Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

A technology of air gasification and gasification furnace, which is applied in the direction of granular/powdered fuel gasification, etc. It can solve the problems of poor discharge of liquid slag at the slag discharge port, increase in equipment cost, and affect work, so as to reduce fuel waste , increase the jet velocity, improve the effect of gasification intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

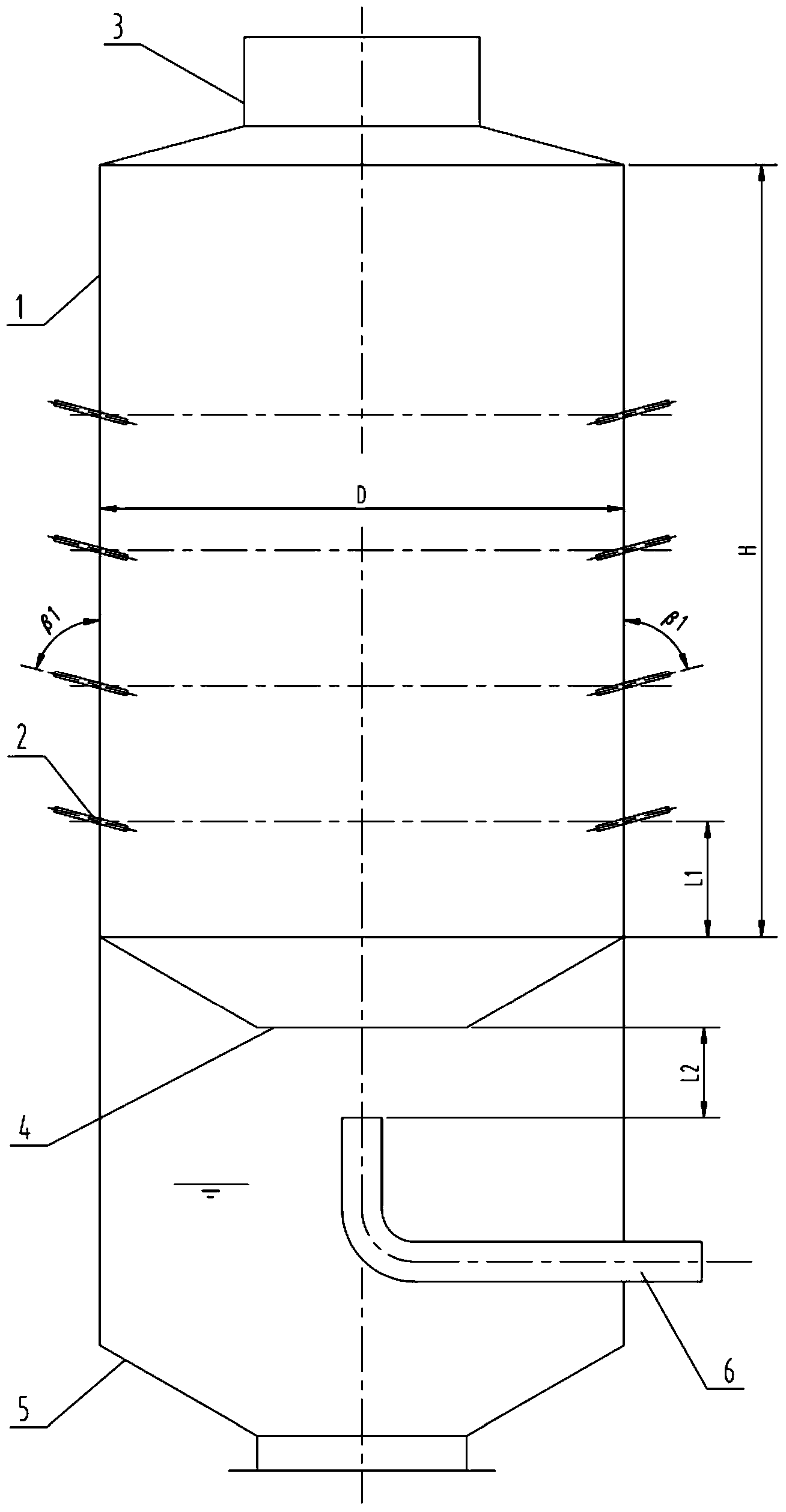

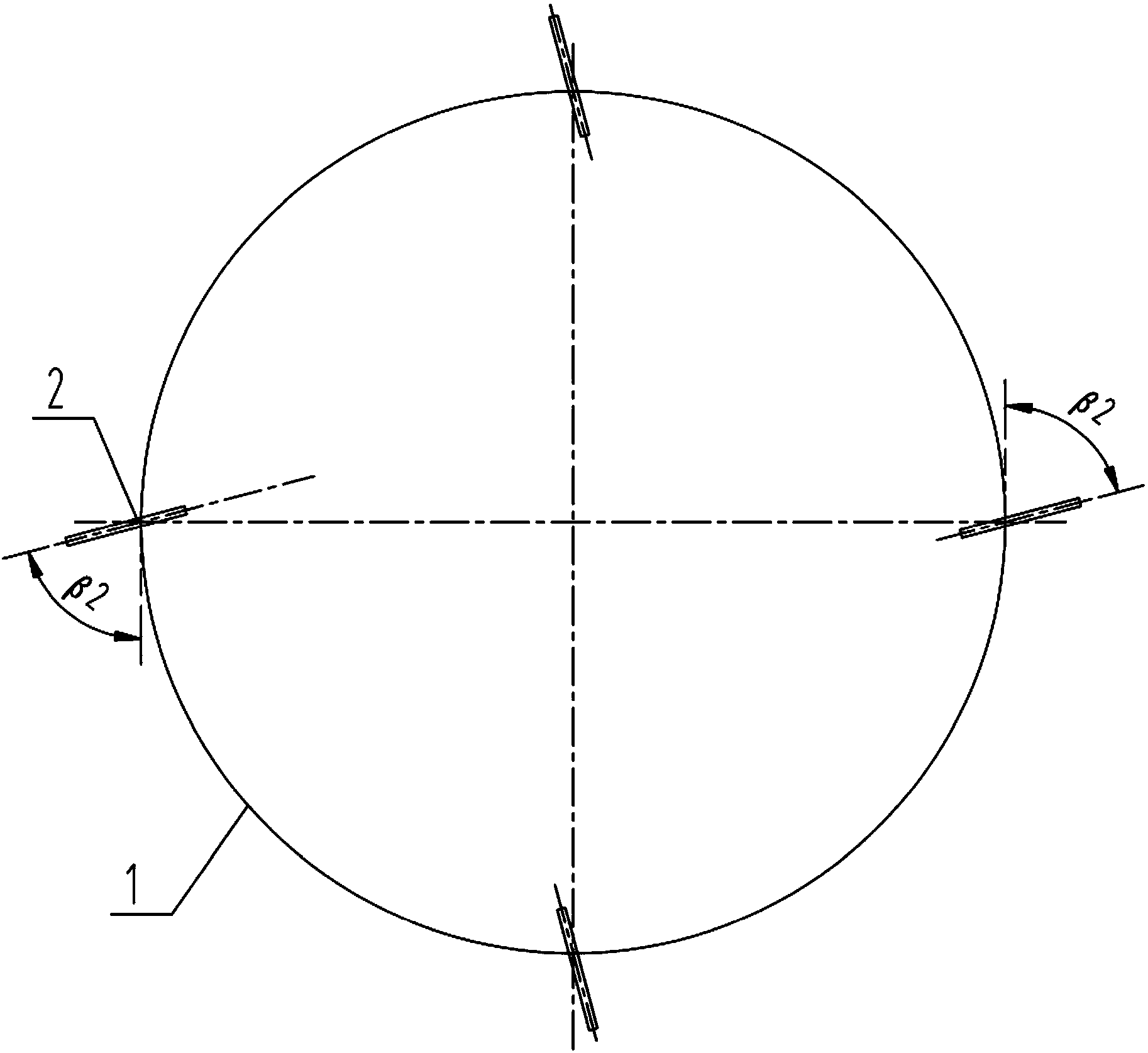

[0027] Such as Figure 1-2 The gasifier shown is composed of a gasifier body 1, a slag pool 5, a furnace bottom nozzle 6 arranged at the bottom of the slag outlet 4 of the gasifier, and four rows of wall burners 2 arranged on the gasifier body , the syngas outlet 3 of the gasifier is located at the top of the gasifier body, and the slagging outlet 4 of the gasifier is located at the bottom of the gasifier body. Bottom burners 6 are arranged below the bottom surface of the slagging outlet 4 of the gasifier. The gasifier body 1 is in the shape of a cylinder. Arranged at intervals, the angle β2 between the axis of the wall burner 2 and the tangent at the intersection of the gasifier body is 70-75°; the angle β1 between the axis of the wall burner 2 and the wall of the gasifier body is 80-90°. The gasification agent injected into the gasification furnace through all the wall burners accounts for 90% of the total gasification agent. The gasification fuel is injected into the gasif...

Embodiment 2

[0037] The following examples will further illustrate the present invention in conjunction with the experimental comparison data of the present invention and traditional structure under the same gasification reaction conditions:

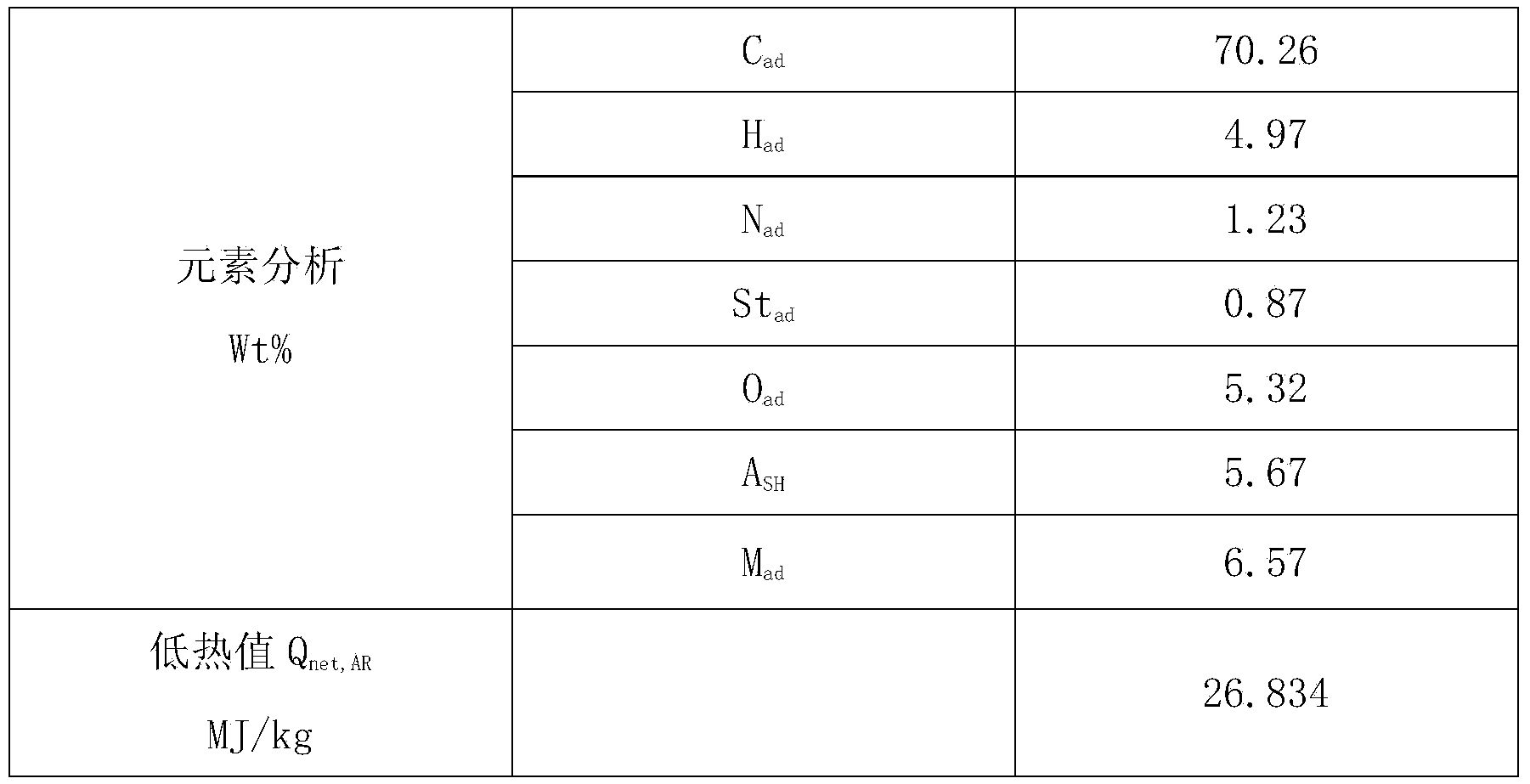

[0038] Take the gasification reaction with a daily processing fuel of 72 tons of coal, a gasification pressure of 0.003 MPa (G), air as the gasification agent, coal powder as the gasification fuel, and a coal powder particle size of 200 mesh as an example. The coal quality analysis is shown in the table below.

[0039]

[0040] The parameter that wall surface burner 2 of the present invention adopts is: wall surface burner 2 has 4 rows, totally 16; The gasification agent injected into the gasification furnace by the wall burners accounts for 90% of the total gasification agent. The gasification fuel is injected into the gasification furnace through the wall burners. Injection via multiple rows.

[0041] The furnace bottom burners are arranged ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com