Method and apparatus for attaching spindles to rails in a fence assembly

a technology of fence assembly and spindle, which is applied in the field of fencing system, can solve the problems of inability to simply place the spindle on the rail and drive a toe nail, the difference between the size of the aperture and the end of the spindle can be problematic, and the end of the spindle will not be able to be inserted into the sam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

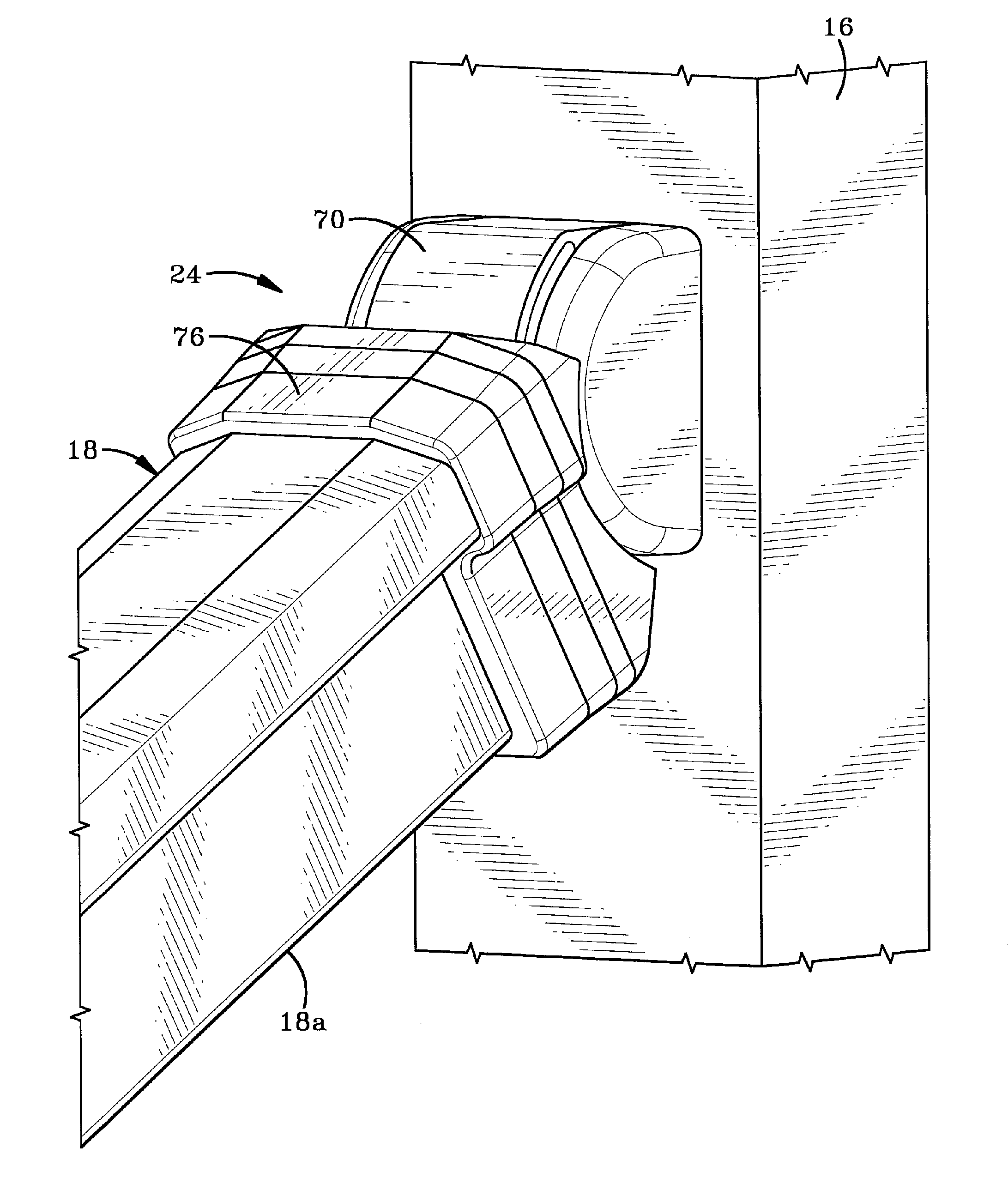

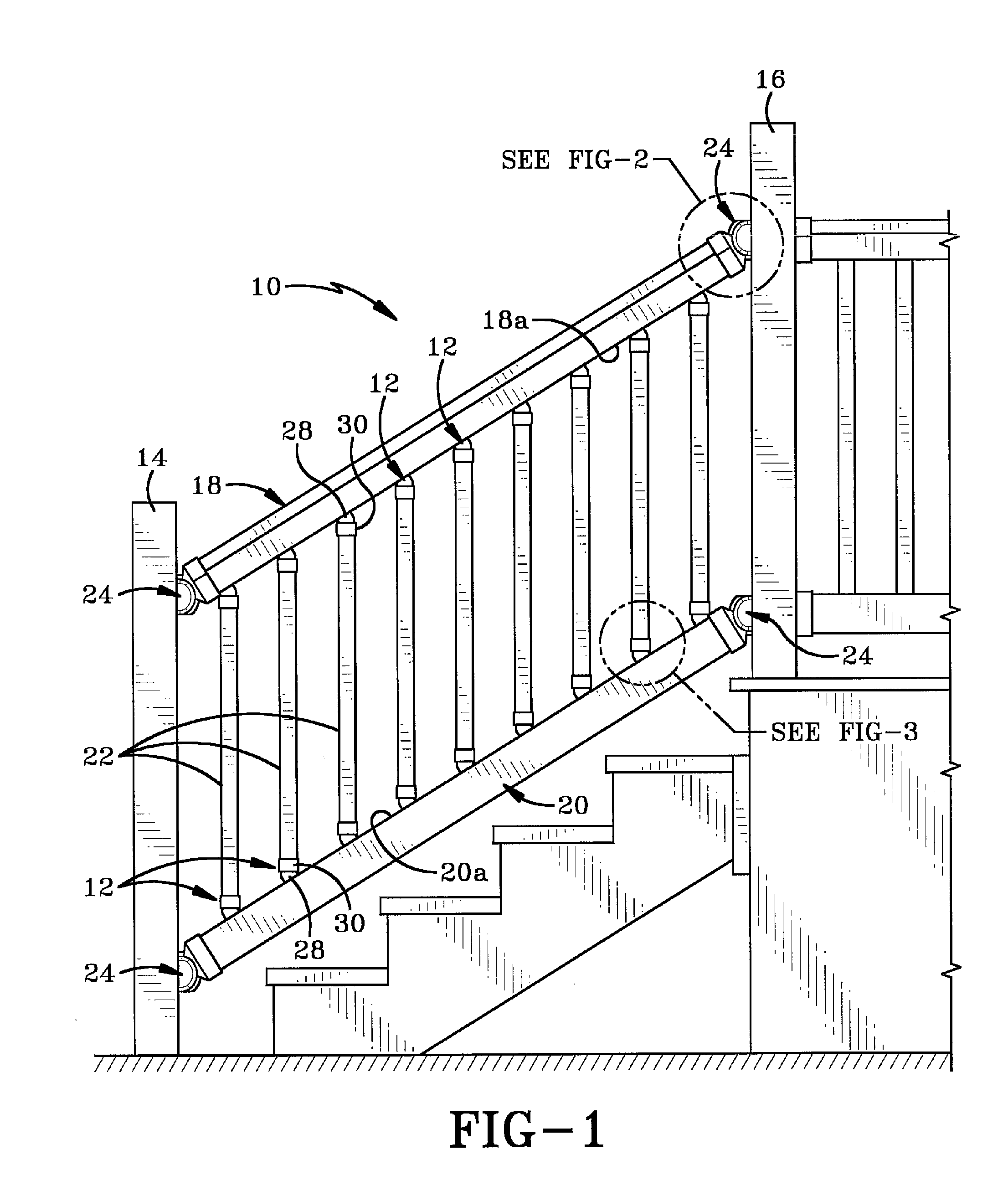

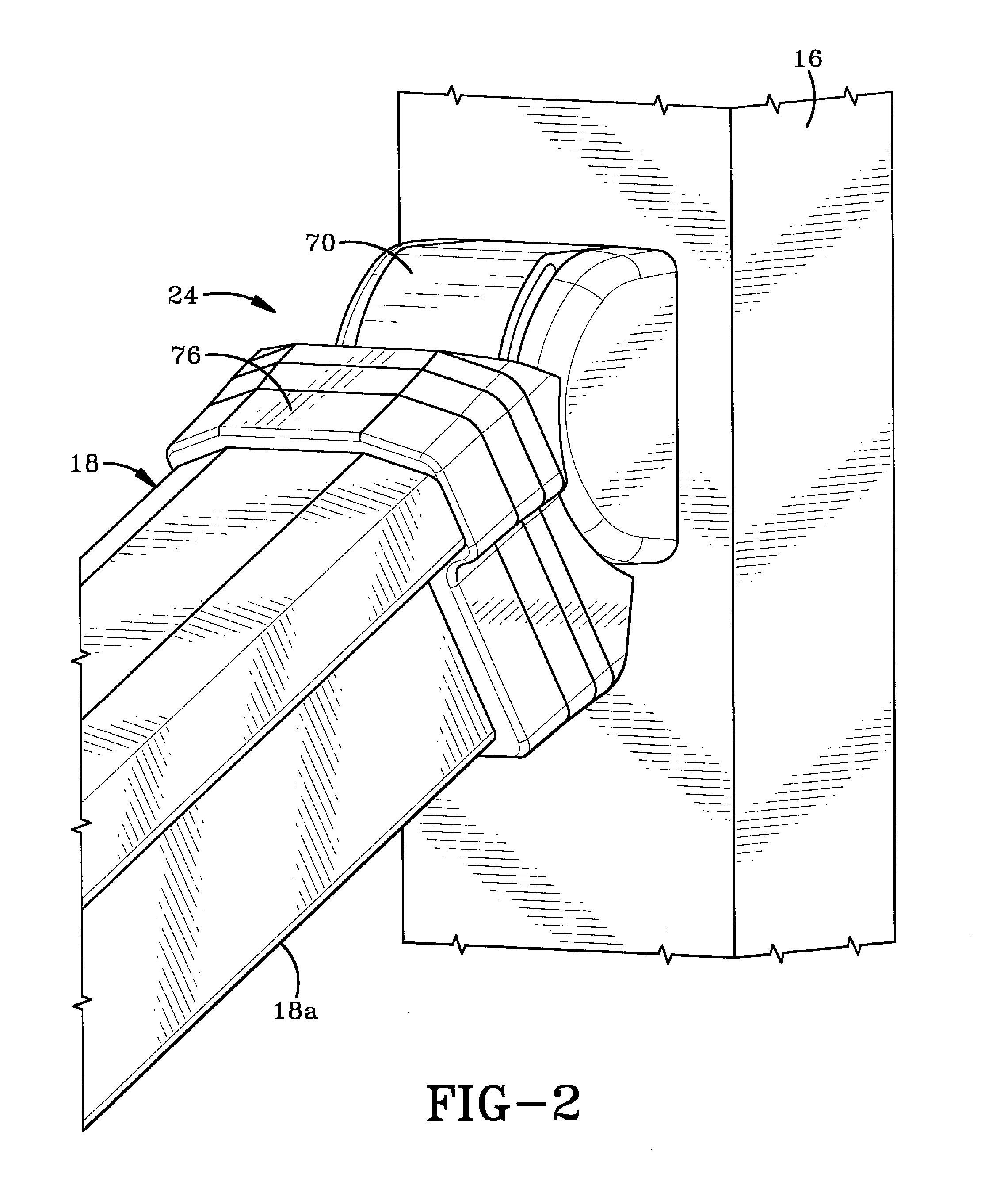

[0021]Referring to FIGS. 1-10, there is shown a stair rail assembly 10 that includes a pair of spaced-apart vertical fence posts 14, 16; a hand rail 18, a foot rail 20 and a plurality of spindles 22 extending therebetween. Each rail 18, 20 is secured to one of posts 14, 16 by way of a rail bracket assembly 24. Each rail bracket assembly 24 is adjustable so as to allow rails 18, 20 to be set at a desired angle relative to posts 14, 16. Suitable bracket assemblies 24 for this purpose are any one of the bracket assemblies disclosed in U.S. Pat. Nos. 6,698,726; 6,986,505; 7,044,451 and 7,147,212 to the present inventor, the entire disclosures of which are incorporated herein by reference. Bracket assemblies 24 enable rails 18, 20 to be set at an appropriate angle for staircases that are built at different angles of steepness. Stair rail assembly 10 further includes a plurality of spindle racking assemblies in accordance with the present invention, which assemblies are generally indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com