Automatic welding device for steel cranked link chain

An automatic welding and bending plate chain technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems affecting assembly quality, welding unevenness, stacking at the arc closing position, etc., to improve assembly speed and assembly quality, The effect of consistent thermal deformation and precise welding slope angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

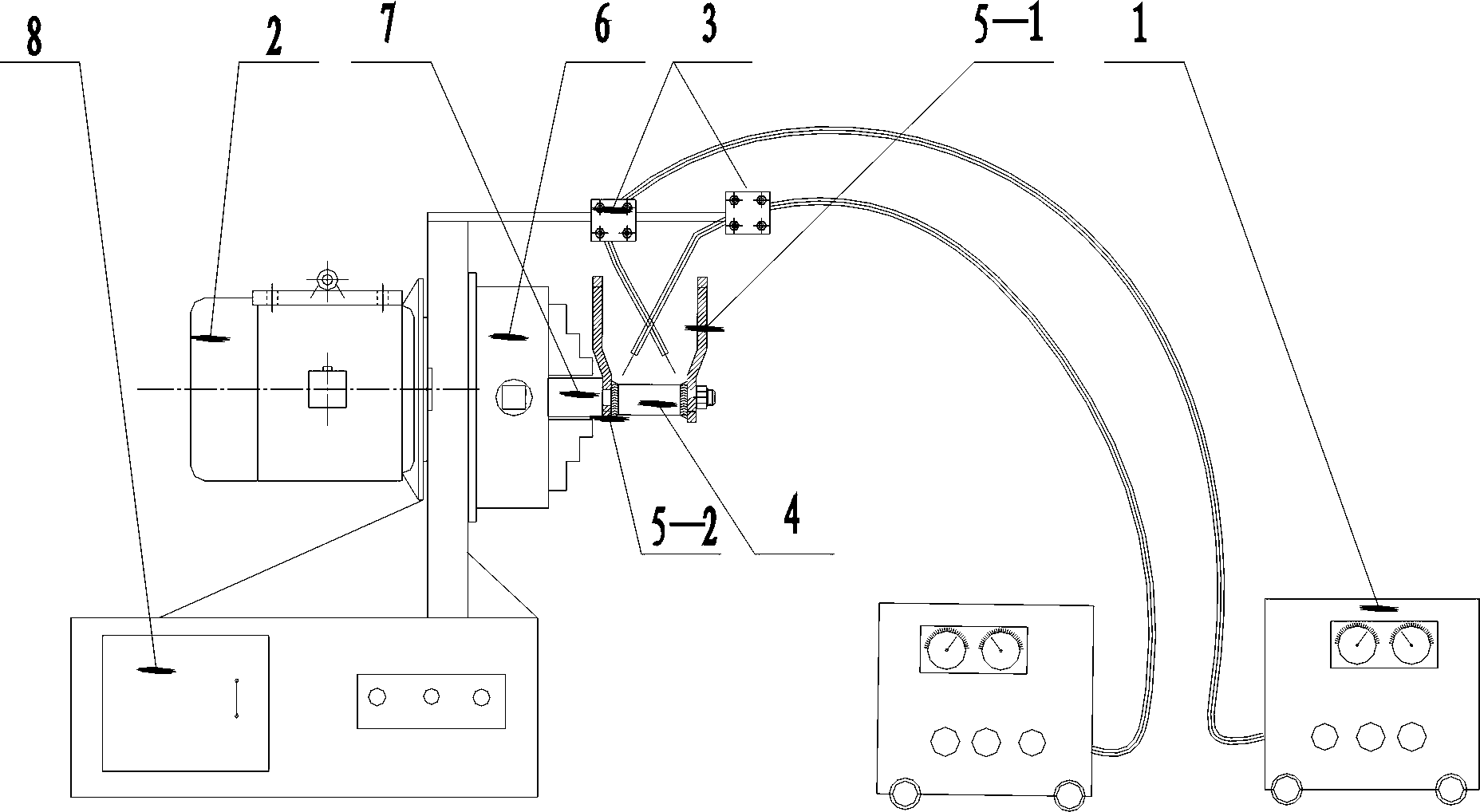

[0011] like figure 1 As shown, an automatic welding device for a steel bent plate chain includes: a carbon dioxide gas shielded welding machine 1, a motor drive device 2, and is characterized in that a fixed chuck 6 is installed on the motor drive device 2, and the fixed chuck 6 Installed on the output shaft 7 of the motor drive device 2, the output shaft 7 is a fixed mandrel for workpiece clamping, and the welding torch of the carbon dioxide gas shielded welding machine 1 is located above the output shaft 7. There are two carbon dioxide gas shielded welding machines 1, and the welding torch of the welding machine is fixed by the welding torch holder 3. The motor driving device 2 is a stepless speed regulation motor. The fixed chuck 6 is a three-jaw chuck.

[0012] The bending plate chain accessory fixing device also includes: a base 8 of the motor drive device 2, and the base 8 is provided with an electrical control part;

[0013] In addition, it also includes: a transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com