Patents

Literature

519results about How to "Accurate angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

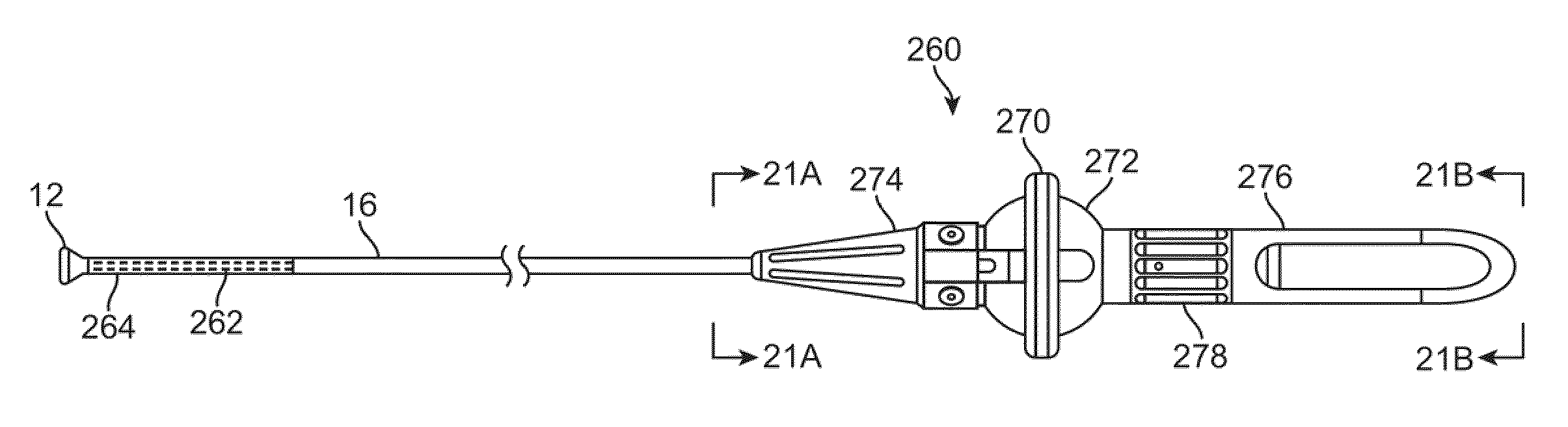

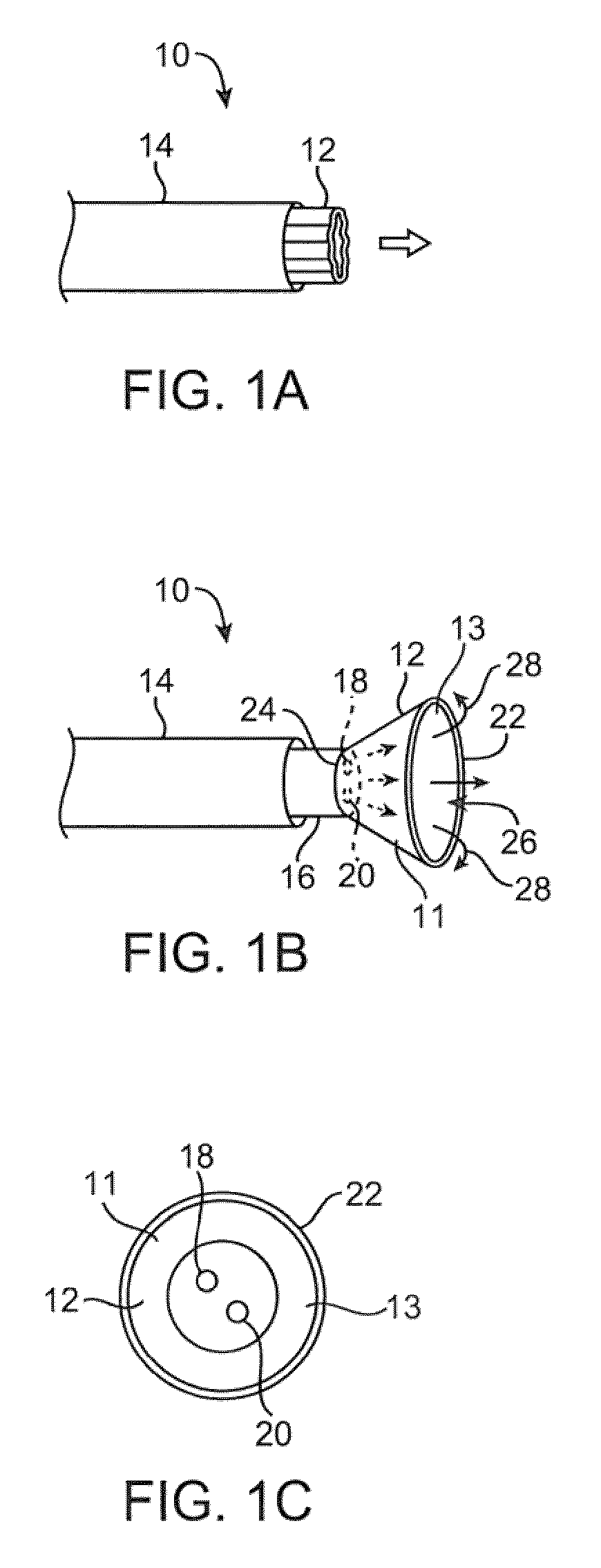

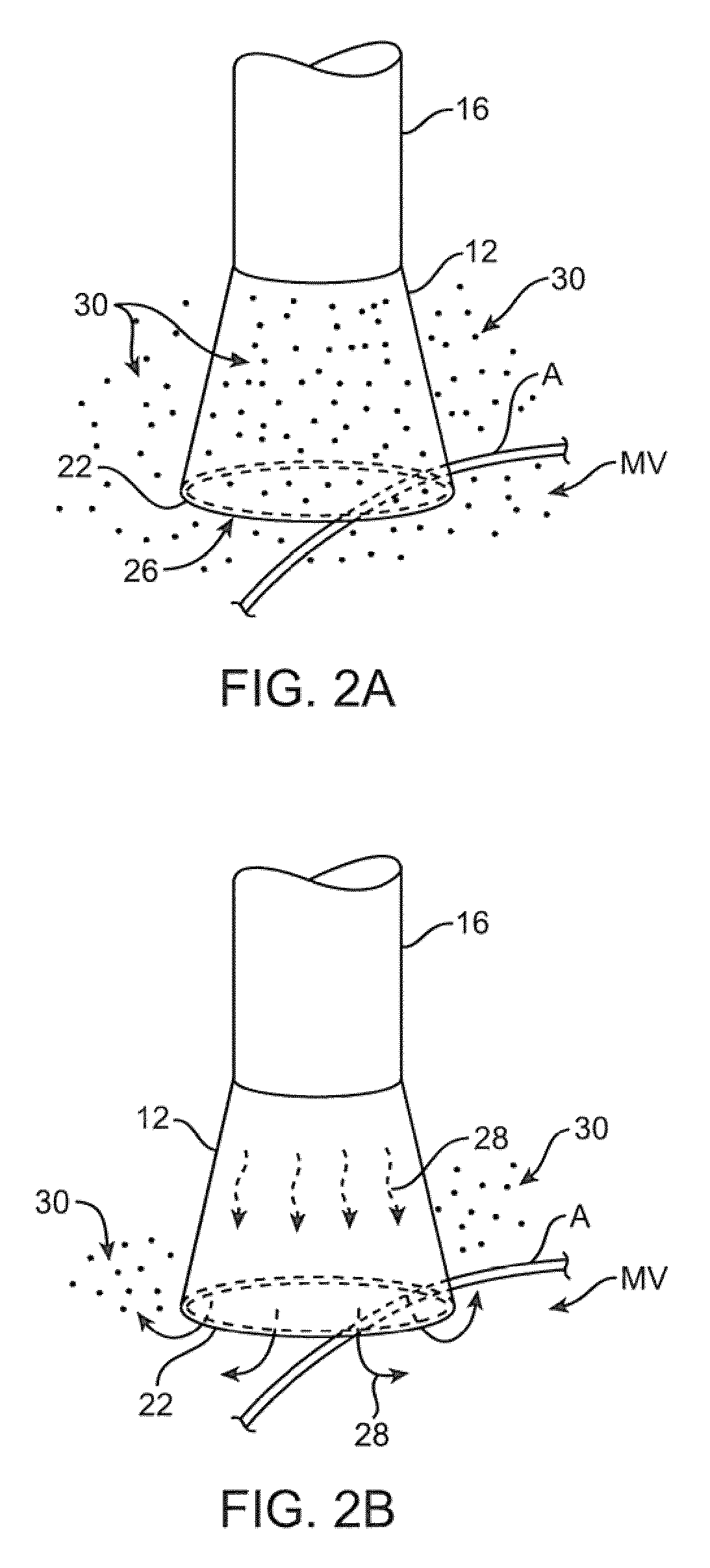

Catheter control systems

ActiveUS20100004633A1Guaranteed simulation effectEfficiently controlling the hood positionSurgeryEndoscopesControl systemSeptal wall

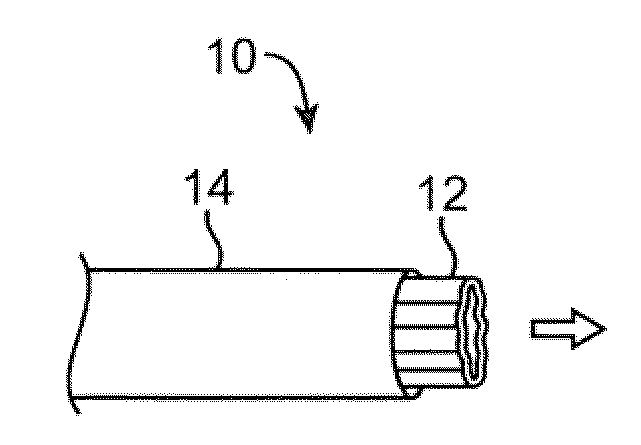

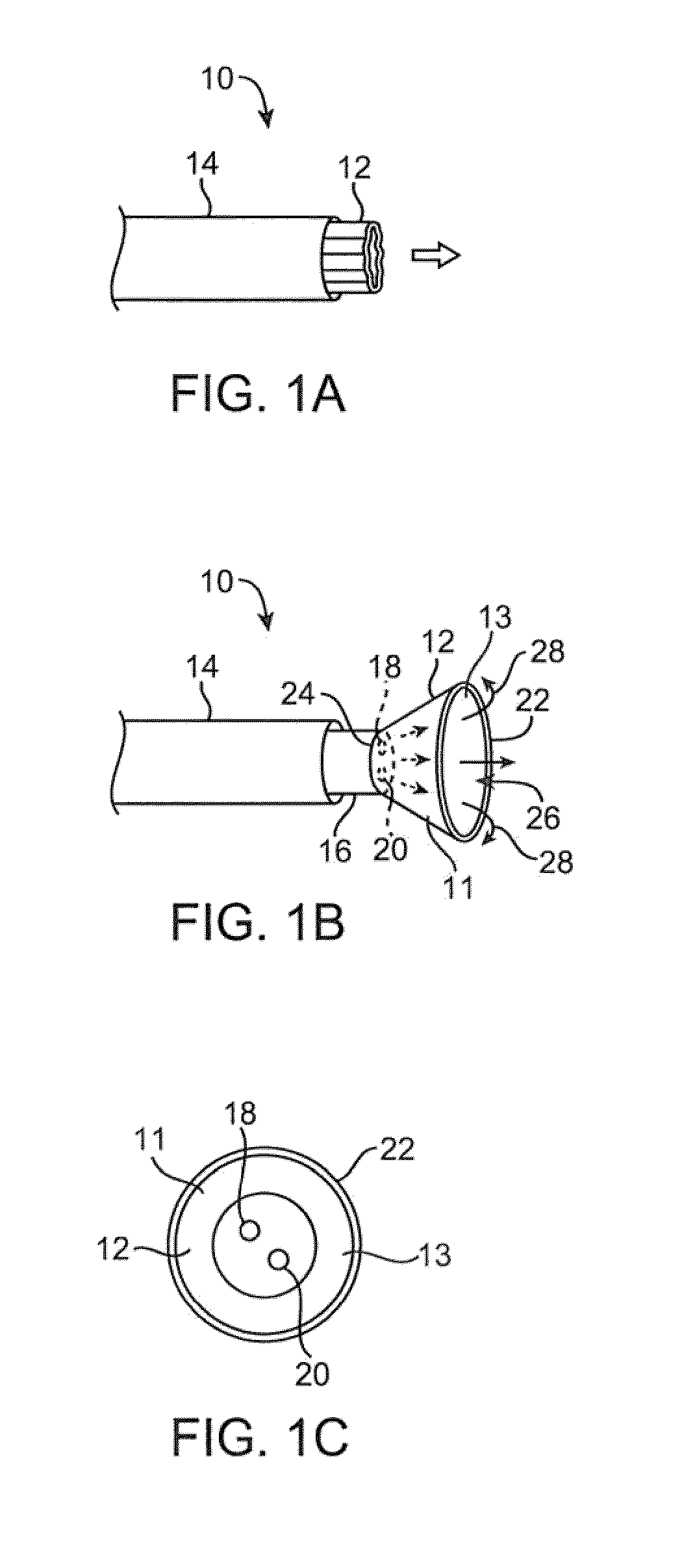

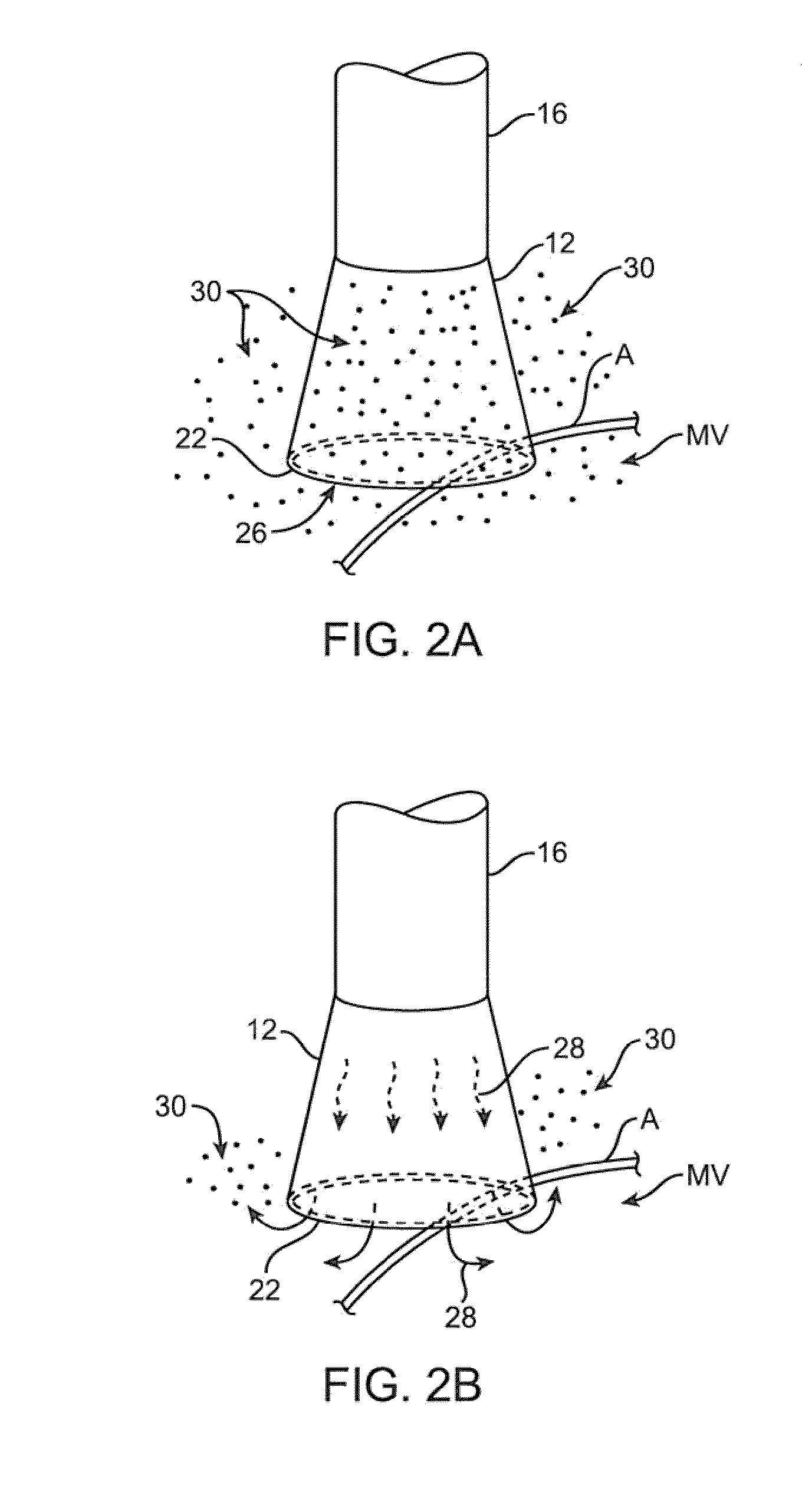

Catheter control systems which facilitate the tracking of an angle of deflection of a catheter distal end can be used for any number of procedures where catheter orientation relative to the body is desirable, e.g., in transseptal access procedures where an accurate angle of puncture of the septal wall is desirable. Such control systems may comprise a steerable handle which is oriented relative to the catheter steerable section to provide for consistent catheter articulation upon corresponding manipulation of the steering ring. Another variation may utilize an orientation indicator to track the deflectable distal end. For instance, an orientation marker as visualized through an imaging hood on the distal end may correspond to identical orientation markers on the control handle such that articulation of a steering mechanism in a direction relative to the orientation markers deflects the catheter distal end in a corresponding direction relative to the visualized orientation markers.

Owner:INTUITIVE SURGICAL OPERATIONS INC

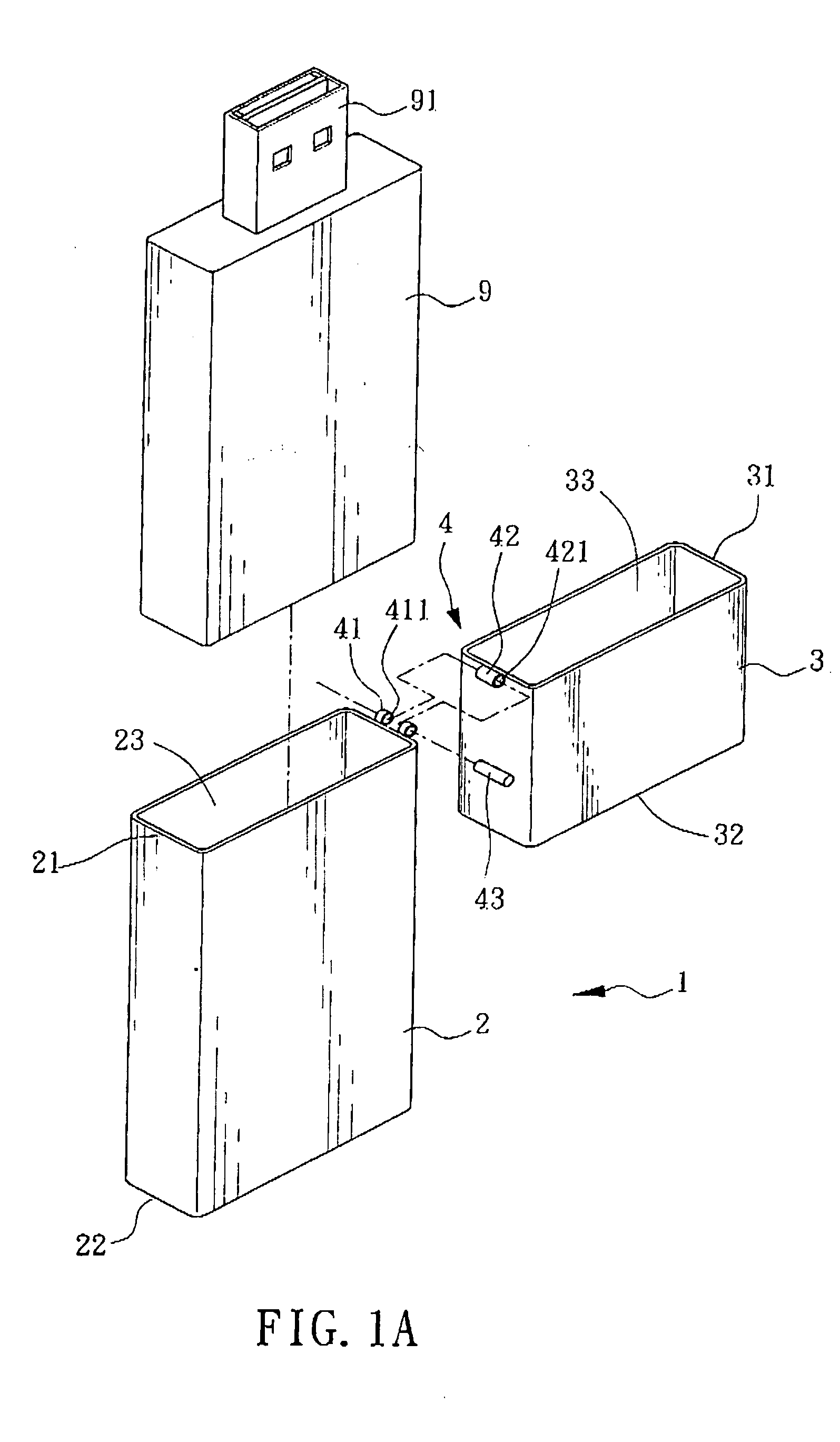

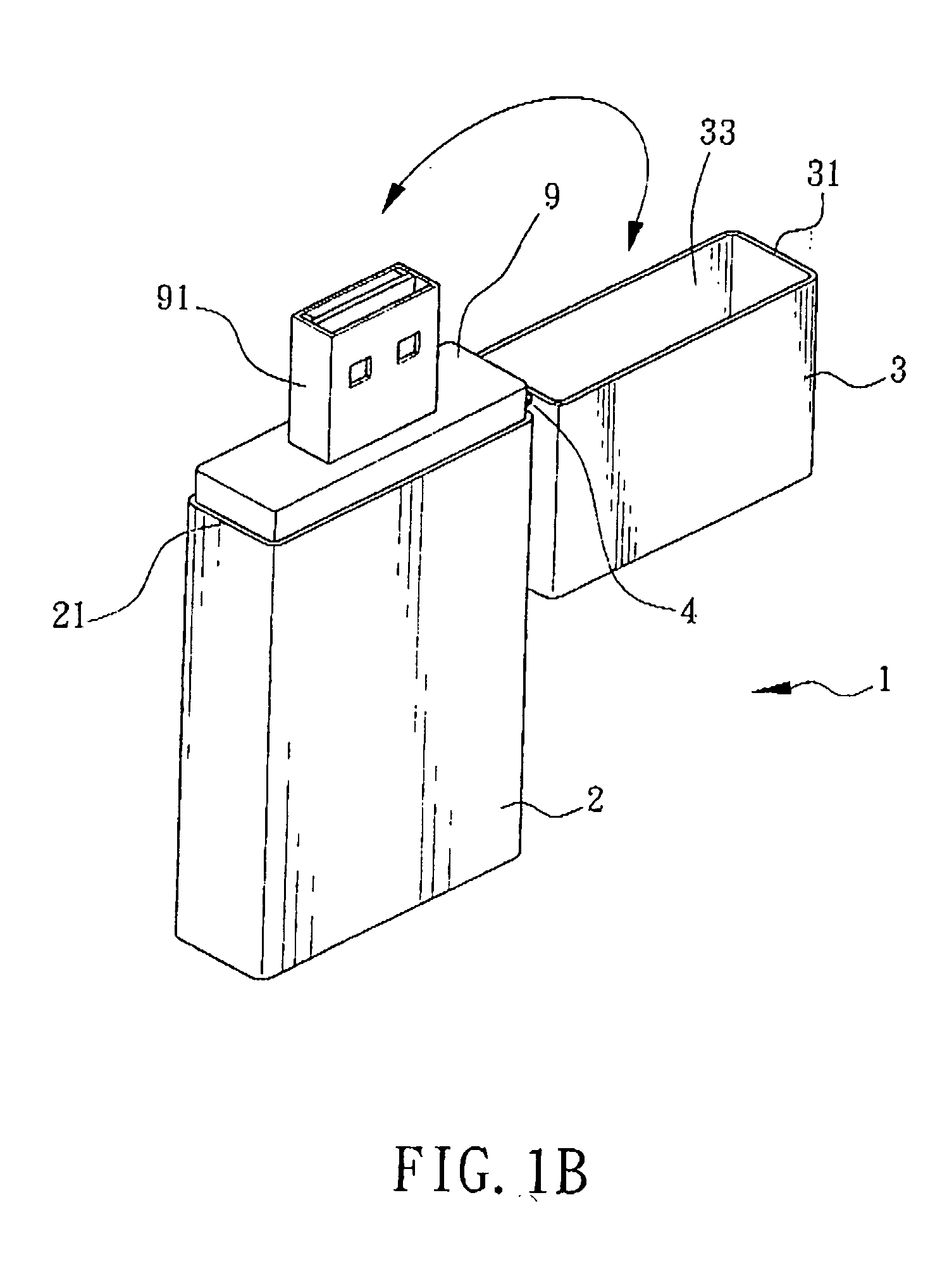

Portable media-accessing device

InactiveUS20050029137A1Opportunities decreaseFunction increaseCoupling device detailsOther accessoriesBiomedical engineeringMedia access

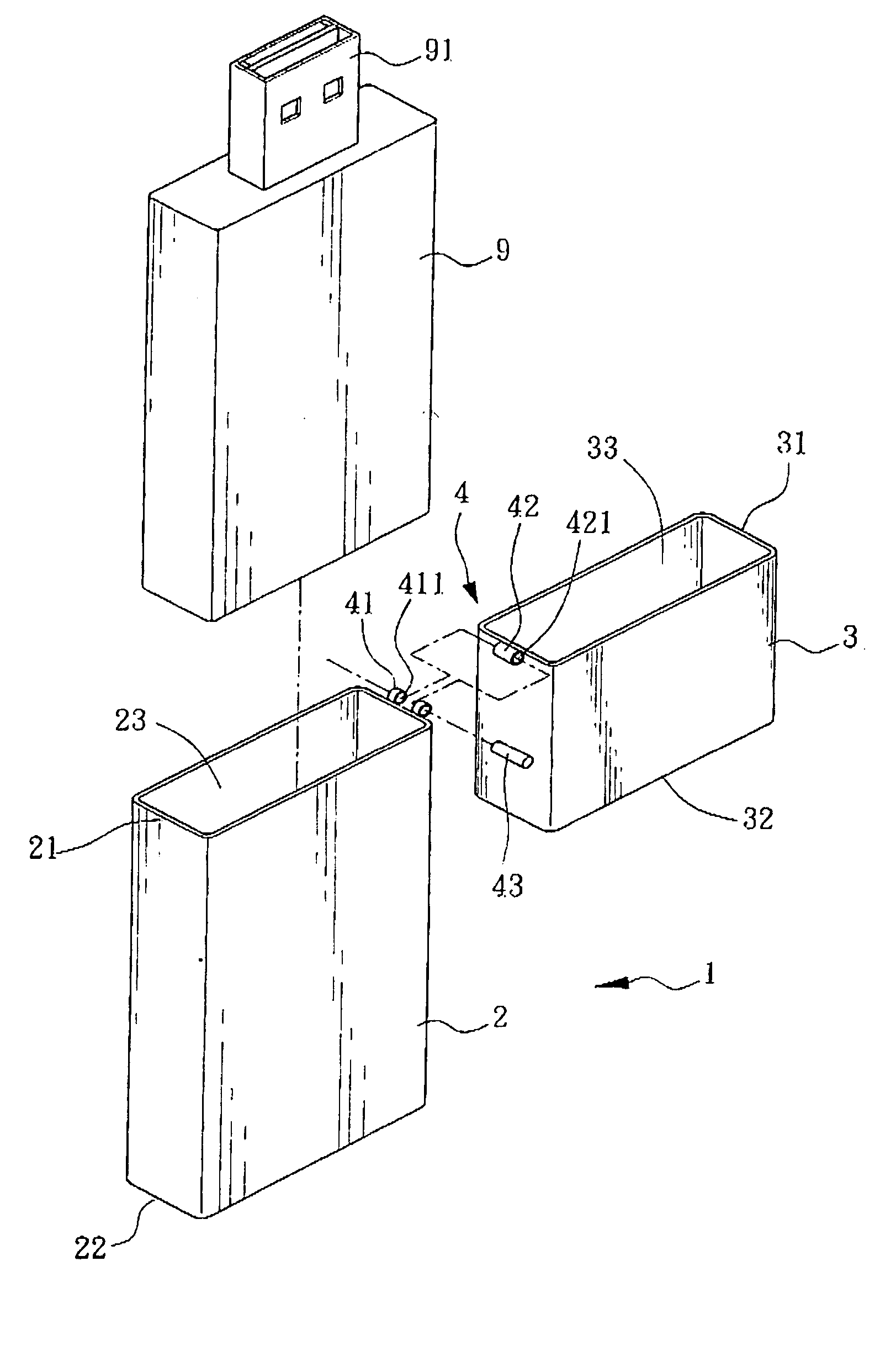

The invention is mainly to provide a portable media-accessing device, which includes a body, an upper lid, and at least one pivotal part. The body has a hollow casing having an opening side communicating to a first accommodation space; the first opening side may provide a memory module to be placed into the first accommodation space; the upper lid has a hollow casing having a second opening side communicating to a second accommodation space; the pivotal part may make the body connected to the upper lid such that, by taking the pivotal part as an axial center, a rotation motion with an appropriate angle between the upper lid and the body is possible.

Owner:BENQ CORP

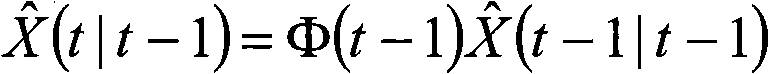

Agricultural machines navigation hierarchical positioning process and system

InactiveCN101285686AAvoid abnormal resultsStable positionNavigational calculation instrumentsNavigation by speed/acceleration measurementsKaiman filterDynamic positioning

The invention discloses a graded positioning method for agricultural machinery navigation, comprising the following steps of acquiring a first positioning parameter, utilizing a Kalman filter to fuse the first positioning parameter, acquiring a second positioning parameter, acquiring a third positioning parameter, utilizing multi-sensor self-adaptive weighted fusion algorithm to fuse the second positioning parameter with the third positioning parameter, acquiring a target positioning parameter and positioning agricultural machinery according to the target positioning parameter. The invention also discloses a graded positioning system for agricultural machinery navigation. By fusing the positioning parameters acquired by measurement equipment for a plurality of times, the graded positioning method can smooth DGPS positioning data, effectively avoid the abnormal results of DGPS dynamic positioning, effectively filter test noise, reduce systematic error, form continuous, stable and accurate the information of the positions and course heading angles of agricultural machinery, and improve the positioning accuracy of agricultural machinery navigation.

Owner:CHINA AGRI UNIV

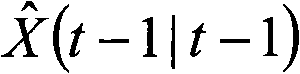

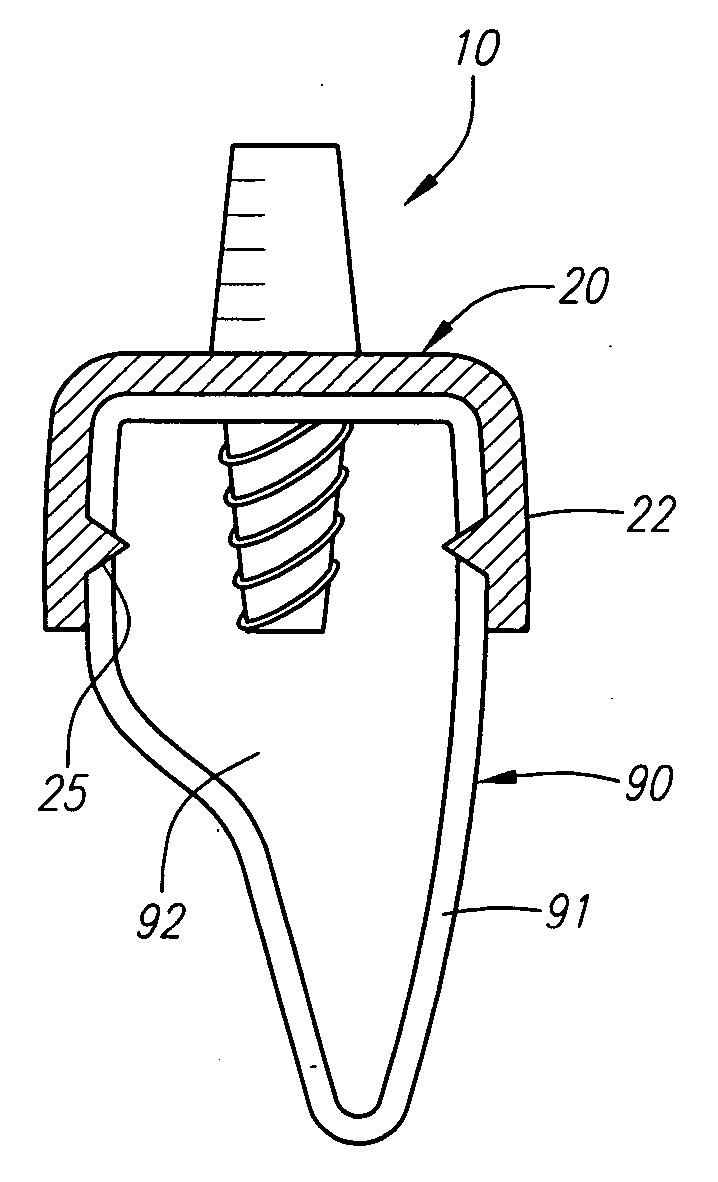

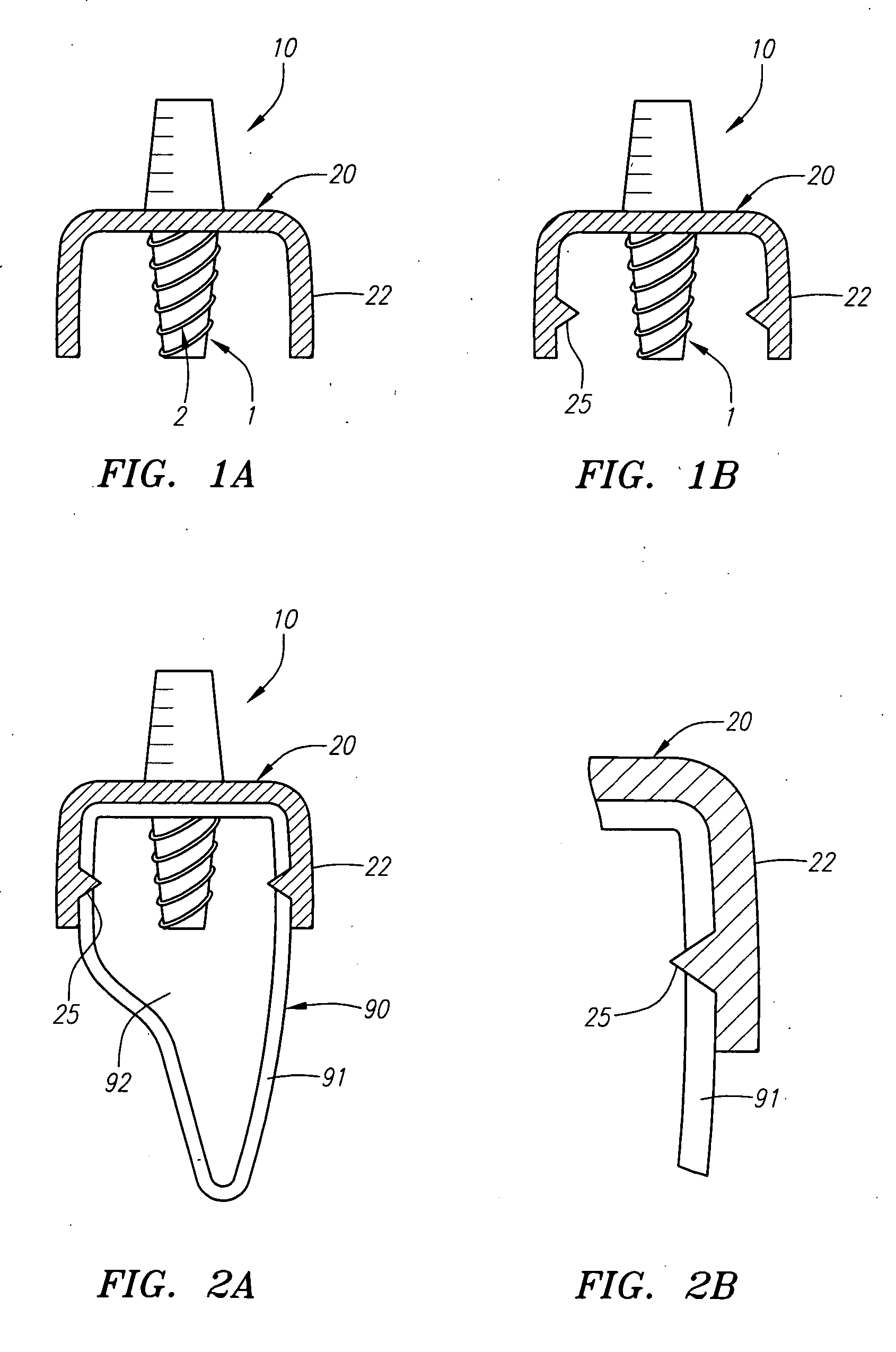

Dental implants with improved loading properties

A dental prosthetic includes an elongate threaded implant adapted to be secured within the trabecular region of a maxilla or mandible. An abutment having a first region adapted to receive a crown and a second region adapted for coupling to the elongate threaded implant is secured to the elongate threaded implant. The abutment and elongate threaded implant extend generally along a common longitudinal axis. A compliant brace is adapted for placement between the first region of the abutment and the elongate threaded implant. The compliant brace includes first, second, and third elongate extensions capable of engaging the cortical region of the maxilla or mandible, thereby minimizing micromotion and allowing for osseointegration despite immediate installation of a crown and immediate mechanical loading. The dental prosthetic may also include an adaptor for coupling the elongate threaded implant and the abutment. Methods for implanting dental prosthetics are also described.

Owner:DYNAMIC IMPLANTS

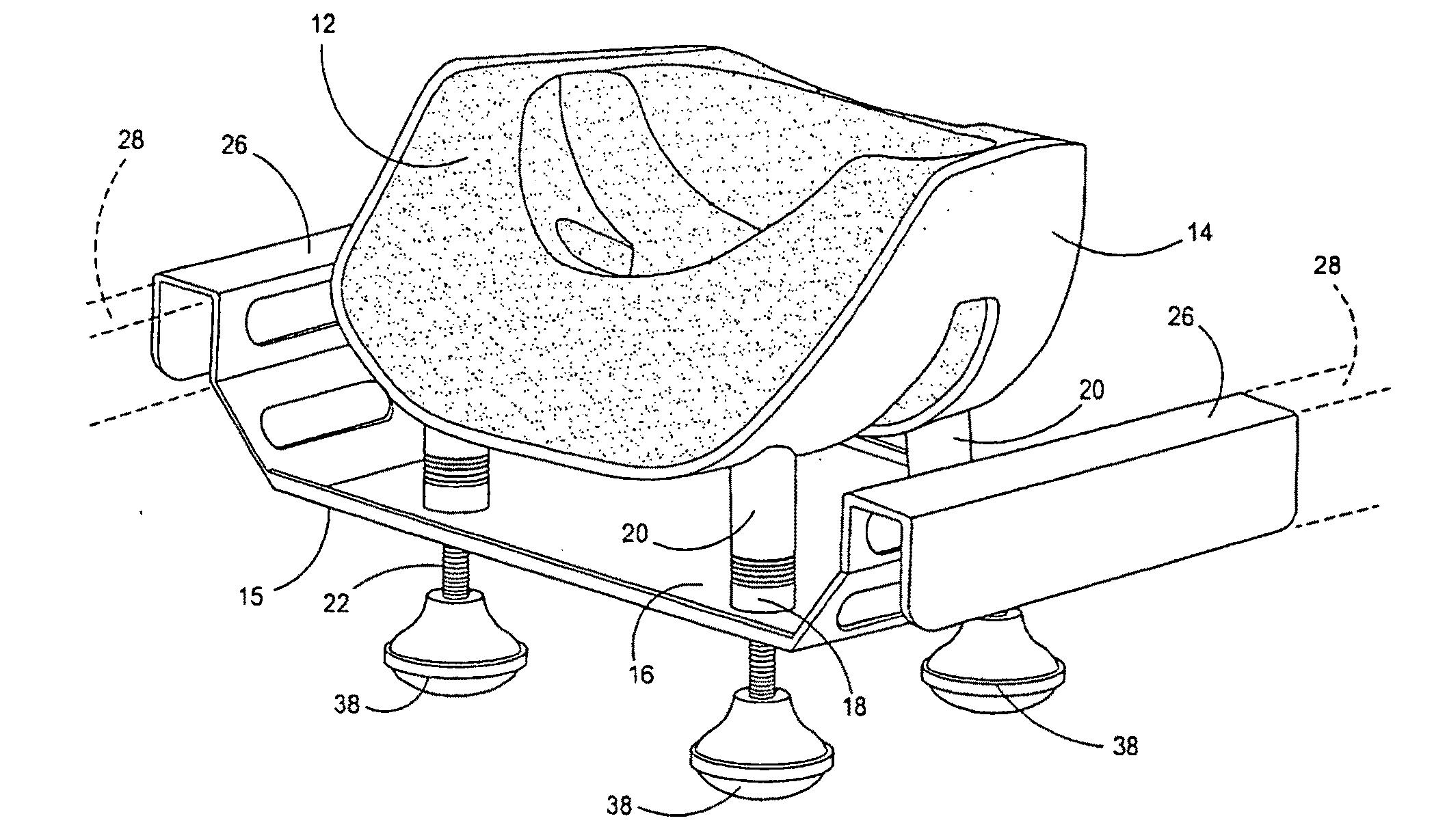

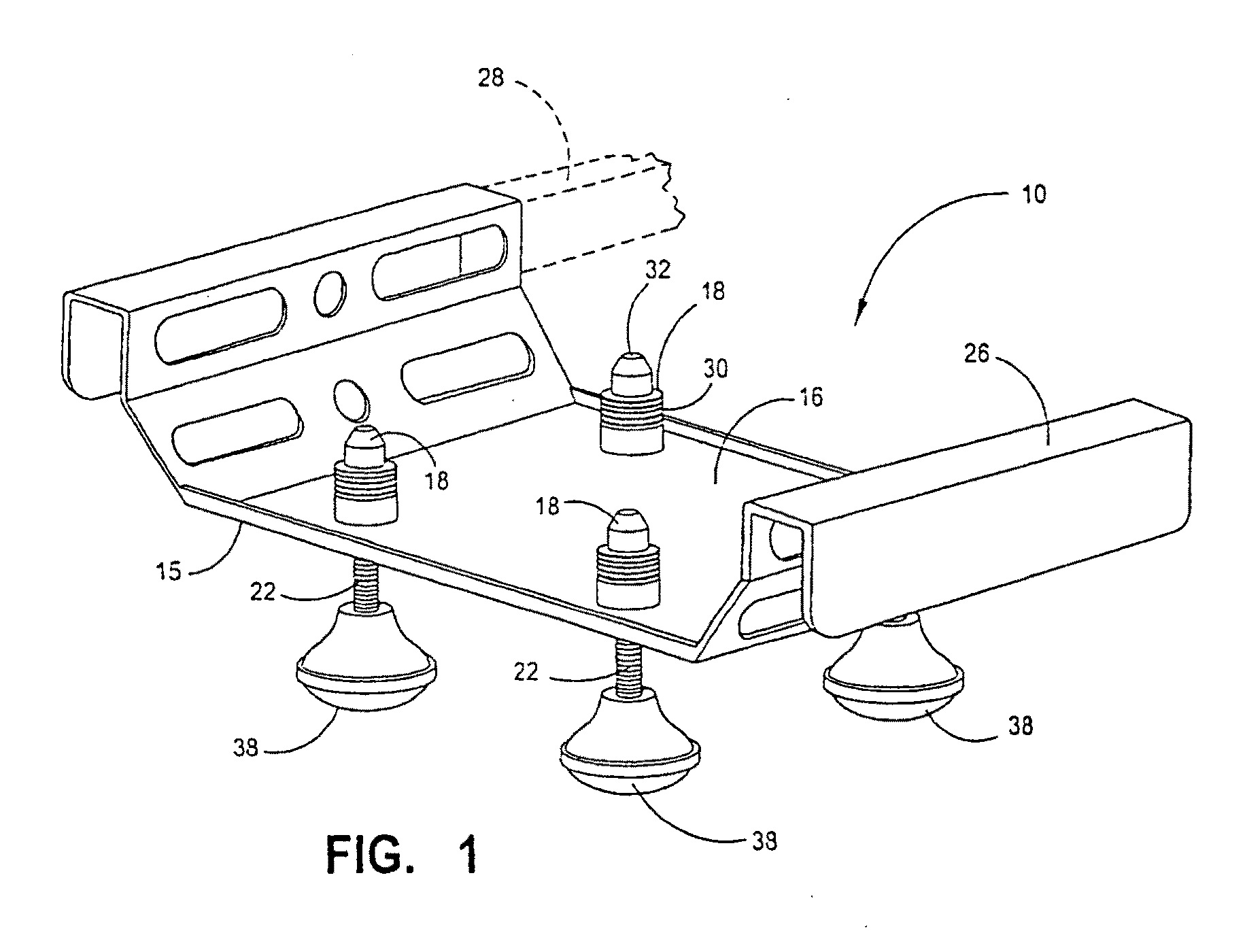

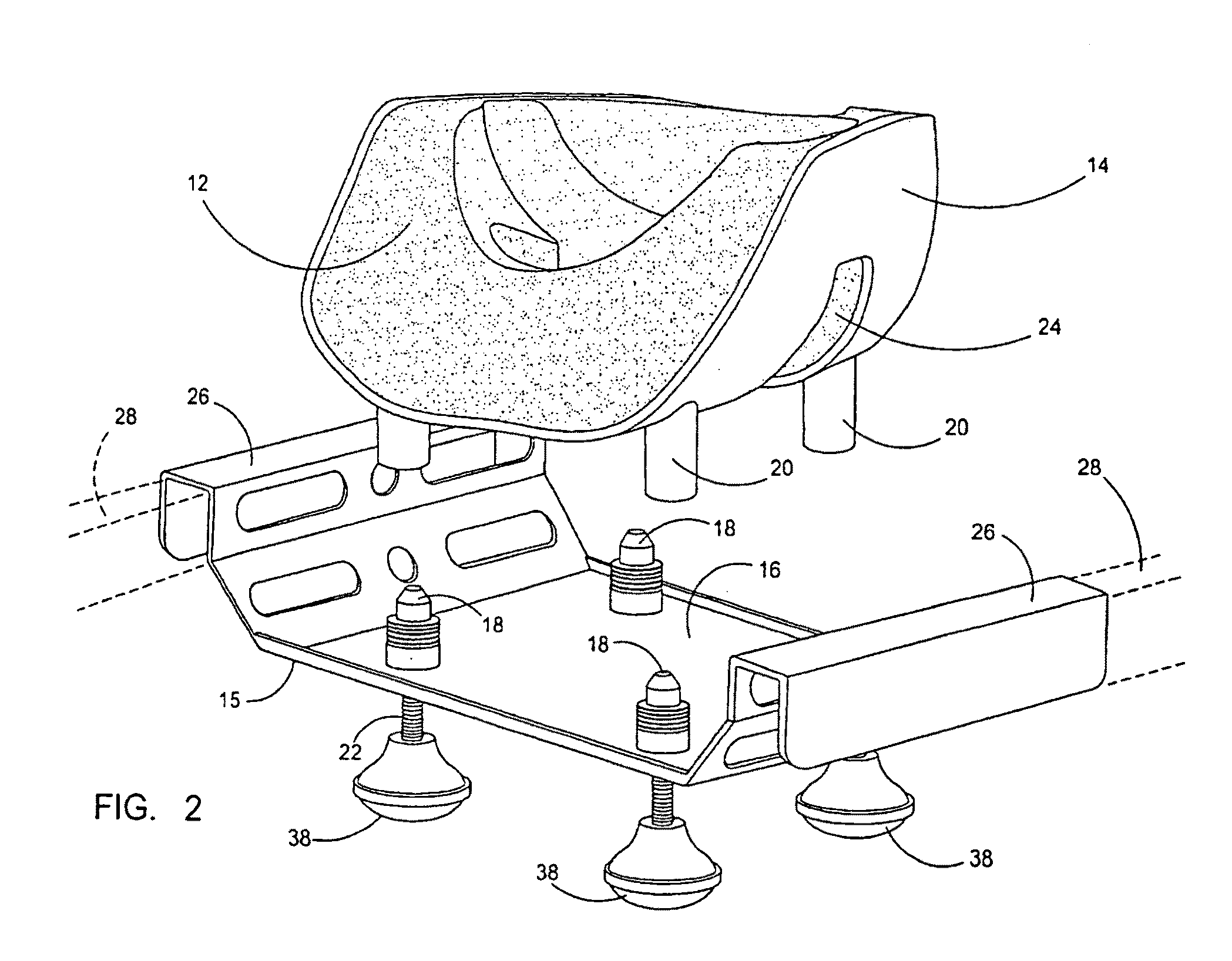

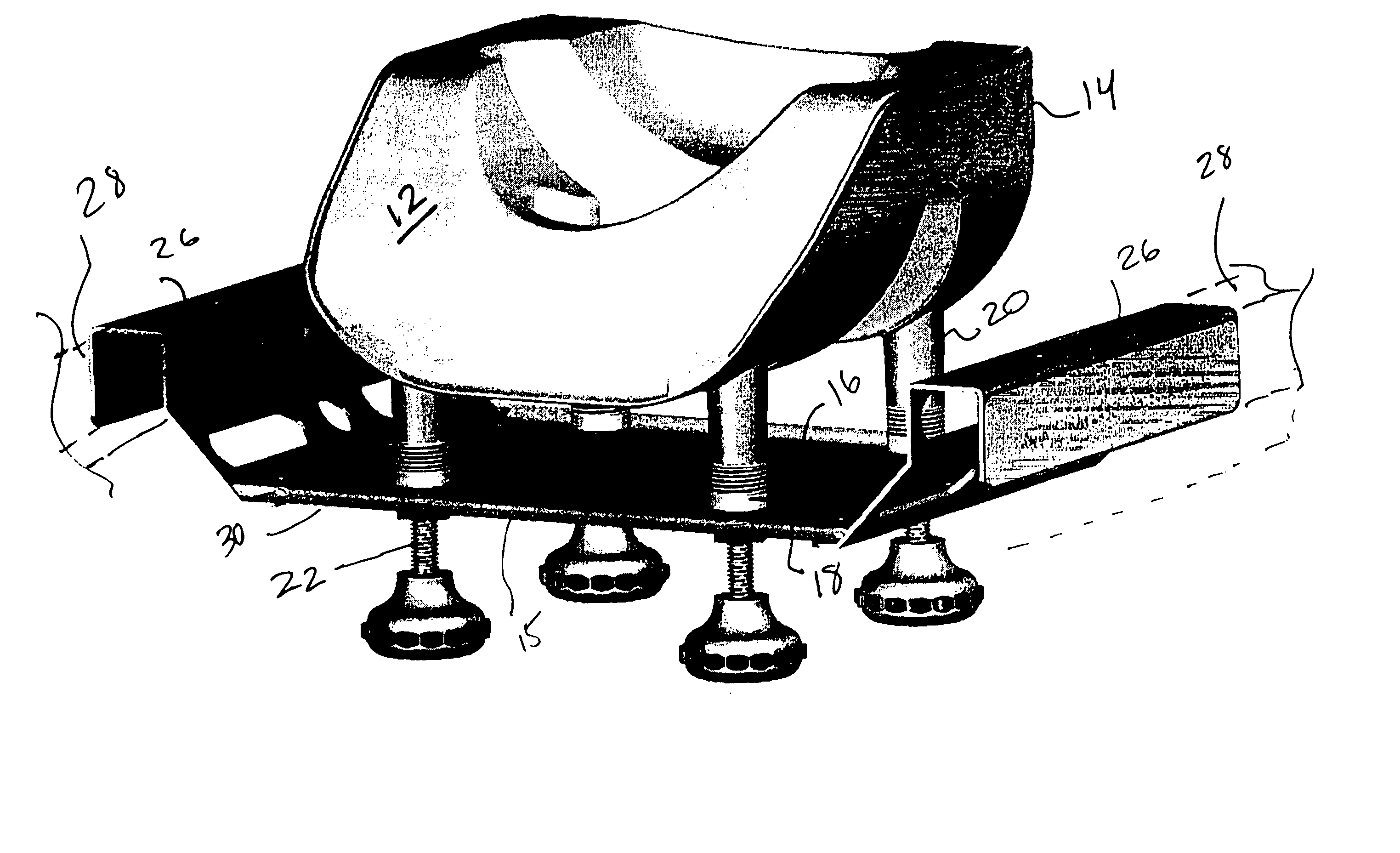

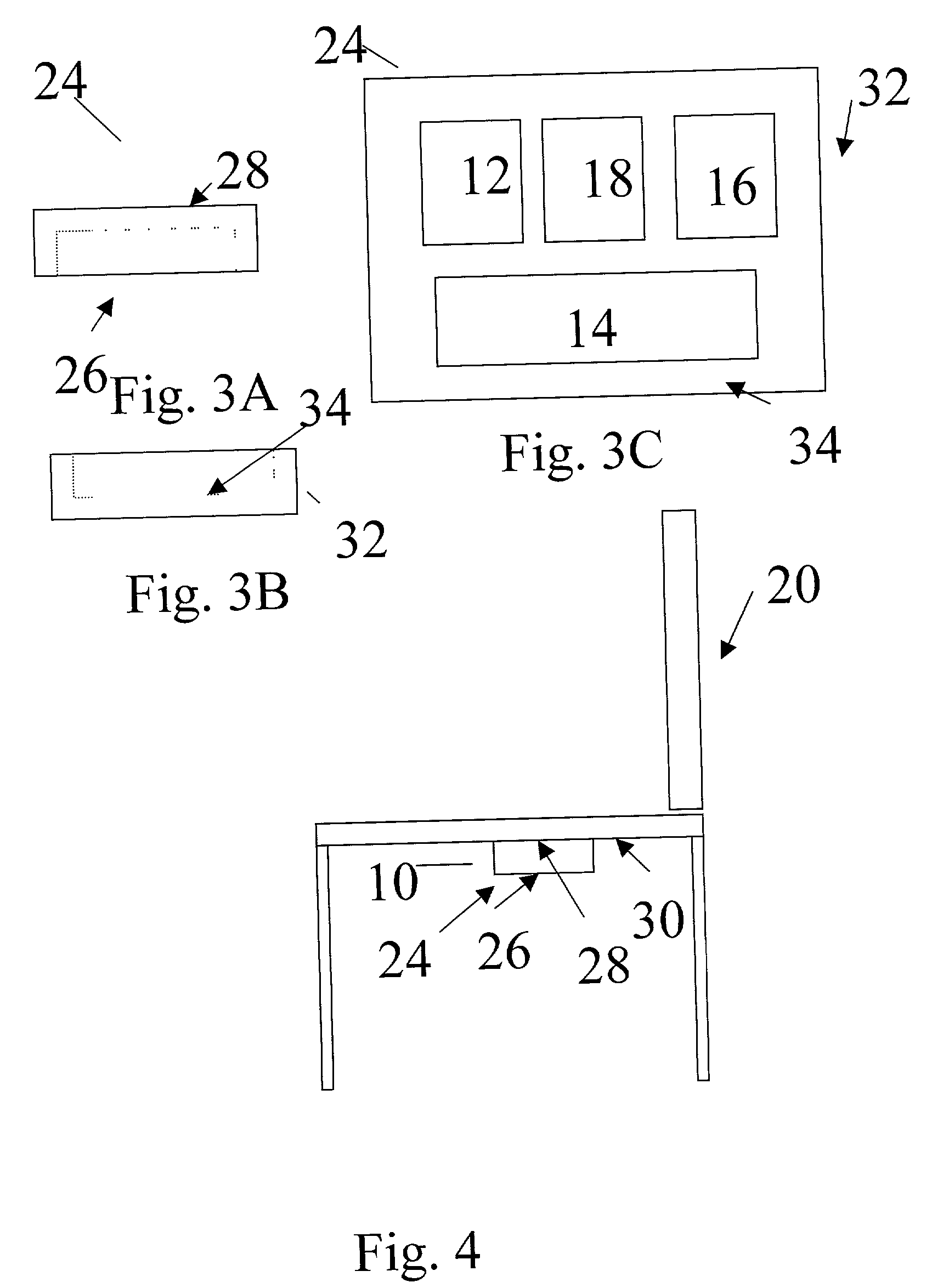

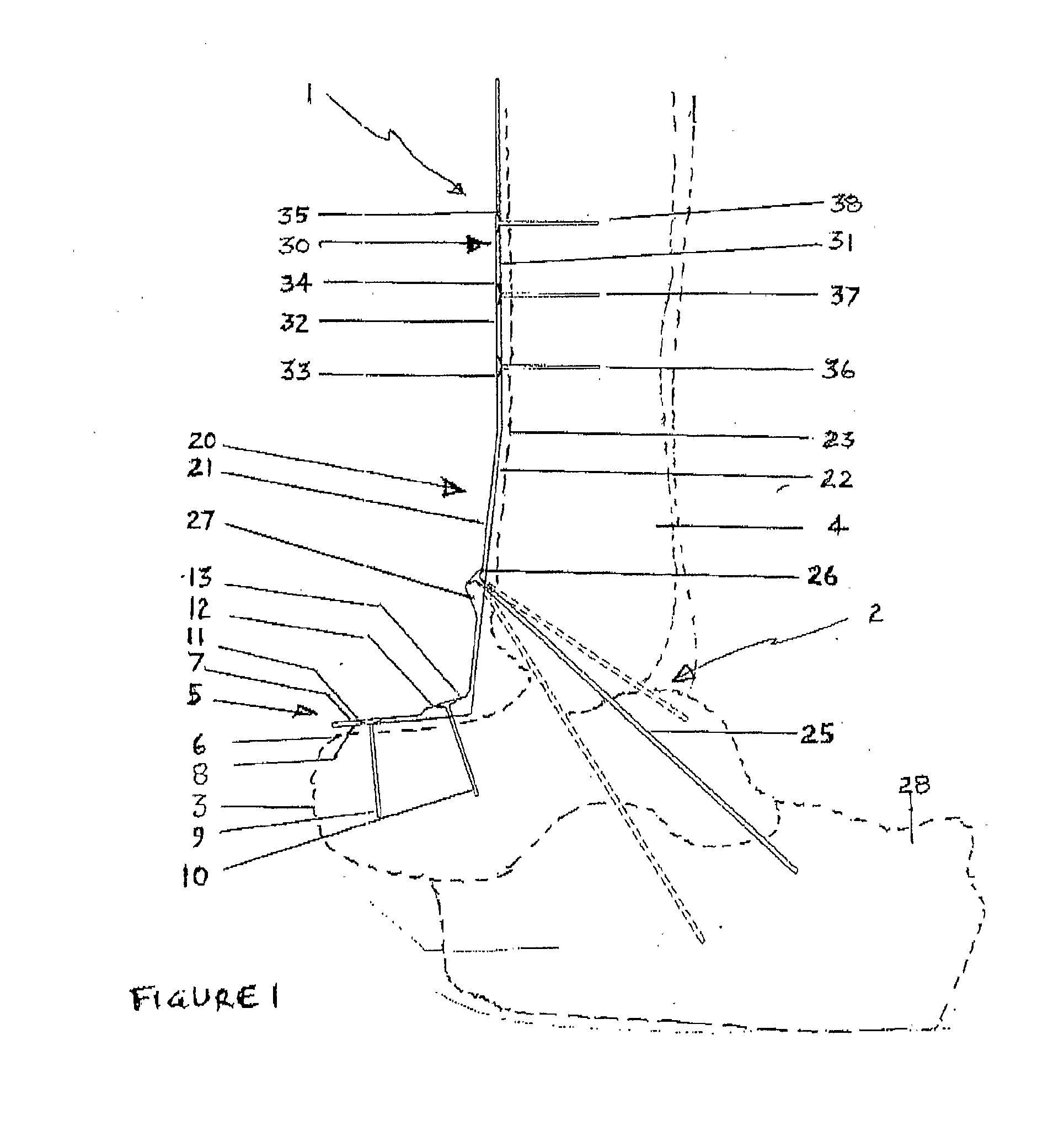

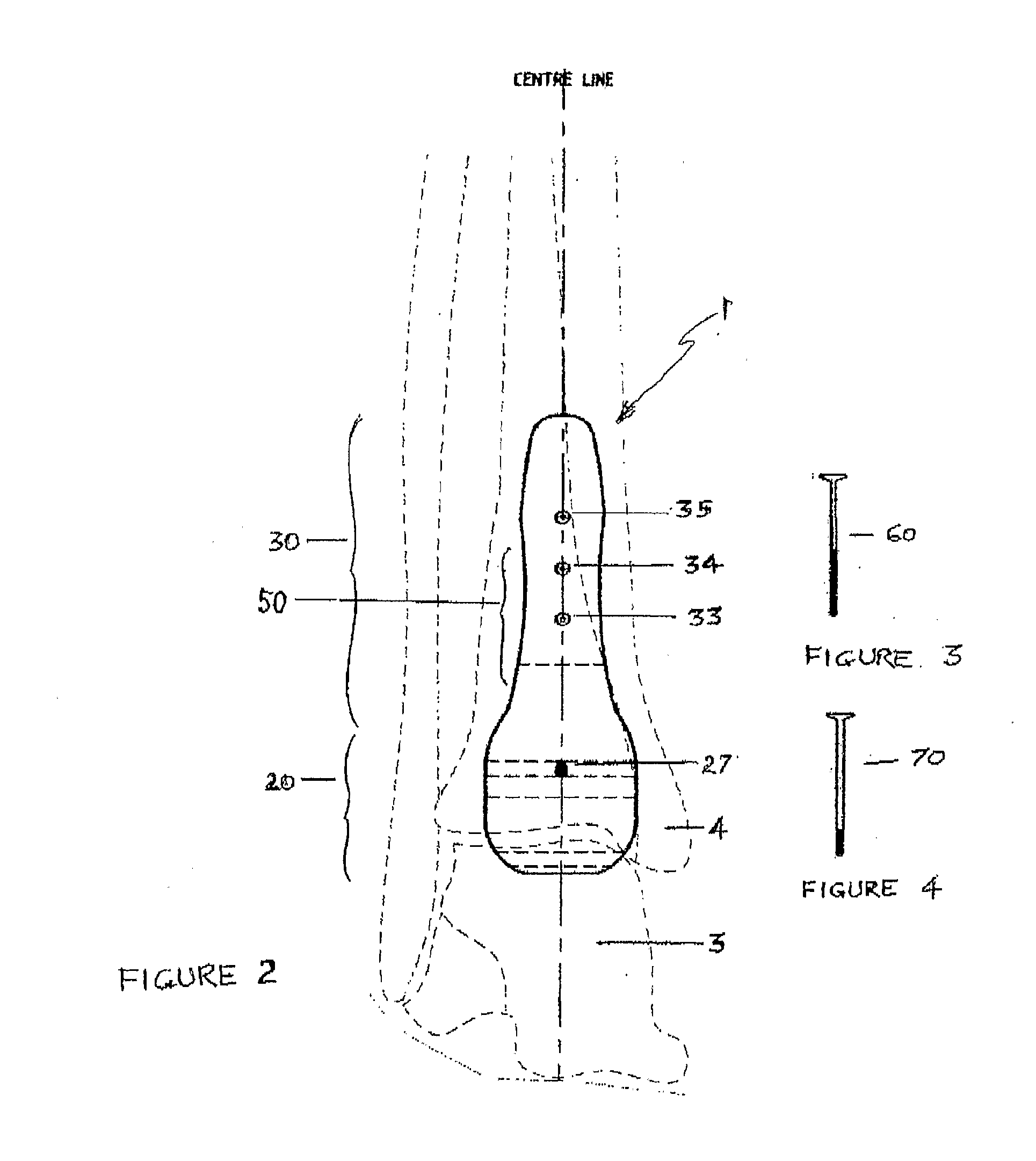

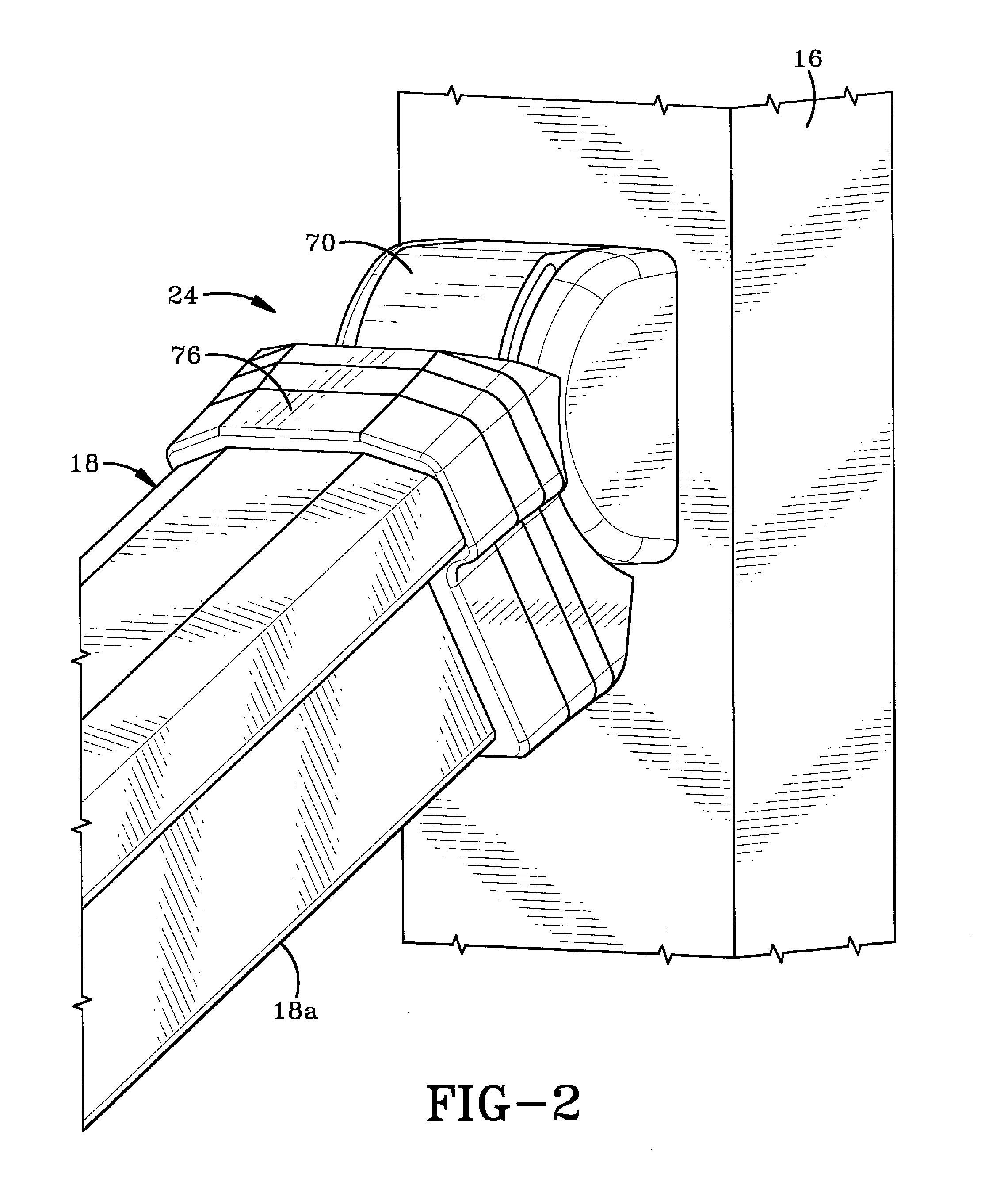

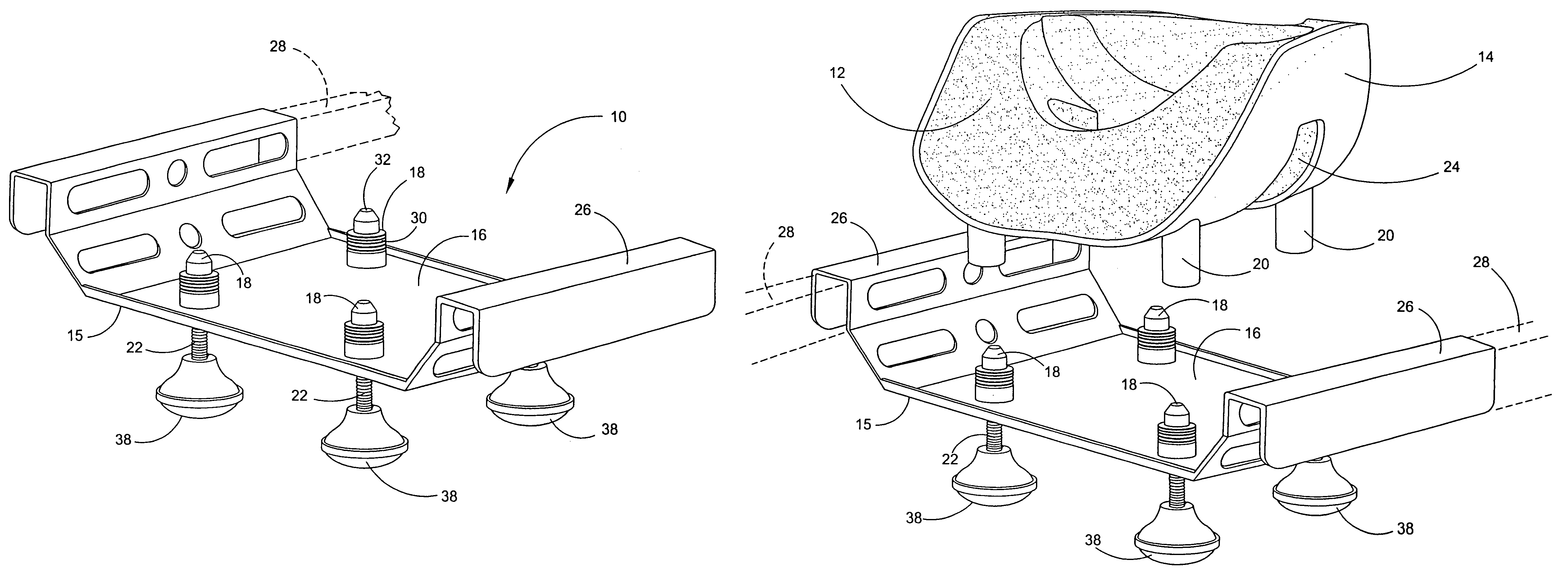

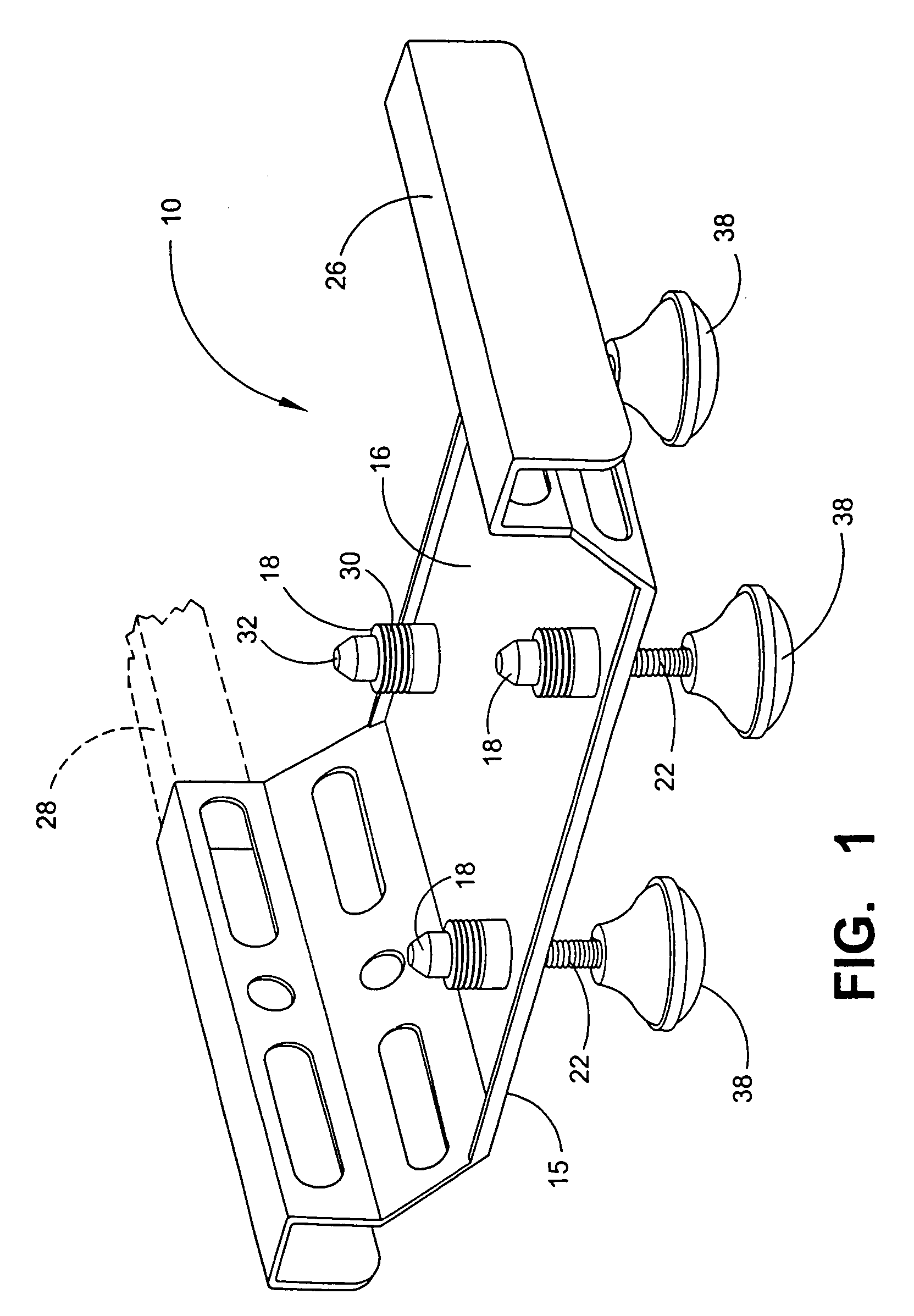

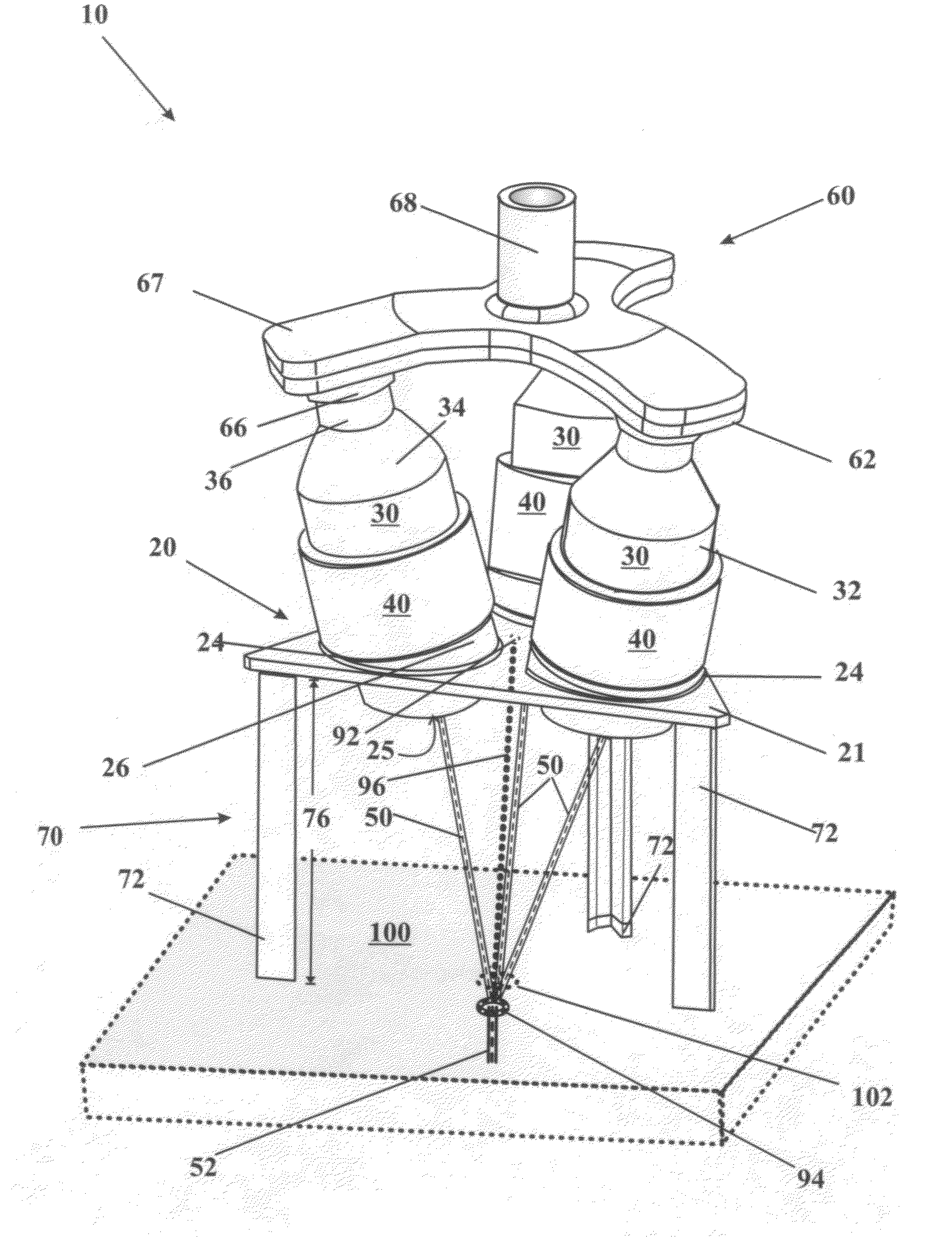

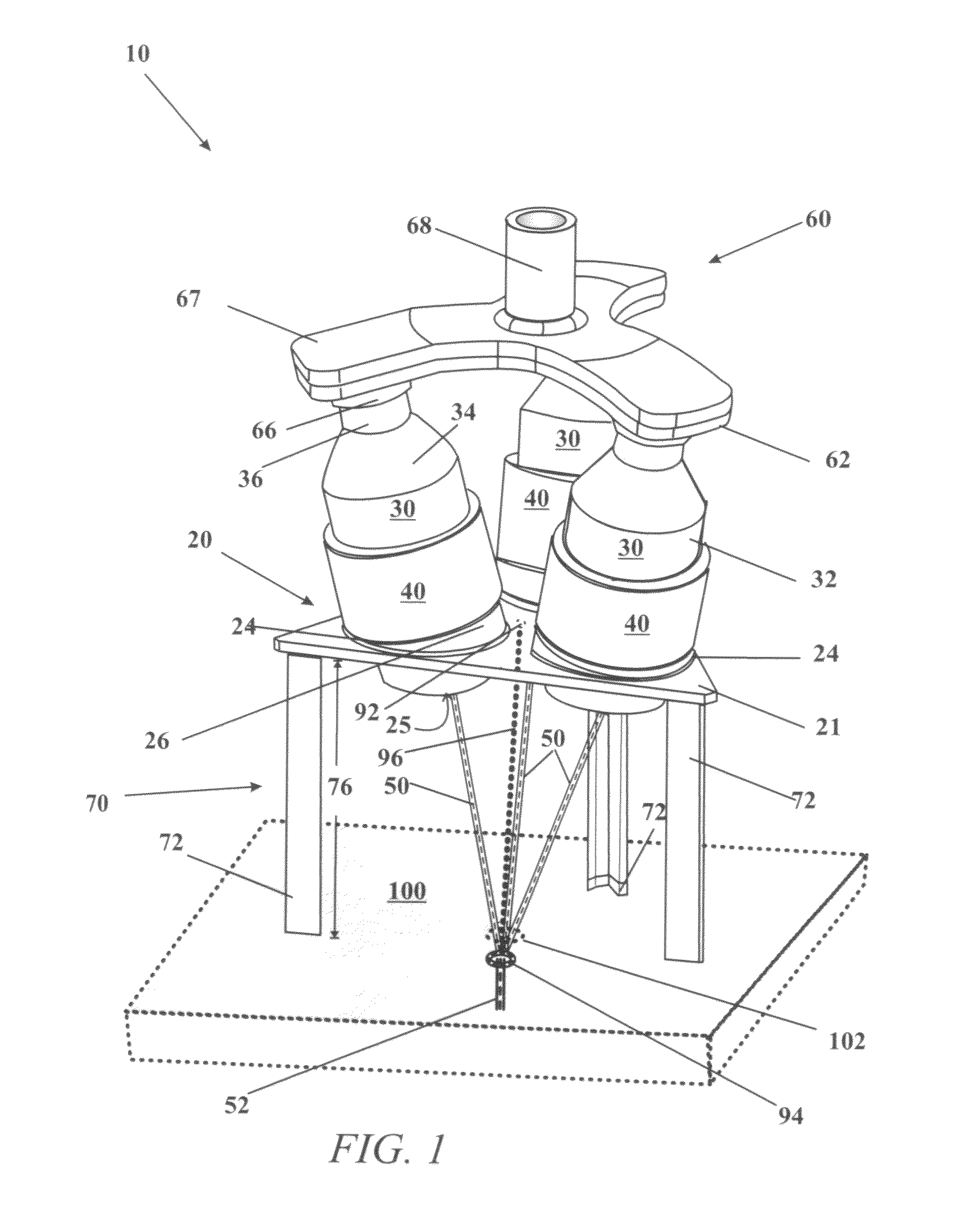

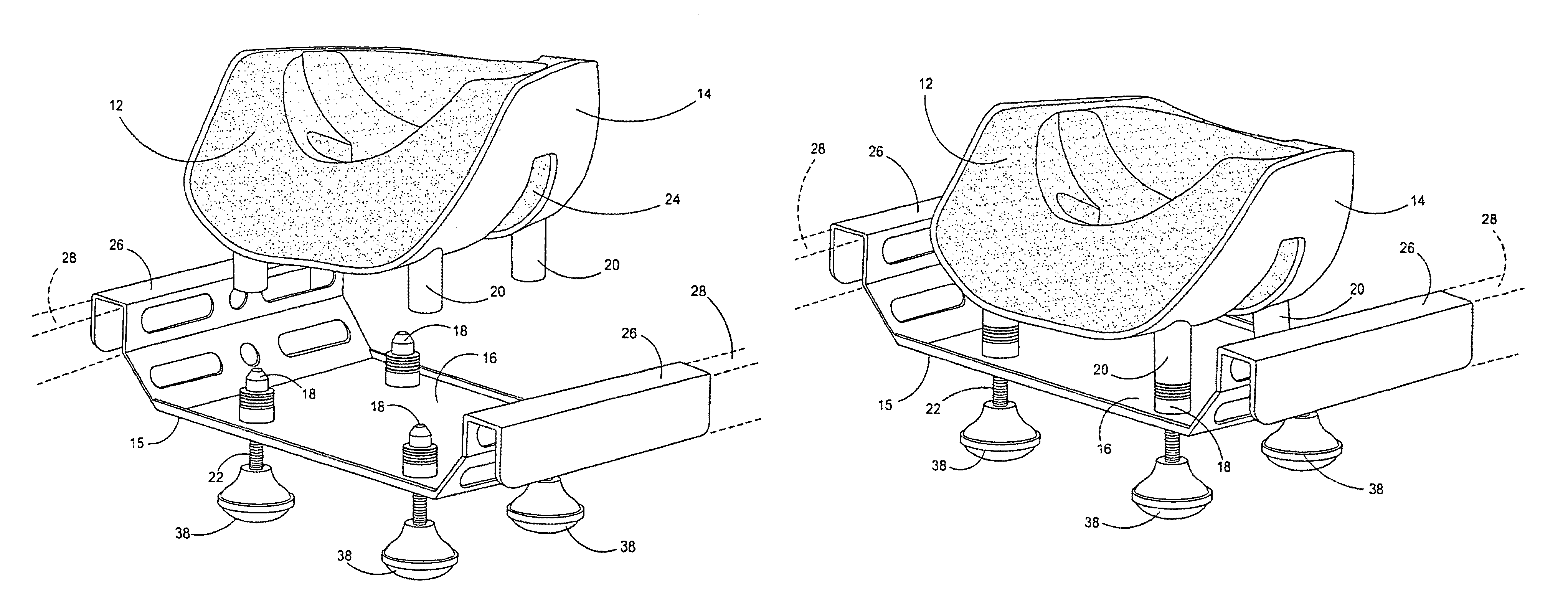

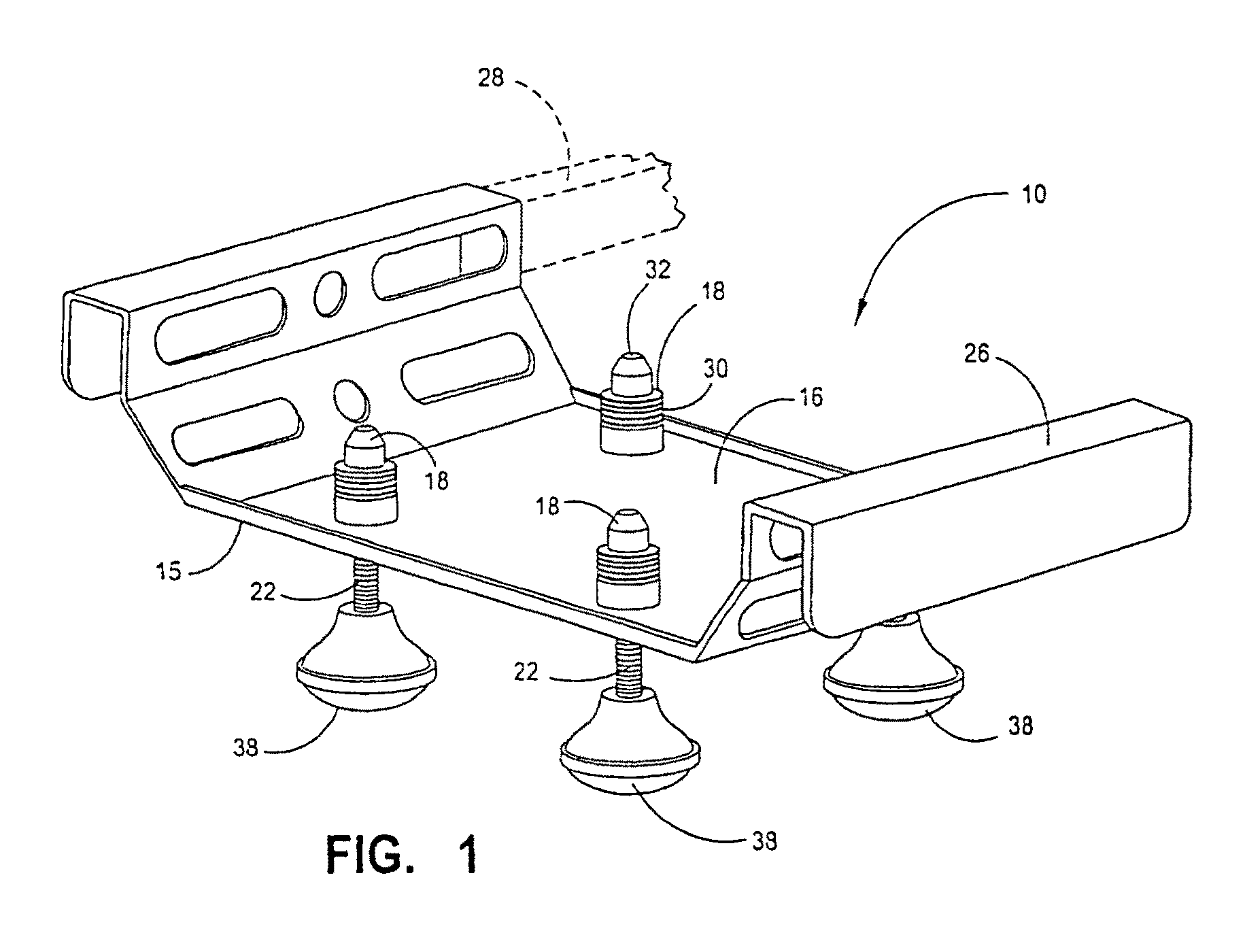

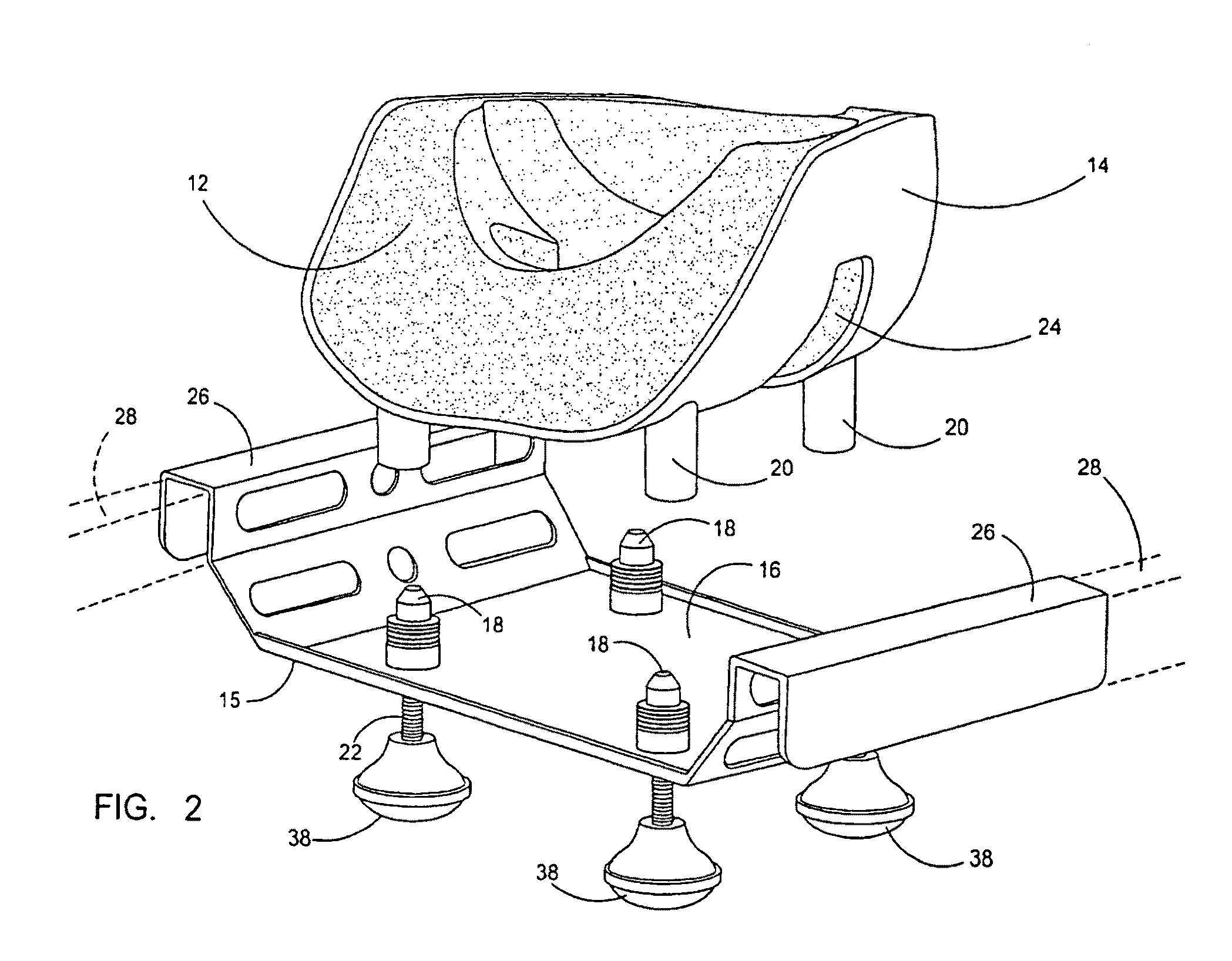

Table engageable support for head cushion supporting anesthetized patient

ActiveUS20090025146A1Lateral shock dampening abilityEasy to adjustOperating tablesSofasProne positionEngineering

A support for the head of a patient lying in a generally prone position. The support features a tray adapted for support on an underlying operating table surface. A plurality of pins projecting from an engagement with the tray are positioned to engage and suspend either a cushion directly or a cushion engaged in a casing. The pins may be adjusted to raise or lower the engaged cushion or casing. A mirror is also provided to provide a reflective view a patient's eyes through slots in the cushion and casing engaged over a patient's face. A video camera may also concurrently be employed to capture electronic images of the patient's eyes and mouth through an aperture in the mirror.

Owner:MAZZEI WILLIAM J +2

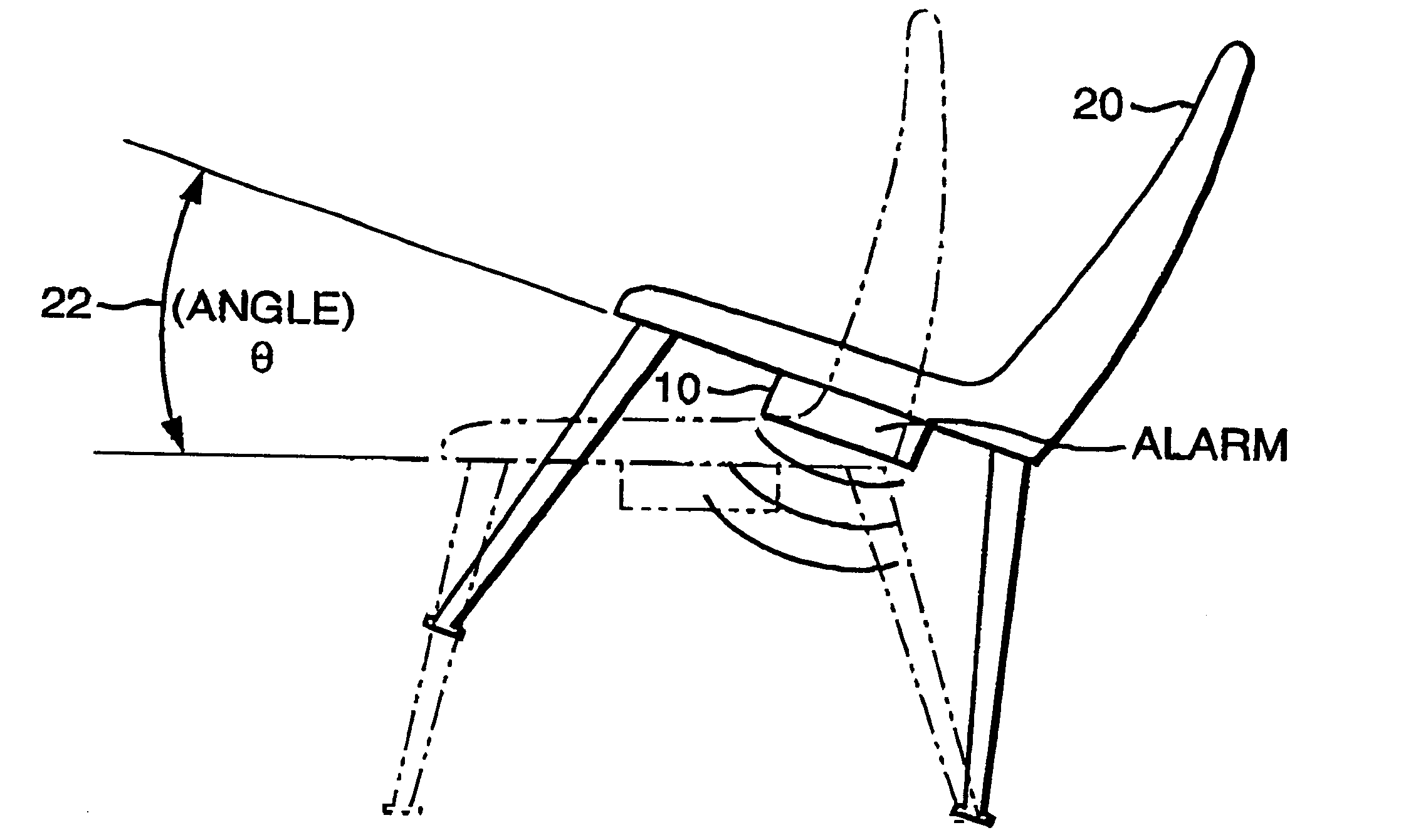

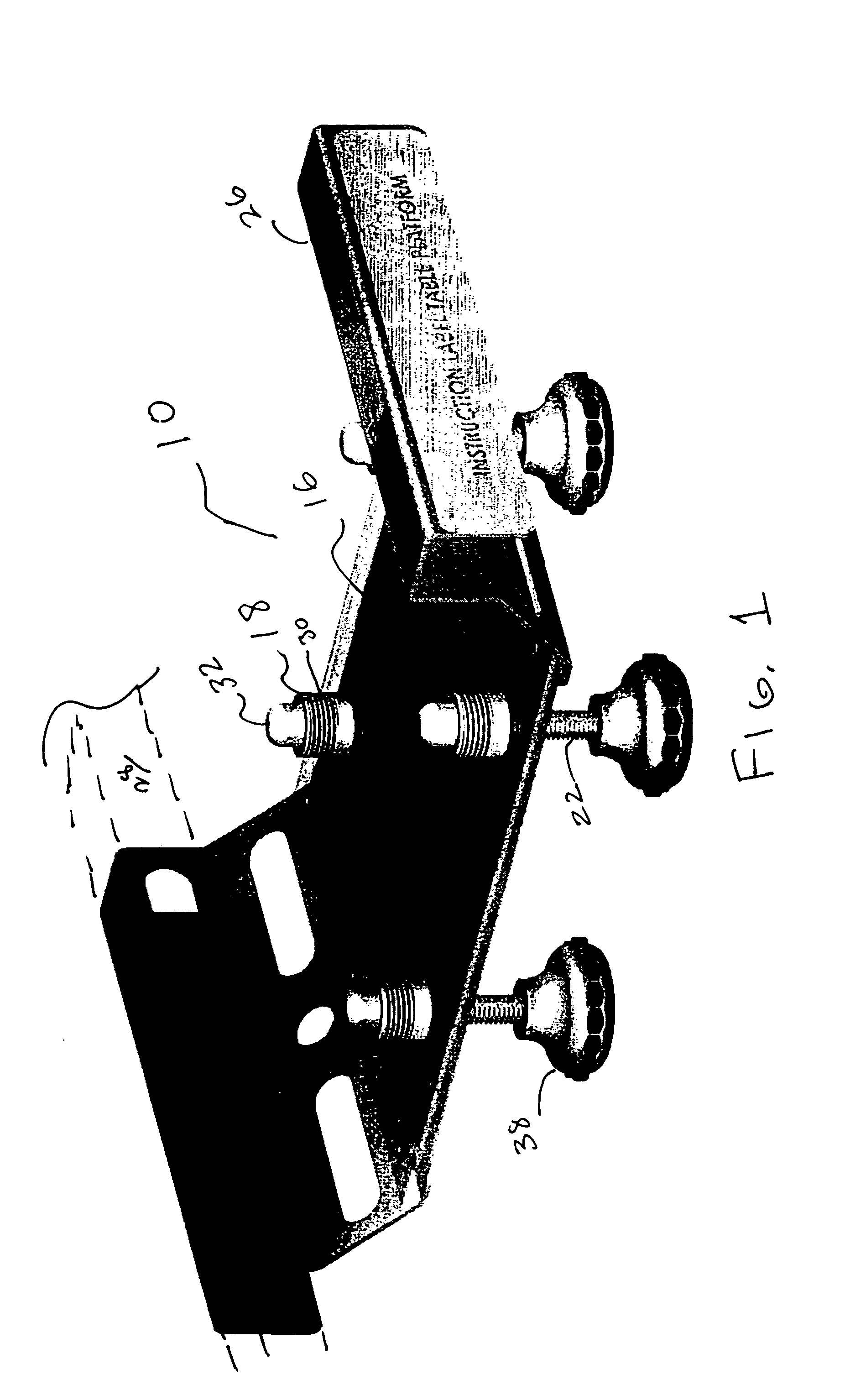

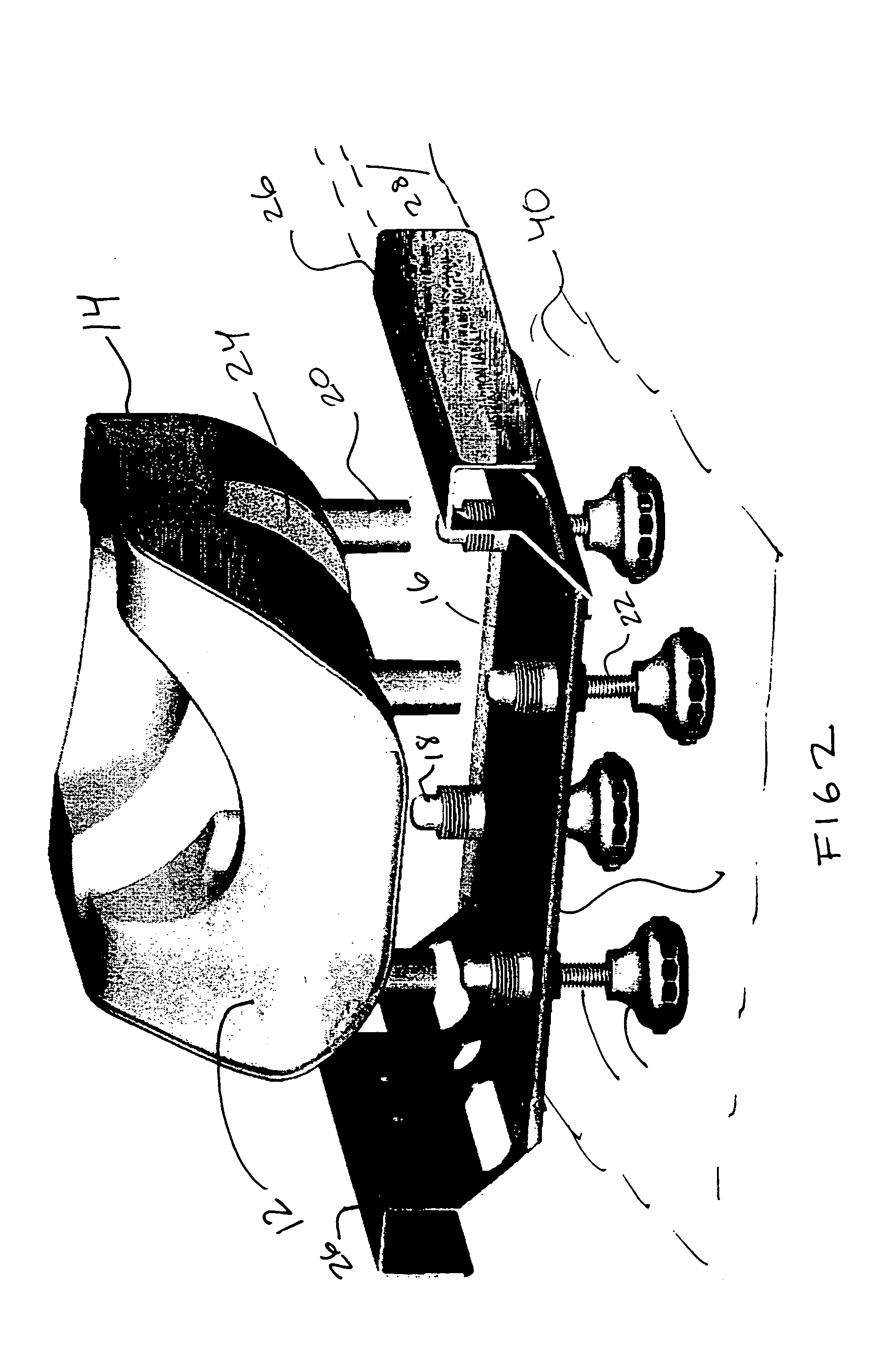

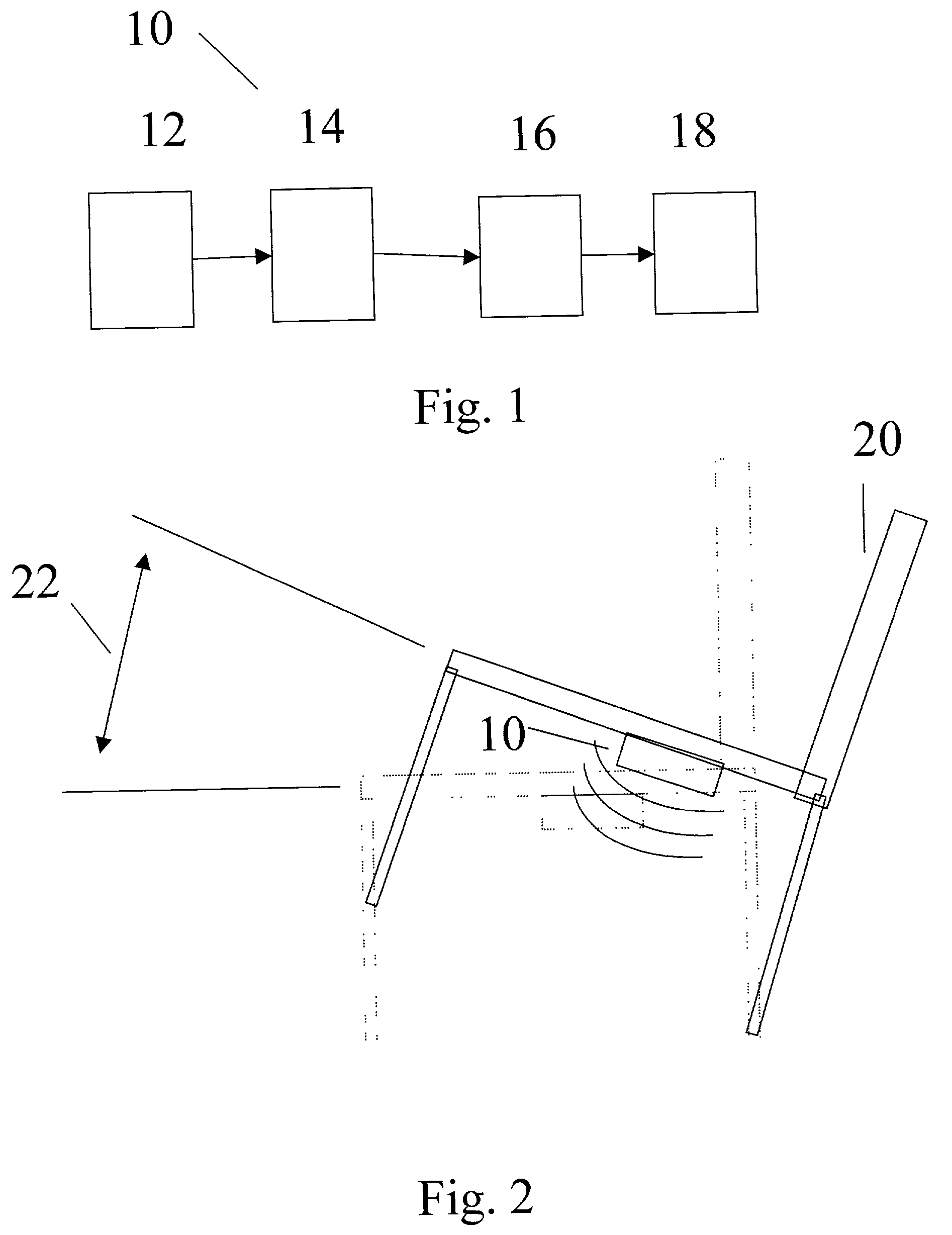

Chair tilt alarm

InactiveUS6392556B2Increase volumeHigh strengthAlarmsKids chairsElectrical and Electronics engineeringBase station

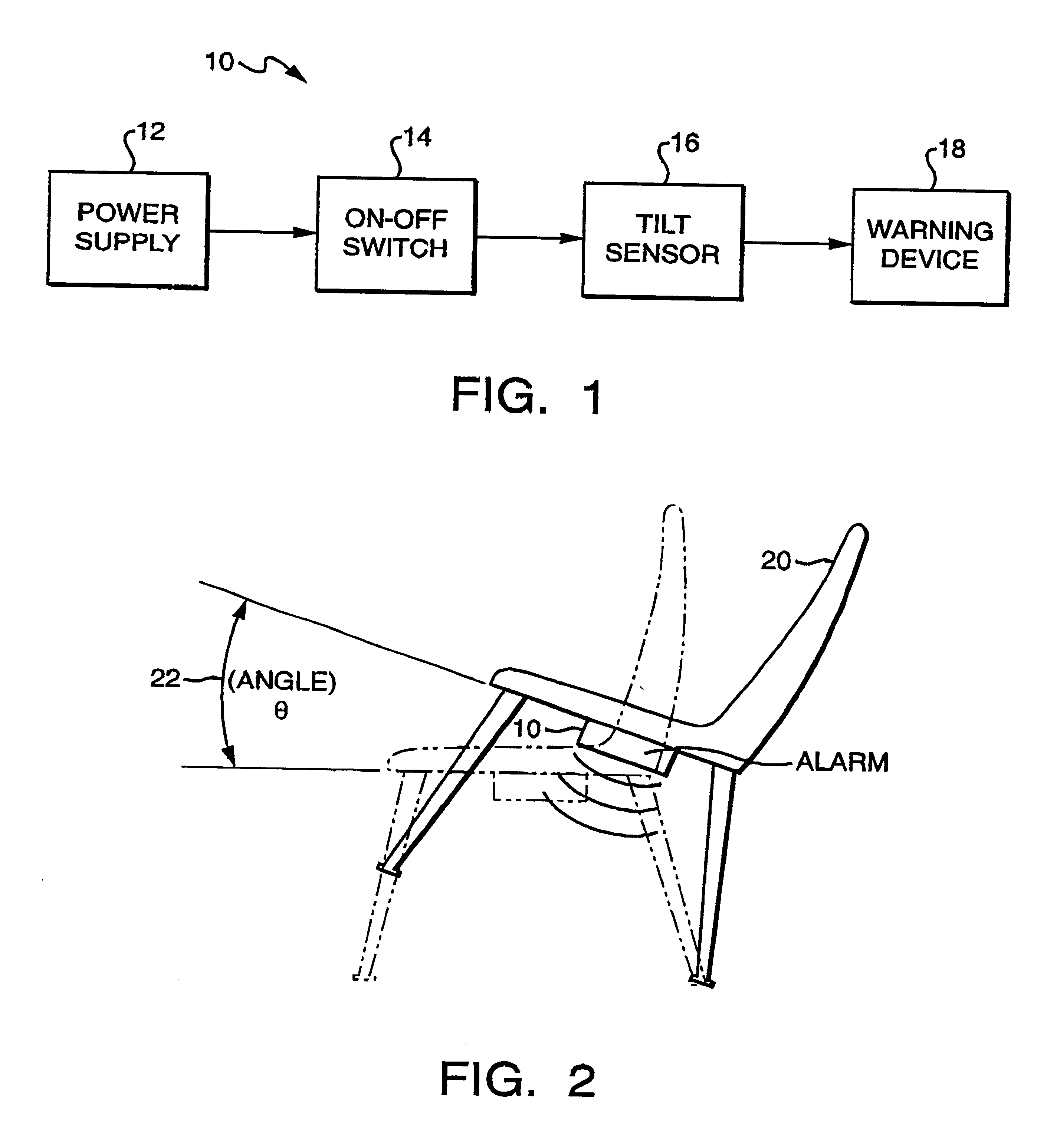

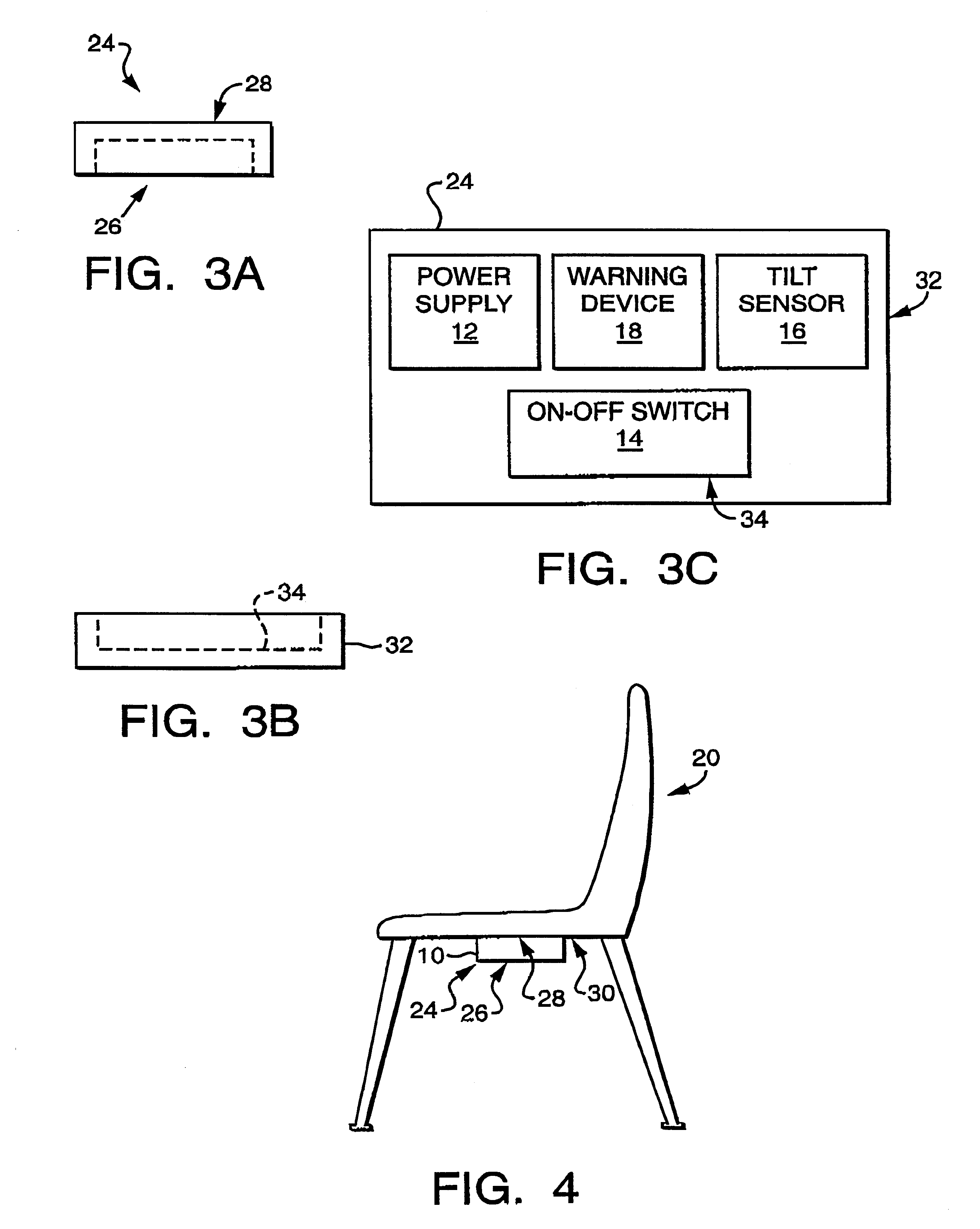

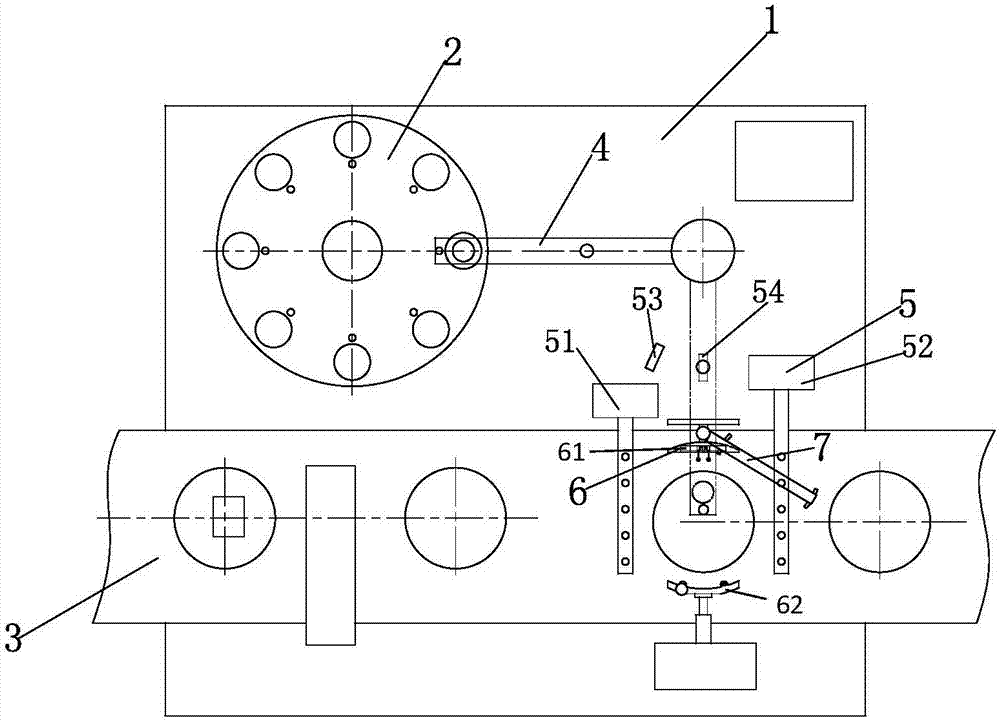

The chair tilt alarm 10 comprises a power supply 12 in electrical communication with an on-off switch 14, a tilt sensor 16, and an warning device 18. The warning device 18 will be activated when the chair 20 is tilted beyond a predetermined angular position 22. As the chair returns toward its righted position, the alarm will deactivate. The chair tilt alarm 10 can be shut off manually or remotely. The chair tilt alarm (10) is also equipped with data storage and transmission modules for reporting of chair tilting at a base station. The chair tilt alarm (10) is also equipped with a counter-balance system to correct the chair to an acceptable position.

Owner:TOMICH DAVID CHRISTOPHER

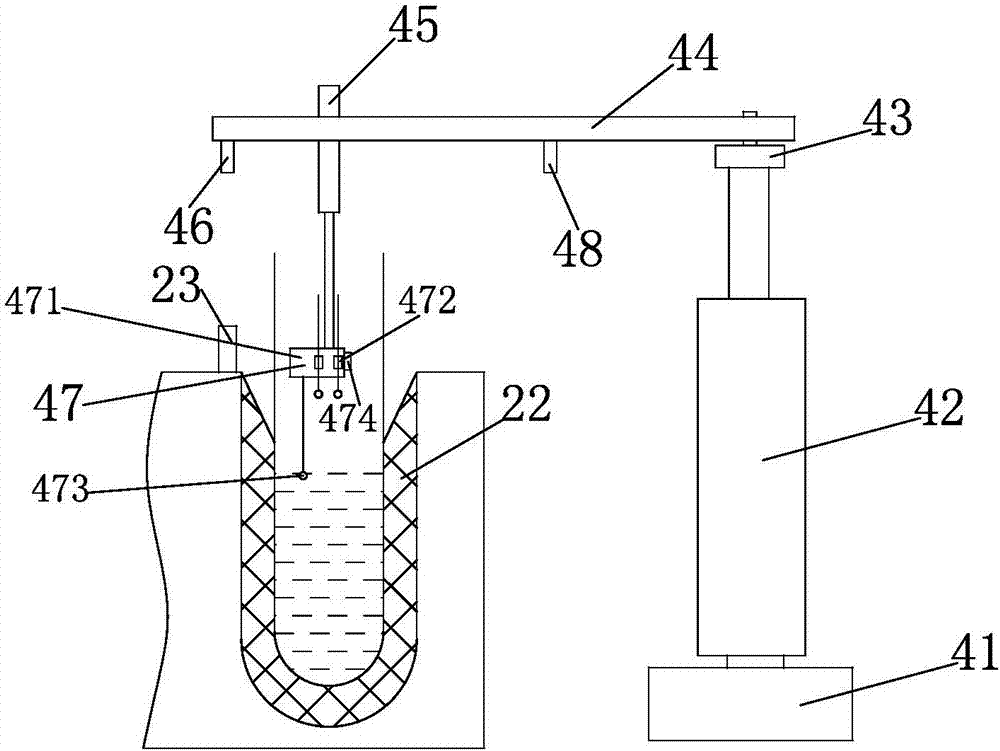

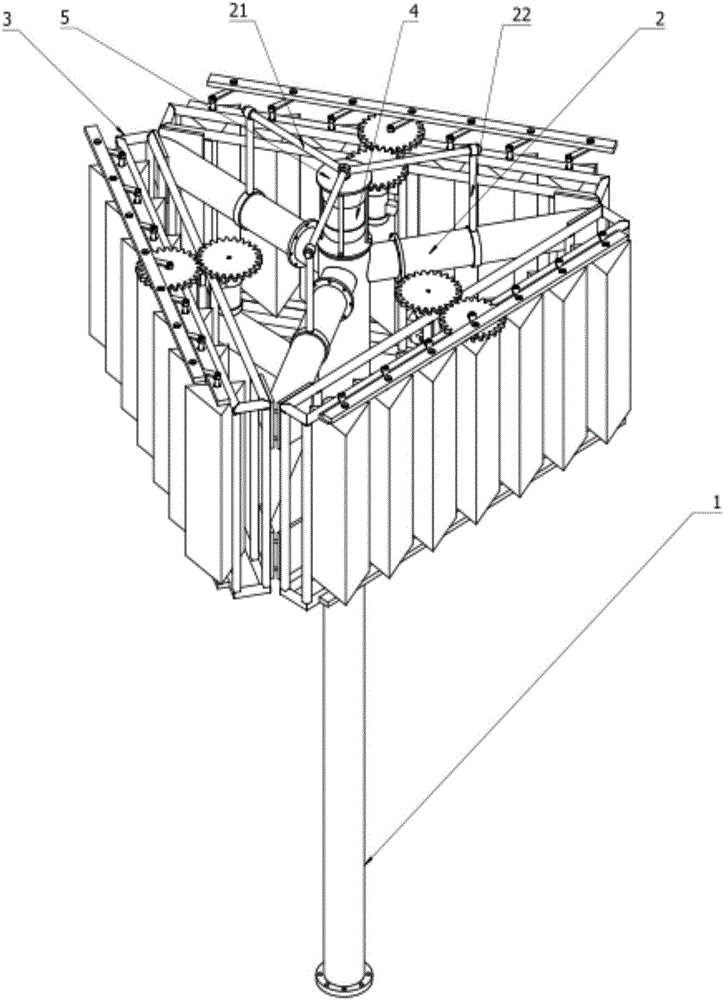

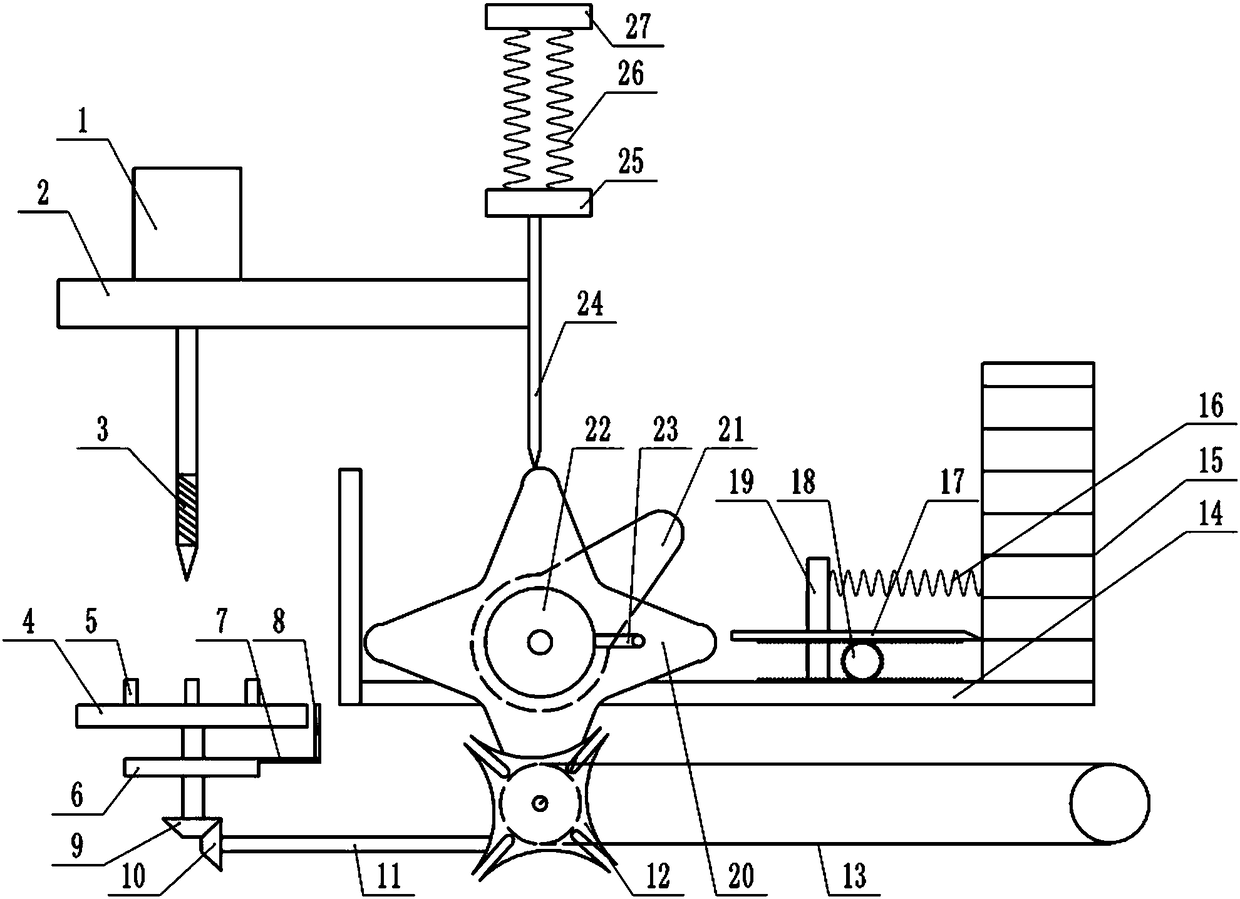

Automatic bacteria inoculator

ActiveCN107118950AImprove work efficiencyRealize automatic sterilizationBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

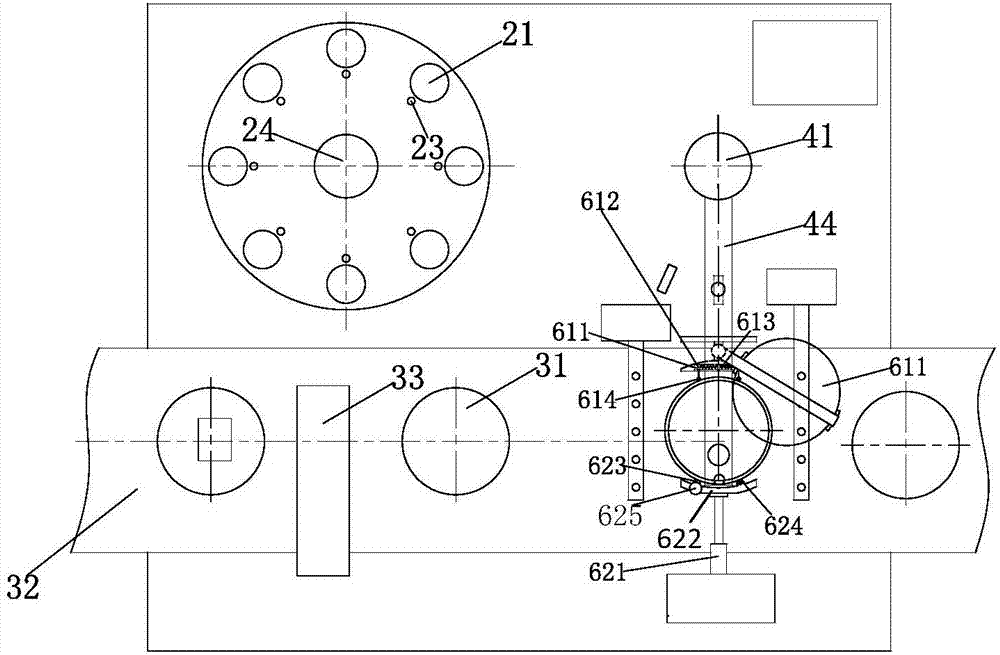

The invention relates to the field of microbiological inspection instruments and apparatus, particularly to an automatic bacteria inoculator comprising an inoculator body, a test tube storage device, a culture dish transferring device, an inoculation device, sterilization devices, a clamping device and a cover fetching device, wherein the test tube storage device is arranged at the rear part of the inoculator body; the culture dish transferring device is mounted in front of the test tube storage device; the inoculation device is distributed on the right side of the test tube storage device; the sterilization devices are arranged on left and right sides of the scribing position of the inoculation device; the cover fetching device is mounted on the inoculator body; and the clamping device is mounted on the inoculator body. The automatic bacteria inoculator adopts instrument operation instead of manual operation, and can automatically sterilize the inoculation environment and a bacteria inoculation ring, shorten the whole inoculation time, improve the working efficiency of bacteria inoculation and scribing, and reach high precision and idealized inoculation effects during bacteria inoculation and scribing.

Owner:GUANGXI WUZHOU SHENGYUAN TEA IND CO LTD

Table engageable support for head cushion supporting anesthetized patient

InactiveUS20050066444A1Lateral shock dampening abilityEasy to adjustOperating tablesSofasProne positionEngineering

A support for the head of a patient lying in a generally prone position. The support features a tray adapted for support on an underlying operating table surface. A plurality of pins projecting from an engagement with the tray are positioned to engage and suspend either a cushion directly or a cushion engaged in a casing. The pins may be adjusted to raise or lower the engaged cushion or casing. A mirror is also provided to view a patient's eyes through slots in the cushion and casing engaged over a patient's face.

Owner:DUPACO

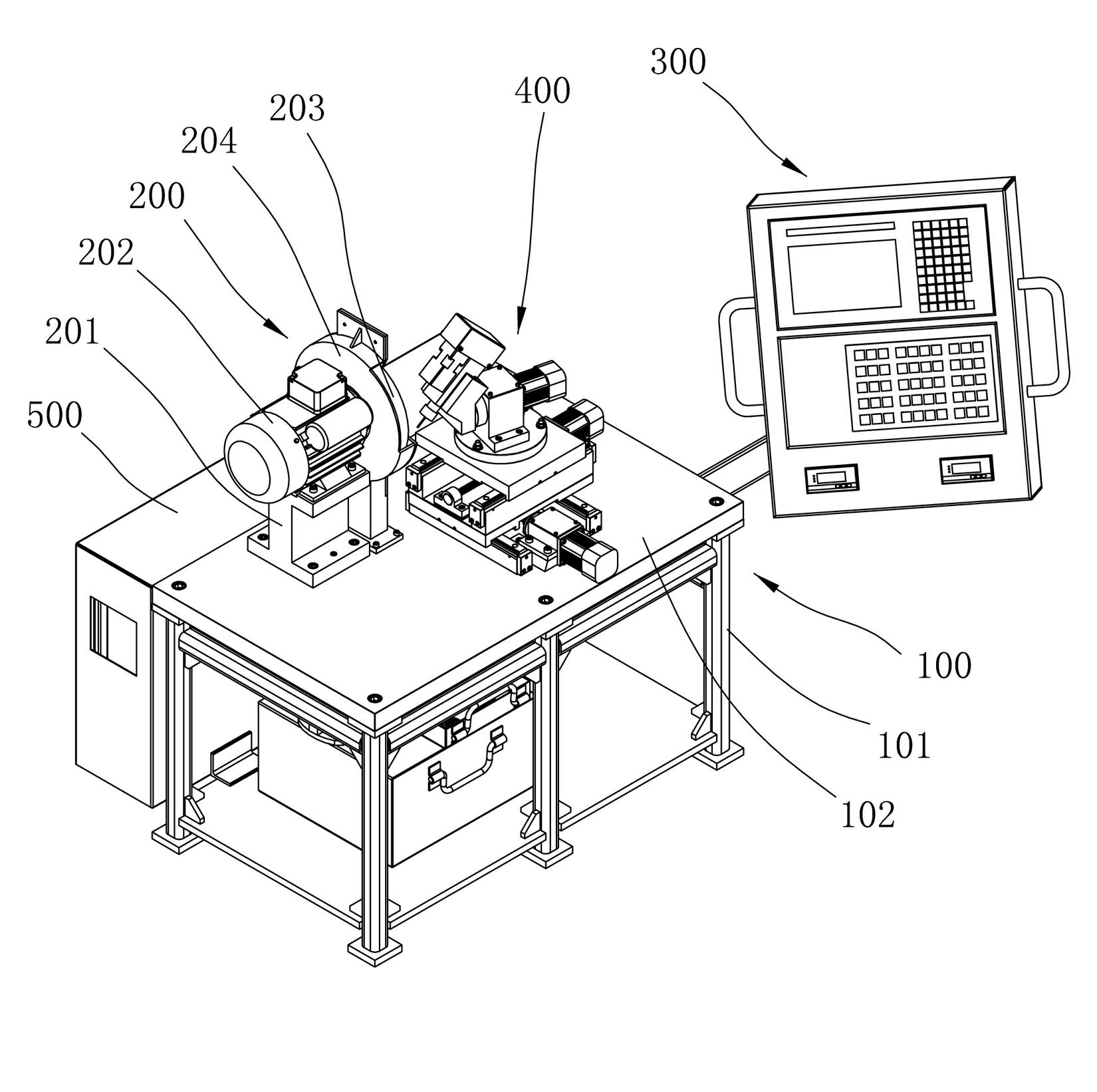

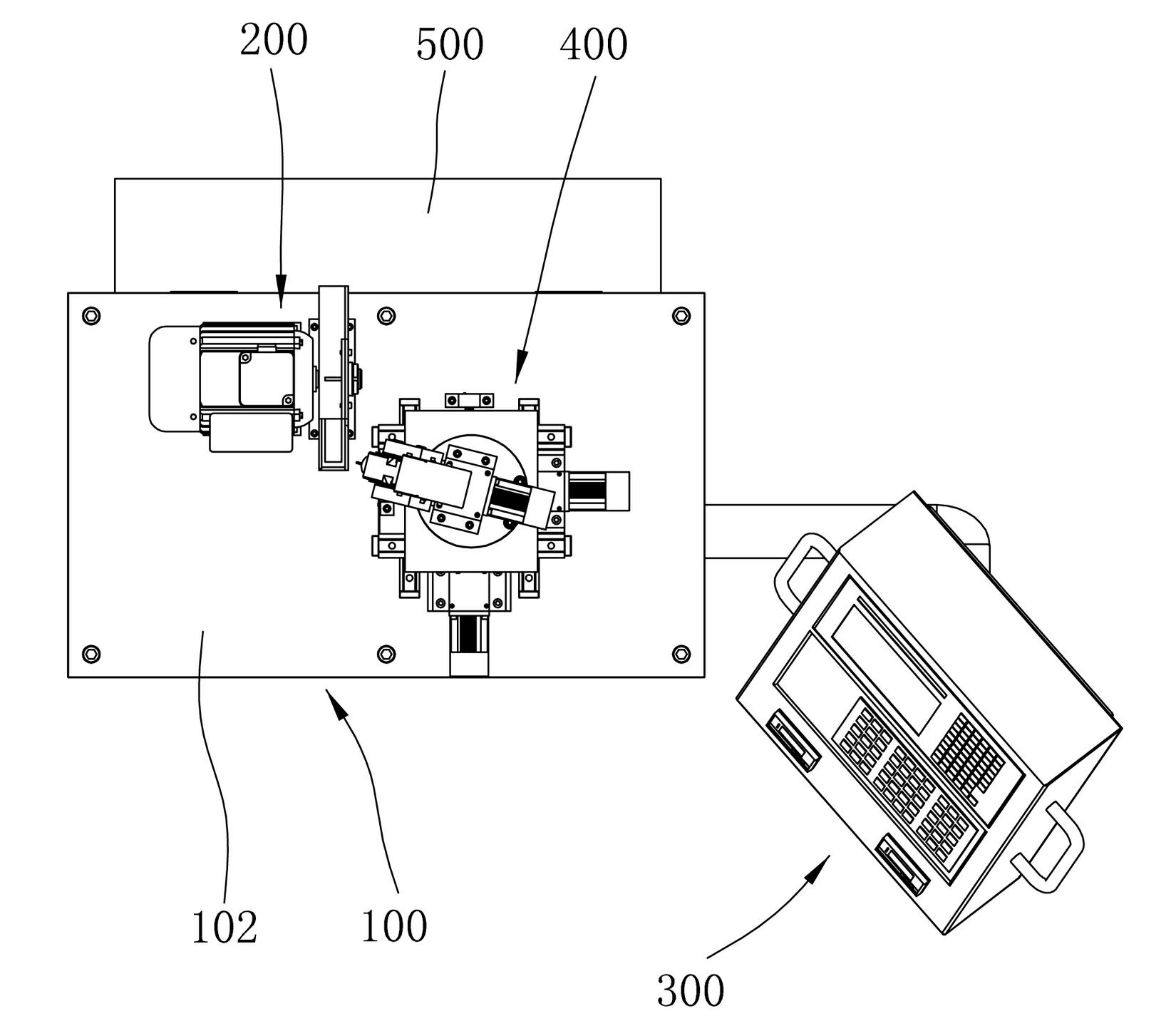

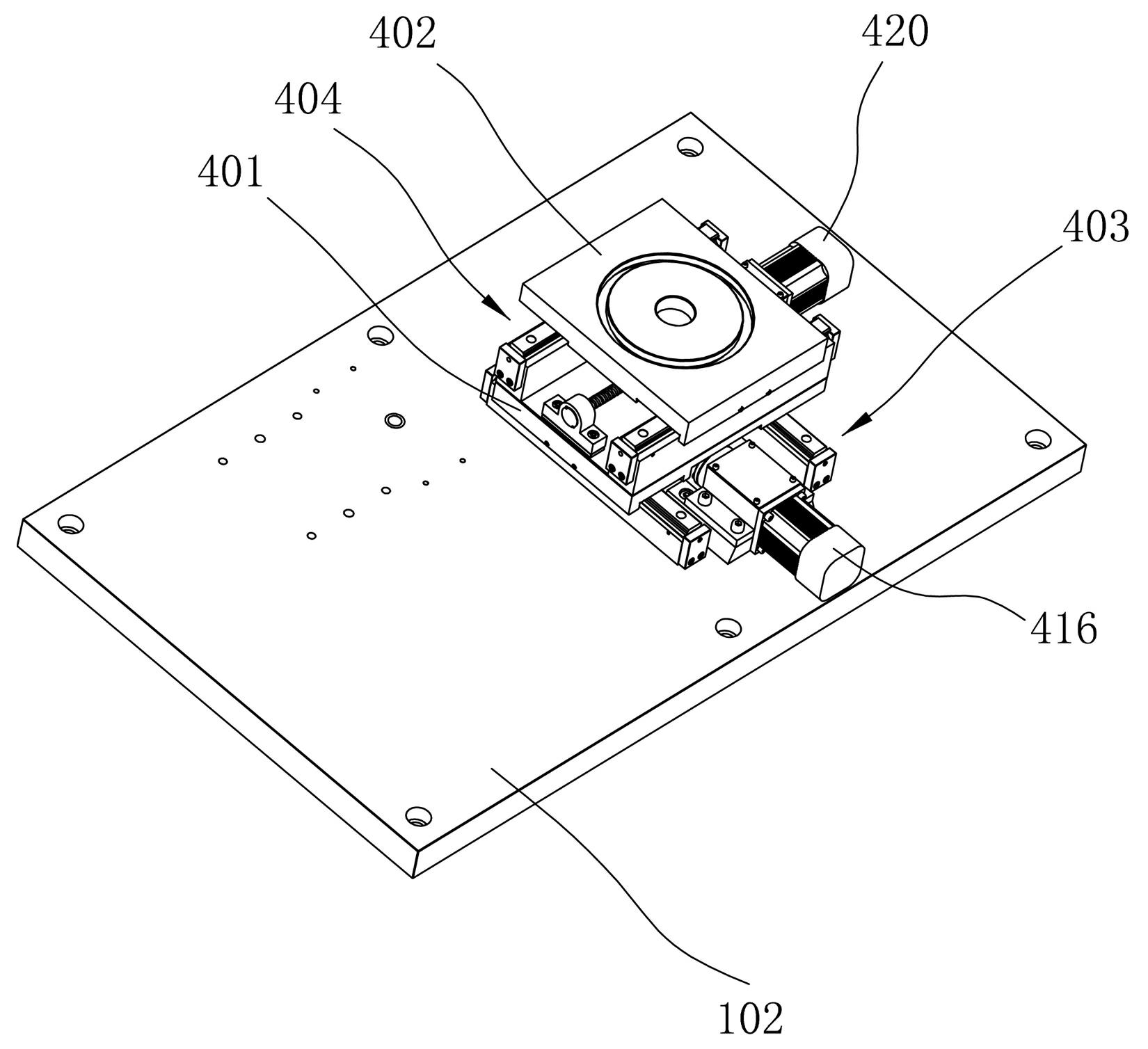

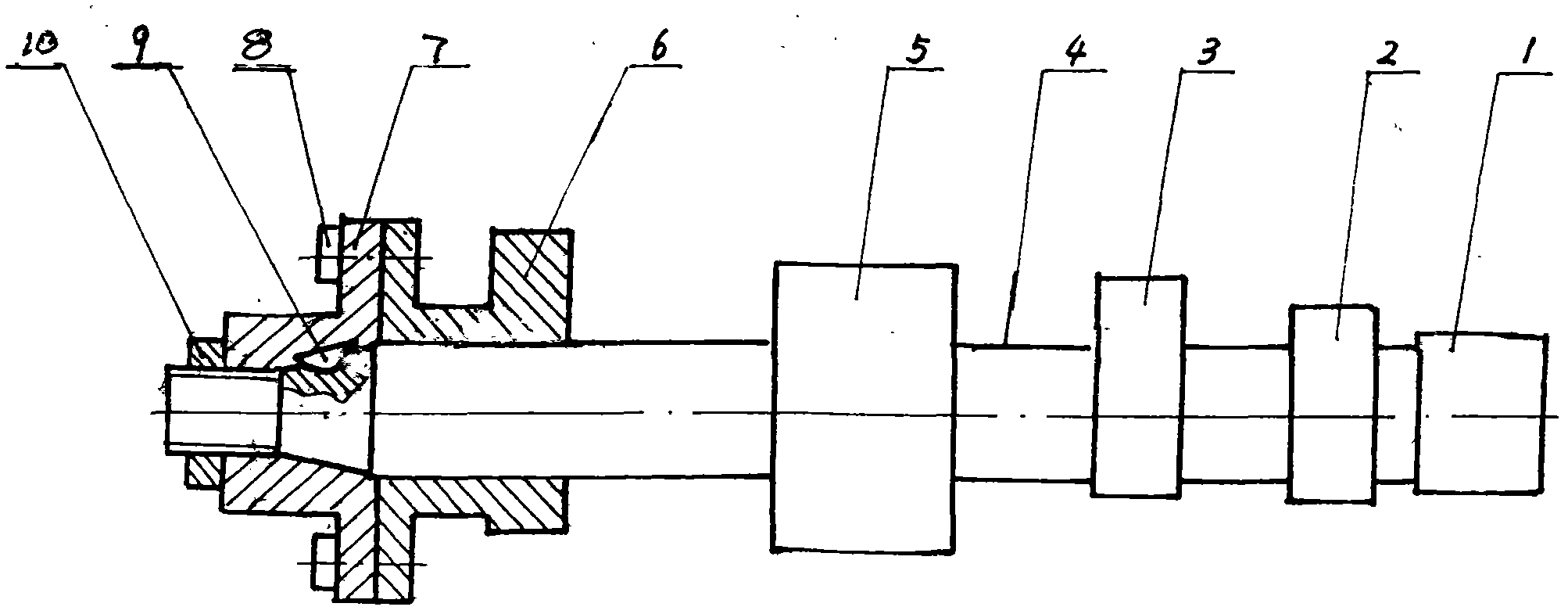

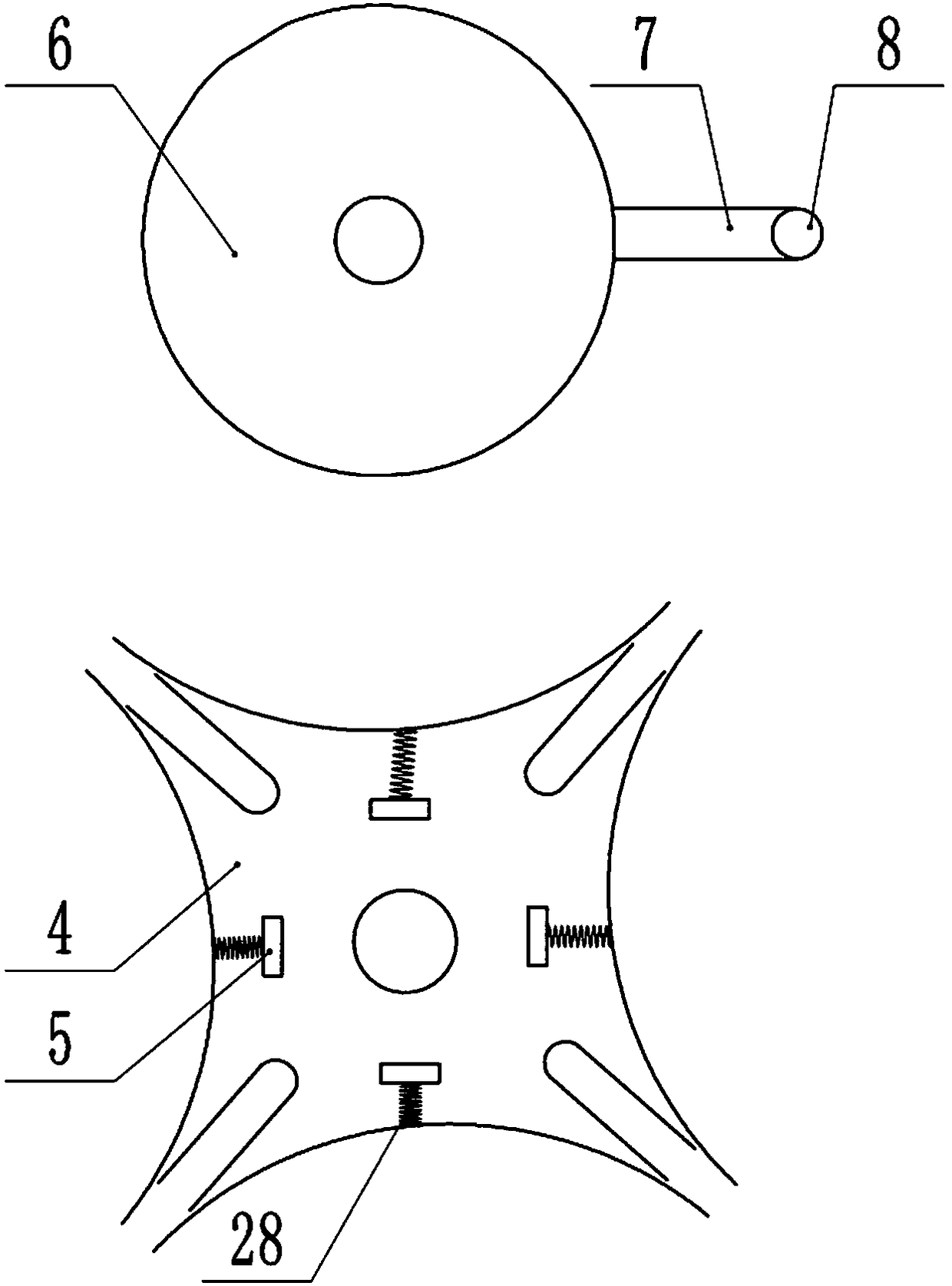

Blade grinding machine for external conical surface of drill

InactiveCN102632436AFlexible operationRun fastDrilling toolsGrinding work supportsNumerical controlEngineering

The invention discloses a blade grinding machine for an external conical surface of a drill, belonging to the technical field of advanced manufacturing system and numerical control machining. The blade grinding machine is controlled by employing a motor and a servo system; a main shaft block is driven by a first guiding device to move in the first direction, while a tool rest mounting base is driven by a second guiding device to move in the second direction; and then a tool rest is rotated by a tool rest driving motor and a main shaft is rotated by a main shaft driving motor, so that a four-dimensional numerical control technology of drill blade grinding is realized and the running of the blade grinding machine provided by the invention is very flexible; in addition, a human-machine operation interface of the blade grinding machine is visual so that the change in the drill blade grinding process can be directly observed; the machine is high in running speed and accurate in angle; any grinding angle of the drill can be adjusted; the difficulty in drill angle adjustment during processing is completely solved; and the blade ground surface of the drill after grinding is bright; therefore, the quality problem of short service life of the drill in the production process is effectively improved; the utilization rate of the drill is greatly brought into play; and the processing efficiency of a product is improved.

Owner:郝玉民

Chair tilt alarm

The chair tilt alarm 10 comprises a power supply 12 in electrical communication with an on-off switch 14, a tilt sensor 16, and an warning device 18. The warning device 18 will be activated when the chair 20 is tilted beyond a predetermined angular position 22. As the chair returns toward its righted position, the alarm will deactivate. The chair tilt alarm 10 can be shut off manually or remotely. The chair tilt alarm (10) is also equipped with data storage and transmission modules for reporting of chair tilting at a base station. The chair tilt alarm (10) is also equipped with a counter-balance system to correct the chair to an acceptable position.

Owner:TOMICH DAVID CHRISTOPHER

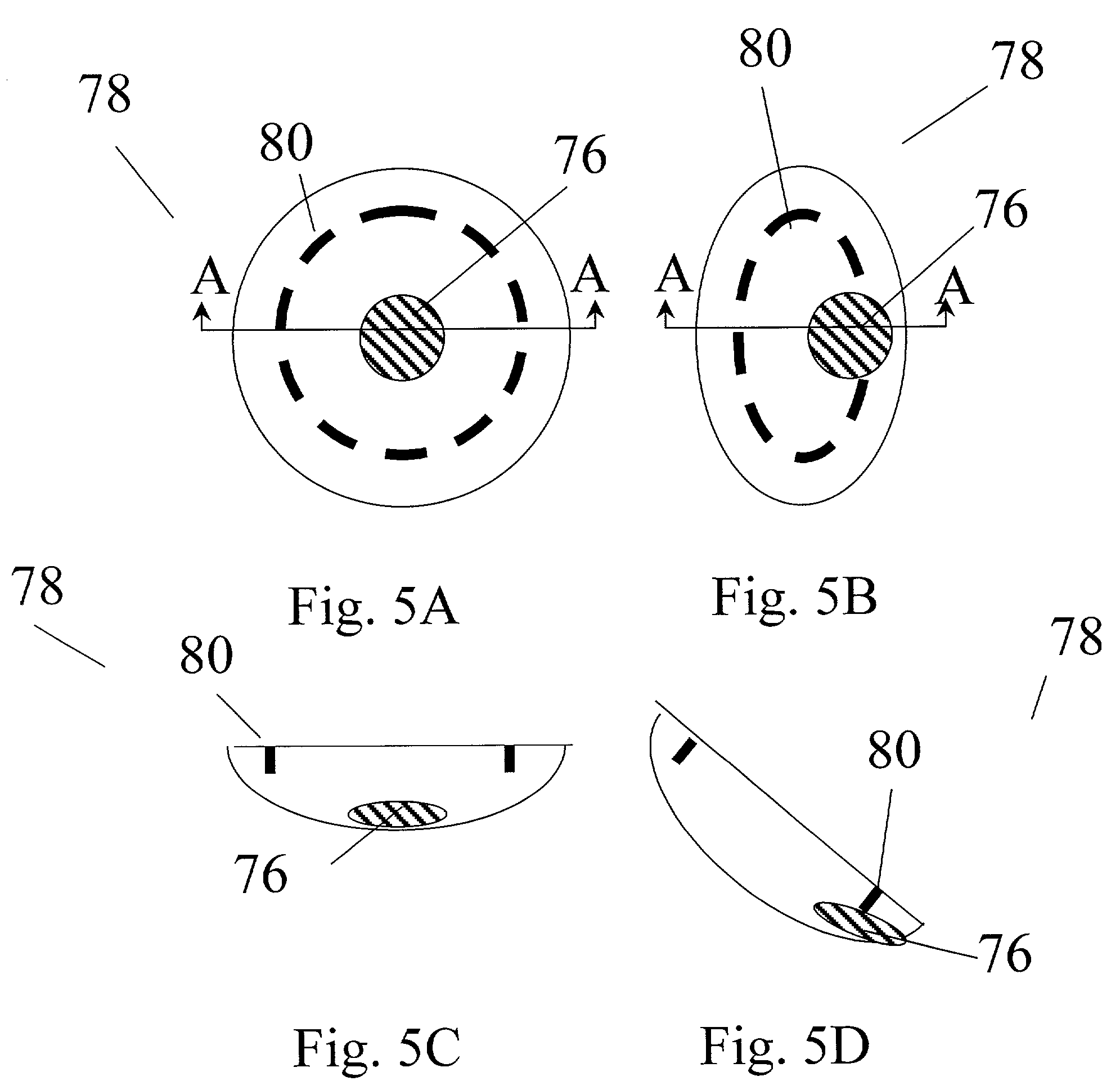

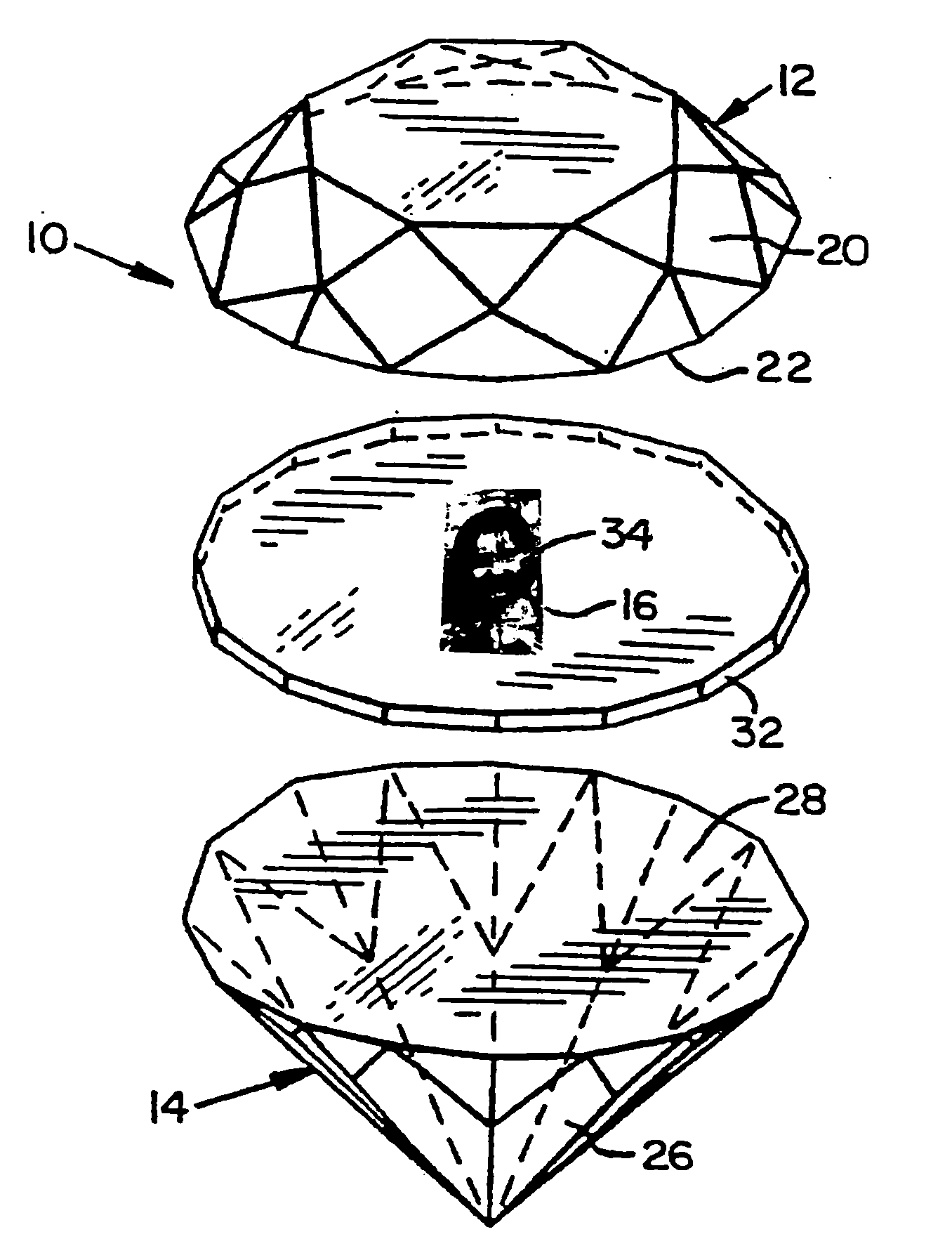

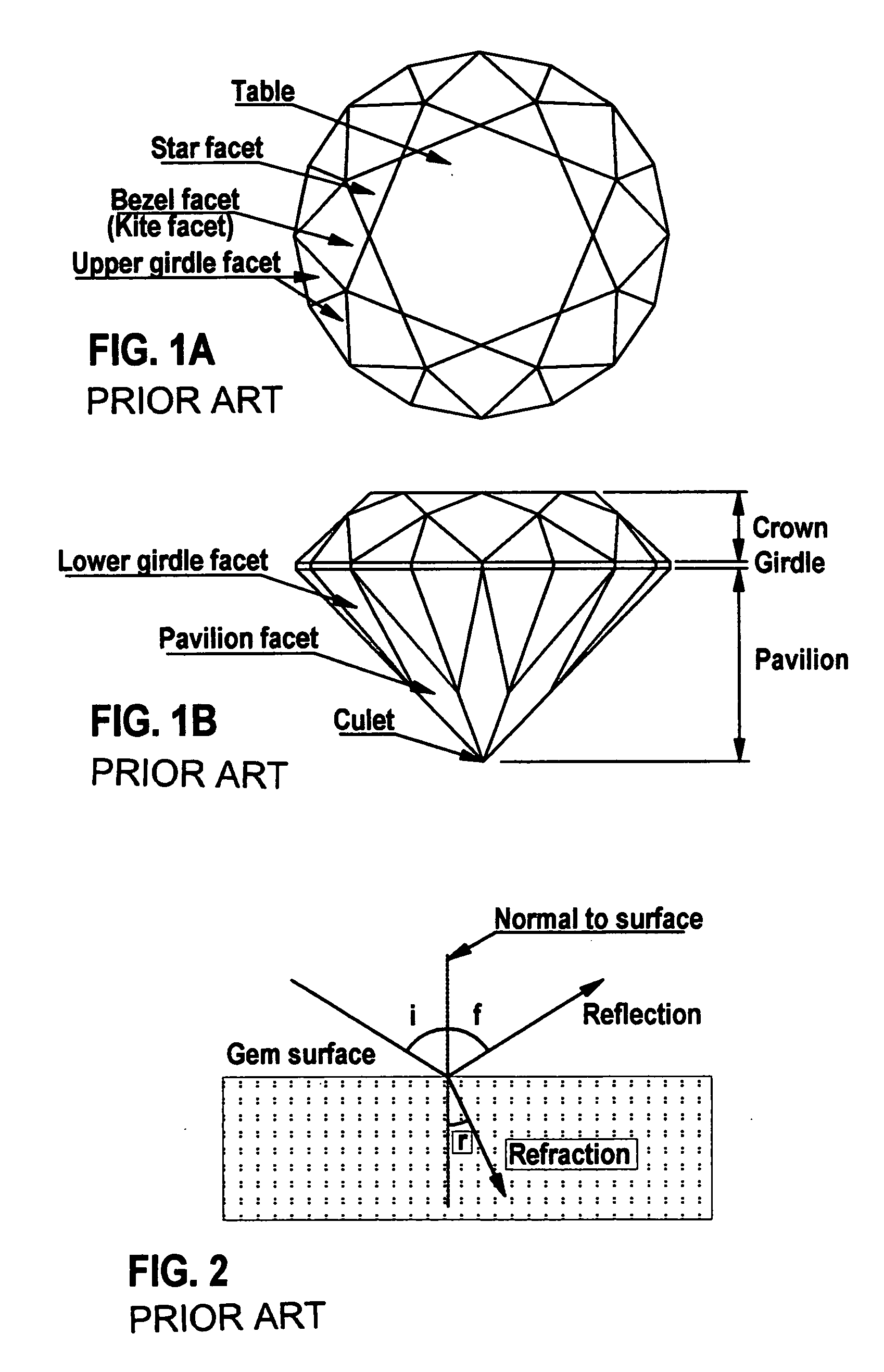

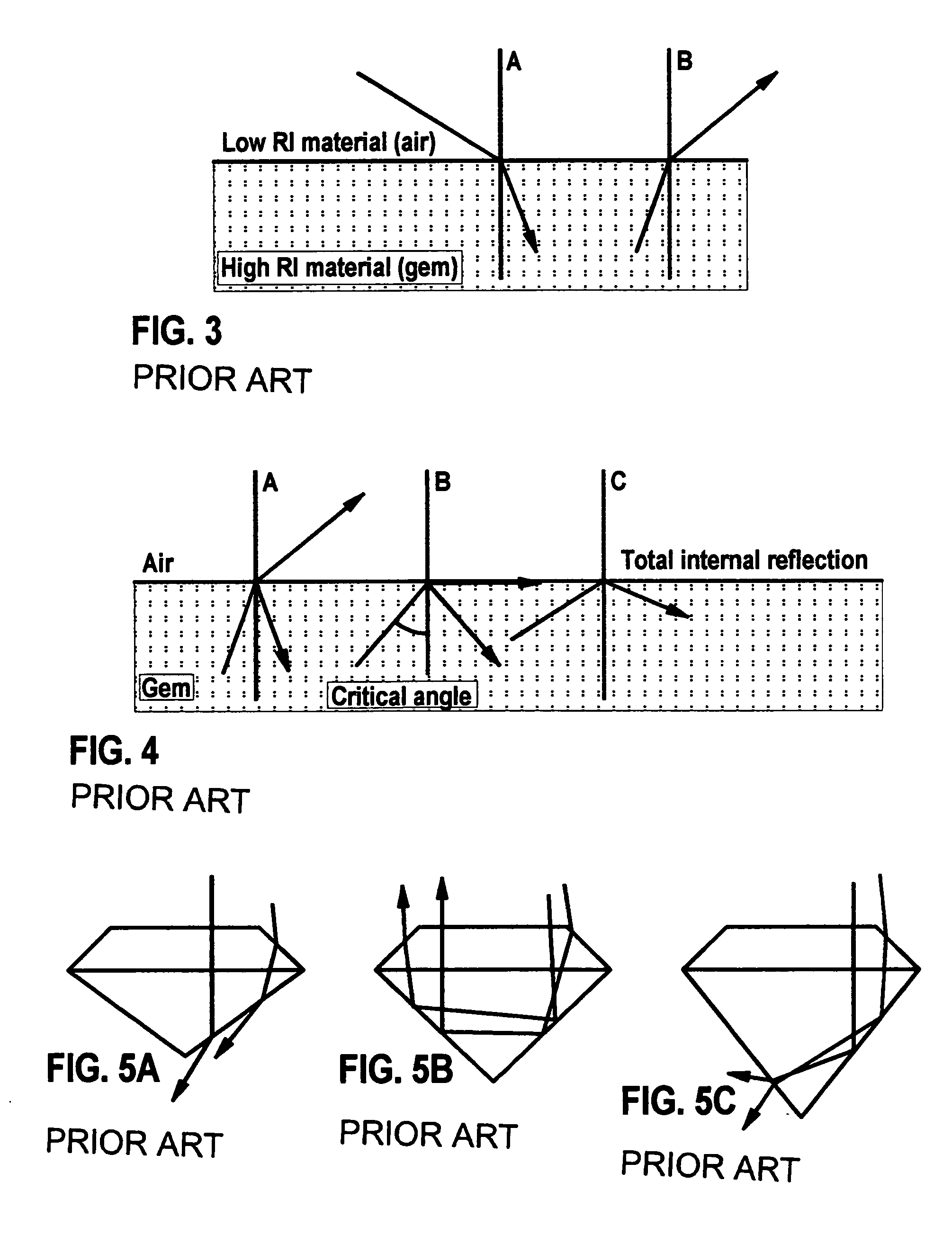

Multiplet jewelry product and method of manufacture

A multiplet jewelry product constructed of two or more layers of gemstone material affixed together with a transparent film disposed therebetween to form a composite unit. A translucent image is imprinted on the transparency film whereby refracted and reflected light is directed through the image imbedded within the gemstone product.

Owner:SIGNITY AMERICAS

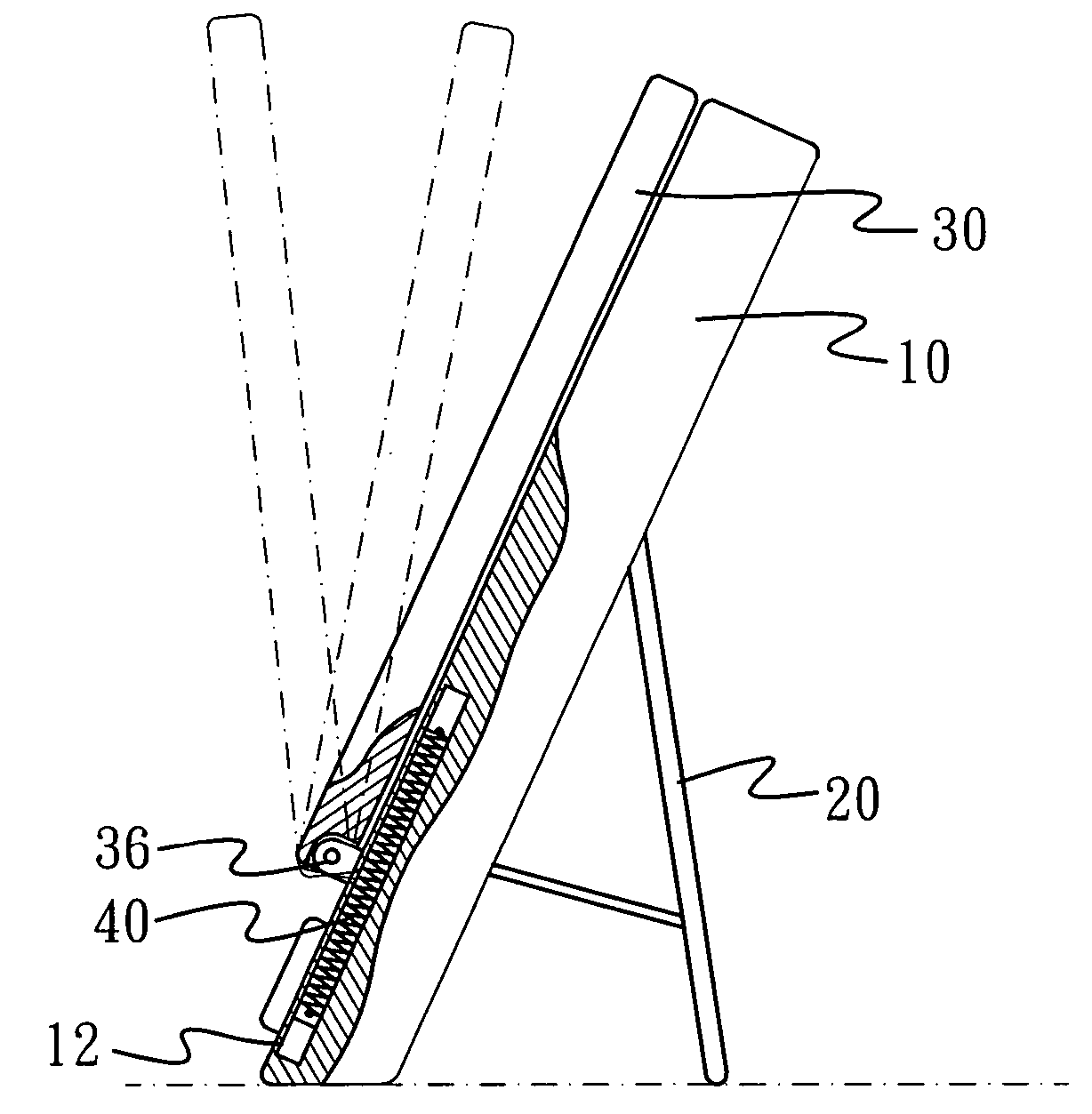

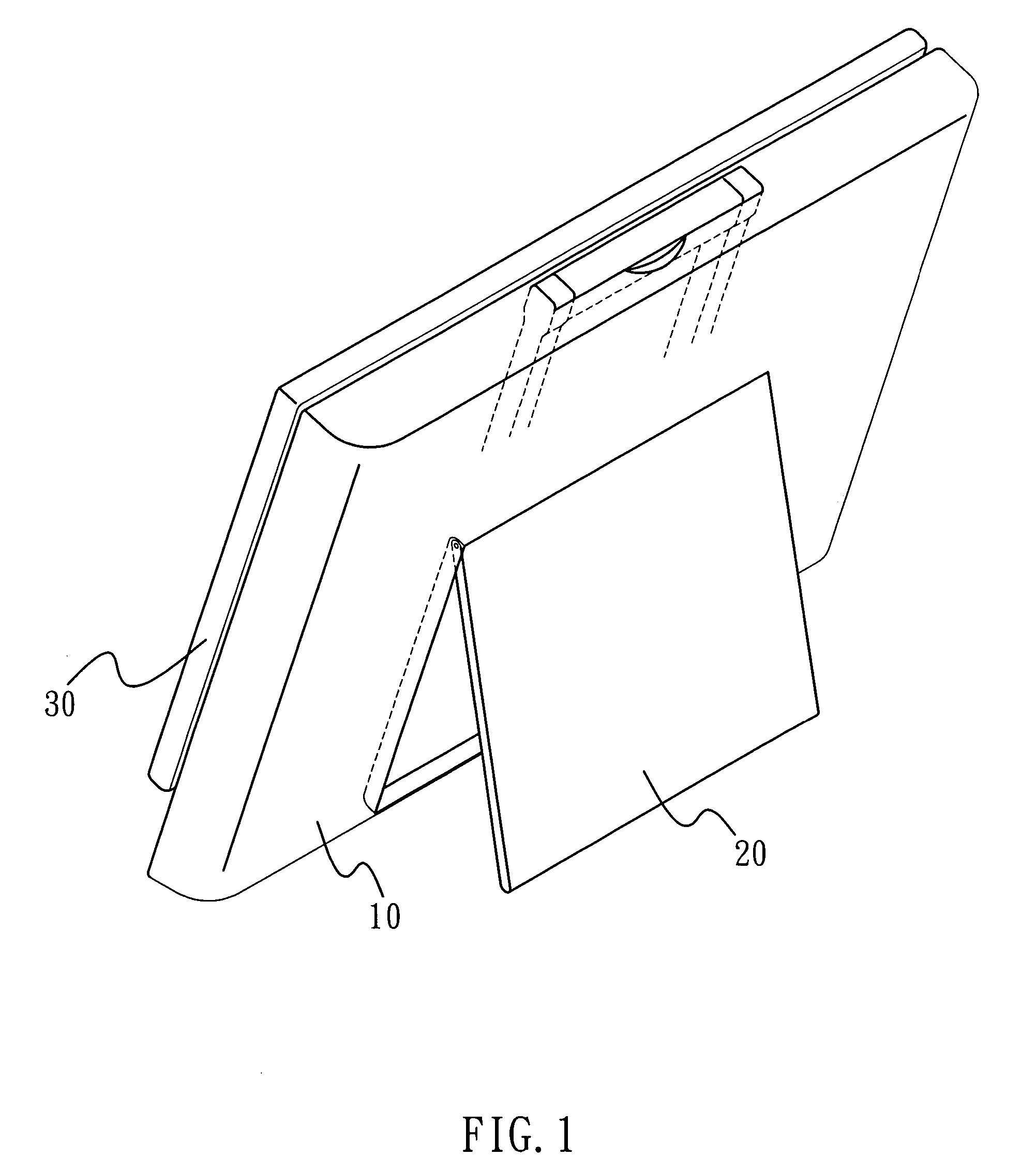

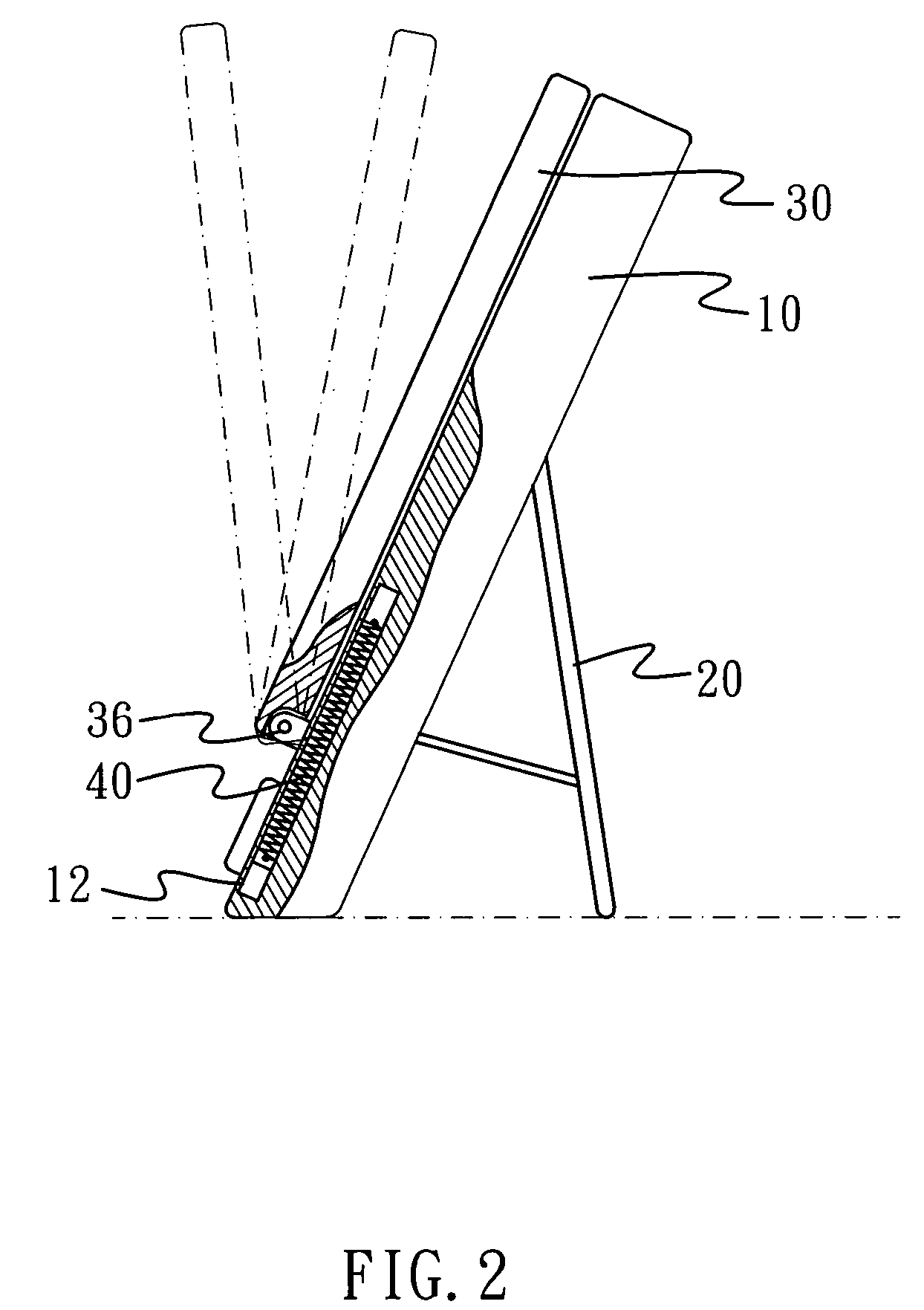

Display moveable in two dimensions

A display movable in two dimensions is disclosed, comprising a base having a track, a sliding member having a frame for supporting a display panel, a sliding bump disposed slidably in said track and on which said frame is connected pivotally and swings in a direction, and a pair of dampers disposed between the sliding member and the base. As such, a longitudinal position and a pitch angle of the display may be adjusted by moving the display in a longitudinal direction and swinging the display in a user's view direction.

Owner:SOLE OPTOELECTRONICS SIHONG CO LTD

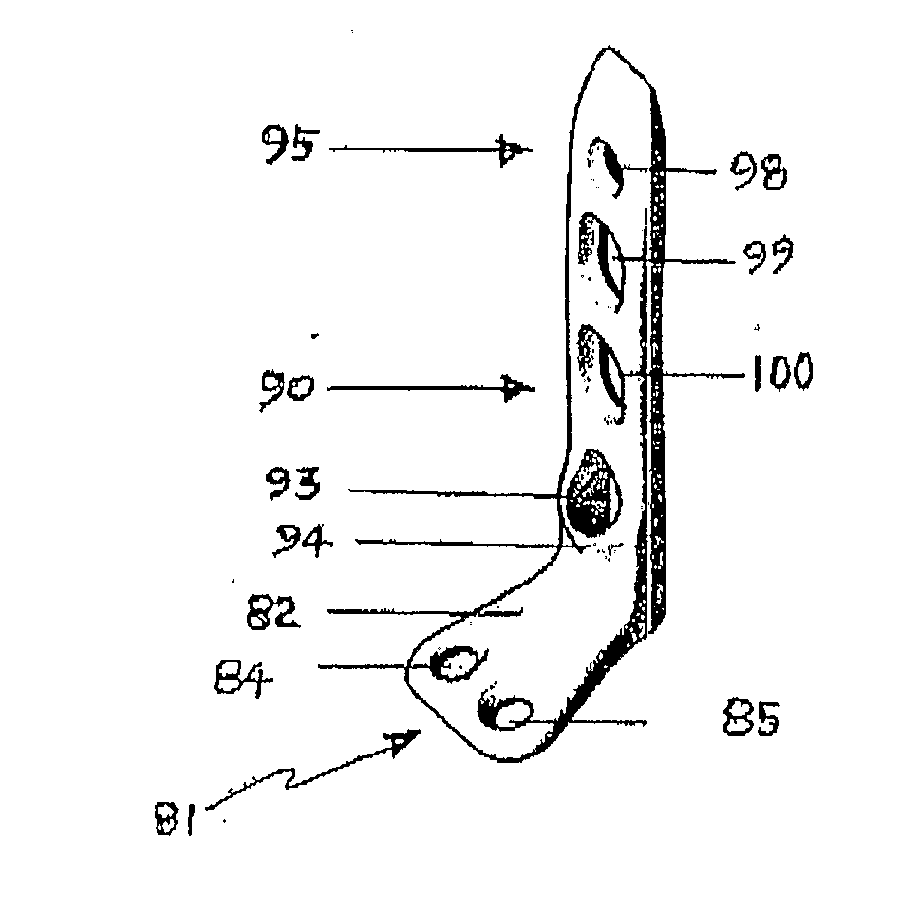

Ankle Fusion Plate

InactiveUS20110184413A1Reduce thicknessPermit recalcification and bondingJoint implantsBone platesJoint arthrodesisAnkle fusions

Owner:SLATER GORDON

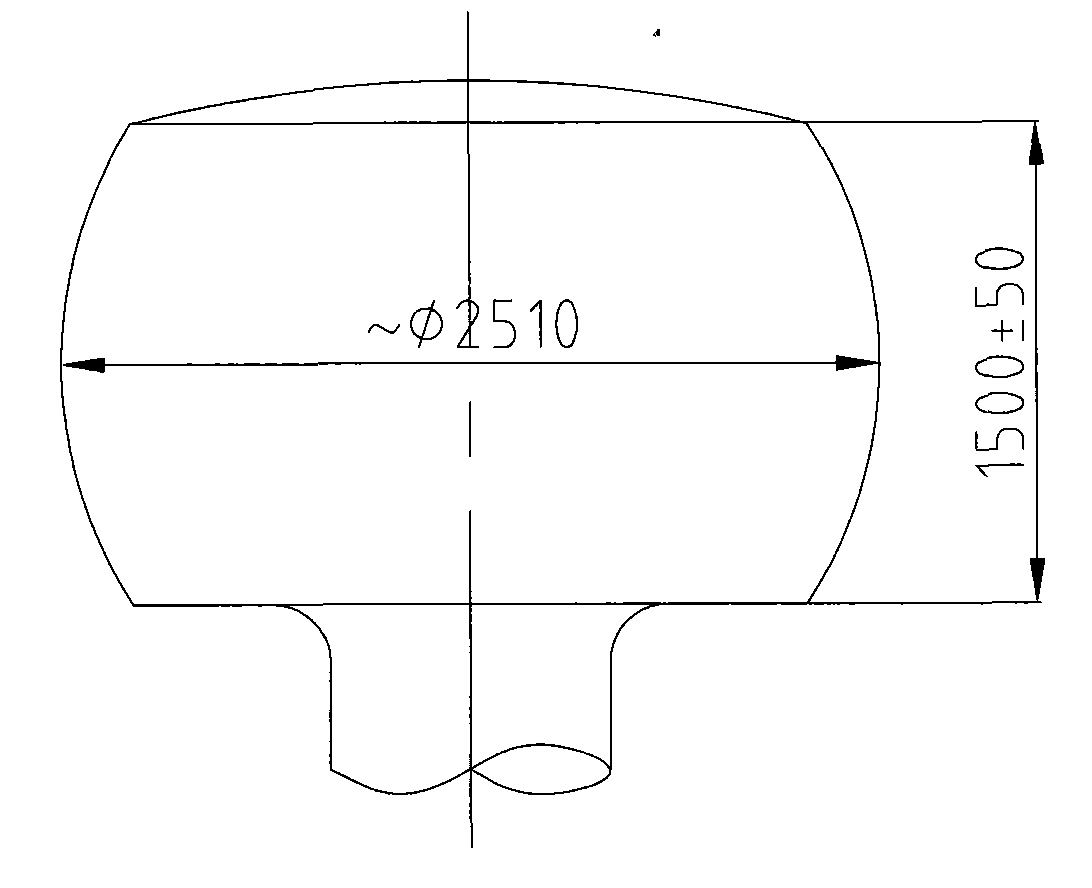

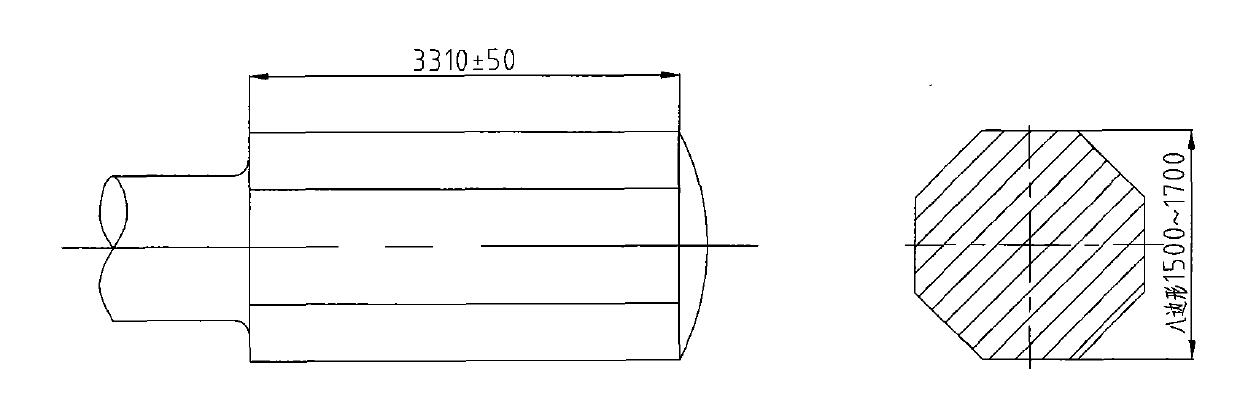

Forging method of main pipe blank with branch pipe nozzles used in nuclear power station

The invention discloses a forging method for a main pipe blank with branch pipe nozzles used in a nuclear power station, comprising following steps: firstly, rolling the ingot body of a forged piece, pressing the ingot to form a clamping handle; secondly, upsetting the ingot; thirdly, drawing out the ingot, and determining the directions of the branch pipe nozzles; fourthly, marking the forged piece, and heating the forged piece to the temperature of 1180 to 1220 DEG C, determining the dimension of each segment to be forged according to the weight of each segment; fifthly, drawing out the straight pipe segment to the preset dimension of the forged piece; sixthly, drawing out the two branch pipe nozzles, and making sure that the angle formed by the two branch pipe nozzles is 45 DEG. The invention is advantageous in that the branch pipe nozzles configured to form an angle can be accurately forged on the pipe wall of the main pipeline, and the properties of the branch pipe nozzles are stable, thereby the main pipe blank with branch pipe nozzles accords with the design requirements of the AP1000 nuclear power station.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

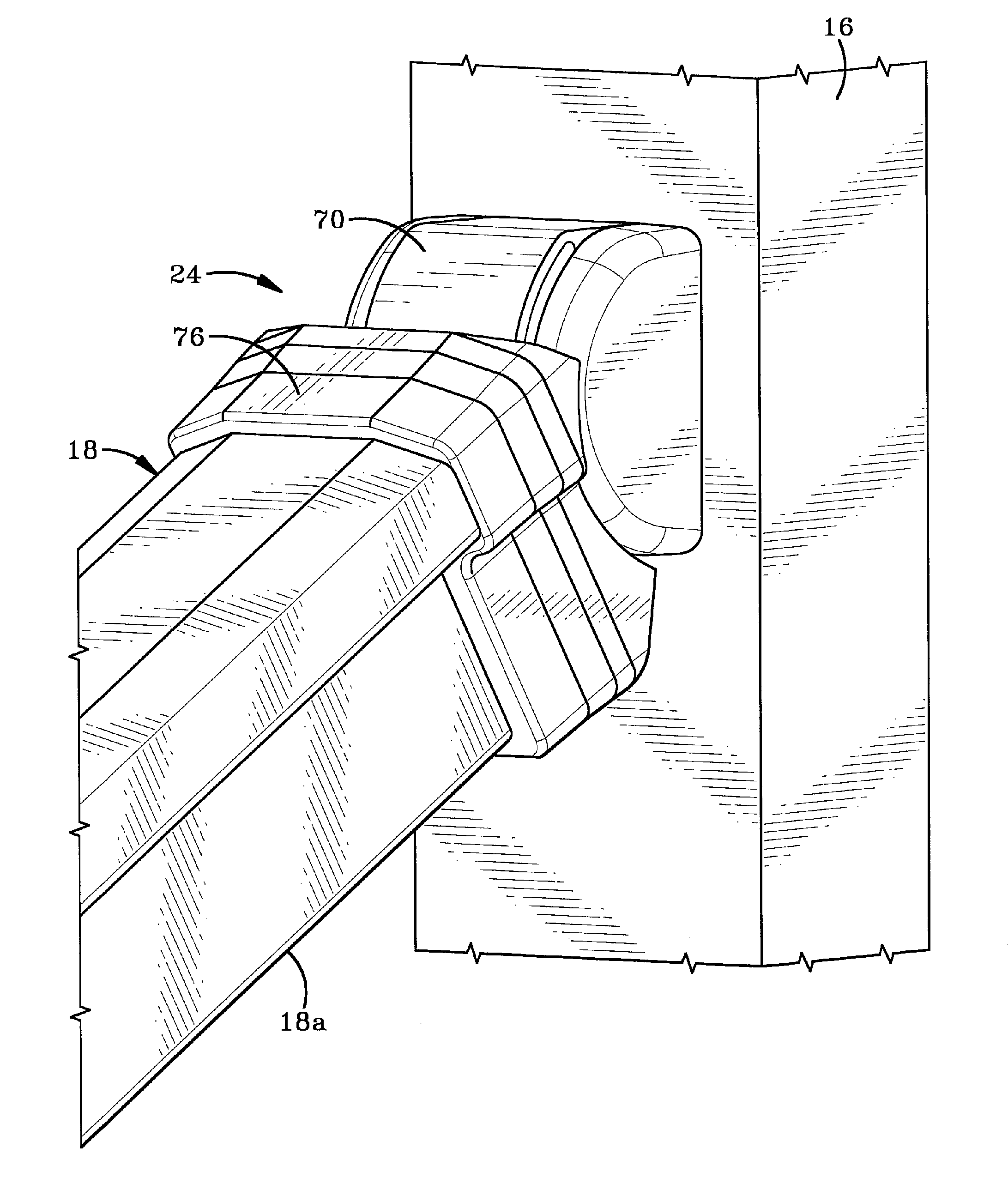

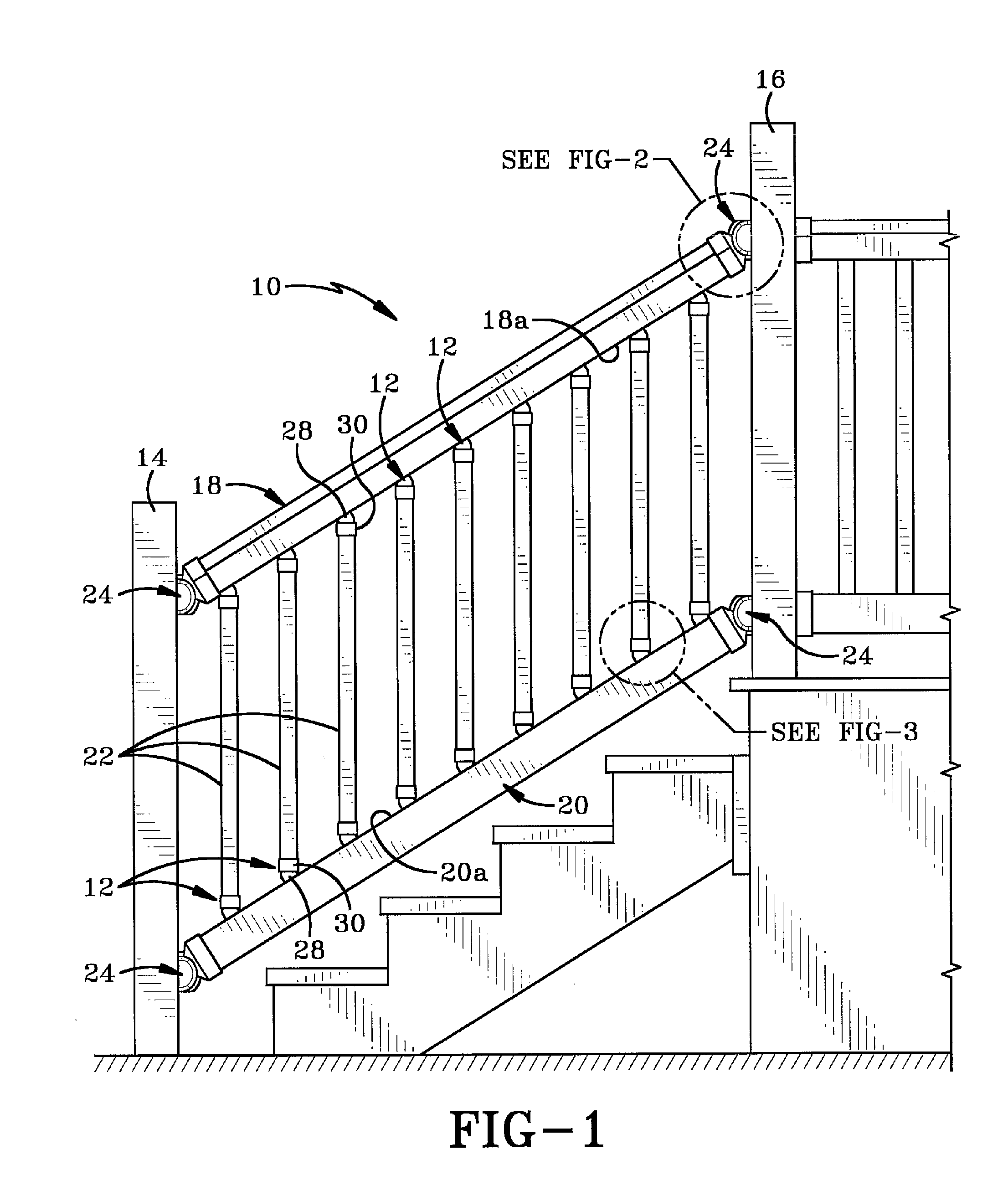

Method and apparatus for attaching spindles to rails in a fence assembly

A racking assembly for adjustably mounting a spindle to a rail. The racking assembly includes a first member which engages the rail and a second member pivotally secured to the first member. The second member retains the spindle at an angle relative to the first member and therefore relative to the rail. As the second member pivots, the angle of the spindle relative to the rail is changed. In a fence rail assembly, each spindle is secured between a pair of rails by a pair of racking assemblies. Each racking assembly is mounted on one of the rails and is individually adjustable so as to set the angle of the spindle relative to the rails. The rails are secured between a pair of vertical posts. Each rail is secured to one of the posts by a bracket that is adjustable to set the angle of the rail relative to the posts.

Owner:PLATT ROBERT E

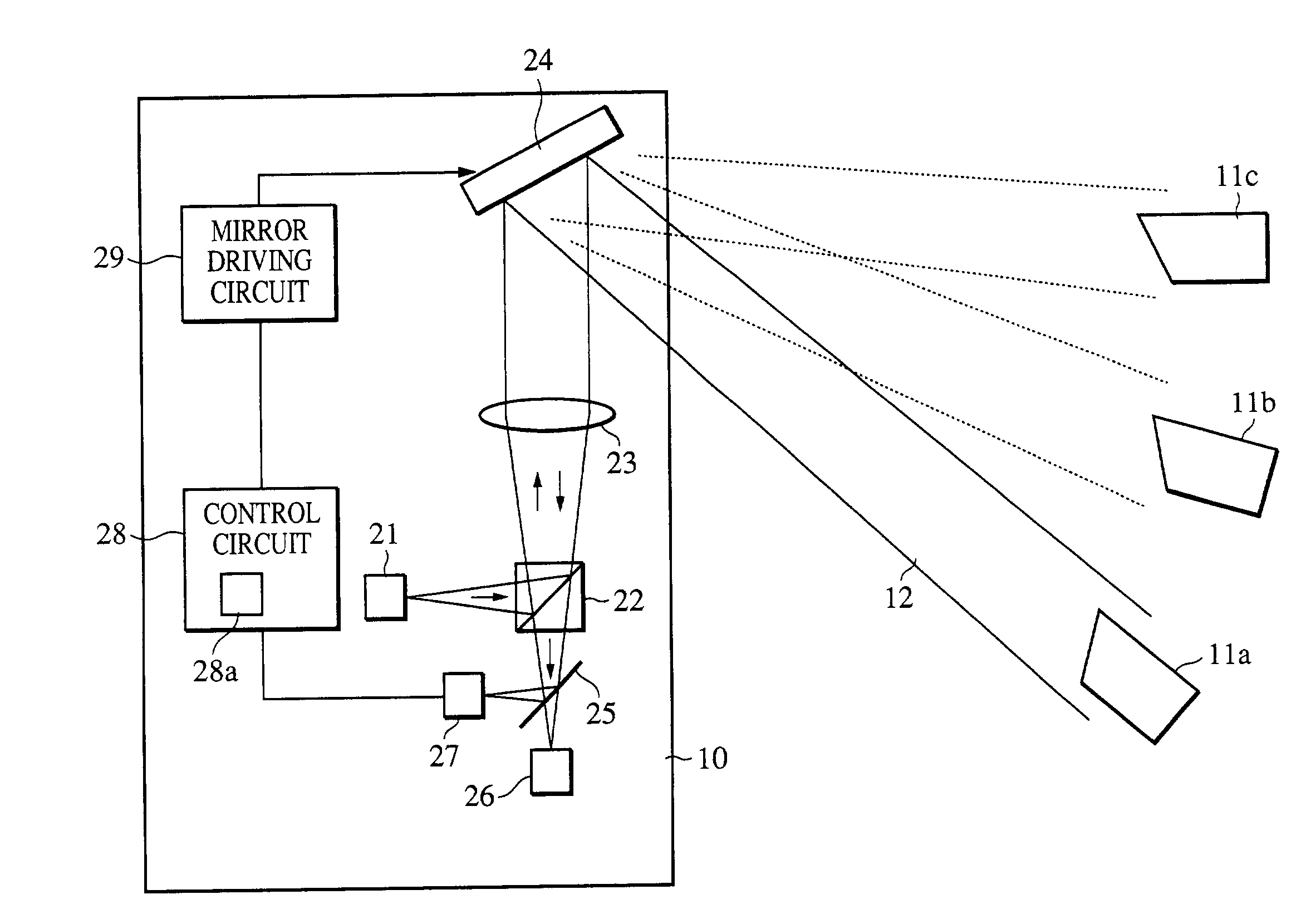

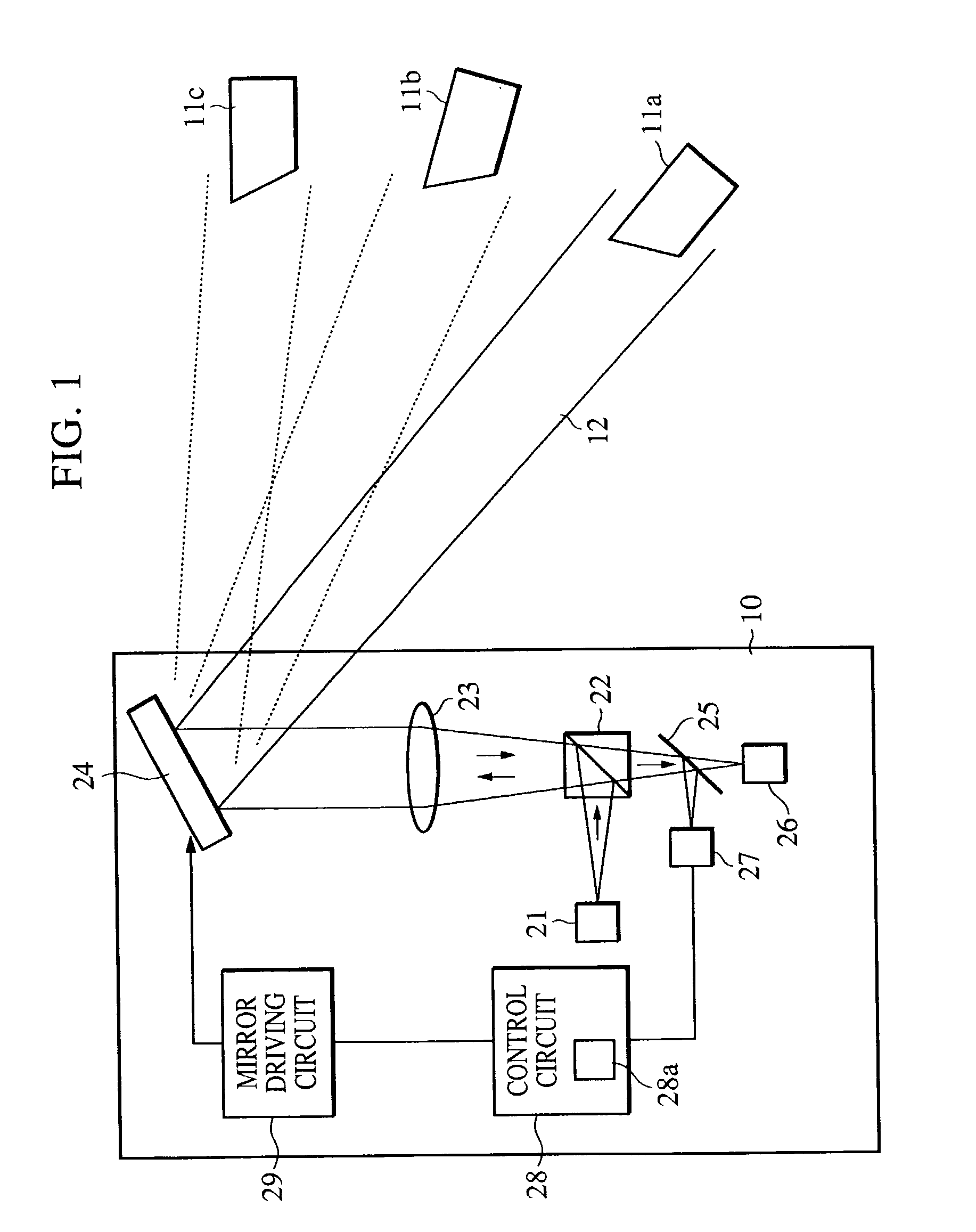

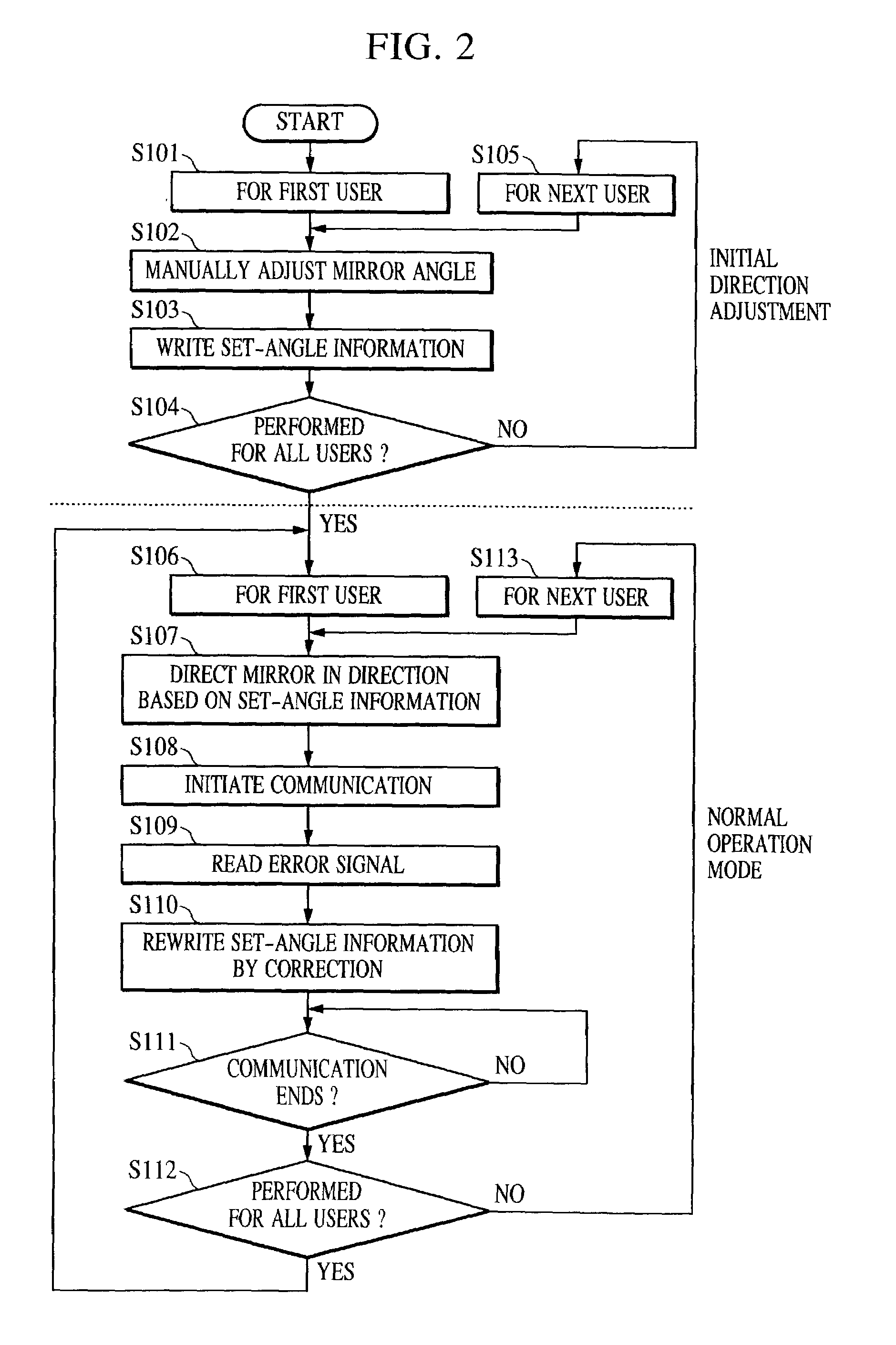

Free-space optical communication apparatus and free-space optical communication system

InactiveUS7058307B2Eliminate timeAccurate angleLine-of-sight transmissionTransmission monitoring/testing/fault-measurement systemsEngineeringTelecommunications equipment

A free-space optical communication apparatus includes a storage unit which stores angle-setting information for the mirror for communicating with each of the plurality of other apparatuses, a mirror driving unit which drives the mirror to an angle corresponding to the stored angle-setting information, an optical detecting unit which, on one occasion for communicating with a specified communication apparatus among the plurality of other apparatuses, detects the incident state of an optical beam sent from the specified apparatus, and a control unit which, based on the detected incident state of the optical beam, determines angle-correcting information for correcting the stored angle-setting information for the specified apparatus, and which, on the next occasion for communicating with the specified apparatus, uses the mirror driving unit to drive the mirror to an angle corresponding to the angle-setting information corrected by the angle-correcting information.

Owner:CANON KK

Table engageable support for head cushion supporting anesthetized patient

InactiveUS7426763B2Lateral shock dampening abilityEasy to adjustOperating tablesSofasProne positionEngineering

A support for the head of a patient lying in a generally prone position. The support features a tray adapted for support on an underlying operating table surface. A plurality of pins projecting from an engagement with the tray are positioned to engage and suspend either a cushion directly or a cushion engaged in a casing. The pins may be adjusted to raise or lower the engaged cushion or casing. A mirror is also provided to view a patient's eyes through slots in the cushion and casing engaged over a patient's face.

Owner:DUPACO INC

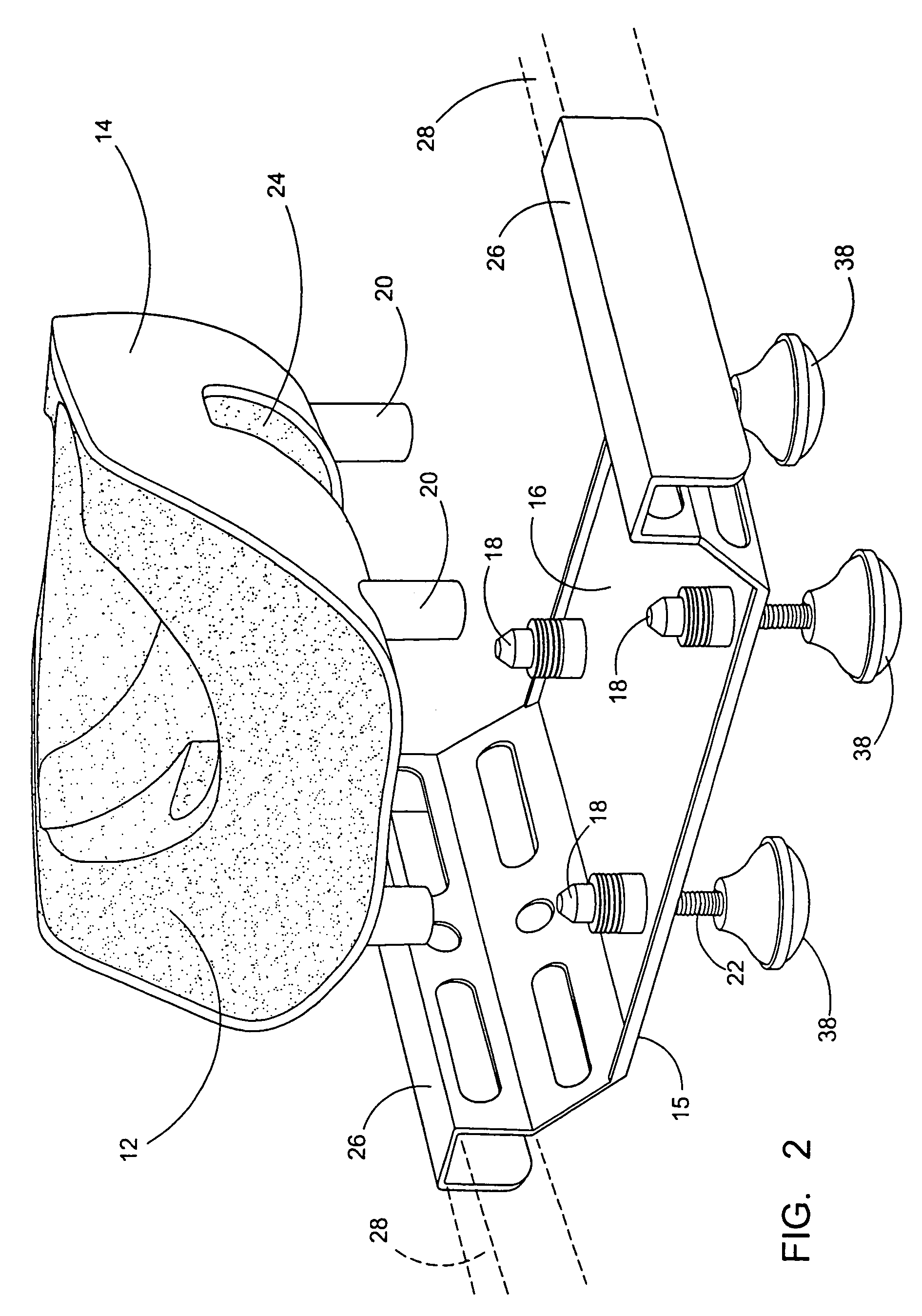

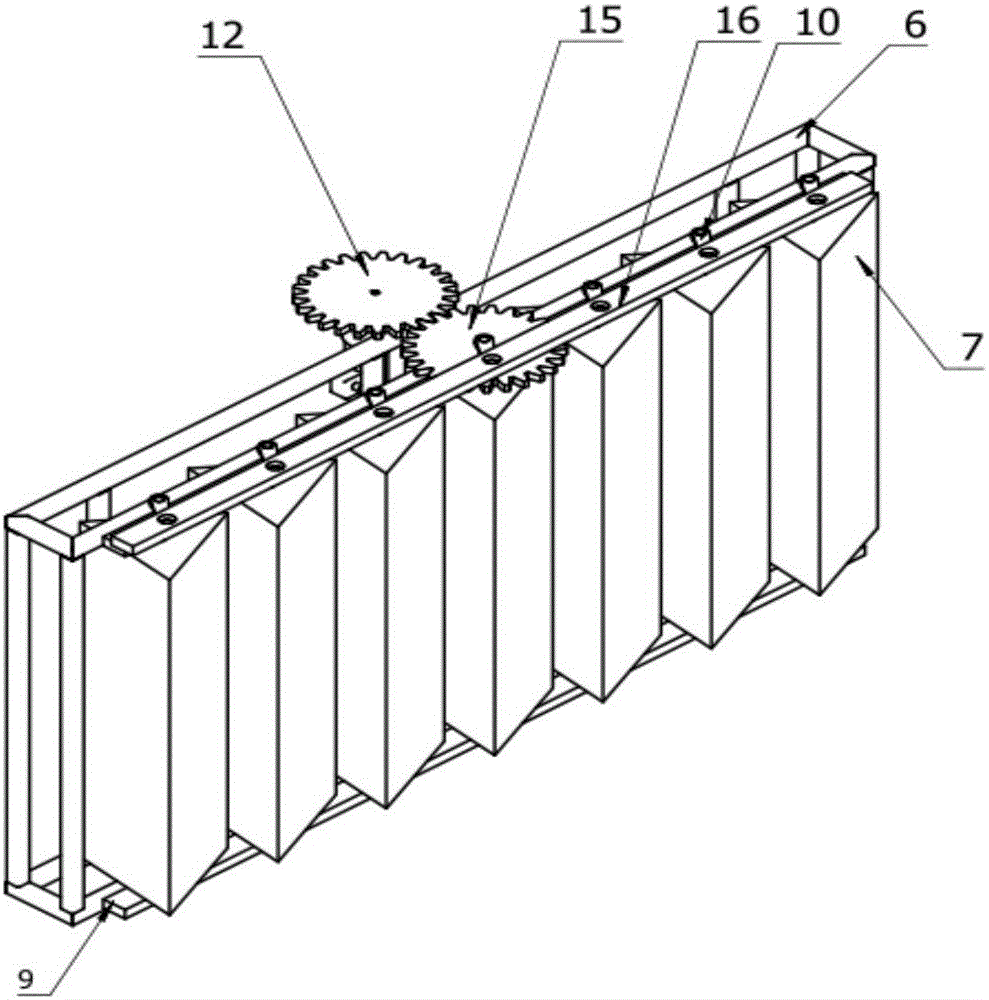

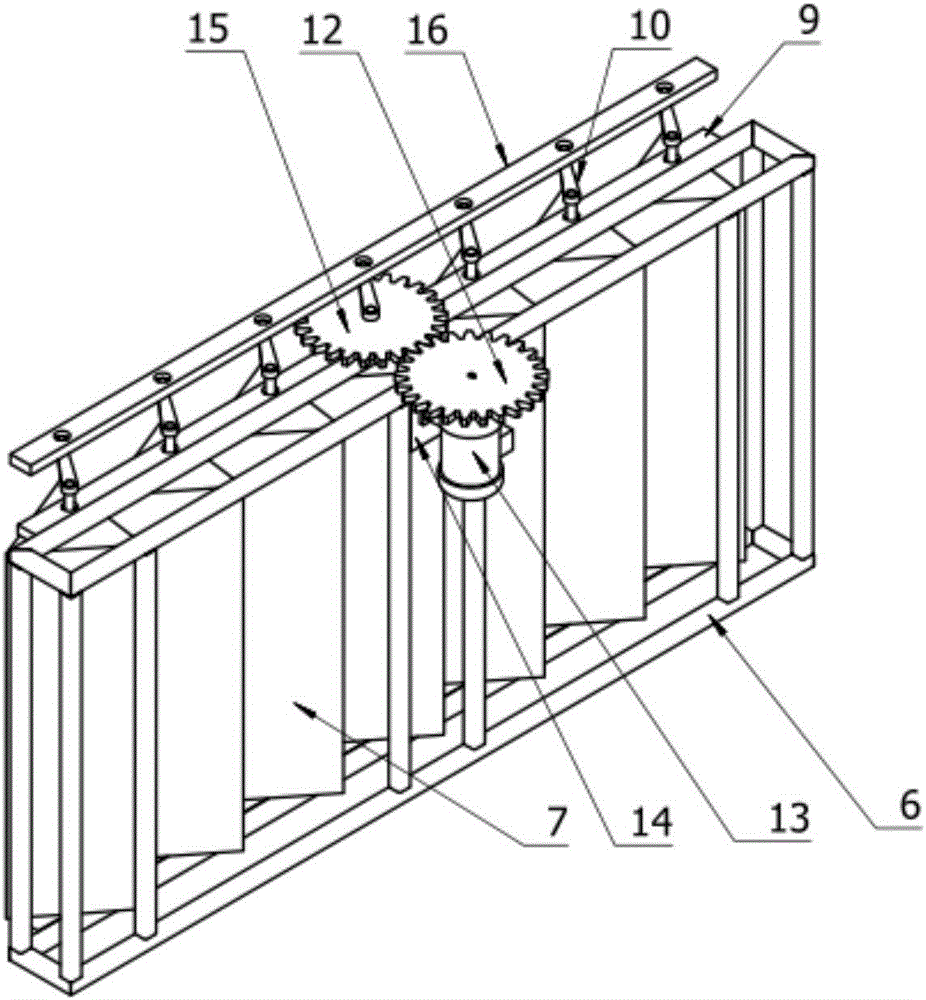

Multi-picture rotatable omnibearing displaying advertising device

InactiveCN106128325AExpansion quantityGuaranteed force balanceIdentification meansMotor driveAgricultural engineering

The invention discloses a multi-picture rotatable omnibearing displaying advertising device. The device comprises a single vertical column (1), a rotating framework (2), a turning plate framework (3), a main stepping motor (4), a rotating arm (21) and a shifting lever (22), wherein the bottom of the single vertical column (1) is connected with the foundation; the top of the single vertical column (1) is connected with a fixed shaft (17) of the rotating framework; the main stepping motor (4) is mounted on a main stepping motor base (5); the main stepping motor base (5) is mounted at the top of the fixed shaft (17) through bolts; the output shaft of the main stepping motor (4) is connected with the rotating arm; the rotating arm is connected with the shifting lever through a split flange; the shifting lever and a rotating drum steel framework (18) of the rotating framework are also connected with each other through a split flange, so that the fact that the motor drives the rotating drum steel framework to rotate is realized; a supporting rod of the rotating drum steel framework is connected with the turning plate framework through bolts. The device can deliver the total quantity of advertisements through a single advertising board, and realizes the fact that advertisement pictures are changed through the motion of a turning plate.

Owner:WUHAN UNIV OF TECH

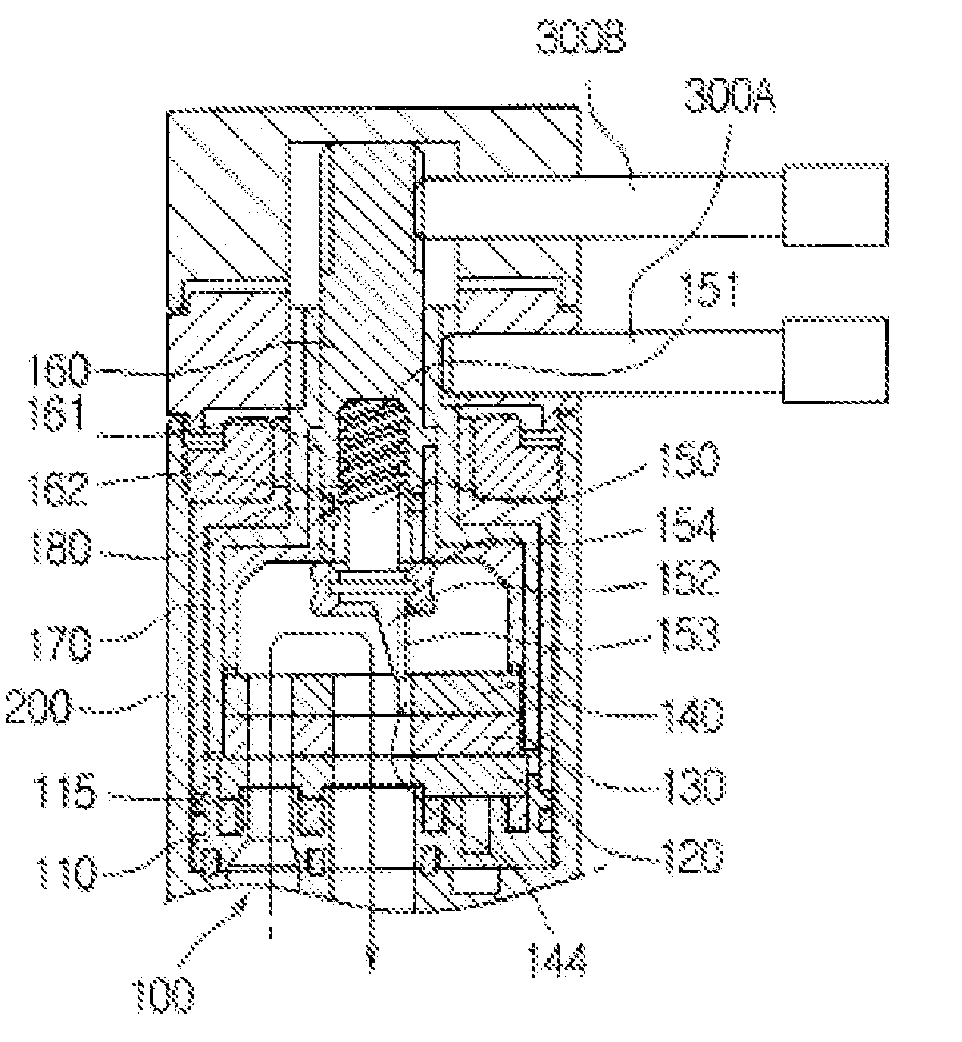

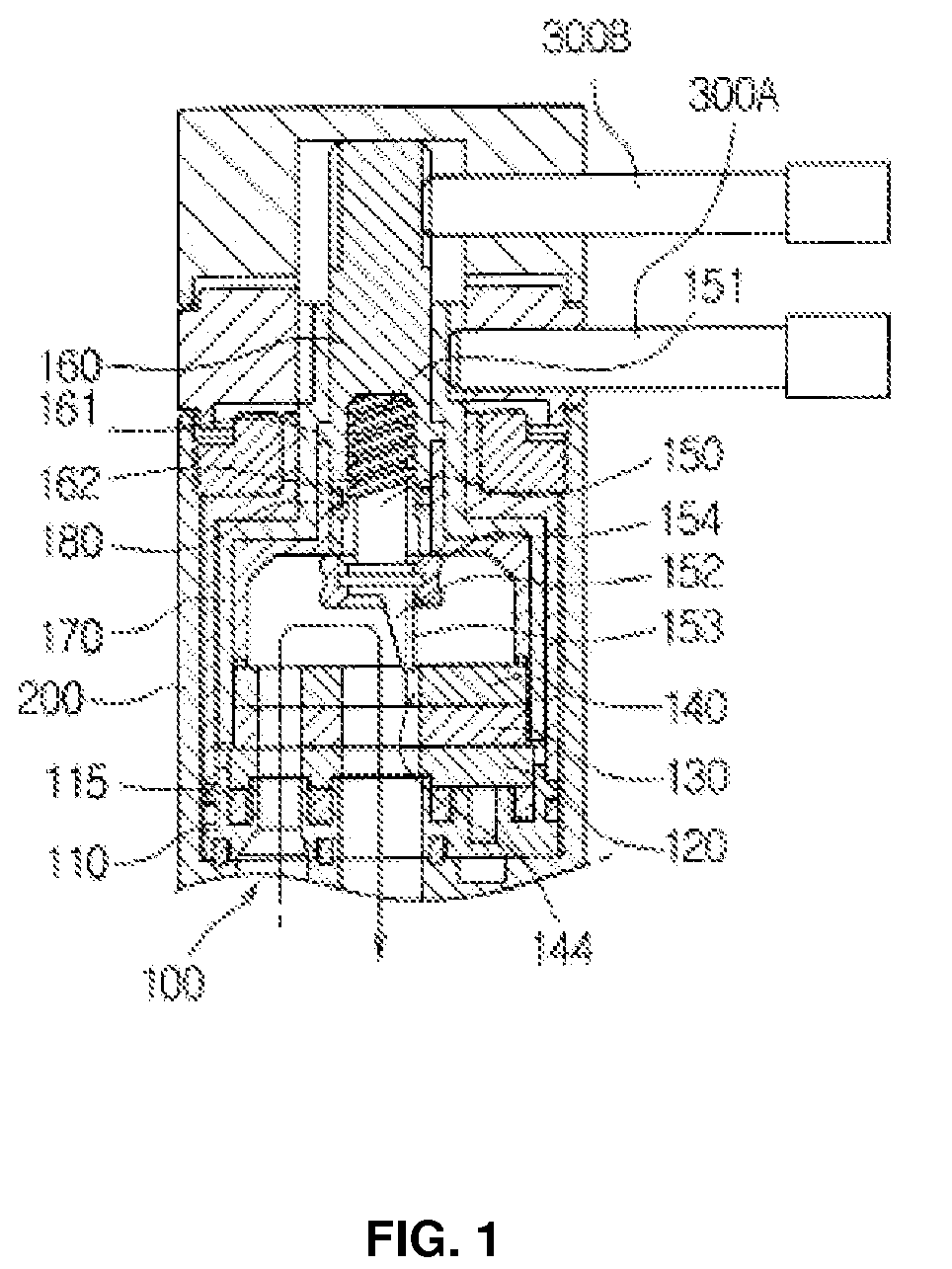

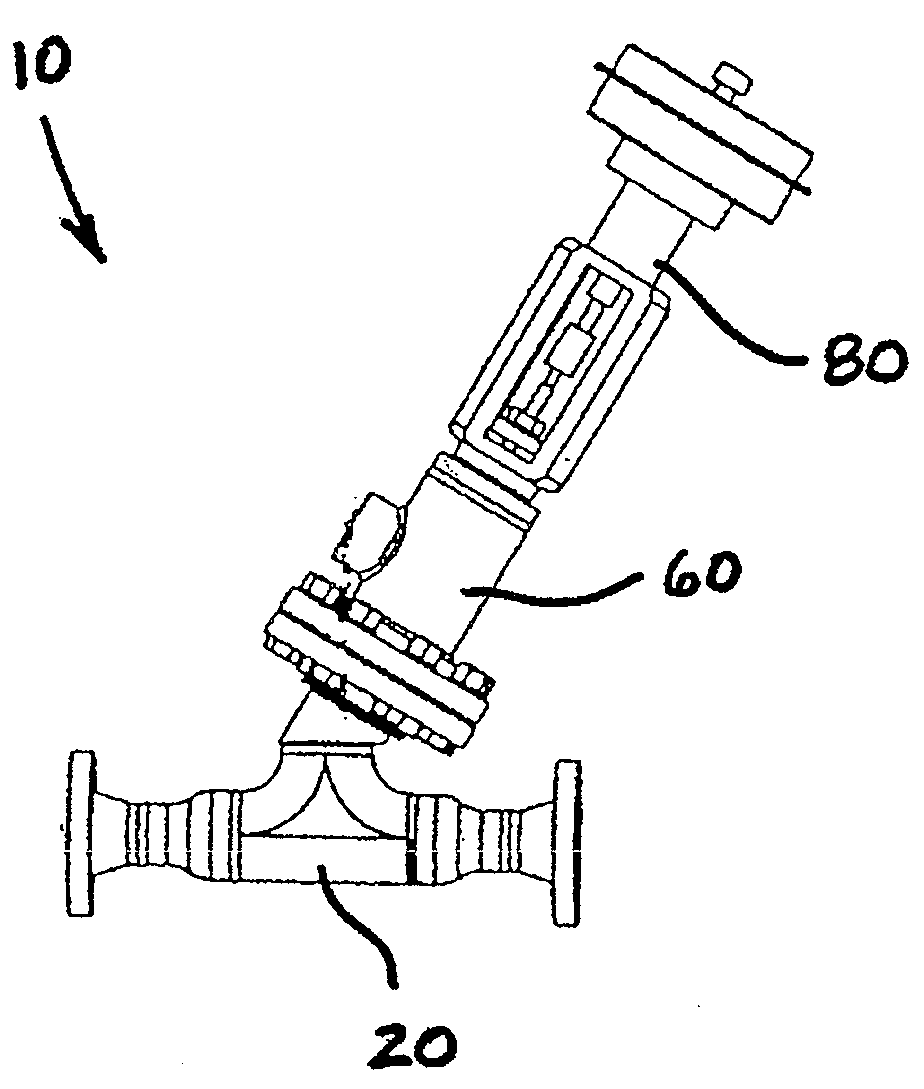

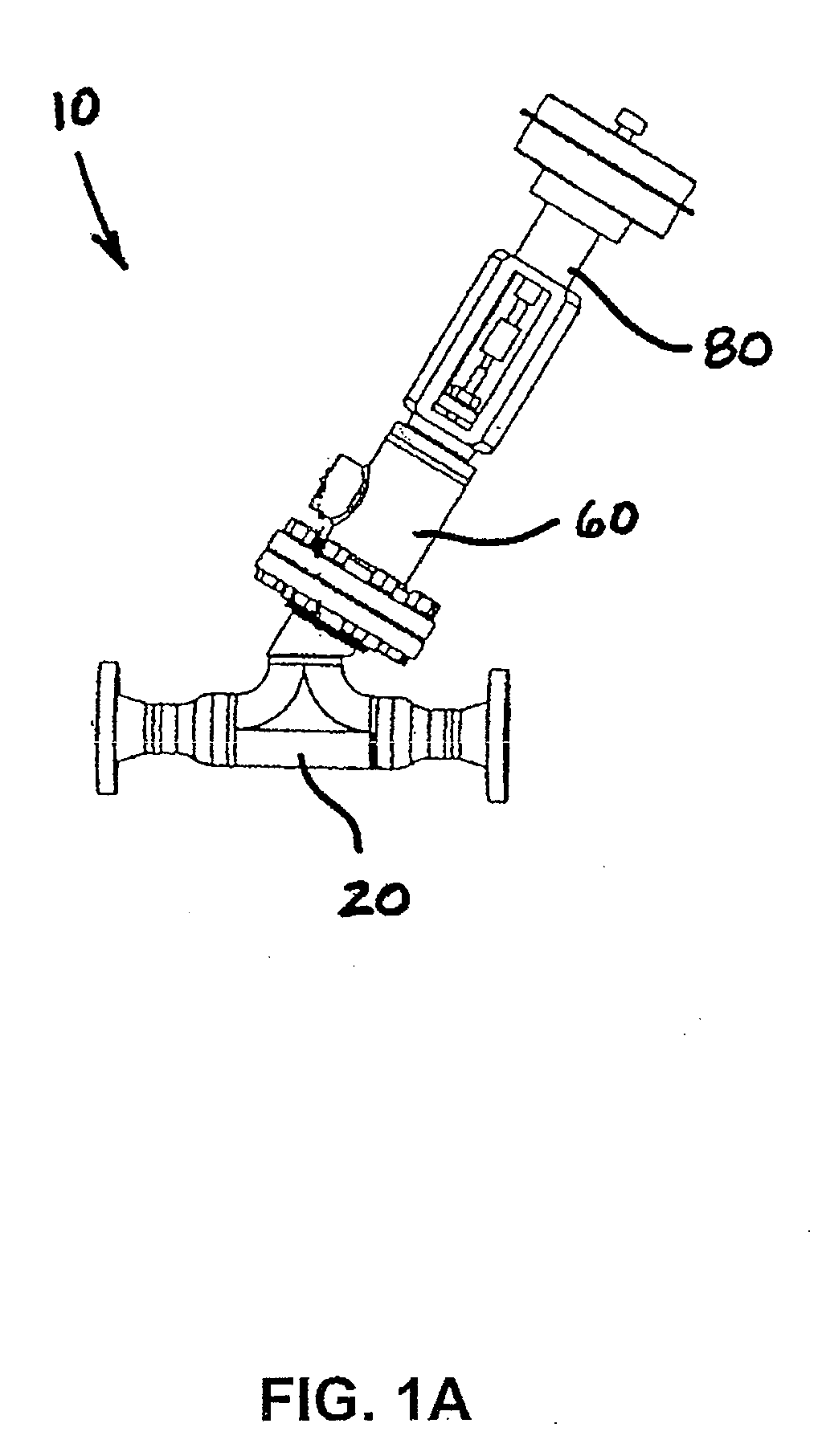

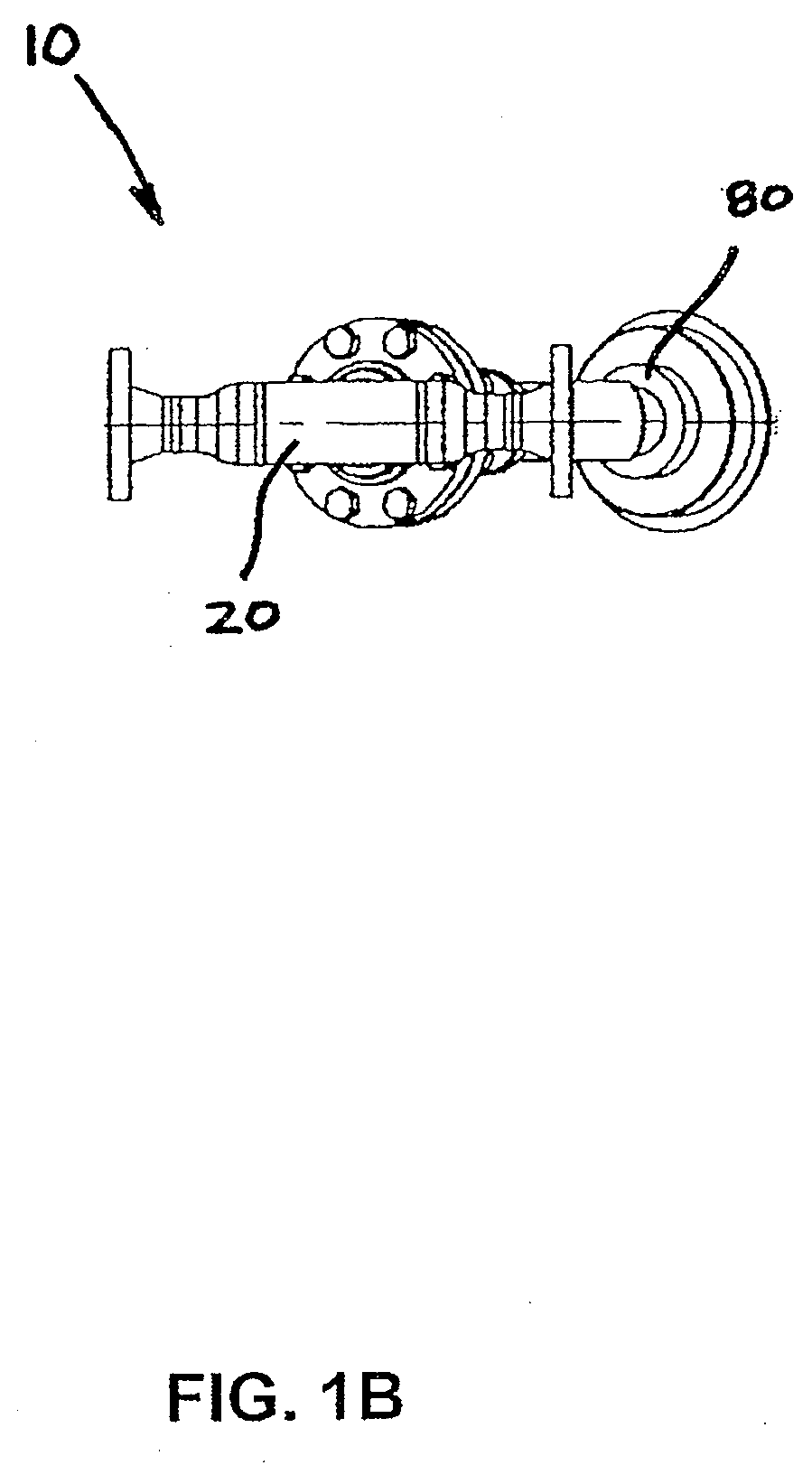

Water control valve

InactiveUS7841362B2Easy to operateAccurate angleOperating means/releasing devices for valvesMultiple way valvesTemperature controlEngineering

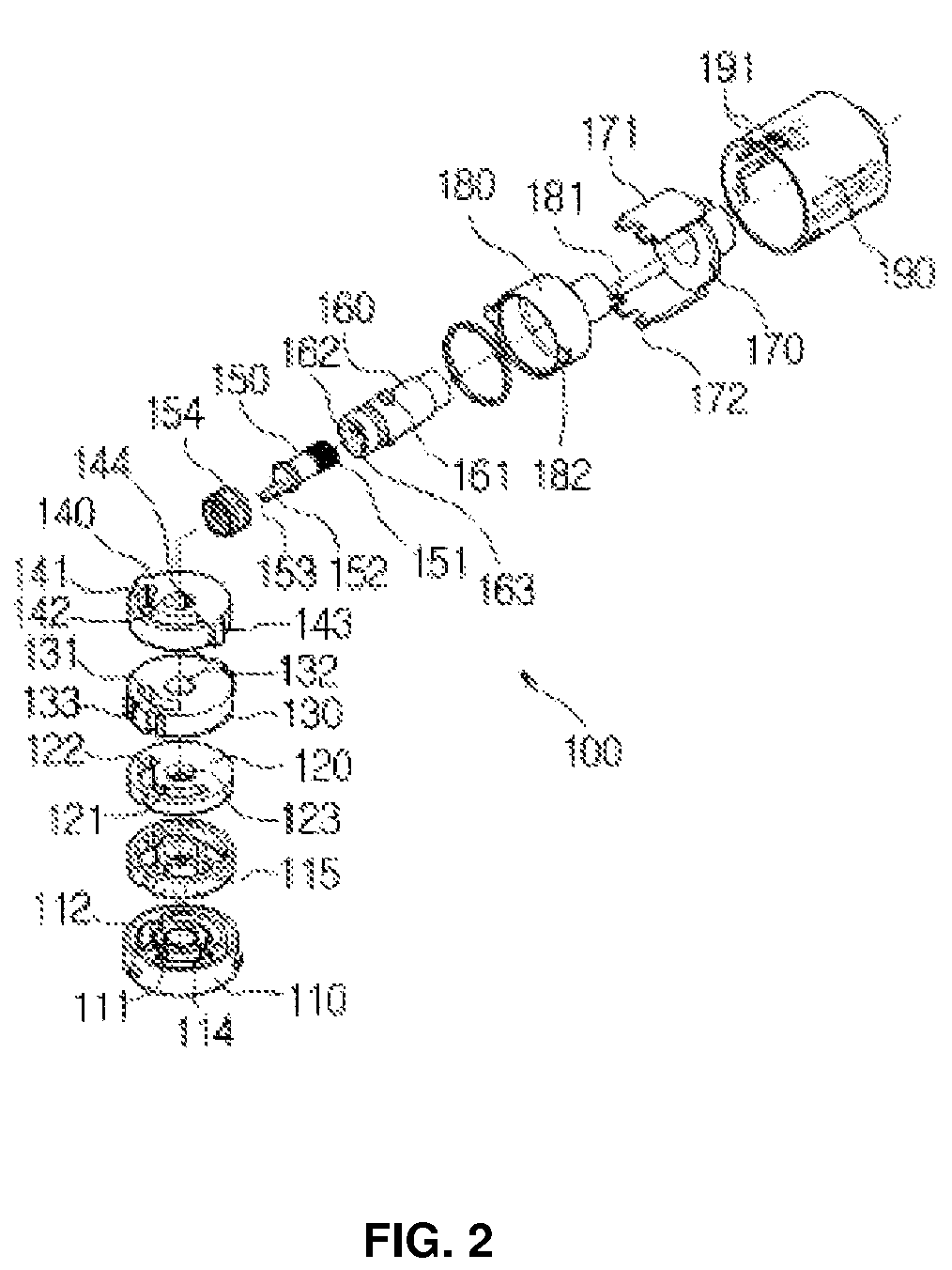

A water control valve, which has one valve cartridge to control the temperature and flow rate of hot water, cold water or a mix of hot and cold water only through rotating motions, is disclosed. The valve cartridge (100) has a first fixed disk (120) to guide hot and cold water into the valve cartridge, a rotary disk (130) to control the flow rate of hot and cold water from the first fixed disk, thus controlling the temperature of water, a second fixed disk (140) to guide controlled water in the cartridge, a temperature control unit (170) to rotate the rotary disk during rotation of a temperature control lever, the moving unit (150) to linearly move toward or away from the second fixed disk, thus controlling the flow rate of discharged water, and a flow rate control unit (160) to cause linear movement of the moving unit by rotation.

Owner:KIM JONG KOO

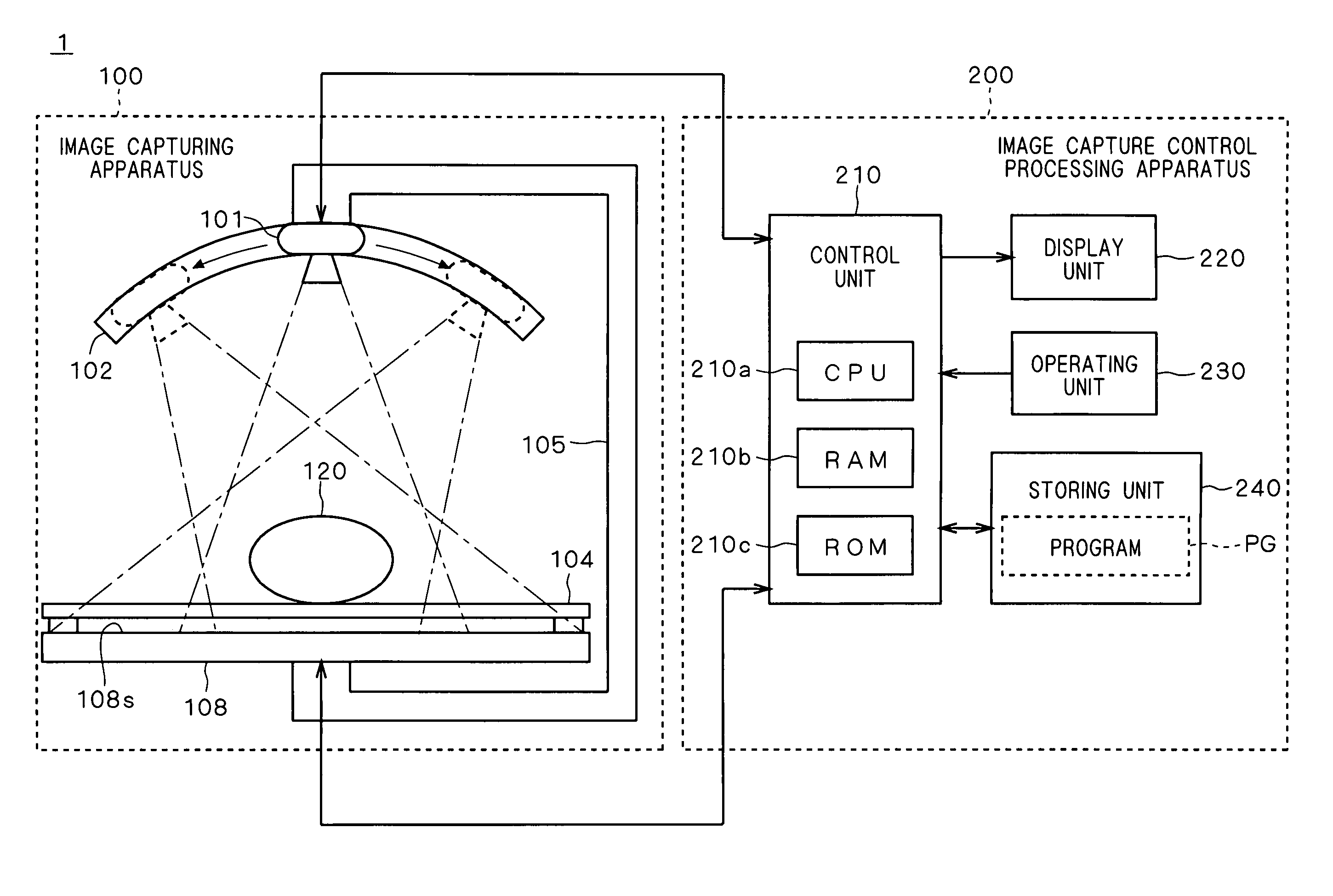

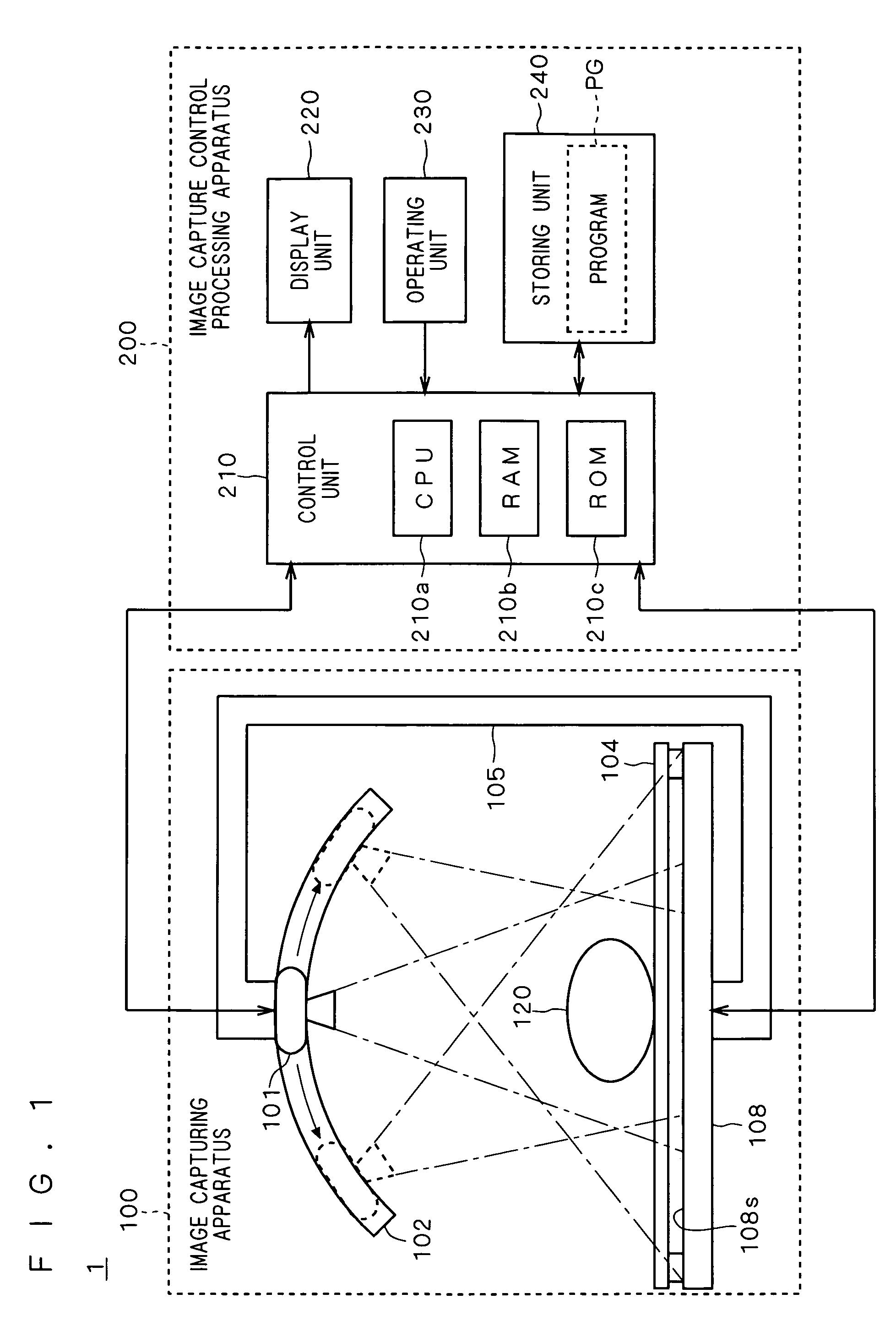

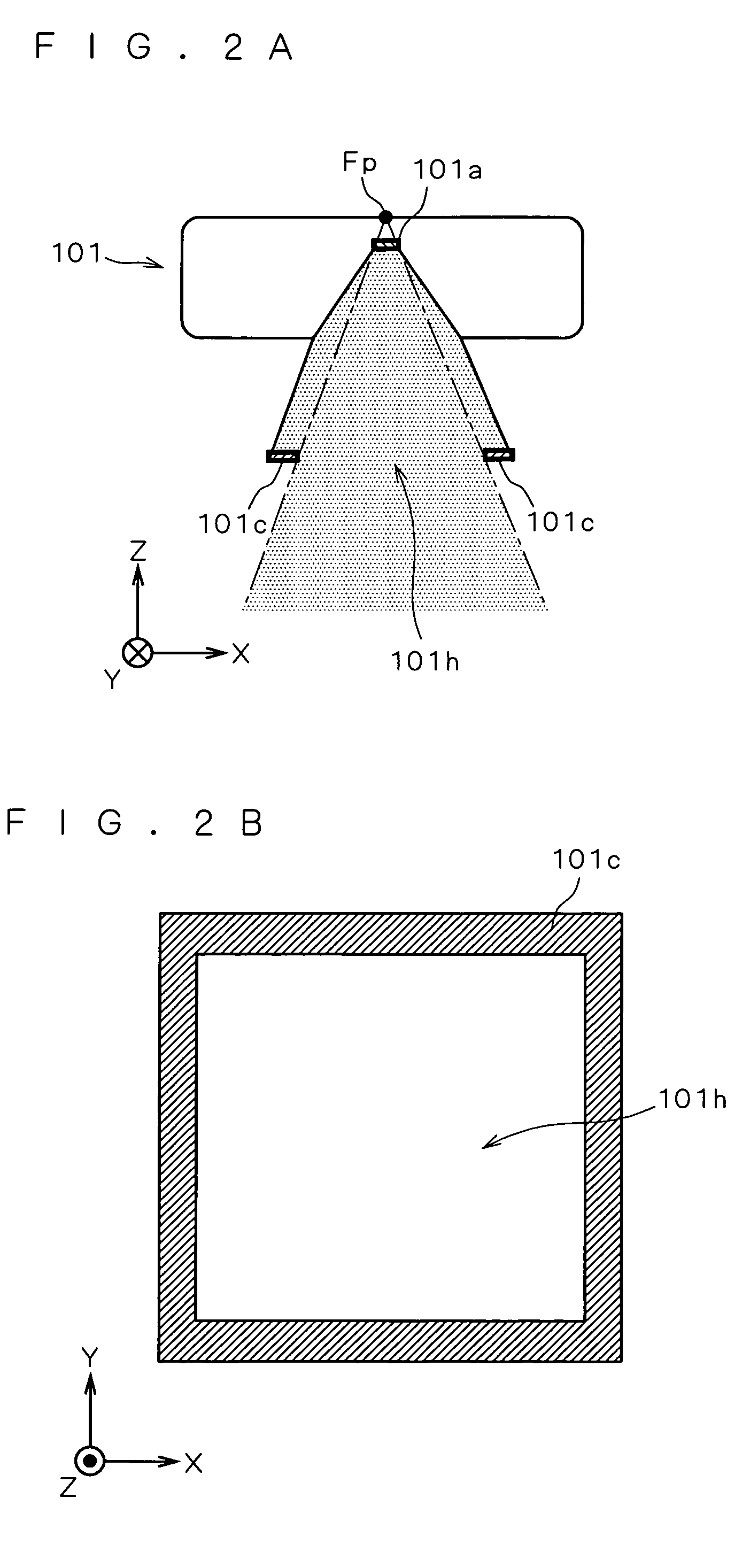

Transmission image capturing system and transmission image capturing method

InactiveUS7708462B2Precise positioningAccurate angleMaterial analysis using wave/particle radiationRadiation/particle handlingFluenceTransmission image

The present invention proposes a technique capable of accurately grasping position and angle of a radiation generator at the time of image capturing. At the time of obtaining a plurality of transmission images by detecting radiation emitted from a emitting generator and passing through a specimen via a predetermined member (for example, a diaphragm) by a detector for a plurality of times while changing a relative position relation and a relative angle relation of the emitting generator to the detector, an outer-edge shape of a radiation area irradiated with the radiation on a detection surface of the detector from the emitting generator is recognized. On the basis of the outer-edge shape of the radiation area and an inner-edge shape of a predetermined member, the relative position relation and the relative angle relation of the emitting generator to the detector are obtained.

Owner:KONICA MINOLTA INC

Holder that converges jets created by a plurality of shape charges

A shape charge holder includes a platform where all the charges are symmetrically positioned about equidistance from each adjacent charge and about an equal distance from a center point. The center point is generally the centroid of the platform. The holder has an explosive bridge fixture which enables simultaneous detonation of at least three shape charges. The charges are angularly mounted in sockets having holes through the platform. When detonated, each jet formed by the exploding shape charge proceeds to a convergence point located orthogonal to the platform. The holder includes a supporting structure that establishes a standoff distance of the platform / charges from a target. In operation, the explosive fixture is attached to each charge and is filled with an explosive that extends to each charge. The explosive fixture includes a single igniter assuring that when the explosive is detonated, so are the shape charges.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Tube truss manufacture process

The invention provides a tube truss manufacture process which comprises the steps as follows: blanking of steel tubes, positioning of intersecting points of tube fitting, welding of tube fitting, calibrating of members, pre-assembling, and disassembling of the pre-assembled truss, wherein all the manufacturing and processing links are carried out in sequence. The manufacture process has the advantages as follows: the assembly precisions of intersecting ends and intersecting holes are high; the size deviation is small; a truss body can be assembled quickly; the workload of calibration is small; formation of physical appearance is good; workload and time for polishing are greatly reduced; the quality of construction and formation can be guaranteed; smoothness and progression of all manufacture links are guaranteed; total construction period is guaranteed; material cost of manufacturing of the tube truss can be saved; inputs of manpower and goods and materials are saved; and economical effects of production are improved.

Owner:河北二十冶建设有限公司

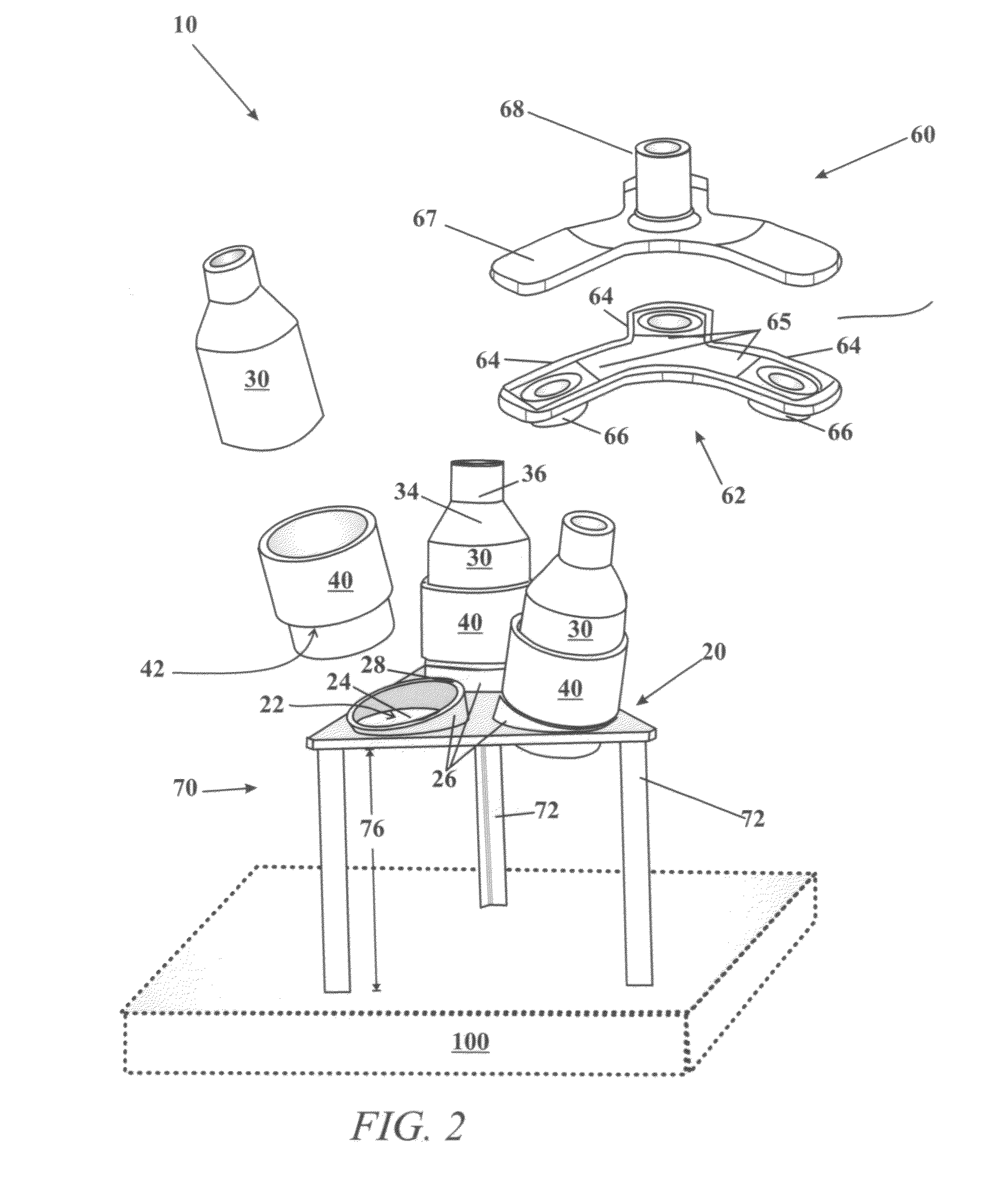

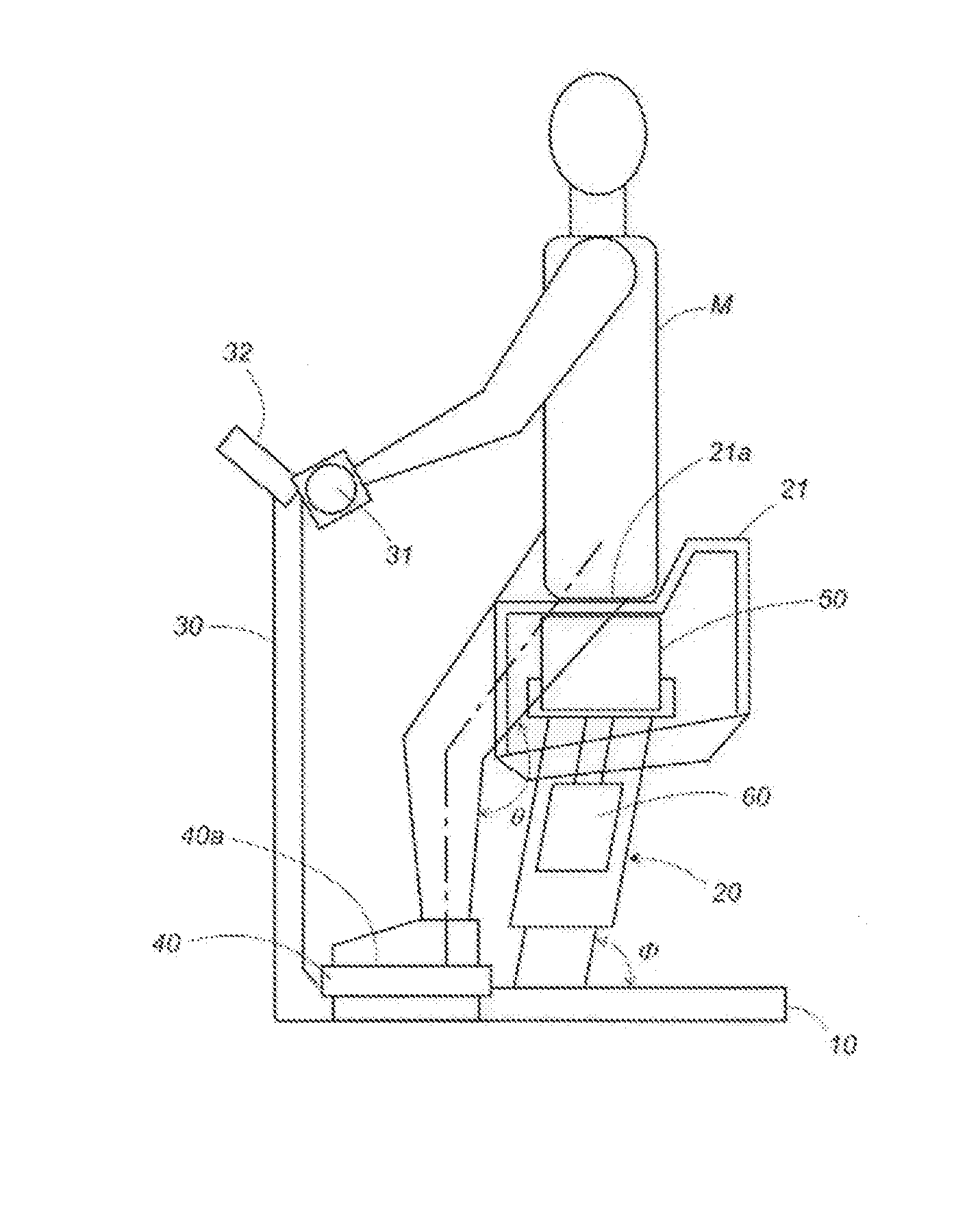

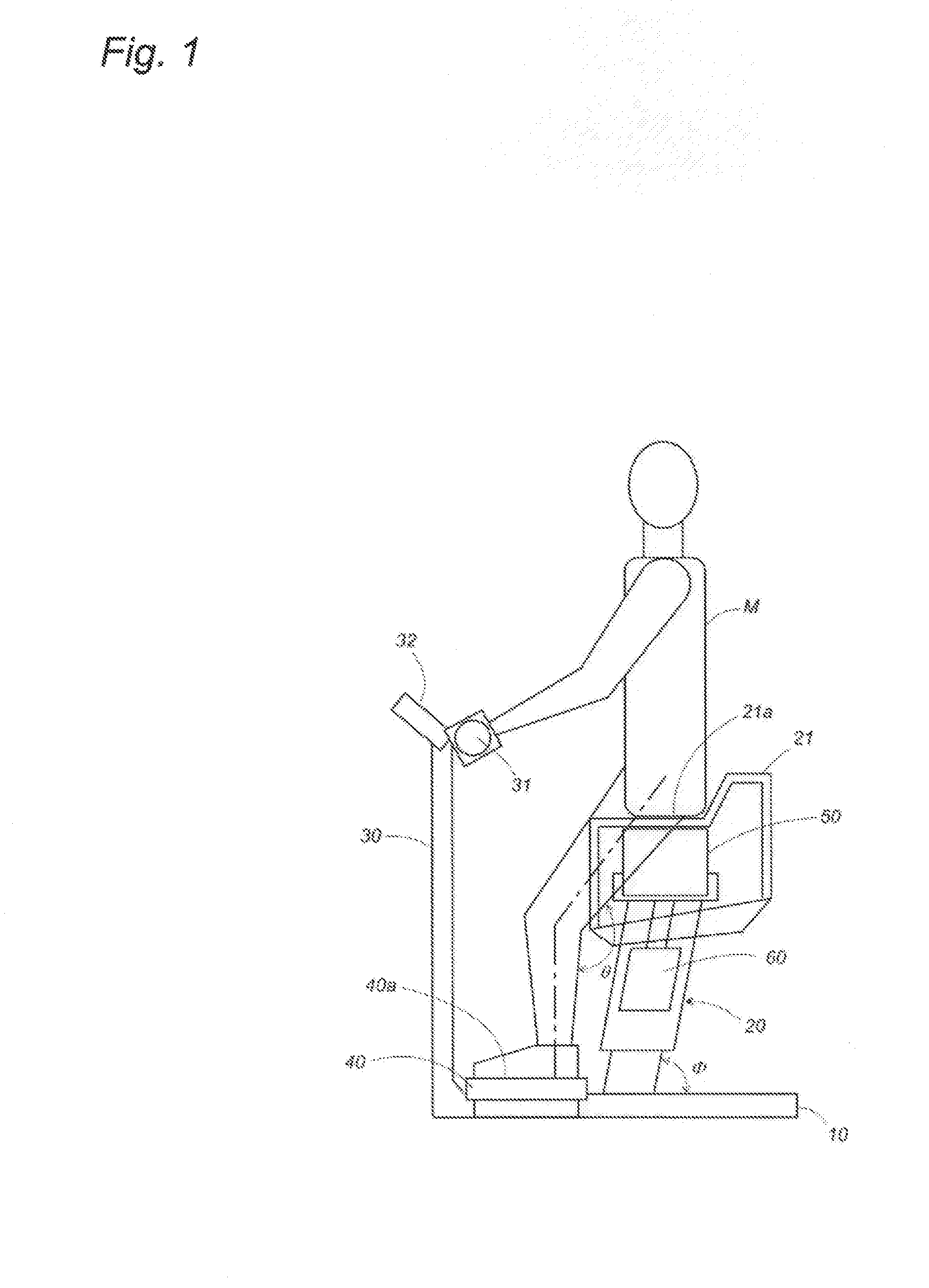

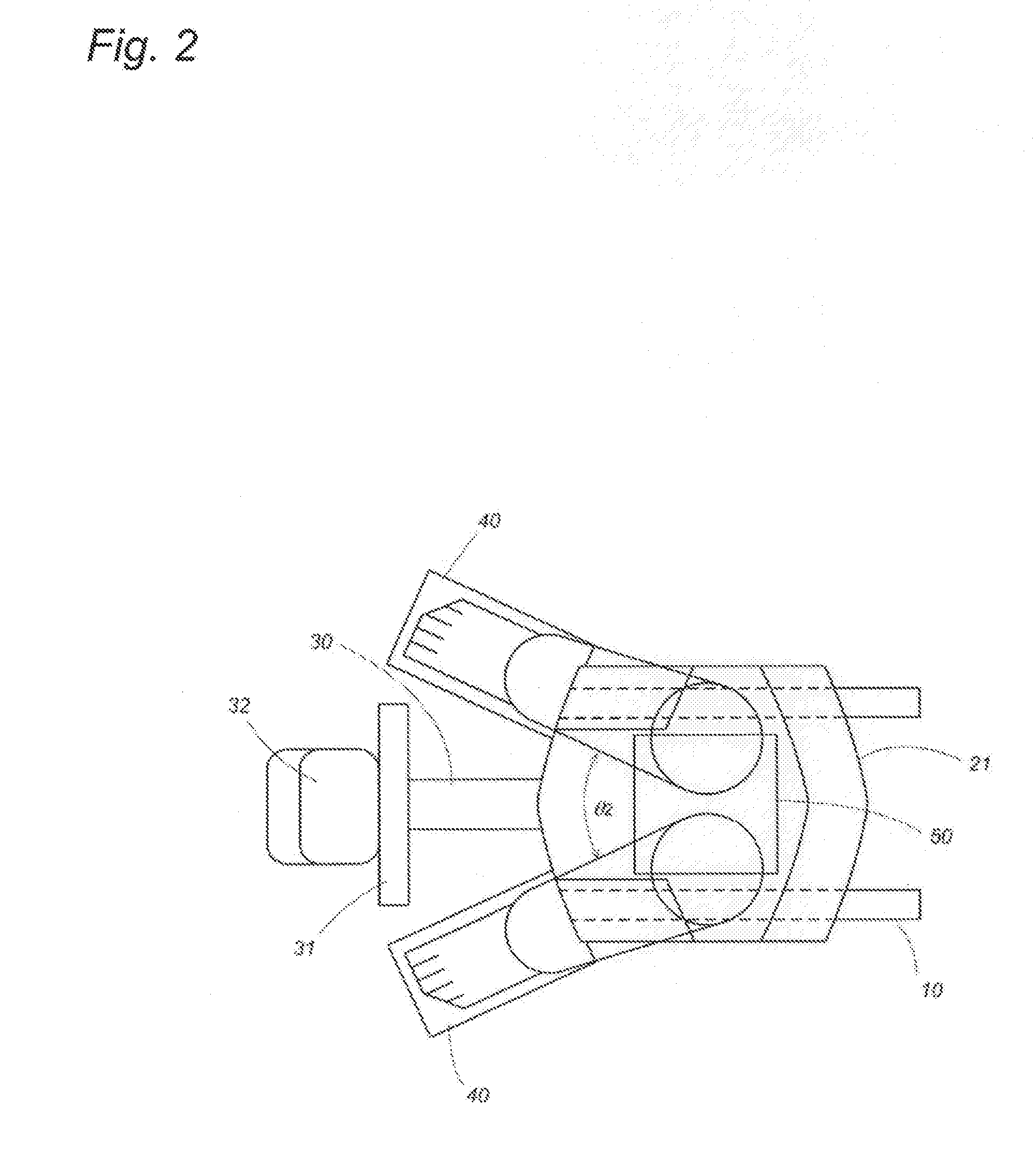

Exercise assisting apparatus

InactiveUS20100234196A1Improve usabilitySeat position quickly and accuratelyStiltsMuscle exercising devicesButtocksManipulator

An exercise assisting apparatus is capable of roughly adjusting a user's knee bending angle generally in accordance with a user's physique followed by a further adjustment in account of individual differences. The exercise assisting apparatus includes a seat supporting buttocks of a user M and a foot base supporting the bottom of the user's feet, and is arranged to swing the seat for urging muscle contraction of the user's legs. An elevator mechanism 60 regulates a position of the seat. A display and manipulator unit 32 has a physique designating section 81 provide a plurality of classes classified according to the user's height, and a moving direction instructing section 82 with pushbuttons which instructs the moving direction of the elevator mechanism 60. The elevator mechanism 60 is controlled by an elevator controller 80, and include a position adjusting section 86 which is configured to read out a position of the elevator mechanism 60 corresponding to the physique designated at the physique designating section for rough adjustment of the position of the elevator mechanism 60, and a position modifying section 87 which is configured to make a precise adjustment of the position of the elevator mechanism 60 while the moving direction instructing section is manipulated.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Table engageable support for head cushion supporting anesthetized patient

ActiveUS8261385B2Lateral shock dampening abilityEasy to adjustOperating tablesSofasProne positionEngineering

A support for the head of a patient lying in a generally prone position. The support features a tray adapted for support on an underlying operating table surface. A plurality of pins projecting from an engagement with the tray are positioned to engage and suspend either a cushion directly or a cushion engaged in a casing. The pins may be adjusted to raise or lower the engaged cushion or casing. A mirror is also provided to provide a reflective view a patient's eyes through slots in the cushion and casing engaged over a patient's face. A video camera may also concurrently be employed to capture electronic images of the patient's eyes and mouth through an aperture in the mirror.

Owner:MAZZEI WILLIAM J +2

Catheter control systems

ActiveUS9101735B2Guaranteed simulation effectEfficiently controlling the hood positionSurgeryEndoscopesControl systemSeptal wall

Catheter control systems which facilitate the tracking of an angle of deflection of a catheter distal end can be used for any number of procedures where catheter orientation relative to the body is desirable, e.g., in transseptal access procedures where an accurate angle of puncture of the septal wall is desirable. Such control systems may comprise a steerable handle which is oriented relative to the catheter steerable section to provide for consistent catheter articulation upon corresponding manipulation of the steering ring. Another variation may utilize an orientation indicator to track the deflectable distal end. For instance, an orientation marker as visualized through an imaging hood on the distal end may correspond to identical orientation markers on the control handle such that articulation of a steering mechanism in a direction relative to the orientation markers deflects the catheter distal end in a corresponding direction relative to the visualized orientation markers.

Owner:INTUITIVE SURGICAL OPERATIONS INC

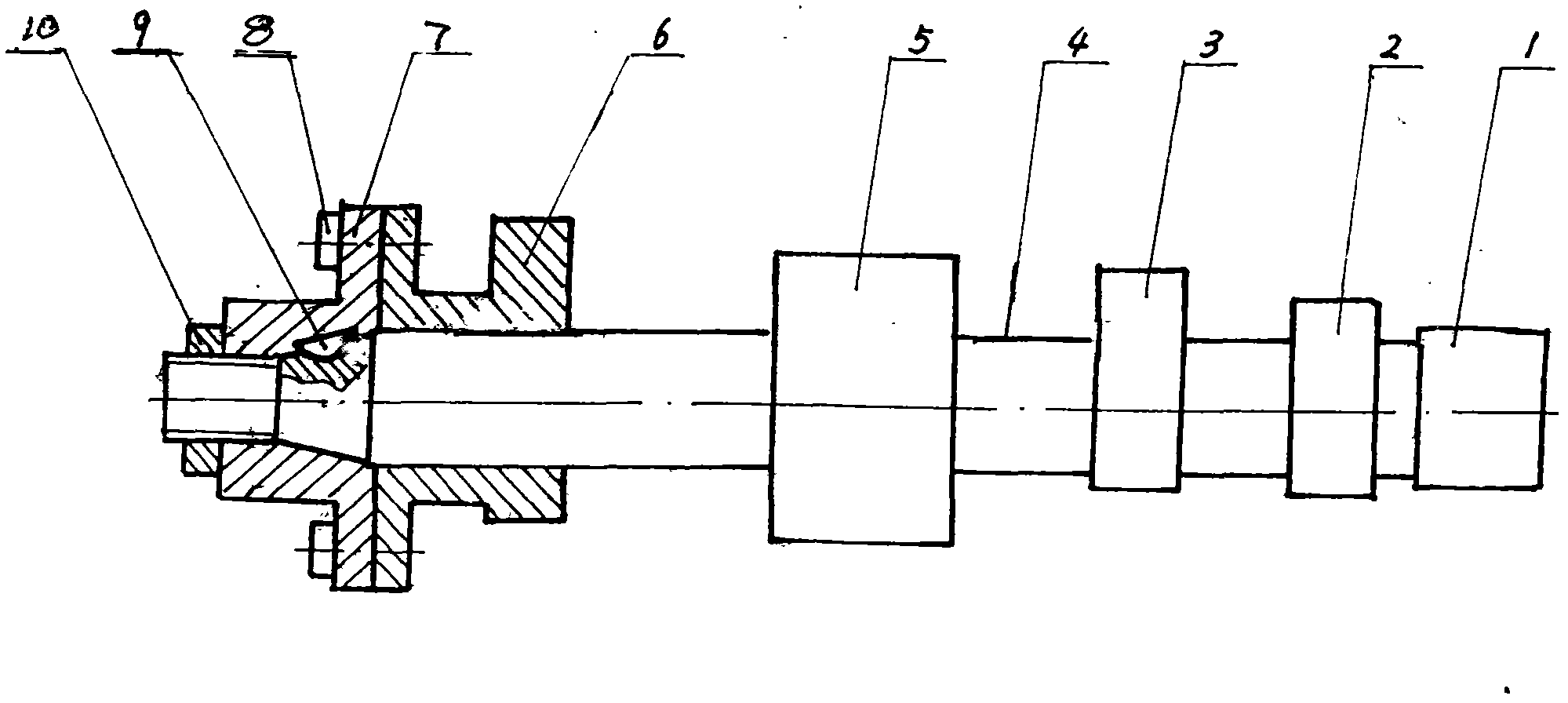

Angled diffuser and steam injection heater assembly

An improved configuration for an in-line direct contact diffuser-type steam injection heater provides for a diffuser whereby steam flow is controlled using an angled sonic diffuser and plug arrangement. The steam flow is controlled by means of a steam plug which selectively exposes holes through which the steam passes. In the preferred embodiment, the configuration provides for a diffuser that had been angled approximately 30° from vertical to facilitate better mixing of the steam with the fluid. The precise angle may be altered depending on the fluid characteristics. A more durable end seal is also used. The end seal is a piston ring which prevents problems associated with the use of elastomeric rings of existing art. A more uniform diameter plug with linear travel is also an improvement over the prior art.

Owner:PROSONIX +1

Assembled camshaft

The invention discloses an assembled camshaft for a single cylinder diesel. A central hole of an oil supply cam of a fuel injection pump of the assembled camshaft is slidably sleeved on the camshaft and is connected with a driving disk; and the driving disk is fastened on the camshaft through a key and a nut. The defects that in the cam of the fuel injection pump of the single cylinder diesel, an oil injection angle cannot be adjusted randomly, necessary conditions are provided for arranging an oil supply angular advance automatic adjustment device on the single cylinder diesel, and the invention has the characteristics that the assembled camshaft is easy to implement, has reliable performance, can be operated quickly and the like.

Owner:运城常运动力机械有限公司

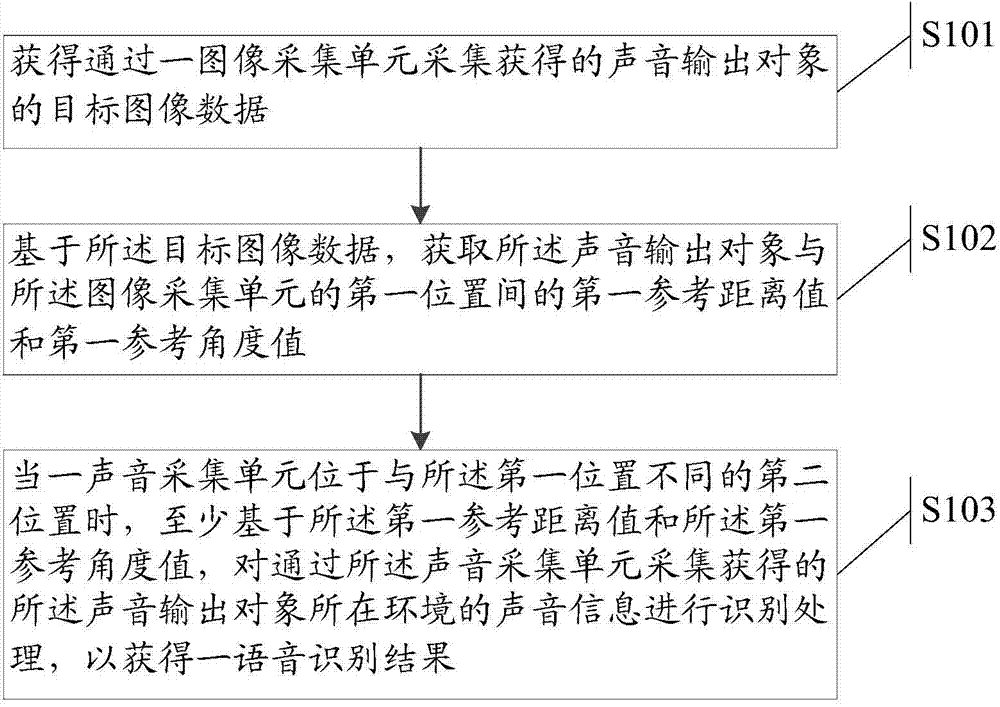

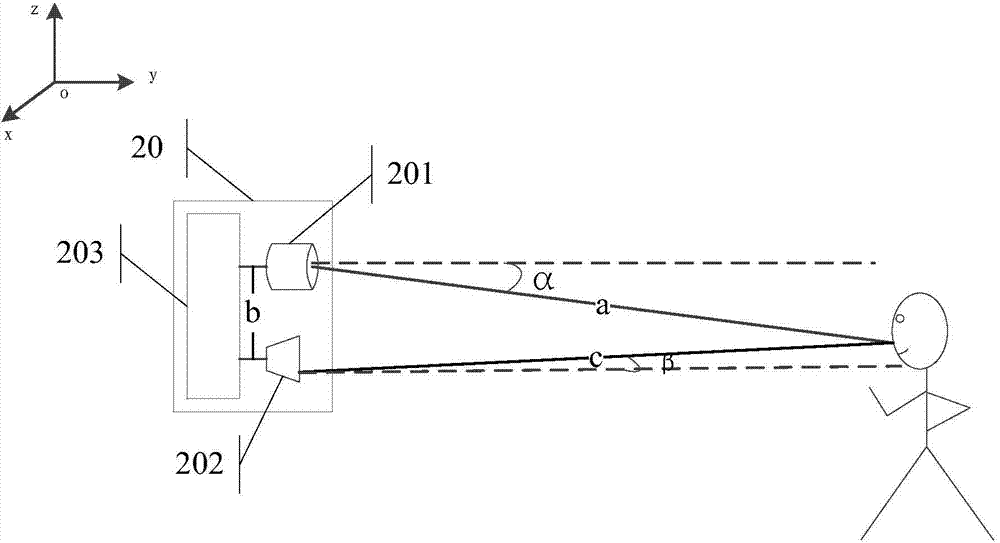

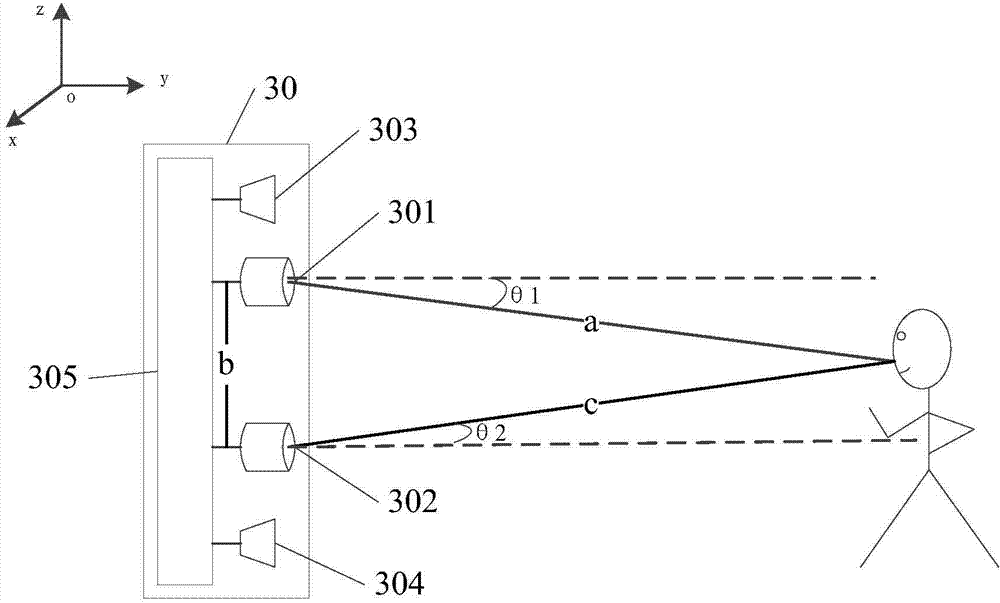

Data processing method and electronic device

ActiveCN104715753AImprove speech recognition rateSolve technical problems that are difficult to achieve a high recognition rateSpeech recognitionInput/output processes for data processingEnvironmental noiseComputer science

The invention discloses a data processing method and an electronic device, so as to solve the technical problem that in the case of large environmental noise in the prior art, a voice recognition system is hard to achieve a high recognition rate. The method comprises steps: target image data, acquired and obtained by an image acquisition unit, of a sound output object are acquired; on the basis of the target image data, a first reference distance value and a first reference angle value between the sound output object and a first position of the image acquisition unit are acquired; when a sound acquisition unit is located at a second position different from the first position, recognition processing is carried out on sound information of the environment of the sound output object acquired and obtained by the sound acquisition unit at least on the basis of the first reference distance value and the first reference angle value so as to acquire a voice recognition result.

Owner:LENOVO (BEIJING) LTD

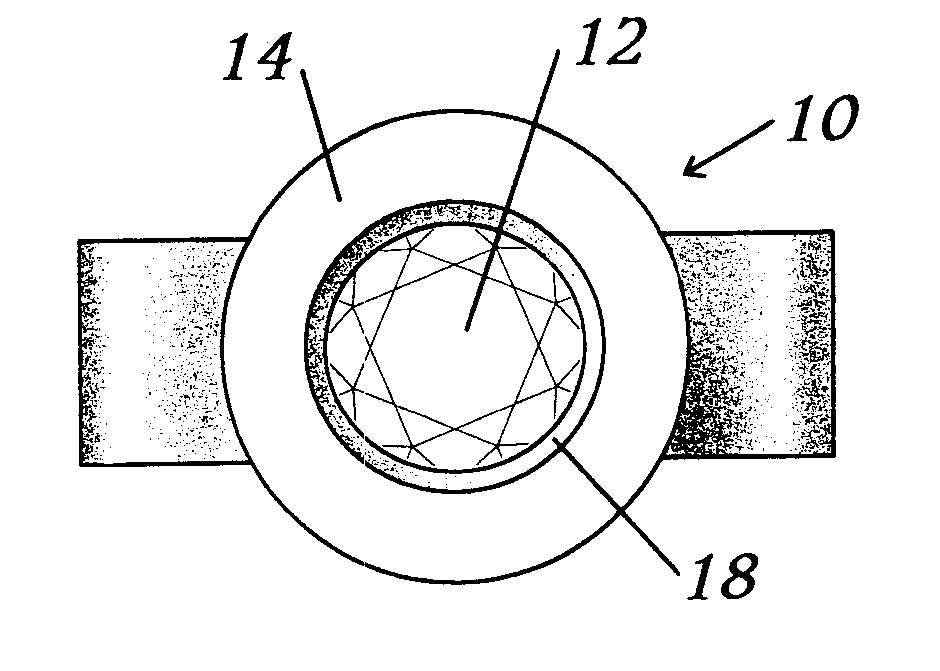

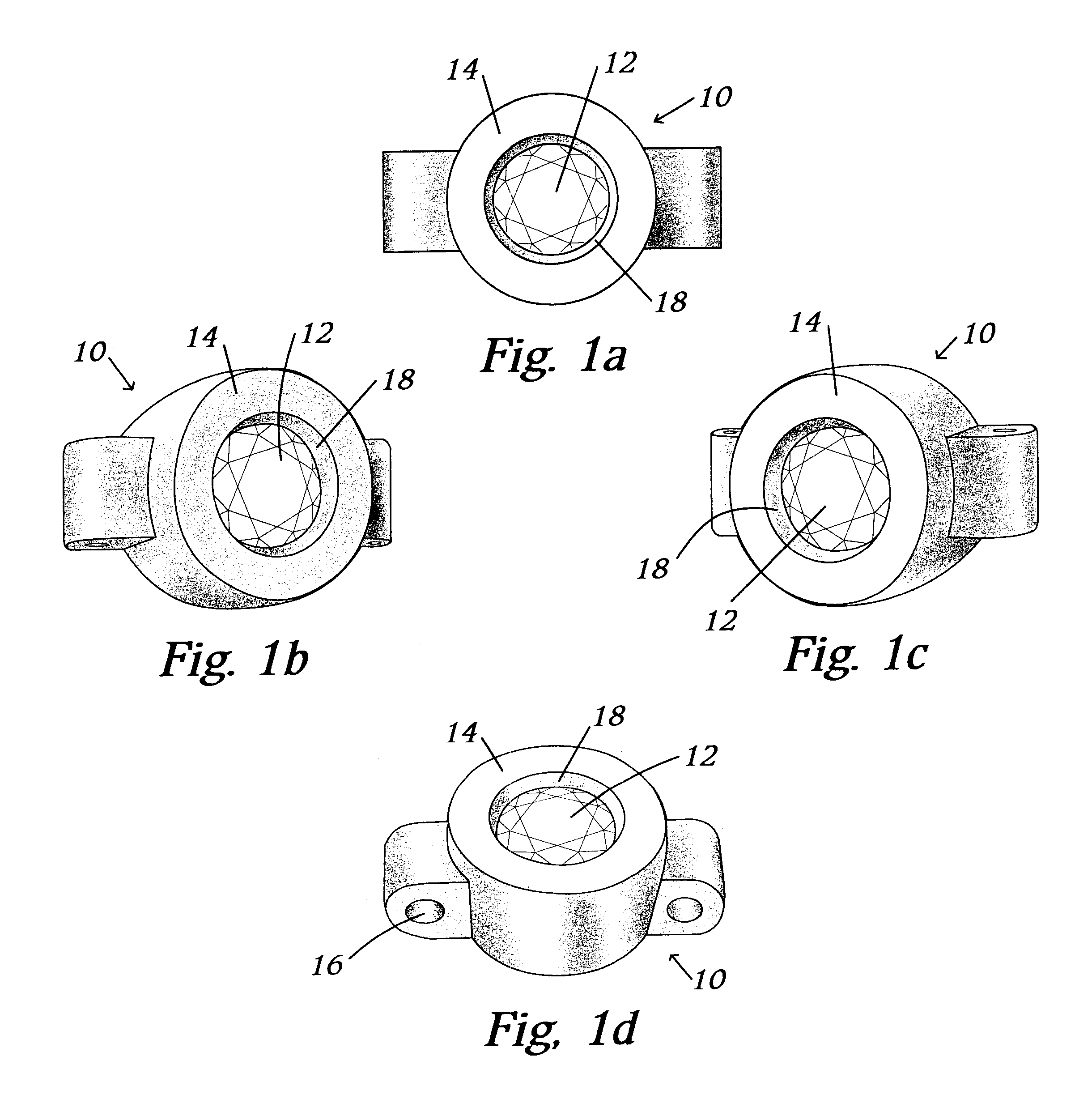

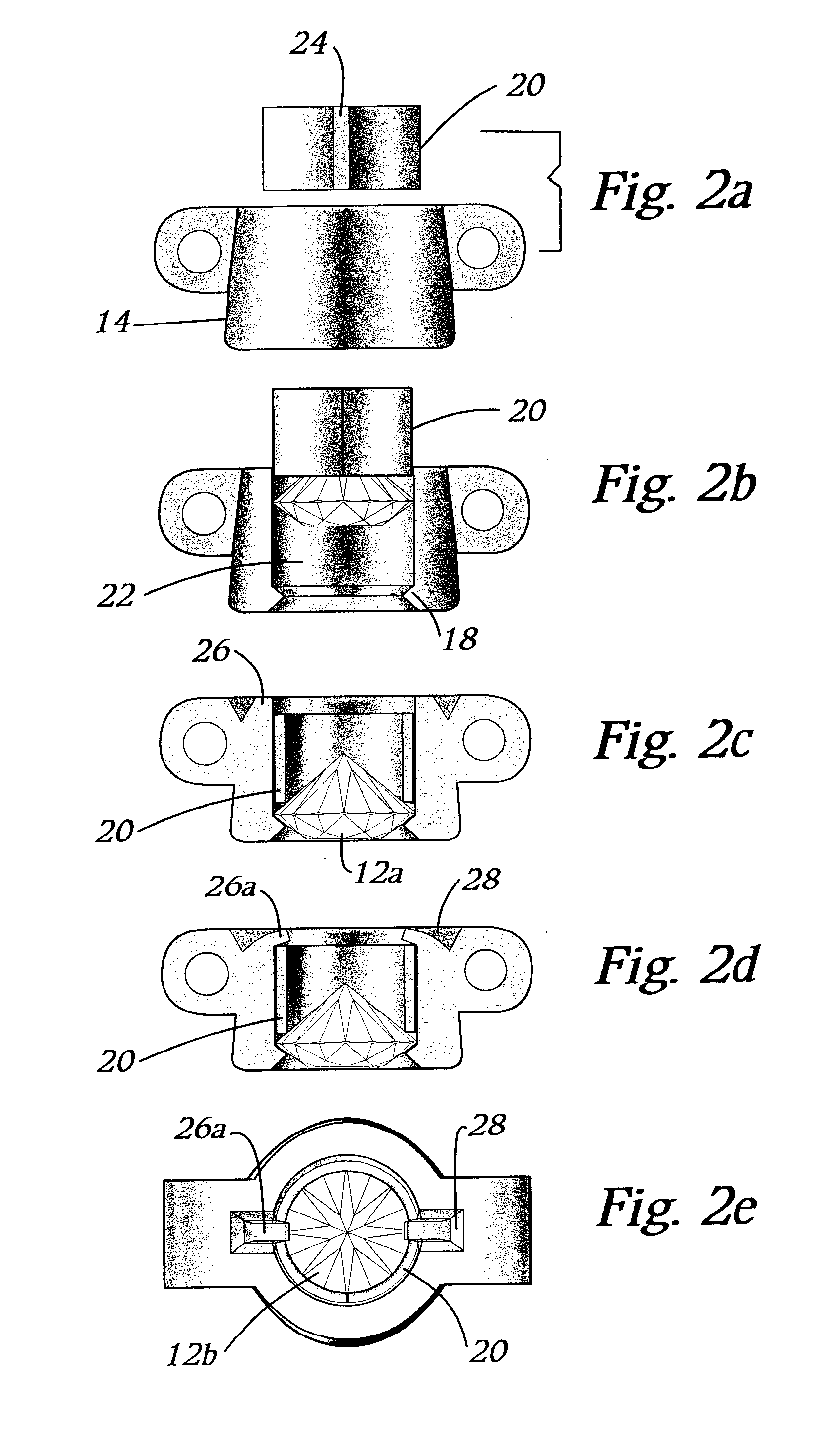

Gem setting

InactiveUS20050199004A1Low costConsiderable laborWatch chainsOrnamental chainsEngineeringMechanical engineering

A method and stone mount for an inside bezel mounting that improves precisely calculating the bezel face angle and contiguous finish on the inside bezel face for enhanced light brilliance that includes mounting the stone from the bottom up using a retaining spring. The stone once inserted into the mounting stops at the bezel lip then the retaining spring once fully inserted can be permanently affixed by bending the countersunk prongs over said retaining spring thus completing the setting.

Owner:BERNSEN ROGER M

Valve end cover drilling device

ActiveCN108515205AEasy to drill downWill not affect normal installationFeeding apparatusLarge fixed membersEngineeringDrill bit

The invention relates to a valve end cover drilling device. The valve end cover drilling device comprises a machine frame and a drilling motor; a vertically-downward drill bit is installed on the drilling motor; a vertically-arranged driven rod is slidably connected to the machine frame, a compressed spring is arranged between one end of the driven rod and the machine frame, the driven rod is fixedly connected with a transverse plate, the drilling motor is installed on the transverse plate, and the machine frame is provided with a reciprocating mechanism which is used for enabling the driven rod to move in a reciprocating mode; a first groove wheel rotationally connected to the machine frame is arranged under the drill bit and provided with a fixture used for clamping a valve end cover; the machine frame is rotationally connected with a first rotary disc, the first rotary disc is fixedly connected with a first driving rod, and a first pin shaft capable of being inserted into a radial groove formed in the first groove wheel is fixedly connected to the first driving rod; a linkage mechanism is connected between the reciprocating mechanism and the first rotary disc; and the reciprocating mechanism is connected with a driving mechanism enabling the reciprocating mechanism to work. Through the scheme, automation rotating of the valve end cover is achieved, and the drill bit drills aplurality of uniformly-distributed threaded holes in the valve end cover.

Owner:重庆博创知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com