Reaction disc assembly

A reaction plate and assembly technology, applied to the analysis of materials, instruments, etc., can solve problems such as difficult processing, achieve the effects of reducing processing difficulty, realizing continuous work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

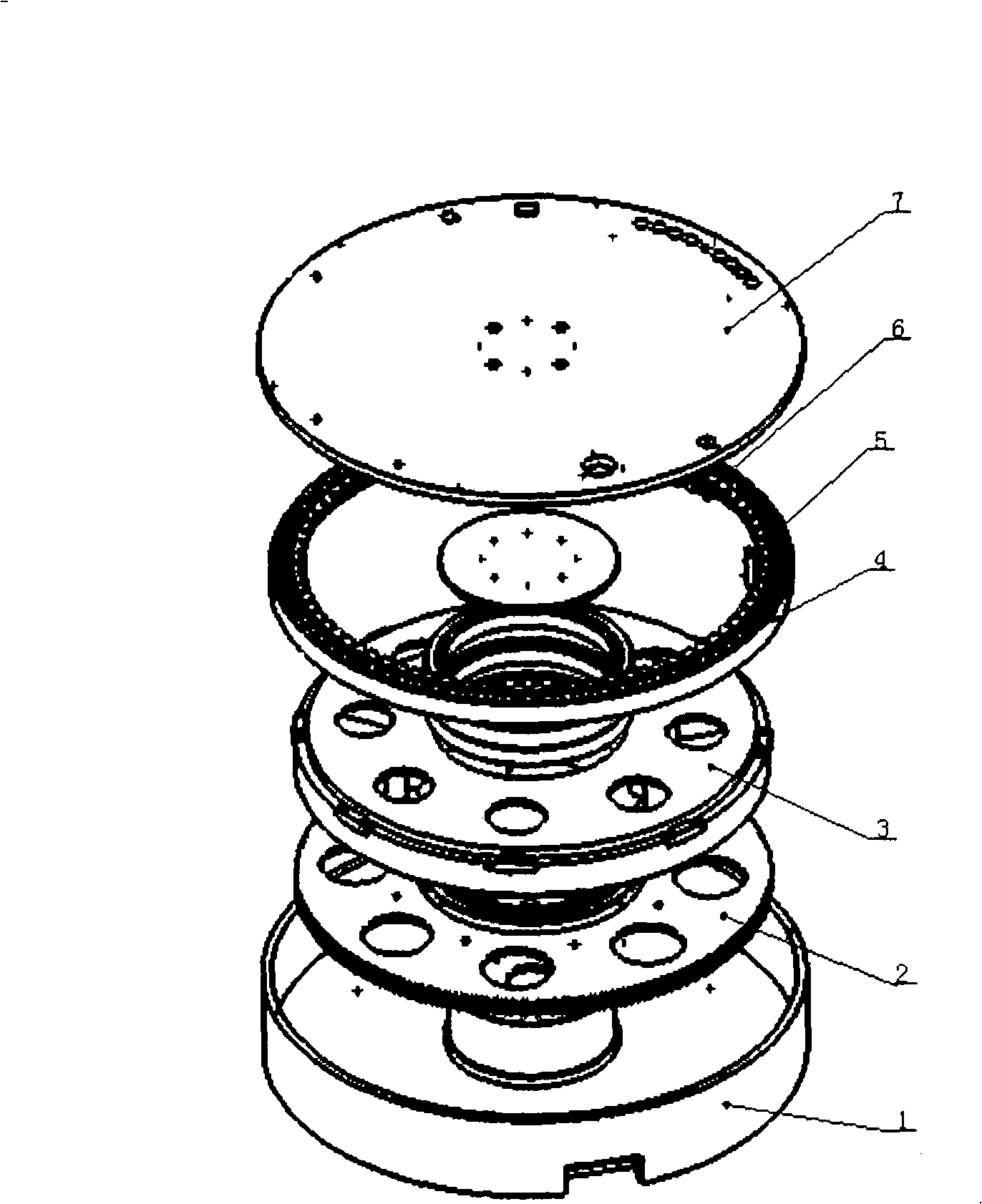

[0008] Such as figure 1 As shown, the reaction disk assembly of the present invention includes: a support seat 1 , a gear disk 2 , a magnetic disk 3 , a reaction disk 4 and a support plate 7 . The gear disc 2, the magnetic disc 3, and the reaction disc 4 are all of a single annular structure and coaxially arranged. The supporting seat 1 is arranged at the bottom of the reaction disk assembly, and is used for fixing the relative position of the reaction disk assembly and adapting to the relative position relationship of the liquid filling needle. The gear plate 2 is arranged above the support base 1 and is driven to rotate by a servo motor. The motor speed is about 600 rpm, and the rotation speed of the gear plate 2 is about 1 rpm. The magnetic disk 3 is arranged on the top of the gear disk 2, driven by the gear disk 2 to rotate through gears, the speed ratio of the pulley is about 1:10, and the magnetic disk 3 is provided with a movable pin 5. The reaction disk 4 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com