Biological purification method of aquiculture waste water and siphoning reciprocating type biological filter

A biological filter and biological purification technology, applied in the field of water treatment in aquaculture systems, to achieve high ammonia nitrogen removal efficiency, improve nitrification reaction efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

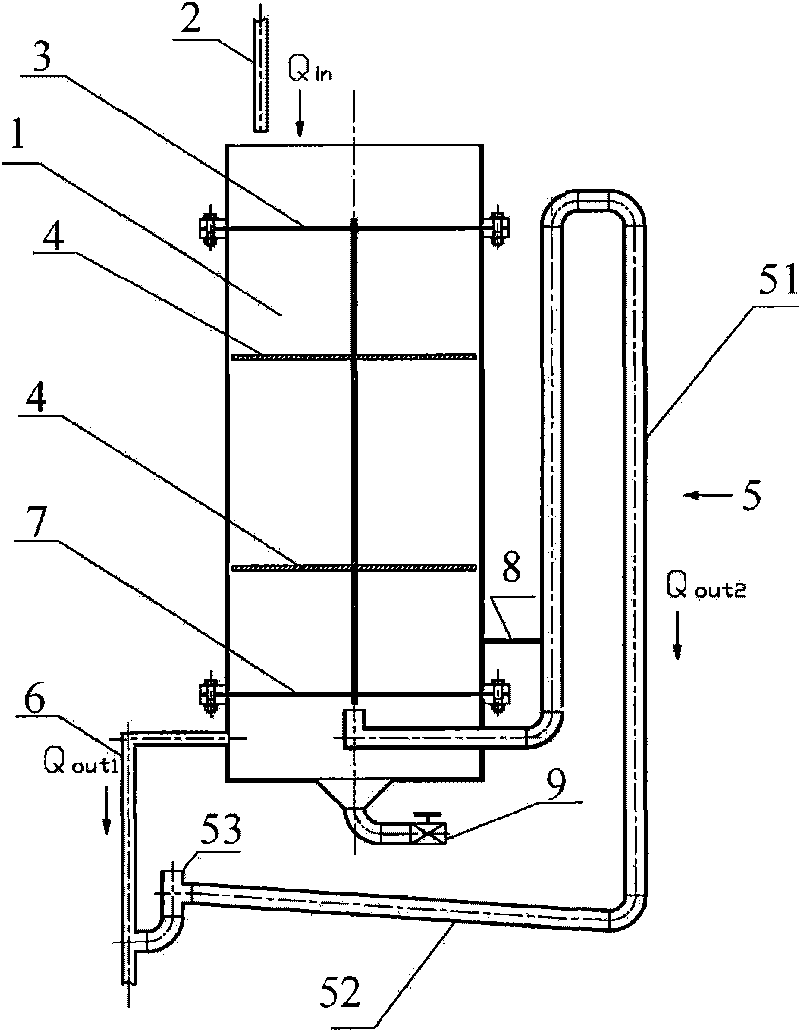

[0044] See figure 1 In this embodiment, the siphon reciprocating biological filter used in the aquaculture system consists of a purification chamber 1, a water inlet pipe 2, a water distribution orifice plate 3, a grid 4, a bottom plate 7, a siphon device 5, and a water outlet pipe. 6. The siphon destruction pipe 8 and the sewage pipe 9 are composed.

[0045] Among them, the purification cavity 1 is a cylindrical cavity with a diameter of 30 cm and an effective height (water distribution hole plate 3 to bottom plate 7) of 50 cm.

[0046] The water distributing orifice plate 3 is fixed on the upper part of the purification chamber 1, and a plurality of holes are evenly distributed on it, the diameter of which is 1.5mm, to allow the water to be purified from the upper water inlet pipe 2 to enter the purification chamber 1 and be combined with the filler ( Not shown) Even contact.

[0047] In other embodiments, the water distribution device of the present invention can also be in other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com