Assembled camshaft

A camshaft, combined technology, used in valve details, engine components, machines/engines, etc., can solve problems such as inconvenient oil supply adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

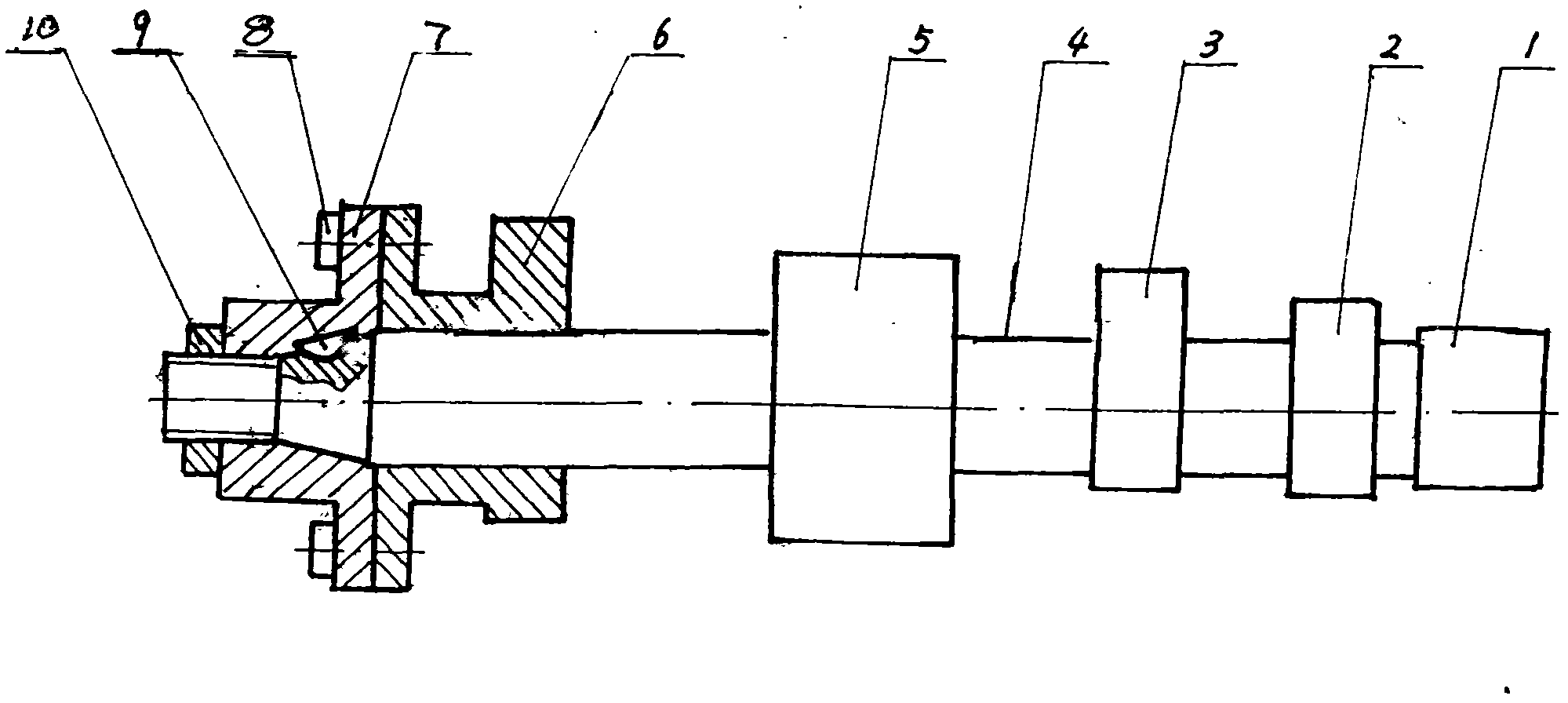

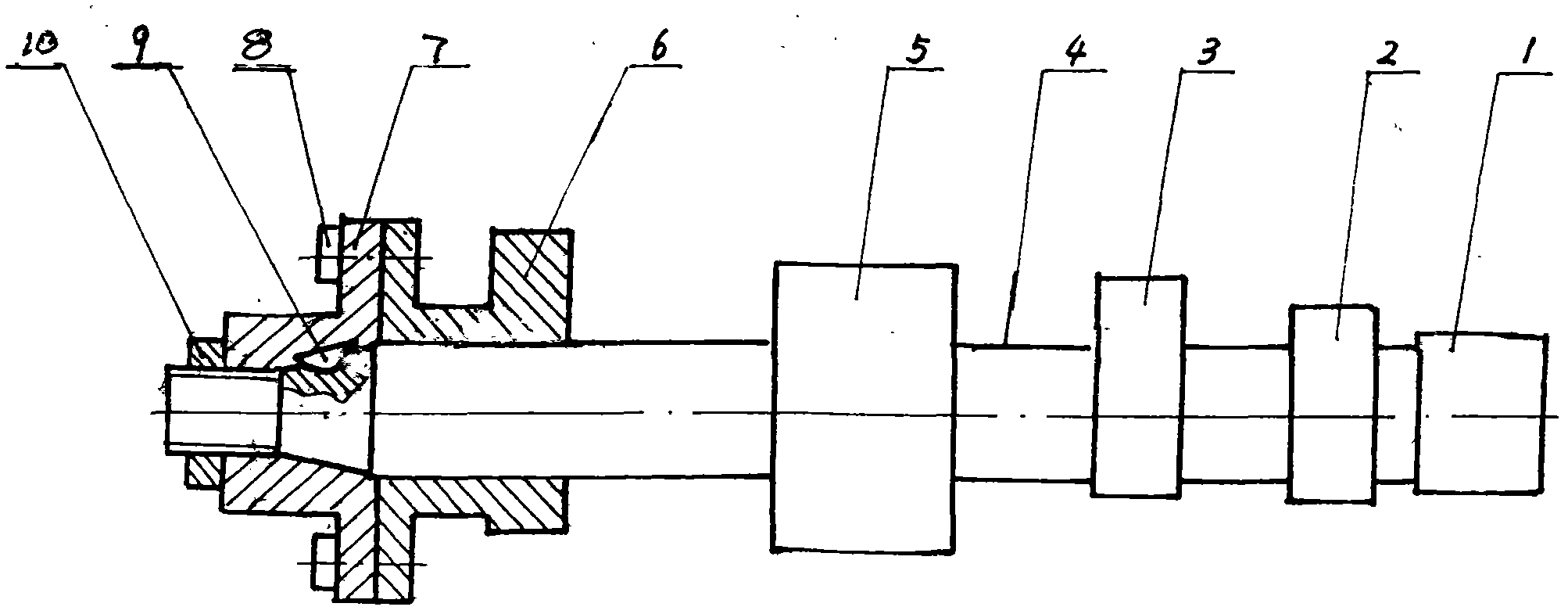

[0006] As shown in the accompanying drawings, the camshaft 4 of the present invention is made with intake cam 3, exhaust cam 2, support journals 1 and 5, the oil supply cam 6 of the fuel injection pump is slipped on the camshaft 4, and the drive disc 7 passes through The key 9 is fastened on the camshaft 4 with a nut 10, and the fuel supply cam 6 of the fuel injection pump is connected with the drive plate 7 through a screw 8.

[0007] When adjusting the advance angle of fuel supply, loosen the screw 8, move the oil supply cam 6 of the fuel injection pump to make it rotate an angle relative to the drive plate 7, and then tighten the screw 8 to complete the adjustment of the advance angle of fuel supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com