Patents

Literature

191results about How to "Realize continuous work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

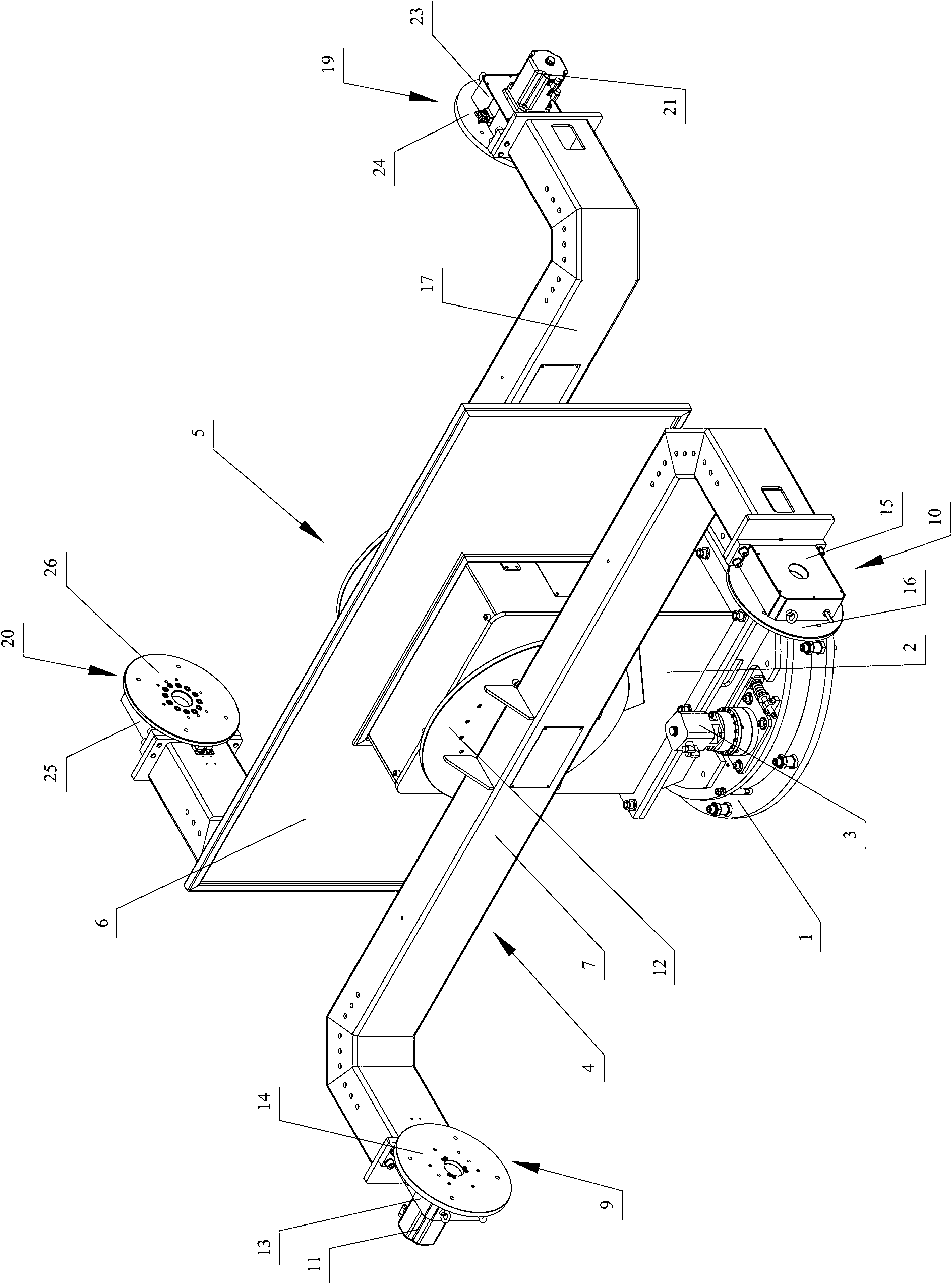

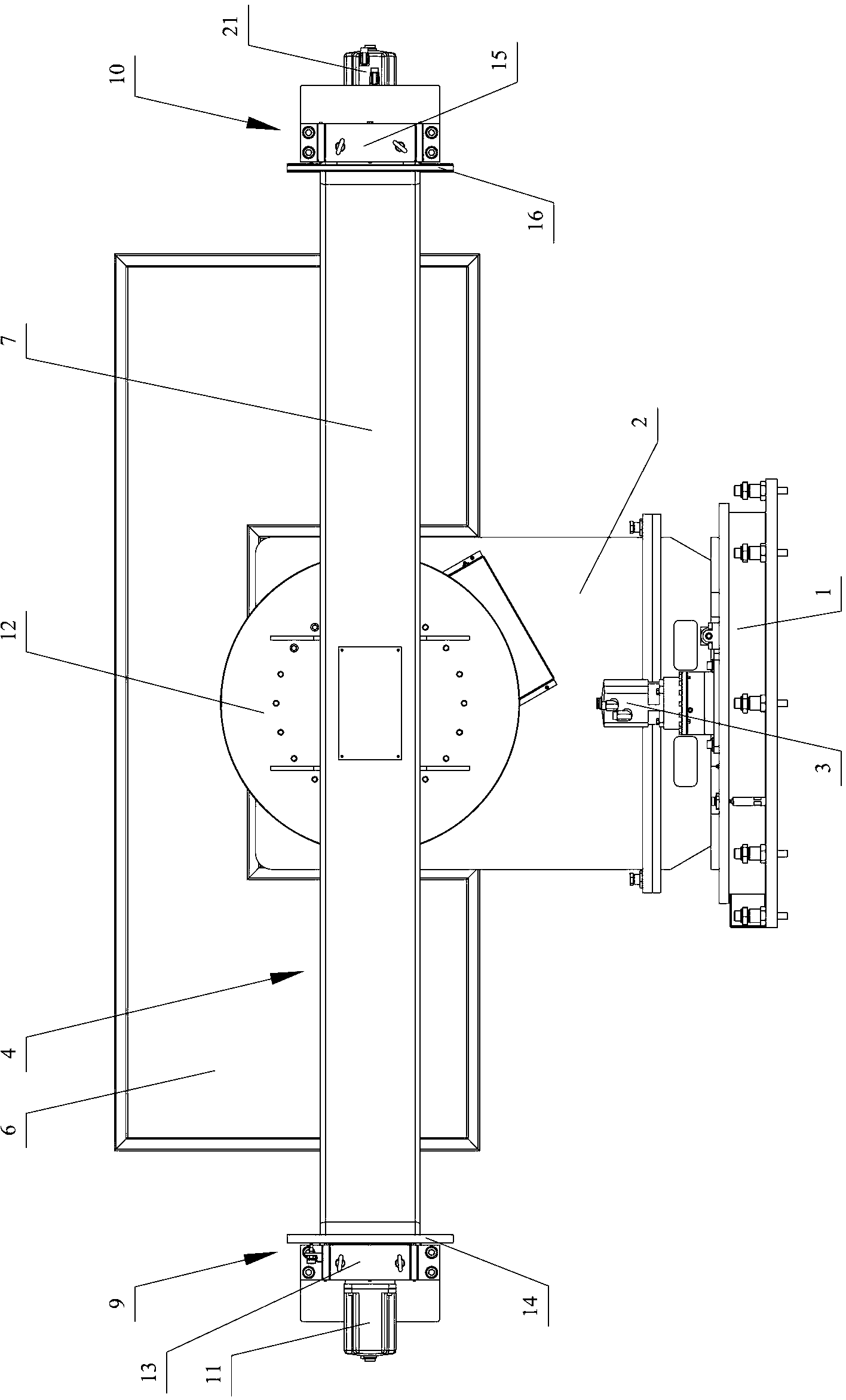

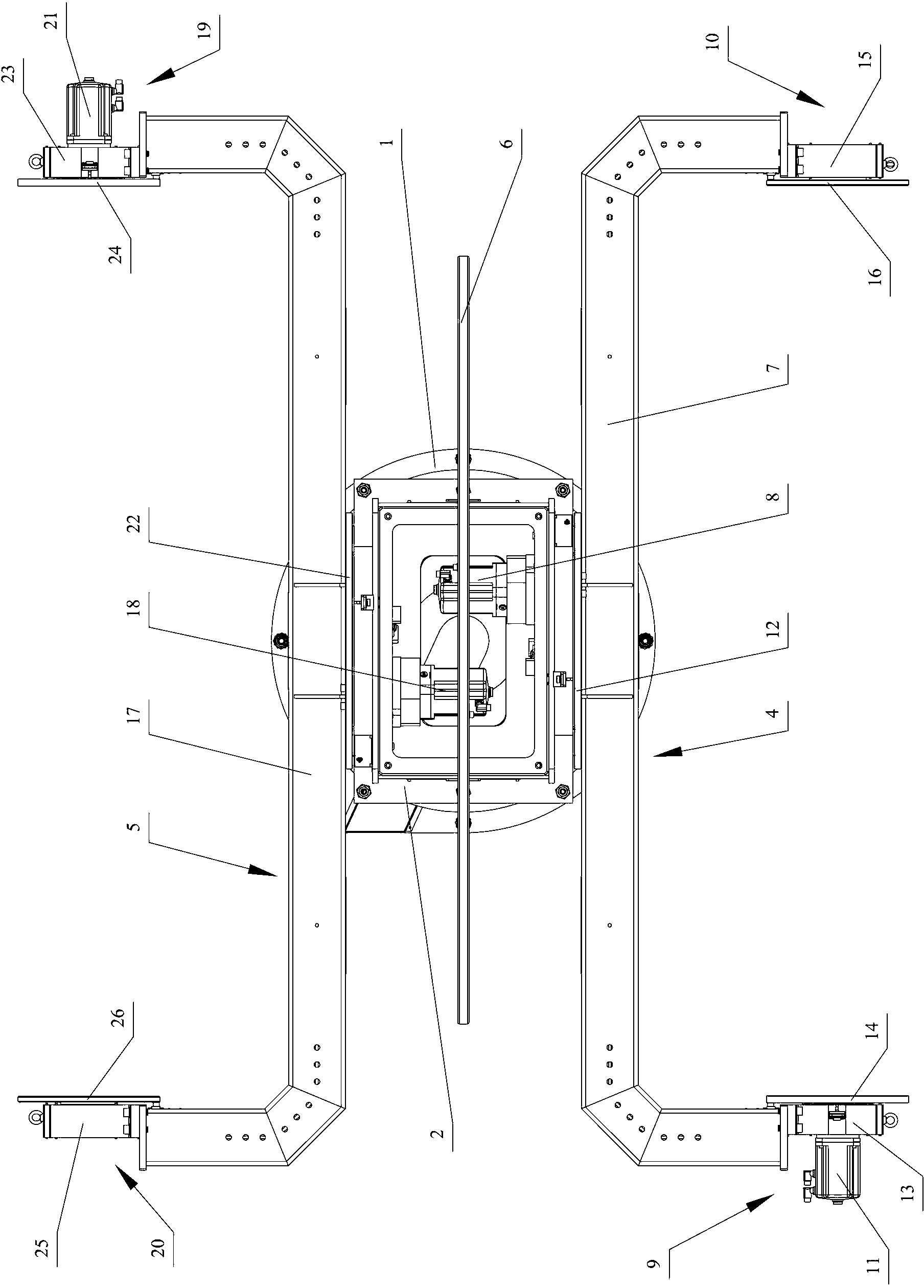

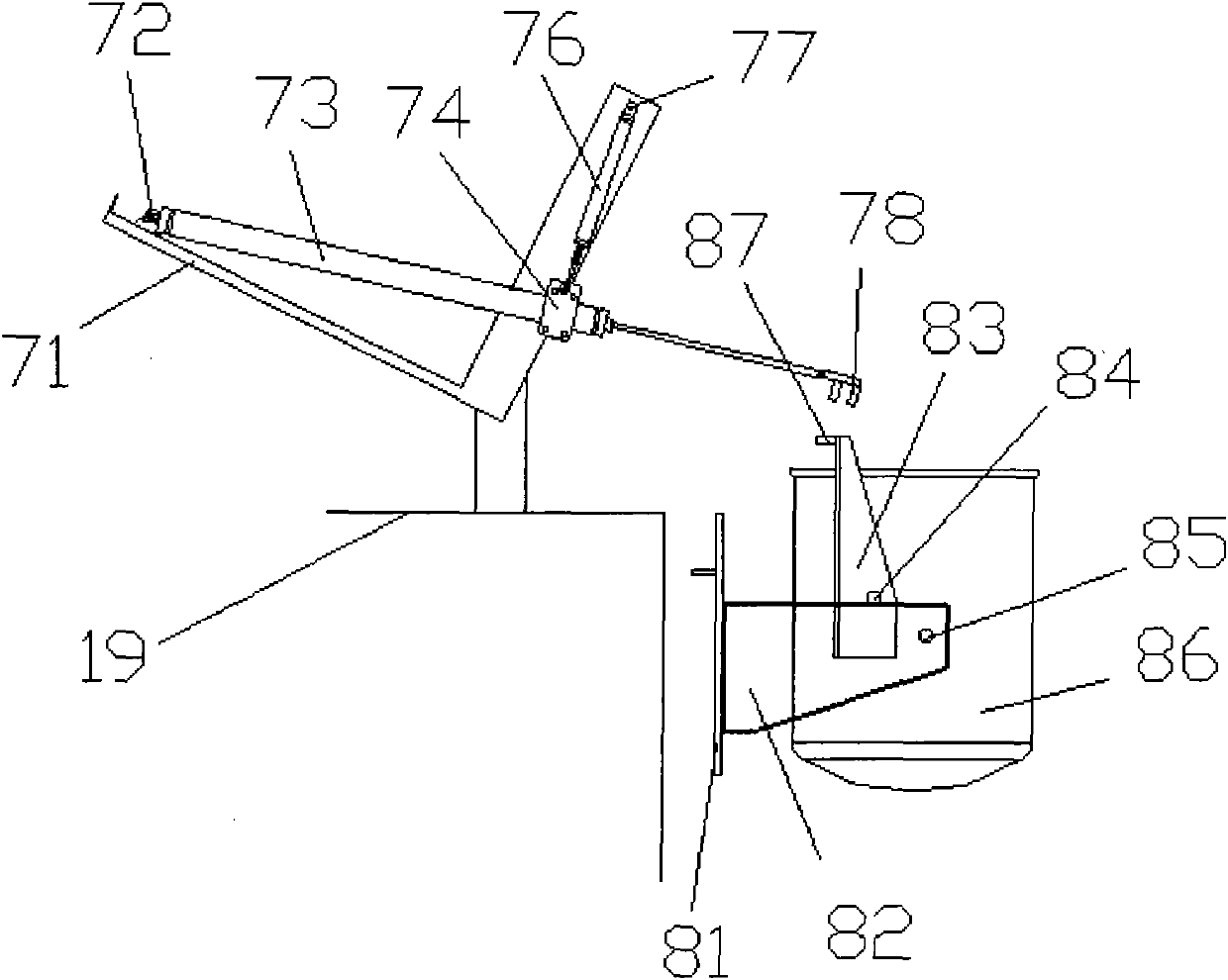

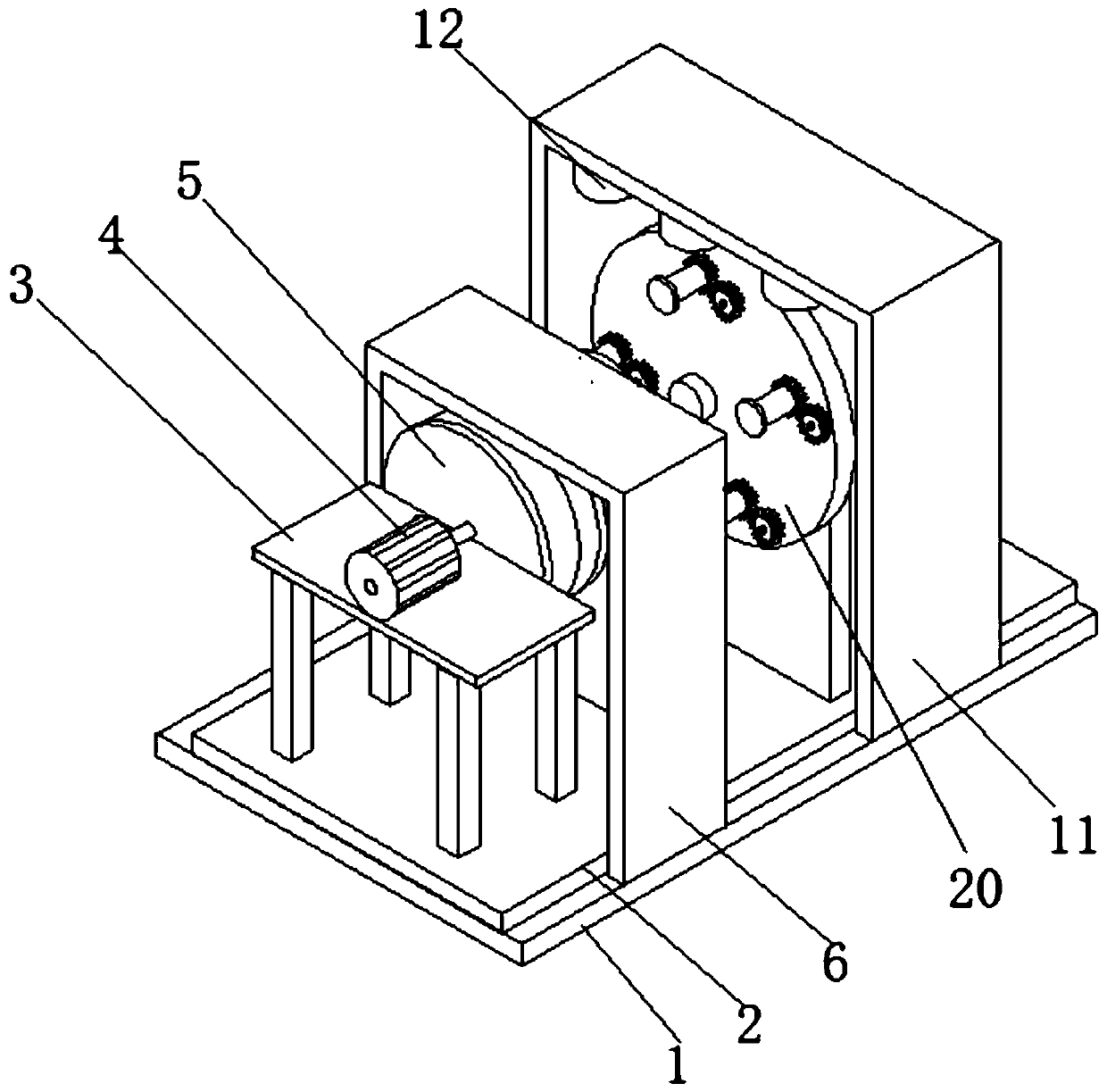

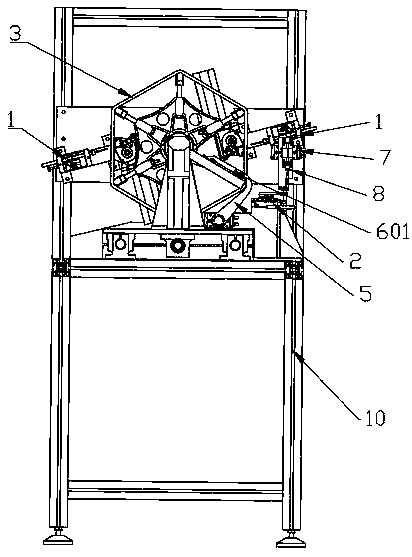

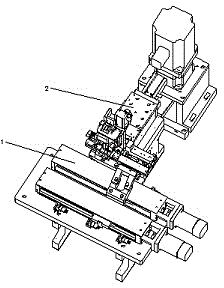

Precision five-axis double-station position changing machine

ActiveCN102699612AReduce production timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesRocker armEngineering

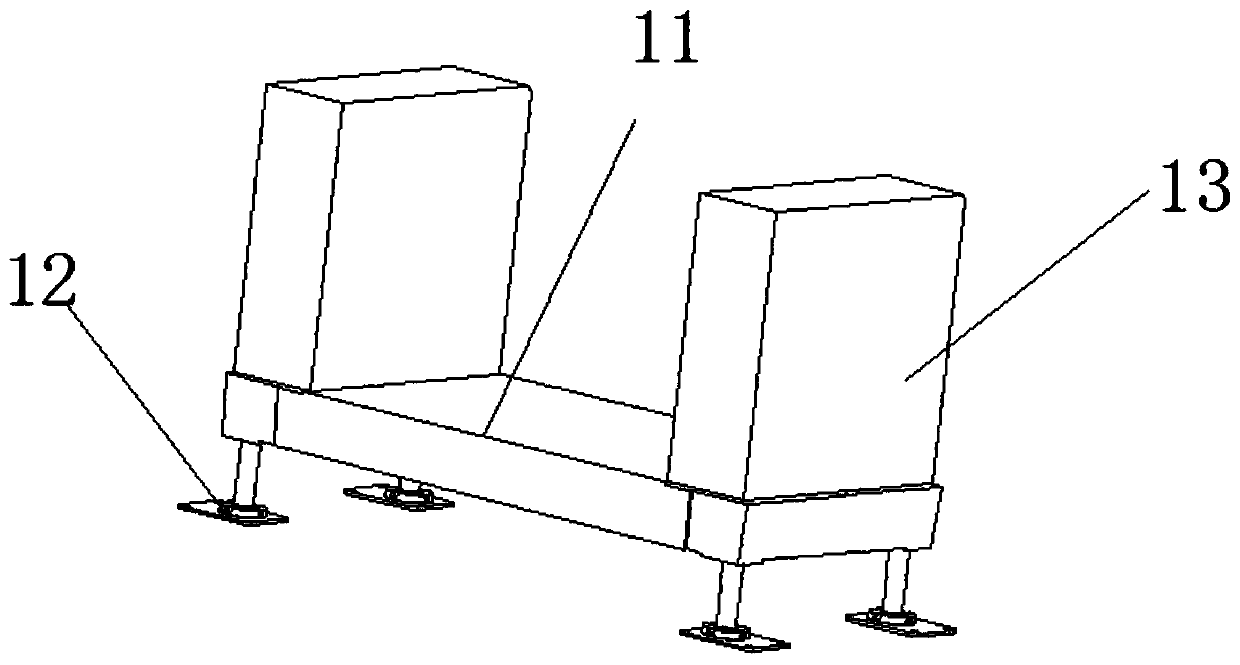

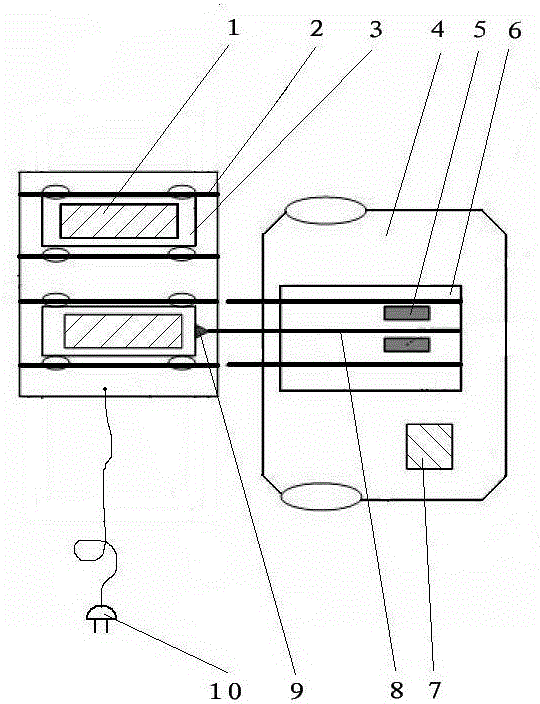

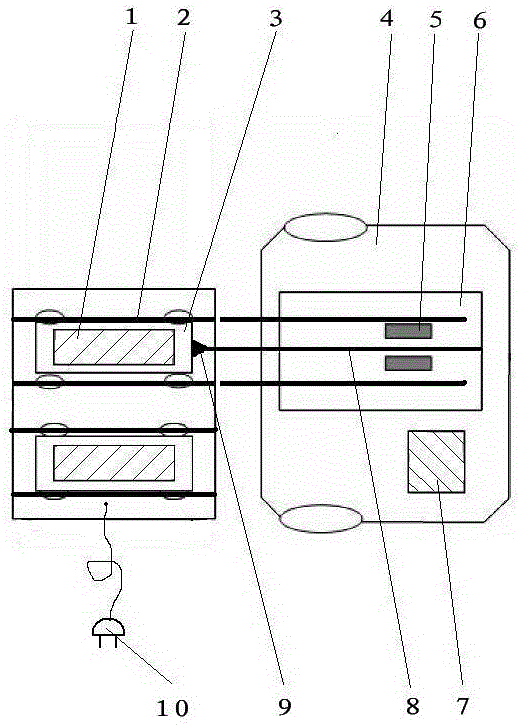

The invention relates to a precision five-axis double-station position changing machine. The machine comprises a rotating base, an upright post box arranged on the rotating base in a horizontal rotating mode, a first servo motor for driving the upright post box to rotate, and a first clamping device and a second clamping device which are respectively arranged on the two sides of the upright post box, wherein the first clamping device comprises a first rocker arm, a second servo motor for connecting the upright post box and the first rocker arm and driving the first rocker arm to vertically rotate, a first headstock and a first tailstock which are arranged on the first rocker arm, and a third servo motor for driving the first headstock to rotate; and the second clamping device comprises a second rocker arm, a fourth servo motor for connecting the upright post box and the second rocker arm and driving the second rocker arm to vertically rotate, a second headstock and a second tailstock which are arranged on the second rocker arm, and a fifth servo motor for driving the second headstock to rotate. Double position-changeable stations are arranged, so that a welding robot can continuously work, time consumption during production is reduced, production efficiency is improved, and rotating accuracy and repositioning accuracy are high.

Owner:XUZHOU HUAHENG ROBOT SYST

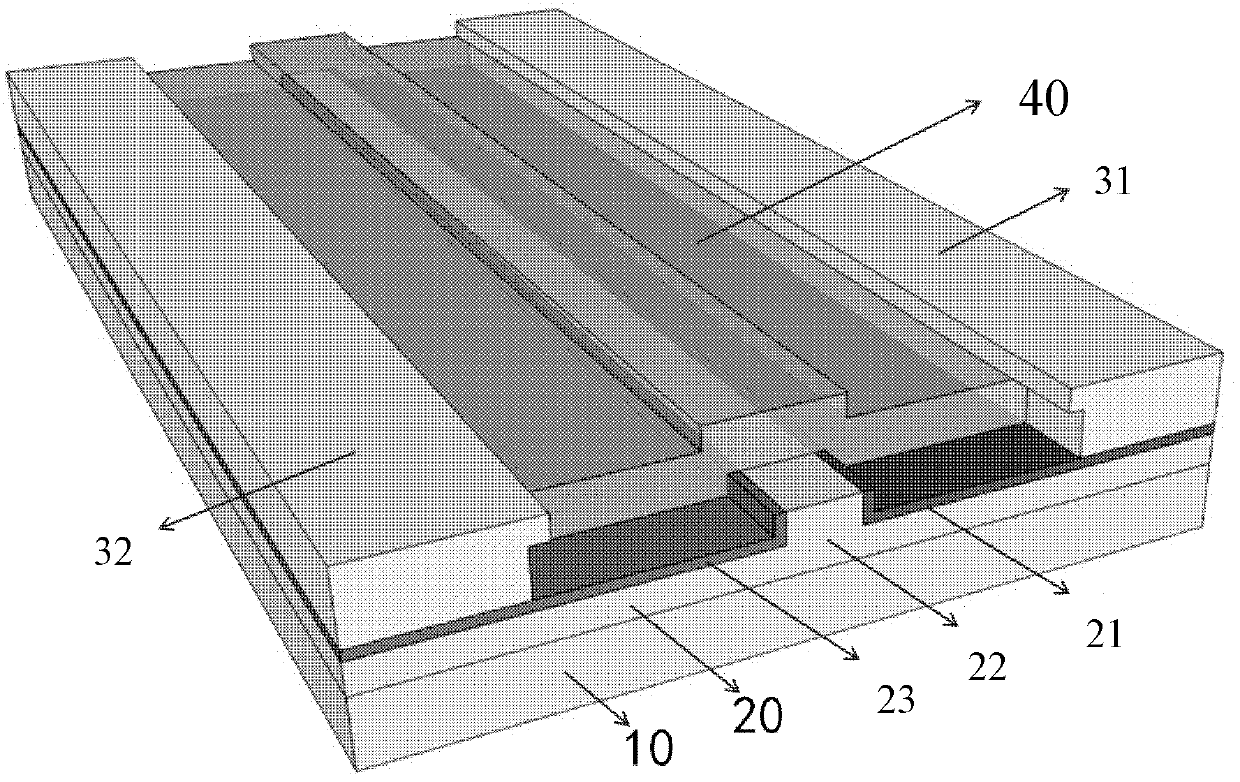

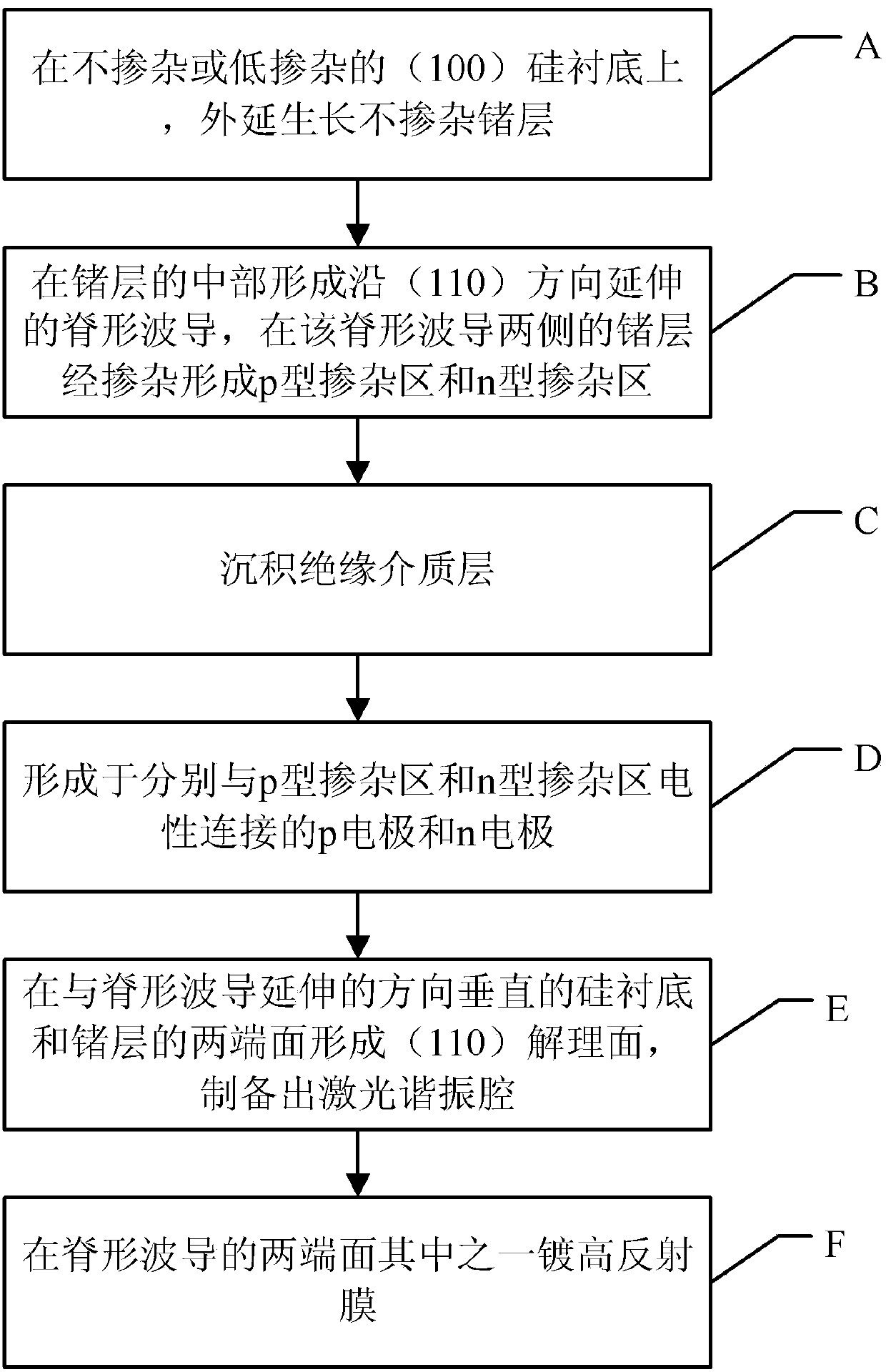

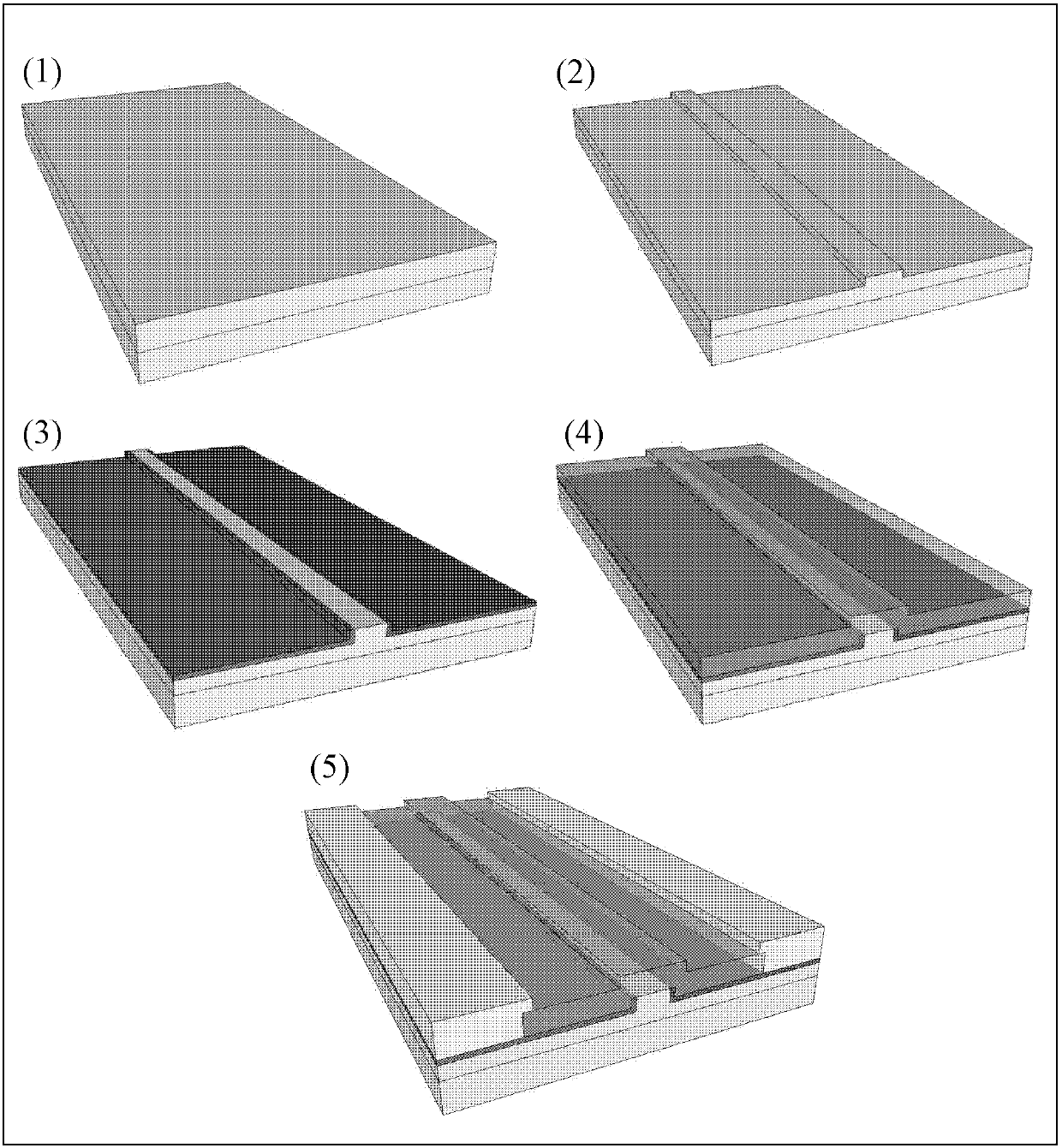

Silicon-based germanium laser device and method for manufacturing same

InactiveCN103427332AImprove crystal qualityImprove performanceOptical wave guidanceResonant cavityCrystal orientation

The invention provides a silicon-based germanium laser device and a method for manufacturing the same. The silicon-based germanium laser device comprises a silicon material, a germanium layer, a p-type doped region, an n-type doped region, an insulating dielectric layer, a p electrode and an n electrode; the silicon material is provide with corresponding crystal orientation; the germanium layer epitaxially grows on the silicon material and comprises a germanium ridge waveguide, the germanium layer is etched to form the germanium ridge waveguide, and the germanium ridge waveguide forms all or partial laser resonant cavities; the p-type doped region and the n-type doped region are positioned on two sides of the germanium ridge waveguide; the p-type doped region, the germanium ridge waveguide and the n-type doped region form a transverse p-i-n diode structure; the insulating dielectric layer is formed above the germanium ridge waveguide, the p-type doped region, the n-type doped region; the p electrode and the n electrode are formed above the insulating dielectric layer and are respectively electrically connected with the p-type doped region and the n-type doped region. The silicon-based germanium laser device and the method have the advantages that the silicon-based germanium laser device is of a horizontal transverse p-i-n germanium ridge waveguide structure, a silicon substrate does not need to be doped, the crystal quality of the germanium layer which epitaxially grows on the silicon substrate can be high, and accordingly the integral performance of the silicon-base germanium laser device can be improved advantageously.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

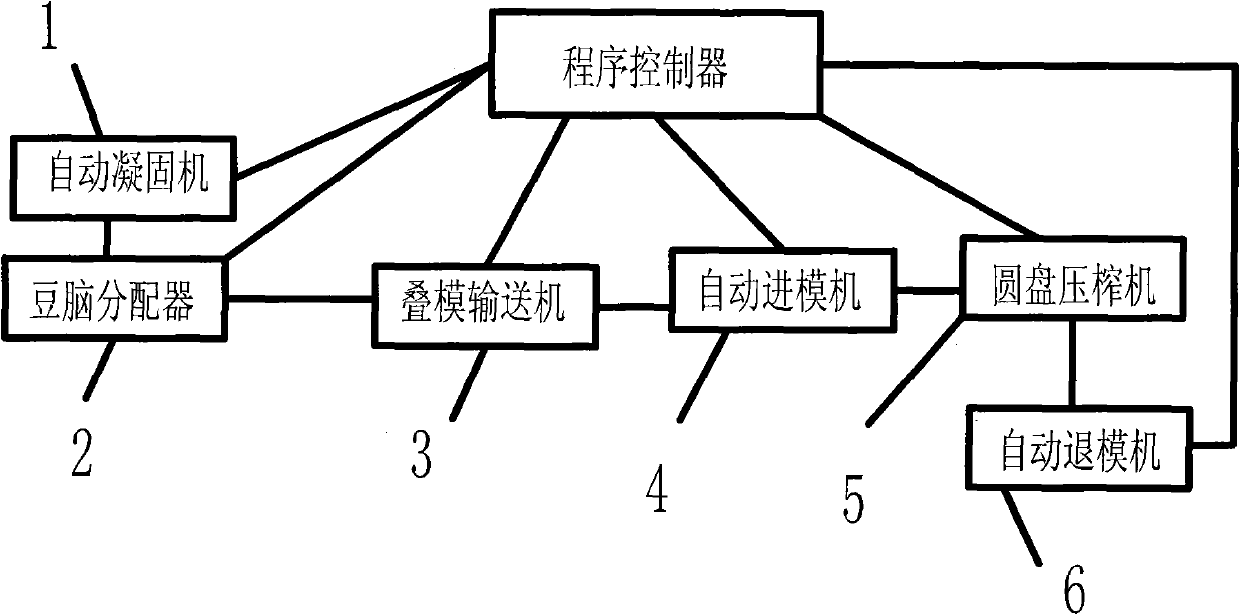

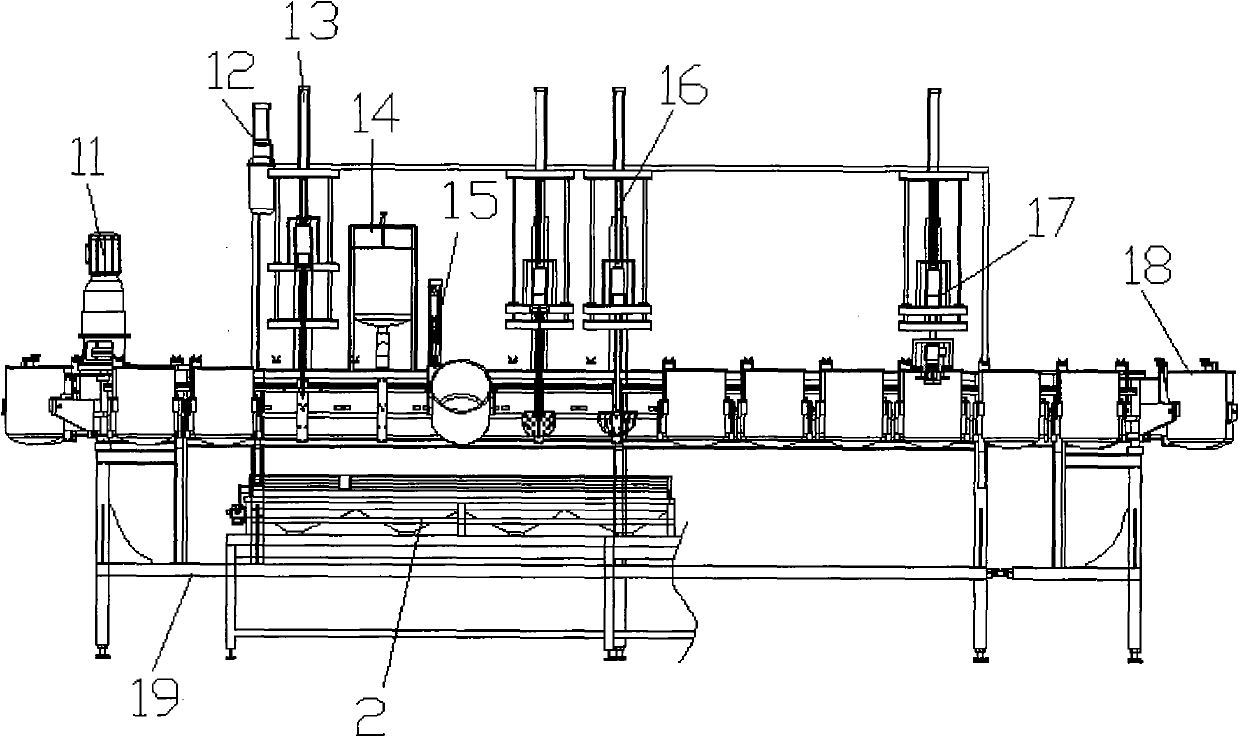

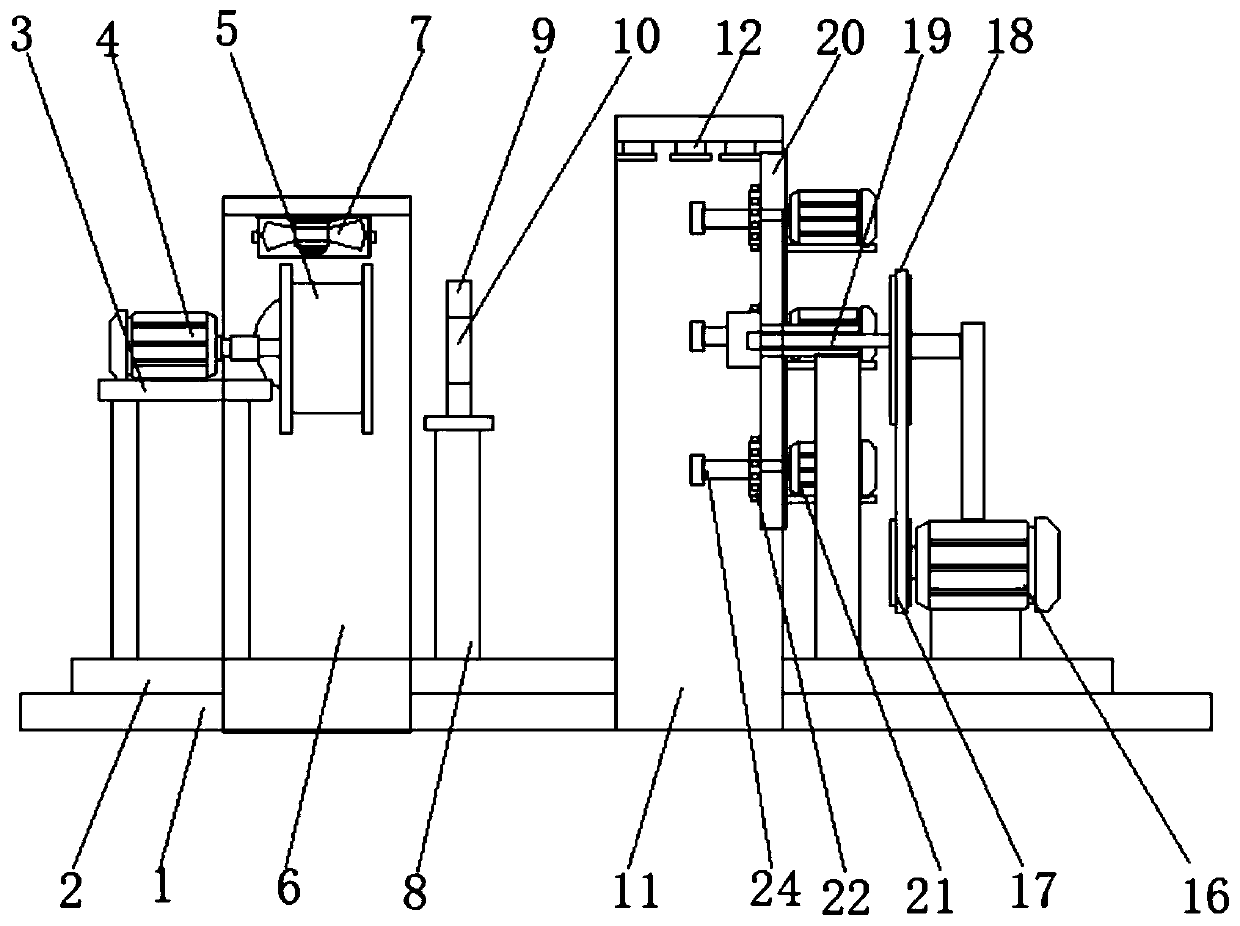

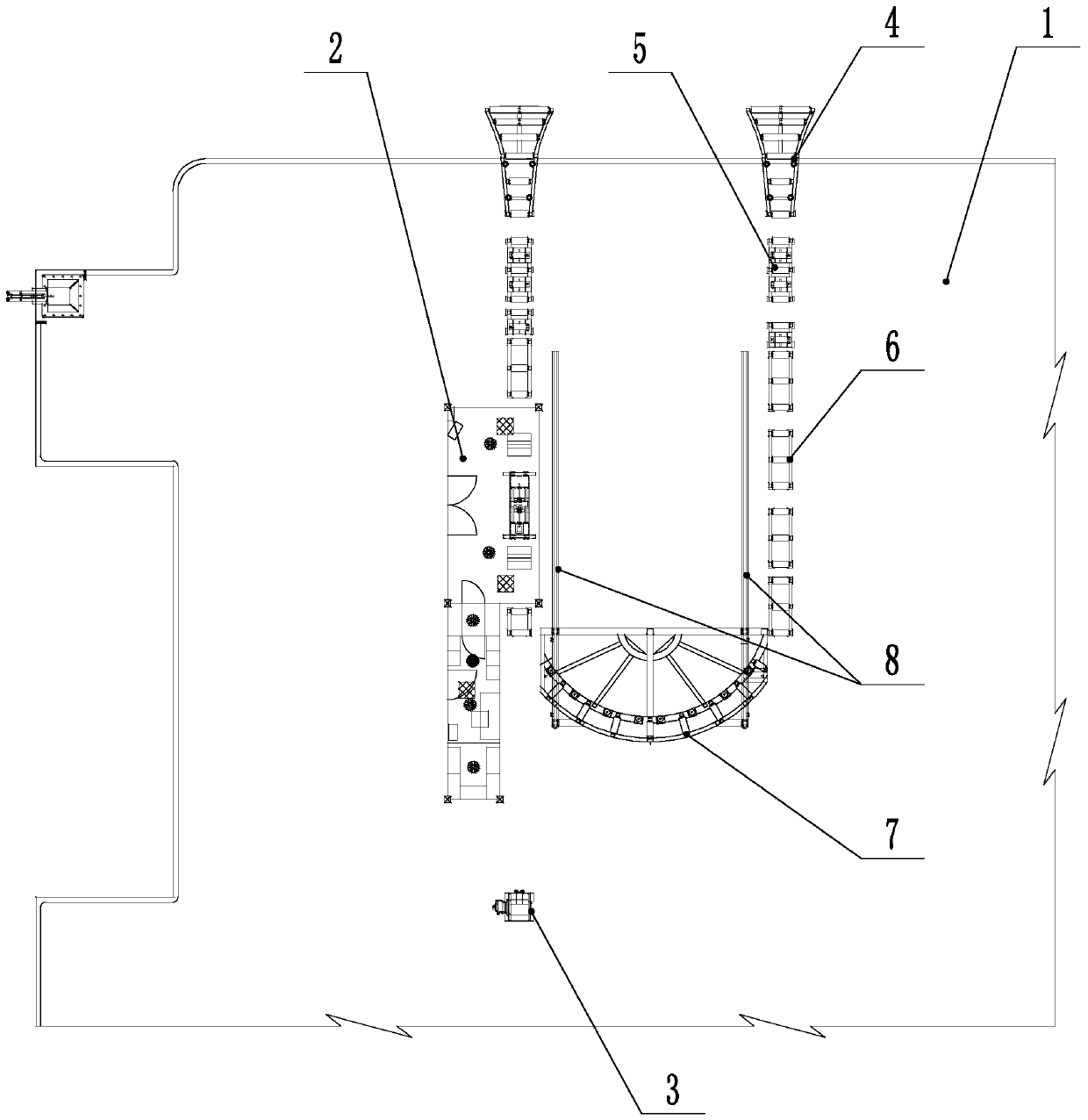

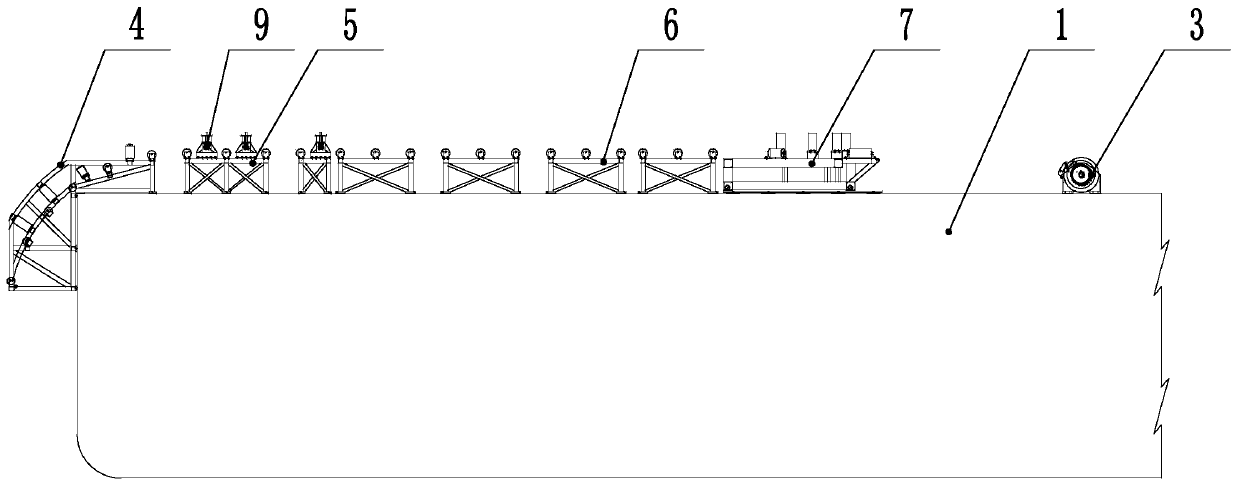

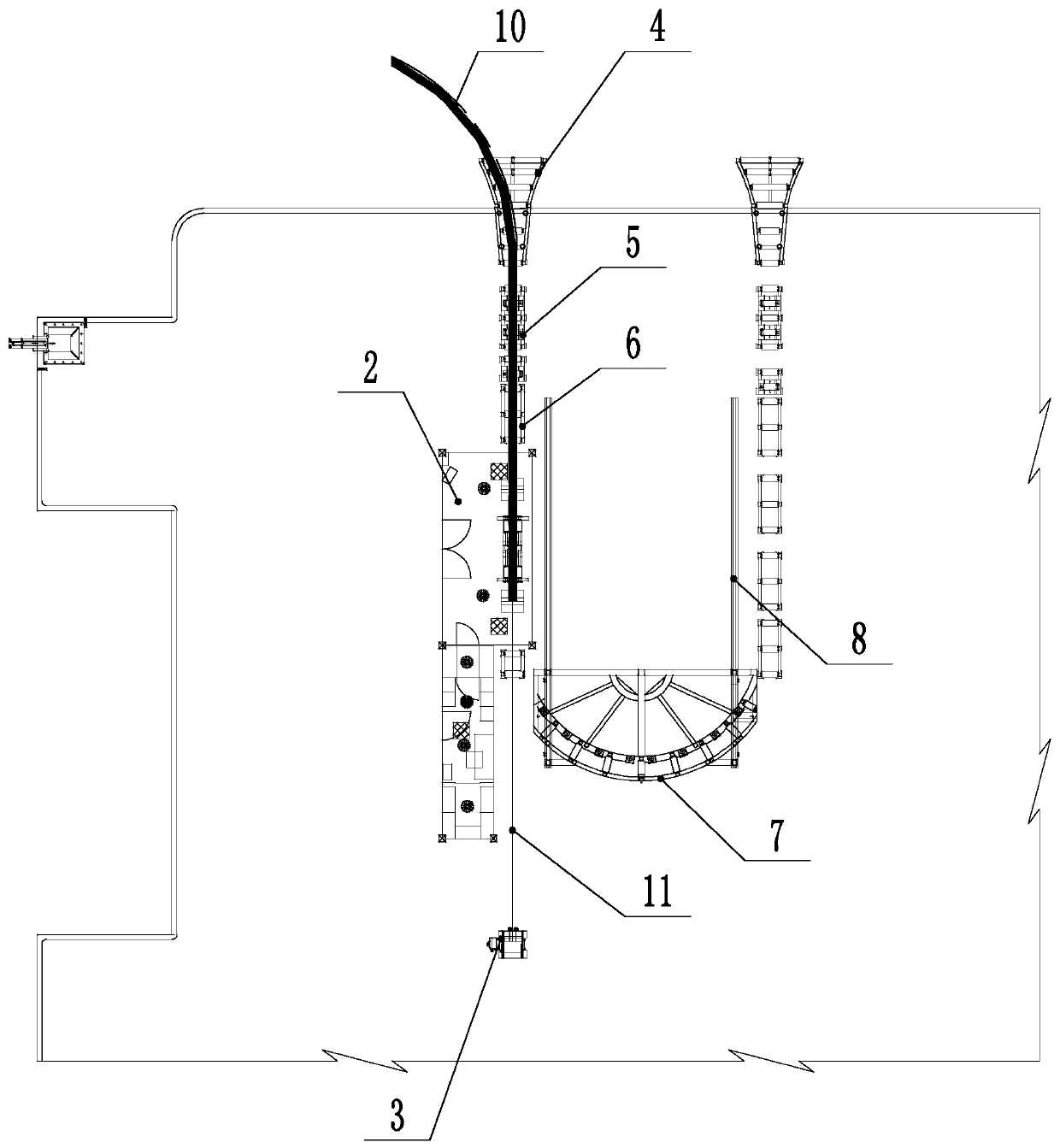

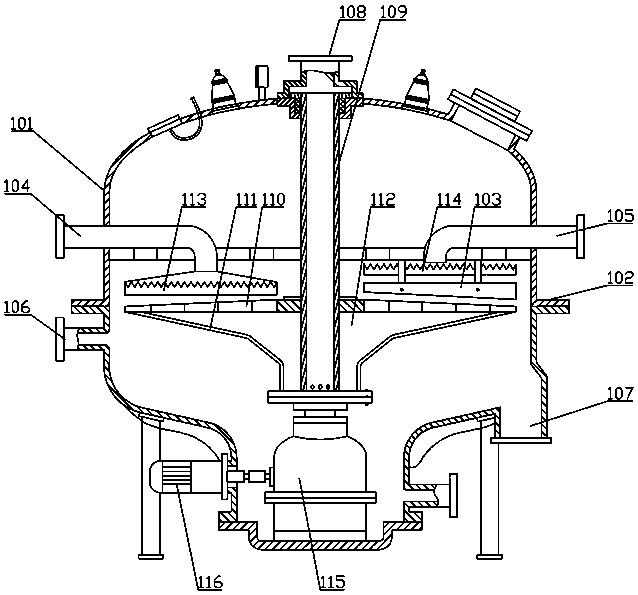

Beancurd billet automatic production system

InactiveCN102018178ALow costReduce manufacturing costCheese manufactureFood shapingManufacturing engineeringCircular disc

The invention discloses a beancurd billet automatic production system which comprises an automatic congealing machine, an uncongealed beancurd distributor, a stack mold conveyer, an automatic mold feeder, a disc squeezer, an automatic mold discharging machine and a program controller, wherein the uncongealed beancurd distributor is arranged below the automatic congealing machine, the uncongealed beancurd distributor and the automatic mold feeder are arranged at two ends of the stack mold conveyer, the automatic mold feeder and the automatic mold discharging machine are arranged at the periphery of the disc squeezer, and the automatic congealing machine, the uncongealed beancurd distributor, the stack mold conveyer, the automatic mold feeder, the disc squeezer and the automatic mold discharging machine are all connected with the program controller. Under the control of the program controller, the beancurd billet automatic production system realizes automated and continuous working process without manual operation, thereby reducing labor cost and production cost, greatly improving production efficiency and sanitary conditions; moreover, the process flow of the beancurd billet automatic production system can be set in advance according to different kinds of bean products and different production processes.

Owner:BEIJING LUOKE MACHINERY

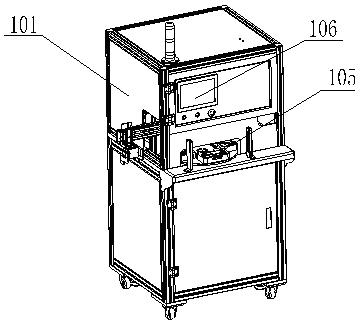

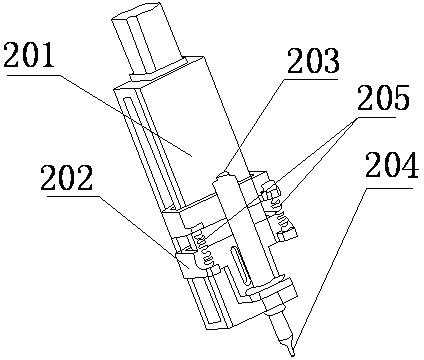

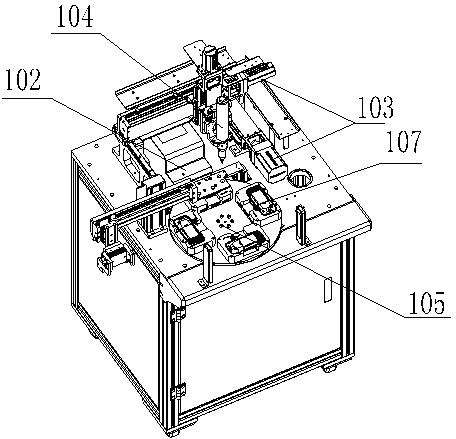

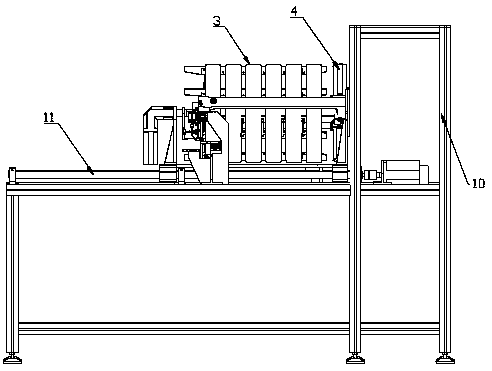

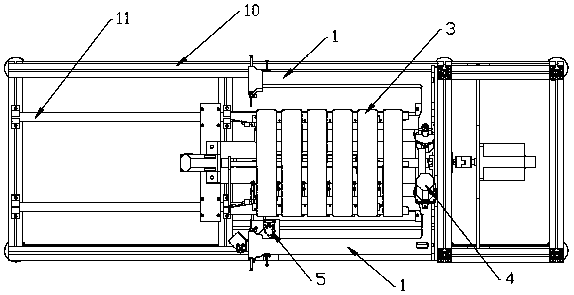

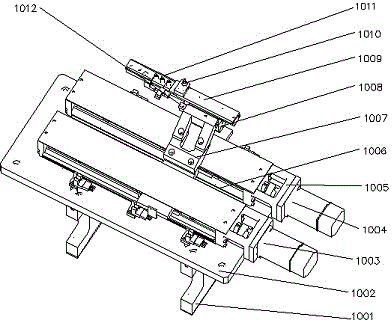

Screw locking machine

InactiveCN102350632AImprove processing efficiencyRealize continuous workMetal working apparatusMachine partsLocking mechanism

The invention discloses a screw locking machine which comprises a machine frame, wherein a feeding mechanism, a three-shaft positioning mechanism, a locking mechanism and a product positioning mechanism are arranged on the machine frame. The screw locking machine provided by the invention can realize the continuous operation of the screw locking machine. The locking mechanism can position any point of the three-shaft positioning mechanism, thereby improving the accuracy and convenience of a locking process. Especially, the locking mechanism prevents a sliding table from generating a huge impact force during an automatic descending process, thereby avoiding scratching a machined part or damaging the threaded hole of the machined part, promoting the processing efficiency of the screw locking machine and reducing the damage rate of a to-be-locked product.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

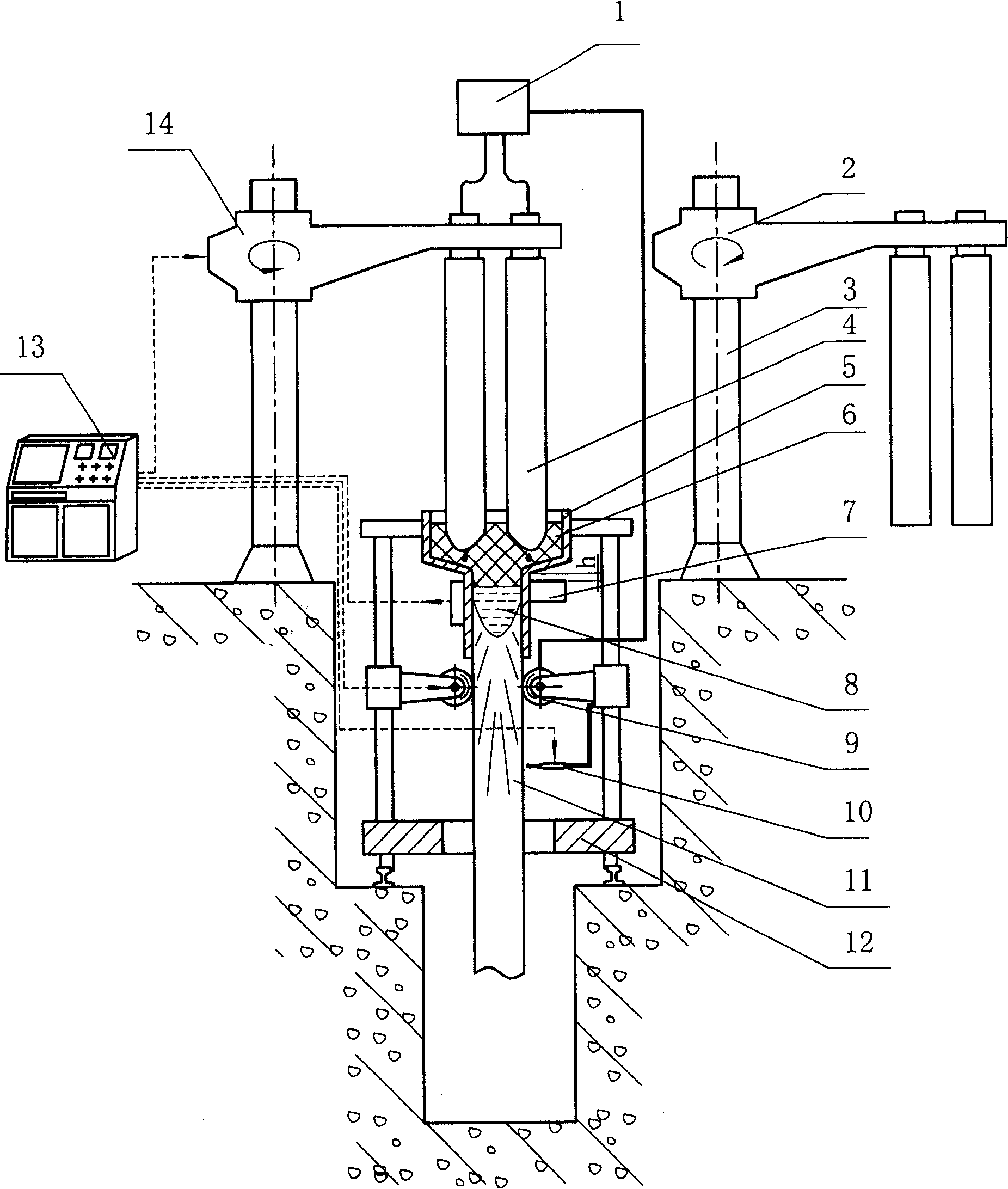

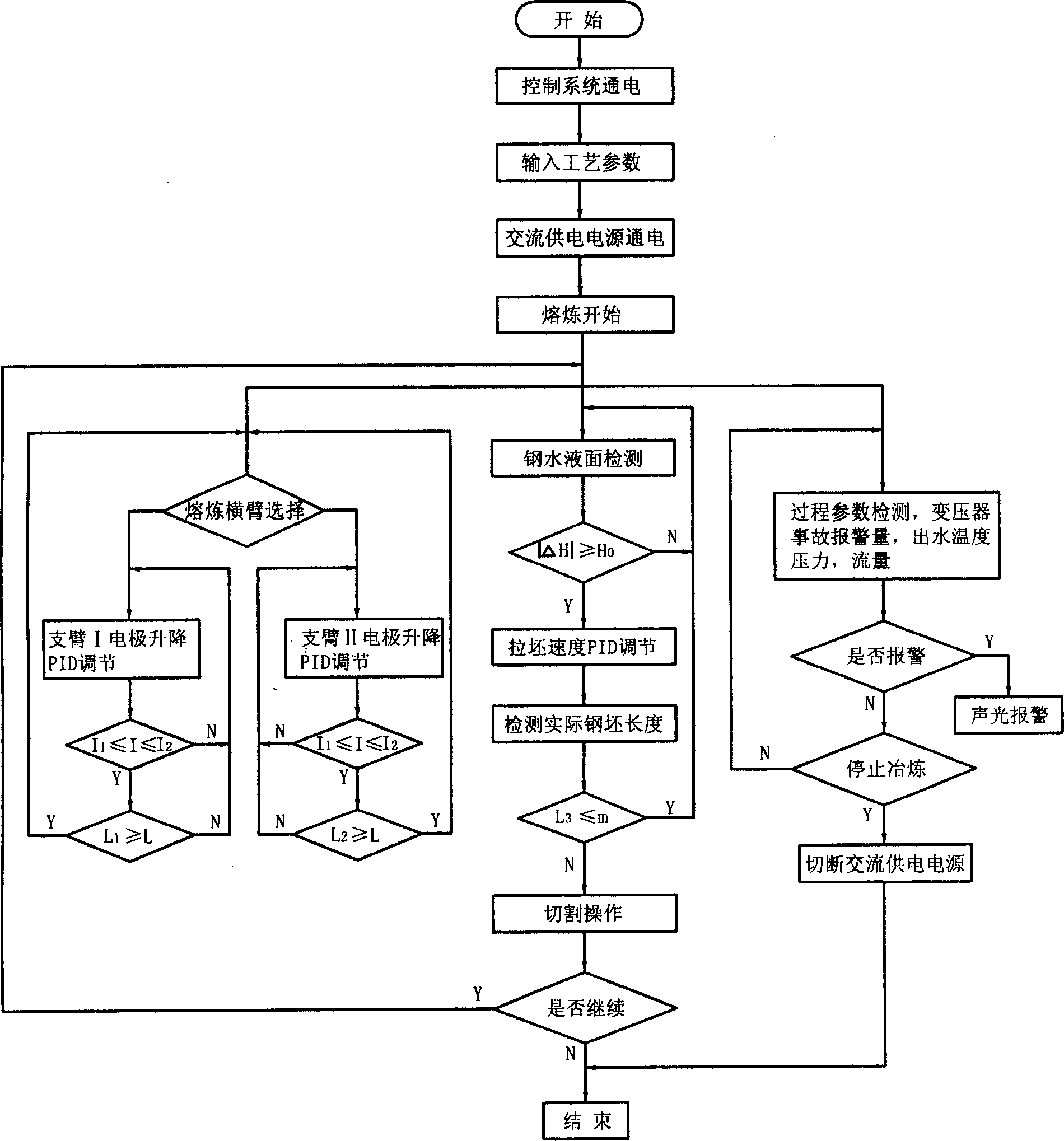

Continuouslly-casting electroslag furnace

A continuous metal cast electroslag furnace includes AC supply, the electric pole elevating, the electric pole and the crystallizer, the supporting mechanism, the liquid steel level detection device, dragging ingot device, the cutting device and the controller. The electric pole elevating is installed in the both sides of the crystallizer which is T hydrocooling crystallizer in the small bore of which is the liquid steel level detection device; the dragging ingot device and the cutting device are installed in the supporting mechanism and the controller is connected to the cross arm of the elevating, the detecting device and the dragging ingot device, the cutting device.

Owner:NORTHEASTERN UNIV

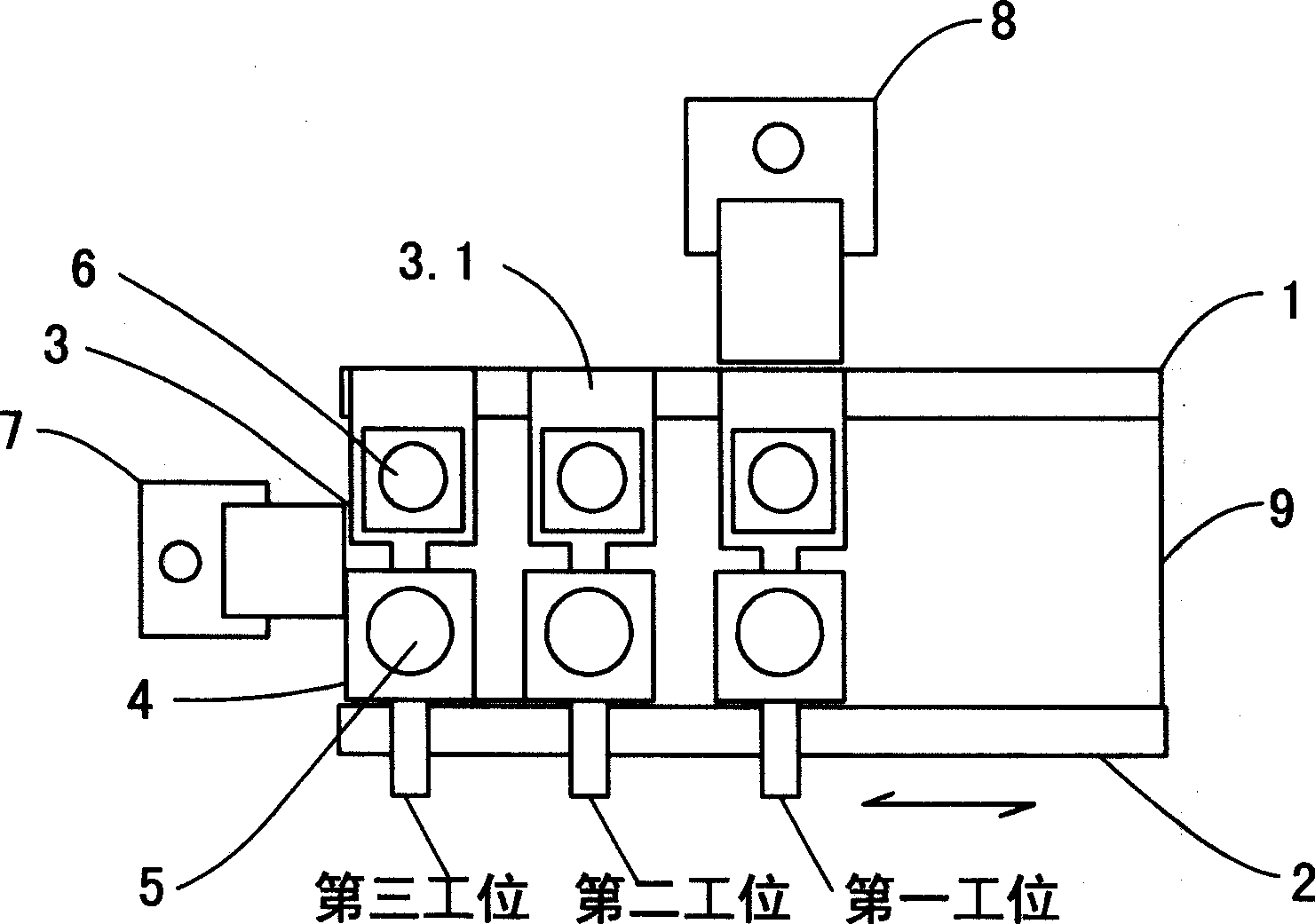

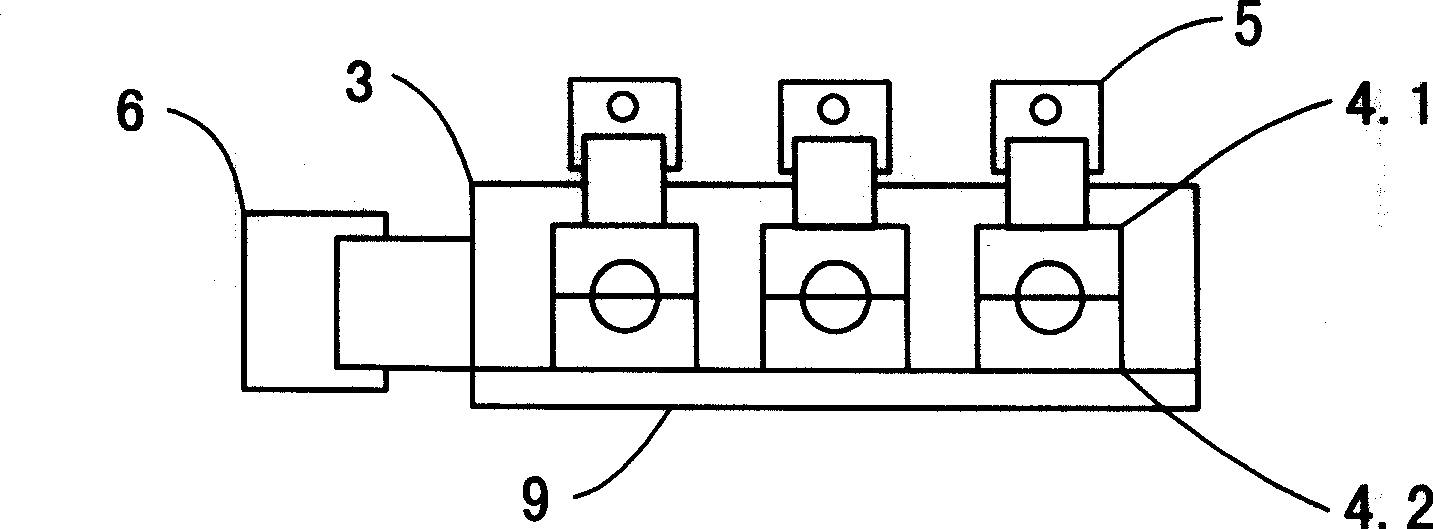

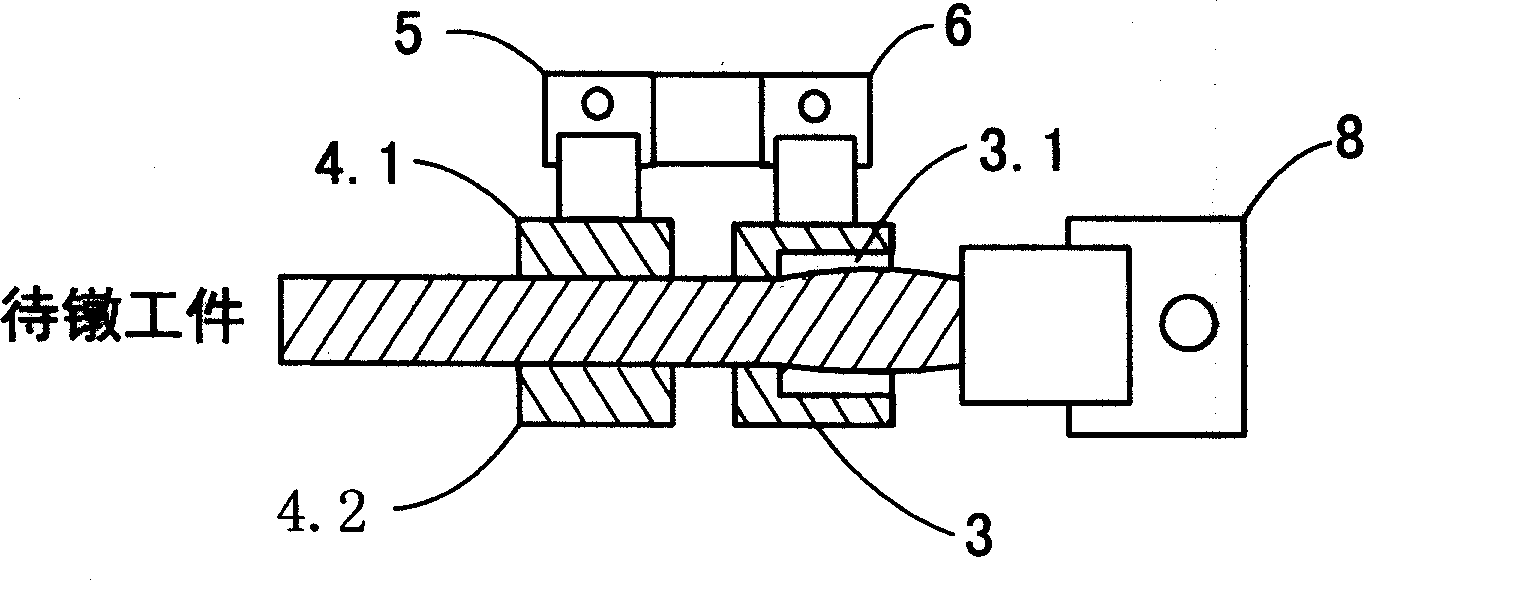

Machine for processing and squeezing pumping rod with three stations

InactiveCN101376158ARealize continuous workReduce consumptionForging/hammering/pressing machinesMachining timeEnergy consumption

The invention relates to a three-station pier extruding machine for a sucker. A mould group is formed by combining three sets of moulds, and mounted in a semi-groove formed by a front baffle, a back baffle and a bottom plate in a sliding state. A displacement oil cylinder for the mould group and a pier extruding oil cylinder are connected to the side part of the mould group. An open-close oil cylinder of the mould and an oil cylinder of a clamp check are connected to an upper semi-mould and an upper plate of the clamp check. An oil extruding rod, a connecting plate, a sealing ring, an upper oil opening and a lower oil opening are installed on the displacement oil cylinder for the mould group, wherein the upper oil opening and the lower oil opening are connected with an oil pump and a controller for definite quantity through a pipeline. Three stations are arranged on one pier extruding machine, thereby realizing the continuous work of the pier extruding oil cylinder and improving efficiency by three to five times; the three-station pier extruding machine for the sucker has the advantages of fast processing speed, high efficiency, low cost, low labor intensity, saved processing time and reduced energy consumption, and is suitable for the application of pier extruding thickening equipment for a sucker rod.

Owner:葫芦岛市渤海石油机械厂

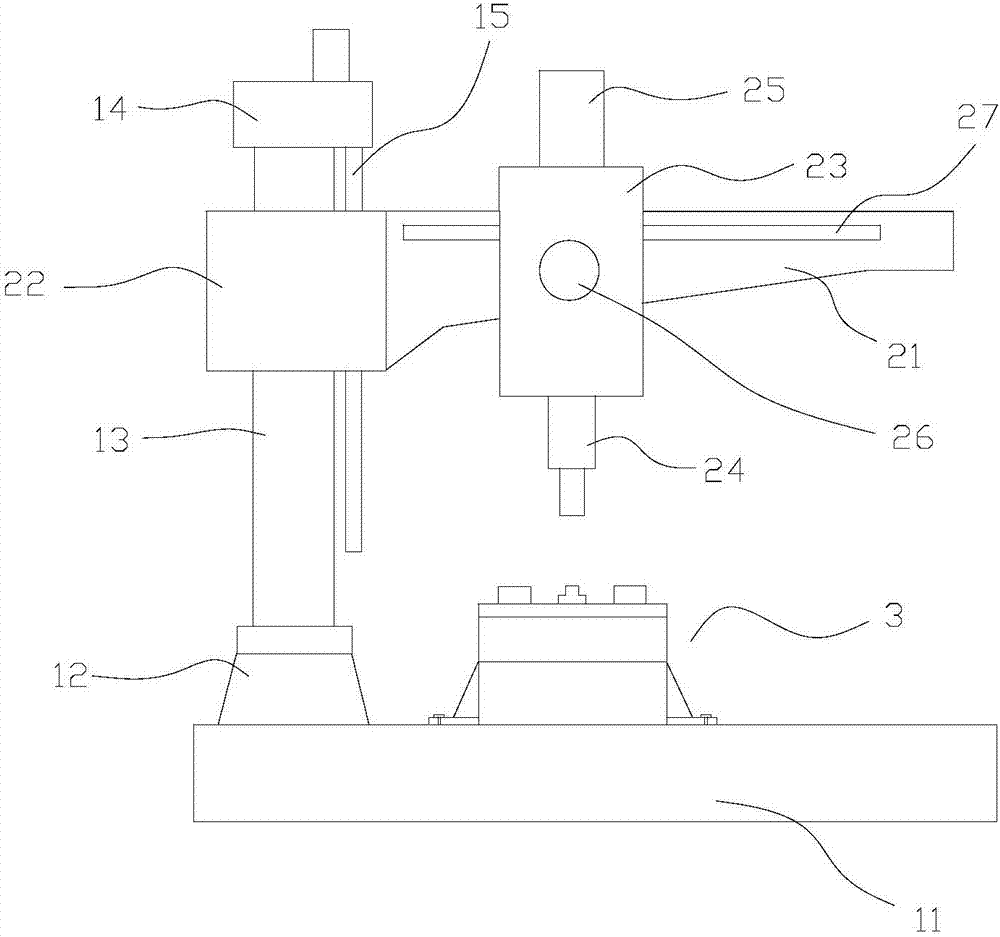

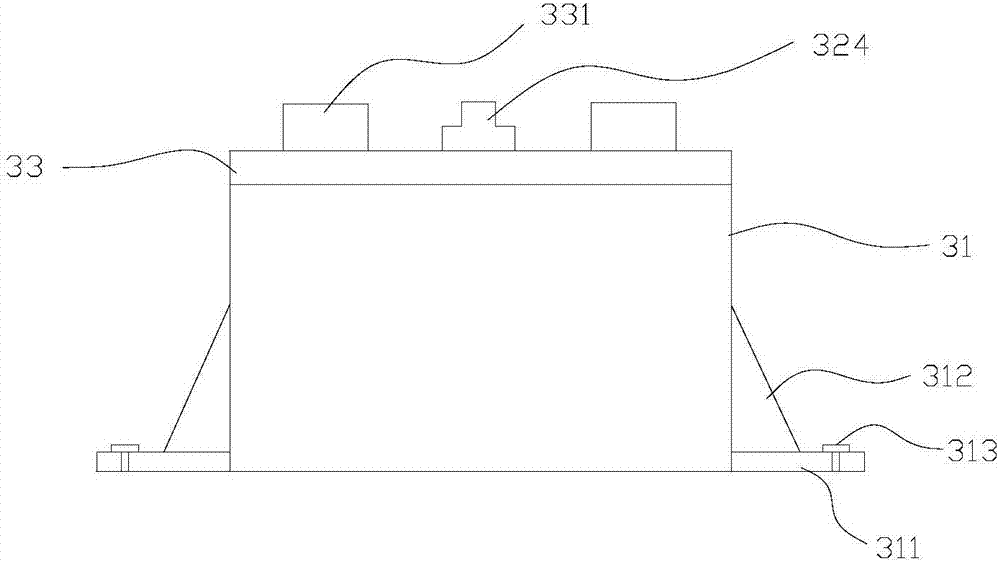

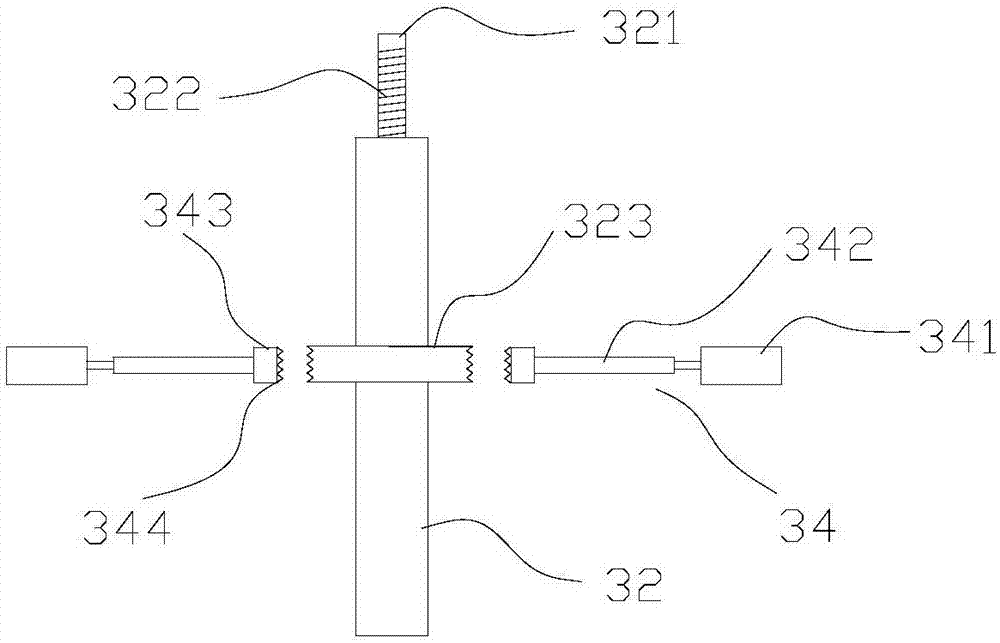

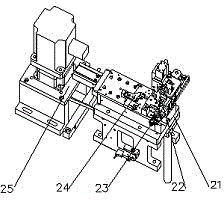

Radial drilling machine with rotary workbench

InactiveCN107243658AImprove processing efficiencyRealize continuous workLarge fixed membersBoring/drilling machinesEngineeringPiston rod

The invention discloses a radial drilling machine with a rotary workbench. The radial drilling machine comprises a base, an outer stand column, an inner stand column, a rocker arm, a spindle box and the rotary workbench. The rotary workbench is fixed to the base and comprises a cylindrical supporting seat fixed to the base, a rotary shaft, a rotary plate arranged on the upper surface of the supporting seat, and a pneumatic braking mechanism. The supporting seat is provided with an inner cavity. Both the rotary shaft and the pneumatic braking mechanism are arranged in the inner cavity of the supporting seat. The rotary plate is fixed to the top end of the rotary shaft. The rotary shaft is driven to rotate by a driver arranged in the inner cavity. The pneumatic braking mechanism comprises an air cylinder, a push rod fixed to a piston rod of the air cylinder, and a brake block fixed to one end of the push rod. Wheel teeth are arranged on the periphery of the rotary shaft, and a clamping block matched with the wheel teeth is arranged on the brake block. According to the radial drilling machine with the rotary workbench, the machining efficiency of the radial drilling machine is improved, manpower is saved, and the possibility of accidents is decreased.

Owner:苏州明雪电子有限公司

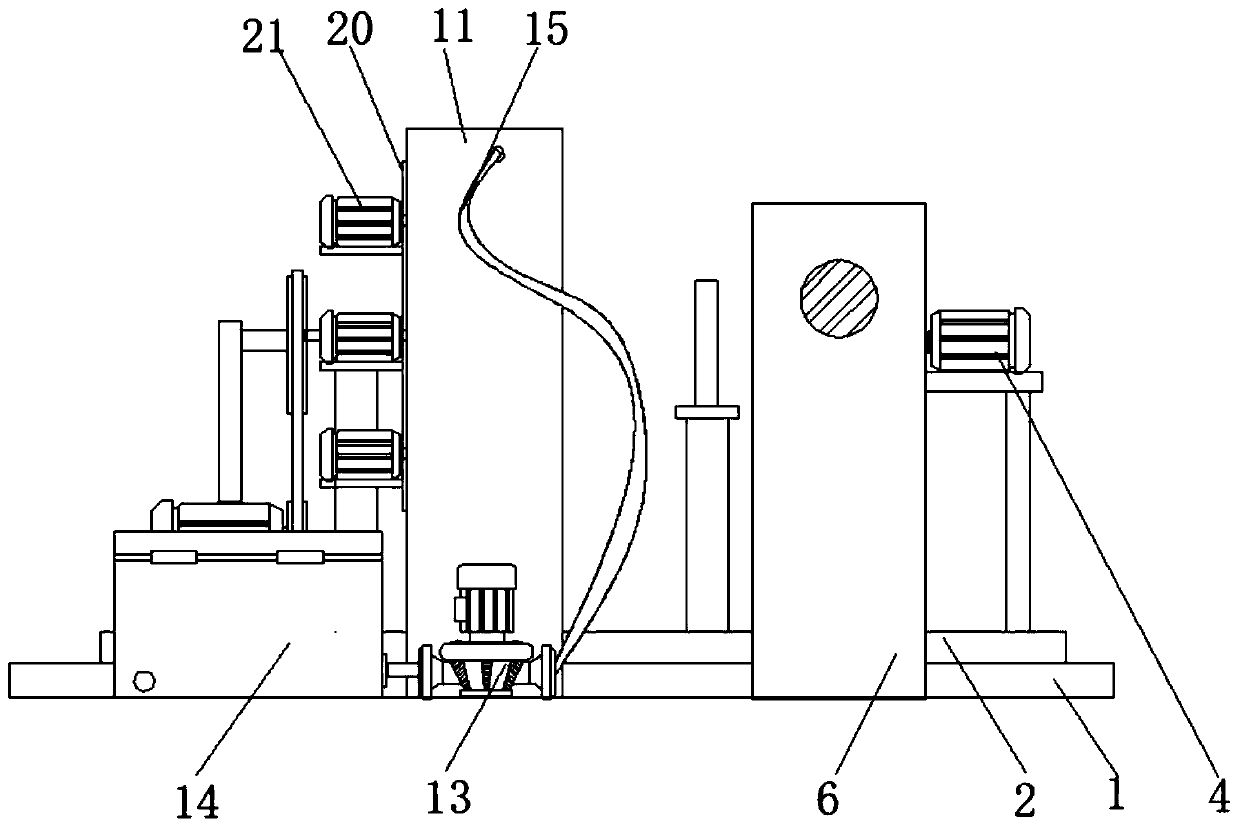

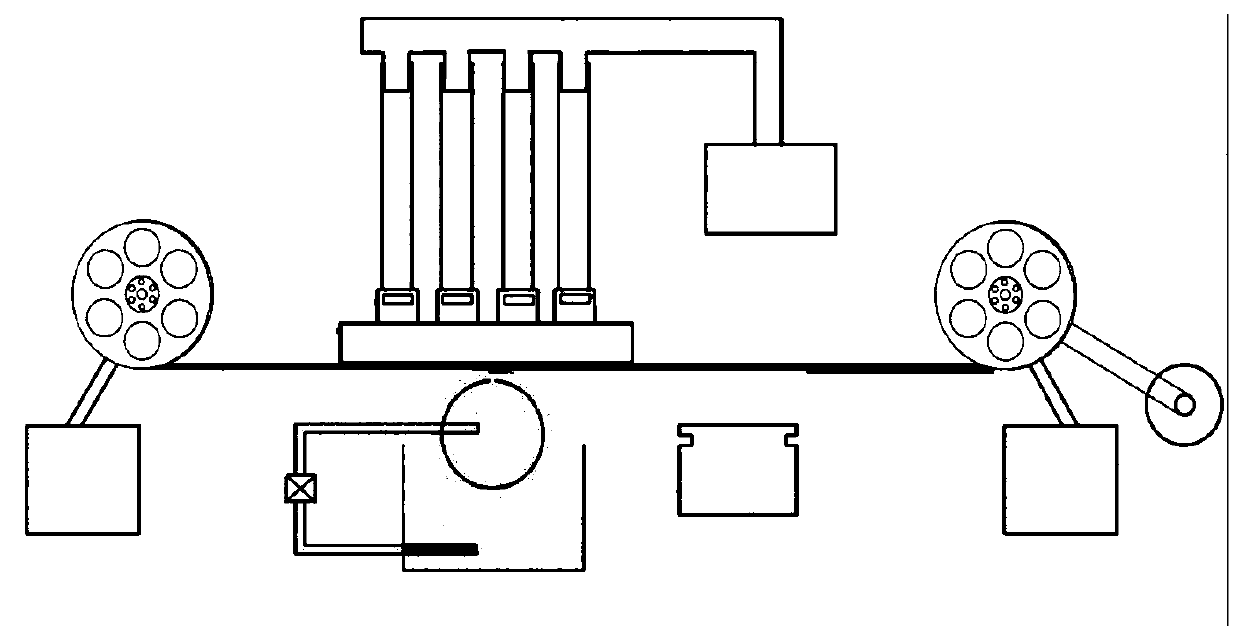

Automatic stranding machine for cable production

ActiveCN111243796ARealize continuous workAvoid affecting the stranding processInsulating conductors/cablesDrive wheelElectric machinery

The invention discloses an automatic stranding machine for cable production, and relates to the field of cable production. The automatic stranding machine comprises a base. The top end of the base isconnected with a connecting seat; the top end of the connecting seat is connected with a mounting seat; a winding motor is mounted at the top end of the mounting seat; a winding roller is connected with the output end of the winding motor; a first mounting bin is connected with one side of the top end of the base; a drying fan is mounted in the first mounting bin; a bottom column is connected withthe position, located at the top end of the connecting seat, of one side of the mounting seat; and a communicating block is connected with the top end of the bottom column. According to the invention, the winding motor, the winding roller, a stranding motor, a driving wheel, a driven wheel, a connecting shaft, a rotating disc and connecting columns are arranged;, the stranding motor drives the rotating disc to rotate so as to drive cables on the outer sides of six sets of connecting columns to rotate; the twisted cables are driven by the winding motor and the winding roller to be wound; continuous work is achieved; the cables being twisted do not need to be disconnected; and therefore the influence on the twisting process is avoided.

Owner:南通辰乐工业科技有限公司

Automatic weaving and twisting machine

ActiveCN108049019ARealize the function of automatic windingSolve the problem of difficult knotsBraidElectronic waste recyclingEngineeringWinding function

The invention discloses an automatic weaving and twisting machine. The automatic weaving and twisting machine comprises a winding mechanism for winding a thread into a beam, an automatic knotter for knotting a winding thread residue, an inner-layer thread residue and an outer-layer thread residue, a thread frame and a power system, wherein the powder system drives the thread frame to perform axialprogressive movement below the winding mechanism and to perform rotary movement along an axis; the winding mechanism separately winds a thread beam; and after finish of winding, the winding thread residue, the inner-layer thread residue and the outer-layer thread residue are knotted by the automatic knotter. As the winding mechanism is provided, separated winding can be finished through one thread; a single thread chain stitch is adopted for winding, so that the automatic winding function is fully achieved; meanwhile, a formed twisted thread can be set out by one cut in the follow-up procedure; and as the outer-layer thread residue, the inner-layer thread residue and the winding thread residue are knotted by the automatic knotter, a bionic manual knotting mode is realized, and the problemof difficult knotting is effectively solved.

Owner:YIBIN HIEST FIBER +1

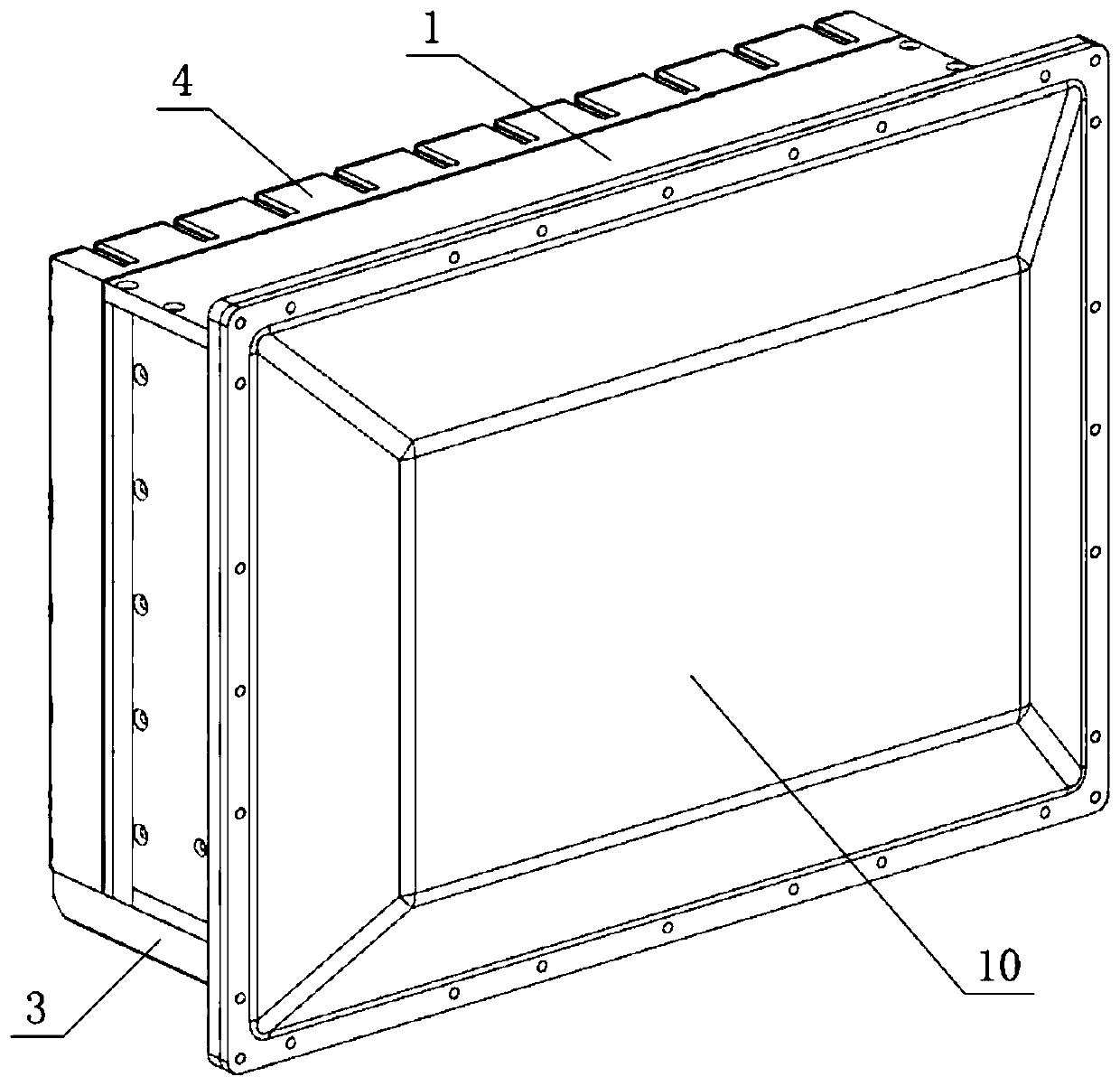

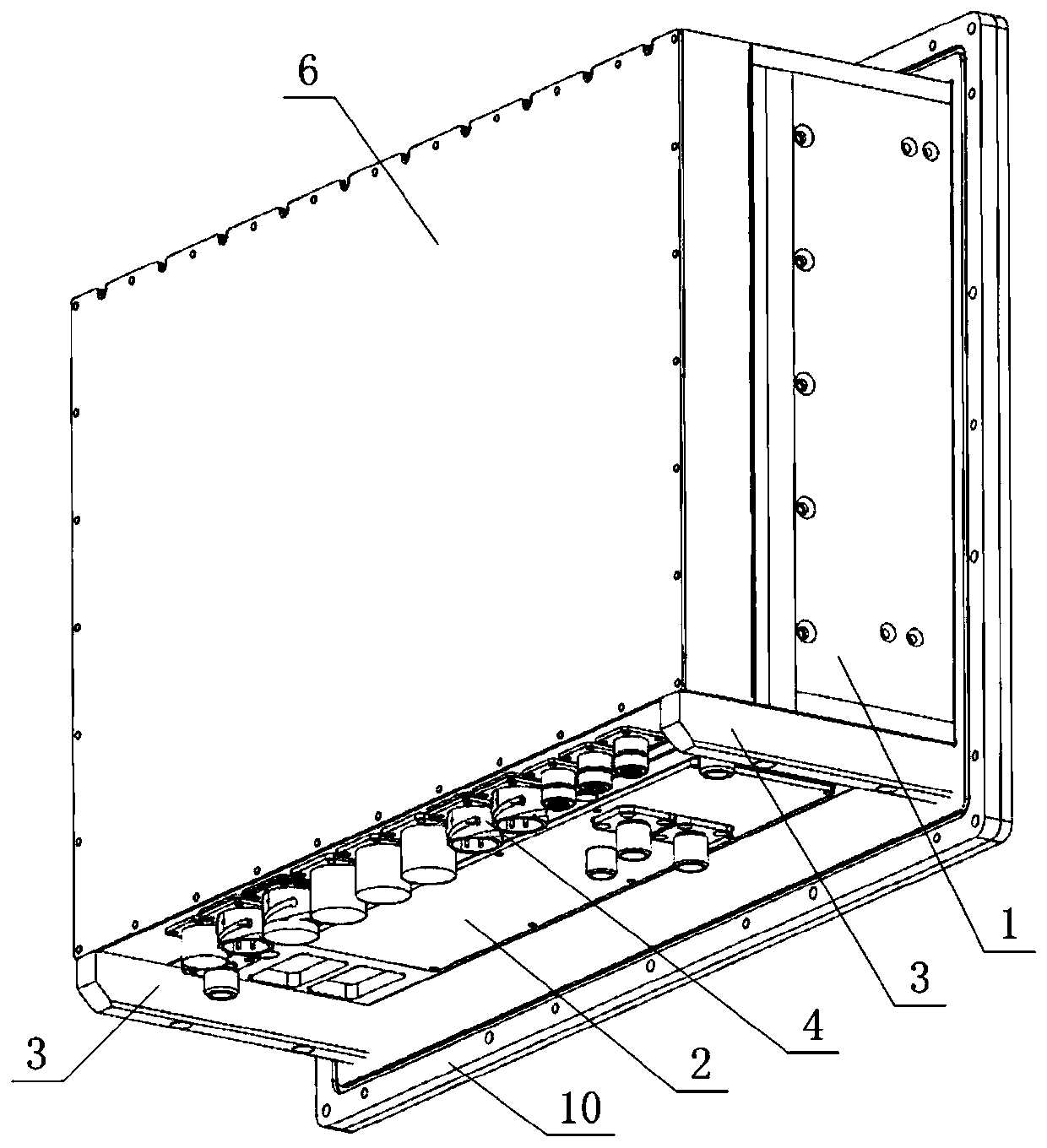

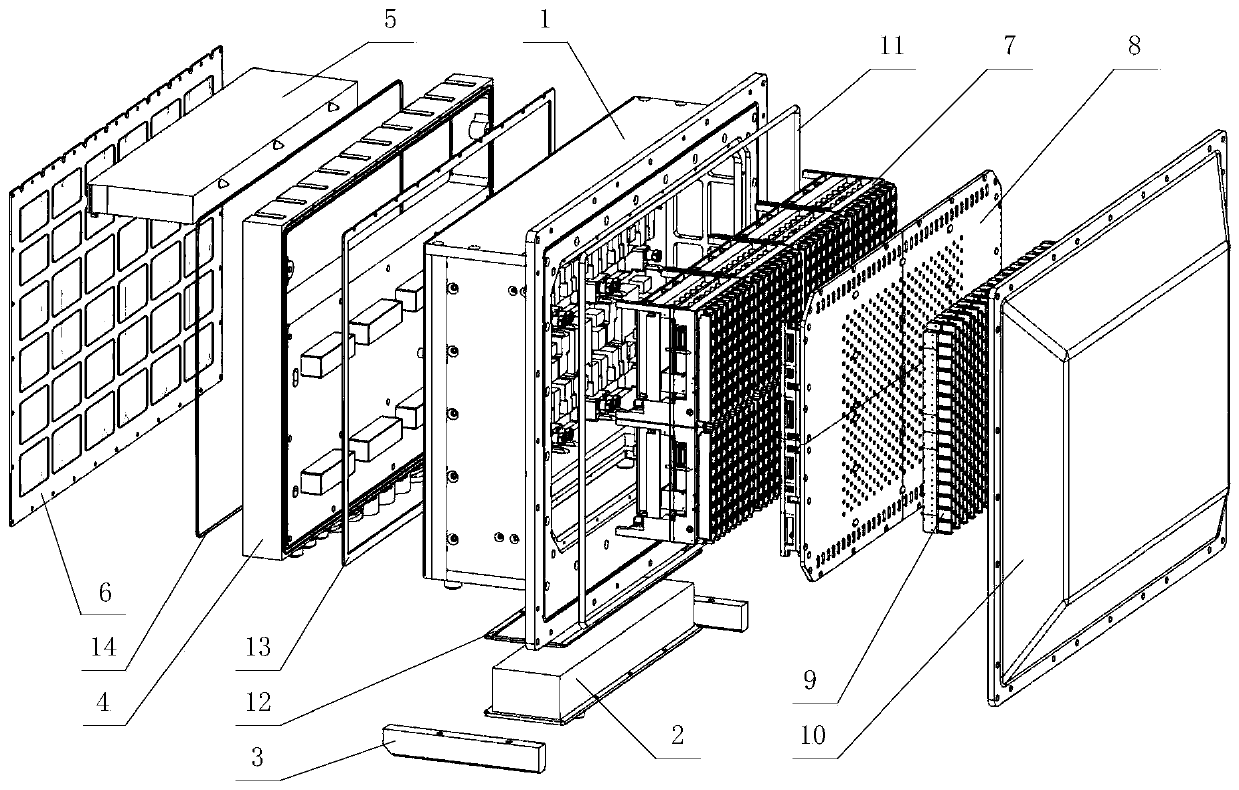

Light and small phased-array antenna

ActiveCN111106421AImprove installation strengthThe modular structure is squareAntenna arraysAntenna supports/mountingsRadar antennasRadome

The invention provides a light and small phased-array antenna, which belongs to the field of radar antenna combination devices. A gas heat exchanger is mounted at the bottom of a box body frame of thephased-array antenna; a switching module is mounted on the back of the box body frame; a control module penetrates through the switching module from the back of the box body frame, enters the box body frame and is mounted on the box body frame; a tile sub-array is installed in the box body frame; the front end surface of the tile sub-array is connected with an antenna adapter plate; the antenna adapter plate is connected with the front end surface of the box body frame; an antenna sub-array is installed on the front end surface of the antenna adapter plate; a radome is installed on the outeredge of the front end face of the box body frame. The phased-array antenna is suitable for the size and weight limitation of a light and small phased-array antenna. The heat dissipation problem of a high-power-consumption assembly in a radar antenna is effectively solved, and normal and continuous work of the phased-array antenna is achieved.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

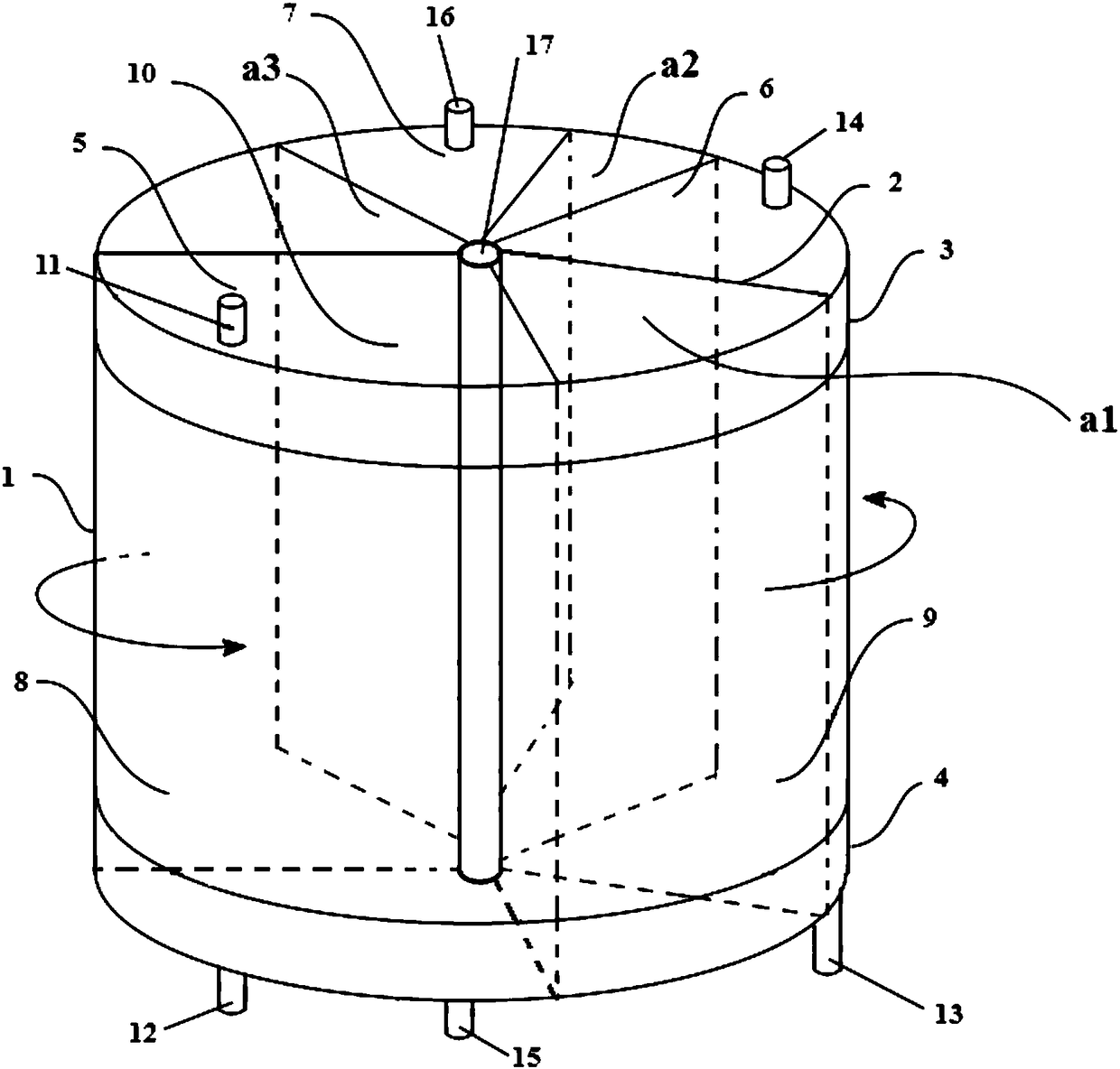

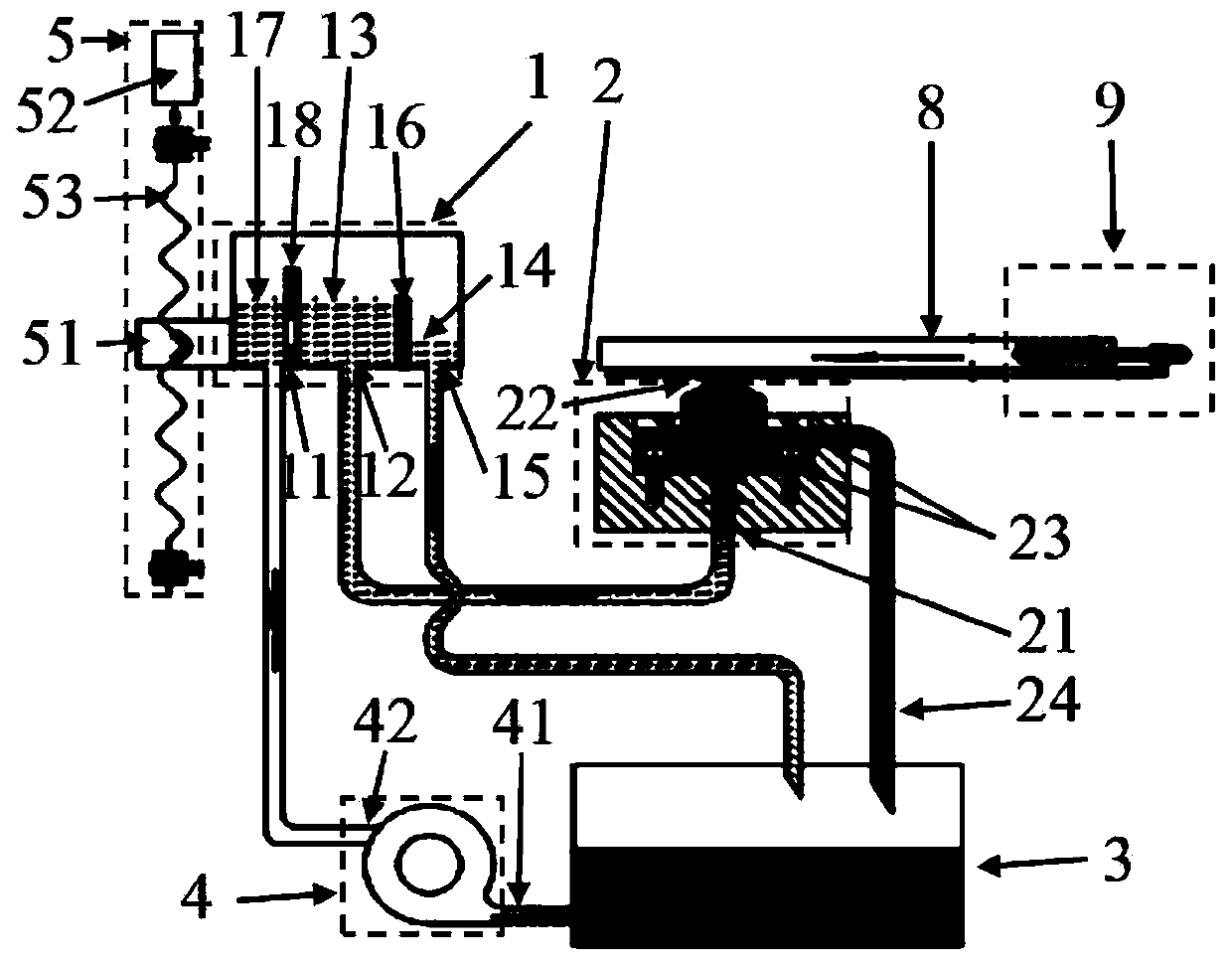

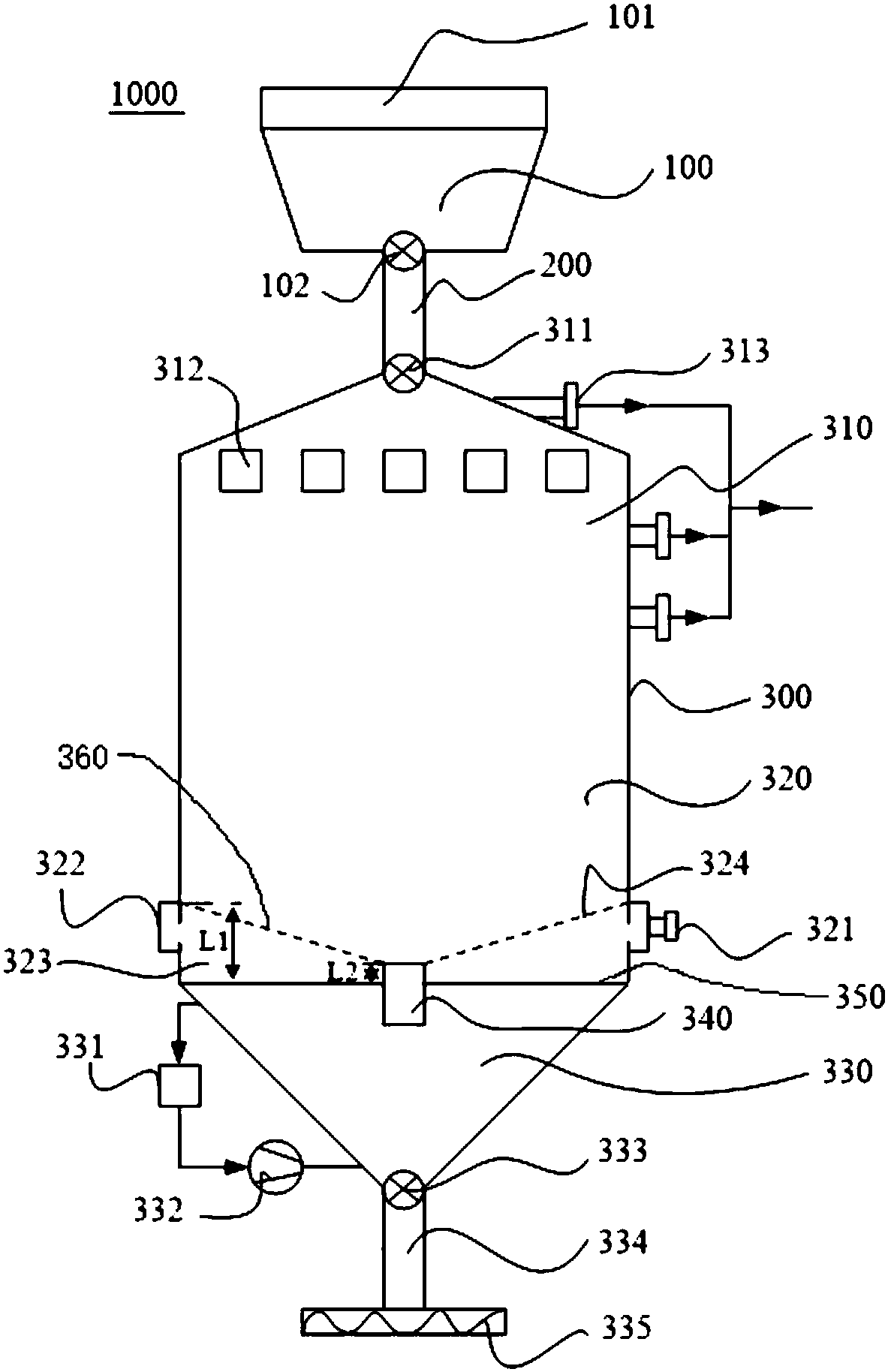

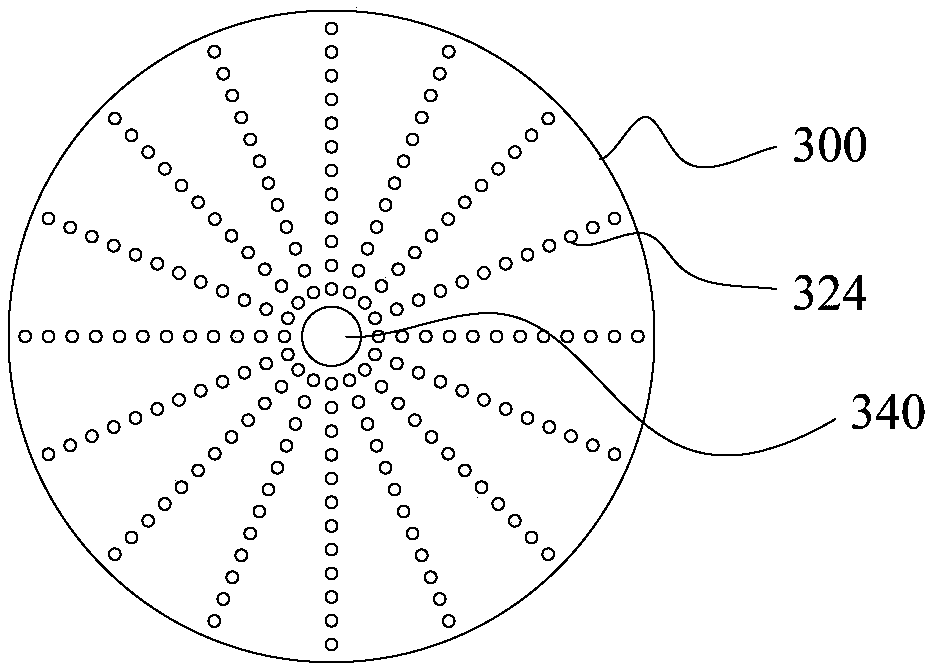

CO2 adsorption system and continuous CO2 adsorption method

InactiveCN108355462ARealize continuous workReduce energy consumptionGas treatmentDispersed particle separationDesorptionSorbent

The invention relates to the field of CO2 adsorption, and discloses a CO2 adsorption system and a continuous CO2 adsorption method. The system comprises an adsorption unit, a gas treatment unit, a desorption treatment unit and a rotating mechanism; the adsorption unit comprises a cylinder body (1), a plurality of baffles (2) distributed in the cylinder body, an upper seal cover (3) of the cylinderbody and a lower seal cover (4) of the cylinder body; the cylinder body is a cylinder with openings at both ends, the baffles are distributed in accordance with the radial direction of the cross section of the cylinder body and extend to pass through the cylinder body along the central axis of the cylinder, and the internal space of the cylinder body is separated to form a plurality of adsorbentloading areas, wherein the adsorbent loading areas each have a fan-shaped cross section and do not communicate with each other; two ends of the cylinder are sealed by the upper seal cover and the lower seal cover respectively, a cylinder body space between the upper seal cover and the lower seal cover is divided into an adsorption section (8), a desorption section (9) and a cooling section (10); the rotating mechanism is used for rotating the cylinder body around the central axis of the cylinder, so that each adsorbent loading area passes through the adsorption section, the desorption sectionand the cooling section in turn. The energy consumption can be reduced, and the adsorption efficiency can be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

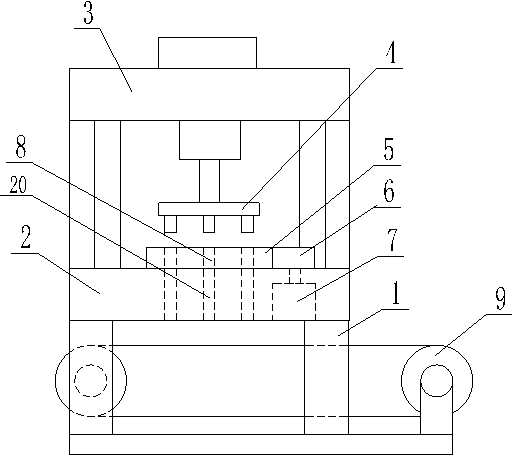

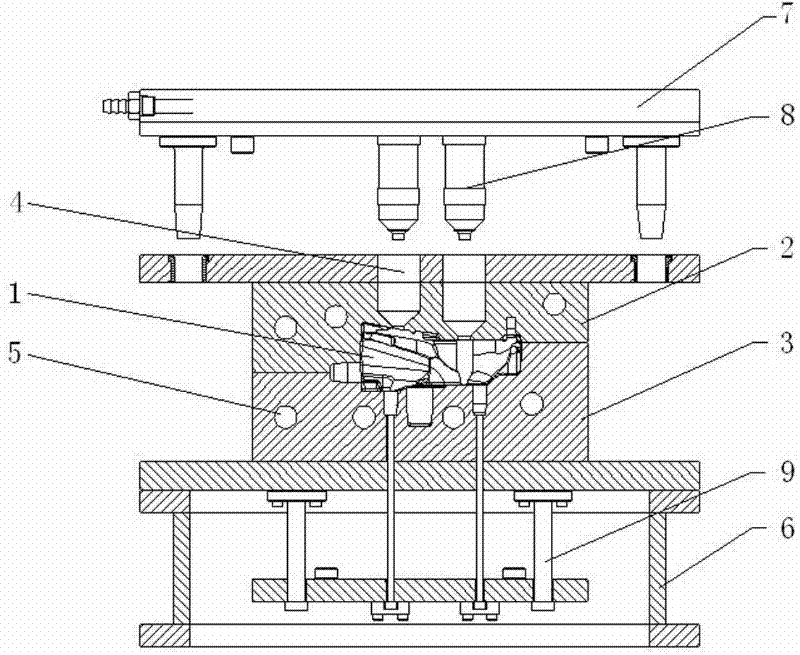

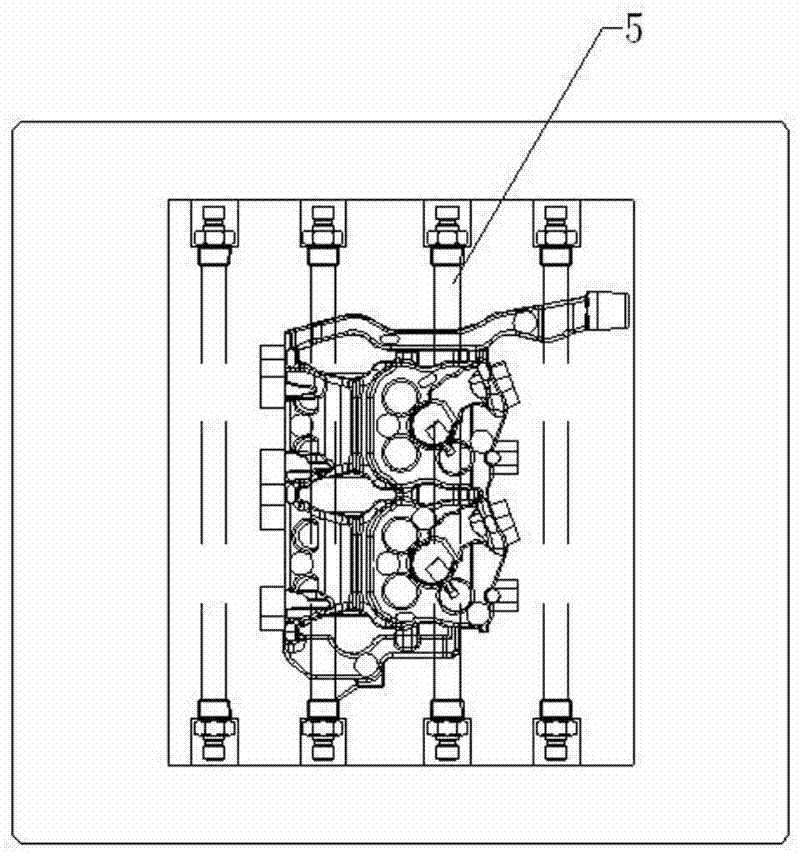

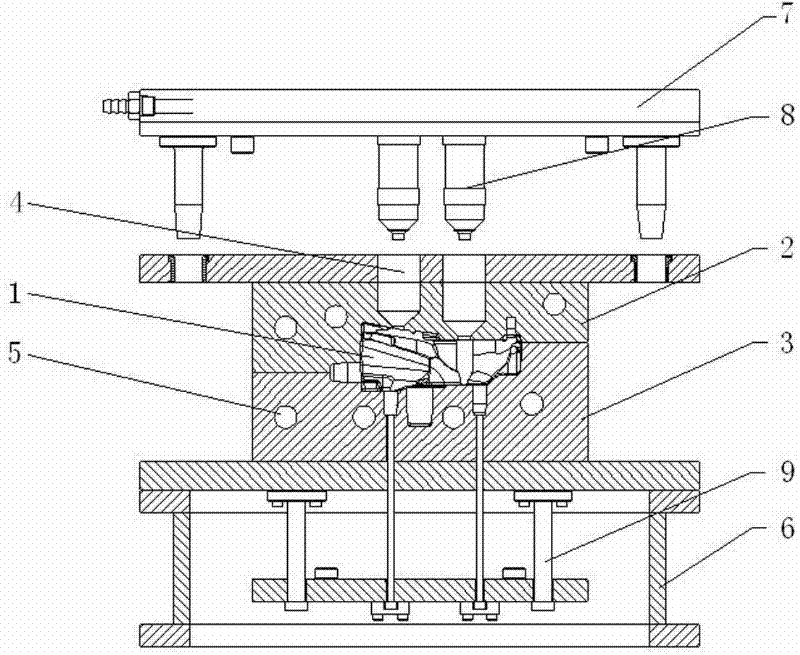

Punching machine with mould capable of being displaced

The invention relates to a punching machine with a mould capable of being displaced. The punching machine with the mould capable of being displaced comprises a supporting leg, wherein a lower mould seat is arranged at the upper end of the supporting leg and is connected with an upper mould seat through a supporting pillar, a punching device is arranged on the upper mould seat, the mould is arranged on the lower mould seat and meshed with a driving wheel, the driving wheel is connected with a motor, a plurality of discharging holes I are evenly formed in the mould, discharging holes II coaxial with the discharging holes I are evenly formed in the lower mould seat, and a transmission belt is arranged at the lower end of the lower mould seat. The punching machine with the mould capable of being displaced is simple in structure and reasonable in design. The driving wheel and the motor are arranged, after the punching machine finishes one time of punching on a plate, the mould is displaced through the motor and the driving wheel, and therefore continuous work of the punching machine is achieved. The transmission belt is arranged at the lower end of the lower mould seat, punched formed parts can be timely conveyed to the next procedure, and therefore production efficiency is improved.

Owner:KUNSHAN HUAKUI MACHINERY ELECTRONICS

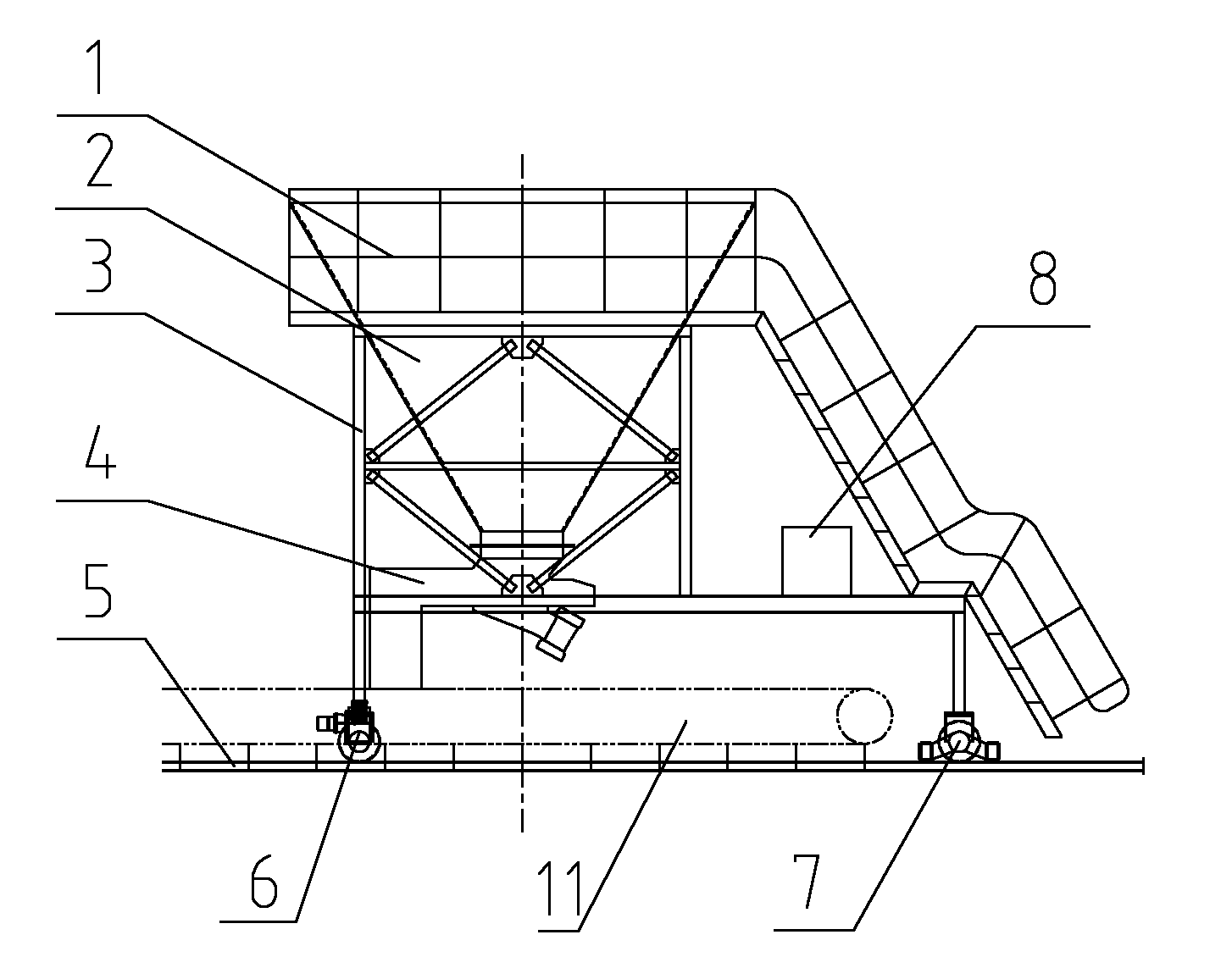

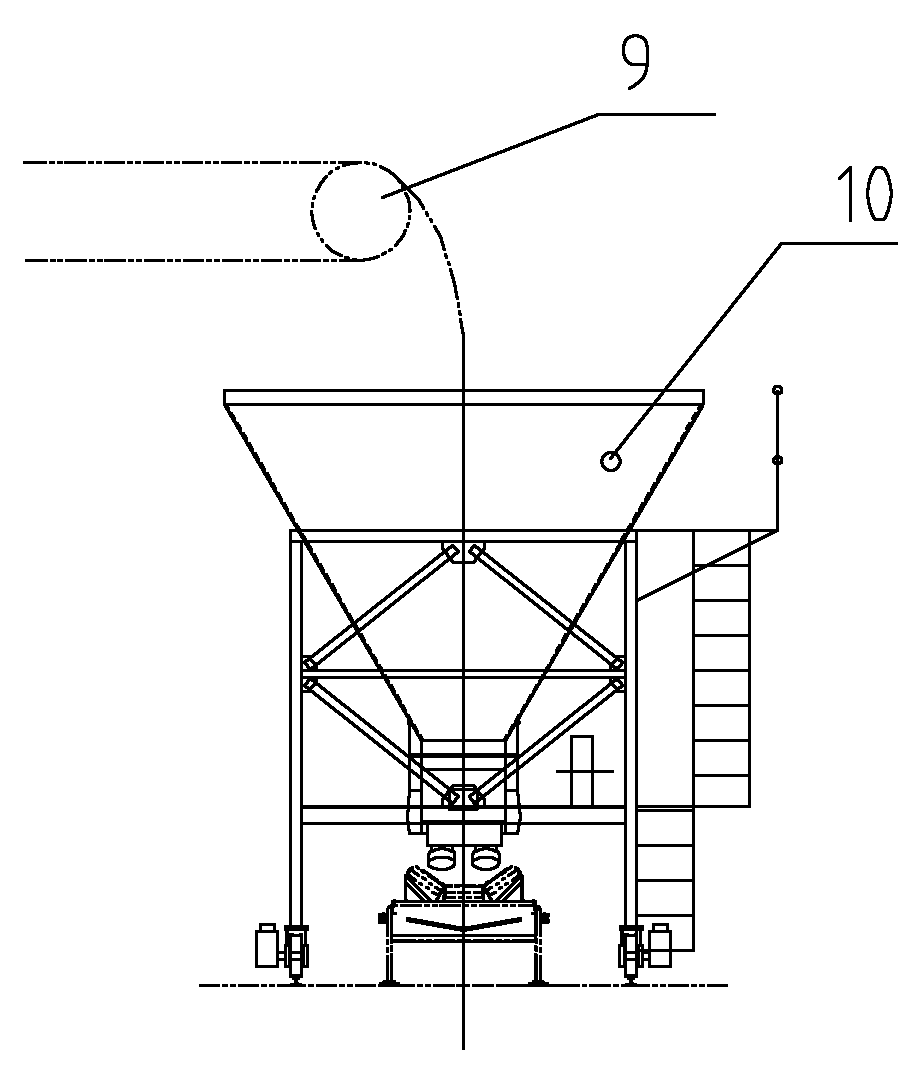

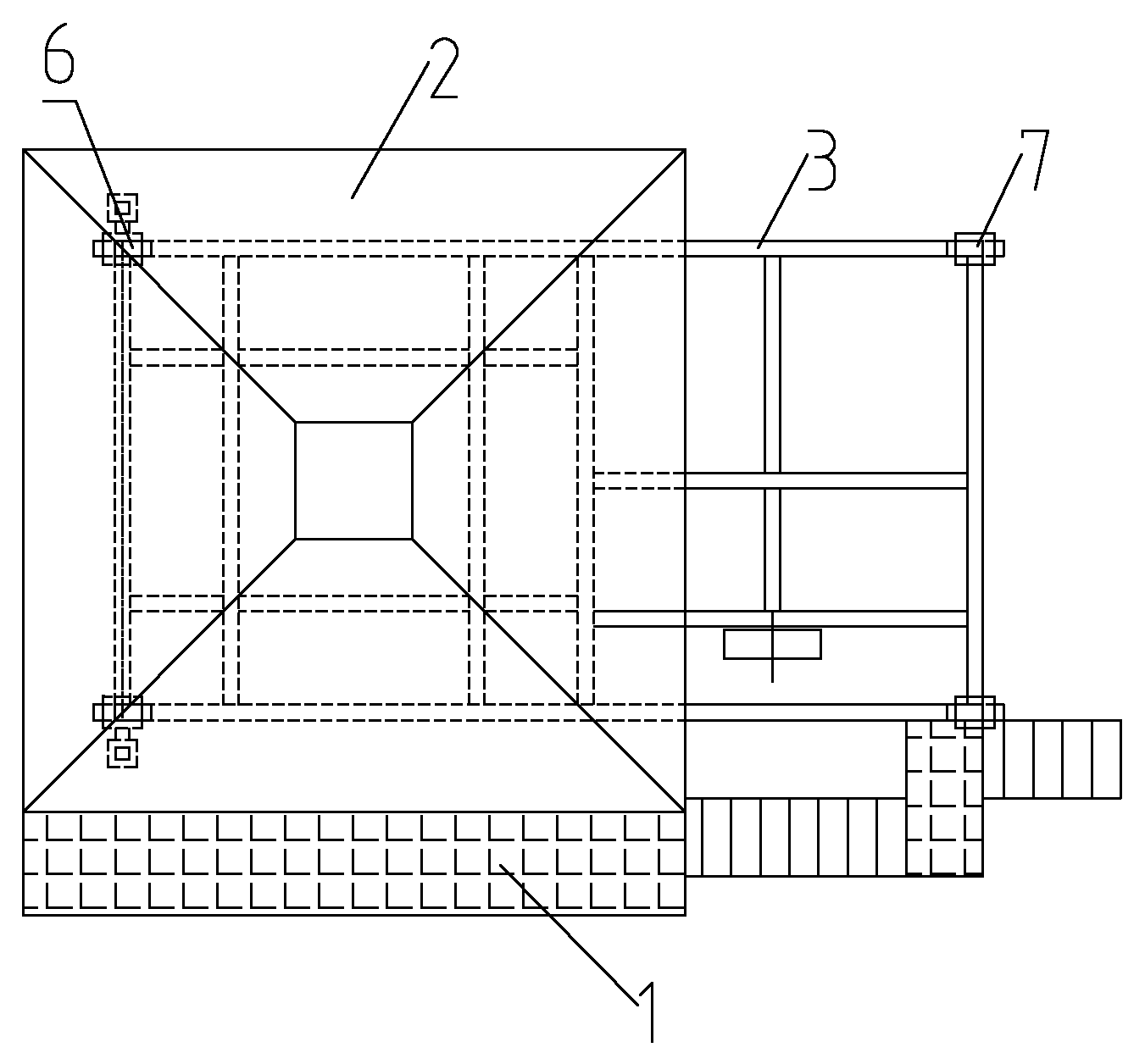

Continuous transfer system and material receiving device thereof

ActiveCN102424278AAvoid pollutionSuitable for continuous transfer operationsControl devices for conveyorsSupporting framesTransfer systemEngineering

The invention provides a continuous transfer system. The material receiving device comprises a frame and a hopper, wherein the hopper is arranged on the frame; and the frame is erected on a belt conveyer of the continuous transfer system and is moved along the direction driving the conveyer. The continuous transfer system realizes mining continuous operation, improves operation efficiency, lowers transfer cost, and prevents dust pollution to transportation lines through the material receiving device which is moved along with the change of discharging positions,. In addition, the continuous transfer system has the characteristics of reasonable structure and high reliability and is particularly suitable for the continuous transfer operation of strip pits.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

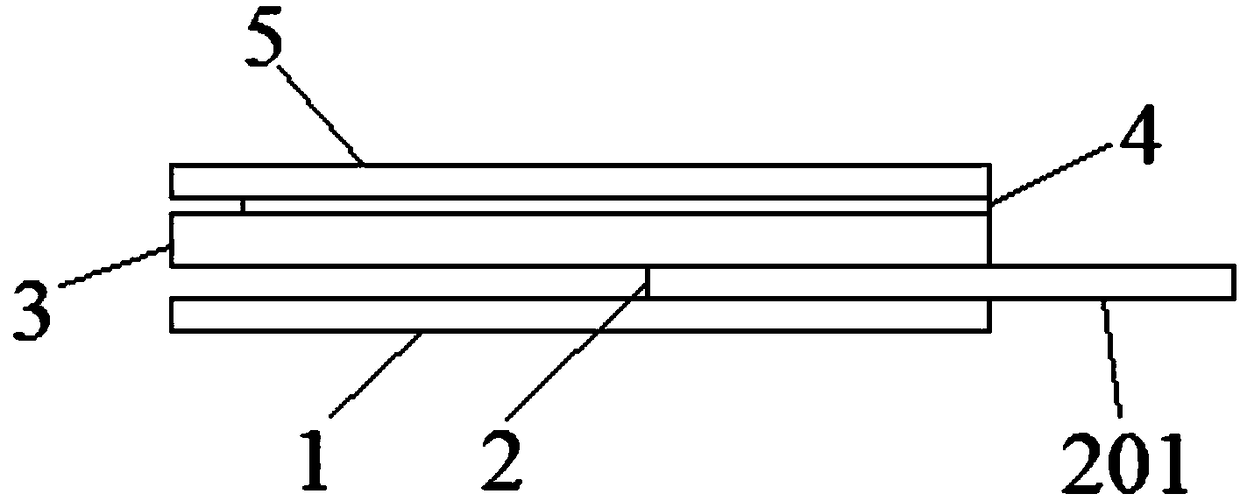

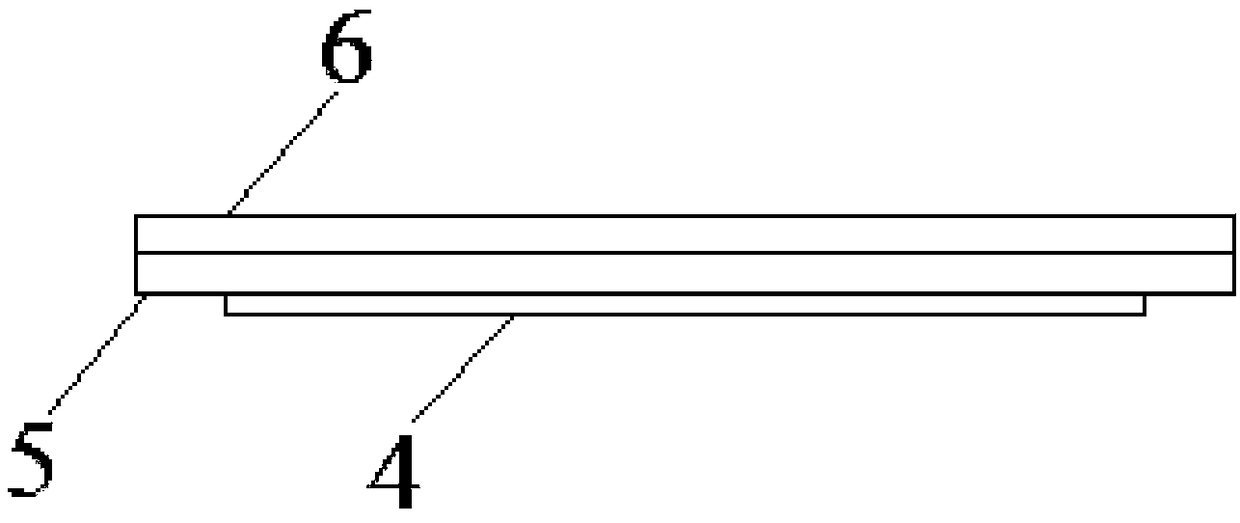

Die cutting method and device for conductive cloth with ultra-thin single-sided adhesive layer

ActiveCN108656703APrecise positioningImprove machining accuracyLamination ancillary operationsLaminationAdhesiveEngineering

The invention relates to a die cutting method and device for a conductive cloth with an ultra-thin single-sided adhesive layer. The die cutting method sequentially comprises the steps of die cutting of the single-sided adhesive layer, die cutting of a handle and a first edge of a blue film layer, and die cutting of an outer contour of the conductive cloth; and the device comprises a first material-conveying unit, a first die-cutting unit, a first waste-discharging unit, a second material-conveying unit, a second die-cutting unit, a third material-conveying unit, a second waste-discharging unitand a third die-cutting unit which are arranged along a moving direction of a material belt in sequence. Compared with the prior art, the method and device provided by the invention eliminate a pre-processing process of the single-sided adhesive layer and a manual laminating process of the single-sided adhesive layer and a conductive cloth layer, match the processing process of the single-sided adhesive layer and a die cutting process of other layers of the conductive cloth together, have high processing precision and good product quality, facilitate positioning of the material belt among different die-cutting units, improve production efficiency and reduce production costs.

Owner:上海昊佰智造精密电子股份有限公司

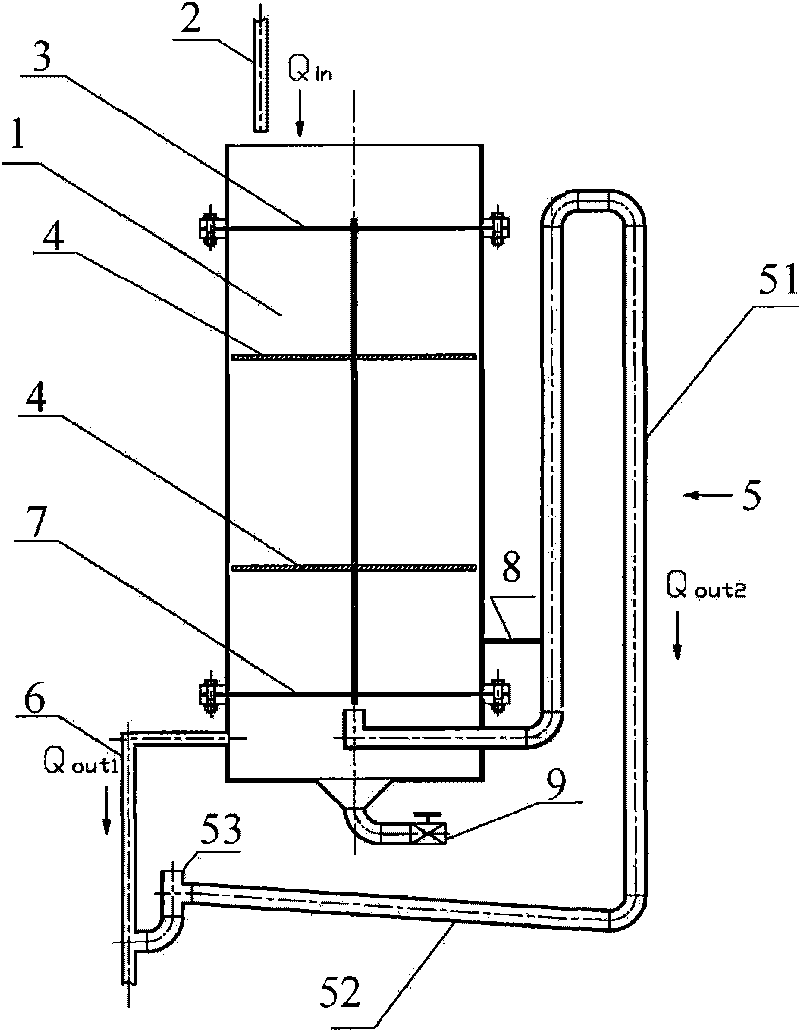

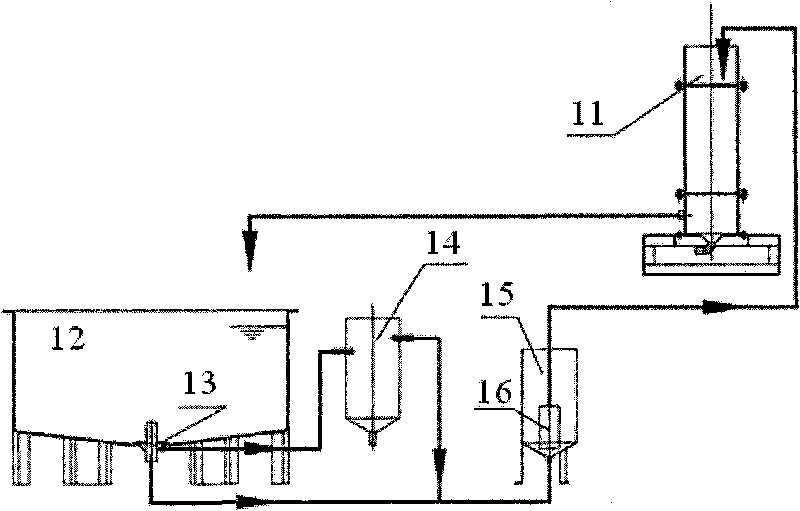

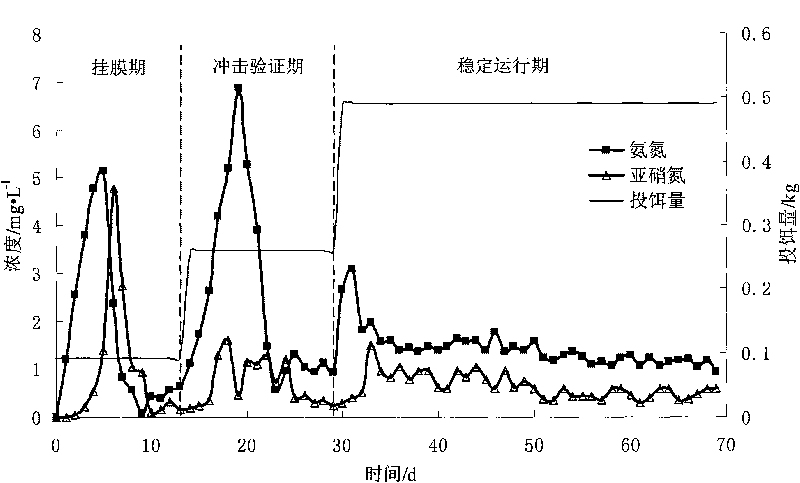

Biological purification method of aquiculture waste water and siphoning reciprocating type biological filter

InactiveCN101717149ARealize continuous workRealize automatic riseSustainable biological treatmentBiological water/sewage treatmentSiphonPurification methods

The invention discloses a biological purification method of aquiculture waste water and a siphoning reciprocating type biological filter. The method comprises the following steps: continuously injecting waste water into a purifying cavity of the filter; discharging water through a water discharging pipeline so that the water level in the purifying cavity rises; when the water level in the purifying cavity is higher than the top of a siphoning device, generating the siphoning, discharging water outwards through the water discharging pipeline and the siphoning device together so that the water level in the purifying cavity falls; destroying and stopping the siphoning, and stopping discharging water outwards by the siphoning device; and repeating the steps. The biological purification method and the filter provided by the invention realize the automatic up and down reciprocating movement of the water level by using the siphoning principle, realize the continuous work of a single cavity, enable the relative displacement to be generated between fillers, and realize the self-purification effect; the movement of the fillers improves the mass transfer condition of nutrient substances between a solid phase and a liquid phase on the surface of a biological film, improves the efficiency of the nitration reaction, and has high removing efficiency of ammonia nitrogen and stable operation; and the invention has simple structure, low manufacturing and operating cost, small floor space and wide application range.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Glue supply device used for continuous, stable and uniform glue coating and glue liquid coating method

ActiveCN109759282ARealize continuous workRealize continuous coatingLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a glue supply device used for continuous, stable and uniform glue coating, and a glue liquid coating method, and belongs to the field of continuous production advection film coating. The glue supply device comprises a glue supply container, a glue spraying device, a low-position glue storage container and a liquid conveying device. The glue supply container comprises a glueinlet, a glue outlet and a glue supply area. The glue spraying device comprises a glue supply opening and a glue coating opening. The liquid conveying device comprises a liquid inlet and a liquid outlet. The liquid outlet of the liquid conveying device is connected with the liquid inlet of the glue supply container, the glue outlet of the glue supply container is connected with the glue supply opening of the glue spraying device, the low-position glue storage container is connected with the liquid inlet of the liquid conveying device, and all connection mentioned above is pipeline connection.The height of the liquid level the glue supply area in the glue supply container is stable and controllable, the highest point of the liquid level is higher than the highest point of the liquid levelof the glue spraying opening in the glue spraying device in the vertical direction, the low-position glue storage container is connected with the liquid inlet of the liquid conveying device, and all connection mentioned above is pipeline connection. The height of the liquid level of the glue supply area in the glue supply container is stable and controllable, the highest point of the liquid levelis higher than the highest point of the liquid level of the glue spraying opening in the glue spraying device in the vertical direction, stable pressure is provided for glue liquid flowing of the gluespraying opening in the glue spraying device, and therefore continuous, stable and uniform glue coating can be achieved for meniscus film coating devices.

Owner:宁波甬安光科新材料科技有限公司

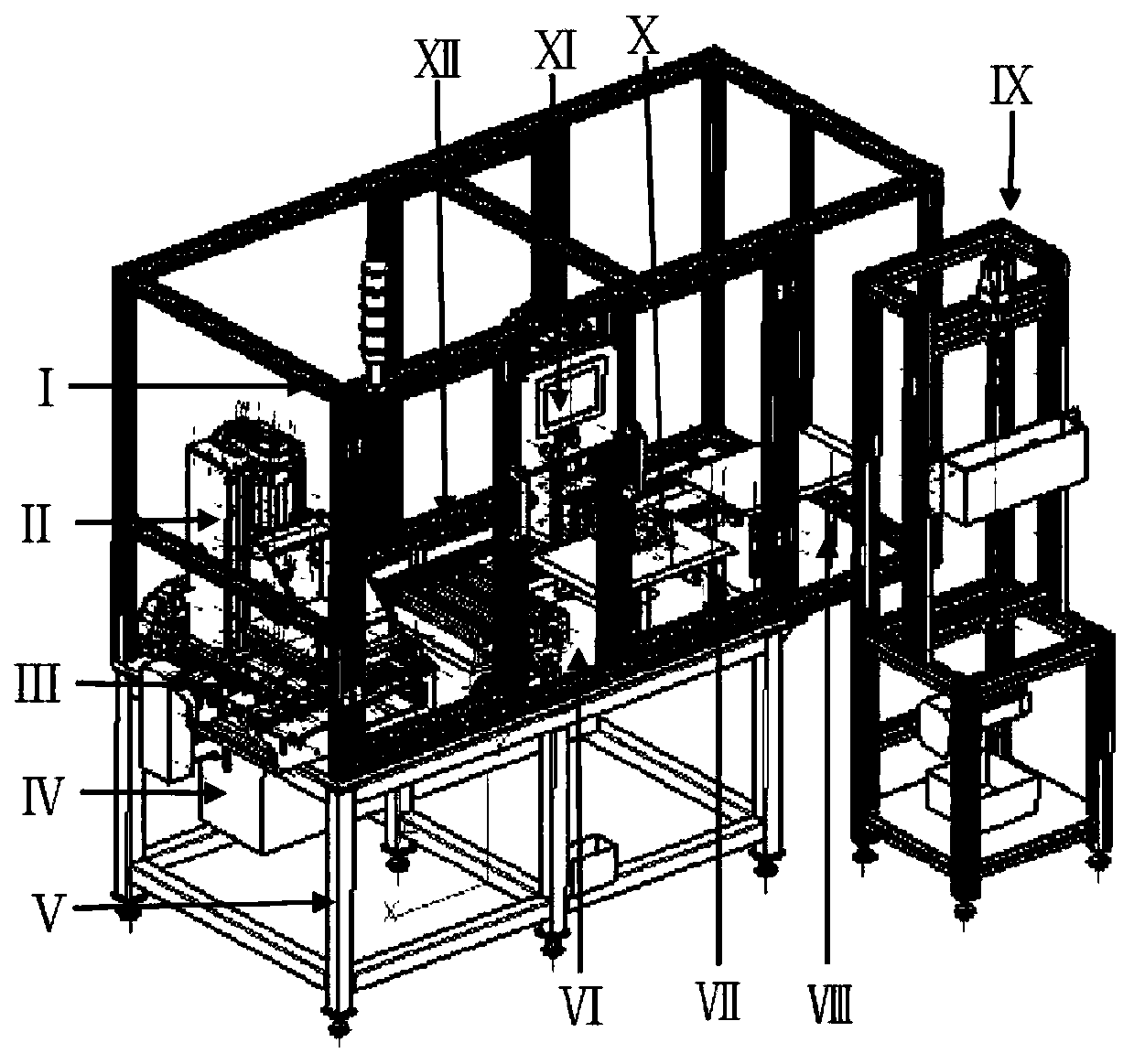

Sand mold 3D printer

PendingCN109967697AReduce volumeImprove printing efficiencyAdditive manufacturing apparatusFoundry mouldsEngineeringStructural engineering

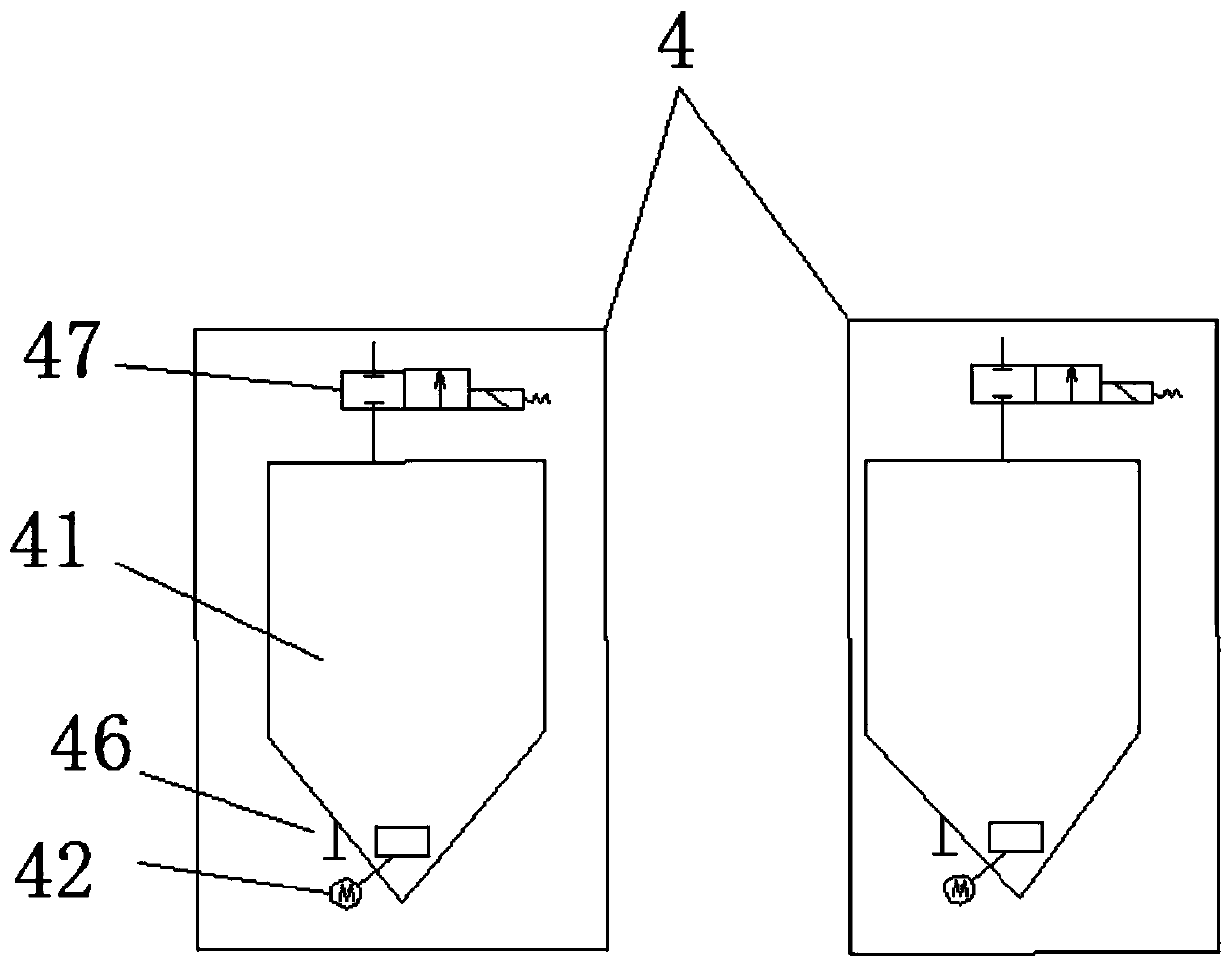

The invention discloses a sand mold 3D printer. The sand mold 3D printer comprises a printing base, cross beams, a ground rail, a sand supplying system, a sand paving beam, a printing beam and workingboxes, wherein the two cross beams are erected on the printing base in parallel, the ground rail is arranged below the cross beams, the sand supplying system is fixed on the cross beams, the two endsof the sand paving beam and the two ends of the printing beam are erected on the cross beams and are in sliding connection with the cross beams, and the working boxes is arranged on the ground rail and is in sliding connection with the ground rail. According to the sand mold 3D printer, the sand supplying system with two sand storage tanks is used for sand supplying, so that the size of equipmentcan be effectively reduced, continuous sand supplying can be ensured; the printing beam and the sand paving beam are driven by a linear motor, so that the operation stability of equipment can be improved, the noise is reduced, the two working boxes are adopted for printing, continuous work of equipment is realized, and the printing efficiency is improved.

Owner:AMSKY TECHNOLOGY CO LTD

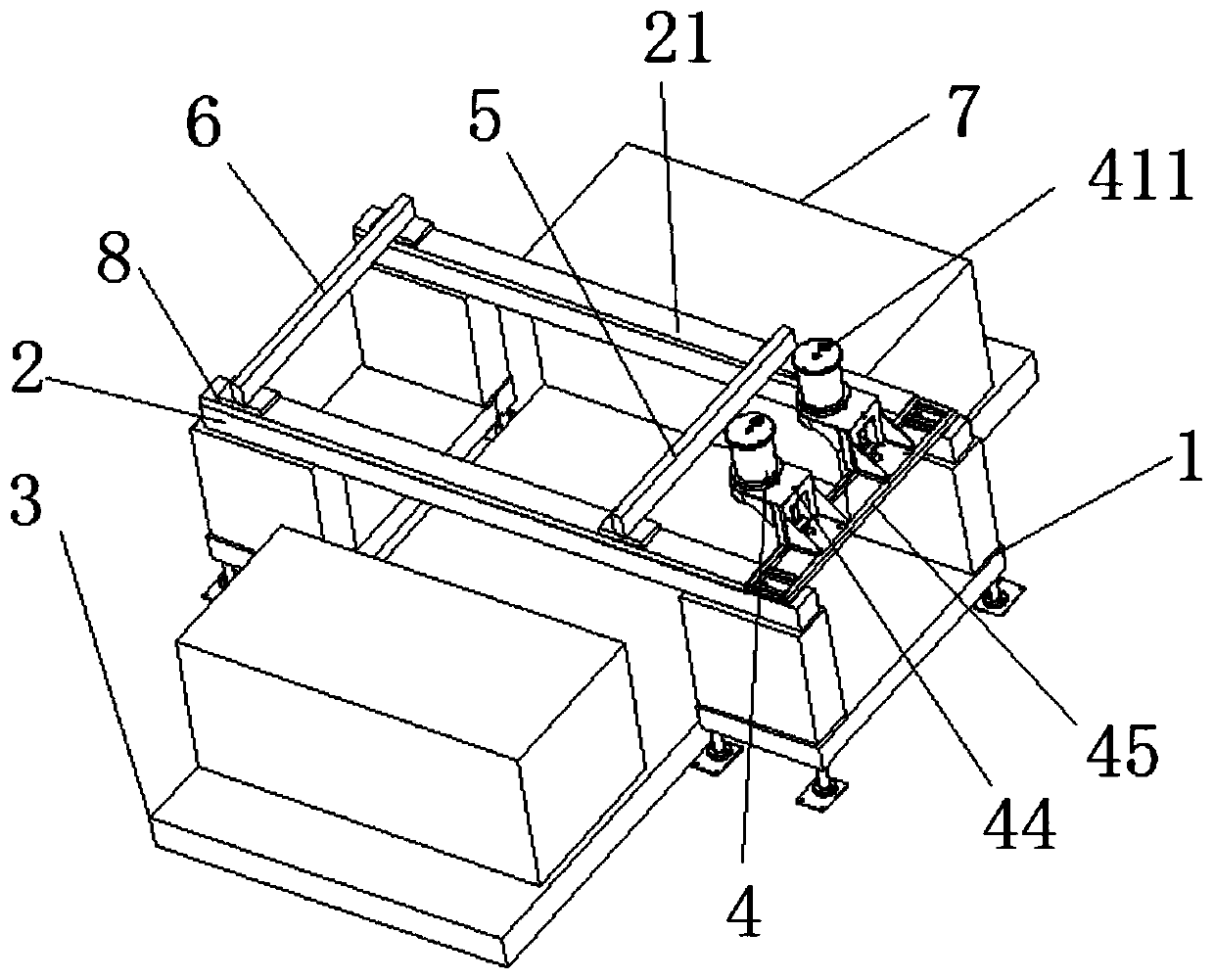

Double-tank double-pump front mixed abrasive jet continuous working system

ActiveCN107953270AImprove processing qualityThe system works stablyAbrasive feedersAbrasive machine appurtenancesVoltage regulationEngineering

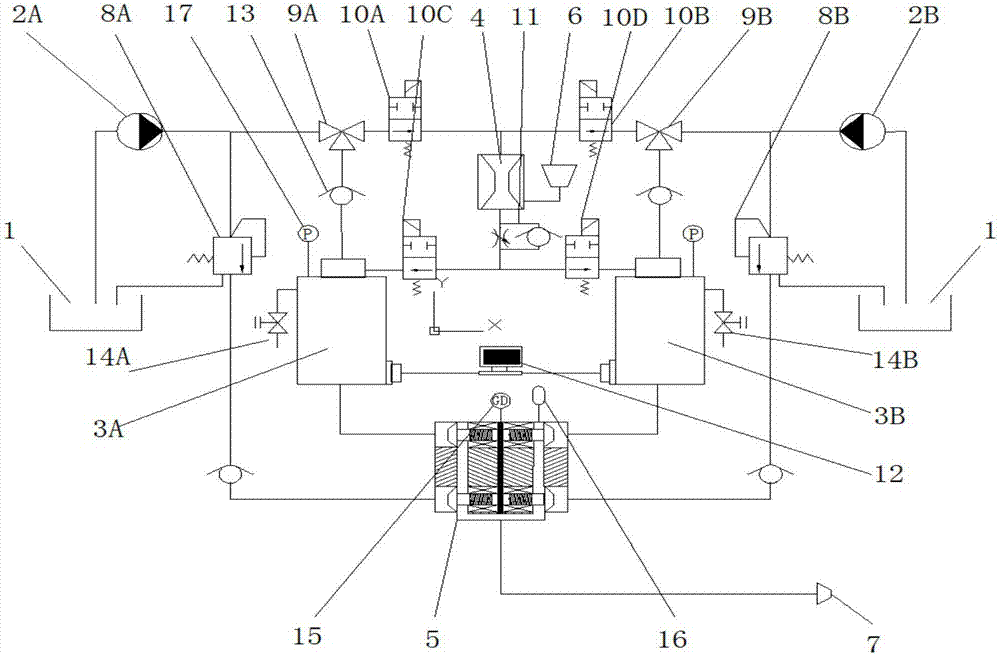

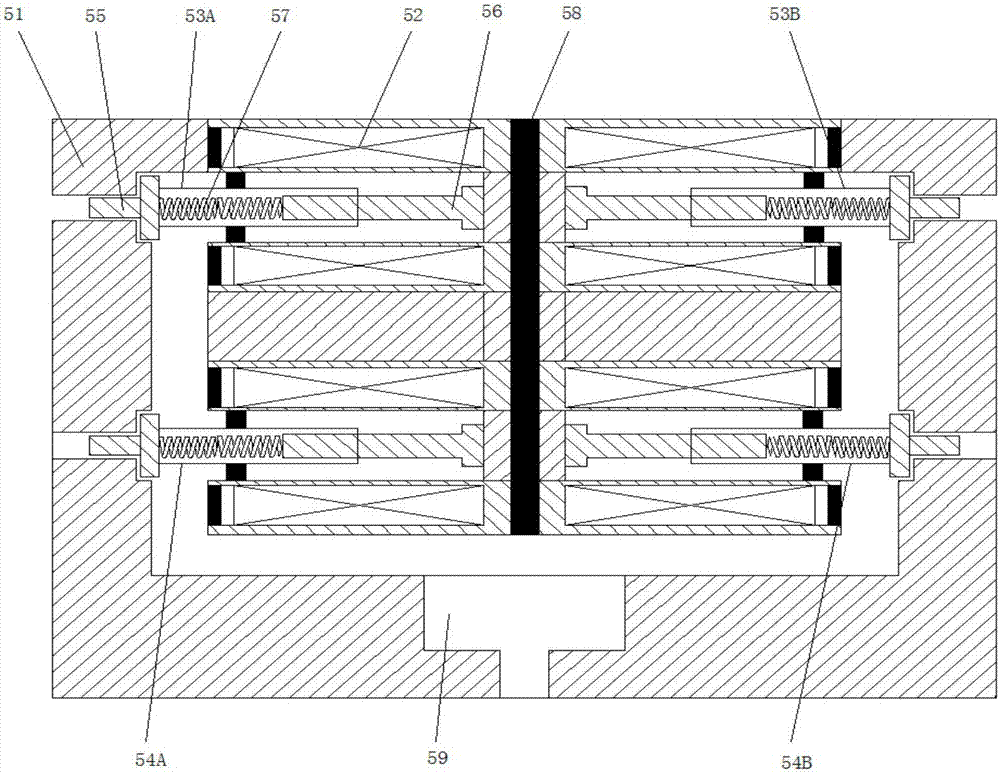

The invention discloses a double-tank double-pump front mixed abrasive jet continuous working system. The system comprises two high-pressure abrasive tanks for alternately feeding a pre-booster device. The pre-booster device includes two groups of sand inlets and water inlets, the two groups of sand inlets and water inlets are connected to the two high-pressure abrasive tanks and water pumps corresponding to the abrasive tanks respectively, the two groups of sand inlets and water inlets are respectively provided with electromagnetic valves, the effective contact areas of the electromagnetic valves on both sides of the sand inlets and the water inlets are the same, the valves are opened and closed by a direct current motor, and the direct current motor is also provided with an energy accumulator for voltage regulation. The outlet of the pre-booster device is connected to a nozzle through a pipeline. The system aims at the problems that the switching of the abrasive tanks in the existingabrasive jet interrupts the sand supply and affects the cutting quality, and the pressure pulsation generated in the boost waiting and switching process is eliminated through the pre-booster device,thereby achieving the continuous work of the front mixed abrasive jet in a true sense.

Owner:WUHAN UNIV

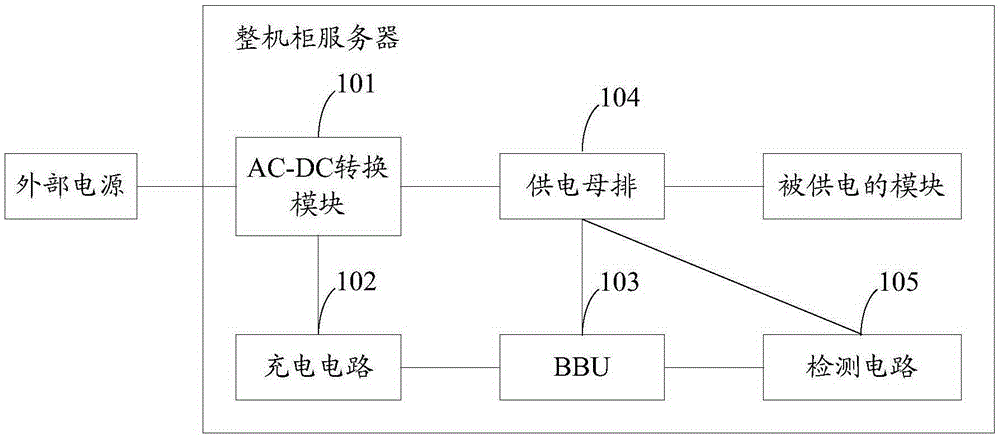

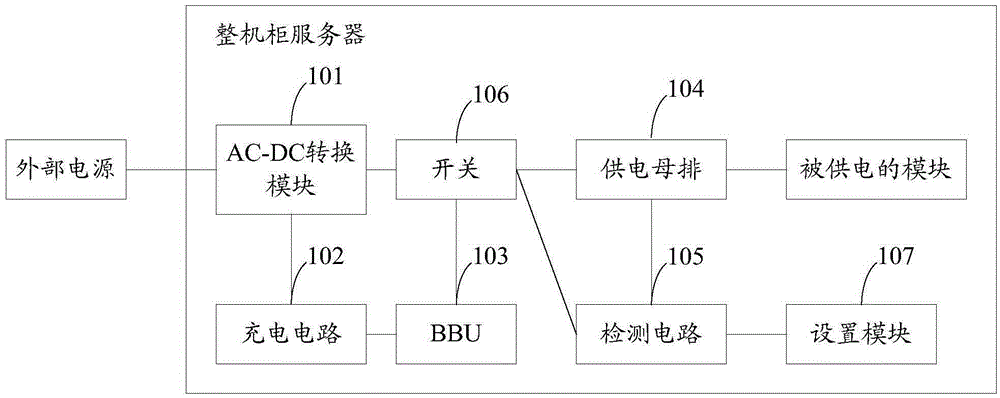

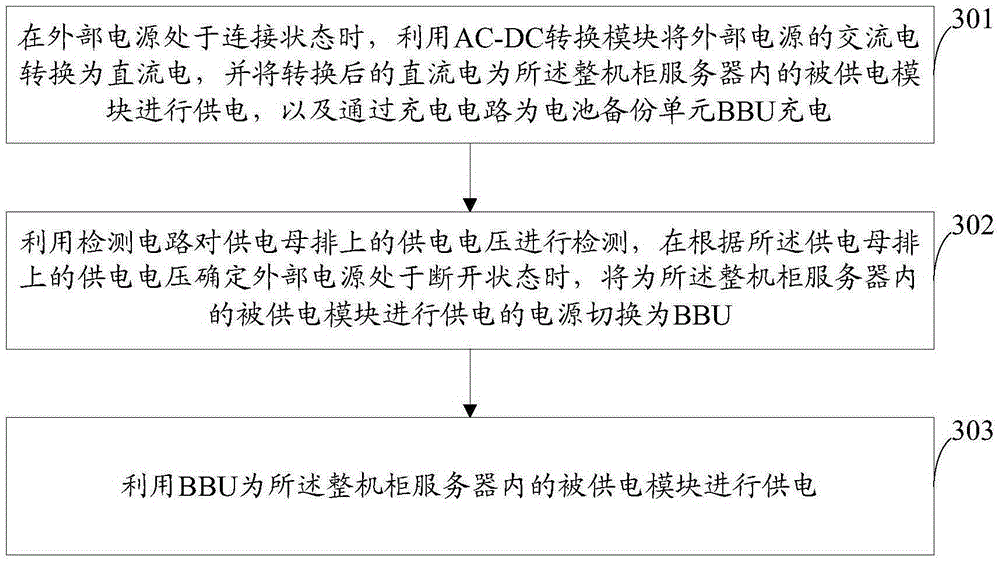

Continuous power supply system and method

The invention provides a continuous power supply system and method. The continuous power supply system comprises an AC-DC conversion module, a charging circuit, a BBU, a power supply busbar and a detection circuit. The AC-DC conversion module is used for supplying power to an entire machine cabinet server through a direct current and for charging the BBU. The charging circuit is connected with the BBU and used for charging the BBU through the direct current converted through the AC-DC conversion module. The BBU is used for supplying power to the entire machine cabinet server when an external power supply is disconnected. The power supply busbar is used for transmitting the direct current converted through the AC-DC conversion module to the entire machine cabinet server. The detection circuit is used for detecting a power supply voltage on the power supply busbar, and switching a power source supplying power to a powered module in the entire machine cabinet server into the BBU when it is determined that the external power source is in a disconnected state according to the power supply voltage on the power supply busbar. According to the scheme, continuous power supply of the entire machine cabinet server can be achieved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Robot capable of automatically replacing working battery and charging platform of robot

PendingCN106684477AContinuously workingRealize continuous workMobile unit charging stationsElectric powerPush pullElectrical and Electronics engineering

The invention discloses a robot capable of automatically replacing a working battery and a charging platform of the robot. The robot is characterized by comprising the working battery and a standby battery, wherein the working battery is fixed on a battery vehicle; the robot is internally provided with two rails, and the battery vehicle is arranged above the rails; the robot is internally provided with an electric control push-pull rod, and an electromagnet is arranged at the top of the push-pull rod; and the electromagnet attracts the battery vehicle to move on the rails. When the battery vehicle moves to a battery position, the working battery is used for normally supplying power to the robot through a battery contact spring and charging the standby battery. When the robot detects that the working battery nearly works out, the robot automatically returns back to the charging platform, the battery vehicle is pushed to the charging platform, then the other standby battery vehicle of the charging platform is pulled back to the battery position of the robot and is used for supplying power to the robot, and the charging platform is used for charging the battery on the replaced battery vehicle. According to the robot and the charging platform, disclosed by the invention, continuous works of the robot are realized.

Owner:广东大仓机器人科技有限公司 +1

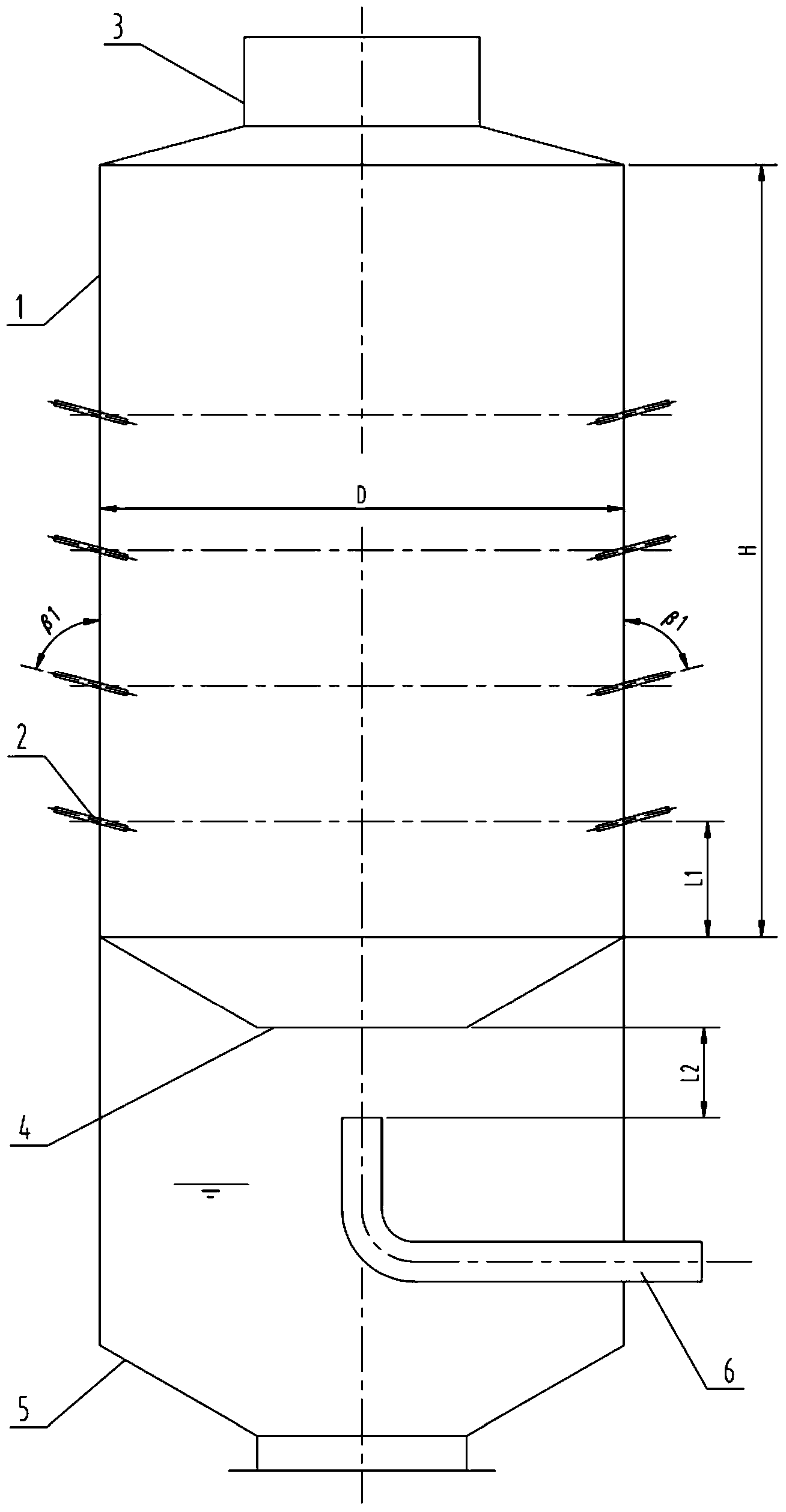

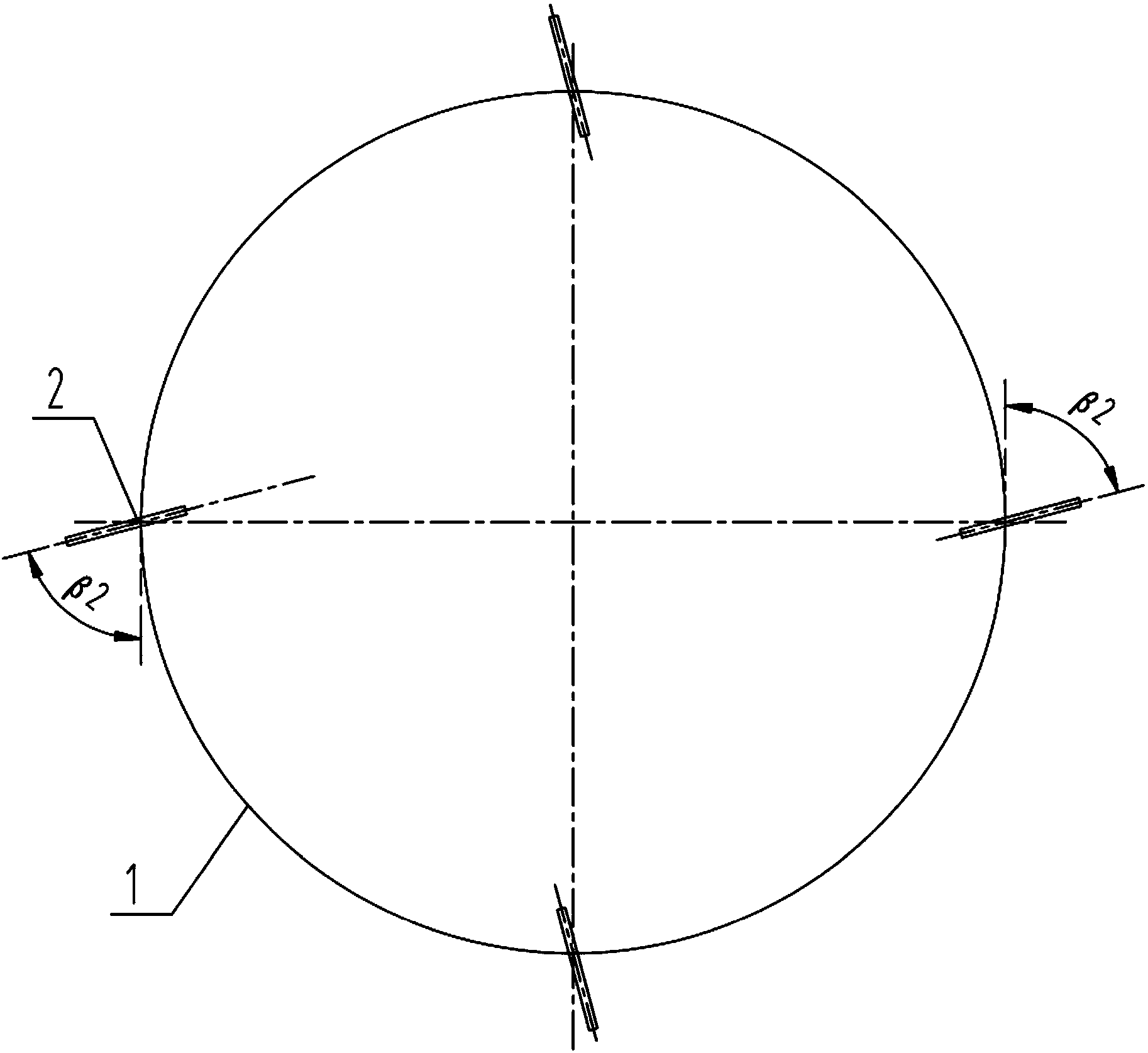

Vertical pyrolysis furnace

PendingCN107686732ARealize continuous workIncrease productivityDirect heating destructive distillationMetallurgyThermal solution

The invention discloses a vertical pyrolysis furnace. The vertical pyrolysis furnace includes a furnace body, and the furnace body defines a preheating section, a pyrolysis section and a cooling section from top to bottom. The preheating section and The pyrolysis section is connected, a partition is provided between the pyrolysis section and the cooling section, and the bottom of the pyrolysis section is provided with a wall that passes through the partition and extends into the cooling section. A discharge pipe, the furnace body is provided with a pyrolysis material inlet connected to the preheating section, a heat carrier gas inlet connected to the pyrolysis section, a heat carrier connected to the preheating section and / or the pyrolysis section Degassing outlet, the bottom of the furnace body is provided with a semi-coke outlet that communicates with the cooling section. According to the vertical pyrolysis furnace of the embodiment of the present invention, the continuous operation of the pyrolysis furnace can be realized by setting the connected preheating section, pyrolysis section and cooling section, and the production efficiency is improved.

Owner:SHENWU TECH GRP CO LTD

Submarine cable connection operation device and operation method thereof

PendingCN109823486ASafe recyclingSafe and reliable connectionCable-laying vesselsOcean bottomGunwale

The invention discloses a submarine cable connection operation device and an operation method thereof and relates to the technical field of submarine cable maintenance operation. A submarine cable maintenance ship is prone to secondary damage when a submarine cable is pulled into water. The submarine cable connection operation device comprises a cable guiding device fixedly connected with a hull,a connecting room and a cable traction winch. The cable guiding device comprises water outlet guide roller sets, a locking guide roller set, a horizontal guide roller set, a U-shaped guide roller setand a guide rail, wherein the protruding outboard portions of the water outlet guide roller sets are arc-shaped in the transverse direction and the vertical direction; the two water outlet guide roller sets are installed on the same side of a ship board; the locking guide roller set is provided with a safety locking device for fixing a cable. After cable connection is completed, the U-shaped guideroller set can slide to a gunwale along a guide rail, and the U-shaped guide roller set is hoisted through a hoisting device to enter water so as to downward release the cable. Bending damage occurring when the cable goes into or out of water or is dragged can be prevented, safe and reliable recovery, connection and downward release of the submarine cable can be effectively guaranteed, and secondary damage can be prevented.

Owner:ZHEJIANG ZHOUSHAN QIMING POWER CONSTR CO LTD +2

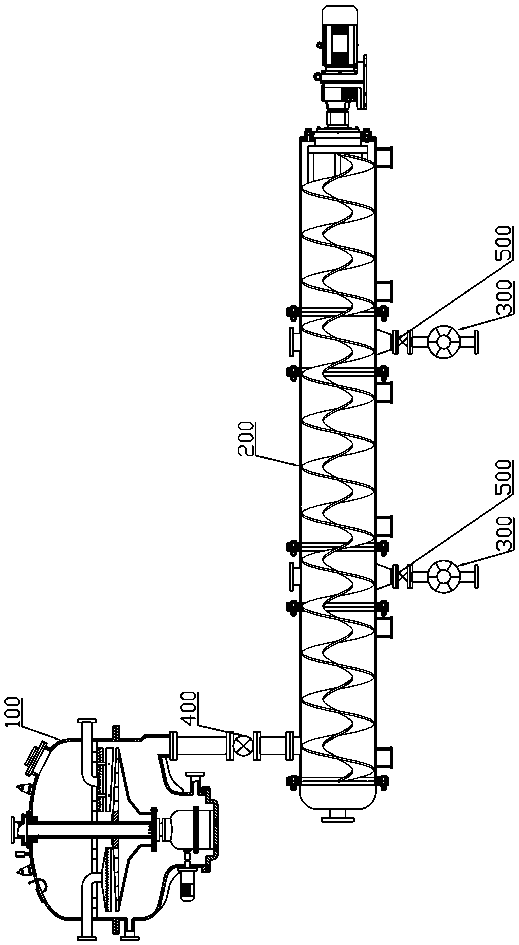

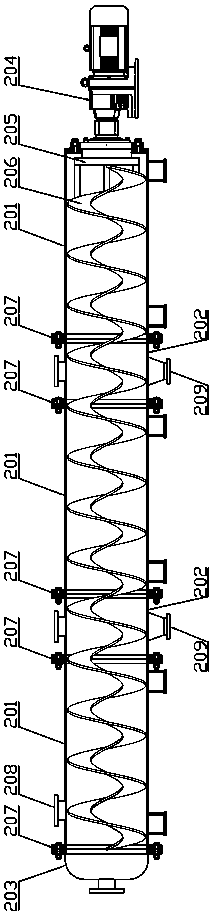

Continuous separating and drying system for wet-process production of insoluble sulfur

PendingCN109896504AIncrease productivityStable deliveryDrying solid materials without heatSulfur preparation/purificationSulfurSlurry

The invention provides a continuous separating and drying system for wet-process production of insoluble sulfur. The technical problem that existing vacuum drying devices are limited in treatment capacity, thereby being incapable of being matched with working efficiency of vacuum filtering devices can be solved effectively. The system comprises a vacuum filtering device, a conveying device and a vacuum drying device. The system is characterized in that the vacuum filtering device comprises a filter shell, a discharging scraper, a turntable driving mechanism and a suction filtering mechanism, the suction filtering mechanism comprises a suction filtering pipe, a filtering disc and a housing, the filtering disc hermetically covers an upper-end opening of the housing to form a separation chamber which is arranged in the filter shell, the filtering disc is driven by the turntable driving mechanism, and a slurry distribution tank, a washing liquid distribution tank and the discharging scraper are arranged above the filtering disc; the conveying device comprises a conveyor shell, a shaftless screw conveyor and a screw conveyor driving mechanism, the conveyor shell is provided with more than two feeding and discharging ports, each discharging port is sequentially connected with a valve and the vacuum drying device, and the screw conveyor is shaftless.

Owner:WUXI HUASHENG RUBBER TECHN

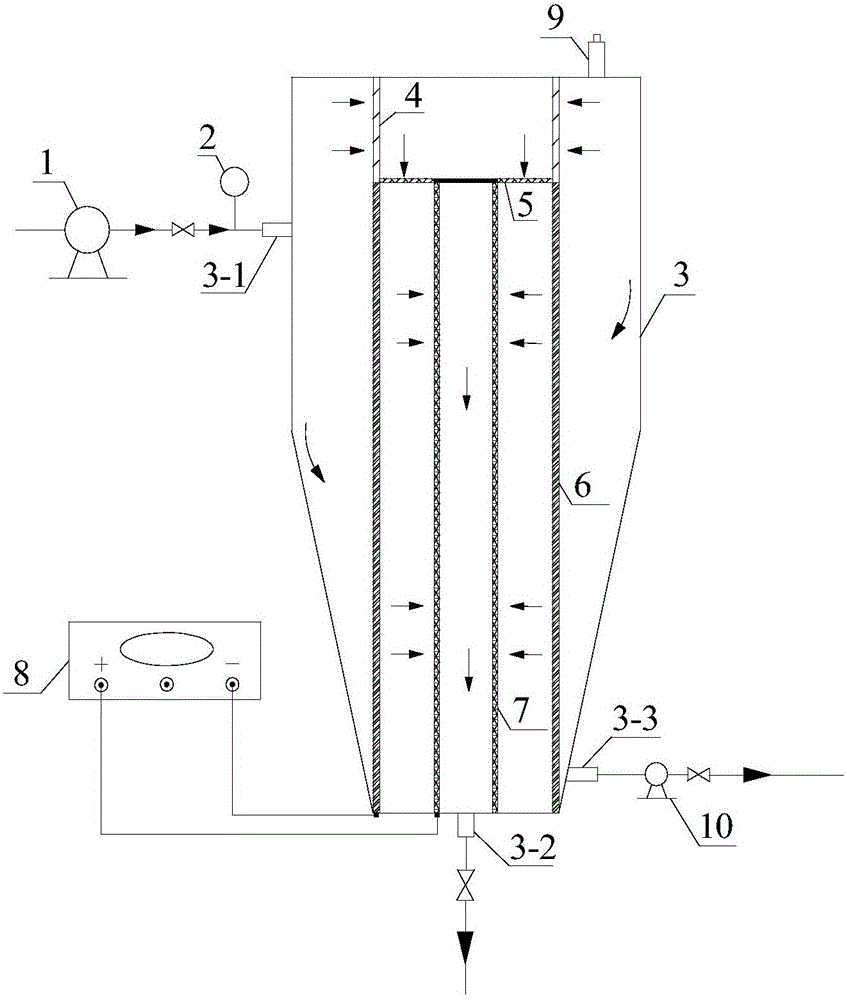

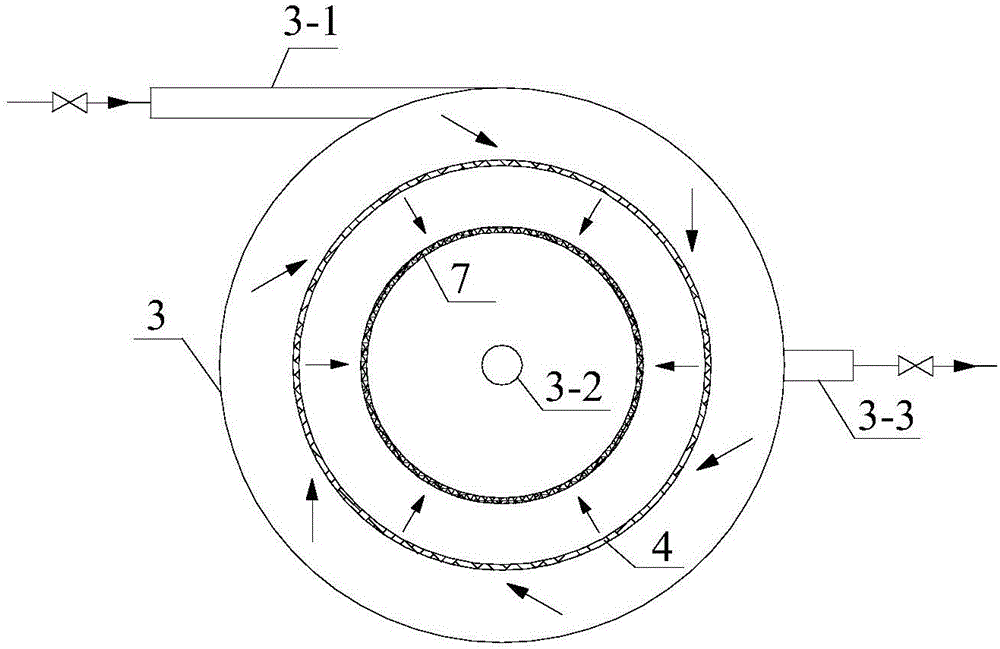

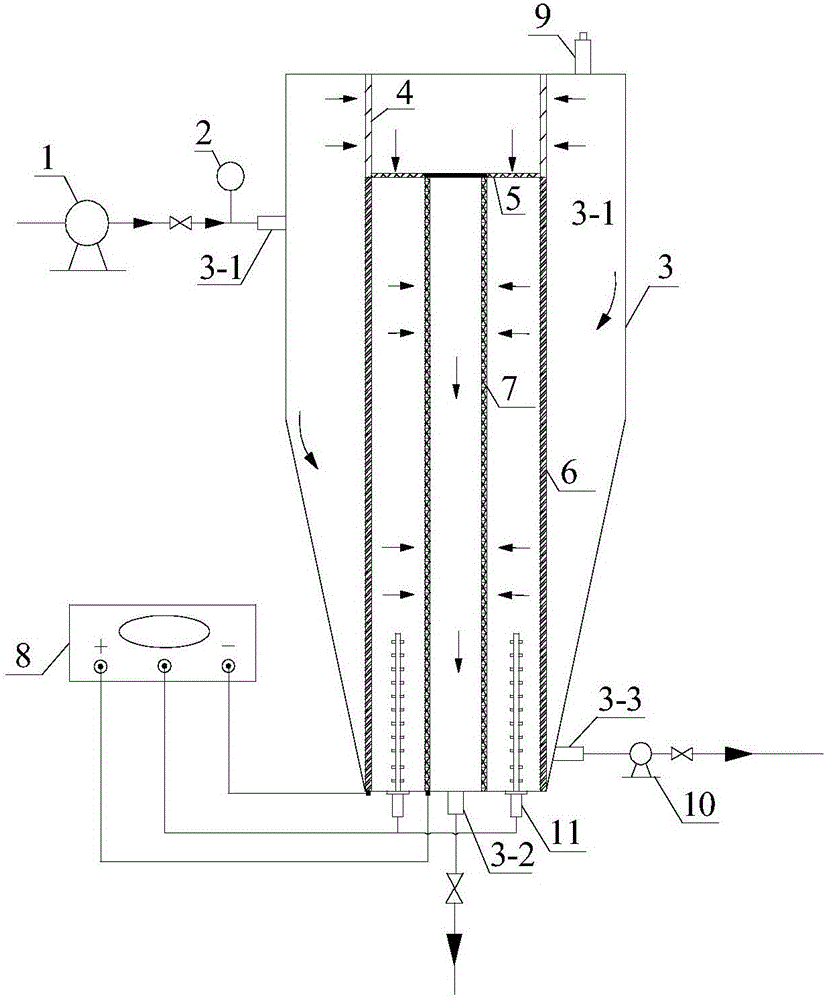

Electrochemical water treatment device and method utilizing same to treat water

ActiveCN105923849APurify thoroughlyEasy to handleWater/sewage treatment by centrifugal separationSpecific water treatment objectivesCycloneFiltration

The invention provides an electrochemical water treatment device which comprises a reaction device, a tangential water inlet formed in the side wall of the upper portion of the reaction device, a water outlet formed in the lower end of the bottom, a drain outlet formed in the side wall of the bottom, a primary coarse filtration screen arranged at the top of the center of the inside of the reaction device, an anode arranged below the primary coarse filtration screen, a secondary fine filtration screen, a cathode, a power supply and a vent valve. The invention further provides a method utilizing the device to treat water. Compared with the prior art, the synergic coupling effect of all processes is achieved within the same reaction device by adopting an ingenious process concept, so that the processes are complementary and are promoted mutually to overcome the shortcomings existing when the processes respectively play the effects, the treatment effect is remarkably improved, the energy consumption is reduced, a reactor structure is optimized, and the occupied area is reduced. The method utilizing the device to treat water is simple in process, high in treating efficiency and capable of performing effective, economical, environmentally friendly and integrated water treatment through hydraulic cyclone separation, two-stage filter screen based filtration and electrochemical oxidation and reduction.

Owner:HOHAI UNIV

Large-thrust high-speed hydraulic cylinder and work method thereof

ActiveCN106015130AInstantaneous high-speed high-thrust output of high-pressure gasHigh speed and large thrust outputFluid-pressure convertersActuator accumulatorsHydraulic cylinderEngineering

The invention relates to a large-thrust high-speed hydraulic cylinder. A hydraulic cylinder body is a sealed cavity which is transversely arranged. A high-speed cylinder barrel is fixedly arranged at the front end of the hydraulic cylinder body in an axial extending manner. A high-speed cylinder piston rod is coaxially sleeved with the high-speed cylinder barrel. The high-speed piston rod coaxially slides in a sealed manner in a high-speed cylinder rod cavity. An energy accumulator piston rod penetrating an energy accumulator gas cavity and a supercharger cavity is coaxially installed in the hydraulic cylinder body. An energy accumulator piston is fixedly arranged at the end portion, at the front end of the energy accumulator gas cavity, of the energy accumulator piston rod. The energy accumulator piston is installed in the hydraulic cylinder body in a sealed and sliding manner. An energy accumulator liquid cavity is formed between the energy accumulator piston and the high-speed cylinder piston rod. A pressure cylinder piston is coaxially manufactured on the energy accumulator piston rod in the supercharger cavity. The pressure cylinder piston is installed in the supercharger cavity in a sealed and sliding manner. By means of the high-thrust high-speed hydraulic cylinder, through the manner that a piton type energy accumulator and the high-speed hydraulic cylinder are directly connected in series, high-speed output of large thrust of the high-speed cylinder can be achieved.

Owner:TIANJIN URANUS HYDRAULIC MACHINERY

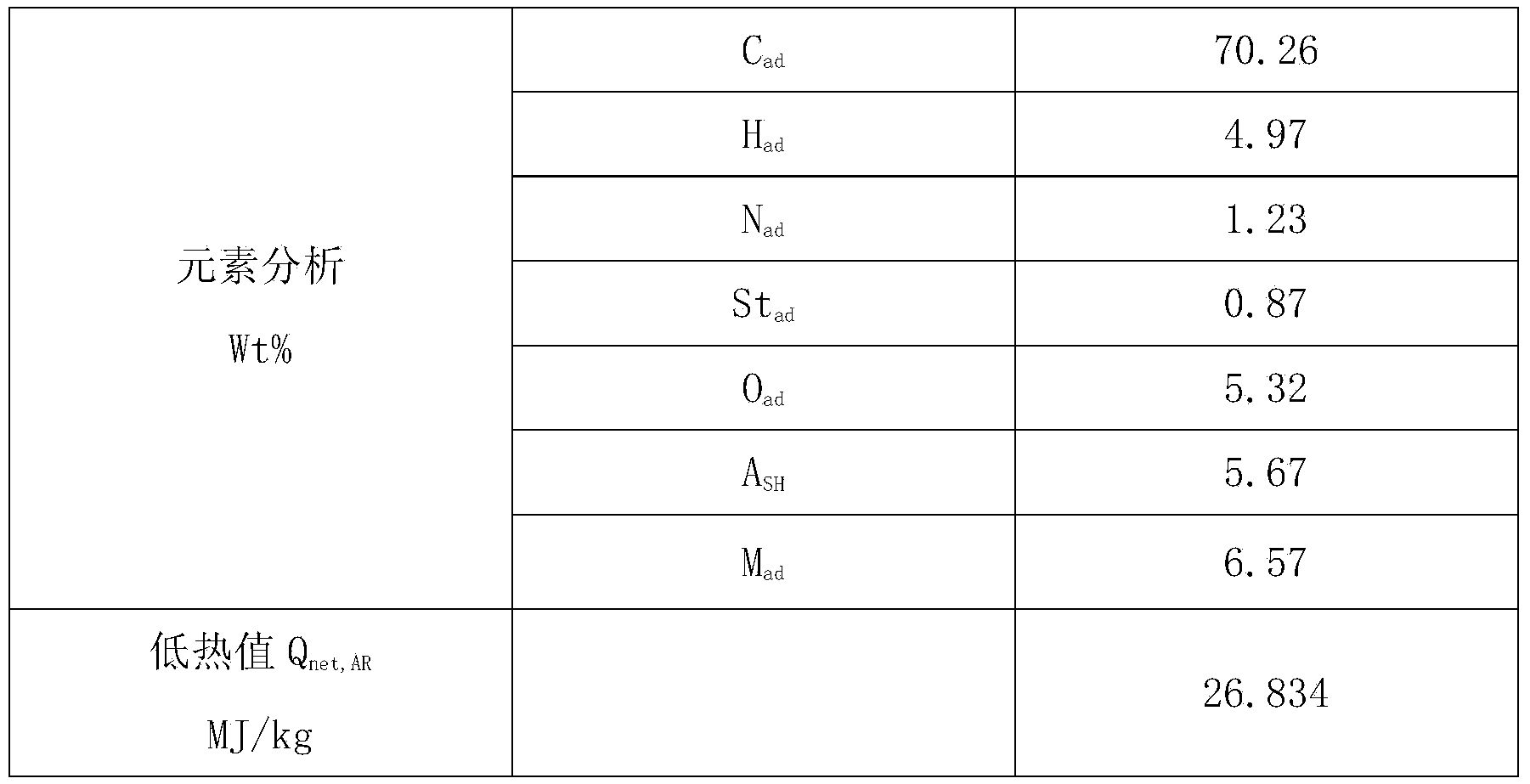

Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

ActiveCN103725327AFully contactedAdequate responseGranular/pulverulent flues gasificationPositive pressureSlag

The invention discloses a gasification entrained-flow bed coal powder gasification furnace and a gasification method of micro-positive pressure air. At present, a normal-pressure fixed bed gasification furnace is commonly applied in an industrial fuel gas preparation industry and an efficient powdered coal entrained-flow bed gasification technology has some difficulties on preparing industrial fuel gas under the condition that the micro-positive pressure air is used as a gasifying agent. The gasification entrained-flow bed coal powder gasification furnace is characterized in that a gasification furnace body is provided with at least one row of wall surface burners; each row of the wall surface burners comprise a plurality of wall surface burners which are arranged along the peripheral direction of the gasification furnace body at intervals; the gasification agent which is sprayed into the gasification furnace by all the wall surface burners accounts for 80%-97% of the use amount of all the gasification agent; a furnace bottom nozzle is arranged below the bottom face of a gasification furnace slag opening; the gasification agent which is sprayed into the gasification furnace by the furnace bottom nozzle accounts for 3%-20% of the use amount of all the gasification agent. According to the gasification furnace, the gasification intensity of a unit volume is high; the quantity of in-furnace coal powder falling into a dreg tank is effectively reduced; the gasification entrained-flow bed coal powder gasification furnace is very suitable for producing the industrial fuel gas by taking the micro-positive pressure air as the gasification agent.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

High-speed needle insertion apparatus

ActiveCN103606795AIncrease productivityReduce noiseContact member assembly/disassemblyEngineeringCam

The invention discloses a high-speed needle insertion apparatus. The apparatus comprises a product feeding mechanism and a cam feeding needle insertion mechanism. The product feeding mechanism comprises a feeding support, a first connection board, a first feeding motor, a second feeding motor, a first KK module, a second KK module, a poking claw connecting piece, a first poking claw, a second poking claw, a product track, a positioning cover plate and a product briquetting. The feeding support is fixedly connected with the first feeding motor and the second feeding motor through the first connection board. The first feeding motor is fixedly connected with the first KK module. The second feeding motor is fixedly connected with the second KK module. The second KK module is fixedly connected with the second poking claw through the poking claw connecting piece. The product track is located on a top of the first poking claw and is fixedly connected with the product briquetting through the positioning cover plate. The cam feeding needle insertion mechanism comprises a cam group assembly, a material belt feeding assembly, a material belt positioning assembly, a cutting-off and pressing-into assembly and a transmission power assembly. The mechanism of the apparatus of the invention is compact and production efficiency is high. The apparatus is especially suitable for complex needle insertion with high precision and small spacing.

Owner:KUNSHAN INNO STAR AUTOMATION TECH

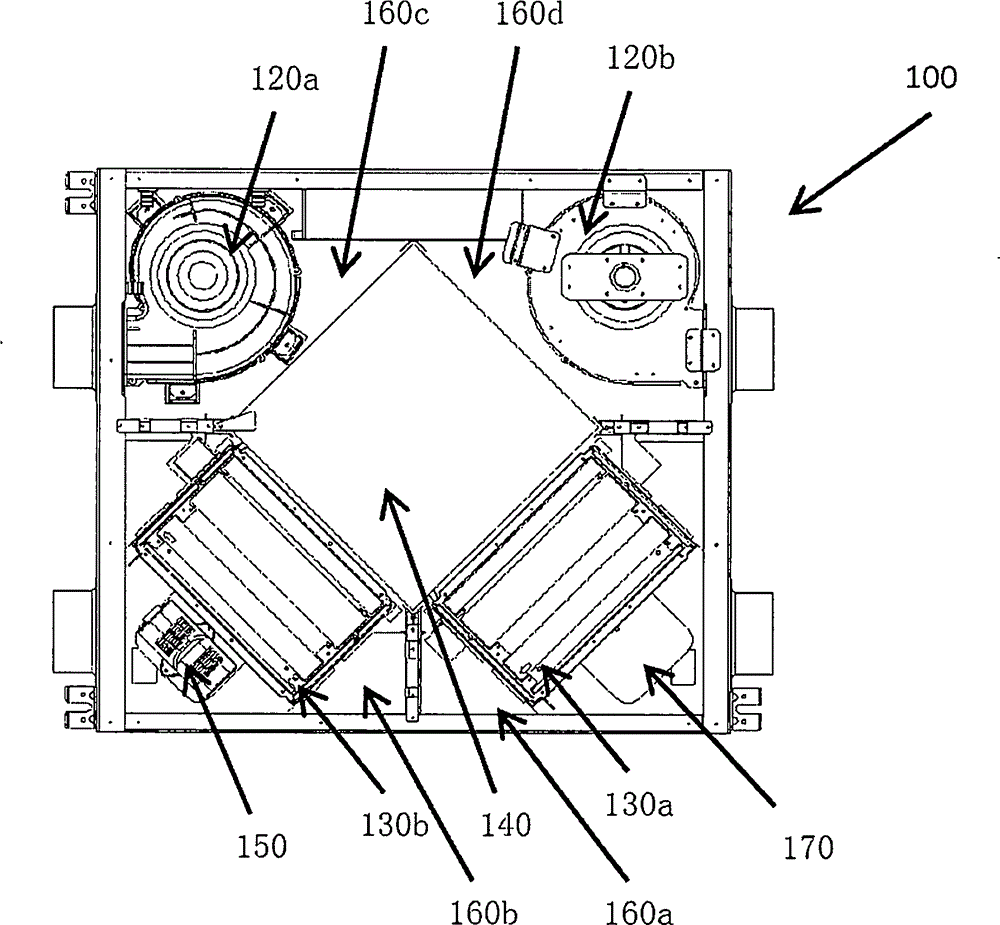

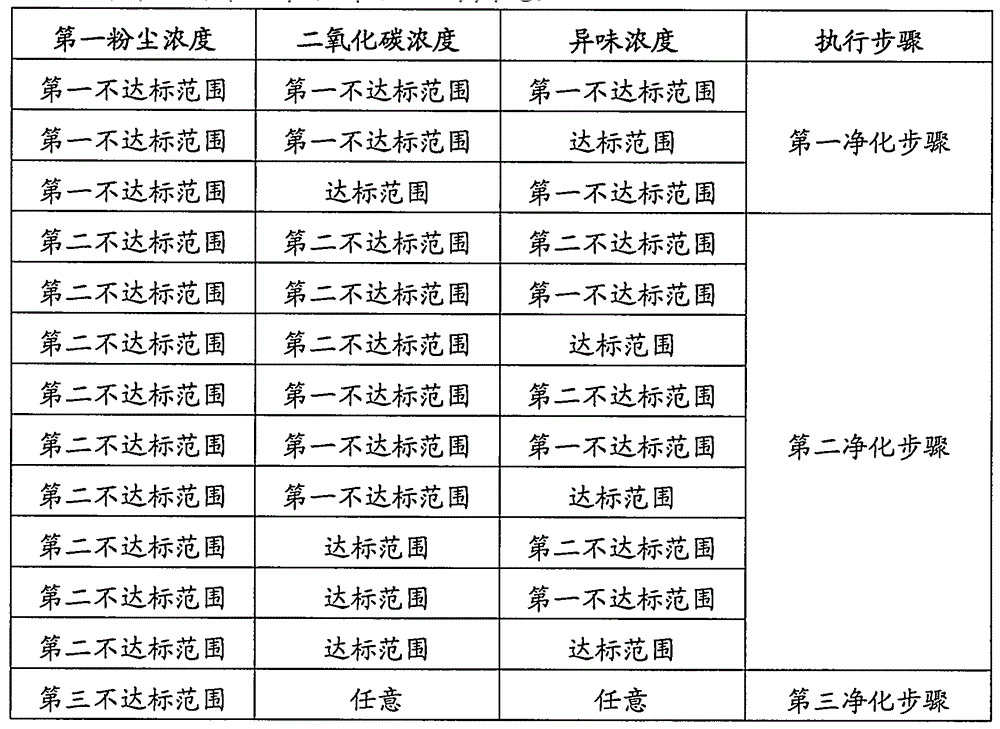

Fresh air purifier and control method thereof

InactiveCN106288111ARealize continuous workRealize intelligent start and stopEnergy recovery in ventilation and heatingMechanical apparatusIndoor air qualityFresh air

The invention discloses a fresh air purifier comprising the following units: a housing; a heat exchange module arranged in the housing, wherein the heat exchange module and the housing enclose to form an air inlet cavity, an air outlet cavity, an air return cavity and a fresh air cavity through a plurality of isolation plates; a first blower and a second blower respectively arranged in the air outlet cavity and fresh air cavity; a filtering module arranged in the air inlet cavity; a first sensor module arranged in the air return cavity, wherein the first sensor module is used for detecting a first dust concentration, a carbon dioxide concentration, a peculiar smell concentration, a temperature and humidity of the return air. The fresh air purifier combines various sensors, and the sensor module is arranged in proper position, thus accurately detecting air parameters; a control method is combined so as to reasonably adjust the indoor air quality, thus satisfying air purifying and heat exchange demands, and improving energy utilization efficiency as possible.

Owner:上海净养环保科技有限公司

Inorganic resin oil heated warm core box

InactiveCN102189217AFlexible layoutHeating evenlyFoundry moulding apparatusEngineeringOil temperature

The invention relates to an inorganic resin oil heated warm core box, which comprises a core box with a sand core cavity. The core box comprises an upper core box and a lower core box; the sand core cavity is formed by the upper core box and the lower core box; the upper core box is provided with a sand jet hole communicated with the sand core cavity; and a plurality of oil heating pipelines are arranged at the periphery of the sand core cavity in the core box and are connected with an external oil temperature machine. The core box is heated and cured through the oil heating pipelines, the oil heating pipelines are convenient to arrange, uniform heating is realized, the temperature is controllable, the core box can continuously work, and processing quality is ensured while processing efficiency is improved.

Owner:SUZHOU MINGZHI TECH

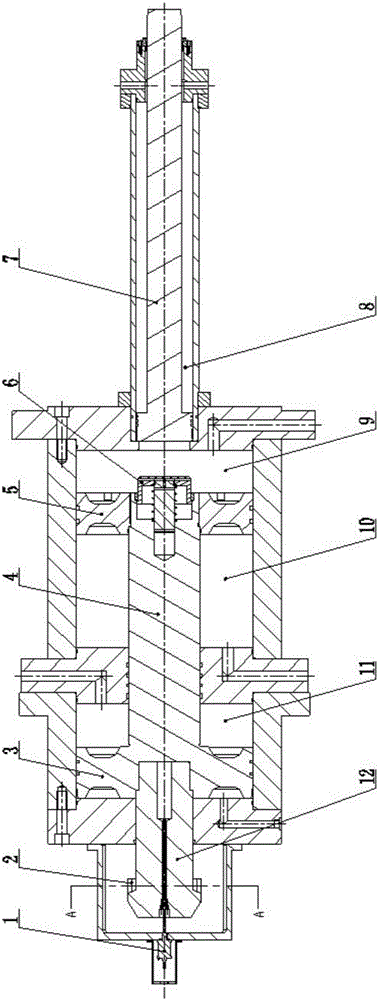

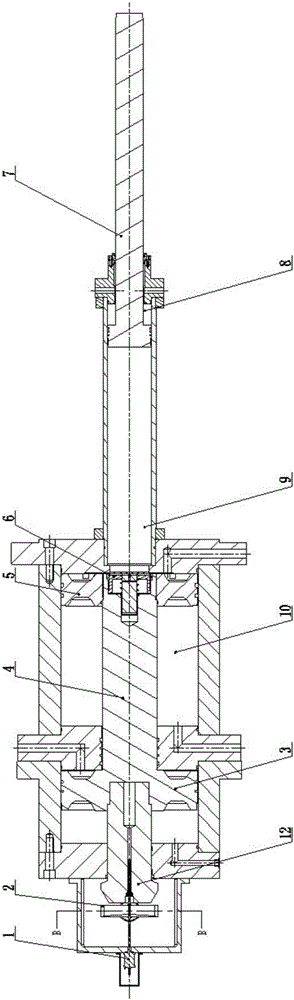

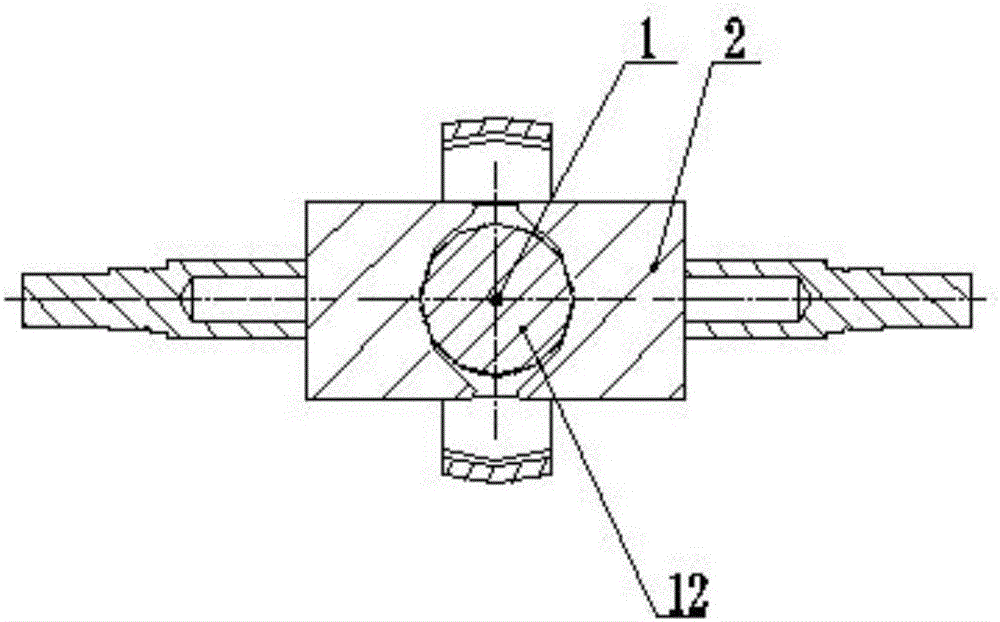

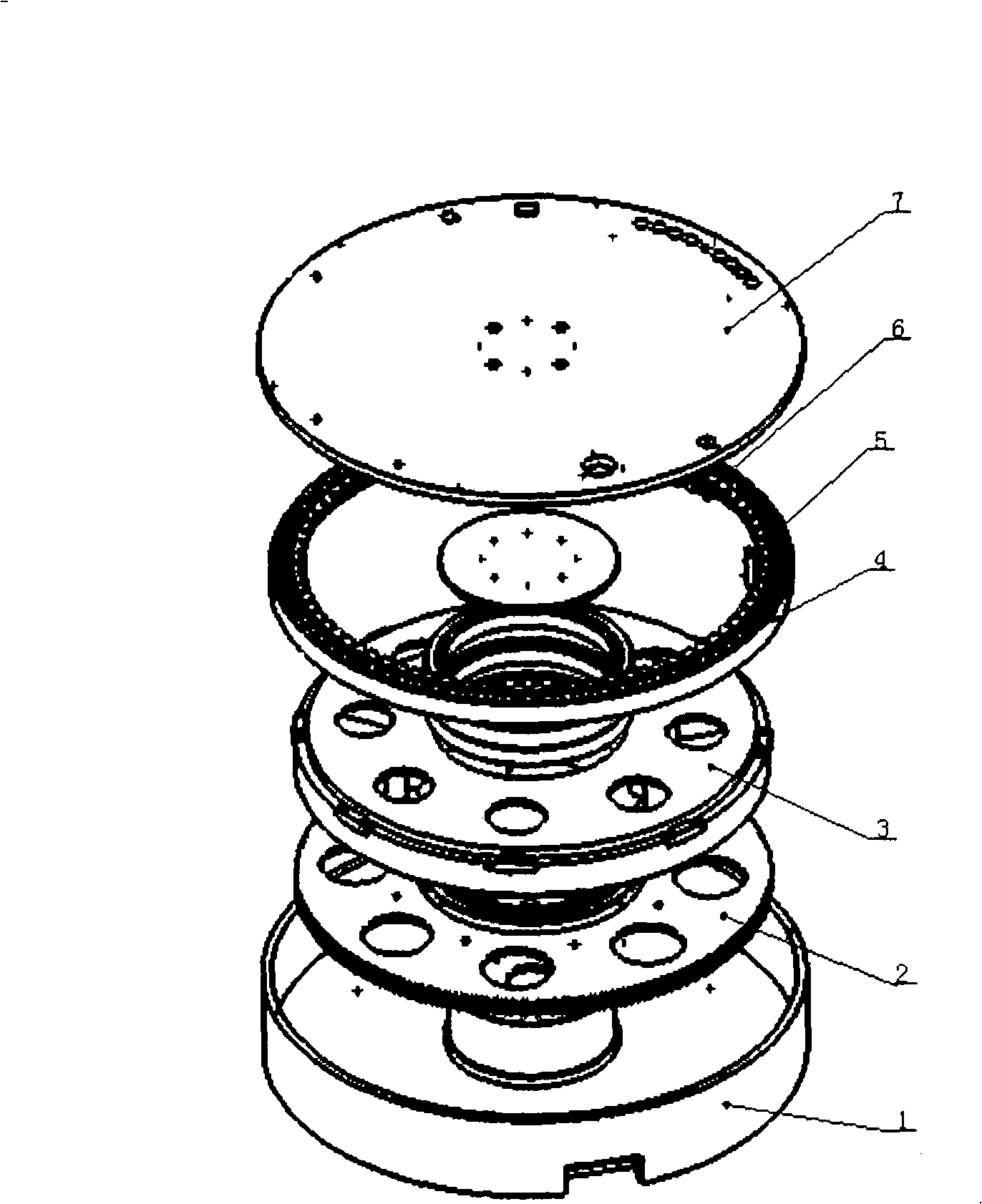

Reaction disc assembly

InactiveCN101539584ARealize continuous workReduce processing difficultyMaterial analysisElectric machineryDISC assembly

The invention relates to a reaction disc assembly, which comprises a bearing seat (1), a gear disc (2), a magnetic disc (3), a reaction disc (4) and a bearing plate (7), wherein the gear disc (2) is driven to rotate by a motor and drives the magnetic disc (3) to rotate through a gear, and the reaction disc assembly is characterized in that the gear disc (2), the magnetic disc (3) and the reaction disc (4) all have a single circular structure respectively and are coaxially arranged.

Owner:BEIJING YUANDE BIO MEDICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com