Forging method of main pipe blank with branch pipe nozzles used in nuclear power station

A technology for main pipes and branch nozzles, which is applied in the forging field of nuclear power main pipe blanks with branch nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

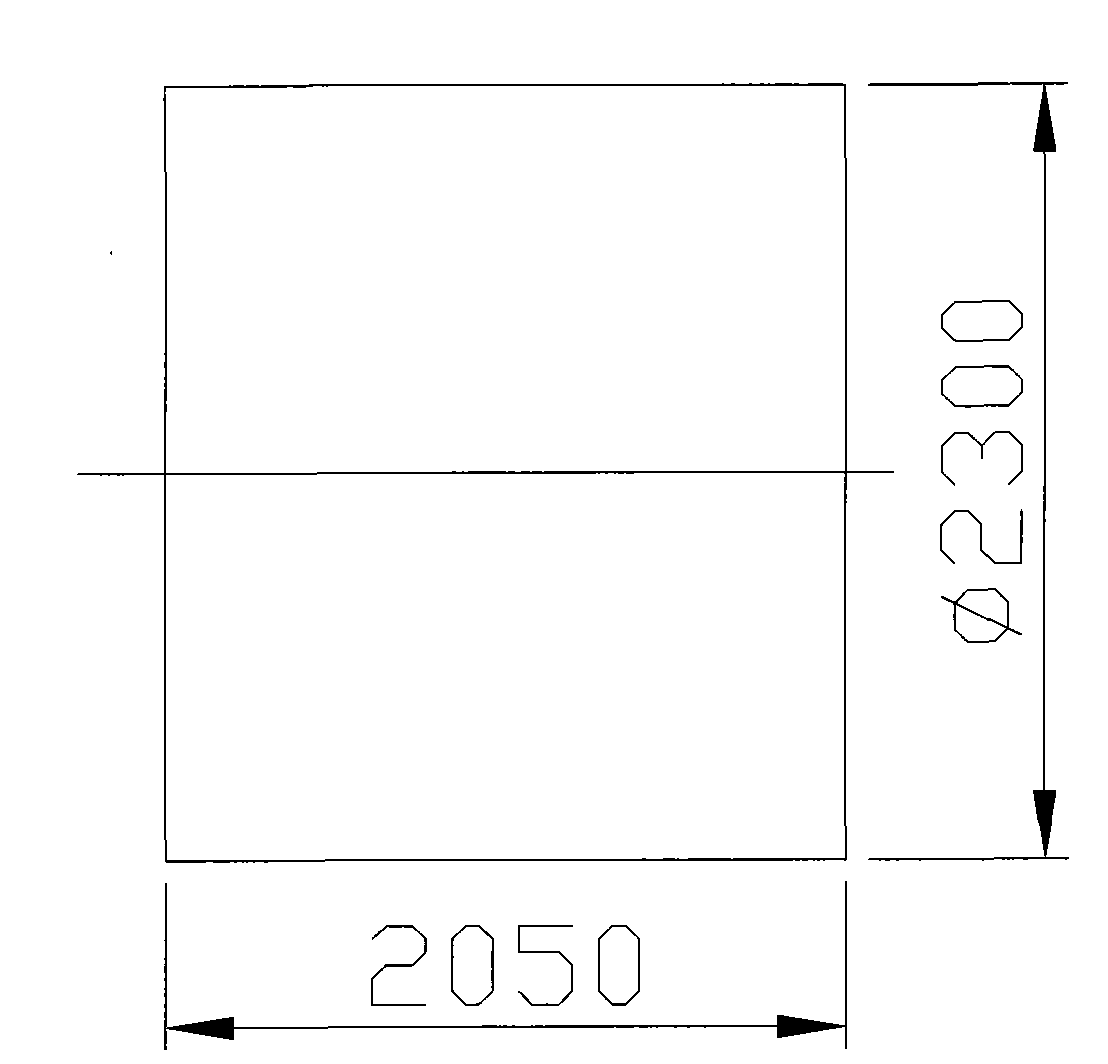

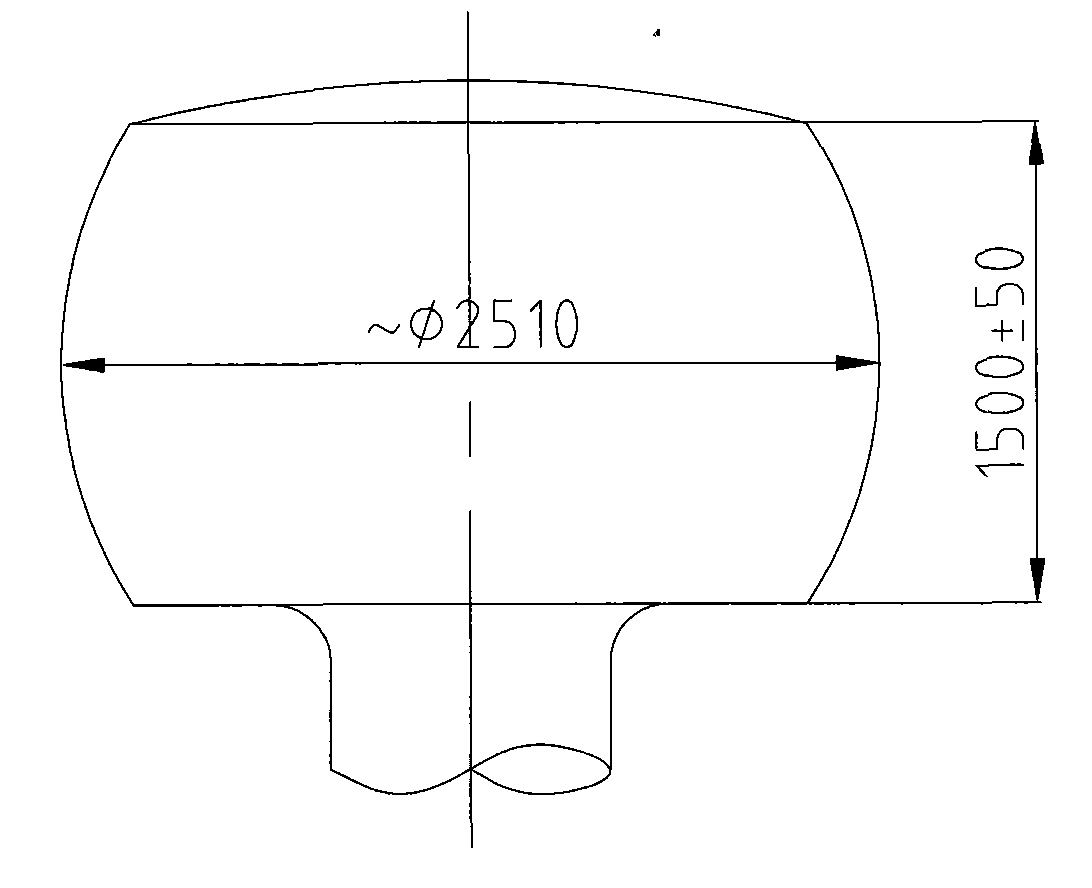

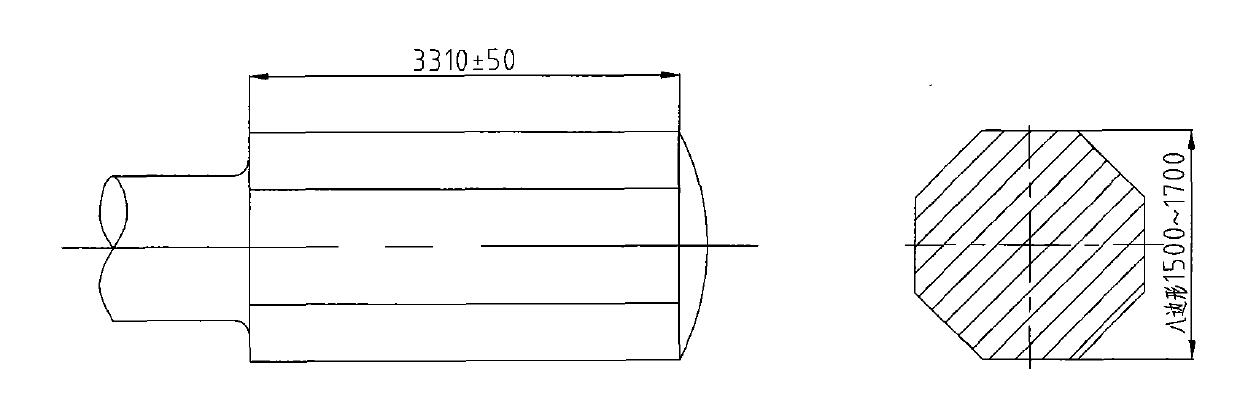

[0020] The material of the main pipeline of AP1000 nuclear power plant is TP316LN (see ASME Code II, SA-336), the outer diameter of the straight pipe is 965mm, the inner diameter is 785mm, the height of the branch nozzle is 387mm, and the diameter of the branch nozzle is 616mm. The biggest difficulty in forging the branch nozzles of the main pipe is that its two branch nozzles are not in the same plane, and the two branch nozzles are at a 45-degree angle to each other (see Figure 5 In the A-direction view, the marked 1# and 2# represent two branch nozzles respectively. It can be seen from the figure that the angle between the two branch nozzles is 45 degrees), and the requirements for grain size are relatively high. Therefore, a special process method should be adopted for forging the branch nozzle of the main pipeline.

[0021] In one embodiment, a 16,500-ton hydraulic press is used to forge an electroslag remelted steel ingot whose material is TP316LN, including the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com