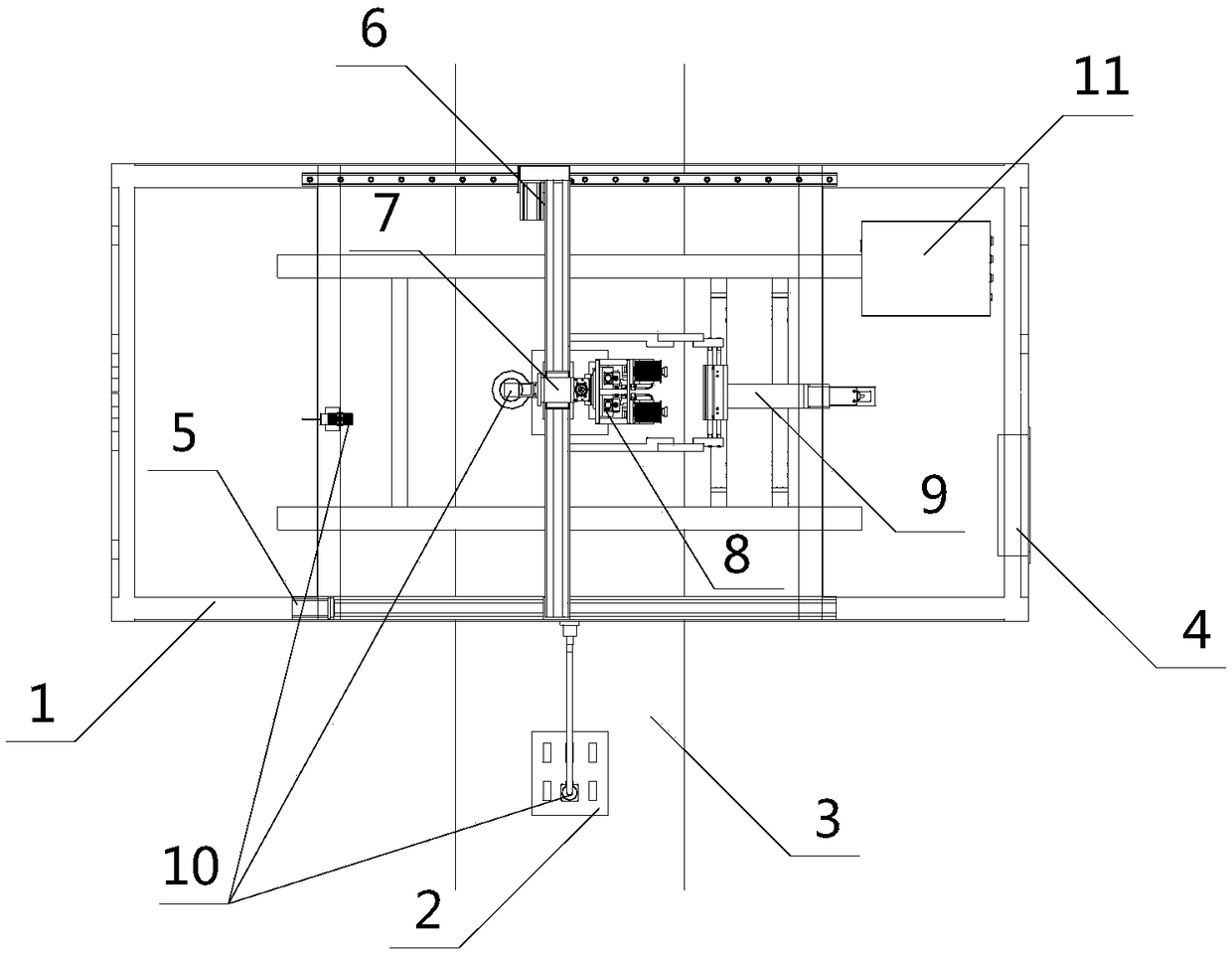

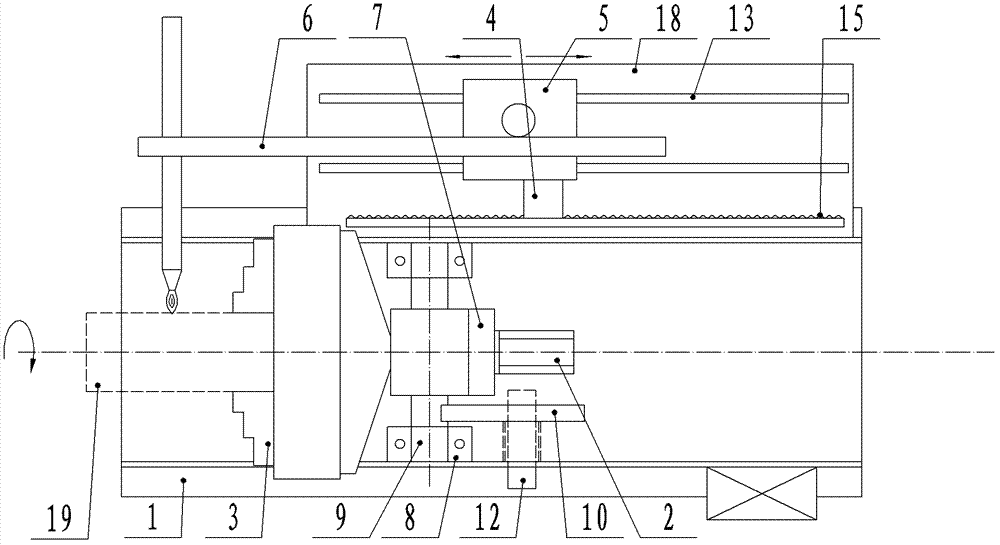

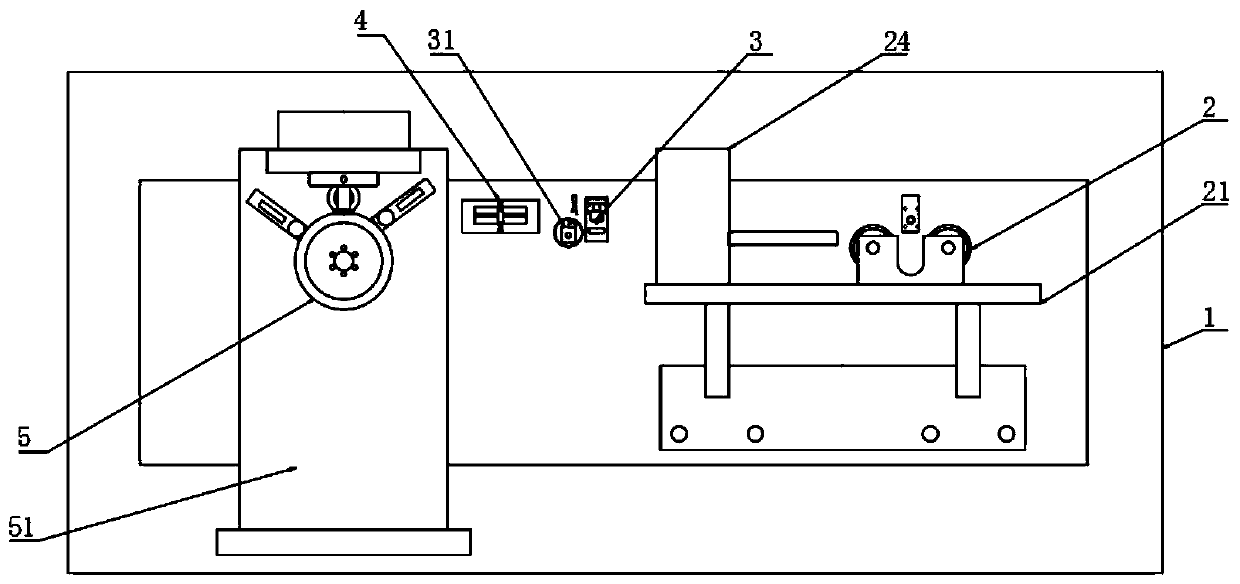

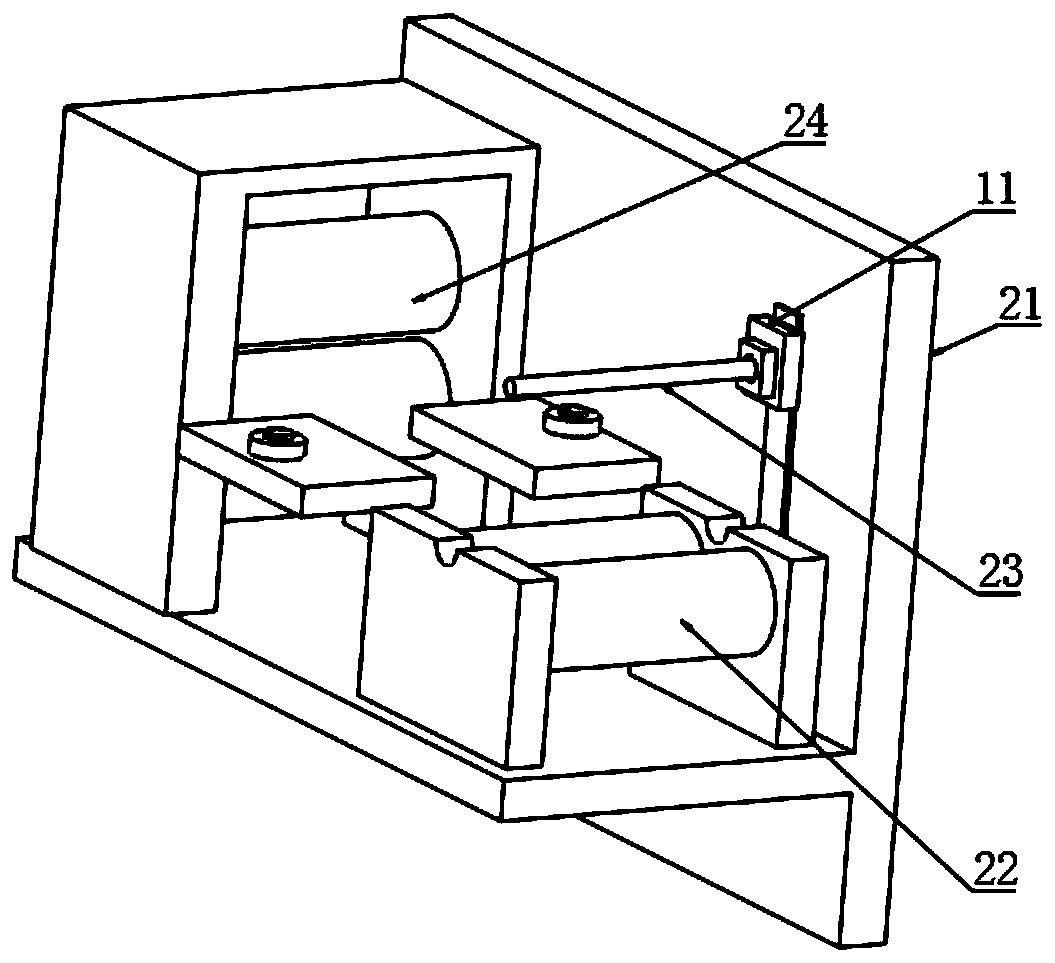

Numerical-control full-automatic positioning and forming welding machine for aluminum-clad wooden doors or windows

ActiveCN103817474AOvercome the high costHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesWeld seamFixed frame

The invention discloses a numerical-control full-automatic positioning and forming welding machine for aluminum-clad wooden doors or windows. The numerical-control full-automatic positioning and forming welding machine comprises a control system, an underframe, a fixed frame, a movable frame, a feeding mechanism and a discharging mechanism. The fixed frame and the movable frame are respectively arranged on two sides of the underframe; the feeding mechanism and the discharging mechanism are disposed between the fixed frame and the movable frame; both the movable frame and the fixed frame are provided with positioning and forming welding devices and longitudinal moving mechanisms; the positioning and forming welding devices arranged on the longitudinal moving mechanisms are capable of moving thereon; the movable frame is driven to slide along transverse guide rails by a transverse driving mechanism. By the aid of the numerical-control full-automatic positioning and forming welding machine, automatic welding of four corners of rectangular aluminum-clad wooden doors or windows is realized rapidly with attractive and smooth weld joints, the defect that wood is affected with damp is overcome; after welding, the aluminum-clad wooden doors or windows are integrated with no spliced seams but smooth and non-defective surfaces, are long in service lives and high in quality; production efficiency is high while production cost is low.

Owner:HUIZHOU YILONG MACHINERY & EQUIP

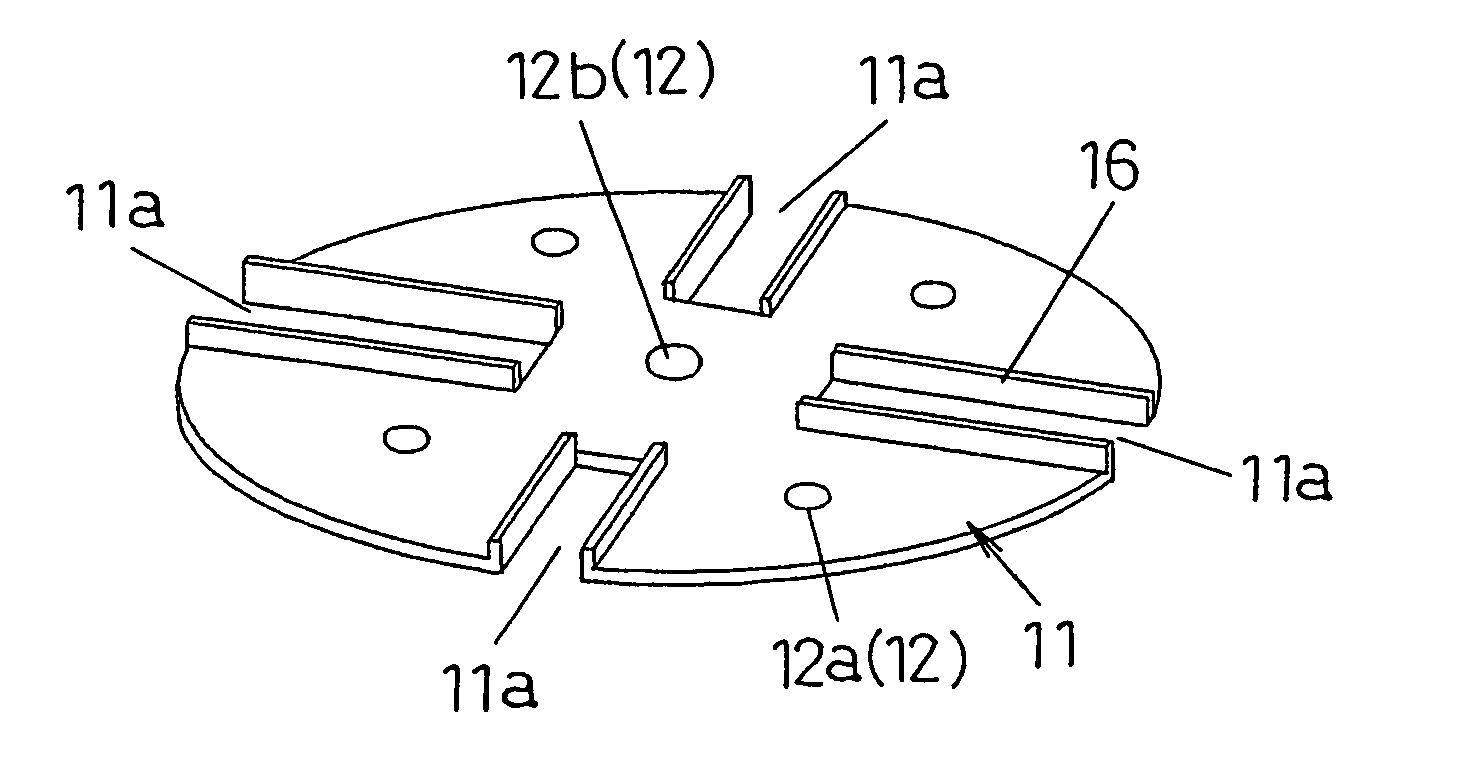

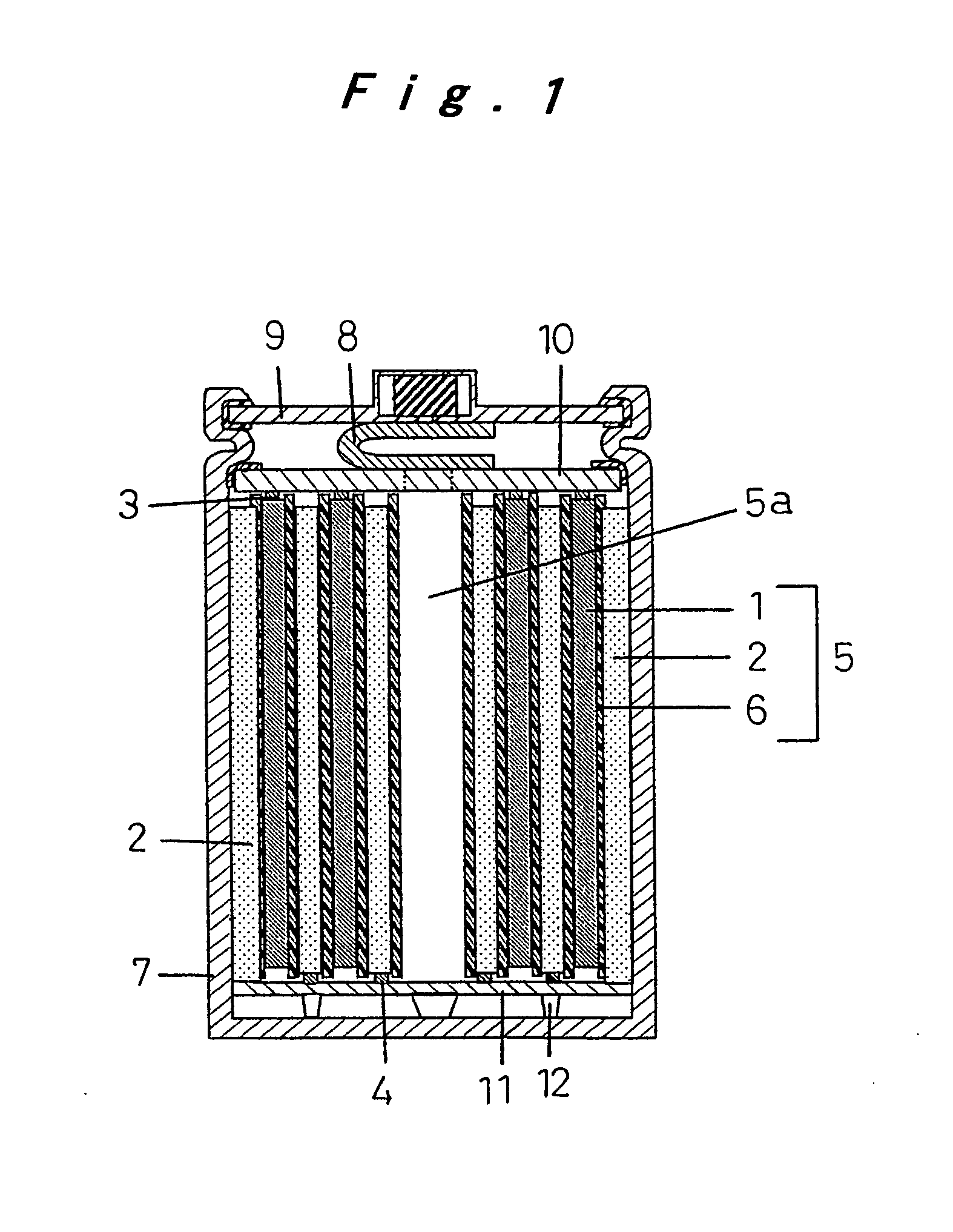

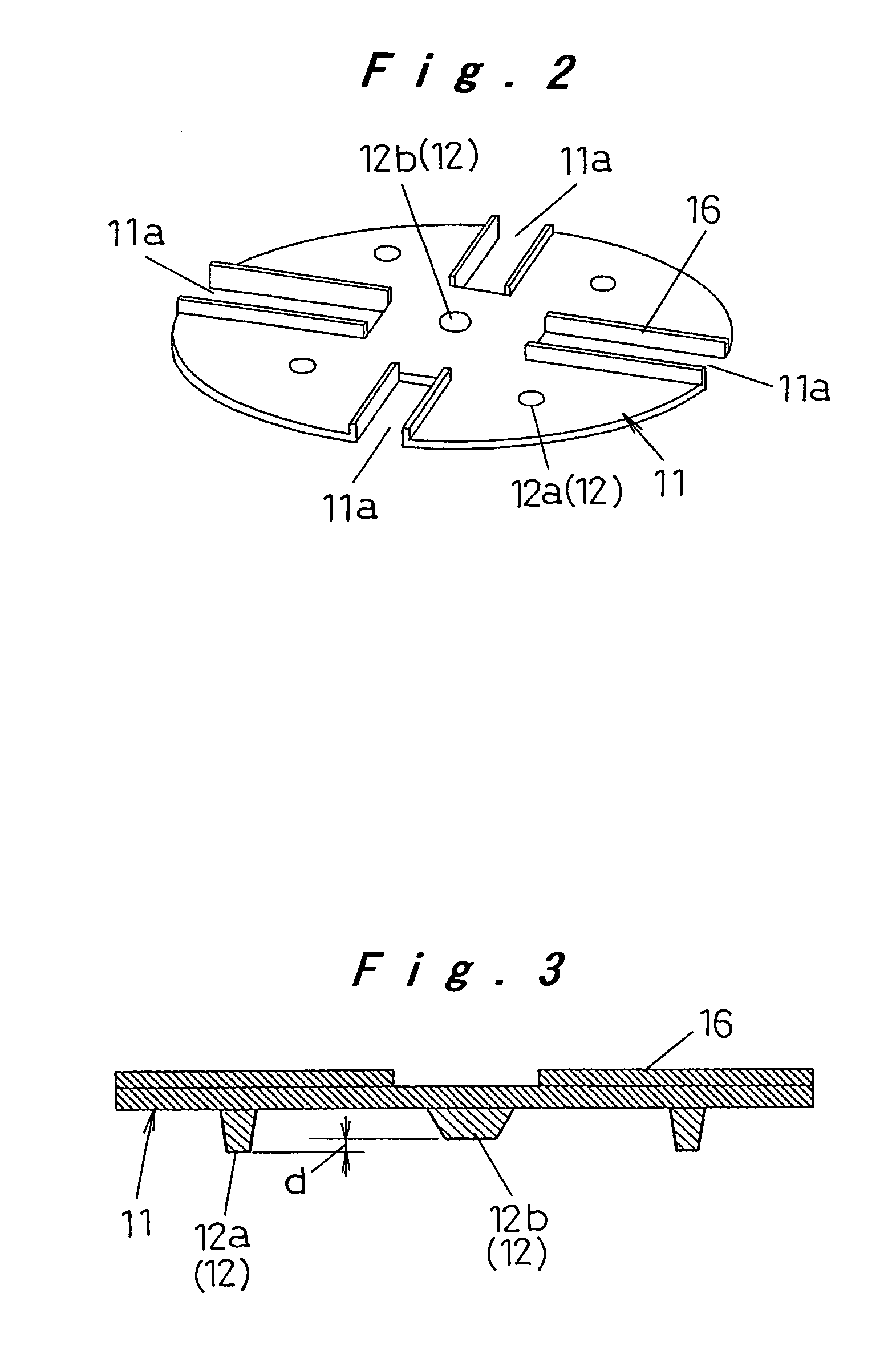

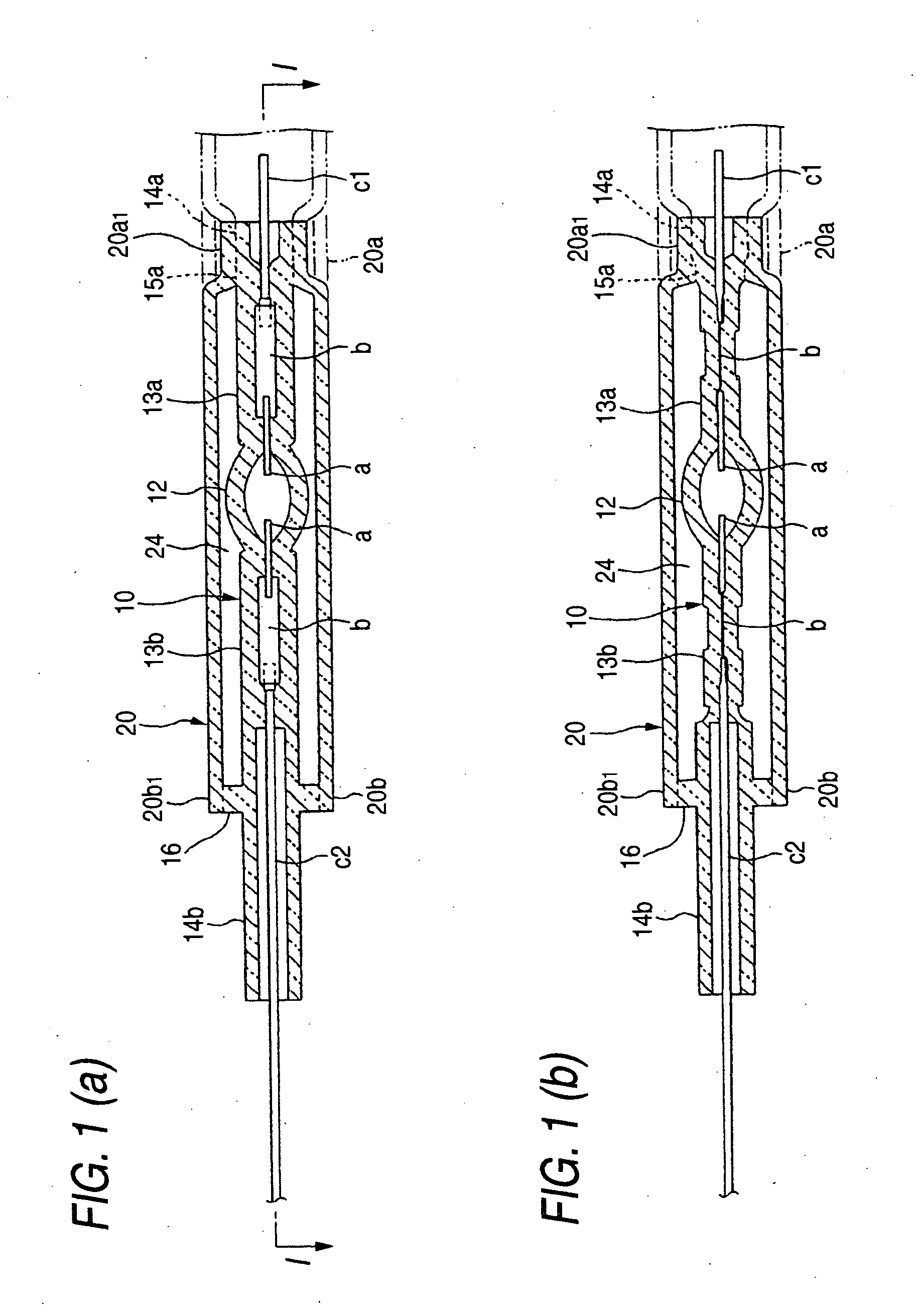

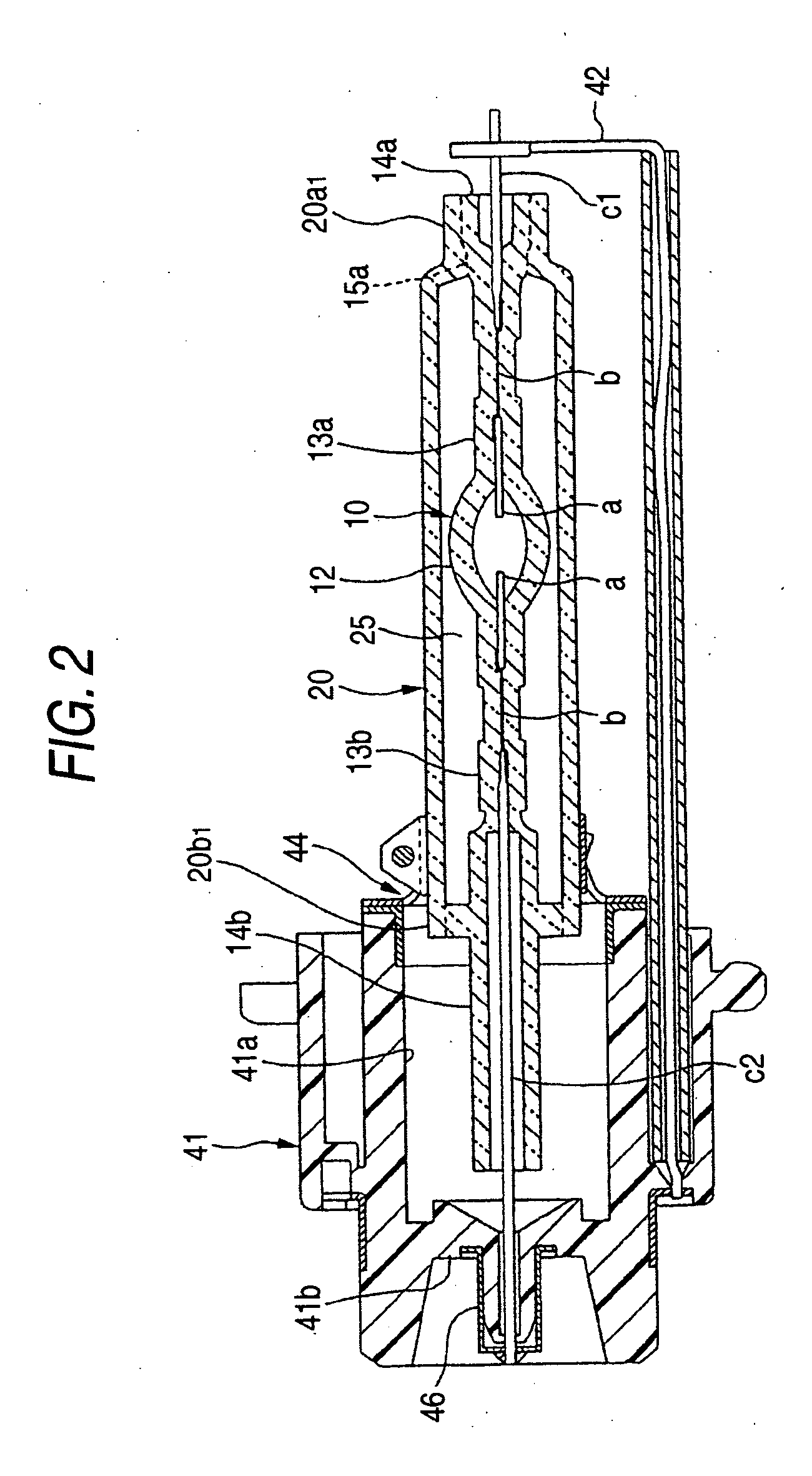

Cylindrical cell and manufacturing method thereof

ActiveUS20070020518A1Stably keeps battery performanceReduce connection resistanceFinal product manufactureSmall-sized cells cases/jacketsEngineeringHigh pressure

A cylindrical battery includes: an electrode plate assembly (5); a positive electrode collector (10) welded to a projecting portion of a core material for a positive electrode of the electrode plate assembly (5); a negative electrode collector (11) that includes a plurality of projections (12) at its lower surface and is welded to a projecting portion of a core material for a negative electrode of the electrode plate assembly (5) at its upper surface; a metal case (7) for accommodating the electrode plate assembly (5) to which the positive and negative electrode collectors (10, 11) are jointed, so as to arrange the negative electrode collector (11) down, the projections (12) of the negative electrode collector (11) being welded to an inner bottom surface of the metal case (7); an electrolyte poured into the metal case (7); and a sealing member (9), electrically insulated from the metal case (7), for sealing a top of the metal case (7), wherein the projections (12) of the negative electrode collector (11) are arranged at a plurality of locations in a region between a portion opposed to a hollow cylindrical portion (5a) of the electrode plate assembly (5) and a peripheral portion. Thus, it is possible to provide the cylindrical battery that is favorable when large current discharge is performed and that has high pressure resistance of the metal case.

Owner:PANASONIC CORP

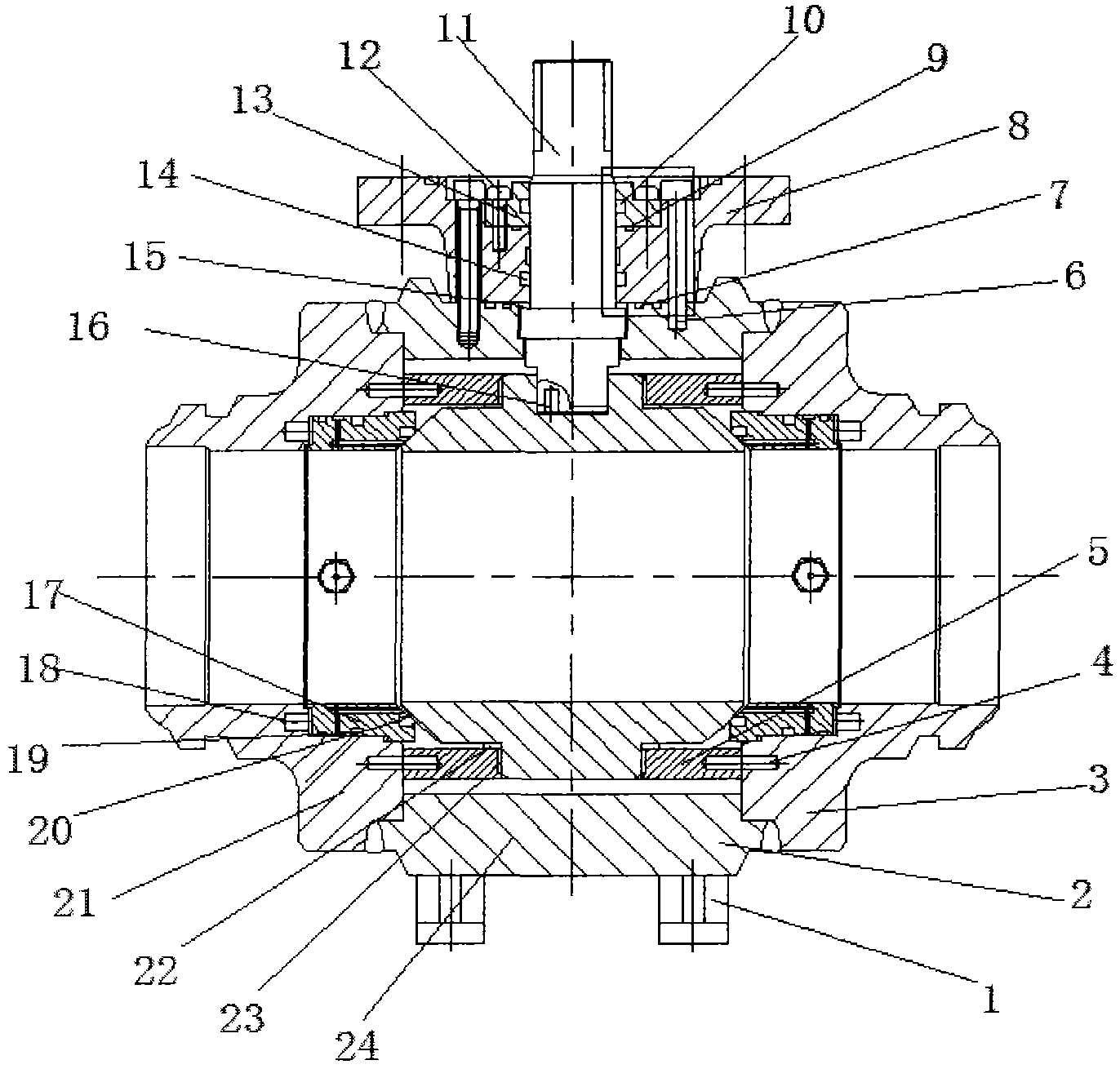

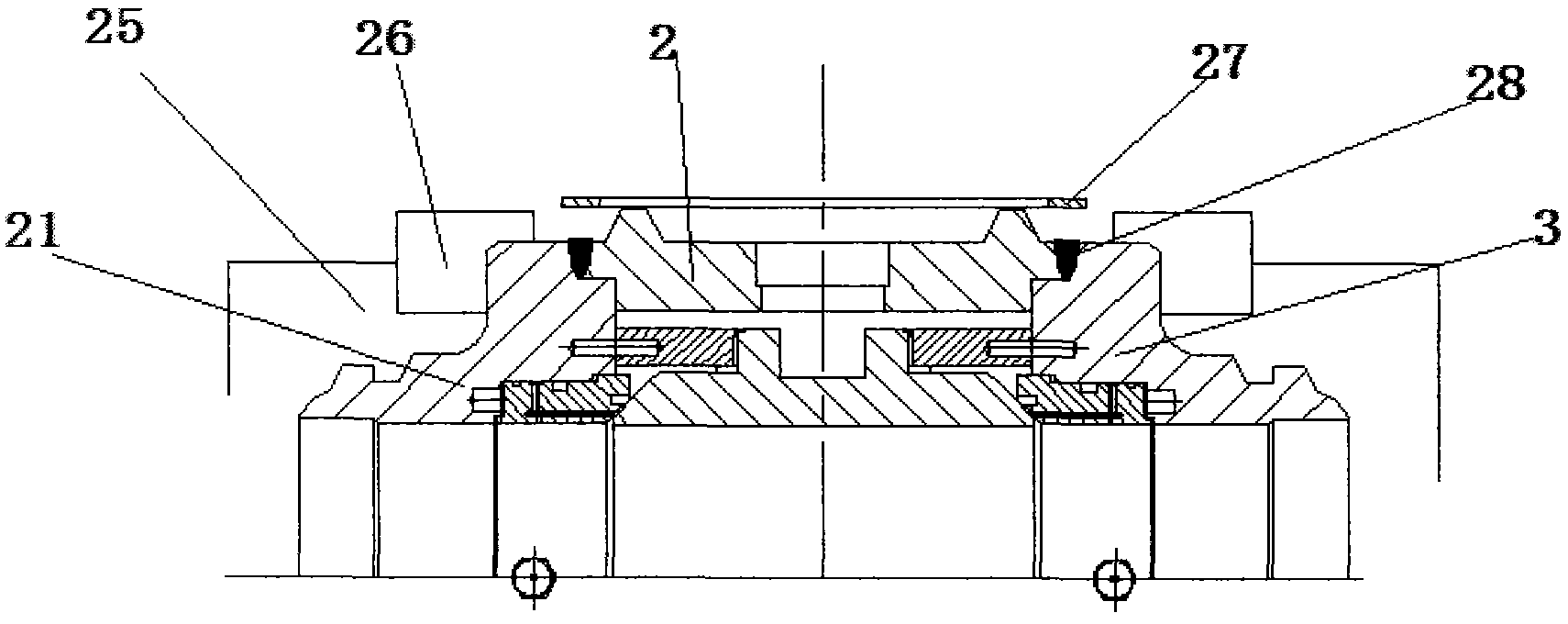

Ball valve with all-welded valve bodies and welding method of ball valve

InactiveCN103672008AReduce labor intensityImprove sealingPlug valvesHigh frequency current welding apparatusEngineeringValve stem

The invention discloses a ball valve with all-welded valve bodies and a welding method of the ball valve. The ball valve comprises a spherical valve spool, a left valve body, a right valve body, a middle valve body, a valve stem, a valve seat, sealing rings, a press plate, a lining plate and the like. The ball valve is applicable to valve systems in gas and liquid delivery pipelines, and a high-frequency welding process is adopted to produce sealed parts. The spherical valve spool is placed in a spherical cavity in the middle valve body together with the lining plate, a thrust plate, a sliding bearing and the like, the sealing rings are mounted on the left and right sides of the spherical valve spool, the valve seat and a valve-seat support ring thereof are mounted on the inner walls of the valve bodies on the left and right sides together with an elastic mechanism, joint parts between the middle valve body and the left and right valve bodies are all sealed by welding, and one end of the valve stem penetrates the middle valve body and is connected with the internal valve spool. The valve stem rotates to drive the spherical valve spool in the cavity to rotate, so that the valve is controlled to be turned off. The ball valve is simple in structure, good in sealing performance, stable in welding and sealing quality, high in production efficiency and applicable to pipeline delivery systems for petroleum, natural gas and the like, and the problem of leakage of conventional valves is solved.

Owner:CRETE GRP CO LTD

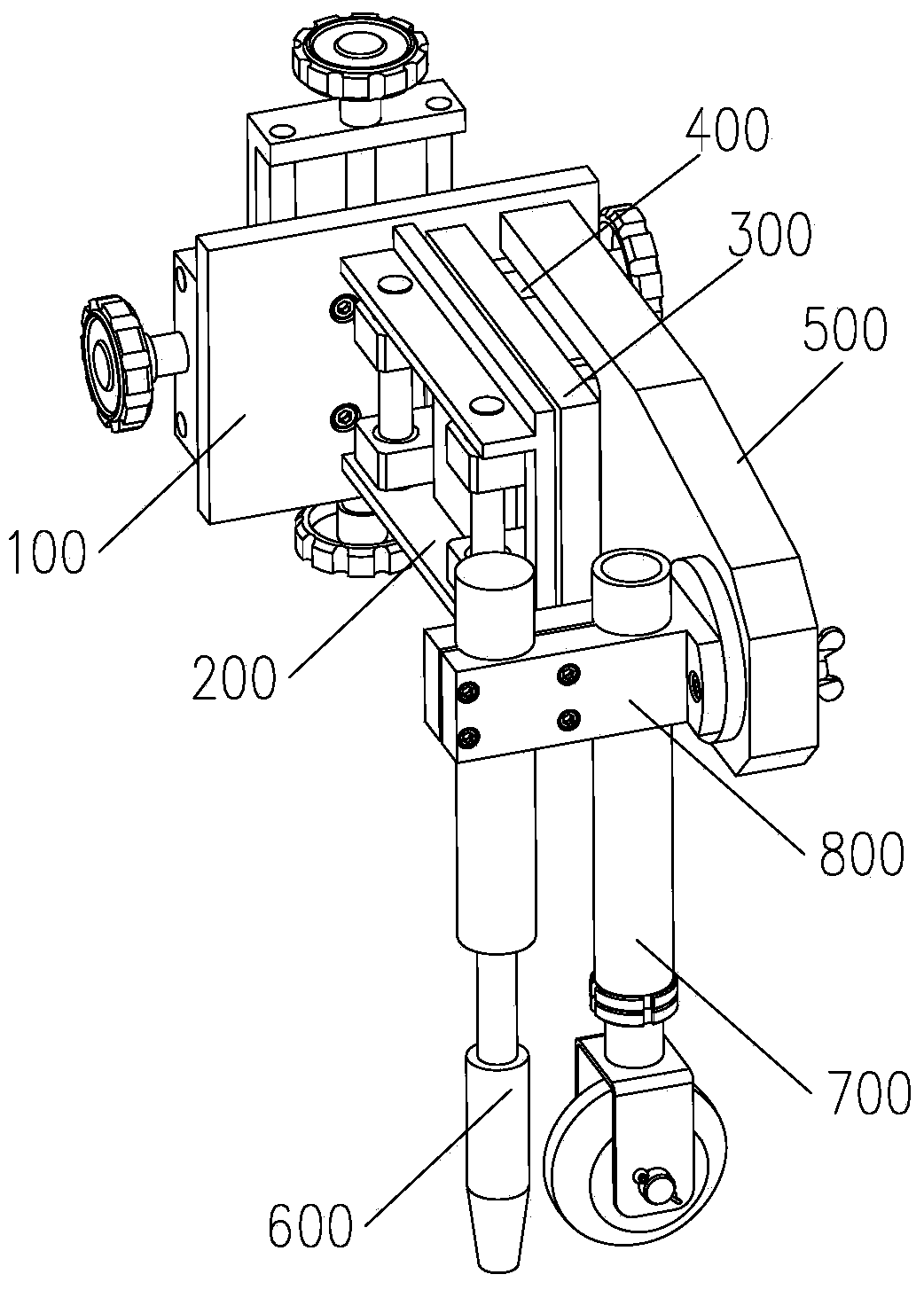

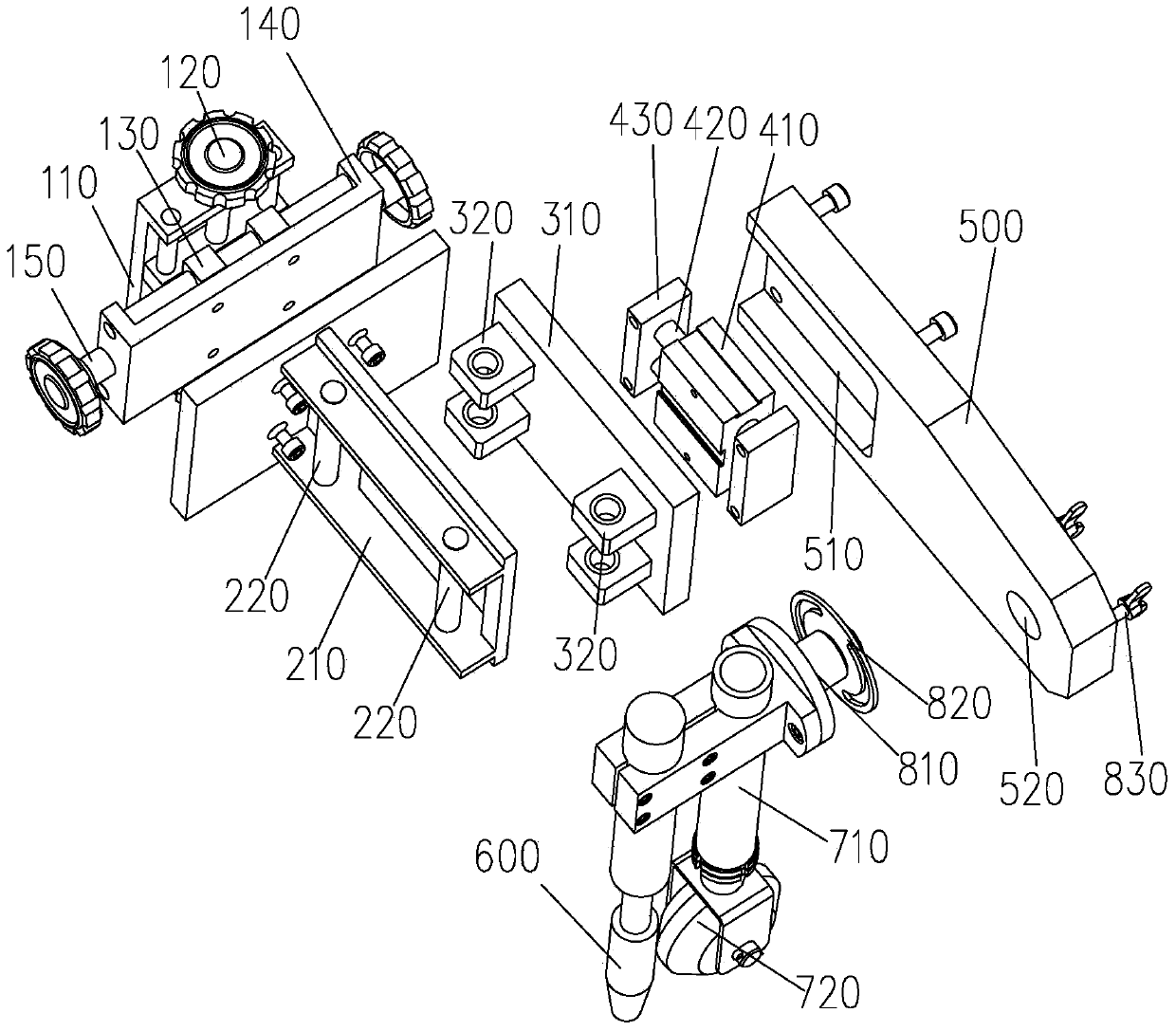

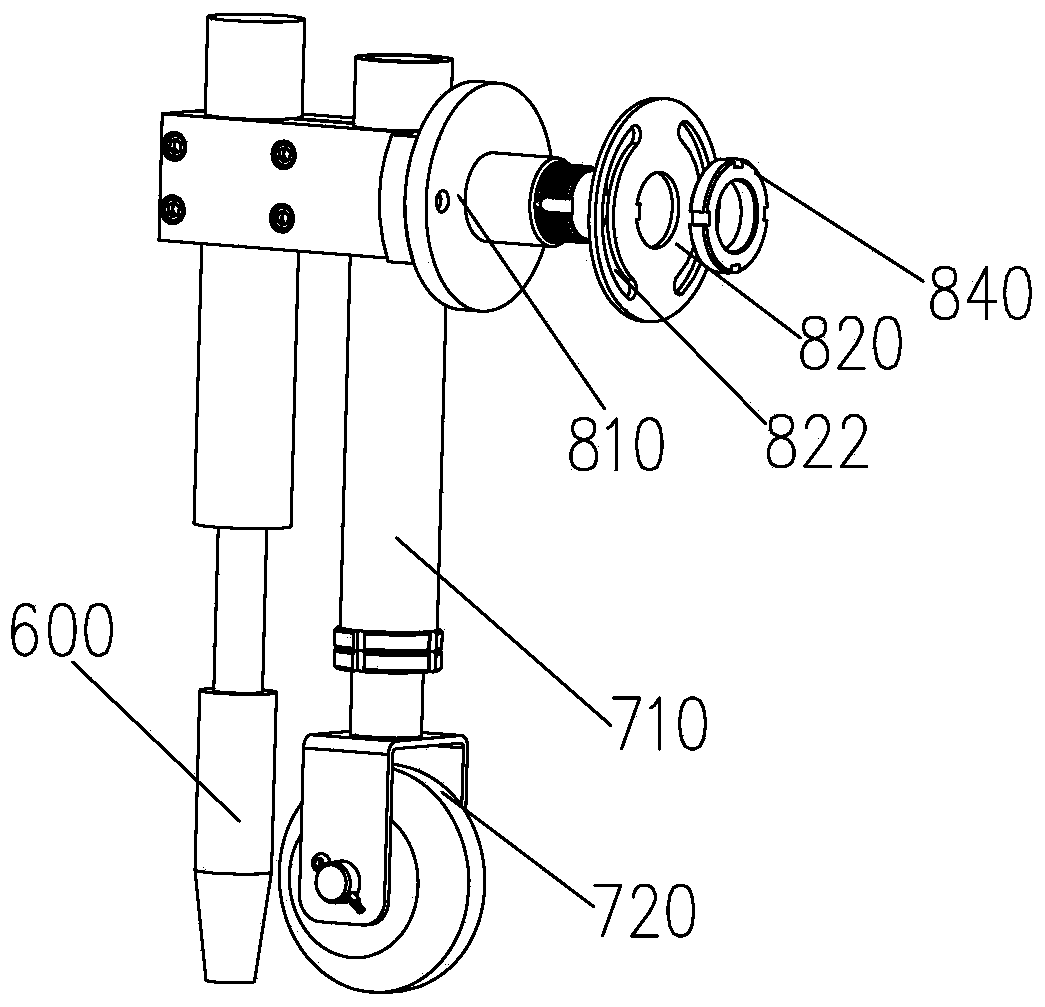

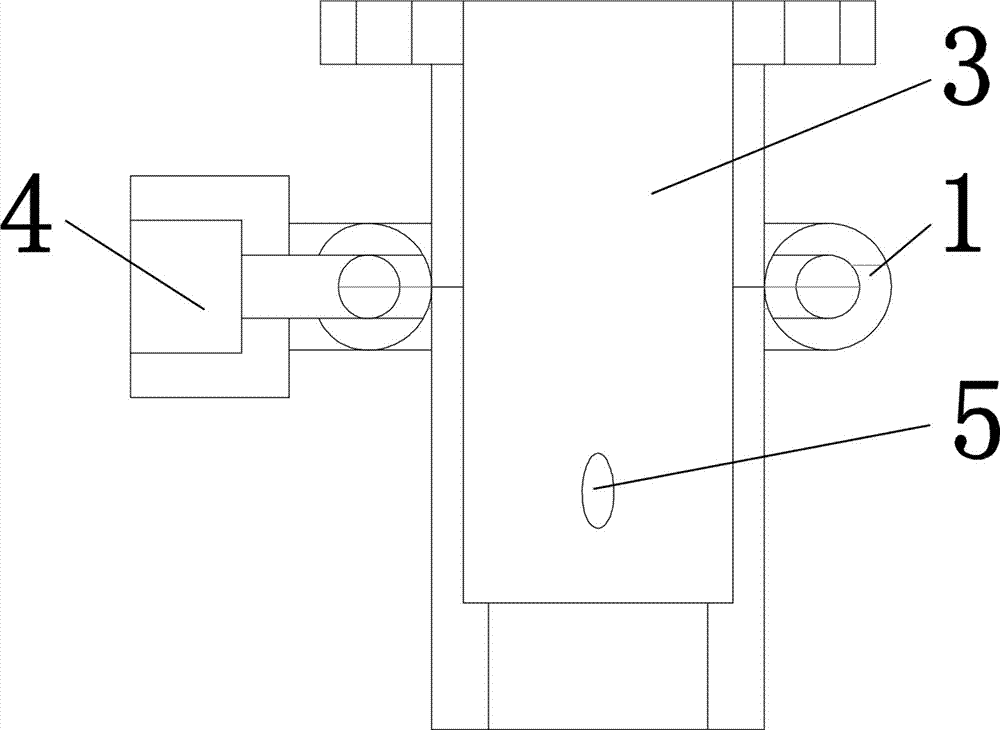

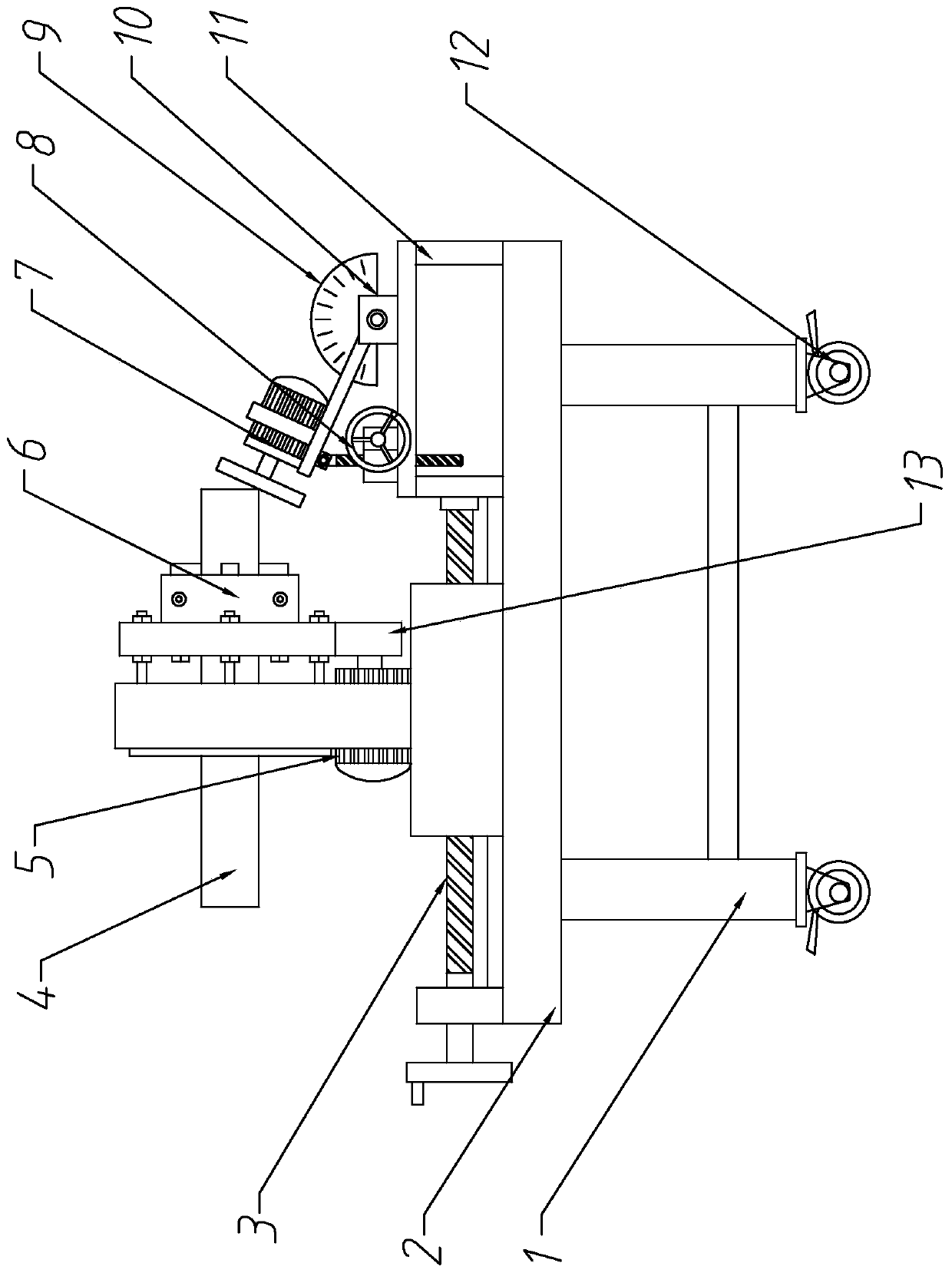

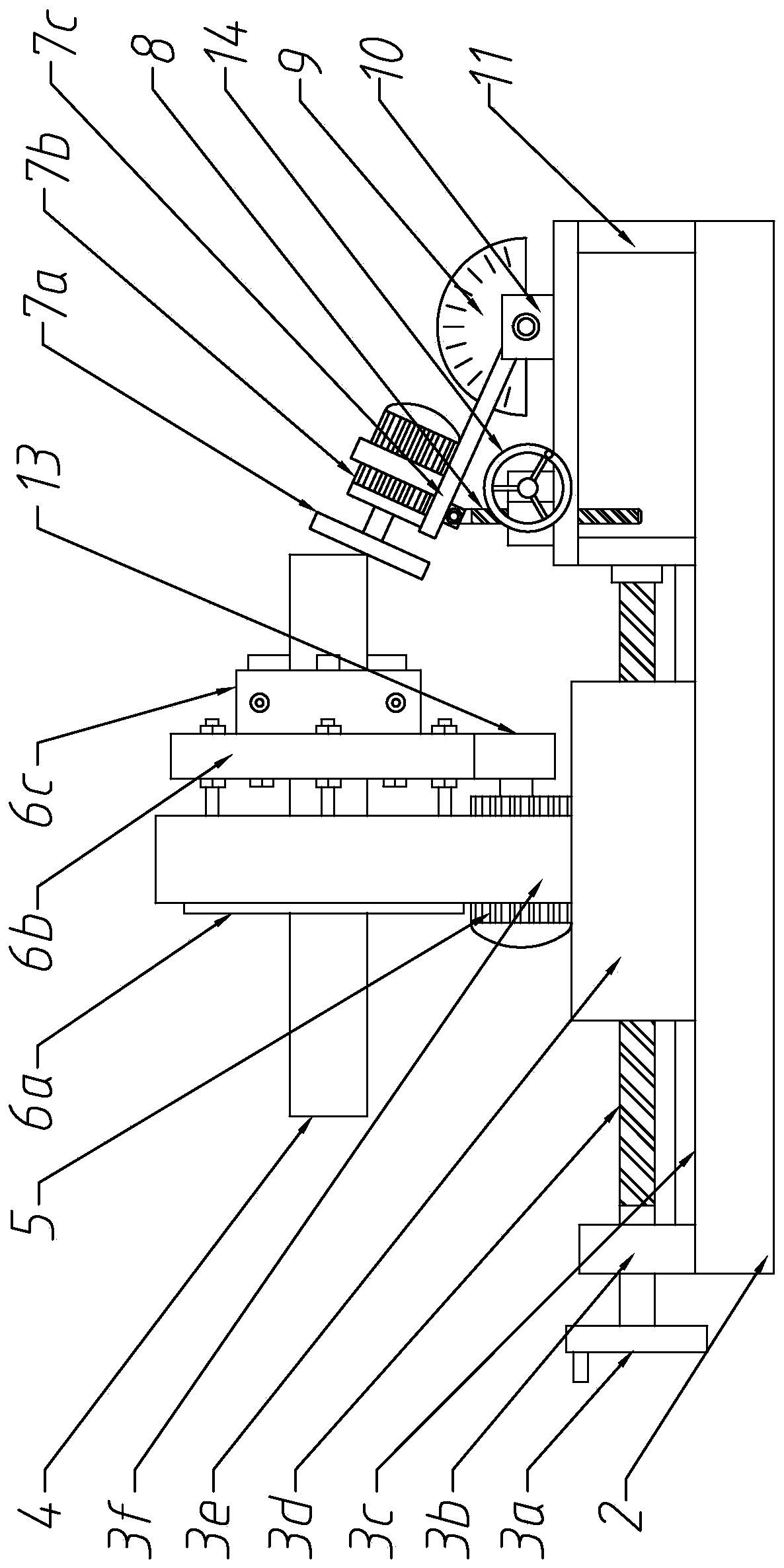

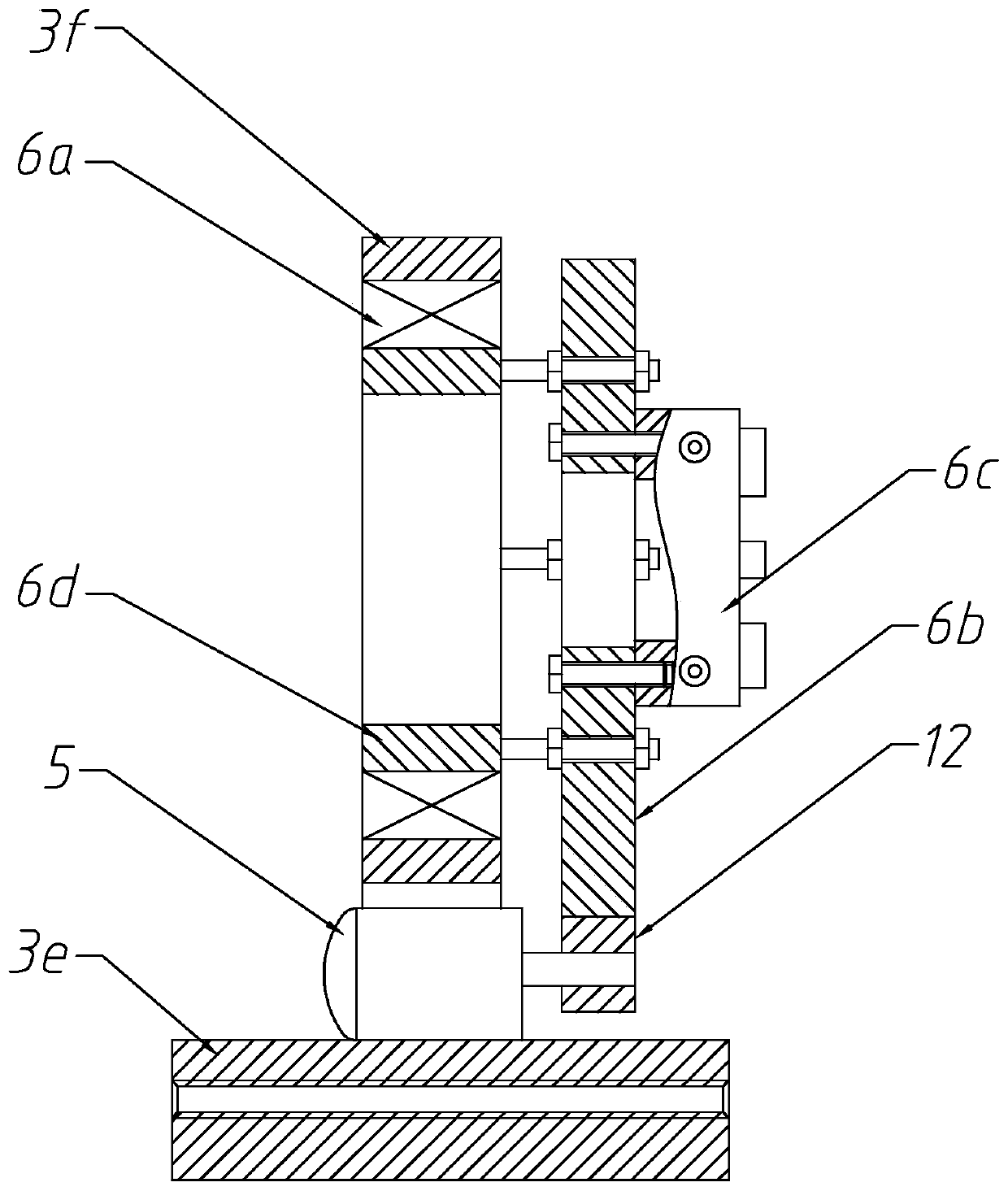

Mechanical welding seam tracking device

The invention discloses a mechanical welding seam tracking device. The mechanical welding seam tracking device comprises a fine adjustment mechanism, a guide rod mechanism, a guide plate mechanism, a horizontal driving mechanism, a connecting plate, a welding gun, a tracking assembly and a steering gear, wherein the fine adjustment mechanism and the guide plate mechanism are respectively connected with the guide rod mechanism, the guide plate mechanism can move up and down relative to the guide rod mechanism, the horizontal driving mechanism is respectively connected with the connecting plate and the guide plate mechanism, the welding gun and the tracking assembly are respectively installed on the steering gear, and the steering gear is installed on the connecting plate. The mechanical welding seam tracking device is simple in structure, no electric sensors need to be arranged, and the cost is effectively reduced; due to the horizontal driving mechanism and the gravity of the mechanical welding seam tracking device, the tracking assembly can make contact with the surface of a workpiece to be welded all the time; due to the guide plate mechanism and the guide rod mechanism which move relative to each other, the mechanical welding seam tracking device is better in flexibility, and the initial position of the welding gun and the initial position of the tracking assembly can be aligned conveniently through the fine adjustment mechanism; due to the steering gear, the angle of the welding gun and the angle of the tracking assembly can be adjusted conveniently.

Owner:上海气焊机厂有限公司

Method for manufacturing holographic mother board by using laser welding imposition

InactiveCN101618627AImprove cutting accuracyReduce weldsLaser beam welding apparatusPrinting formes reproductionThermal deformationEngineering

The invention relates to a method for manufacturing a holographic mother board by using a laser welding imposition, which comprises the following steps: arranging nickel boards of unit holographs according to the requirements, and welding each unit holograph by using the laser energy to manufacture a holographic mother board which has a large dimension and comprises a plurality of unit holographs. The invention has the advantages that the method can be used for splicing unit holographs of arbitrary dimensions and is particularly suitable for splicing unit holographs of large dimensions; the laser welding has the characteristics of fine, smooth and flat welding joints, small thermal deformation and the like and can realize digitally-controlled automatic operation, thus the splicing speed is quick, and the splicing precision is high; and the holographic mother board formed by welding can be electroformed and reproduced into a plurality of mother boards, and the large board formed by laser welding can be also directly arranged on a moulding press for use.

Owner:HUBEI XINGLONG PACKAGING MATERIAL

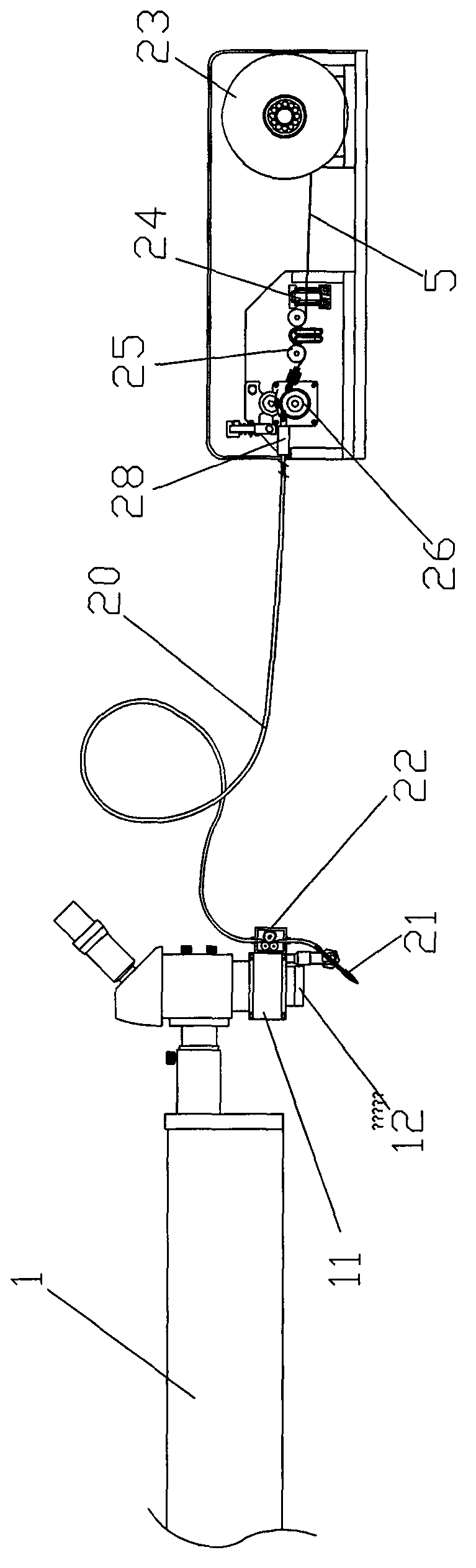

Automatic wire feeding system of automatic laser welding machine

The invention relates to an automatic wire feeding system of an automatic laser welding machine. The automatic wire feeding system is matched with a laser head for use. The automatic wire feeding system of the automatic laser welding machine comprises a welding wire drum, a welding wire correcting mechanism, a welding wire straightening mechanism, an air blowing and wire feeding device, a tail end wire feeding speed control mechanism and a control driving unit in sequence, wherein the welding wire drum is provided with a wound welding wire, the welding wire correcting mechanism is used for correcting the welding wire, the tail end wire feeding speed control mechanism is used for precisely controlling the wire feeding speed, the control driving unit is connected with the welding wire correcting mechanism, the welding wire straightening mechanism, the air blowing and wire feeding device and the tail end wire feeding speed control mechanism and is used for controlling the speed, the air blowing and wire feeding device is provided with a wire blowing pipe used for blowing and feeding the welding wire and is connected with a wire feeding hole of the wire blowing pipe, the tail end of the wire blowing pipe is provided with a welding wire outlet end which is fixedly connected with an end laser head, and the port axis of the welding wire outlet end penetrates through a laser condensation welding focus on the optical axis of the laser head. The automatic wire feeding system can be used for automatically conveying the welding wire to a welding point, and operating personnel do not need to convey the welding wire by hand, so that the condition that time and effort are consumed due to the fact that the welding wire is manually and imprecisely conveyed is avoided, the labor cost is reduced, the welding quality is conveniently ensured, and the application range of the laser welding machine is enlarged.

Owner:SHENZHEN TONGFA LASER EQUIP

Intelligent welding system and method

PendingCN109332840AReduce manual debugging workloadImprove work efficiency and product qualityMetal working apparatusSoldering auxillary devicesAssembly lineWorkload

The invention relates to an intelligent welding system and method. The system comprises an assembly line, an industrial personal computer, a moving platform, a clamping assembly, a visual system and awelding assembly, wherein the visual system, the clamping assembly and the welding assembly are arranged on the moving platform; the assembly line, the moving platform, the clamping assembly, the welding assembly and the visual system are electrically connected with the industrial personal computer; the clamping assembly can clamp a circuit board moving on the assembly line so as to arrive at thepreset position; and the welding assembly can be used for welding the circuit board clamped by the clamping assembly. According to the intelligent welding system and the method provided by the invention, the visual system acquires image information of the circuit board moving to the preset position, the industrial personal computer recognizes welding pad information on the circuit board, weldingpulse information is generated by combining pre-stored printing information, and the circuit board clamped by the clamping assembly is automatically welded, so that the previous artificial debugging workload is greatly reduced, the working efficiency and the product quality are improved, the welding parameters cannot be adjusted aiming at circuit boards of different circuit structures, and the intelligent degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

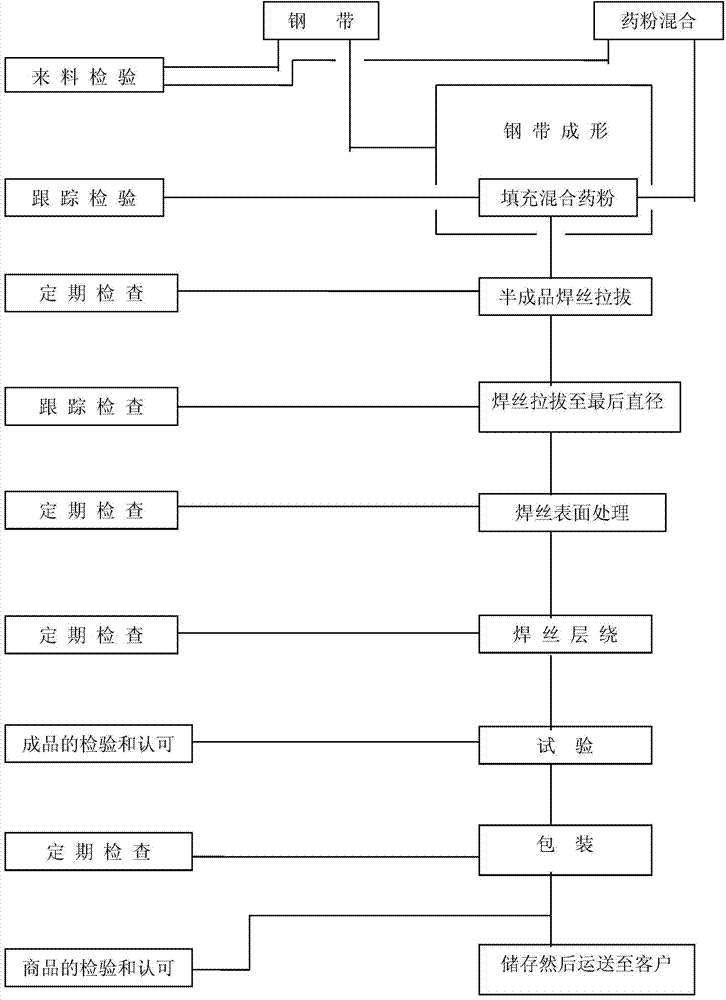

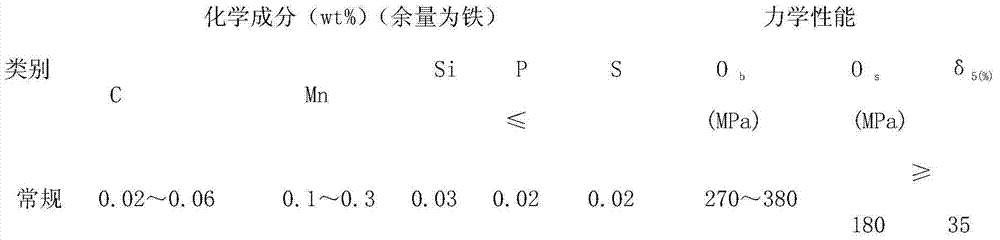

Alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas

InactiveCN103495817AImprove toughnessHigh and low temperature impact toughness valueWelding/cutting media/materialsSoldering mediaManganeseRutile

The invention provides an alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas. The alkaline welding flux cored wire comprises flux cored powder and a steel belt wrapping the flux cored powder. The alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas is characterized in that the flux cored powder of the flux cored wire is composed of, by weight, 10-25% of rutile, 15-35% of silicon manganese alloy, 25-40% of iron powder, 4-15% of nickel powder, 1-10% of aluminium magnesium alloy, 1-6% of marble, 1-6% of fluorite and 3-15% of ferrovanadium. The alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas has the advantages that the flux cored wire can be applied to welding of high-strength and high-ductility steel which is of the level larger than or equal to 700Mpa and guaranteeing overall performance, welding joints are purified and clean in the welding process, nonmetallic inclusion is little, the content of diffusible hydrogen is low, and the low temperature impact toughness value of welding metal is high.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Structure and method for coaxial protection gas blowing of laser welding machine

ActiveCN106984899ANot easily oxidizedEvenly ventedLaser beam welding apparatusAcute angleEngineering

The invention discloses a structure for coaxial protection gas blowing of a laser welding machine. The structure comprises a surrounding coil pipe and protection gas inlet pipes. The surrounding coil pipe is wound around the outer side of a laser coaxial sleeve. One end of the surrounding coil pipe is connected with a protection gas inlet. The three protection gas inlet pipes are arranged and arranged at the lower end of the surrounding coil pipe to connect the surrounding coil pipe with the laser coaxial sleeve. The included angle between each protection gas inlet pipe and the laser coaxial sleeve is an acute angle. The position, connected with the protection gas inlet pipes, of the laser coaxial sleeve is provided with a coaxial sleeve protection gas inlet. The structure has the beneficial effects that through the arrangement of the surrounding coil pipe and the protection gas inlet pipes, protection gas is evenly distributed on the periphery of a welding head, gas outflow is even, a welding line is not prone to oxidization during welding, the welding process is stable, the welding line is smooth, the quality is enhanced, and welding gas holes are avoided; and compared with side-face single-direction gas inflow, waste of the protection gas is not prone to being caused, the usage amount of the protection gas is reduced, splashing objects entering the coaxial sleeve during welding can be blown away, and lens damage is prevented.

Owner:WUHAN YIFI LASER EQUIP CO LTD

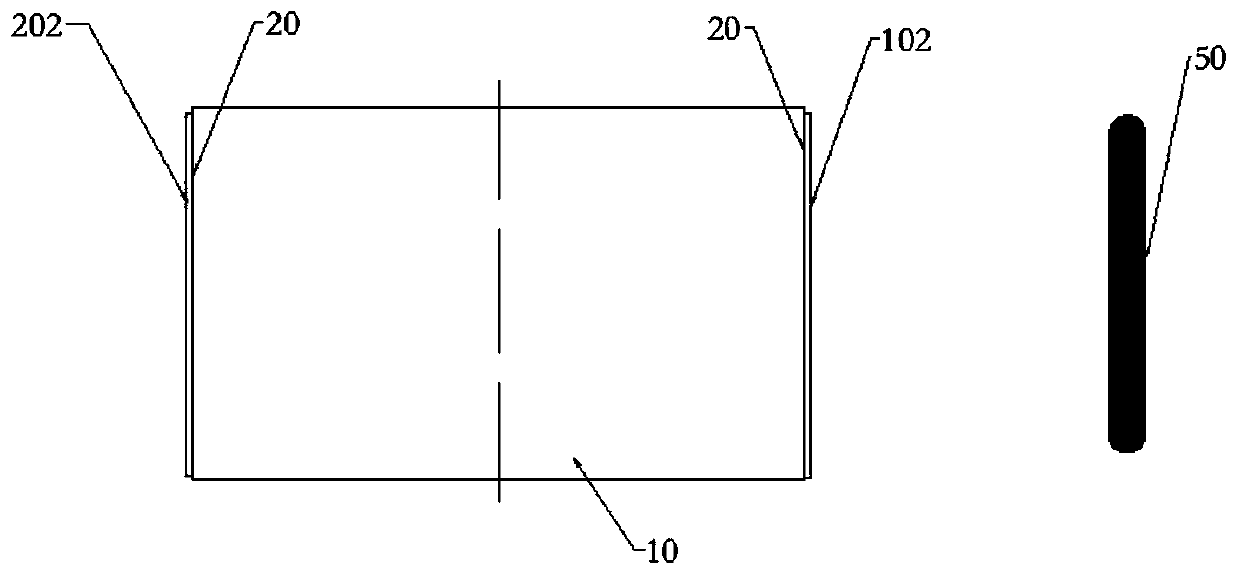

Assembling method of square winding type lithium ion battery and lithium ion battery

InactiveCN109818082AIncrease energy densityReduce invalid widthFinal product manufactureSecondary cells manufactureProcess lossBusbar

The invention belongs to the technical field of battery assembly, and relates to an assembling method of a square winding type lithium ion battery and the lithium ion battery. The assembling method ofthe lithium ion battery comprises the following steps of: shaping a roll core in at least one hot pressing and / or cold pressing manner; making a positive electrode blank area and a negative electrodeblank area at the two ends of the roll core respectively; flattening at least one part of the positive electrode blank area and the negative electrode blank area of the shaped roll core to respectively form a positive electrode flattening area and a negative electrode flattening area; respectively welding the positive electrode flattening region and the negative electrode flattening region with the positive electrode busbar and the negative electrode busbar in a laser welding manner; and putting into a shell to obtain the square winding type lithium ion battery. The battery energy density ofthe square winding full-tab design is improved, the problems of small effective volume proportion of the winding cores, low battery energy density, difficulty in parallel assembly of multiple windingcores and the like in the traditional assembly process are solved, and the process is simple, feasible, efficient, controllable and low in process loss.

Owner:SHANDONG FOREVER NEW ENERGY

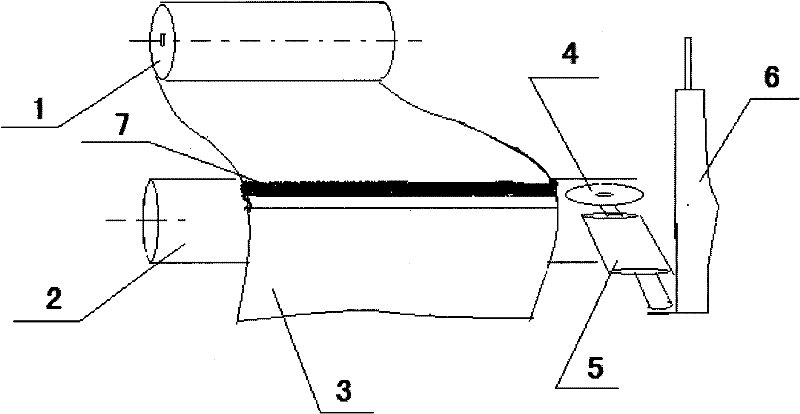

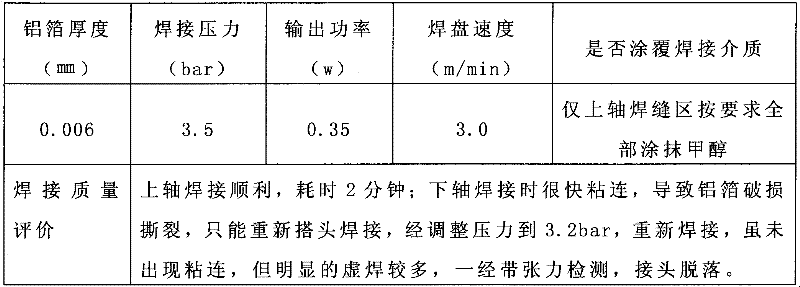

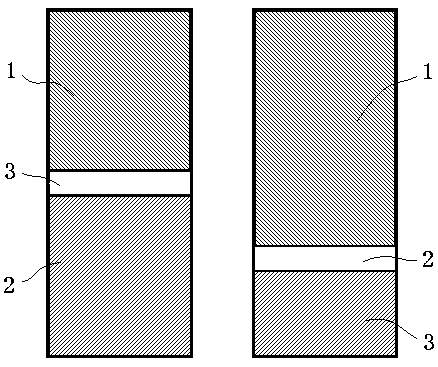

A welding method for double-zero aluminum foil joints

ActiveCN102284799AAvoid stickingWeld smoothWelding/cutting media/materialsSoldering mediaOrganic solventUltrasonic welding

The invention discloses a double-zero aluminum foil connector welding method. The upper part and the lower part of a double-zero aluminum foil connector are separated after precise rolling and dual combination and are respectively lapped on an upper anvil roller and a lower anvil roller coated by a welding medium, and lapping head parts are reserved; double-zero aluminum foils on an upper rollingshaft and a lower rolling shaft are respectively lapped on the upper double-zero aluminum foil and the lower double-zero aluminum foil through lapping joints, and the welding medium is coated betweenthe double-zero aluminum foil on the upper rolling shaft and the upper double-zero aluminum foil and between the double-zero aluminum foil on the lower rolling shaft and the lower double-zero aluminum foil; the joints are fixed, parameters of the welding process are adjusted, a welding machine is started, the lapping head areas of the double-zero aluminum foils are coated by the welding medium, aweld seam with a smooth surface is formed after a welding plate passes through the lapping head areas coated by the welding medium, and the welding medium adopts a volatile organic solvent. The double-zero aluminum foil can be effectively prevented from being bonded with the ultrasonic welding plate during welding, the weld seam can be maintained smooth, the welding area is clean and pollution-free, and anhydrous ethyl alcohol is preferred to be used as the welding medium.

Owner:JIANGSU DAYA ALUMINUM

Method and apparatus for welding shroud glass tube in arc tube for discharge lamp

InactiveUS20050255783A1Reliable shieldingCarry-out quicklyTube/lamp screens manufactureElectroluminescent light sourcesSecondary sideInert gas

A method of secondarily welding one end of a shroud glass tube covering an arc tube body having a discharge emitting portion, having the other end welded primarily to one of the arc tube body ends, to the other end side of the arc tube body, while discharging air from, and introducing an inactive gas into, the tube through the opening end of the glass tube to hold a negative pressure. Heating and melting from a side is carried out. The opening end of the glass tube is connected to a piping passage component for discharging air and introducing an inactive gas through a rotatable magnetic fluid seal unit. Secondary welding is carried out with the rotation of the glass tube around an axis. The glass tube rotated with respect to secondary side heater is uniformly heated, molten and softened circumferentially, and welded along the arc tube body outer periphery.

Owner:KOITO MFG CO LTD

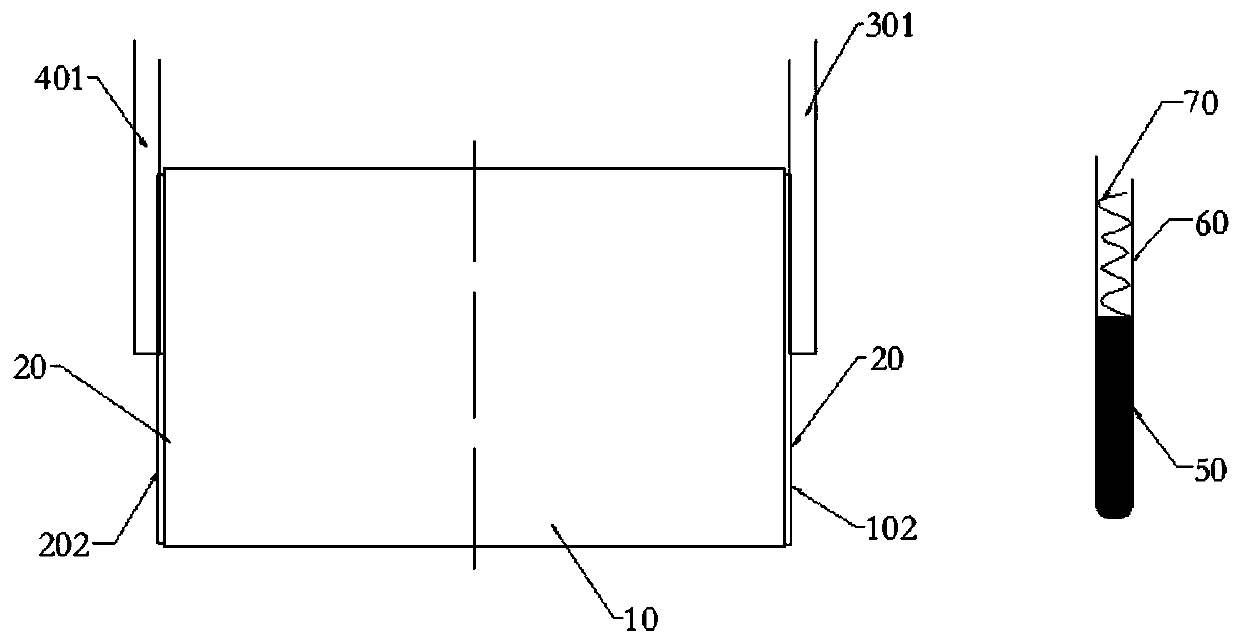

Anti-magnetic shielding apparatus for repairing welding of electrolytic tank horizontal bus in strong magnetic field environment

InactiveCN104827172AImprove the effect of shielding magnetic field wavesReduce or even eliminate the magnetic fieldWelding accessoriesForce linesElectrolysis

The invention relates to the repairing of the electrolytic tank aluminum bus, especially to an anti-magnetic shielding apparatus for repairing welding of an electrolytic tank horizontal bus in a strong magnetic field environment. The anti-magnetic shielding apparatus is characterized in that the apparatus comprises complete and continuous shielding anti-magnetic covers that are made of materials with high magnetic permeability and cooperate well at a welding part and a welding machine; and guiding plates that can be dismounted are arranged at the rear ends of the shielding anti-magnetic covers in a cooperation mode. According to the invention, the structure is unique; the magnetic force lines can be shielded and guided; the magnetic field can be reduced even eliminated inside the shielding space; and thus objectives of successful welding and welding quality guarantee can be achieved.

Owner:QINGTONGXIA ALUMINUM GRP

Welding pipe groove grinding device

InactiveCN110549189APolished evenlyFlat grinding deviceEdge grinding machinesGrinding work supportsEngineeringWelding

The invention provides a welding pipe groove grinding device. The problem that the welding quality is affected due to uneven grinding of a groove of existing grinding equipment is solved. The groove grinding device comprises a supporting table and a welding pipe, wherein a propelling mechanism is arranged on the supporting table, the propelling mechanism comprises a first hand wheel, a bearing block, a sliding rail, a first screw rod, a sliding support, a supporting plate and a support, the bearing block is fixed at one end of the supporting table, the support is fixed at the other end of thesupporting table, one end of the first screw rod penetrates through the bearing block to be rotationally connected to the support, the first hand wheel is fixed on the other end of the first screw rod, the sliding support is in threaded connection with the first screw rod, the supporting plate is fixed on the sliding support, a clamping mechanism is arranged on the supporting plate, and a grindingdevice is arranged on the support. According to the welding pipe groove grinding device, the operation is simple, the use is convenient, the welding groove can be ground smooth and uniform, and the welding quality can be effectively improved.

Owner:胡峥

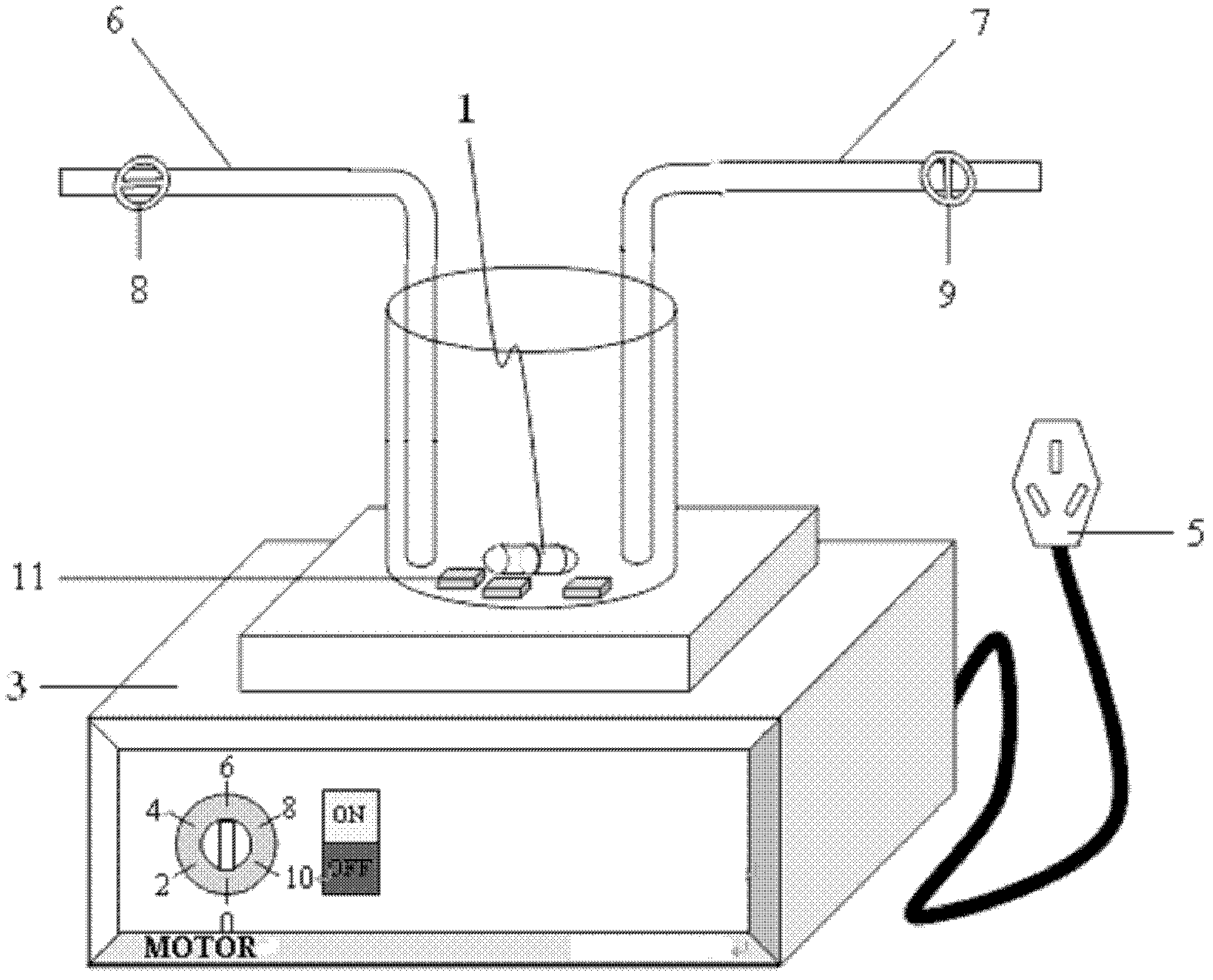

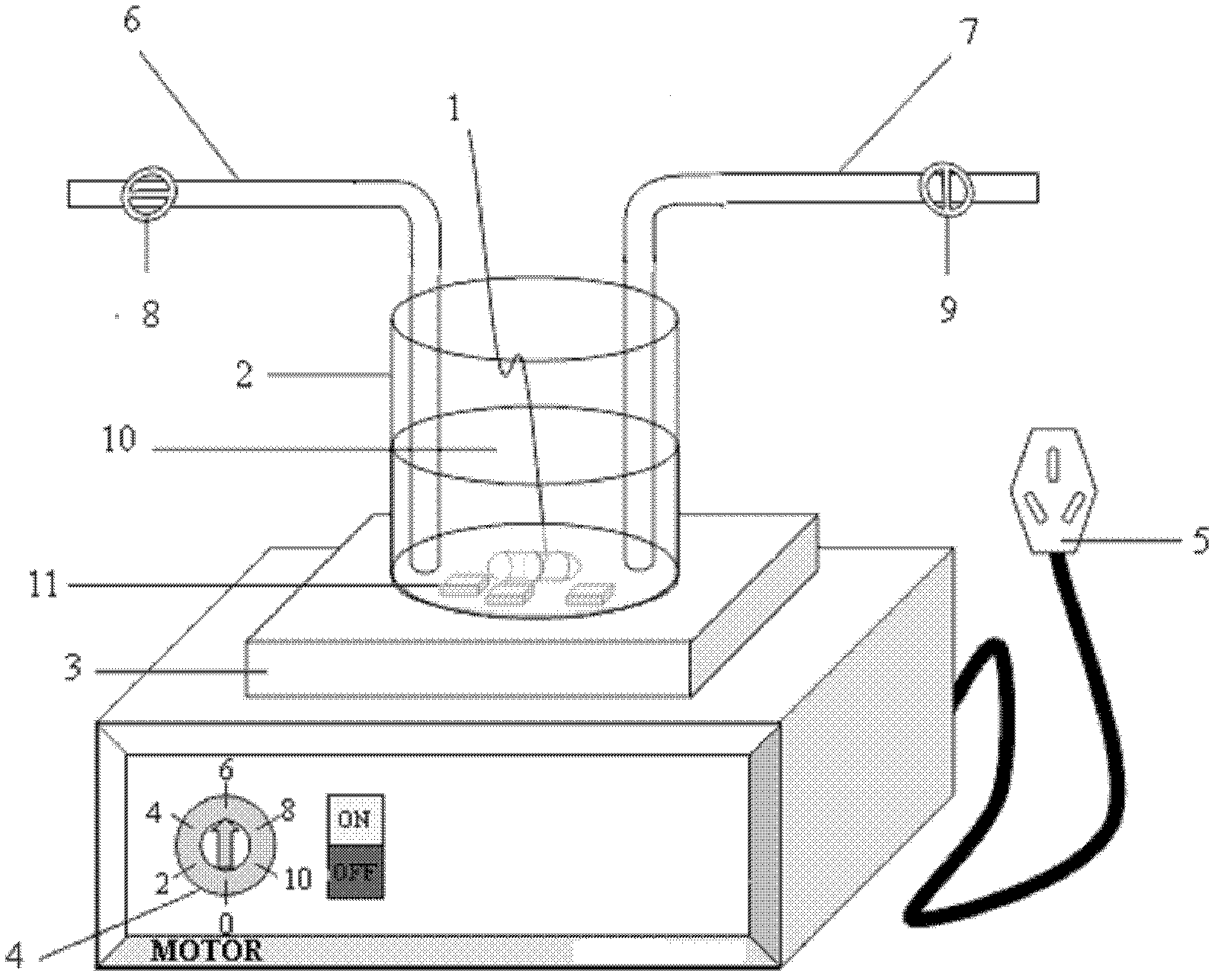

Device and method for blackening or browning copper blocks

ActiveCN103124473ATime controllableGood qualityInsulating substrate metal adhesion improvementMetallic material coating processesChemistryCopper

The invention provides a device for blackening or browning copper blocks. The device for blackening or browning the copper blocks comprises a container containing the copper blocks and blackening or browning medicine liquid and a stirring device, wherein the stirring device is used to stir the blackening or browning medicine liquid in the container. The invention further provides a method using the device for blackening or browning the copper blocks. The method includes: enabling ingredients of the blackening or browning medicine liquid in the container to remain effective through the stirring device and a circulation loop formed by a liquid inlet pipe, a liquid discharge pipe and the blackening or browning medicine liquid in a blackening or browning medicine liquid vat; and respectively arranging automatic valves on the liquid inlet pipe and the liquid discharge pipe to control blackening or browning time. By using the method, the copper blocks are even in blackening or browning, and good in quality.

Owner:ZHUHAI FOUNDER TECH HI DENSITY ELECTRONICS +1

Automatic welding device for steel cranked link chain

InactiveCN103769791AConsistent currentConsistent wire feed speedWelding/cutting auxillary devicesArc welding apparatusMotor driveThermal deformation

An automatic welding device for a steel cranked link chain comprises a carbon dioxide gas shielded welding machine and a motor driving device, wherein a fixing chuck is installed on the motor driving device and installed an output shaft of the motor driving device, the output shaft is a fixing mandrel of a workpiece installing clamp, and a welding gun of the carbon dioxide gas shielded welding machine is located above the output shaft. The automatic welding device for the steel cranked link chain ensures a cranked link chain welding position to be smooth and free of welding defect, simultaneously welding slope angles are accurate, and the thermal deformation degree is identical. After distressing treatment is performed, the assembling speed and the assembling quality can be greatly improved.

Owner:湖北源林链条有限公司

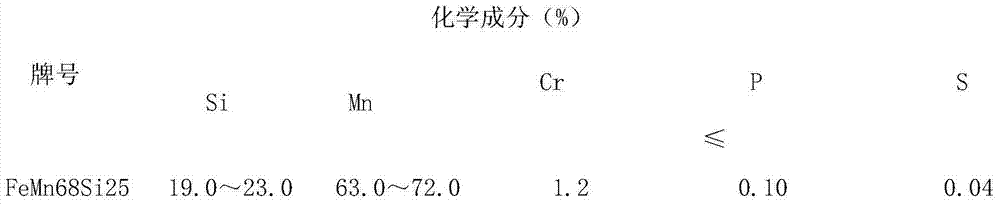

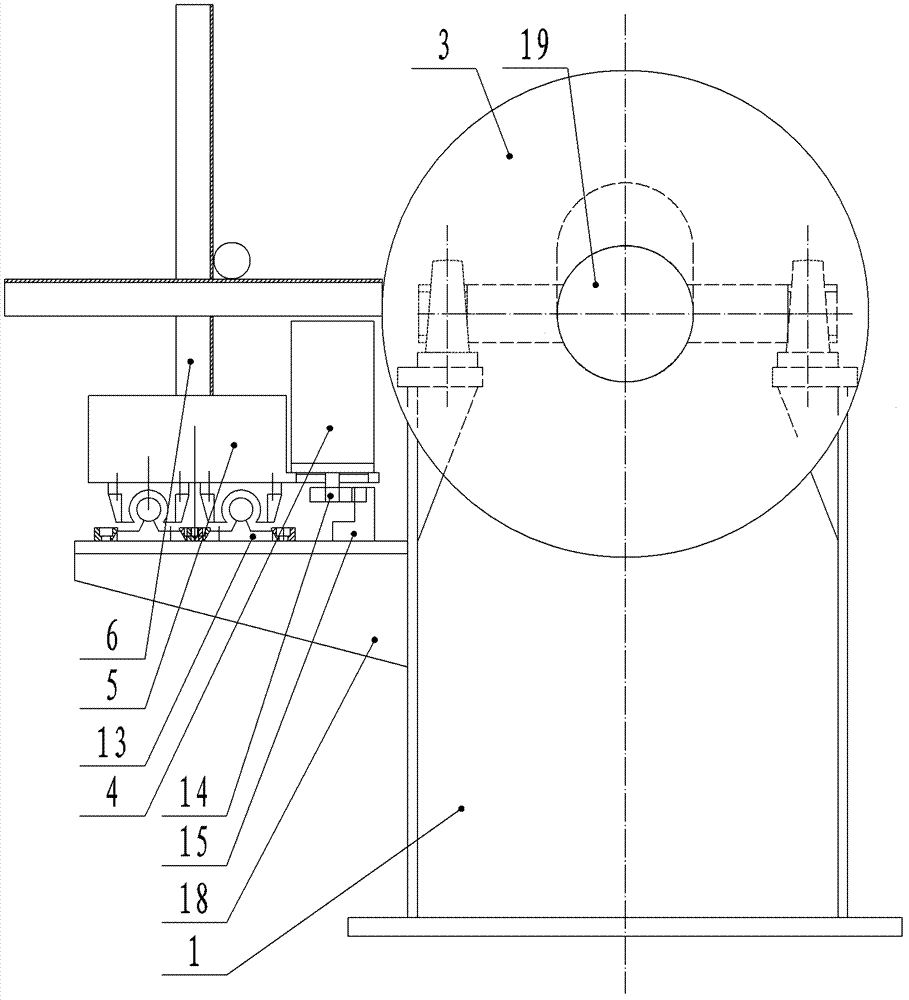

Multifunctional pipe connecting flange automatic welding and cutting machine

ActiveCN103358059AImprove welding efficiencyWeld smoothWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMultiple function

The invention provides a multifunctional pipe connecting flange automatic welding and cutting machine, and relates to an automatic welding and cutting machine. The multifunctional pipe connecting flange automatic welding and cutting machine overcomes the defects that in a manufacturing process of a pressure container, welding between a connecting pipe and a flange mainly depends on manual operation, a weld pass is easily uneven when formed or a welding line is too full or the welding height is not enough, and production efficiency is low. The multifunctional pipe connecting flange automatic welding and cutting machine is characterized by comprising a circumference rotating system, a linear travelling system and a control system used for controlling the circumference rotating system and the linear travelling system, and the circumference rotating system and the linear travelling system are arranged on a machine frame. The circumference rotating system comprises a circumference stepping motor, a clamping plate and a vertical rotating device, wherein the clamping plate is connected with an output shaft of the circumference stepping motor. The linear travelling system comprises a linear steeping motor, a pulling board, a left-and-right guide device and a clamping arm, wherein the pulling board is connected with the linear steeping motor, the left-and-right guide device is matched with the pulling board, and the clamping arm is connected with the pulling board and used for clamping a welding gun. The control system is connected with the circumference stepping motor and the linear steeping motor. According to the technical scheme, welding efficiency is improved, the welding line is level, and the pipe orifice of the cylinder connection pipe can be cut in a curve mode.

Owner:ZHEJIANG IND EQUIP INSTALLATION GRP

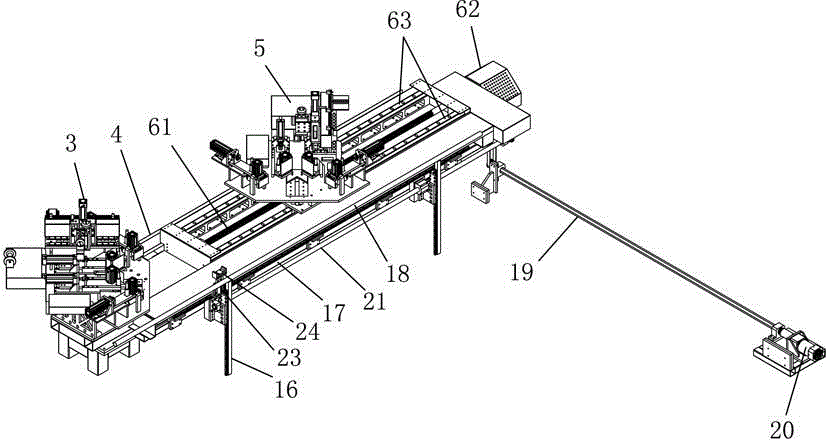

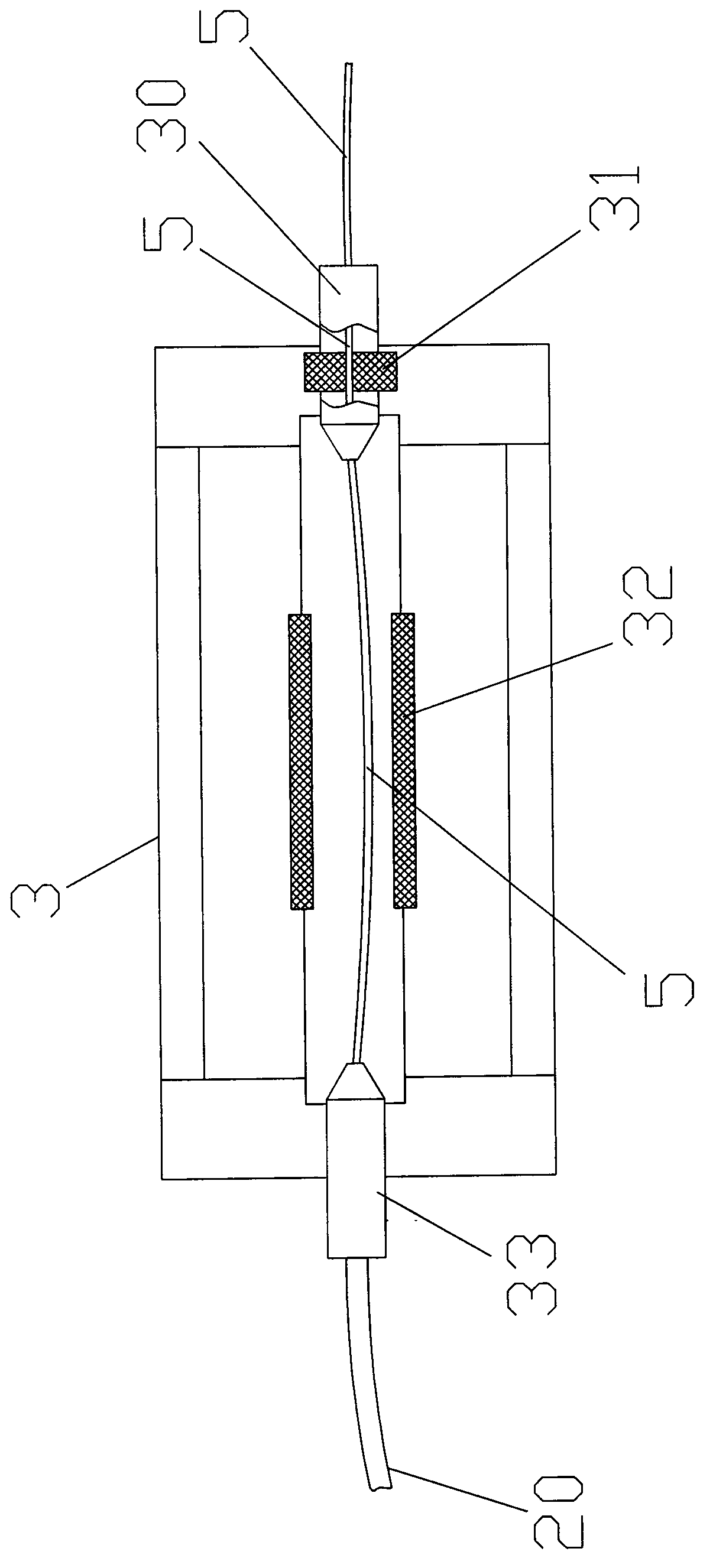

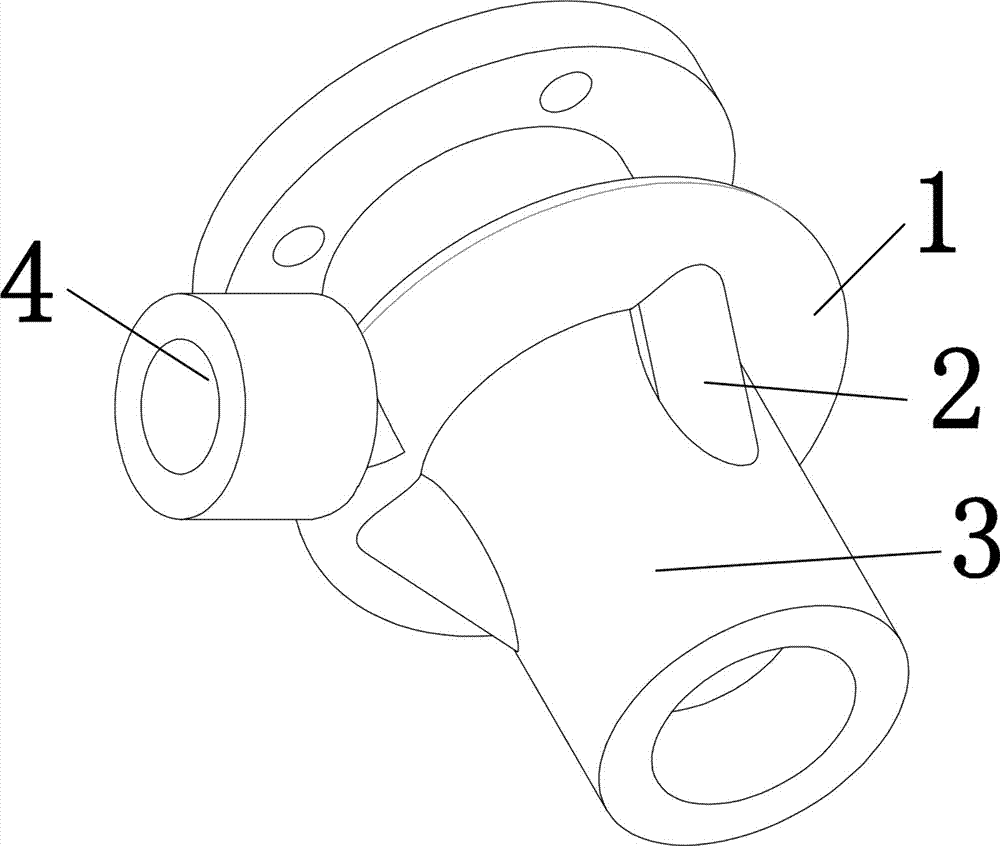

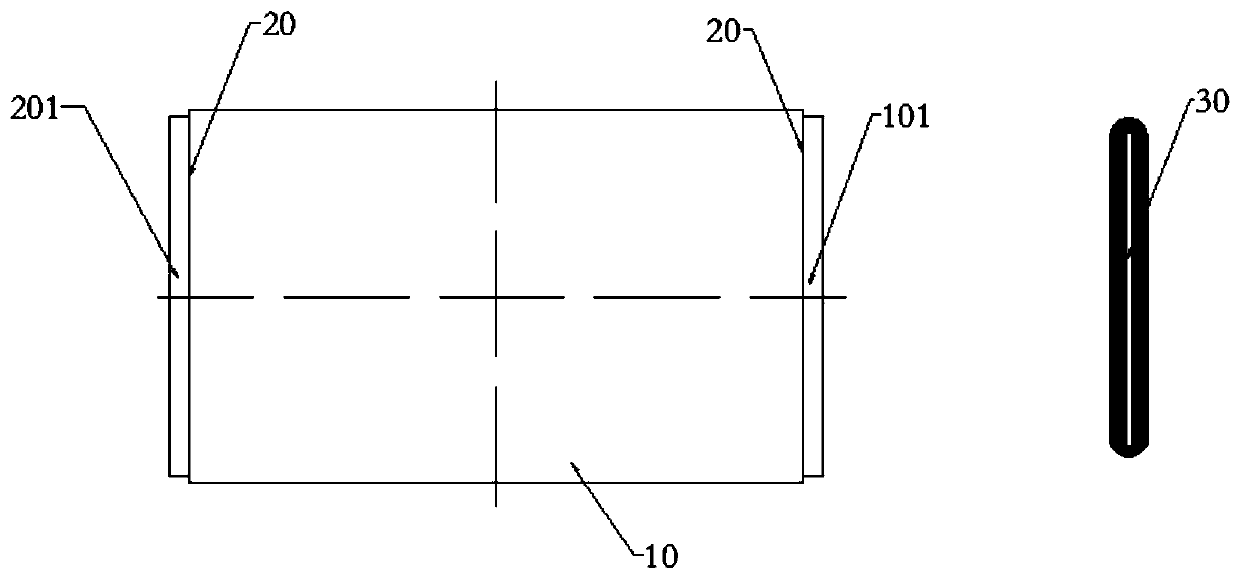

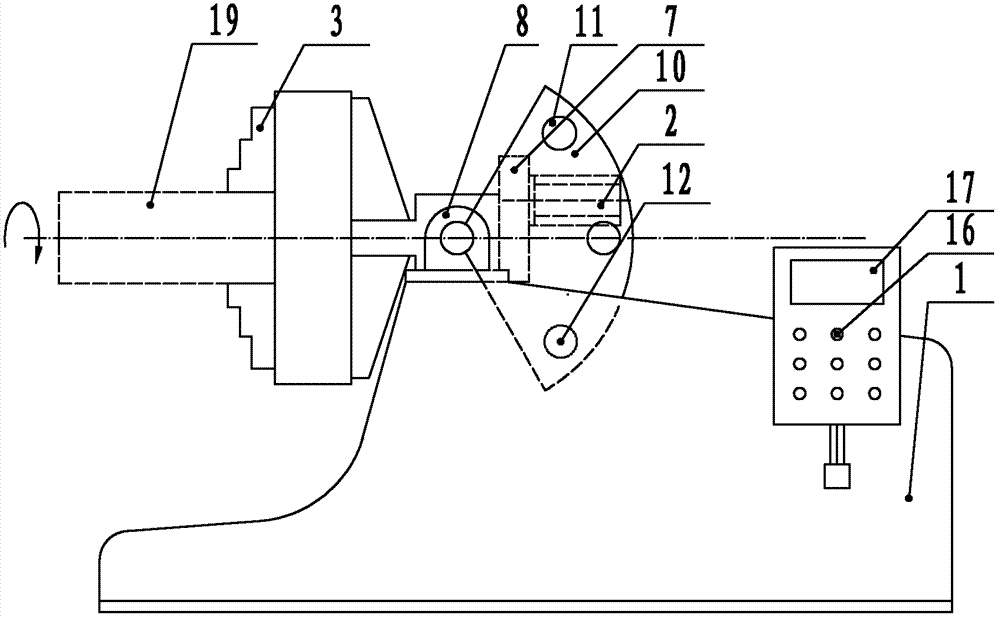

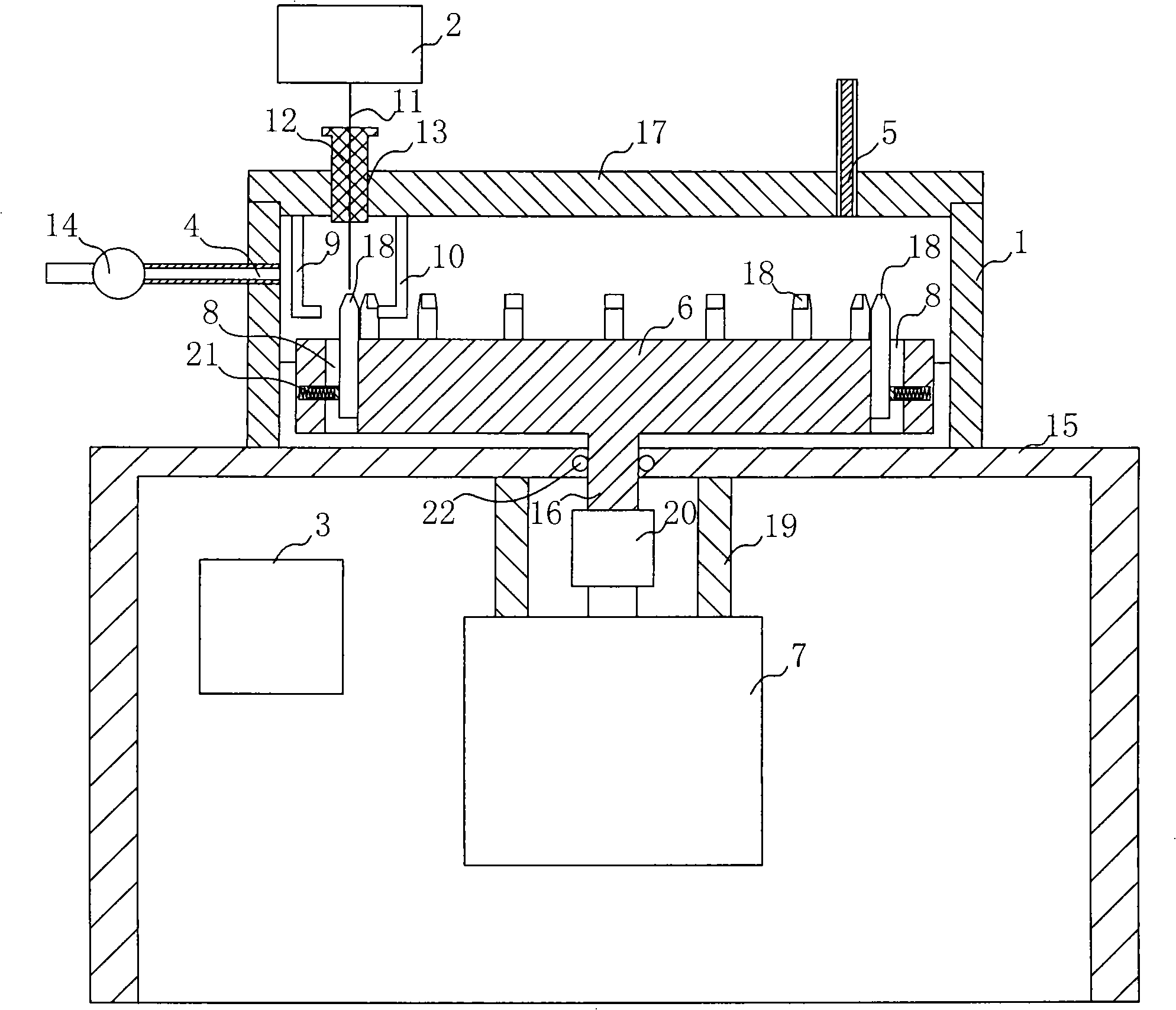

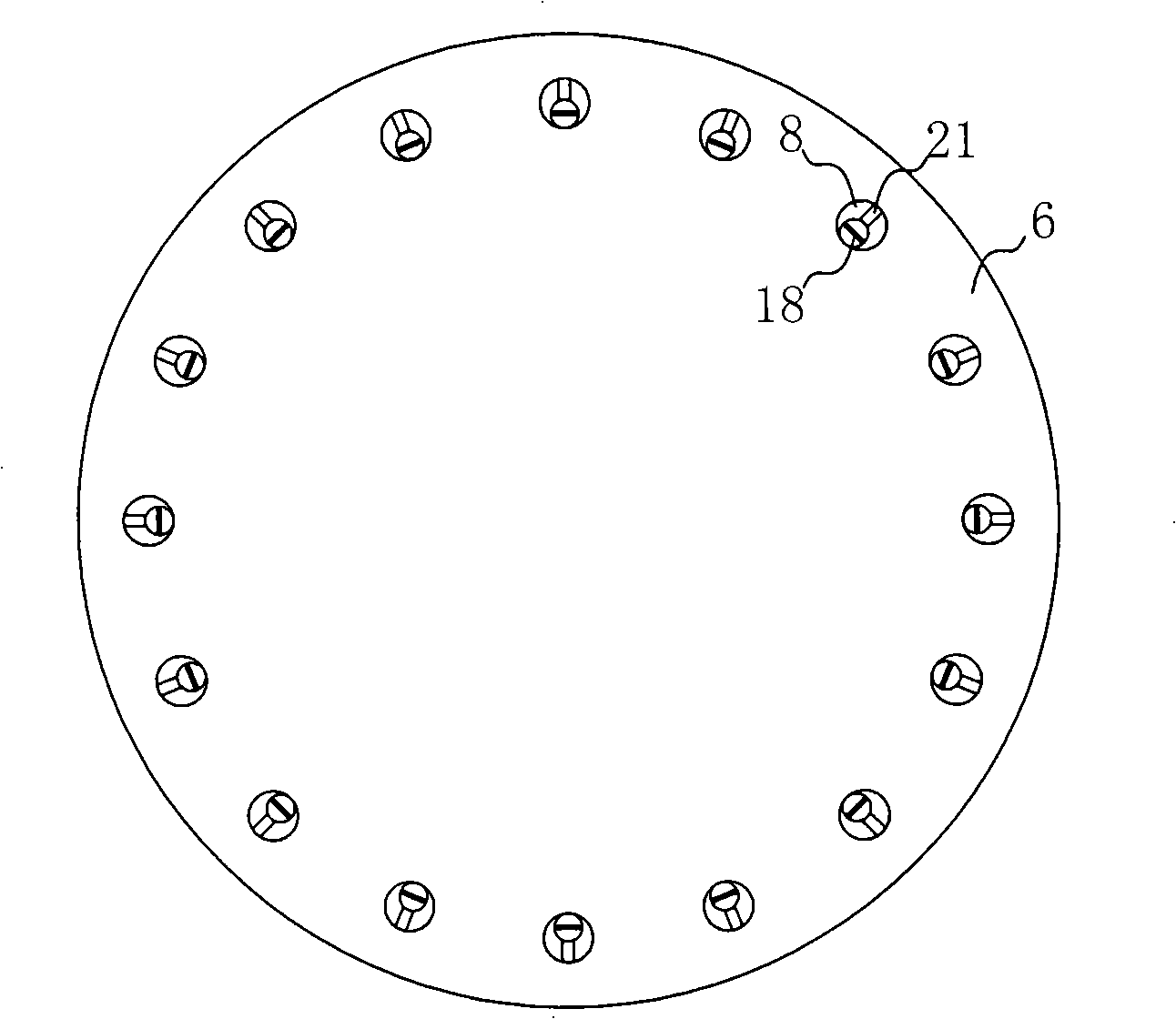

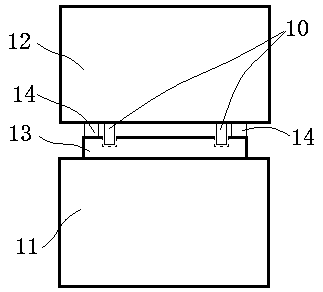

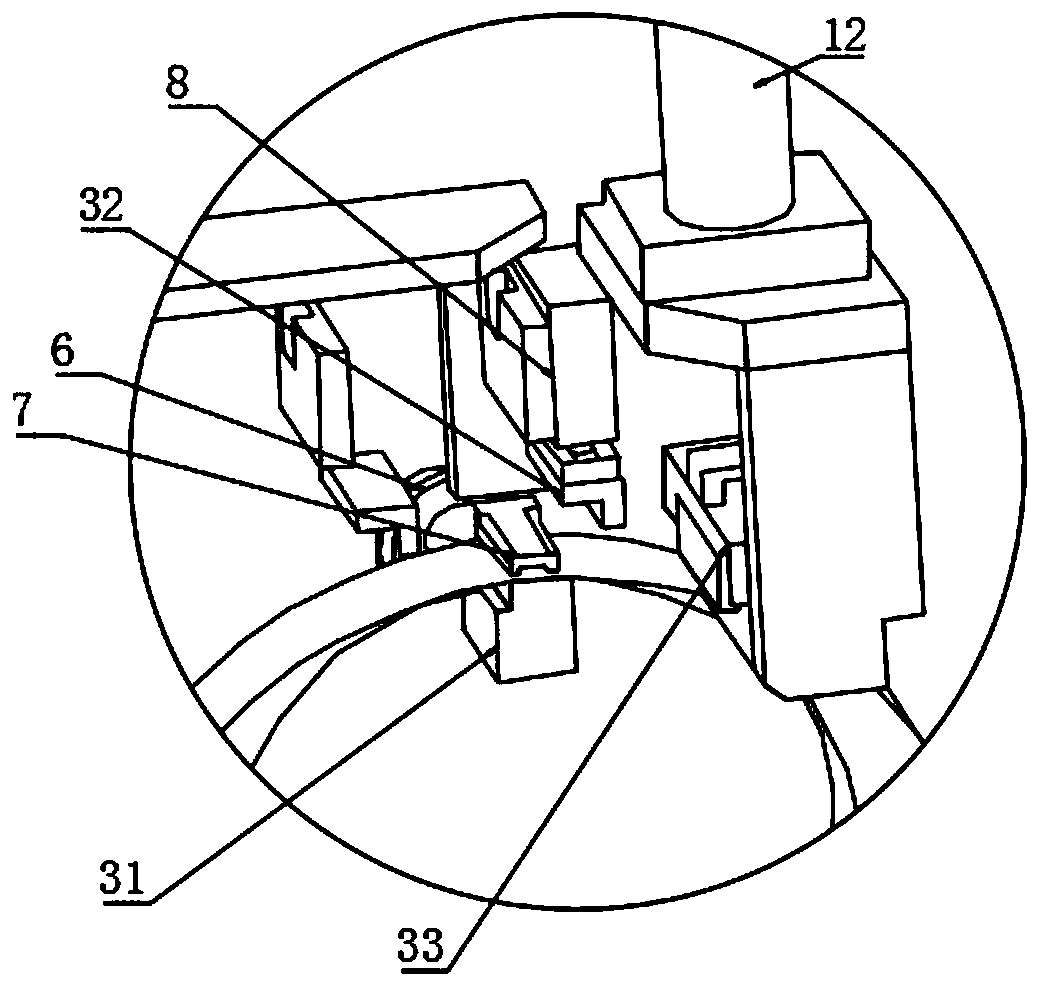

Automatic welding machine of gold sample tube

InactiveCN101337300AImprove welding efficiencyWeld smoothWelding/cutting auxillary devicesArc welding apparatusEngineeringDrive motor

The invention discloses an automatic welding machine for a gold sample cell, which comprises an argon chamber (1), an argon arc welding machine (2), a program controller (3); an admitting port (4) and a vent port (5) are arranged in the argon chamber; a turnplate (6) is arranged in the argon chamber; the turnplate is connected with a driving motor (7); a plurality of gold tube locating holes (8) are formed on the turnplate; each gold tube locating hole is positioned on a circumference which takes the rotating center of the turnplate as the center thereof; an infrared emitter (9) and an infrared receiver (10) are respectively arranged in the argon chamber on the two sides right above the gold tube locating holes; the tungsten welding pin (11) of the argon arc welding machine is arranged in the argon chamber; the end part of the tungsten welding pin is arranged right above the gold tube locating holes; and the program controller is connected with the argon arc welding machine, the driving motor, the infrared emitter and the infrared receiver. The method adopts automatic welding, so that the welding efficiency is high, the success rate of welding is 100%, the welding line is even and smooth, the welding time is short, and the maximum heating temperature of the sample does not exceed 40 DEG C.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

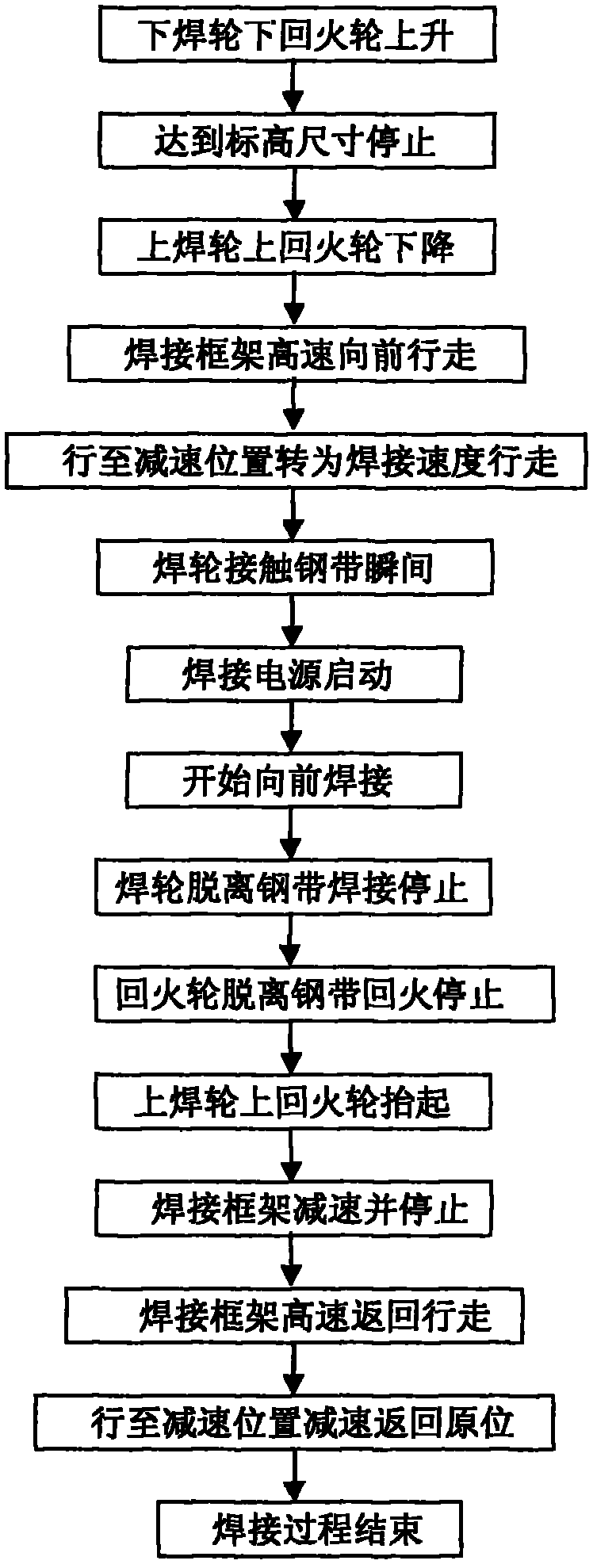

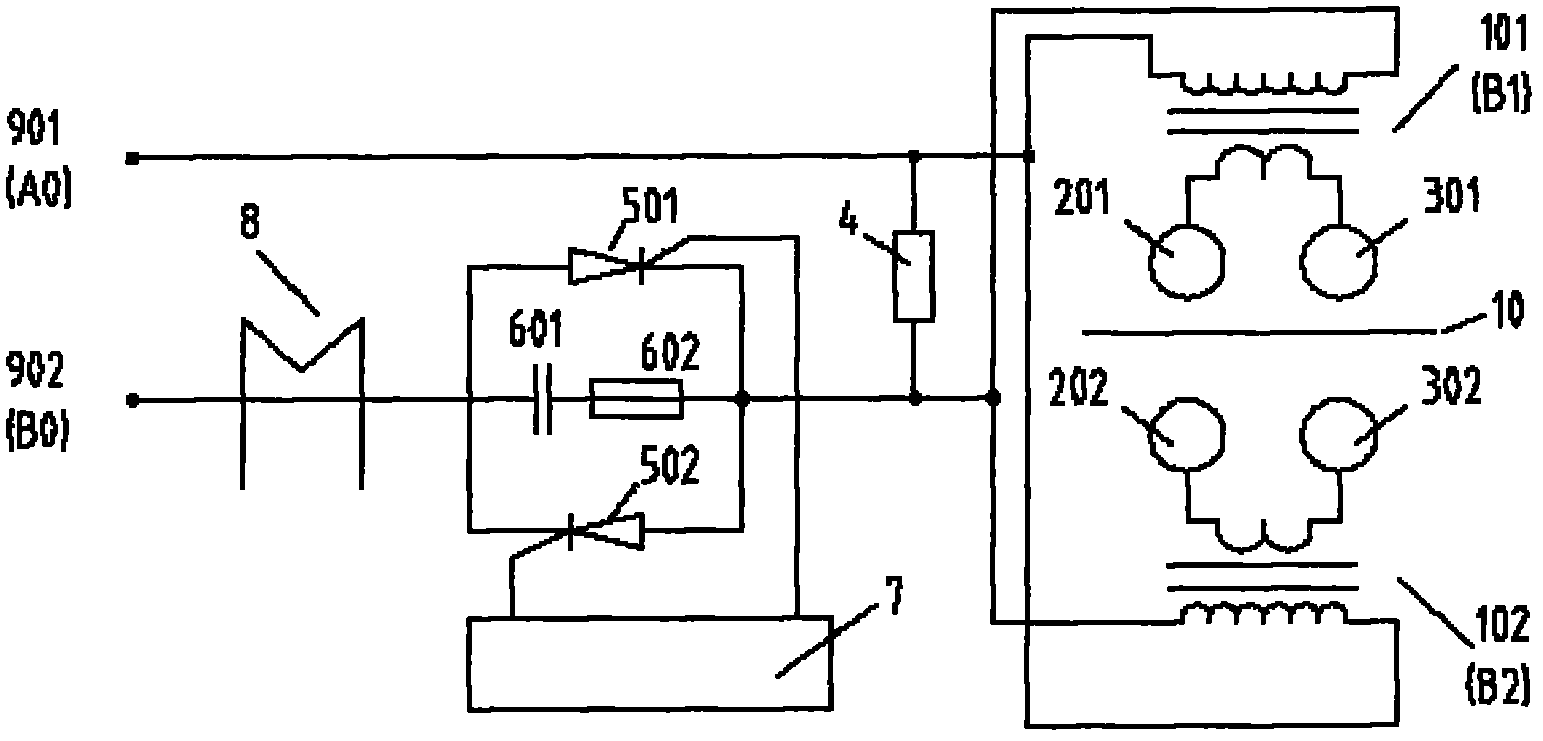

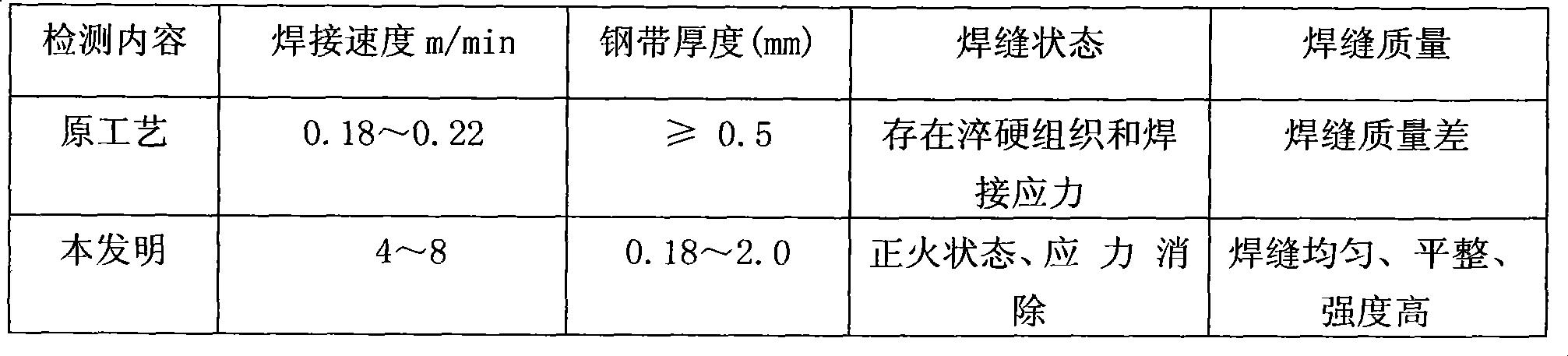

Cold-rolled strip welding technology method

InactiveCN103831520AEliminate residual welding stressAvoid crackingWelding electric supplyRectilinear seam weldingElectrical resistance and conductanceResistance capacitance

The invention relates to a cold-rolled strip welding technology method. A welding framework drives an upper welding wheel, a lower welding wheel, an upper tempering wheel and a lower tempering wheel to walk forwards; the instant the upper and the lower welding wheels are in contact with a steel belt, controlled silicon is closed through a trigger circuit, an original edge of a welding transformer is powered on, a loop of an auxiliary edge of the welding transformer is closed, The current flows through the steel belt to act to generate heat through the resistance of the steel belt, and when the heat is continuously accumulated to enable metal on the welding portions to be combined through fusing; when the welding wheels separate away from the steel belt, welding is stopped; when the fire retuning wheels separate away from the steel belt, tempering is stopped, and the upper welding wheel and the upper tempering are lifted; the welding framework is decelerated and stopped; the welding framework returns at a high speed to walk to the deceleration position to decelerate to return to the original position, and the welding process is over; as shown in the attached chart 2, the resistor is a sucking resistor and equivalently serves as a load to have the buffering effect; the resistance-capacitance circuit is resistance-capacitance sucking protection controlled silicon; a mutual inductor compensates for sampled signals.

Owner:TIANJIN YIBO STEEL MAKING

Reliability evaluating method of electronic packaging micro-welding spot

InactiveCN109813752AReliable preparationWeld smoothMaterial heat developmentSoldering apparatusSurface finishingExtremes temperature

The invention discloses a reliability evaluating method of an electronic packaging micro-welding spot. The method includes the following steps of firstly, selecting a first metal plate and a second metal plate for surface treatment, and welding the welding surfaces of the first metal plate and the second metal plate through brazing; secondly, cutting the welded first metal plate and second metal plate to prepare a sample; thirdly, vertically placing the sample in a temperature loading device, forming the temperature gradient at the upper end and the lower end of the micro-welding spot of the sample, and starting to record the loading time when the temperature is stabilized; fourthly, loading different times to the sample under the temperature gradient in the third step, and evaluating thereliability of the electronic packaging micro-welding spot within the region of the temperature gradient by analyzing the thickness variation conditions of intermetallic compounds under the differentloading times. The stable and controllable temperature gradient can be obtained, the temperature gradient range is large, and therefore the reliability of the electronic packaging micro-welding spot in the region of the extreme temperature gradient can be effectively evaluated.

Owner:CHONGQING UNIV OF TECH

Counter balance flange joint and application thereof

PendingCN110671278AReduce processing difficultyIncreased bending stiffnessWind motor assemblyWind motor supports/mountsMachining processAdhesive

The invention relates to a counter balance flange joint, which includes an upper flange tower and a lower flange tower, wherein a propping stiffening plate is welded on the inner wall of the upper flange tower; a guiding stiffening plate is welded on the inner wall of the lower flange tower; an upper flange plate is connected with the upper surface of the propping stiffening plate through a structural adhesive; the lower surface of the guiding stiffening plate is connected with a lower flange plate through a structural adhesive; bolt holes are formed in the upper flange plate and the lower flange plate; high-strength bolts penetrate through the upper flange plate and the lower flange plate through the bolt holes, so as to connect the upper flange tower with the lower flange tower; mountingholes are formed in the propping stiffening plate and the guiding stiffening plate respectively; connecting rods clamped with the corresponding stiffening plates are arranged inside the mounting holes; the two connecting rods are fastened and connected with annular auxiliary mechanisms arranged on the inner sides of the propping stiffening plate and the guiding stiffening plate. Compared with theprior art, the counter balance flange joint has the advantages of low welding amount, simple machining technology, high tower anti-fatigue level and no deformation during transportation.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Double-station production steel belt rounding and welding flanging machine

PendingCN110666522AReduce splashWeld smoothOther manufacturing equipments/toolsLaser beam welding apparatusWeld seamLaser soldering

The invention discloses a double-station production steel belt rounding and welding flanging machine, and particularly relates to the technical field of steel belt processing. The double-station production steel belt rounding and welding flanging machine comprises a machine table, a rolling mechanism, a cutting mechanism, a welding mechanism and a flanging mechanism; the rolling mechanism, the cutting mechanism, the welding mechanism and the flanging mechanism are sequentially and fixedly arranged on one side of the machine table from right to left; the welding mechanism comprises a fixed claw, a movable claw and a laser welding head; the fixed claw is welded on the machine table; connecting pieces are positioned on two sides of the fixed claw and fixedly connected with the fixed claw; theconnecting pieces are hinged with the movable claw; and the laser welding head is positioned below the fixed claw. According to the double-station production steel belt rounding and welding flangingmachine, the laser welding head and a flanging wheel are arranged, the two ends of steel belt are extruded, aligned and fixed by the movable claw, subsequent laser welding is facilitated, a driving wheel drives steel belt ring to rotate, the flanging wheel extrudes and flanges the side edge of the steel belt, the automation degree is high, after laser welding, a product welding seam is smooth, theworking procedure is reduced, and the overall production cost is reduced.

Owner:东莞市正信激光科技有限公司

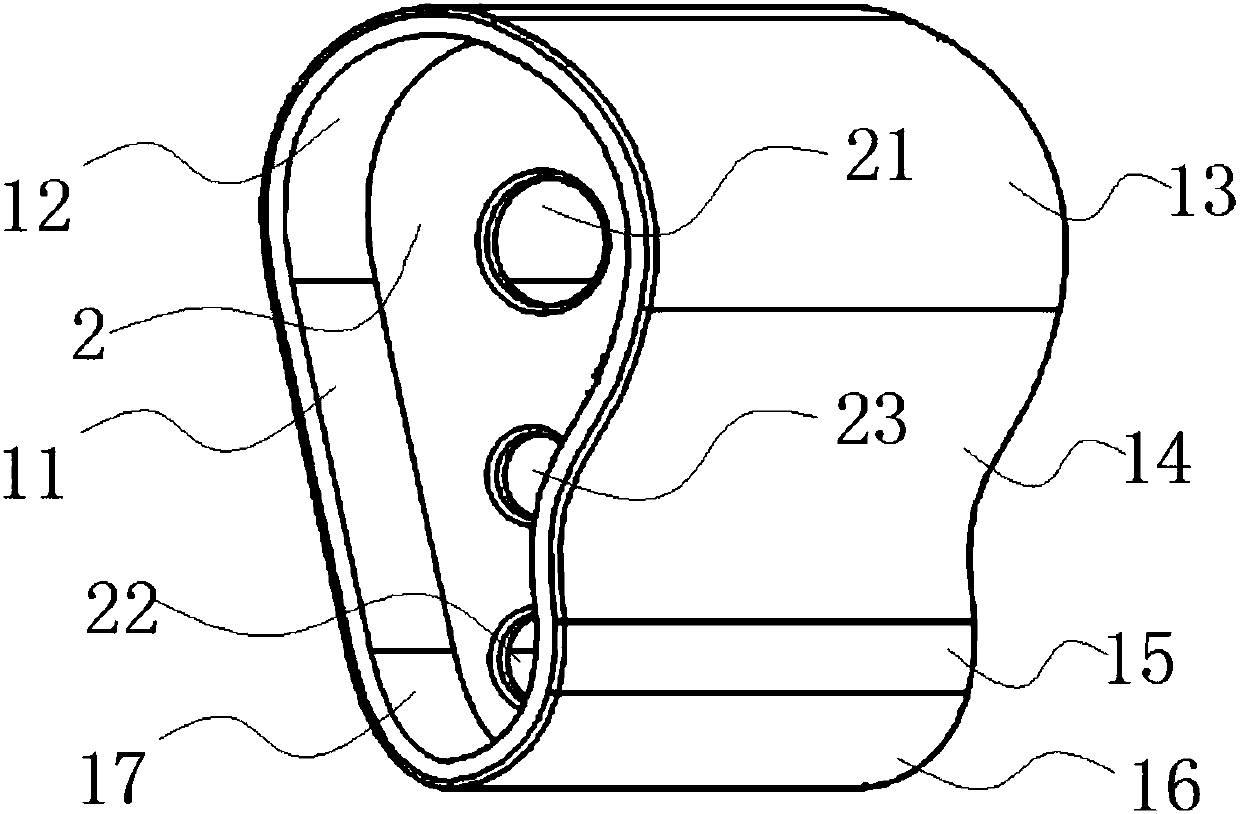

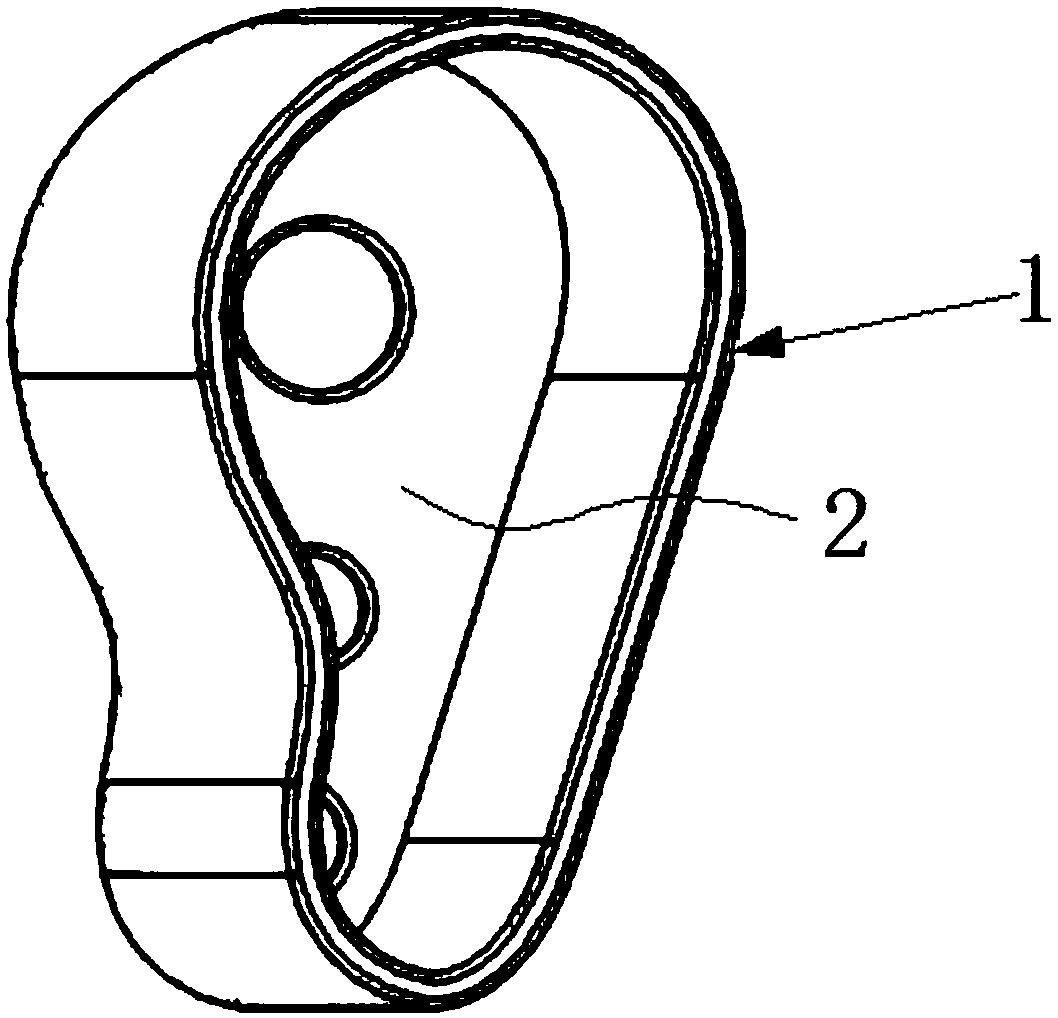

Laptop rotary shaft cavity and manufacturing technology thereof

InactiveCN107842550AImprove matchWon't loosePivotal connectionsDigital processing power distributionManufacturing technologyEngineering

The invention discloses a laptop rotary shaft cavity and a manufacturing technology thereof. The rotary shaft cavity comprises a cylindrical cavity body and a blocking piece arranged in the cylindrical cavity body. An accommodating space is formed in the cylindrical cavity body. The blocking piece and the inner wall of the cylindrical cavity body are in spot welding connection, and the blocking piece is perpendicular to the inner wall of the cylindrical cavity body. The blocking piece is welded to the inner wall of the cylindrical cavity body by adopting laser spot welding. The rotary shaft cavity provided by the invention is simple in structure, attractive in appearance, convenient to process and form, and high in rate of matching with a rotary shaft of a laptop; after mounting, the rotary shaft is not prone to loosening, the matching rate is high, rotation is stable, and the service life of the product is long; and the blocking piece and the cylindrical cavity body are connected through laser spot welding, no residue exists, the connecting position is flawless, and the laptop rotary shaft cavity and the manufacturing technology thereof are suitable for high-end laptop products.

Owner:KUNSHAN WISPREN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com