Patents

Literature

41results about How to "Increase the number of rows" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

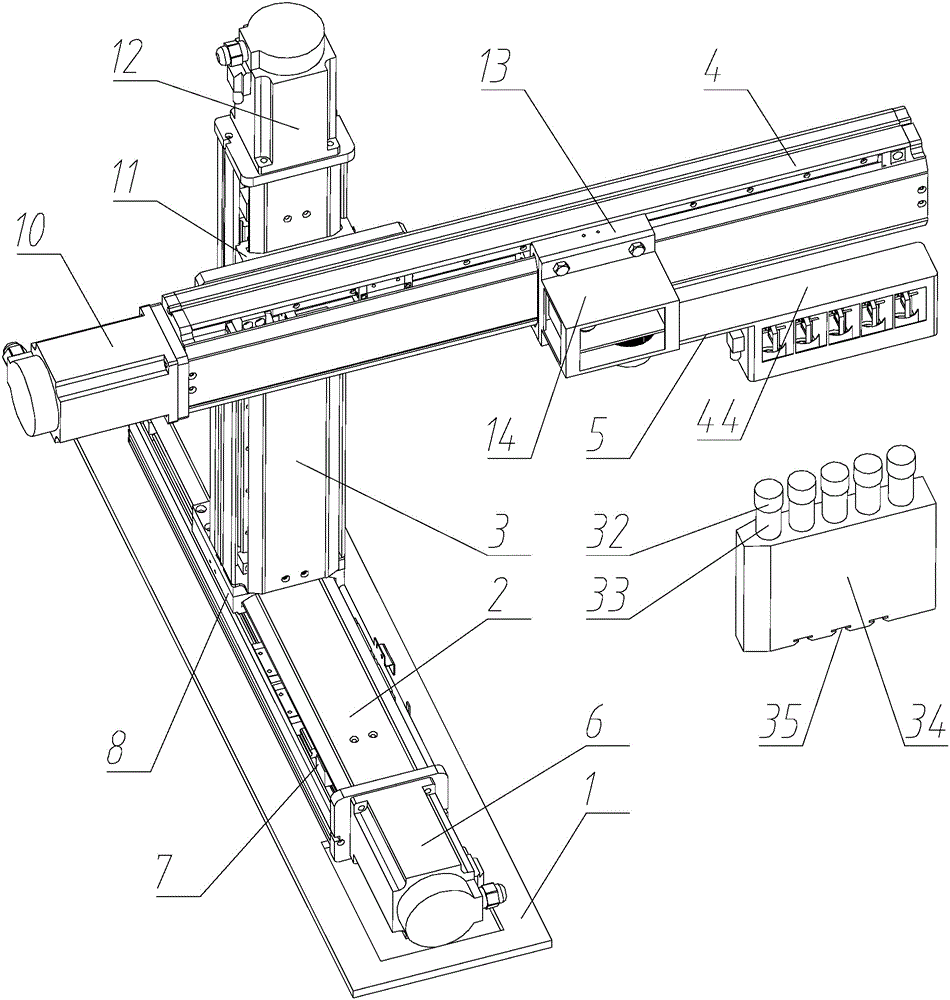

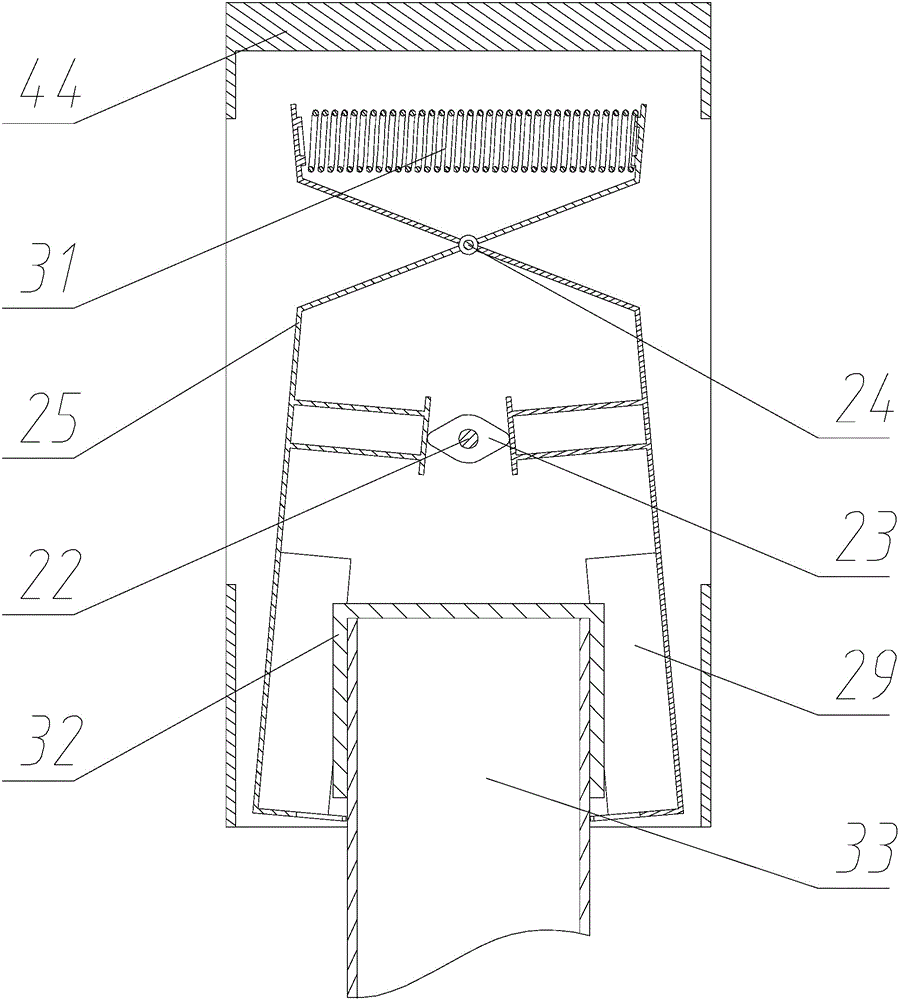

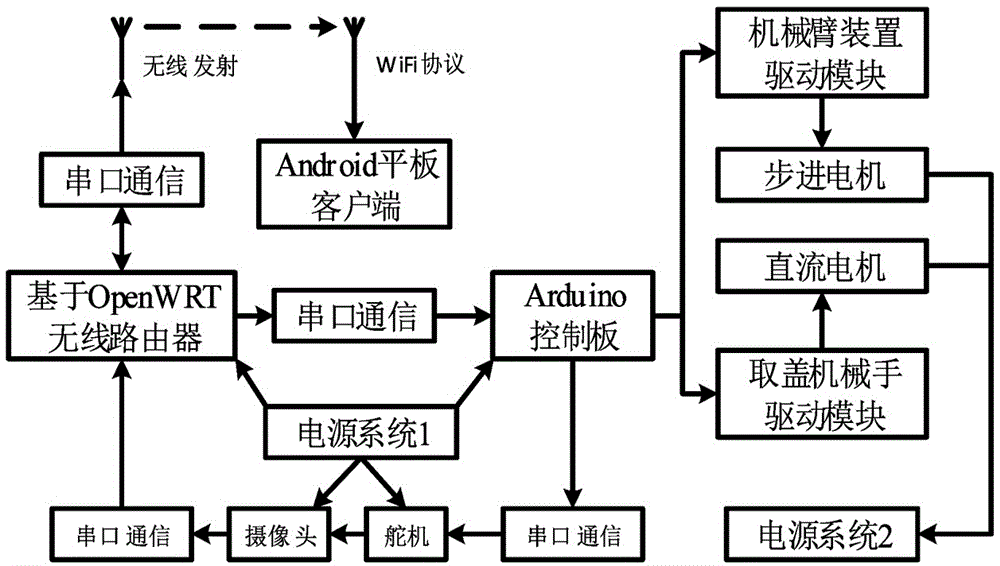

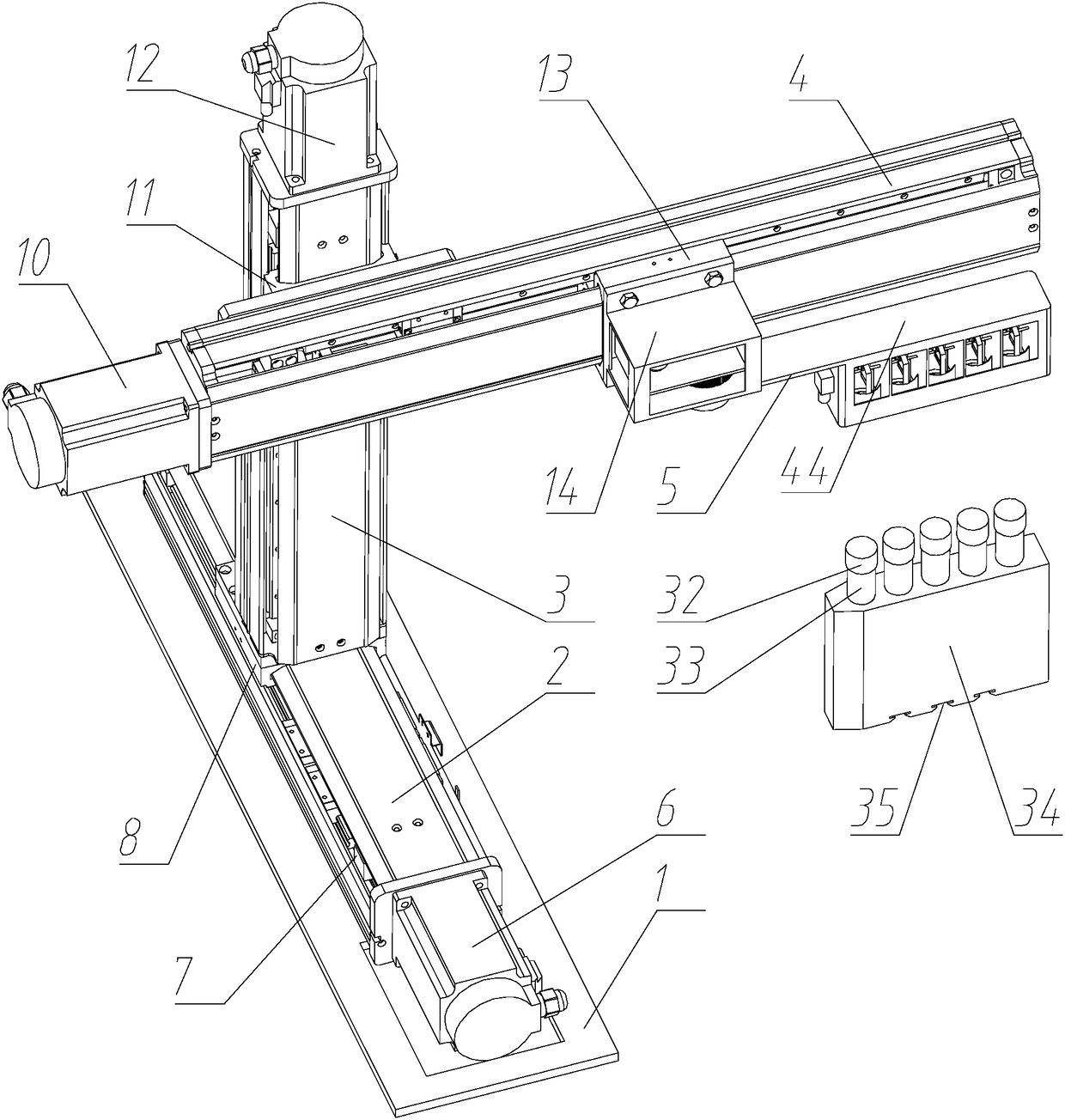

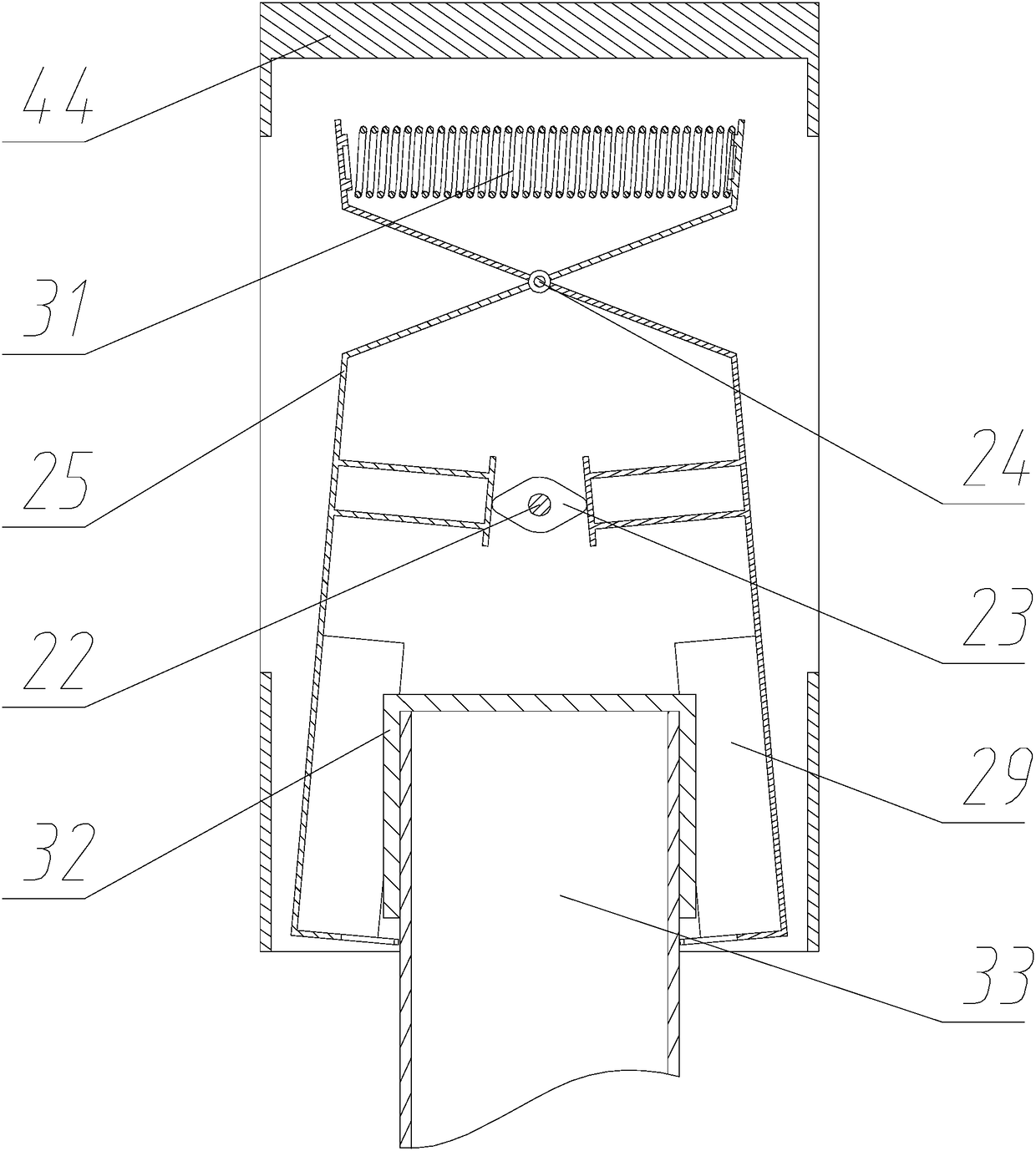

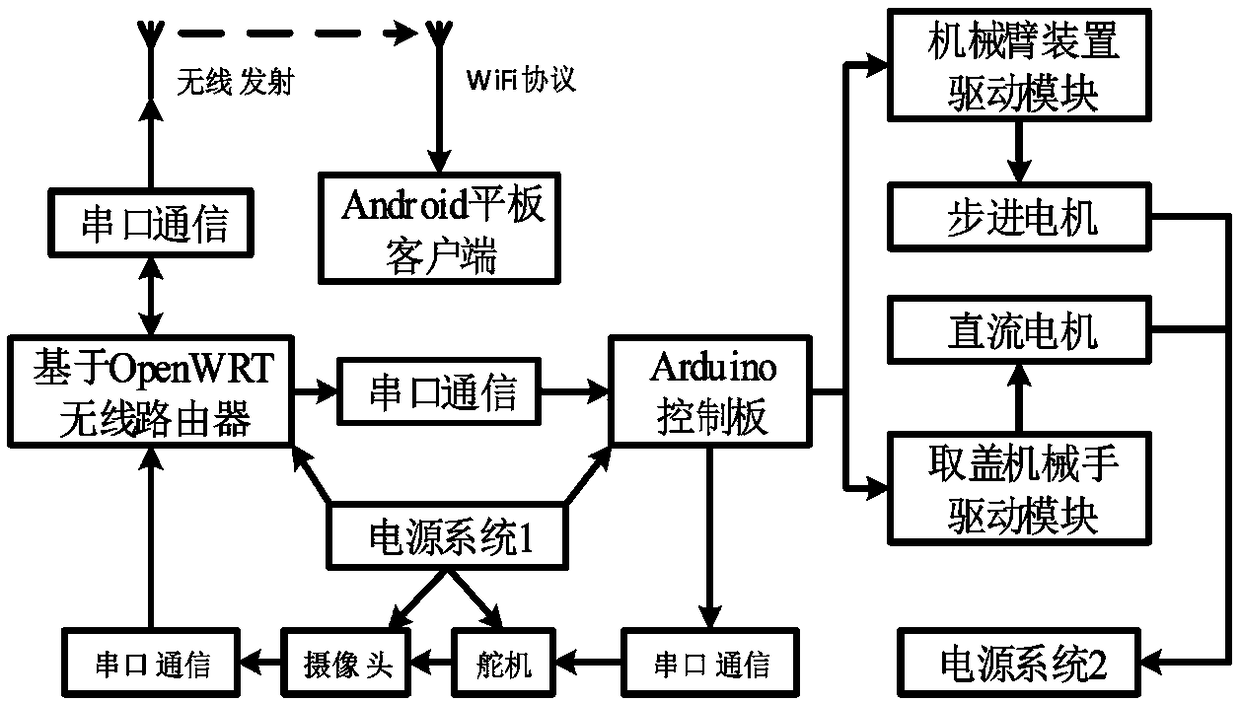

Automatic fast test tube cover taking robot and cover taking method

ActiveCN106272368AReduce the numberTime-consuming and laborious to solveProgramme-controlled manipulatorGripping headsBlood collectionEngineering

The invention relates to an automatic fast test tube cover taking robot and a cover taking method. The robot comprises a base, wherein an X-axis mechanical arm for controlling movements in front and back directions is arranged on the base, a Z-axis mechanical arm for controlling up and down movements is vertically arranged on the X-axis mechanical arm, a Y-axis mechanical arm for controlling left and right movements is vertically arranged on the Z-axis mechanical arm, and a cover taking mechanical hand is arranged on the Y-axis mechanical arm; and a mechanical arm rotation driving mechanism is arranged at one end of the cover taking mechanical hand, and a cover taking mechanism is arranged at the other end. The automatic fast test tube cover taking robot can automatically complete a cover taking task of a blood collection test tube, can adapt to blood collection test tubes and test tube racks in different specifications, and can recover test tube covers.

Owner:CHINA THREE GORGES UNIV

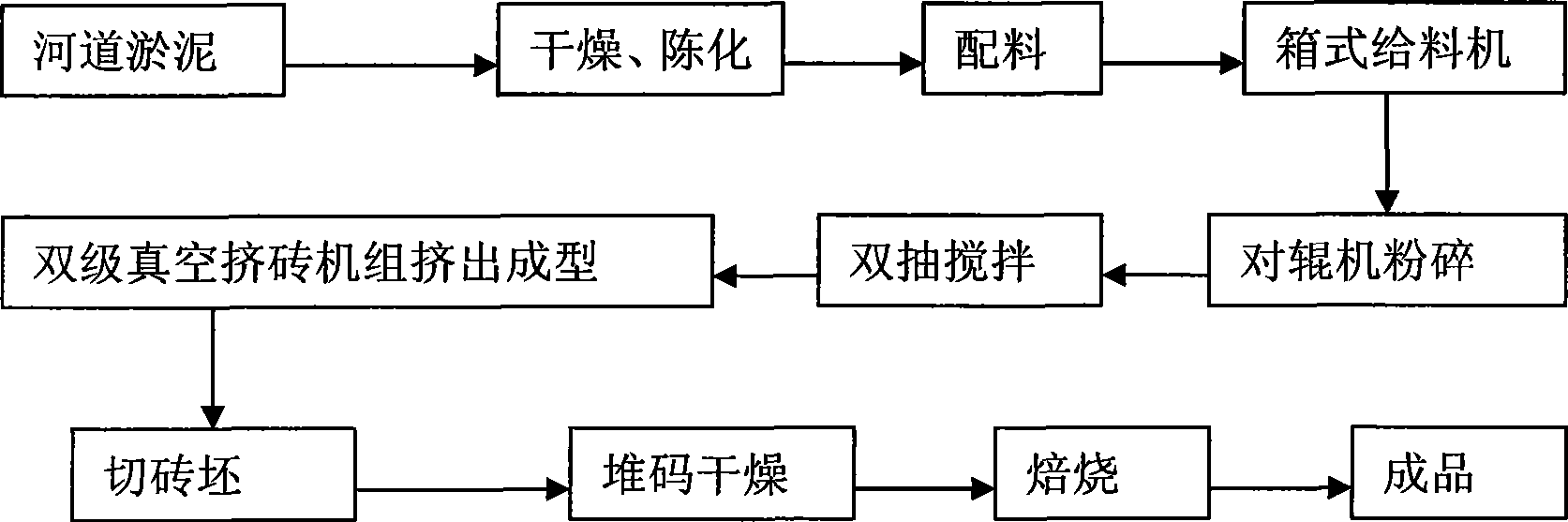

Riverway sludge self-heat preserving sintering porous brick and production method thereof

The invention relates to a heat-insulating wall body material for a building, and discloses a riverway sludge self heat-insulating sintered porous brick and preparation thereof. The riverway sludge self heat-insulating sintered porous brick comprises the following raw materials in percentage by mass: 30 to 50 percent of riverway sludge, 20 to 40 percent of riverway sludge dry powder, 20 to 30 percent of cinder and 1 to 8 percent of microporous forming materials. The riverway sludge self heat-insulating sintered porous brick has superior self heat-insulating property, and can realize building energy conservation by more than 50 percent in the aspect of enclosure of a common building structure.

Owner:上海鑫晶山淤泥研发有限公司

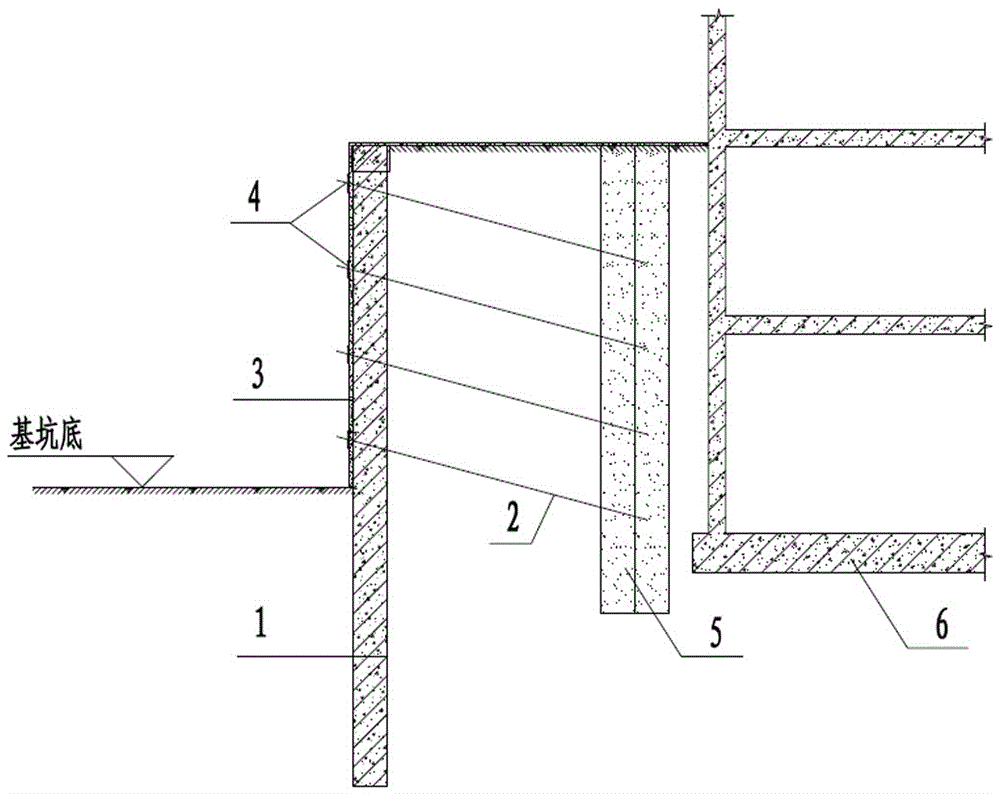

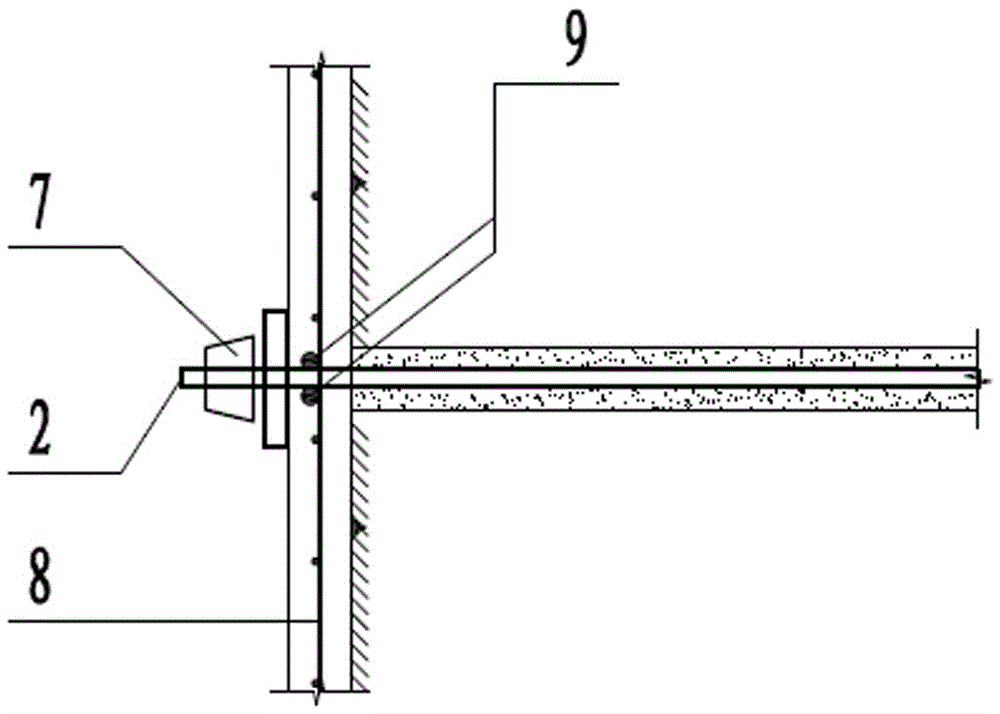

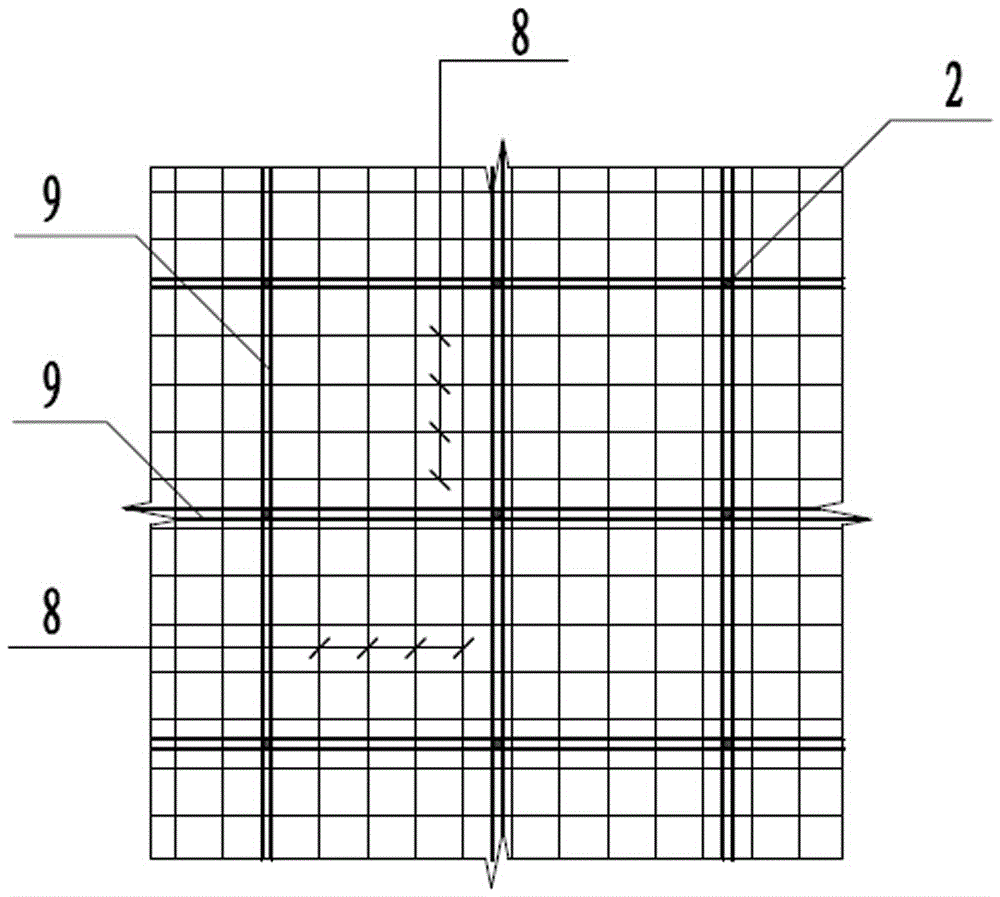

Row pile anchoring cement soil pile continuous wall supporting structure and construction process thereof

InactiveCN106677192ATo achieve force transmissionMaximum bending moment reductionExcavationsPre stressAxial force

The invention relates to a row pile anchoring cement soil pile continuous wall supporting structure. The row pile anchoring cement soil pile continuous wall supporting structure comprises a concrete pavement, row piles, a total-length bonding anchor rod and a single row of cement soil pile continuous wall or multiple rows of cement soil pile continuous walls; the concrete pavement is arranged along the side wall of a foundation trench, and the row piles are close to the concrete pavement to be arranged in the side wall of the foundation trench; and the total-length bonding anchor rod is arranged between the row piles, the front end of the total-length bonding anchor rod is fixed to the concrete pavement through an anchor plate or a prestress locking device, and the tail end of the total-length bonding anchor rod is inserted into the cement soil pile continuous wall / cement soil pile continuous walls in a downwards-inclined manner. According to the supporting structure, the total-length bonding anchor rod is adopted, a stress mechanism is similar to that of a soil nail, and the axial force is small in two ends and large in middle in the length direction, and therefore the axial force of the ends of the anchor rod in the supporting structure is small, and the force transmission effect can be achieved only by arranging the small anchor plate and being in cooperation with the concrete pavement.

Owner:周同和

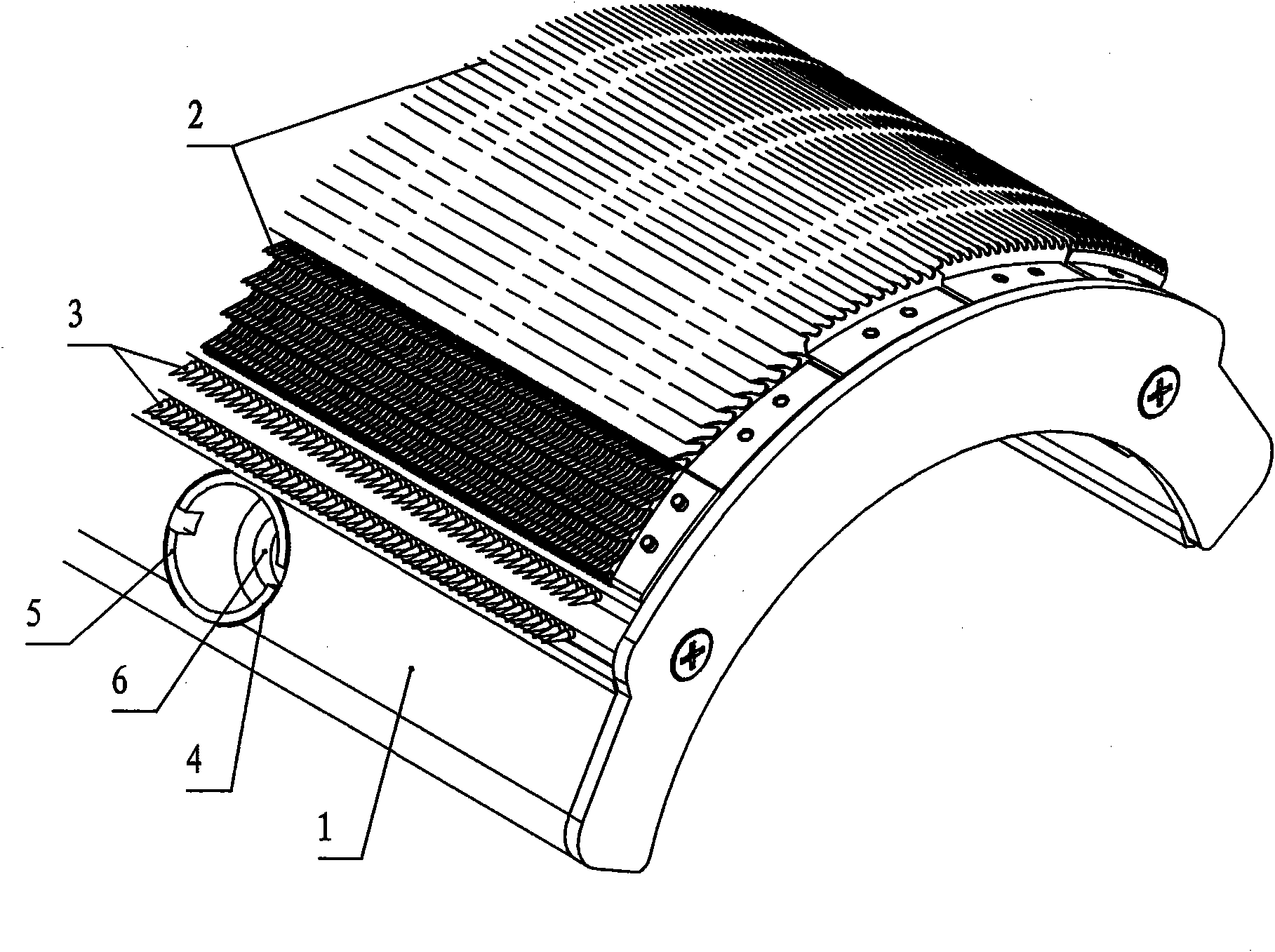

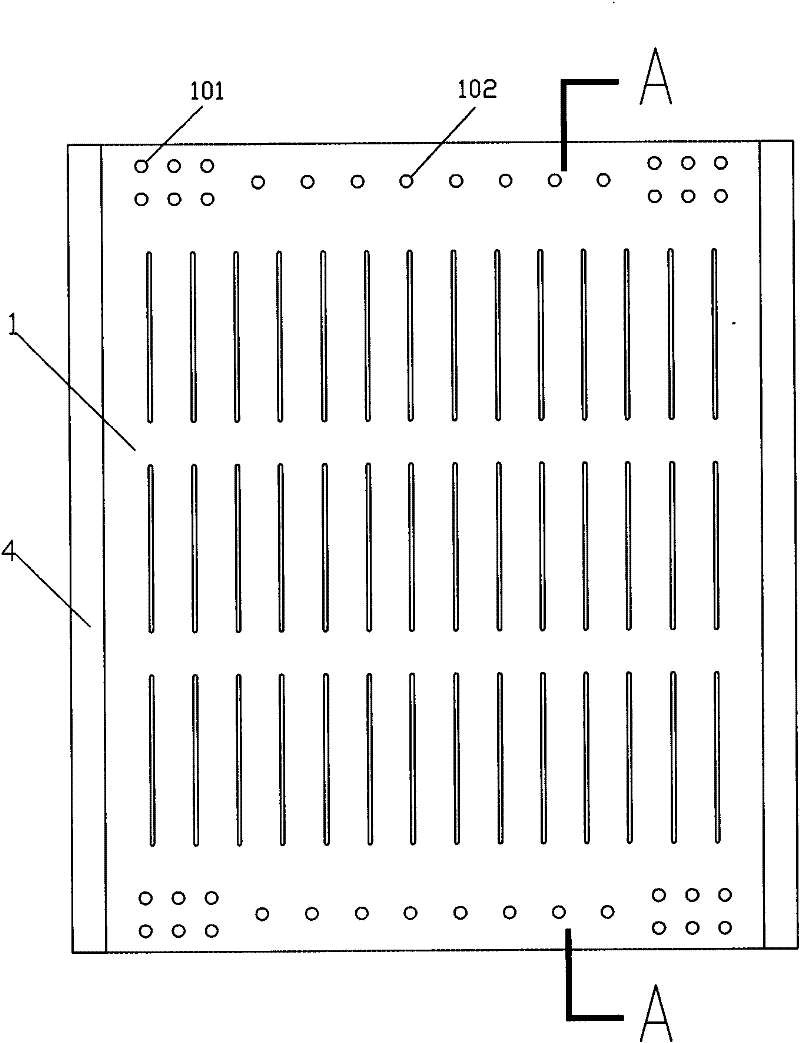

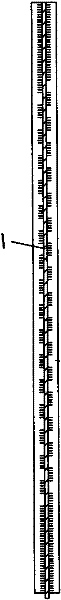

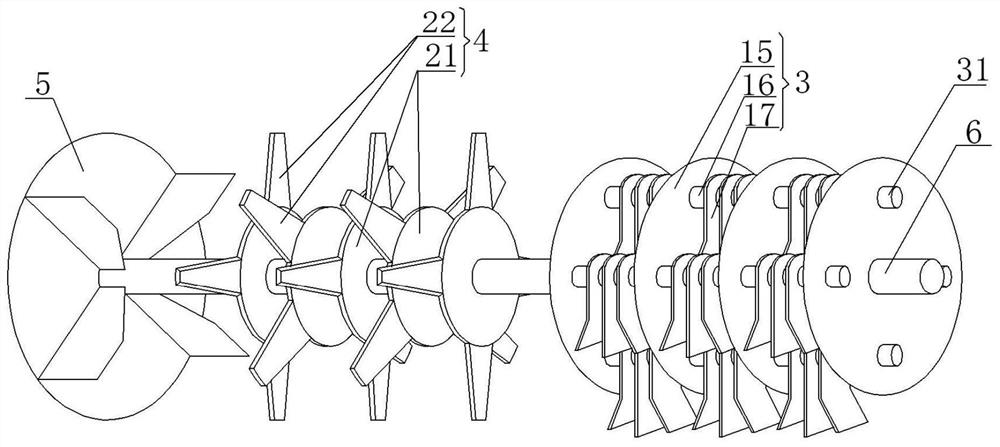

Comb pin saw tooth cylinder of cotton comber

The invention provides a comb pin saw tooth cylinder of a cotton comber. The cylinder comprises a base; a combing area of the base is provided with a plurality of groups of saw tooth groups; the saw tooth density from the front part to the back part of the combing area is from thin to thick; and the forefront of the combing area of the base is also provided with a plurality of pin strips using comb pins, and the density of the comb pins of the pin strips is lower than that of the saw teeth of saw tooth groups arranged behind the pin strips. In the cylinder, the forefront of the combing area of the cylinder is provided with the comb pins, so that the puncturing, finishing and shredding effects are better when combing, and the fiber is not damaged; and the middle-back part of the combing area adopts a saw tooth cylinder structure, the effects of removing cotton neps, impurities and flock powder are better in combing, and the high-speed and high yield are supported. The cylinder has the advantages of integrating the advantages of the comb pin cylinder and the saw tooth cylinder, discarding demerits, greatly improving the carding quality and reducing the consumption of raw cotton, along with skillful and reasonable structure.

Owner:ZHEJIANG JINFENG TEXTILE MACHINERY

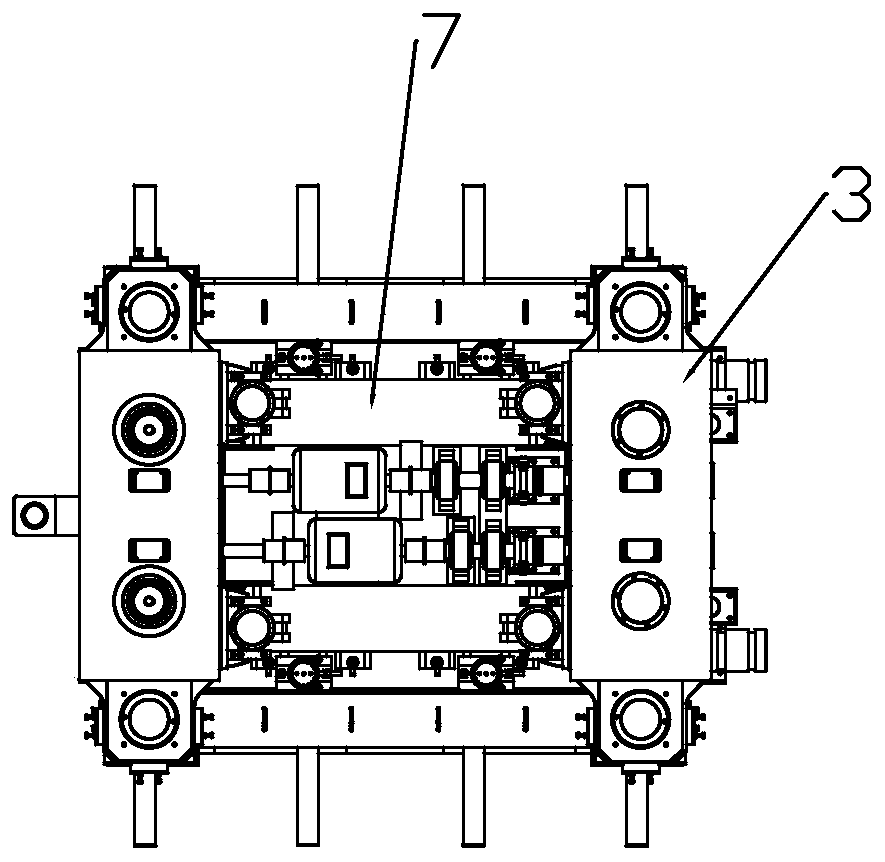

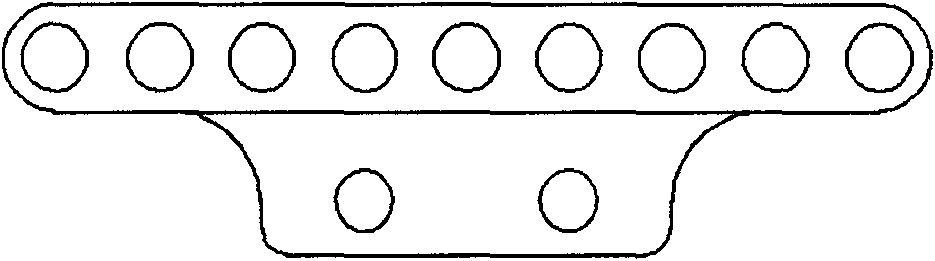

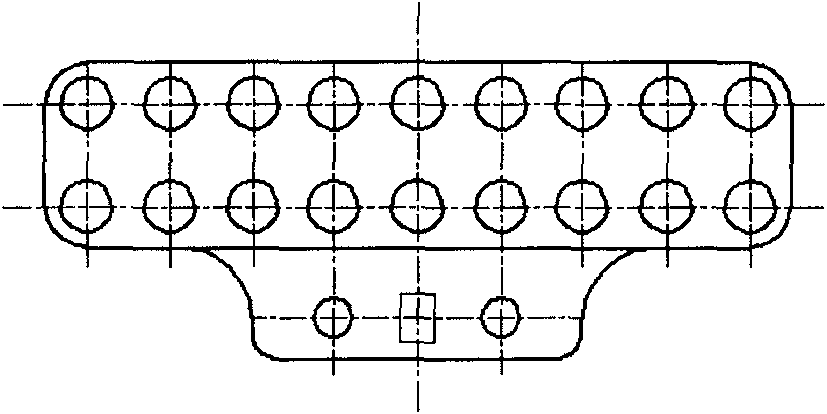

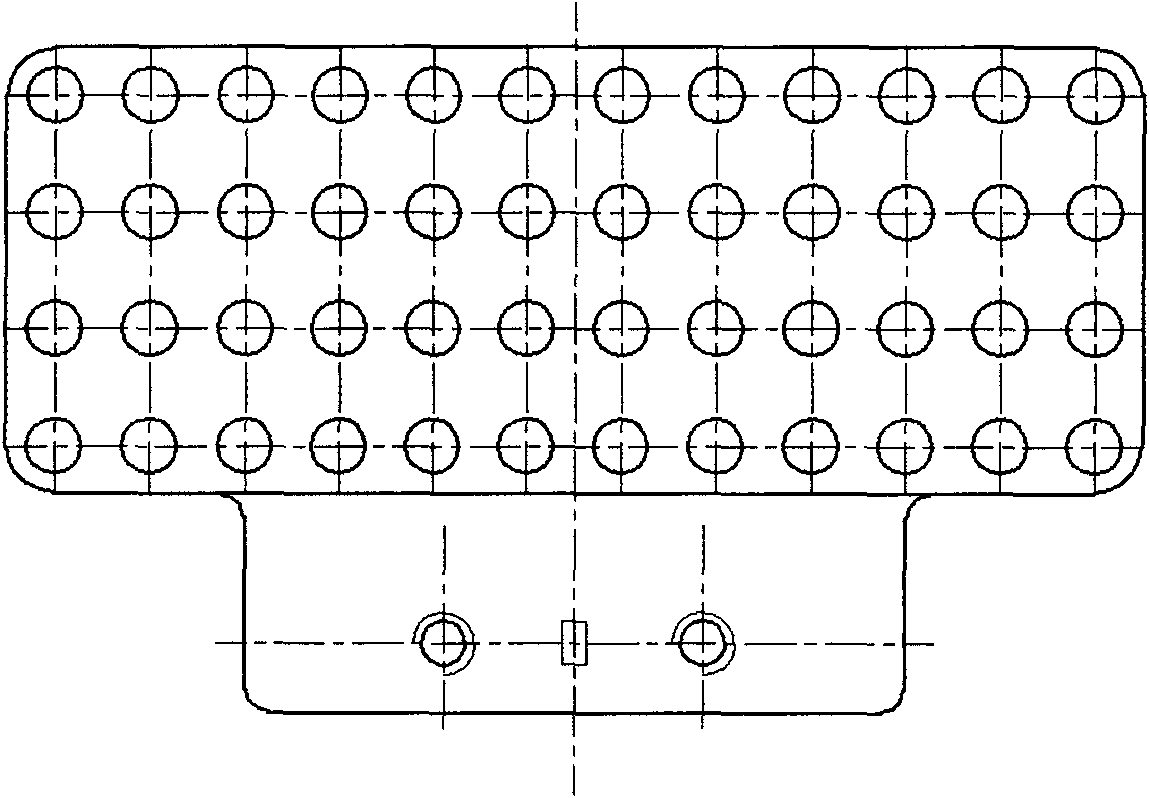

Capsule filling machine

The invention relates to a capsule filling machine belonging to the field of pharmaceutical machinery and comprising a capsule filling machine module which is used for placing capsules and is provided with three rows or more than three rows of capsule filling holes. The invention increases the number of filled capsules during each processing period by increasing the number of the rows of the capsule filling holes, thereby further increasing the production speed; in addition, the invention realizes the waste rejection and the discharging of the capsules by a capsule waste rejecting mechanism and a capsule discharging mechanism.

Owner:BEIJING HANLIN HANGYU TECH DEV

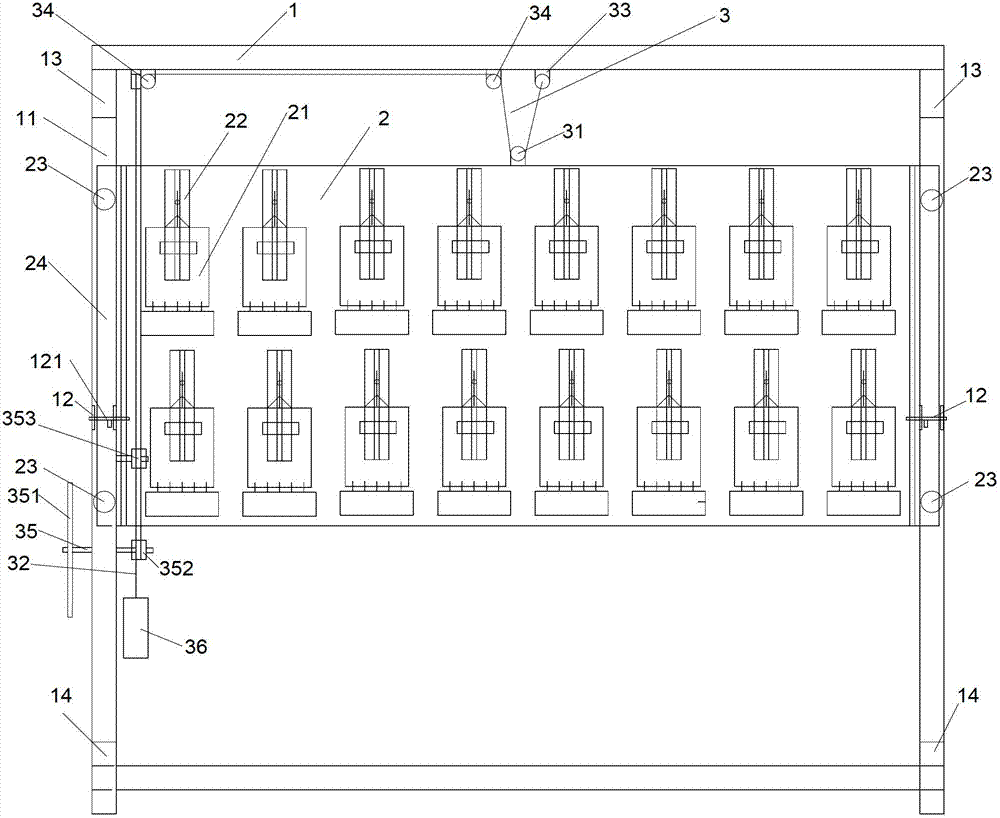

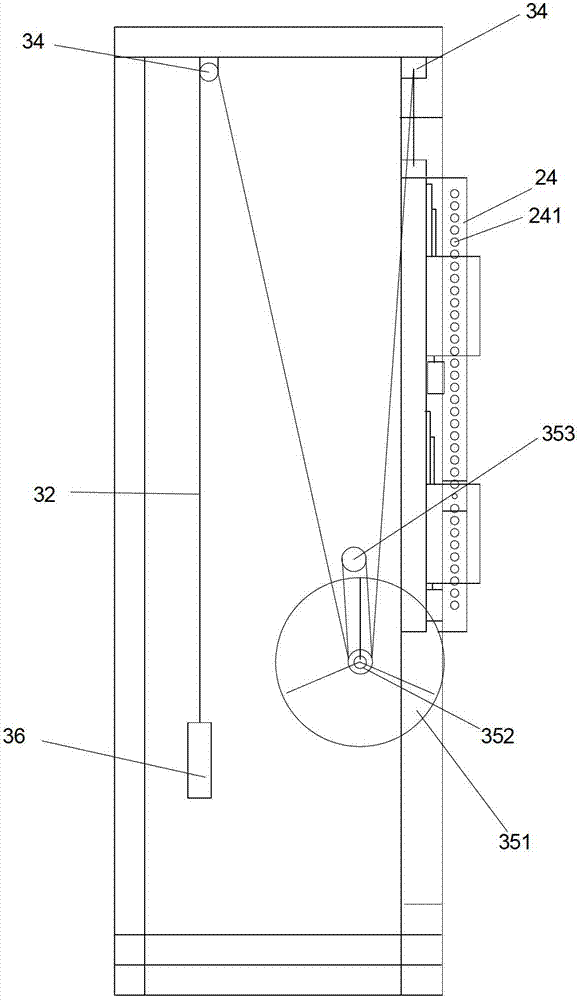

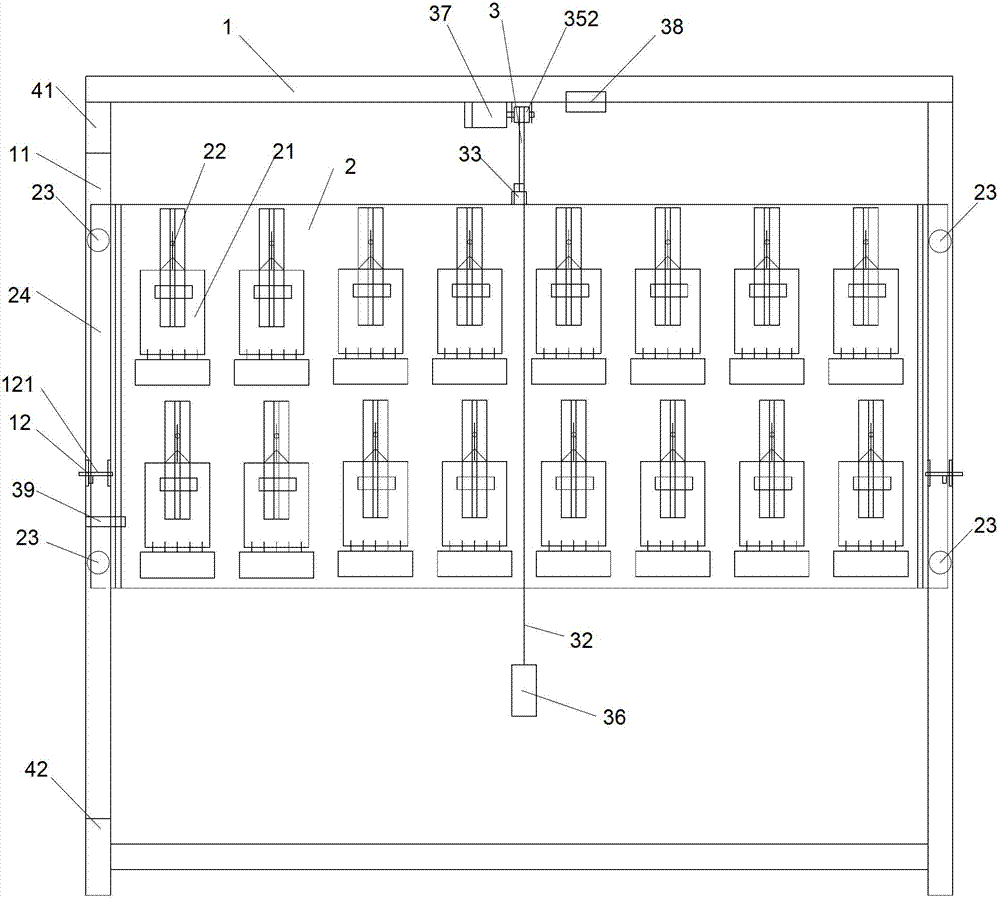

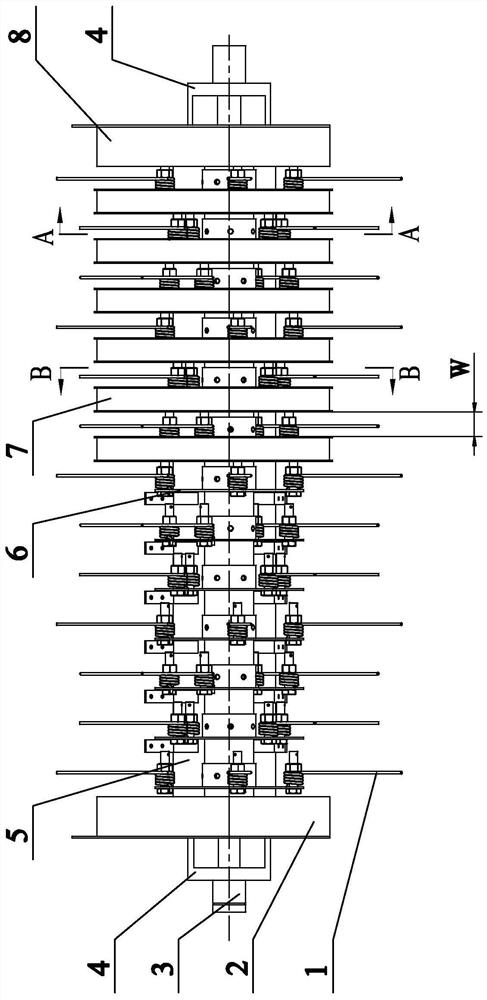

Lifting and descending device for electric energy meter checking device

ActiveCN102736053AEasy to assemble and disassembleImprove work efficiencyElectrical measurementsEngineering principlesFixed frame

The invention relates to a lifting and descending device for an electric energy meter checking device. The lifting and descending device is characterized by comprising a fixed frame (1), wherein a movable plate (2) is arranged in the fixed frame (1); electric energy meters (21) are arranged on the movable plate (2); and a driving mechanism (3) which controls the movable plate (2) to lift and descend vertically is arranged between the fixed frame (1) and the movable plate (2). When an operator needs to assemble or disassemble a certain row of electric energy meters, a hand wheel is rotated to drive a pull wheel to rotate, and a steel wire rope which is embedded in the pull wheel drives the movable plate to move vertically through friction, so the electric energy meters are moved to the most appropriate place by the operator, a positioning bolt is inserted into a positioning strip through hole and used for fixing the movable plate, and the operator can safely, conveniently and effortlessly assemble and disassemble the electric energy meters. The lifting and descending device for the electric energy meter checking device has the advantages that the electric energy meter checking device is in accordance with a man-machine engineering principle; the operator can conveniently and effortlessly assemble and disassemble the electric energy meters; and compared with a fully-automatic lifting and descending device, the lifting and descending device is high in working efficiency, simple in structure and low in cost.

Owner:南通海睿知新信息科技有限公司

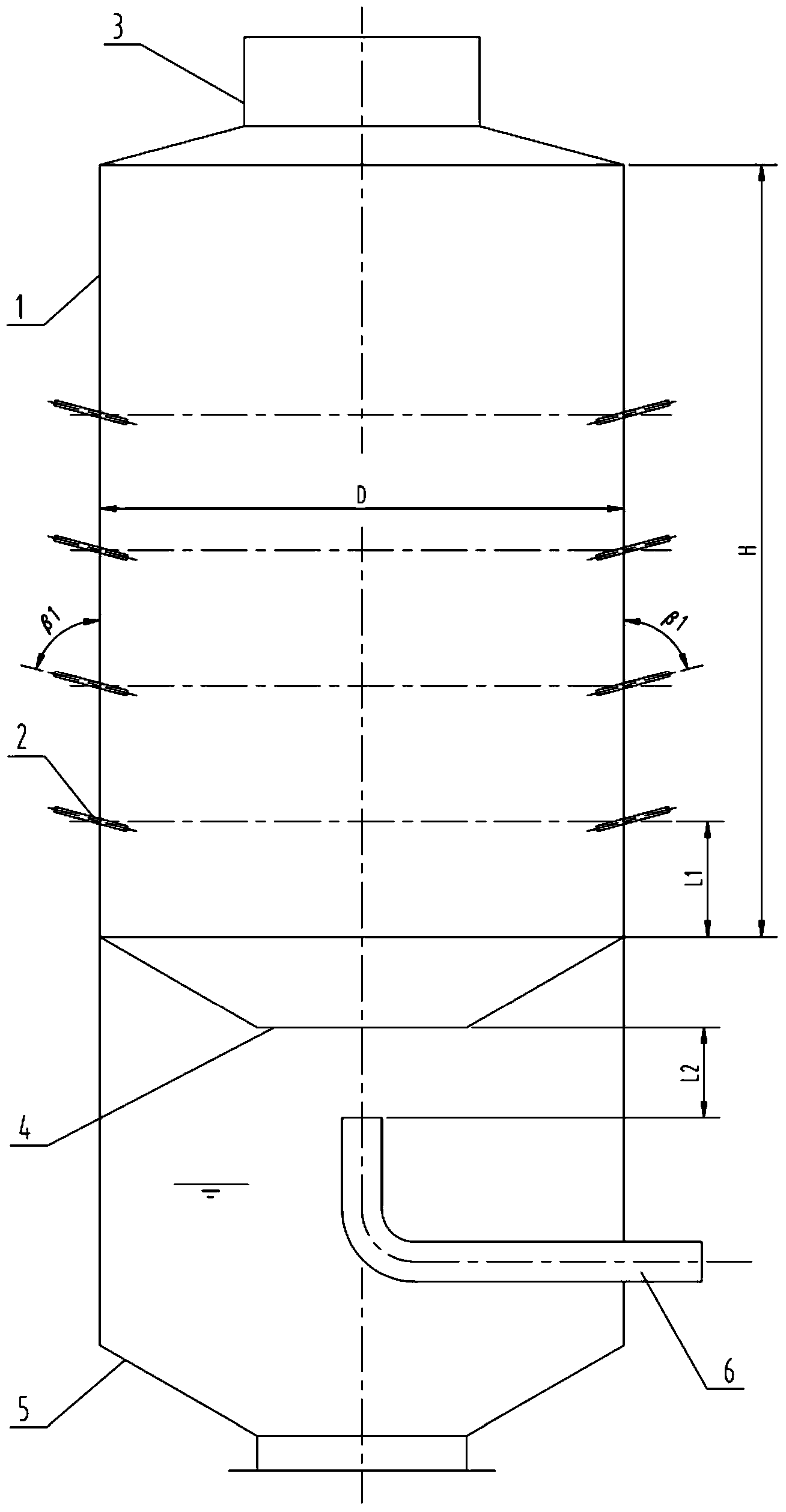

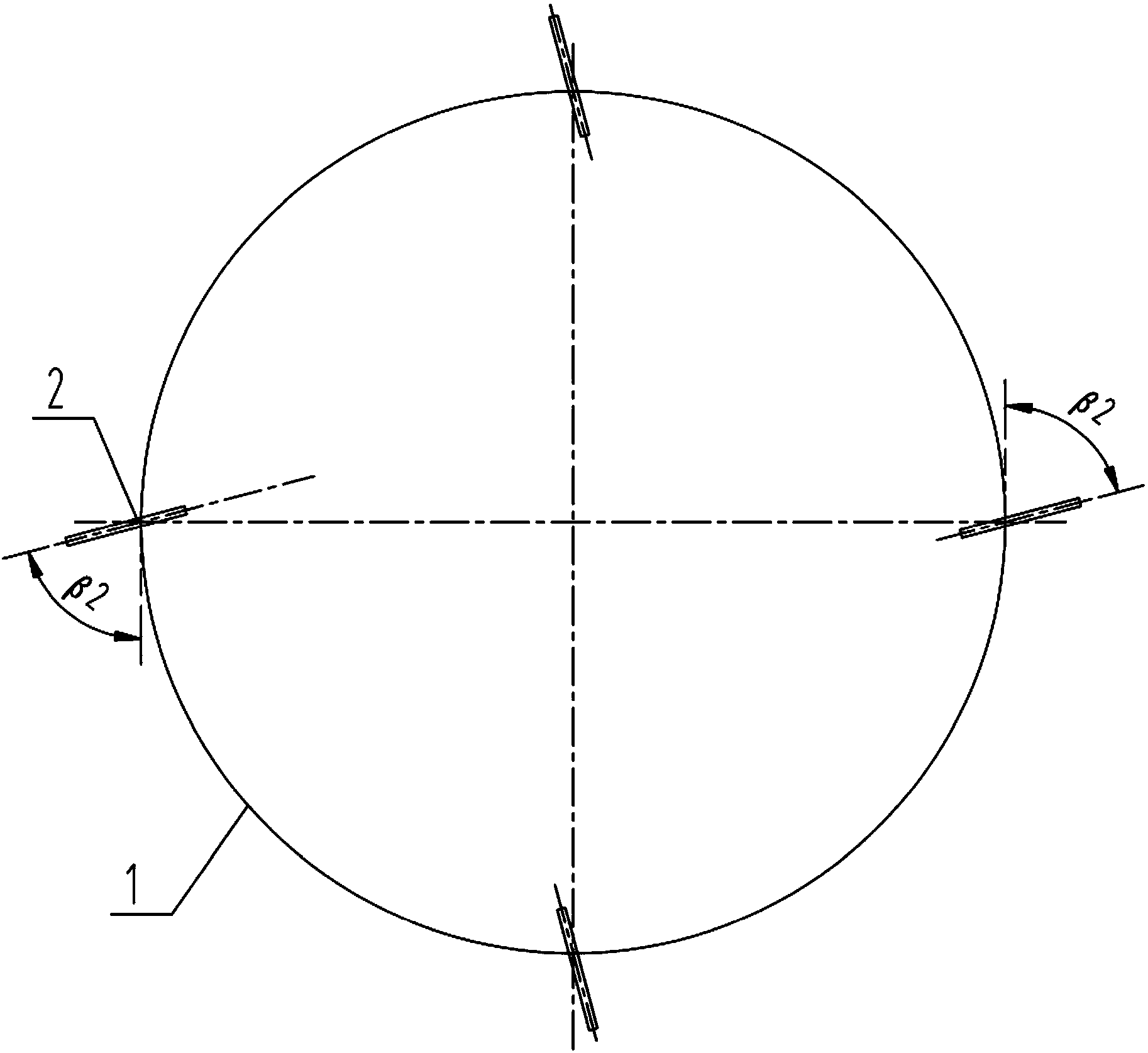

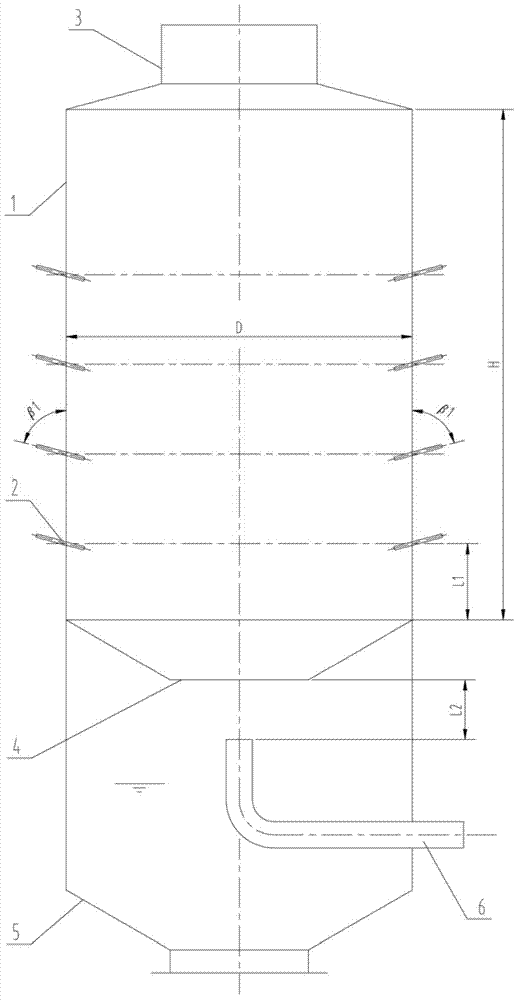

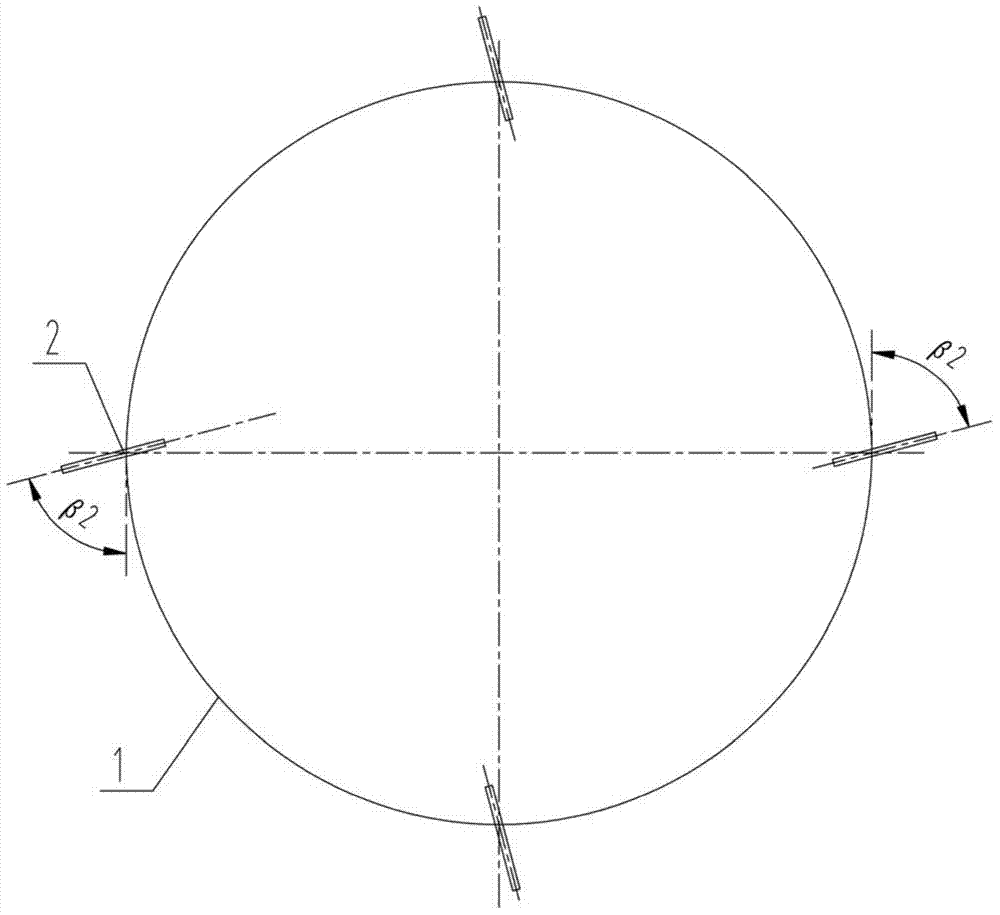

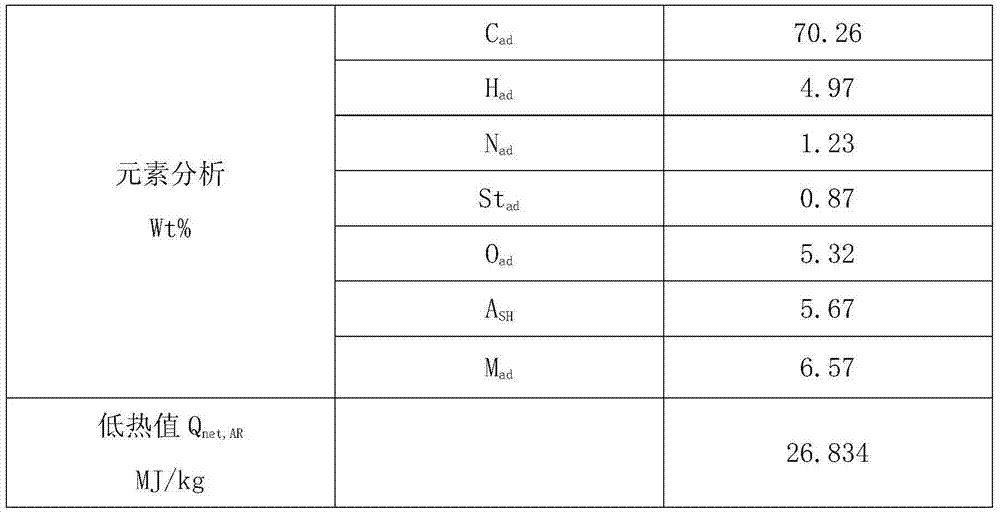

Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

ActiveCN103725327AFully contactedAdequate responseGranular/pulverulent flues gasificationPositive pressureSlag

The invention discloses a gasification entrained-flow bed coal powder gasification furnace and a gasification method of micro-positive pressure air. At present, a normal-pressure fixed bed gasification furnace is commonly applied in an industrial fuel gas preparation industry and an efficient powdered coal entrained-flow bed gasification technology has some difficulties on preparing industrial fuel gas under the condition that the micro-positive pressure air is used as a gasifying agent. The gasification entrained-flow bed coal powder gasification furnace is characterized in that a gasification furnace body is provided with at least one row of wall surface burners; each row of the wall surface burners comprise a plurality of wall surface burners which are arranged along the peripheral direction of the gasification furnace body at intervals; the gasification agent which is sprayed into the gasification furnace by all the wall surface burners accounts for 80%-97% of the use amount of all the gasification agent; a furnace bottom nozzle is arranged below the bottom face of a gasification furnace slag opening; the gasification agent which is sprayed into the gasification furnace by the furnace bottom nozzle accounts for 3%-20% of the use amount of all the gasification agent. According to the gasification furnace, the gasification intensity of a unit volume is high; the quantity of in-furnace coal powder falling into a dreg tank is effectively reduced; the gasification entrained-flow bed coal powder gasification furnace is very suitable for producing the industrial fuel gas by taking the micro-positive pressure air as the gasification agent.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

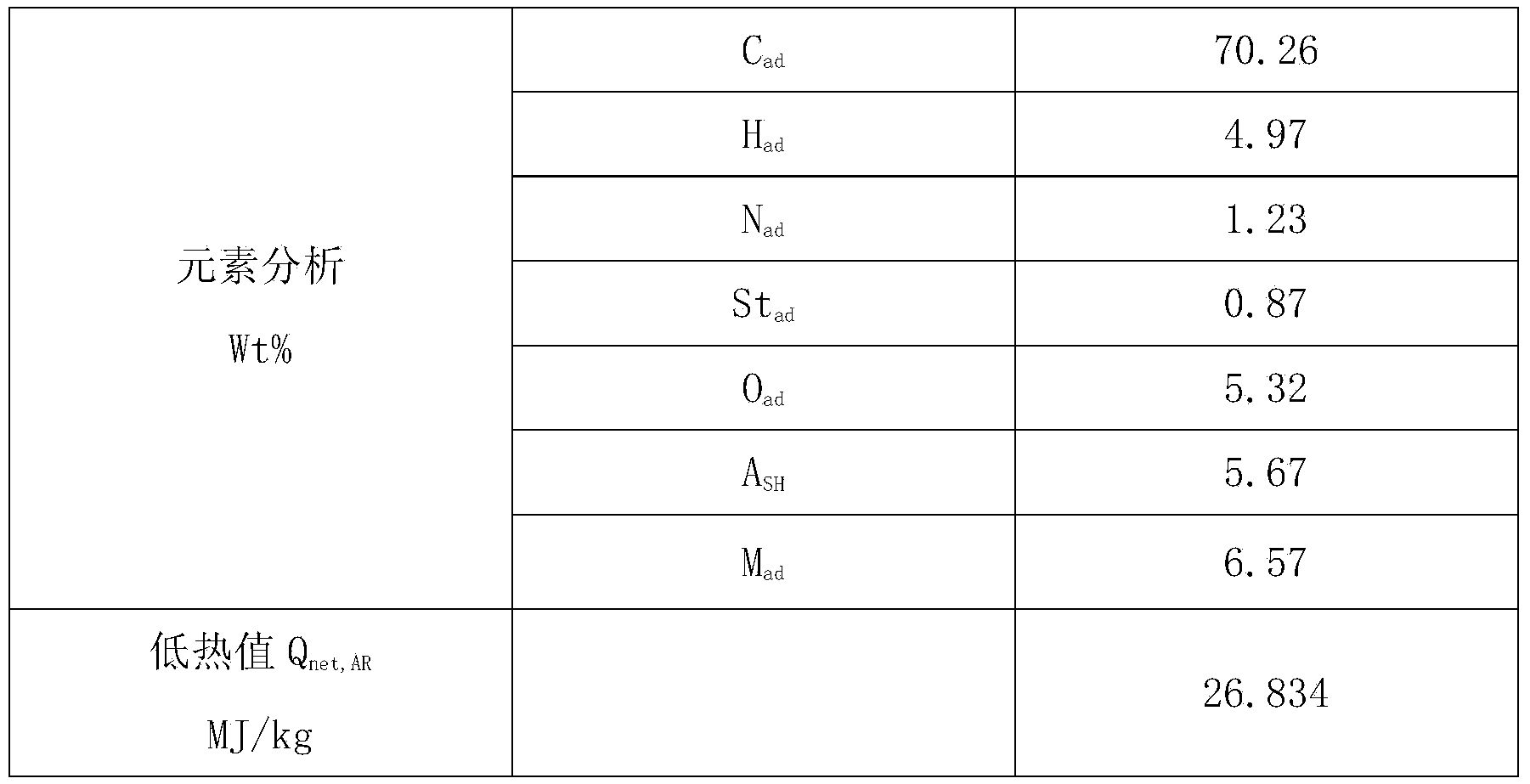

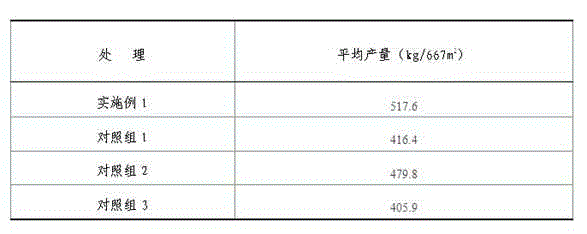

Special compound microbial fertilizer for corn top dressing

ActiveCN104402610AIncrease the number of ear rowsIncrease the number of rowsFertilising methodsOrganic fertilisersAgricultural scienceGrain weight

Special compound microbial fertilizer for corn top dressing comprises double-strain bacterial fertilizer, potassium humate and urea, and is used for top dressing in a five-leaf stage or a bell stage of corn; double strains subjected to mixed fermentation have a significant synergetic effect; an ear bald rate of the corn can be decreased; the row number per ear, the grain number per row, the grain number per ear and the thousand grain weight of the corn are increased; and the yield is increased by 7.3-21.6% as compared with that of different processing control groups.

Owner:HENAN ACAD OF SCI INST OF BIOLOGY LIABILITY

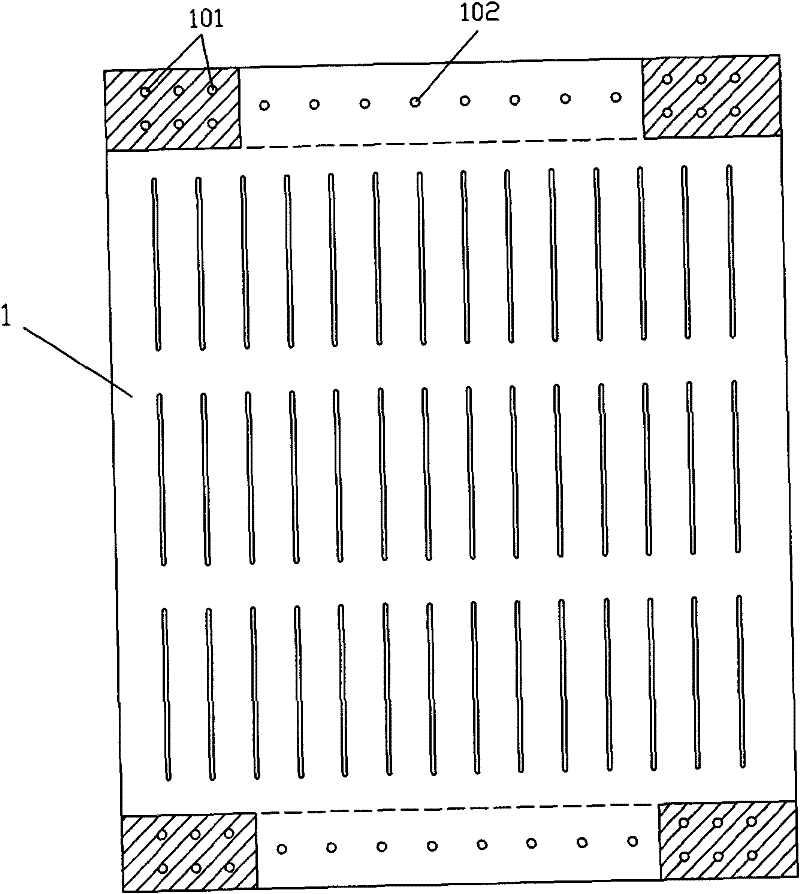

A structure to prevent bolt slippage in steel plate shear wall with seams

ActiveCN101967850BIncrease the number of rowsOvercome slippageShock proofingInstabilityVertical load

A structure for preventing slippage of connecting bolts between a steel plate shear wall with a vertical seam and a frame beam. The upper and lower ends of the main steel plate with vertical seams are provided with bolt holes for connecting with the upper and lower frame beams, and the bolt holes at the corners of the upper and lower ends of the main steel plate with vertical seams are provided. The arrangement density and the number of rows are larger than those in the middle part; the edges of the main steel plates with vertical seams are stiffened to form a closed system. The present invention adopts a targeted layout form for the bolts connecting the steel plate shear wall with slits and the frame beam, and adopts a closed edge stiffening system at the same time, which overcomes or delays the occurrence of bolt slippage and eliminates the bolt slippage caused by bolt slippage. noise, and avoid the great loss of the good seismic performance of the steel plate shear wall with slots caused by the slippage of the bolts, to ensure that the steel plate shear walls with slots are fully bolted on site so that they can be disassembled and replaced after earthquake damage, and to avoid steel plates with seams Shear walls are subjected to excessive vertical loads. The closed edge stiffening system also solves the corner instability problem of the slotted steel plate shear wall that induces or aggravates bolt slippage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

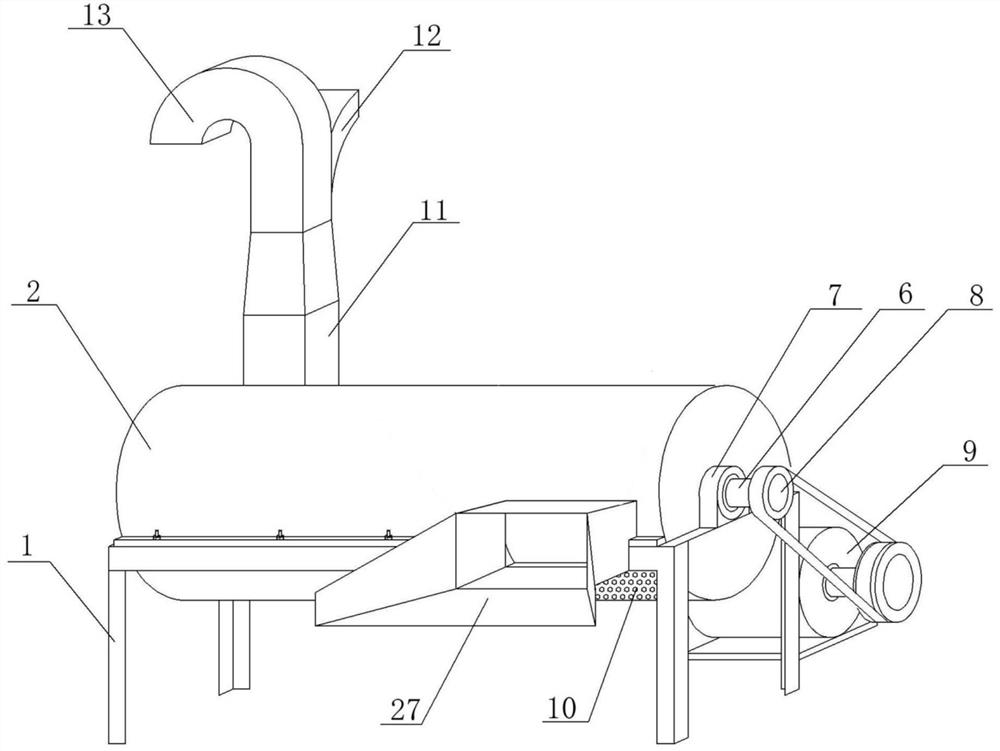

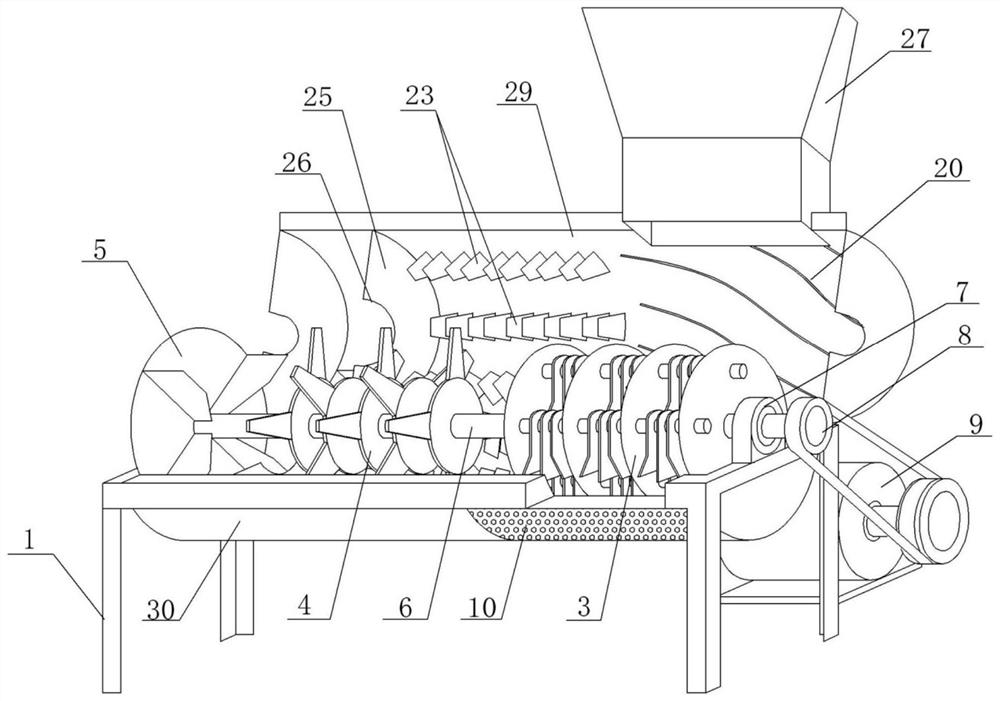

Soil and powder removing, smashing and rubbing integrated machine for straw forage

PendingCN113383650AGreat suctionIncrease the number of rowsSievingScreeningAgricultural engineeringMechanical engineering

The invention relates to a soil and powder removing, smashing and rubbing integrated machine for straw forage. The machine comprises a frame body, a barrel body, a soil removing mechanism, a smashing and rubbing mechanism and a fan, the barrel body is arranged on the frame body, and the soil removing mechanism, the smashing and rubbing mechanism and the fan are sequentially arranged on a main shaft; a feeding hole is formed in the barrel body corresponding to the soil removing mechanism, and a soil filtering screen is arranged at the lower part of the barrel body corresponding to the soil removing mechanism; a discharge pipe is arranged on the barrel body corresponding to the fan, a discharge port and a powder removal port are formed in the upper part of the discharge pipe respectively, and a dust filter screen is arranged between the discharge port and the powder removal port. The machine is simplified in structure, convenient to maintain and capable of achieving the functions of soil removal, cutting, smashing, rubbing and powder removal of straw at the same time, it is guaranteed that rubbing is finer and smoother, the effect is better, and straw or grass straw such as corn straw and rice straw with different hardness can be treated at the same time.

Owner:李明波

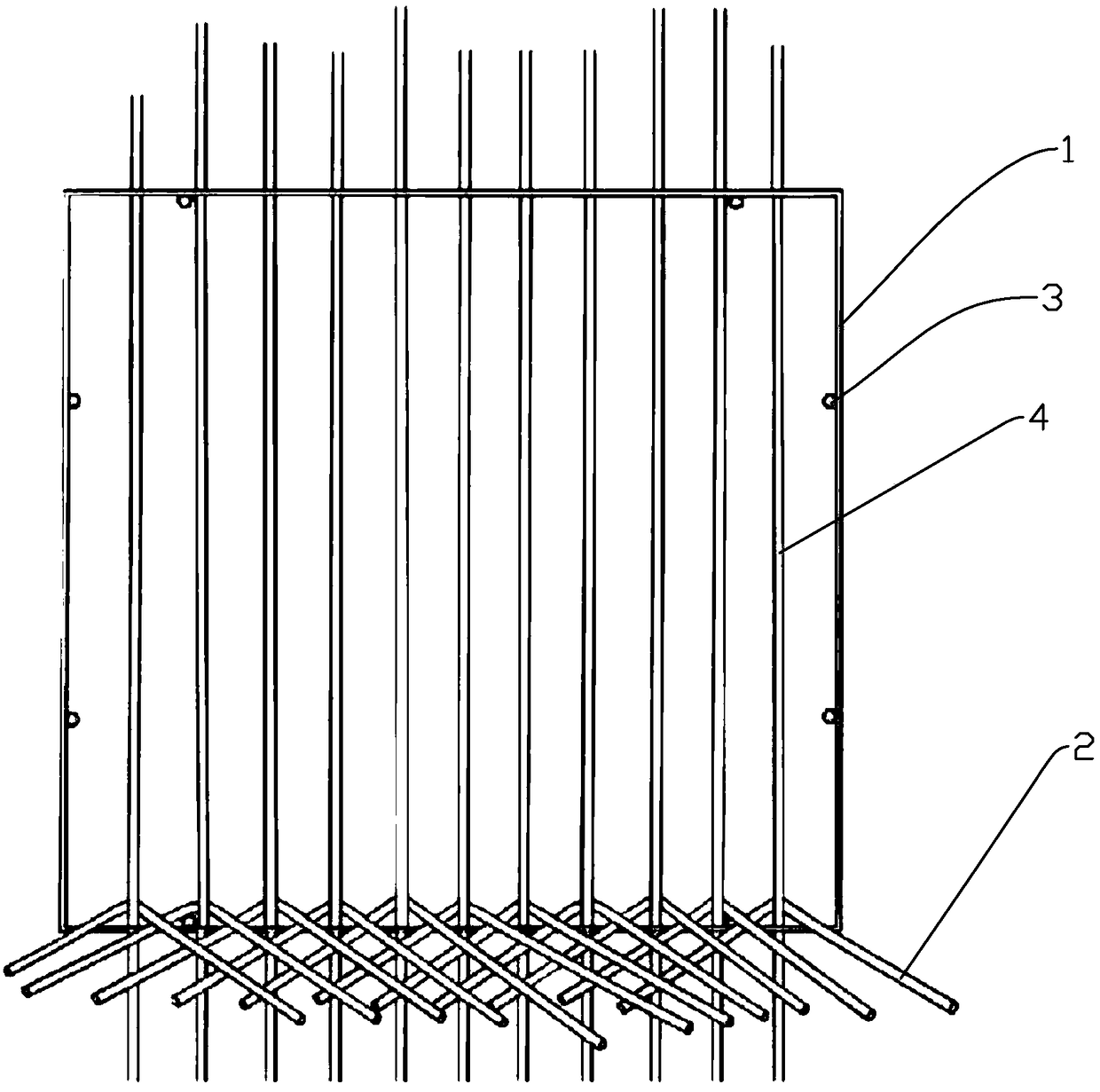

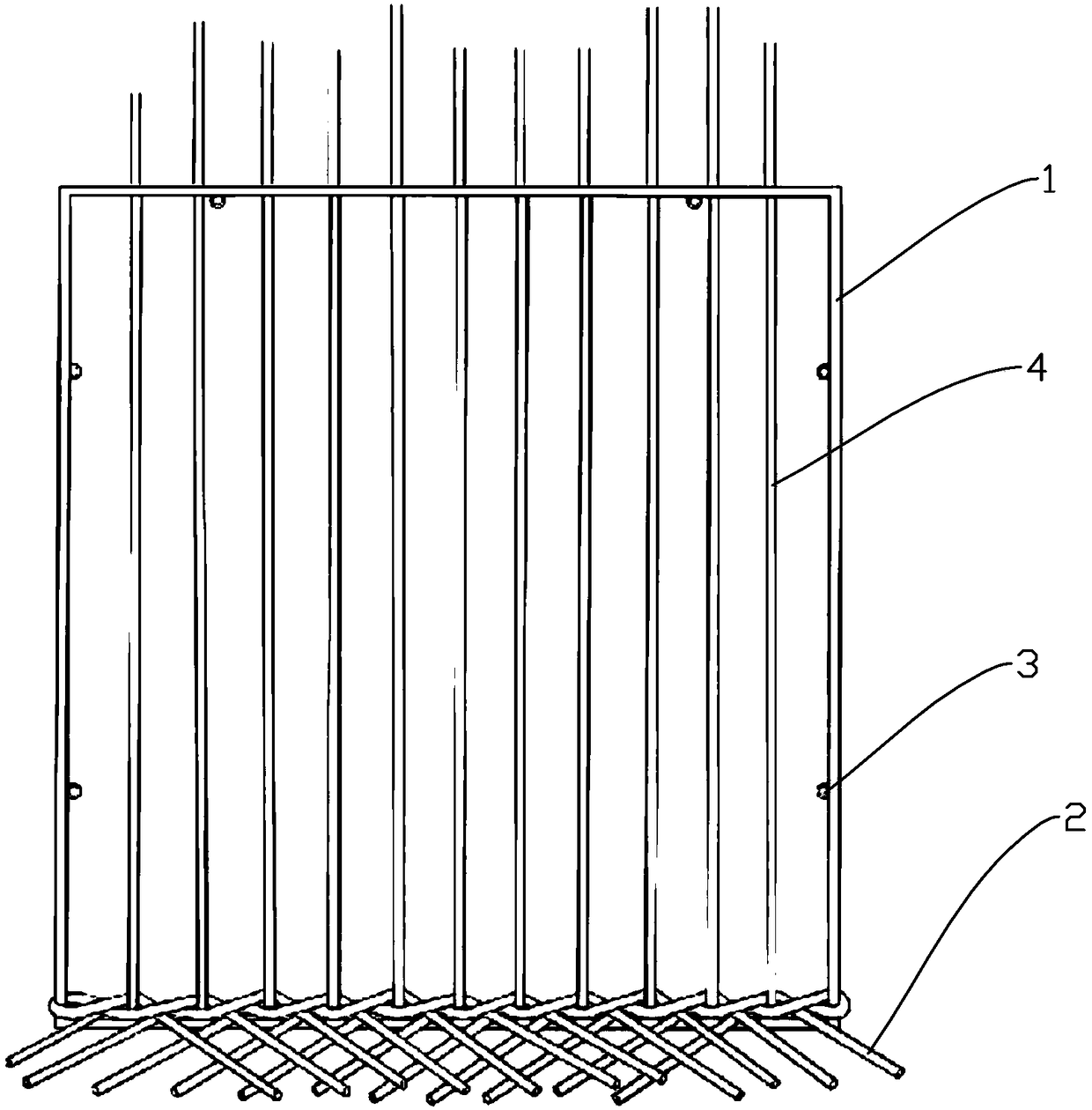

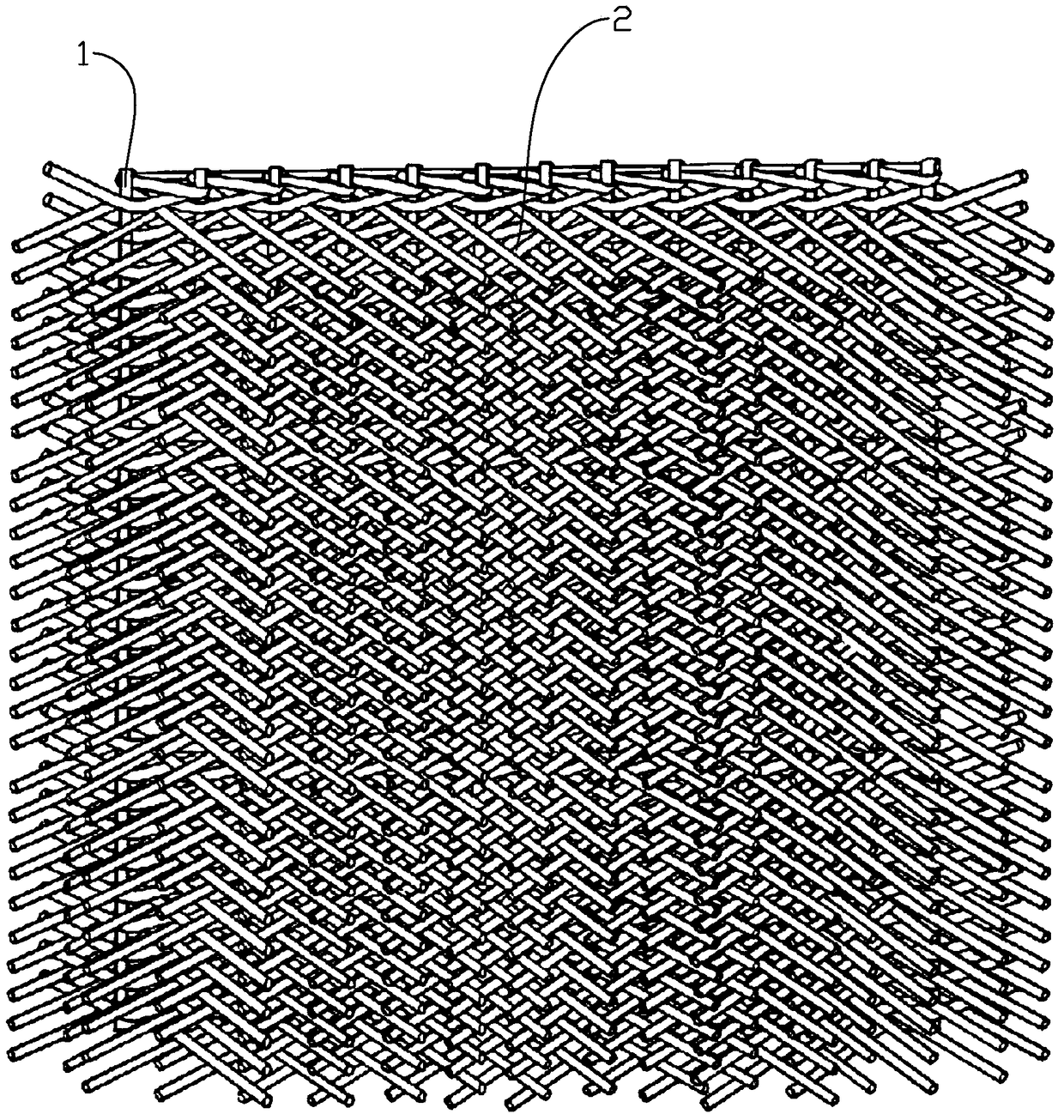

Building material for wall woven decoration suitable for standardized production and production method of building material

ActiveCN108687901ARealize batch standardized productionTo achieve the purpose of modularization and standardizationCovering/liningsCane mechanical workingEngineeringNatural material

The invention discloses a building material for wall woven decoration suitable for standardized production. The building material comprises a frame, a woven layer is formed in the frame by weaving, and the woven layer is preferably made of natural materials. The production method of the building material comprises the following steps of preparing the frame and a weaving material, forming the wovenlayer by weaving in the frame by means of the frame and covering the inside of the frame and the frame with the woven layer. According to the building material and the production method, the woven layer is formed by weaving in the frame, and the woven finished product becomes an independent module; multiple modules can be seamlessly connected or freely combined and assembled, so that by the adoption of the building material and the production method, the purposes of modularization and standardization are realized, a user can freely assemble finished products at a decoration site after purchasing the multiple woven finished products at a production site, and the use is extremely convenient; and weaving mainly adopts the pure natural materials, a natural and warm feeling is provided for people and is much better than the feeling of non-industrial standard parts, and the building material and the production method can realize batch standardized production of natural knit materials.

Owner:覃大立

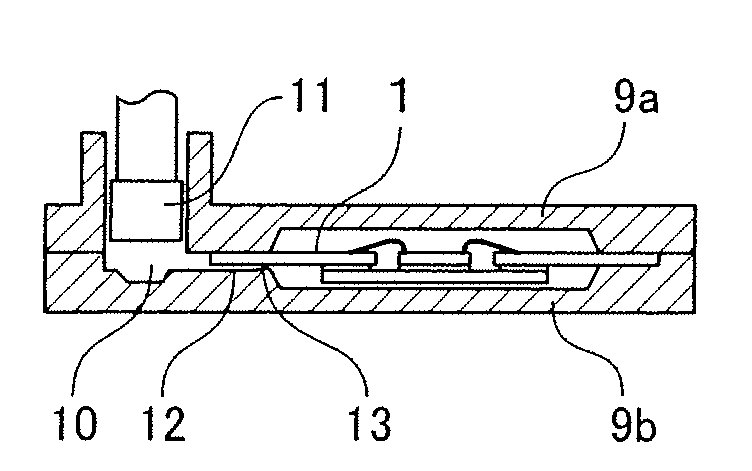

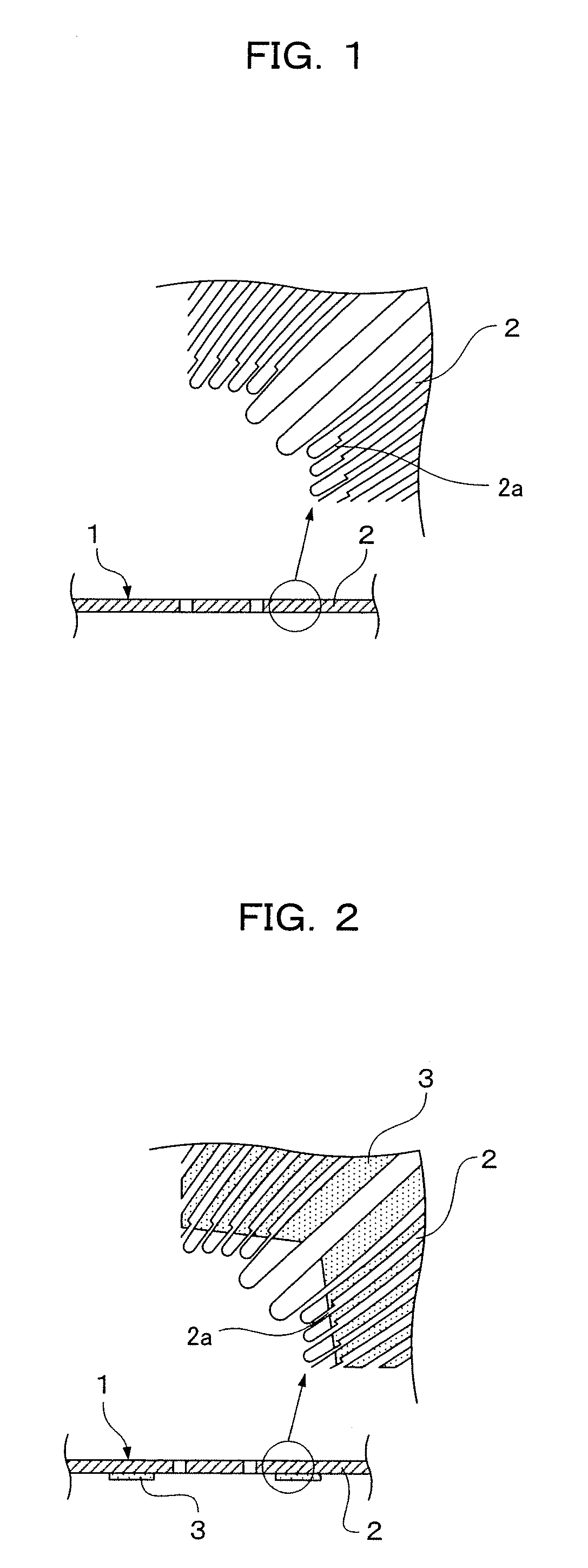

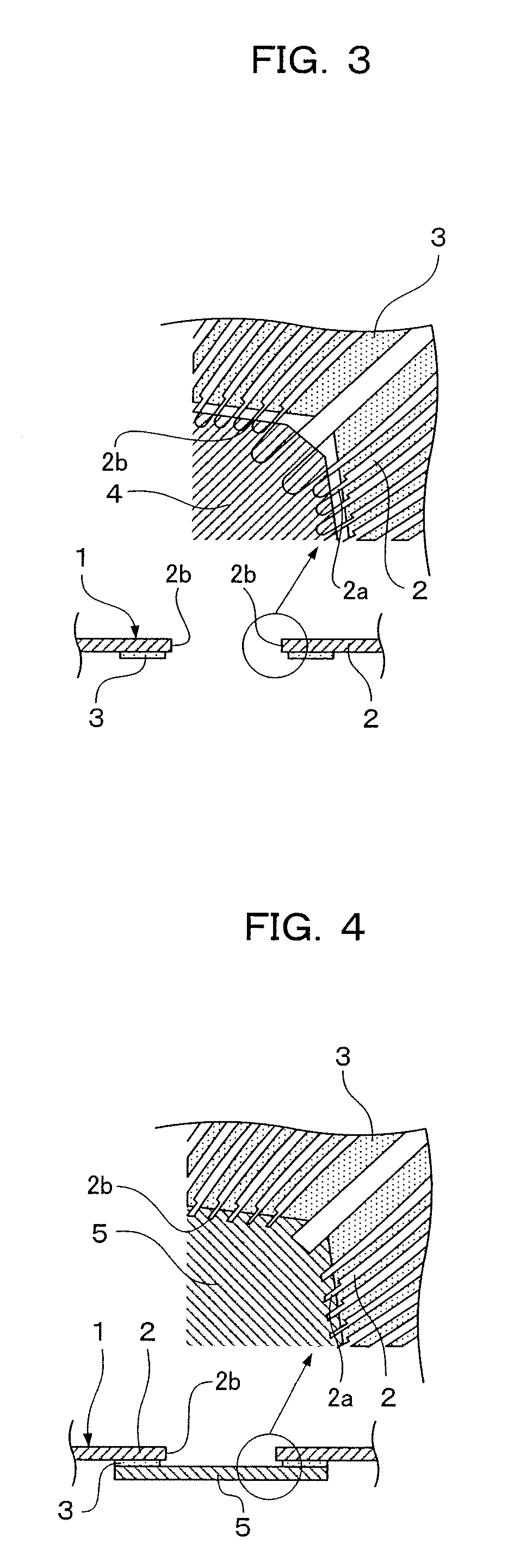

Lead frame, semiconductor device, method of manufacturing the lead frame, and method of manufacturing the semiconductor device

ActiveUS20090045492A1Improve productivityMolding condition is restrictedLine/current collector detailsSemiconductor/solid-state device detailsSemiconductor chipEngineering

A lead frame is provided which can prevent a short circuit between wires and the ends of adjacent leads, the short circuit being caused by wire sweep during the injection of molding resin, in a configuration where the electrodes of a semiconductor chip and the leads disposed around the semiconductor chip. The lead having sides substantially perpendicular to the direction of a resin flow has an end whose upstream side relative to the resin flow is constricted.

Owner:TESSERA ADVANCED TECH

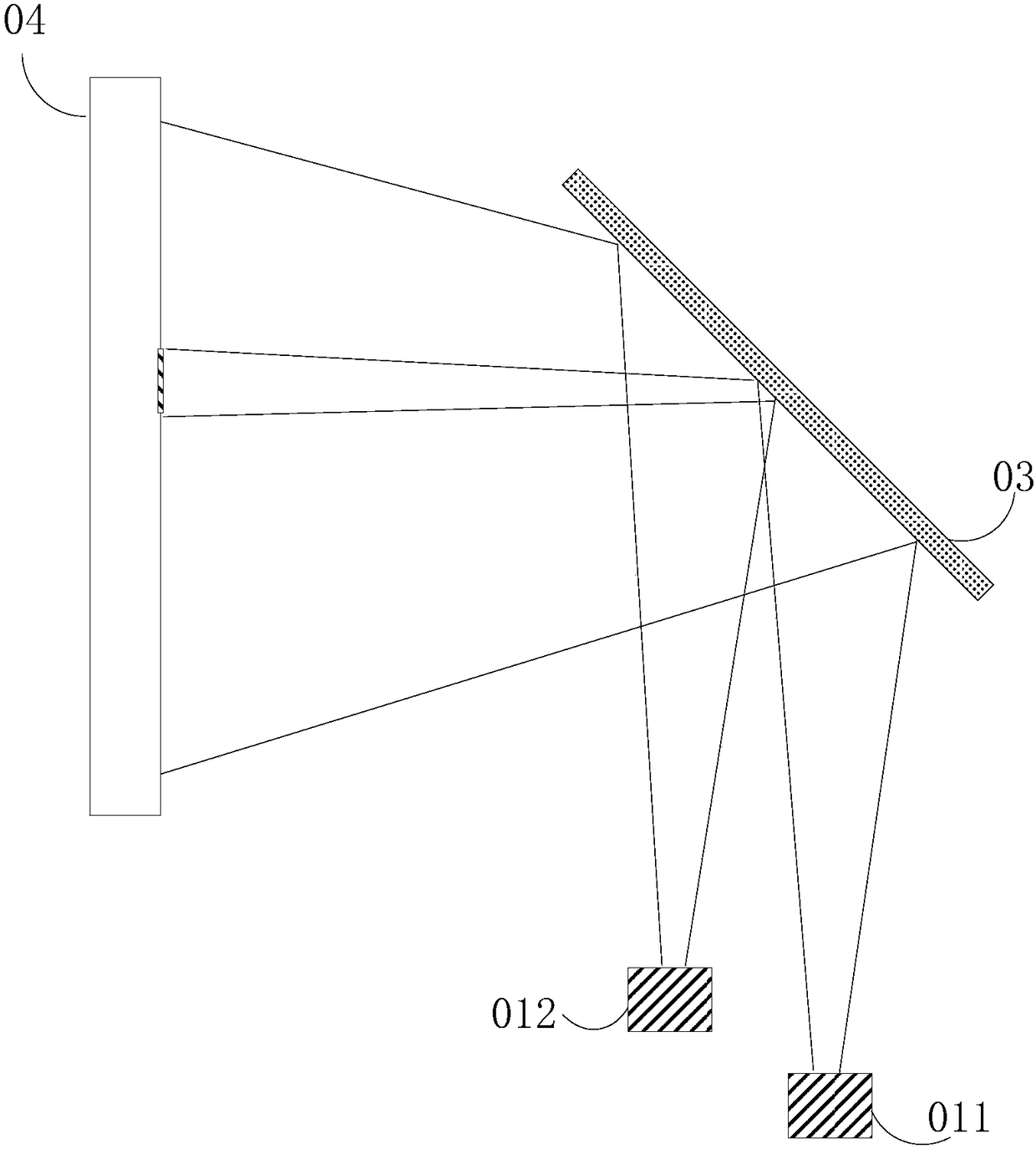

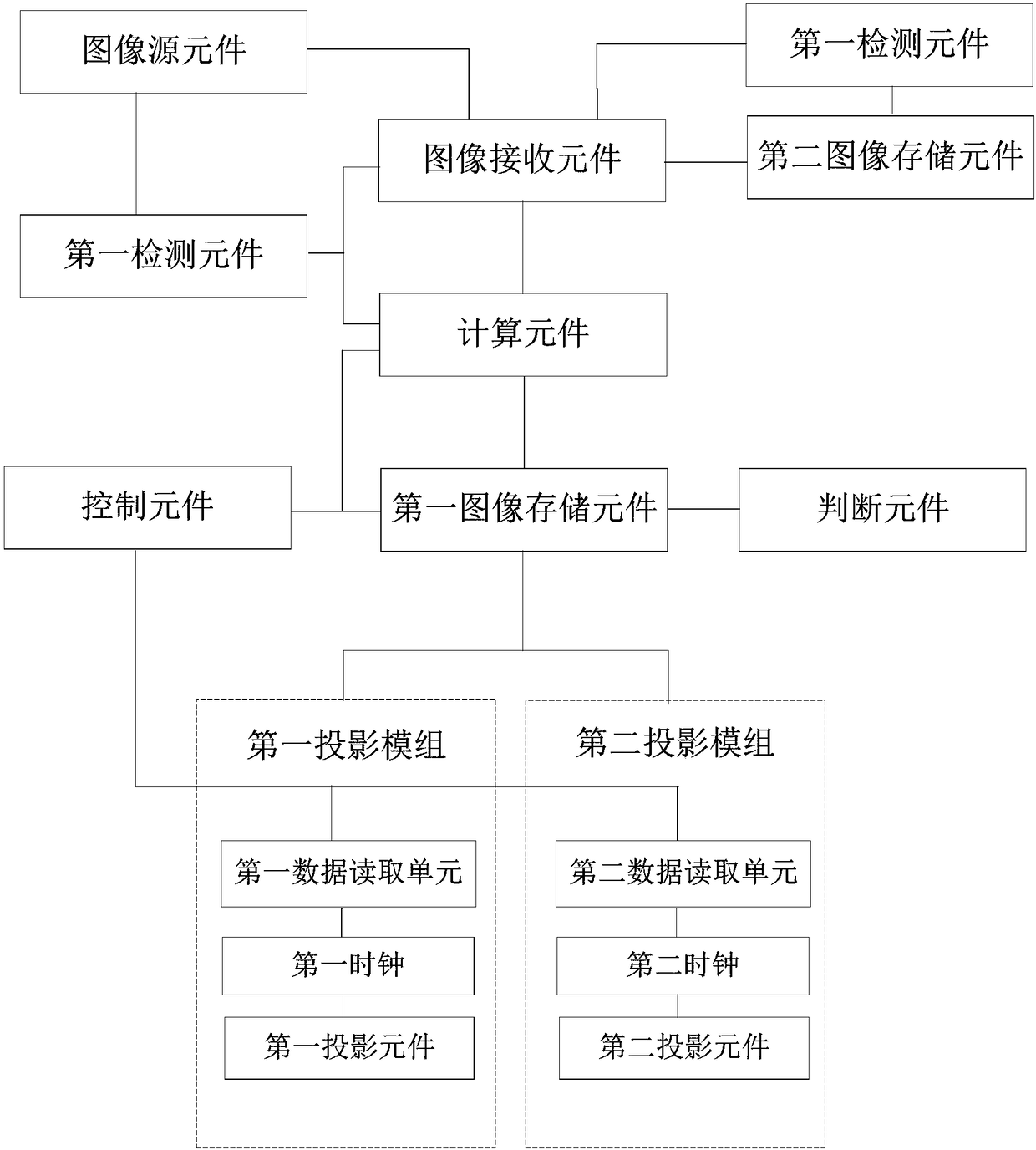

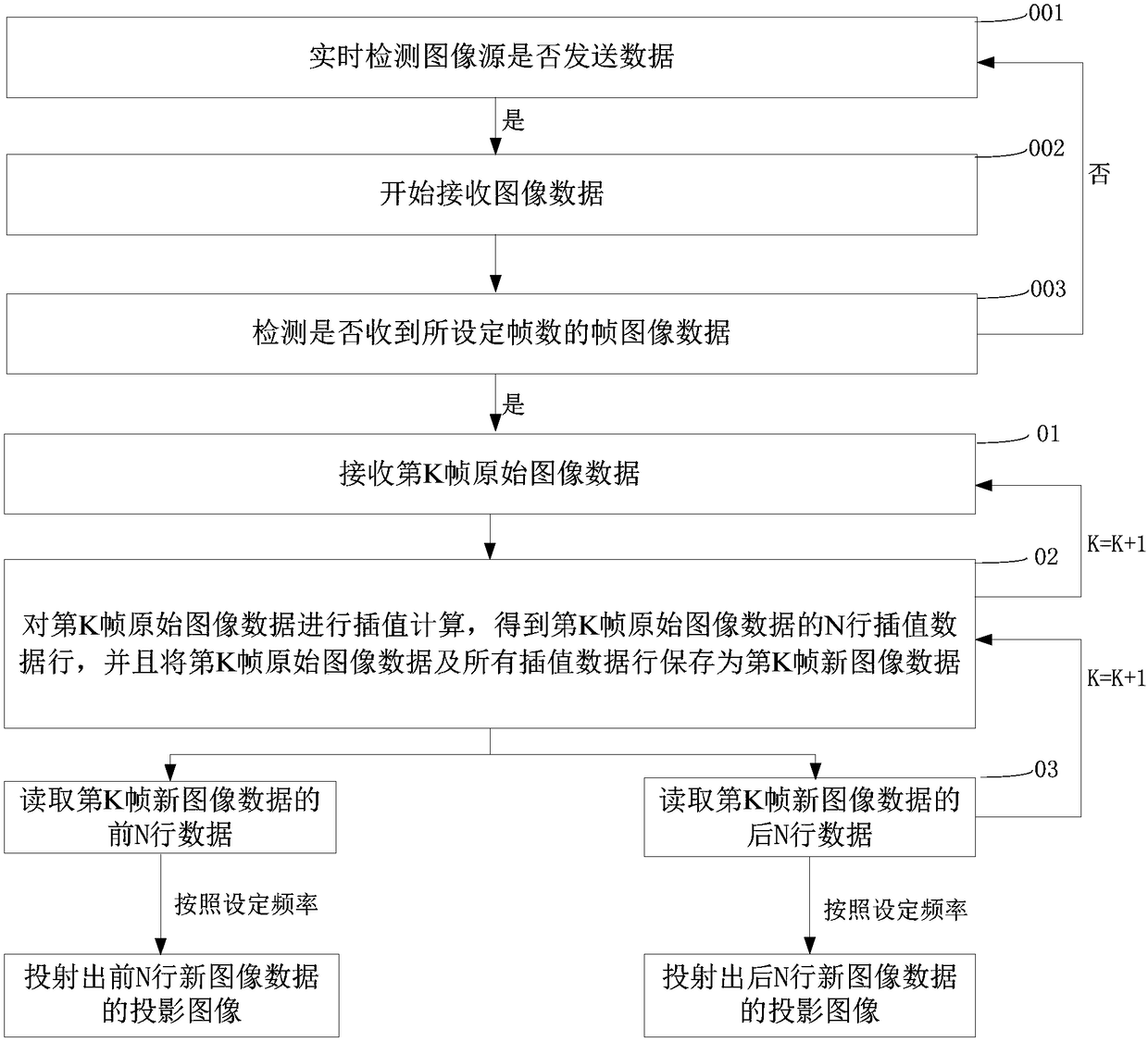

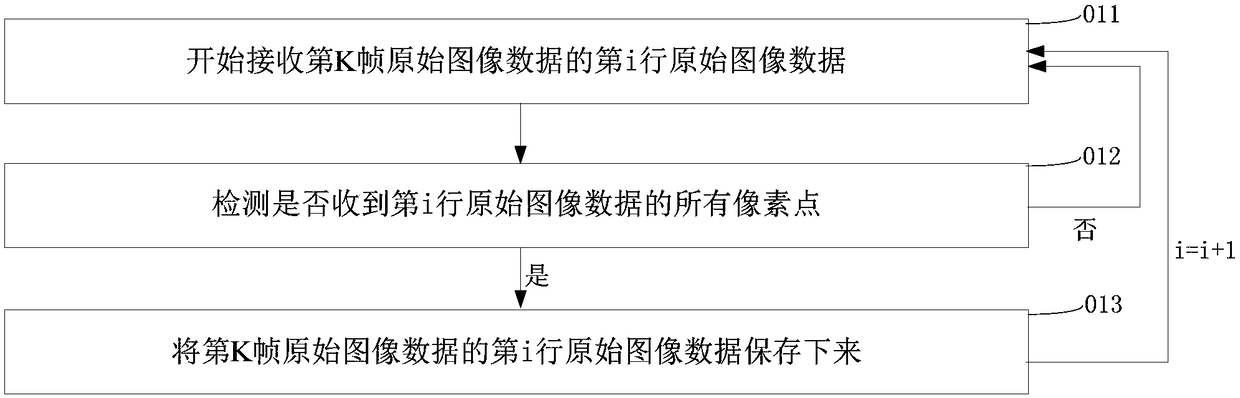

Projection system and projection method, and storage medium

InactiveCN108063930AIncrease the number of rowsComplete splicingPicture reproducers using projection devicesImaging processingImaging quality

The invention provides a projection system and a projection method, and a storage medium. Two projection modules and an image processor are combined; the image processor increases rows of original image data, the two projection modules read different parts in transverse direction of new image data and project a projection image of new image data of each part vertically, a projection adapter performs difference pre-calibration on micro-projection beams projected by a micro-projection module, and the projection image projected finally is spliced completely, has a regular shape, has no observation image quality defect, and has improved resolution ratio, so that the projection images of all parts are spliced vertically to form a target projection image, pixels of the image output finally are doubled in vertical direction and the brightness thereof is doubled, the image area is doubled in transverse direction, the logic speed from the image processing process to the projection process is improved, and less energy is consumed.

Owner:全普半导体科技(深圳)有限公司

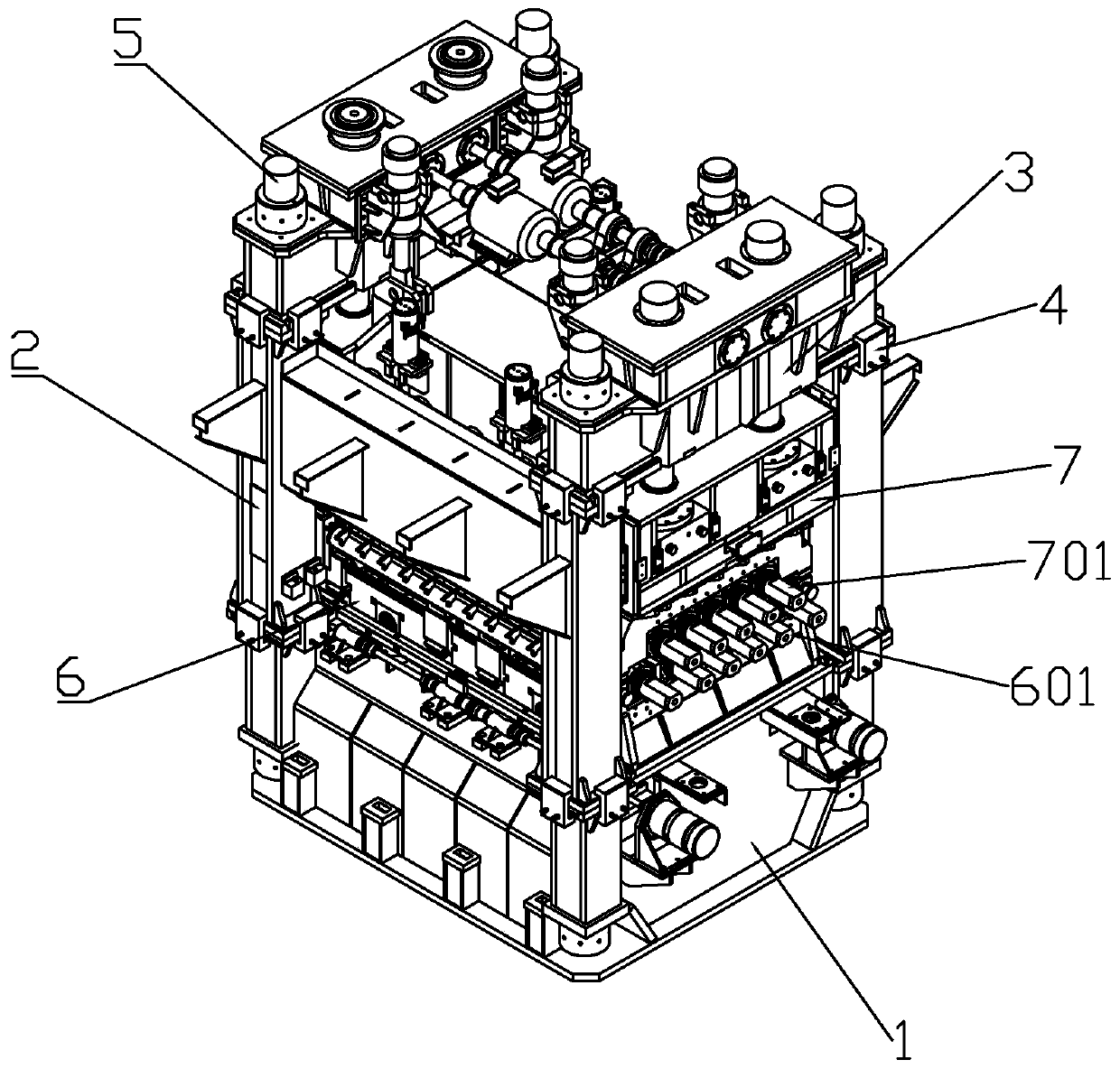

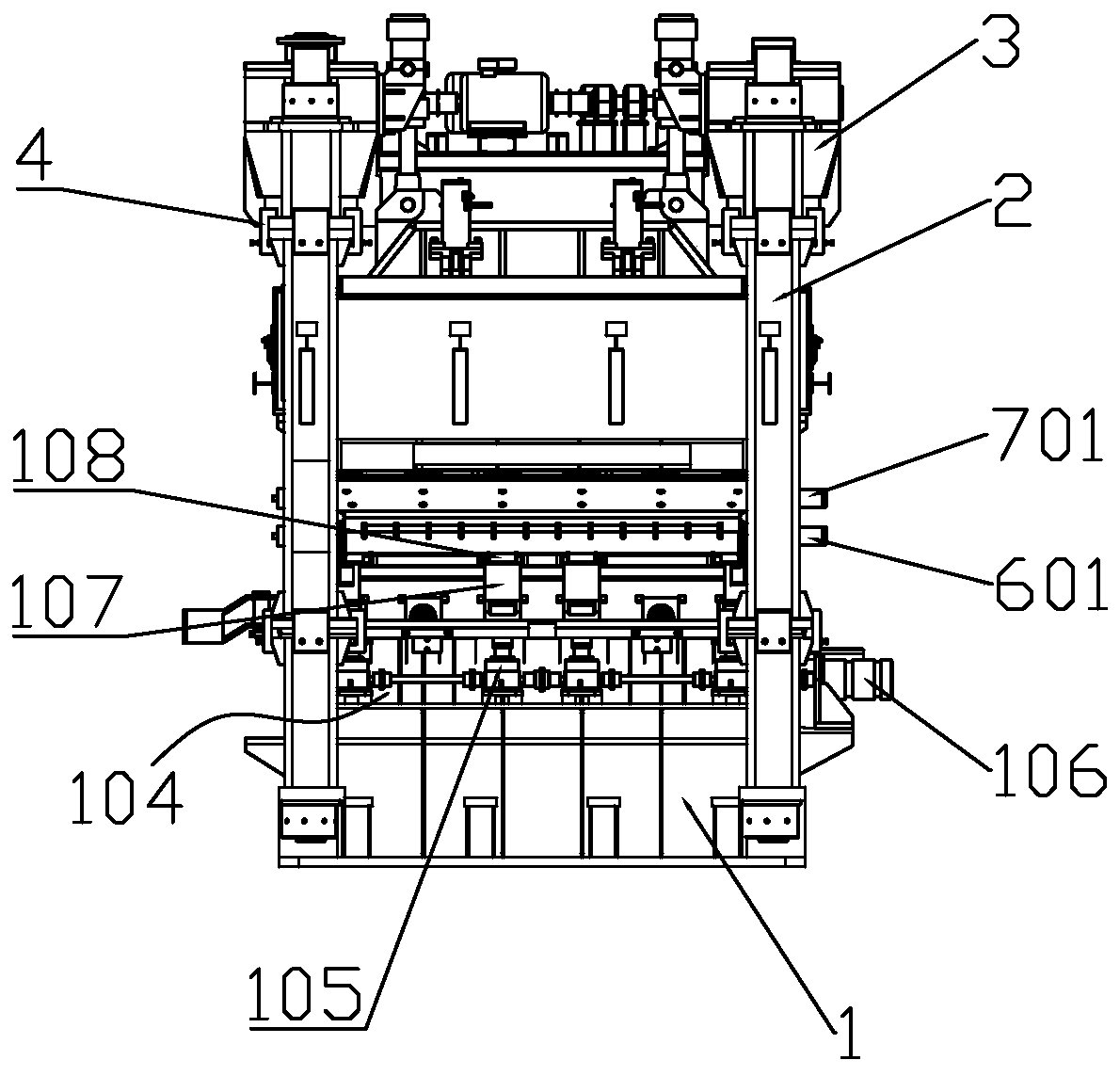

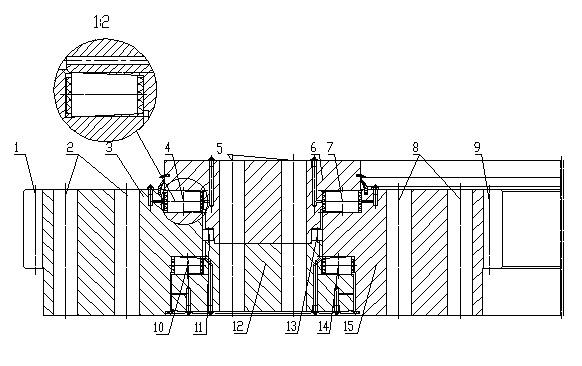

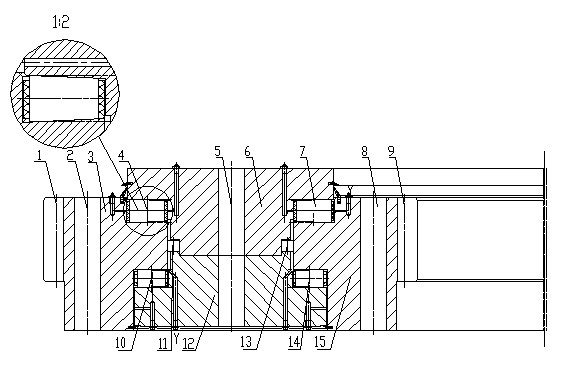

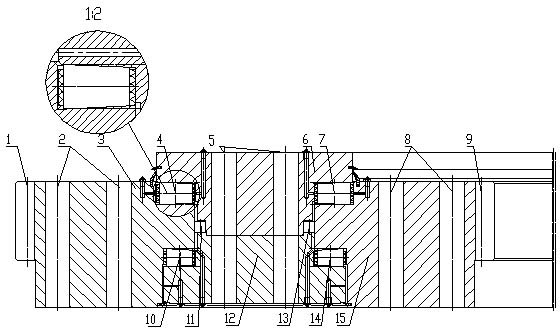

Multi-roller-spacing high-rigidity high-load steel plate straightener

ActiveCN111036711AEliminate gapsGuaranteed to bear the straightening forcePressesPre stressMechanical engineering

The invention discloses a multi-roller-spacing high-rigidity high-load steel plate straightener which comprises a prestress interlocking rack. The prestress interlocking rack comprises a lower base frame arranged on the ground; two upper cross beams are connected above the lower base frame through four vertically arranged hollow stand columns; interlocking mechanisms are arranged between the lowerbase frame and the hollow stand columns as well as between the upper cross beams and the hollow stand columns; tensioning prestress mechanisms are arranged in the hollow stand columns; a horizontallyarranged lower roller system device is connected to the lower base frame; and the upper cross beams are connected with an upper roller system device opposite to the lower roller system device. The multi-roller-spacing high-rigidity high-load steel plate straightener provided by the invention is applied to the field of medium heavy plate straightening, has the characteristics of the high-rigidityinterlocking rack, side roller belt load adjustment, online roller gap adjustment, structure compactness, fast response, high-speed roller changing of a multi-roller system and the like, can realize reciprocating type straightening and favorable straightened plate shapes, and can particularly meet the straightening straightness requirement of a high strength steel sheet with an extra thickness range.

Owner:北京冶自欧博科技发展有限公司

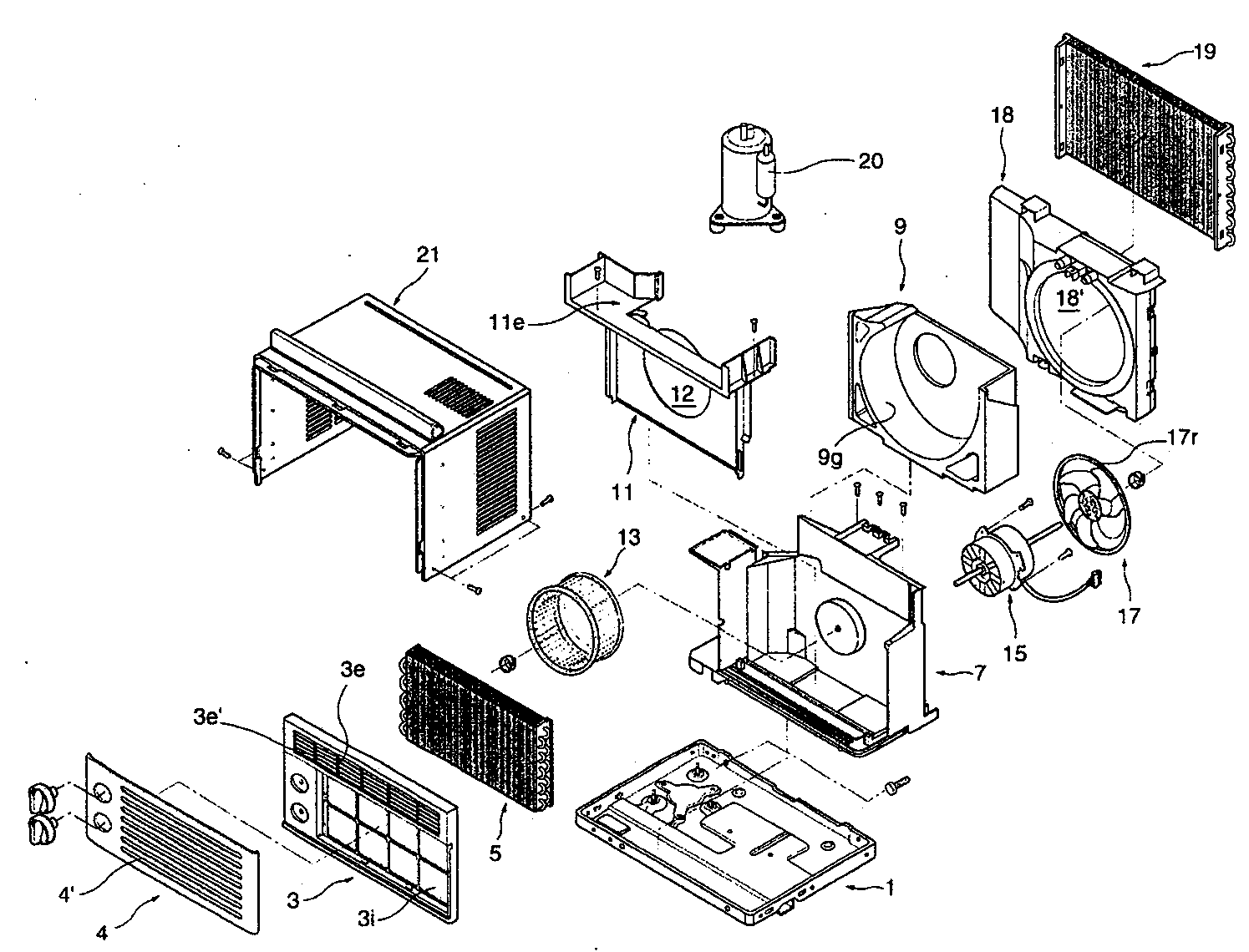

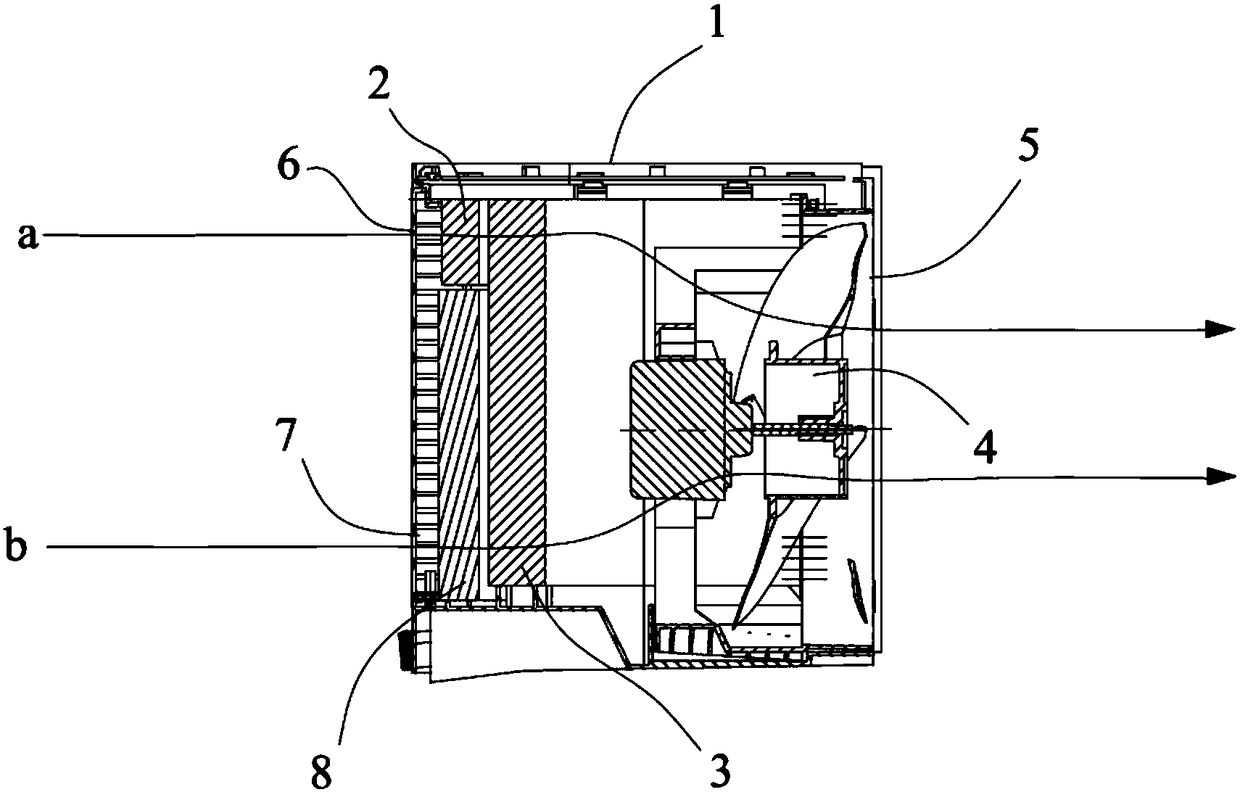

Compact window air conditioner

InactiveCN101871677AIncrease the number of rowsImprove comfortLighting and heating apparatusAir conditioning systemsElectric machineryEngineering

The invention discloses a compact window air conditioner, comprising a compressor, an indoor heat exchanger, an outdoor heat exchanger, an indoor fan, an outdoor fan, a housing, a chassis and a partitioning plate which is arranged on the chassis and divides the entire air conditioner into an indoor part and an outdoor part, wherein the indoor fan and the outdoor fan are Sirocco fans with double-inlet and double-outlet. The indoor fan and the outdoor fan share an electric motor which is installed inside the Sirocco fan at outdoor side. According to the invention, the fans of the indoor part and the outdoor part are the Sirocco fans with double-inlet and double-outlet which share the same electric motor, the heat exchange efficiency can be enhanced, and the structure is compact so that there is enough space for increasing the row number of heat exchangers. Two-side blowing is adopted indoor and swinging grids are installed at the outlet, thus large-range blowing is achieved and comfort of human body can be raised.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

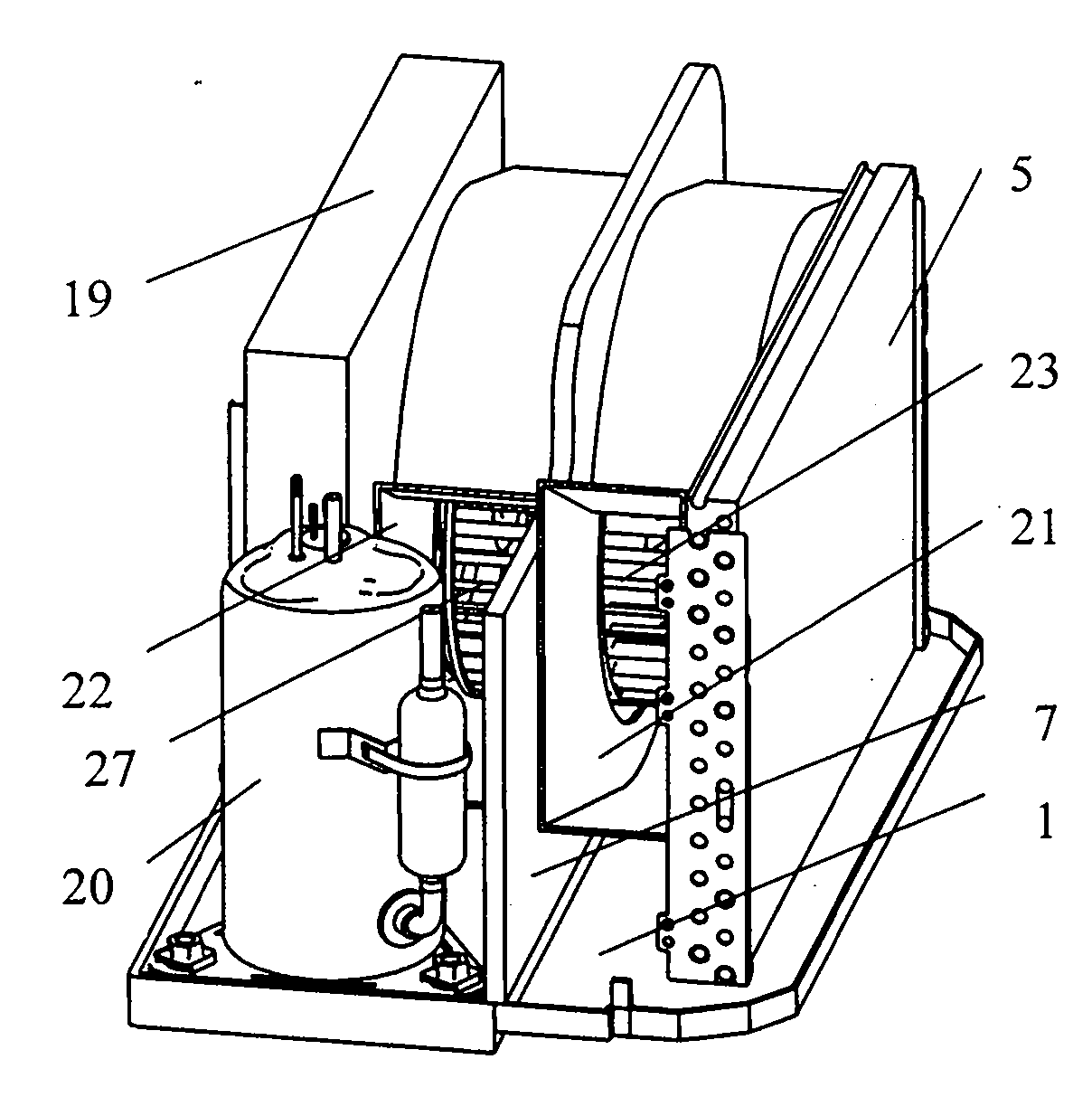

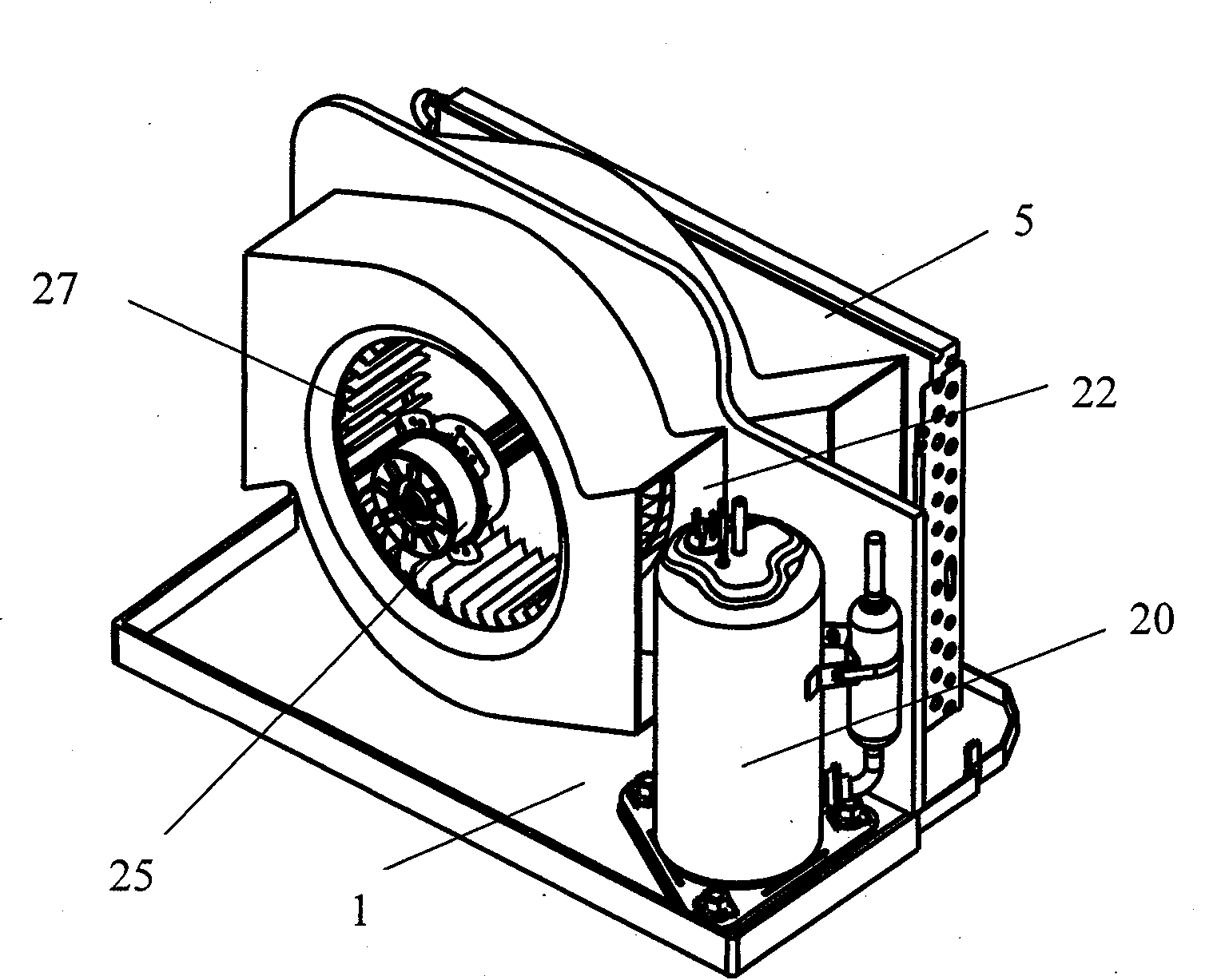

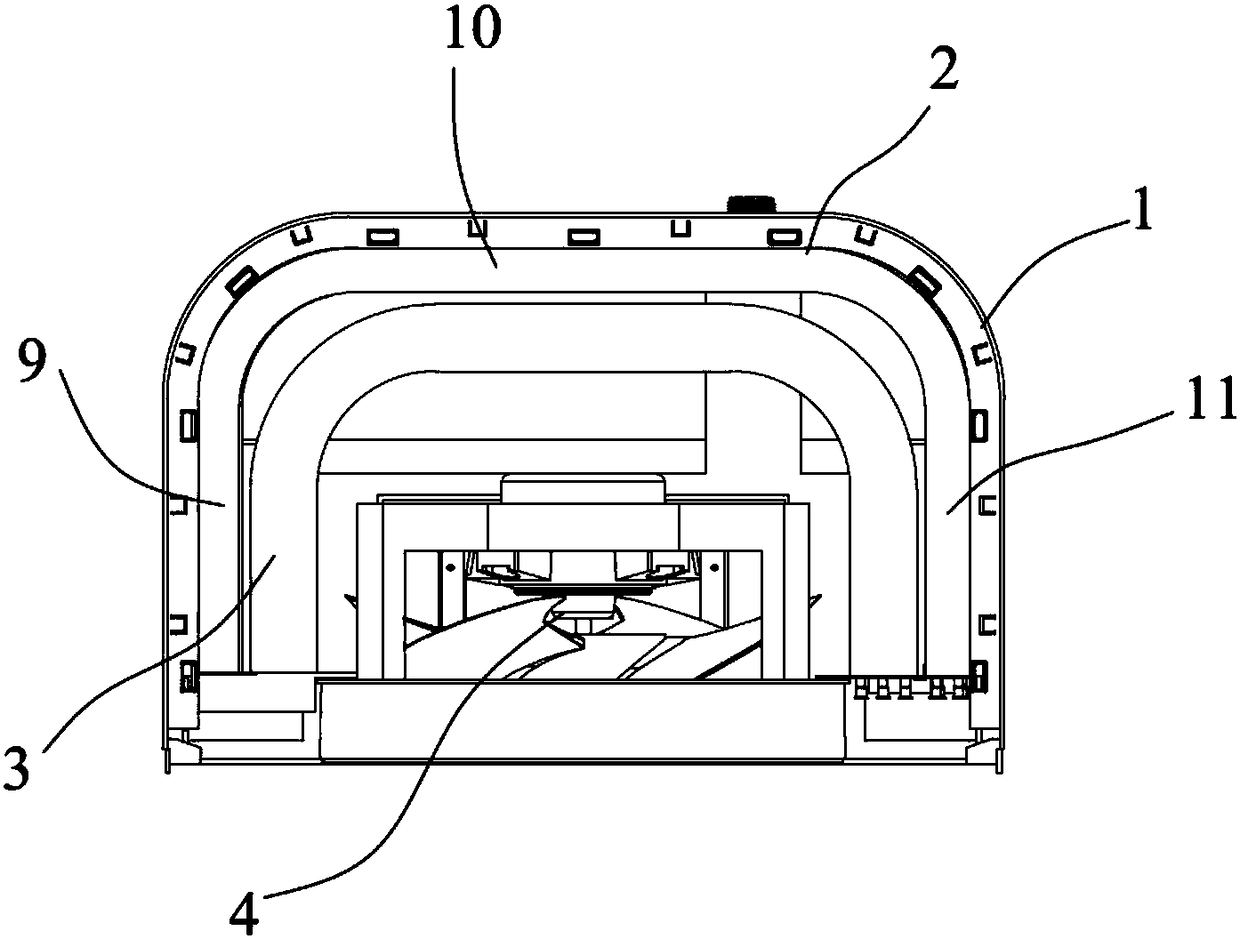

Dehumidifier

InactiveCN108224595AGuaranteed high air volumeExtend effective dehumidification timeLighting and heating apparatusSpace heating and ventilation detailsBusiness efficiencyEngineering

The invention discloses a dehumidifier. The dehumidifier comprises a dehumidifier body and further comprises a first condenser, a second condenser, an evaporator and a draught fan, all of which are arranged in the dehumidifier body. The first condenser and the evaporator are arranged on one side of the second condenser. The dehumidifier body is provided with an air inlet and an air outlet. The draught fan can generate a first airflow path sequentially passing by the air inlet, the first condenser, the second condenser, the draught fan and the air outlet and a second airflow path sequentially passing by the air inlet, the evaporator, the second condenser, the draught fan and the air outlet, and the windward face area of the evaporator is smaller than that of the second condenser. The dehumidifier aims at solving the technical problems that in the prior art, the dehumidification capability of the dehumidifier is attenuated, the air volume is attenuated, and the energy efficiency ratio isreduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

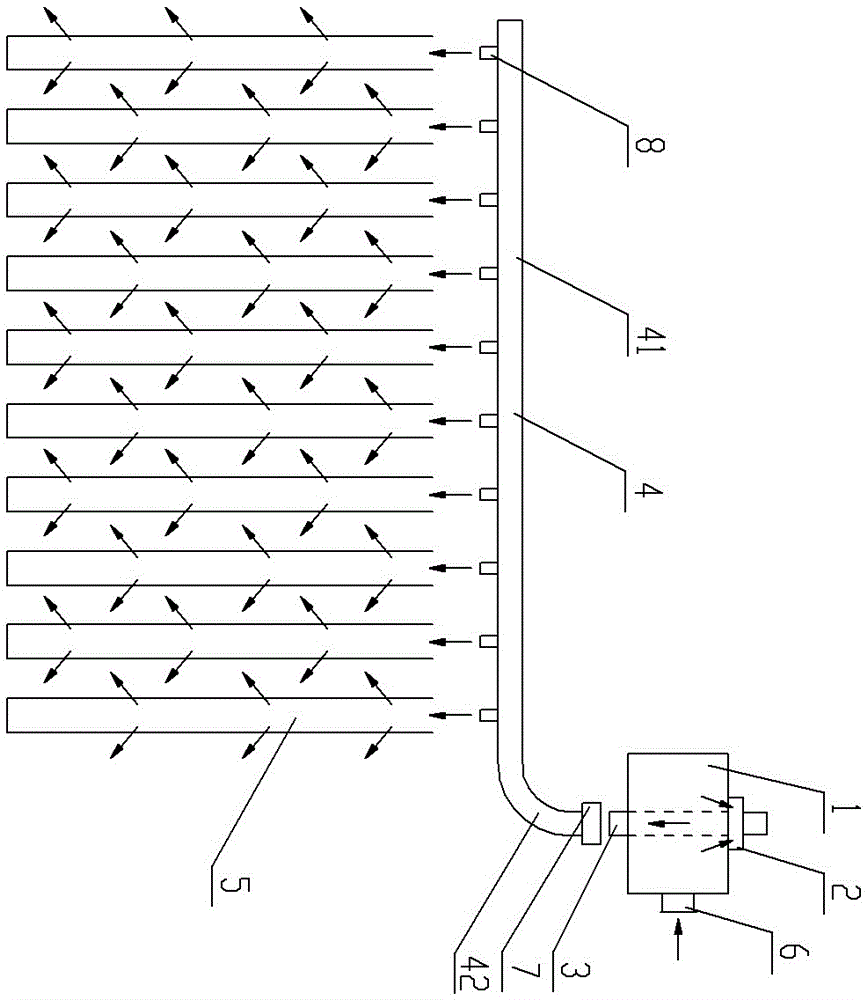

Separate type injection deashing device

InactiveCN106268084AIncrease the number of rowsReduce in quantityDispersed particle filtrationEngineeringNozzle

The invention provides a separate type injection deashing device which can reduce quantity of pulse valves and air pockets, reduce investment cost and reduce maintenance workload. The separate type injection deashing device comprises an air pocket, a pulse valve, an injection pipe and a filter bag as well as a junction pipe, wherein an air pocket air inlet is formed in the air pocket, a compressed air source is connected with the air pocket air inlet, an air pocket air outlet is formed in the air pocket and arranged at the upper part of the air pocket, a valve seat of the pulse valve is embedded into the air pocket air outlet, an air inlet of the pulse valve is connected with the air pocket air outlet, an air outlet of the pulse valve is formed inside the air pocket, one end of the junction pipe penetrates through the air pocket to be communicated with the air outlet of the pulse valve inside the air pocket, the other end of the junction pipe is detachably connected with the corresponding injection pipe arranged below the junction pipe, and a nozzle outlet in the lower side of the injection pipe faces an opening of the filter bag.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

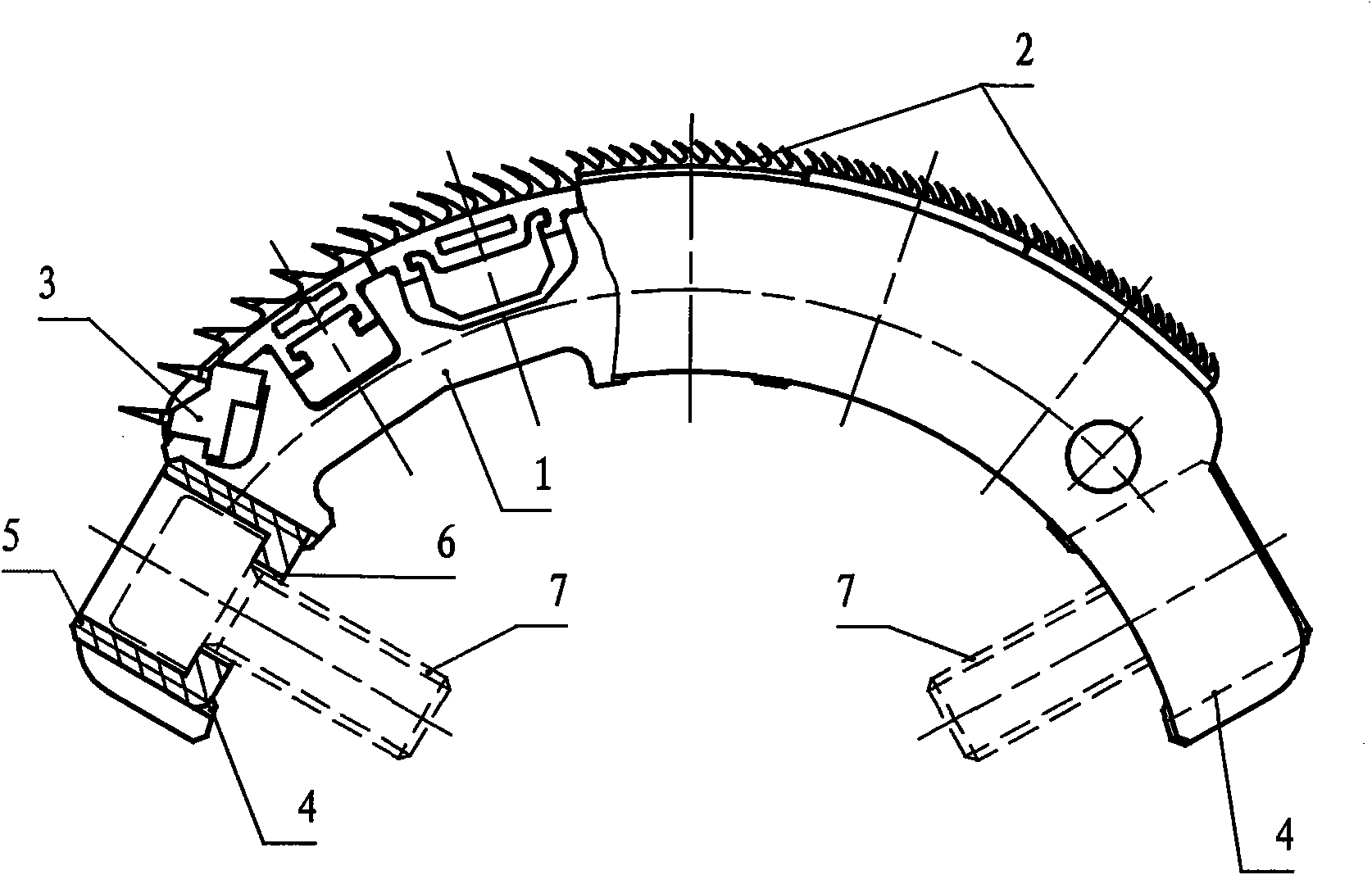

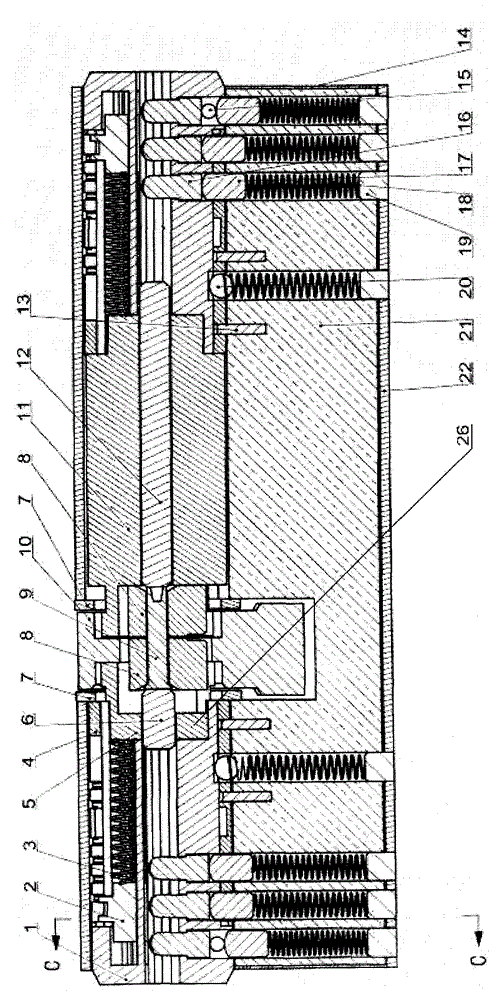

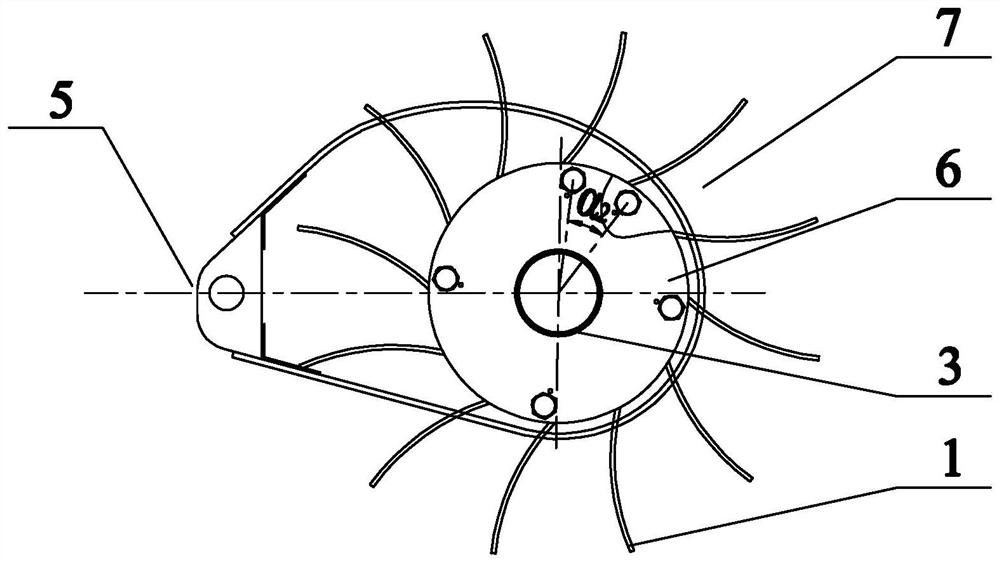

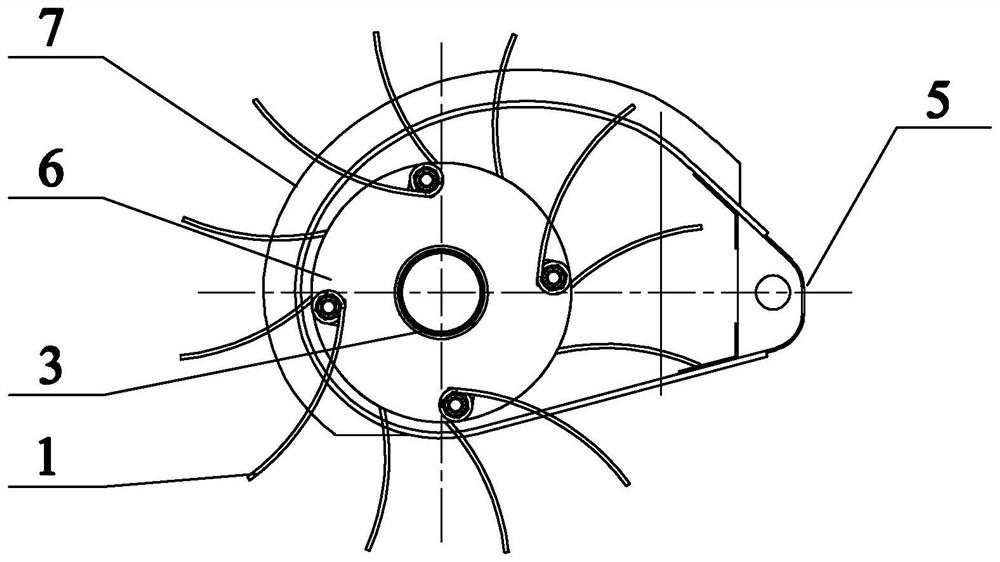

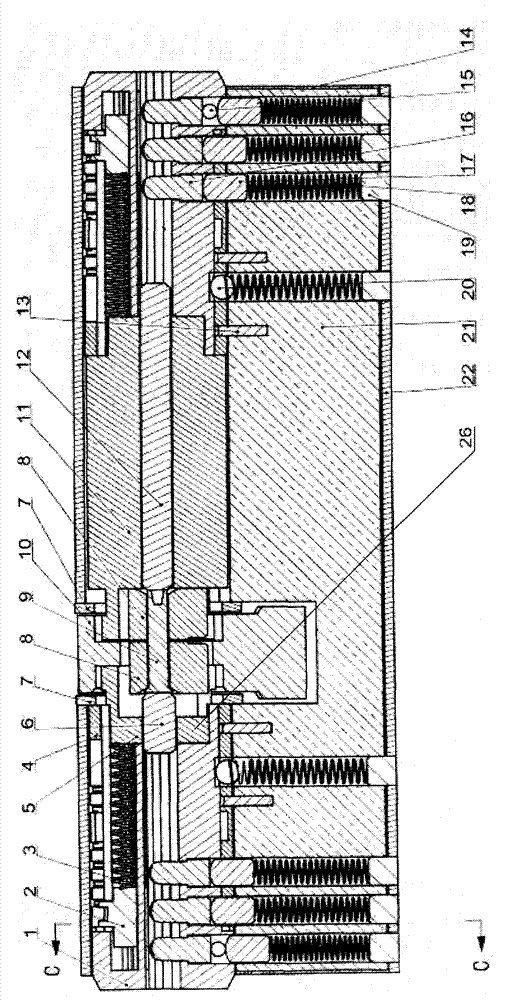

Rotary bearing with six rows of rolling cones

InactiveCN102635633AReduce slidingAdd pure scrollingRoller bearingsBearing componentsEngineeringMechanical engineering

The invention discloses a rotary bearing with six rows of rolling cones. The rotary bearing is divided into an inner ring, an outer ring and a middle ring, and is characterized in that the middle ring is divided into an upper part and a lower part which are fixed with each other through a bolt, wherein three rows of rolling cone roller ways are formed between the inner ring and the middle ring as well as between the middle ring and the outer ring respectively; and rolling bodies are arranged in the roller ways. The rotary bearing has a reasonable structure and is cost-saving and easy to implement; the problem that an axial size of the conventional rotary bearing is required to be enlarged in order to meet the requirement for relatively high bearing capacity is solved; and the bearing capacity of the rotary bearing is improved by over 50% than the common rotary bearing with three rows of columns.

Owner:MAANSHAN FANGYUAN SLEWING RING

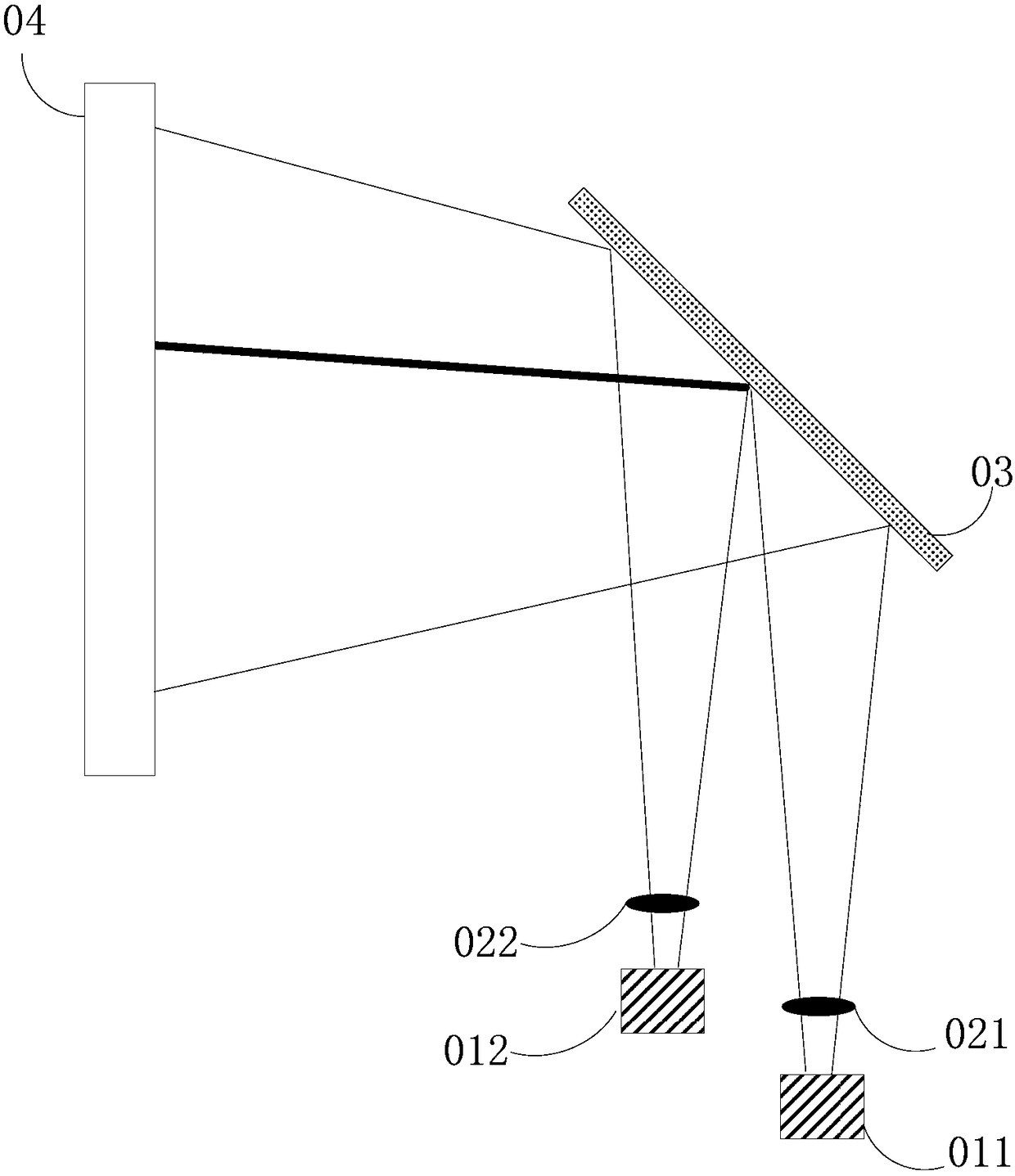

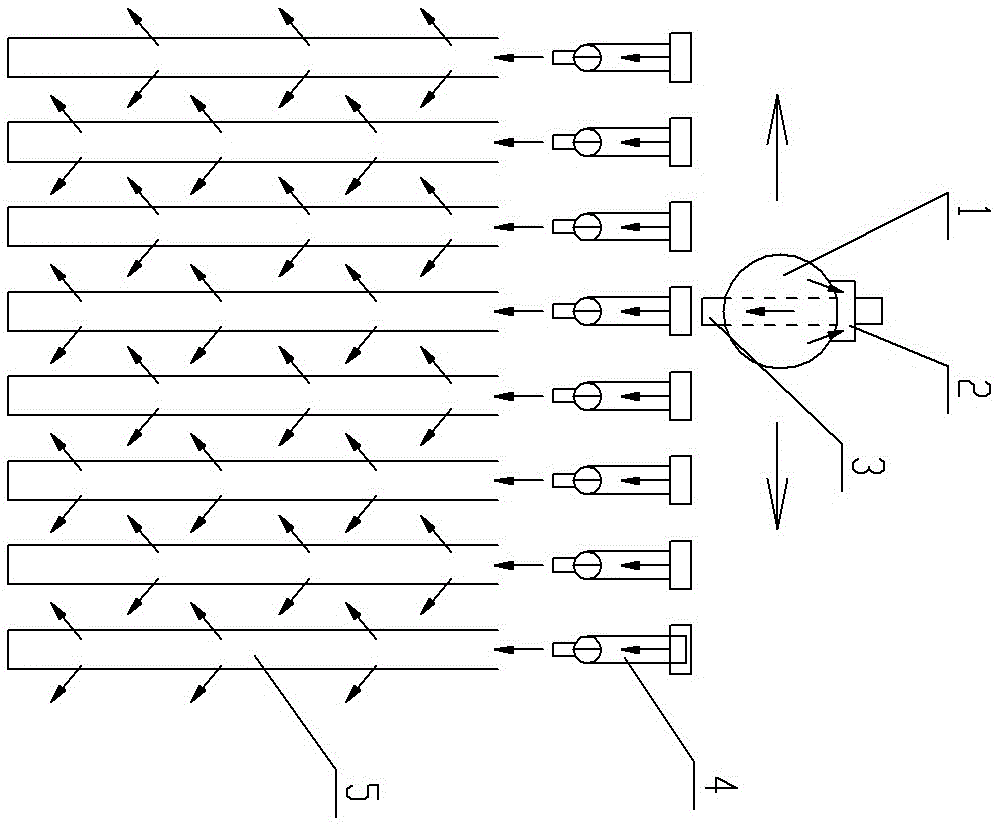

Dual-mode projection device and projection method, and storage medium

InactiveCN108259868AIncrease the number of rowsIncrease brightnessPicture reproducers using projection devicesImaging processingDual mode

The invention provides a dual-mode projection device and projection method, and a storage medium. Two projection modules are combined with an image processor, the number of columns of original image data is increased by using the image processor, and the two projection modules are cooperatively used to read a part of new image data, meanwhile projection images of the new image data of each part are projected on the horizontal direction, the projection images corresponding to the new image data of each part are spliced into a target project image, the final output image pixel is doubled on thehorizontal direction, the brightness is doubled, the horizontal image area is doubled as well, the logic speed from an image processing process to a projection process is improved, and the energy consumption is reduced, therefore, the dual-mode projection device and projection method are particularly suitable for large-frame miniature image output devices, such as micro-laser projection devices.

Owner:全普半导体科技(深圳)有限公司

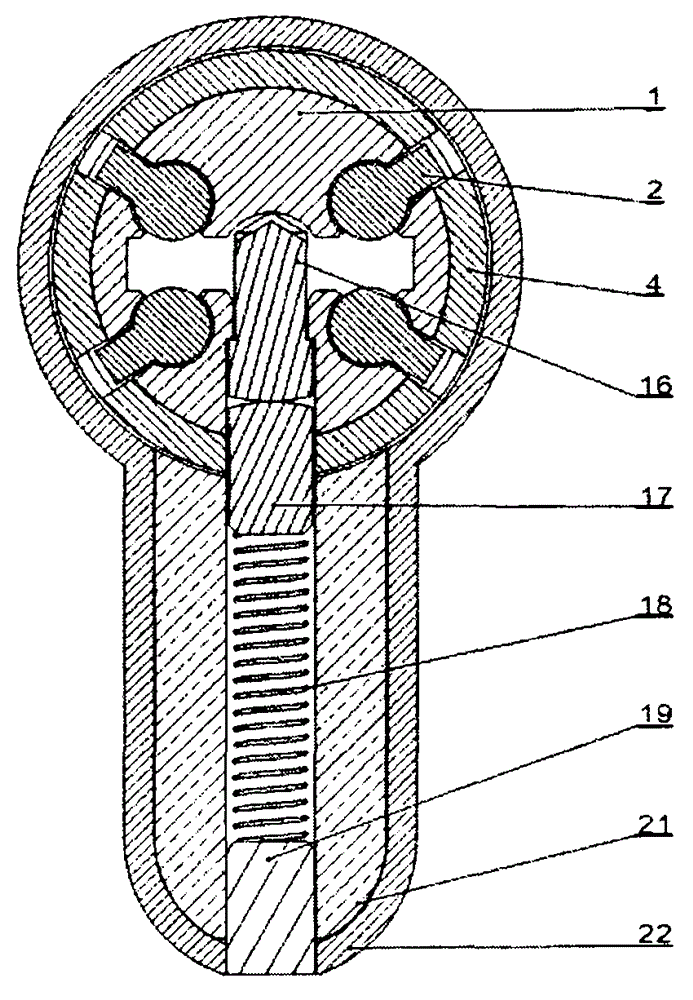

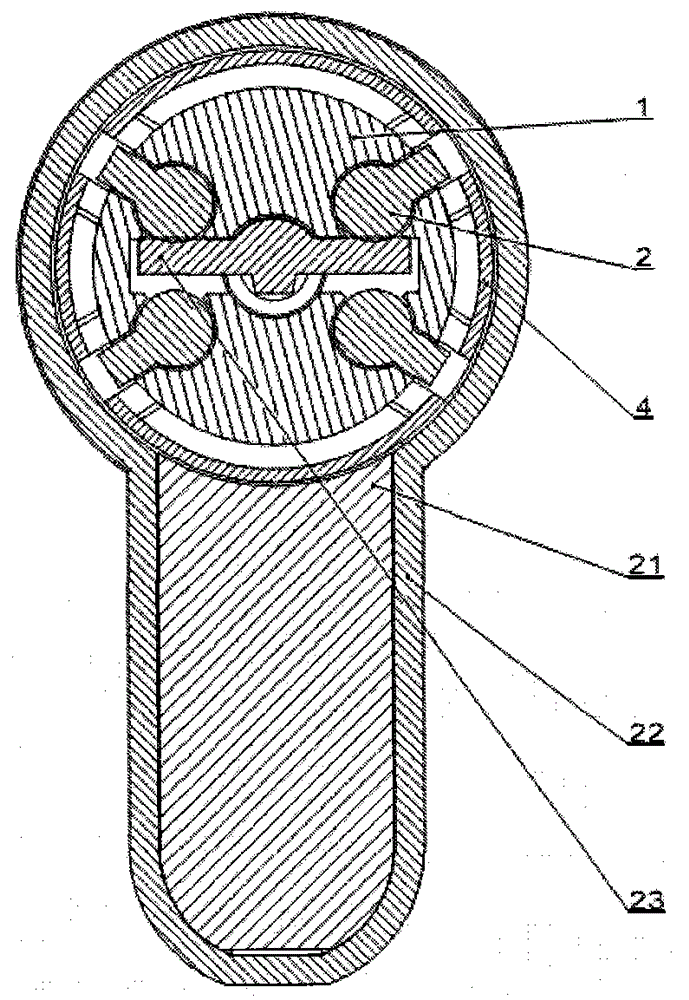

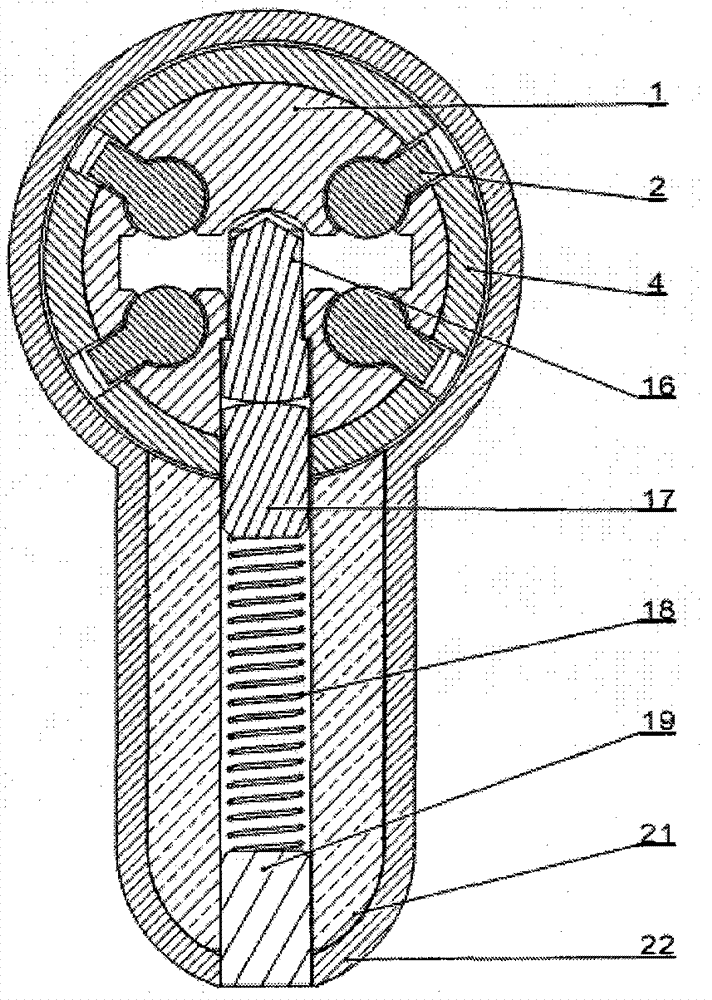

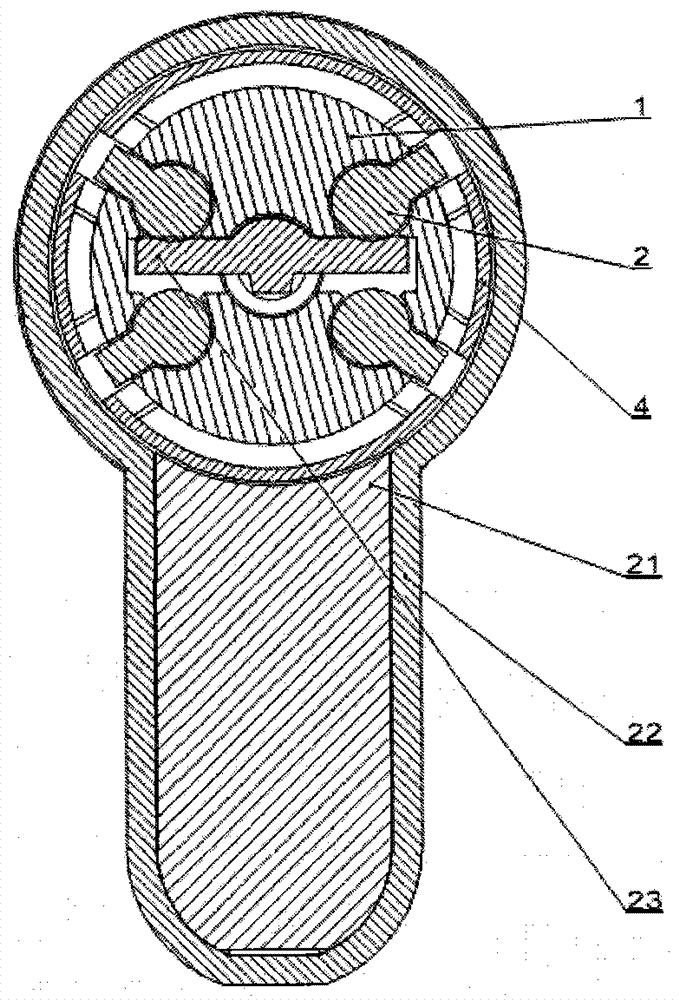

Anti-theft lock cylinder for flat cross-shaped key

InactiveCN104948019AIncreased theoretical key volumeConsistent sizeCylinder locksAnti theftEngineering

The invention relates to an anti-theft lock cylinder for a flat cross-shaped key. Four cylindrical holes are formed in each of two ends of a lock liner, an axial pin tumbler is arranged in each cylindrical hole, and an axial pin tumbler reset spring is arranged in one end of each axial pin tumbler. Four radial cylindrical holes are formed in each of two ends of a lock liner support, a radial pin tumbler is arranged in a first hole, an engineering ball is arranged at one end of the radial pin tumbler, a radial sliding pin tumbler is arranged at the other end of the engineering ball, and a radial pin tumbler reset spring is arranged at the other end of the radial sliding pin tumbler; a radial pin tumbler is also arranged in each of a second hole and a third hole, a radial sliding pin tumbler is arranged at one end of each radial pin tumbler, a radial pin tumbler reset spring is arranged at the other end of each radial sliding pin tumbler; a positioning ball is arranged in a fourth hole, and a radial pin tumbler reset spring is arranged at one end of the positioning ball. The anti-theft lock cylinder for the flat cross-shaped key has the advantages that since a cylindrical lock liner blocking tube formed by stamping is adopted, the anti-theft lock cylinder is simple in structure and low in cost and is uniform in size when produced on a large scale.

Owner:王崇钢

Helical tooth roller type peanut picking device

PendingCN114793595ASolve the \"blocking pile\"Solve the problem of \"throwing up\"LoadersDigger harvestersWork cycleAgricultural engineering

The invention discloses a spiral tooth roller type peanut picking device, and belongs to the technical field of agricultural machinery. Comprising picking teeth, a roller protection plate, a spiral picking roller, a left side plate, a right side plate and a rear side plate, a center shaft of the picking roller is installed on bearings of the left side plate and the right side plate, and the left side plate and the right side plate are fixedly connected with the rear side plate. Four to eight pick-up teeth are evenly arranged on the tooth roller discs in the circumferential direction of the tooth roller discs, the pick-up teeth are fixed on the tooth roller seat, the tooth roller discs are installed on the center shaft at equal intervals in the axial direction of the center shaft, and the pick-up teeth of the adjacent tooth roller discs are arranged in the same rotating direction in the circumferential direction in a staggered mode by 15 degrees to 30 degrees. During picking operation, the picking teeth are in contact with peanut plants in sequence, and the phenomenon of'heap 'can be effectively avoided. And the protective plates are arranged between the adjacent tooth roller seats and are mounted on the rear side plate. The roller rotates along with the center shaft and is matched with the unit to move forwards, the elastic teeth pick up peanut plants from bottom to top, and a working cycle of picking, lifting, pushing and backlash is completed in sequence.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY +1

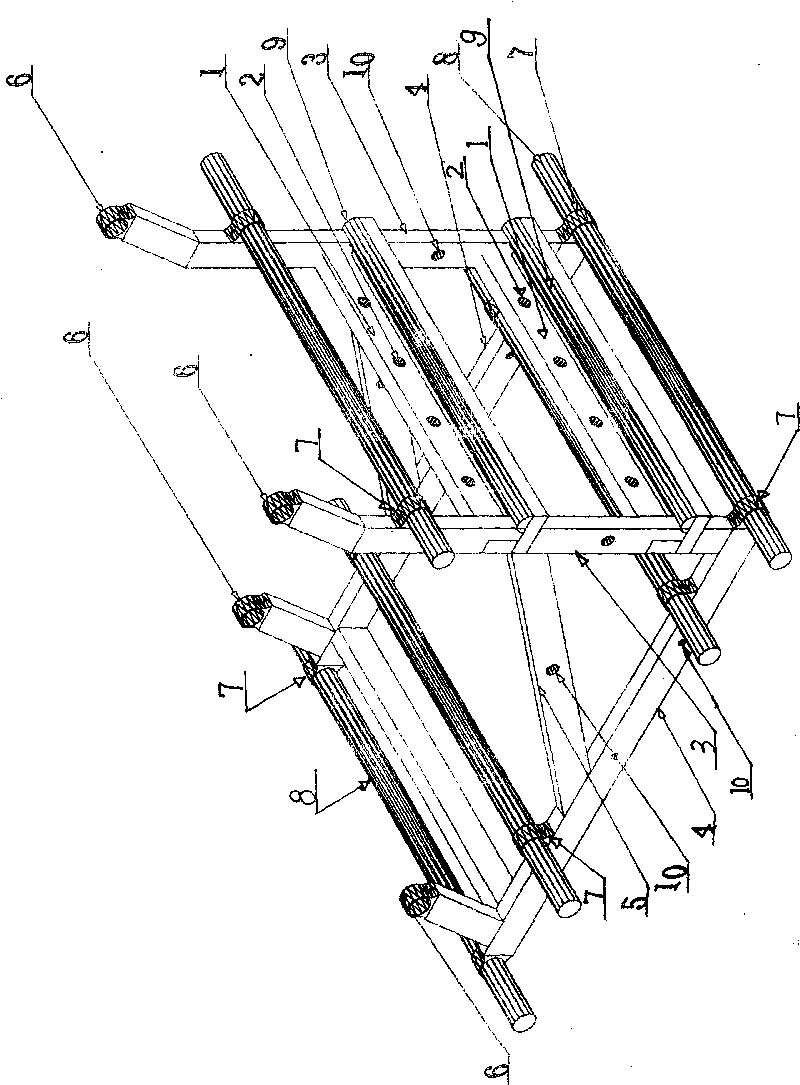

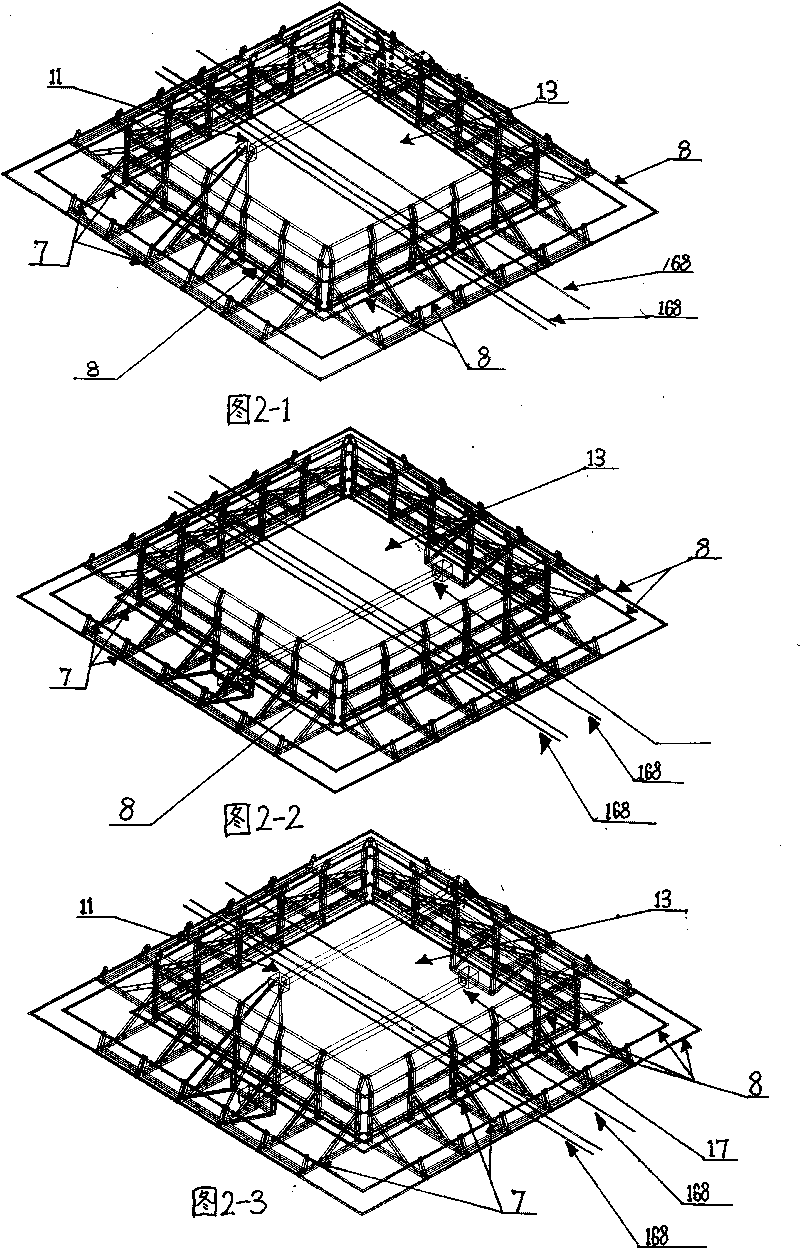

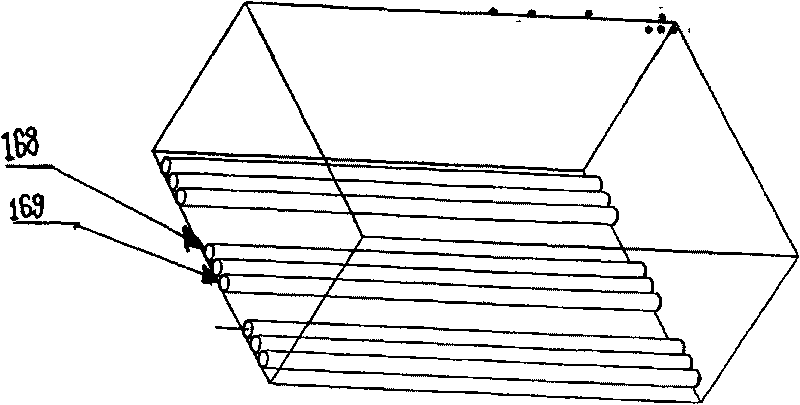

Cast-in-place prestressed slab and beam mould, construction method thereof and cast-in-place slab and beam manufactured by same

InactiveCN101761188AIncrease or decrease quantityIncrease the number of rebar layersFloorsGirdersPre stressEngineering

The invention relates to a cast-in-place prestressed slab (beam) mould. A monomer of the mould includes a frame which is connected with a main beam together through an upright post and is parallel to the main beam. A plurality of grooves (holes) for fixing prestressed bars are formed on the frame; a prestressed rib leveling straight bar is arranged on the frame; a plurality of screw holes used for mutual connection among a plurality of mould monomers, pipes (columns), pipe (column) buckles and support frame clamping bases are arranged on the uptight column and the main beam; and when the slab (bema) is manufactured by using the mould, two lateral end parts of each of the mould monomers can be connected into a straight shape or a rectangle shape or a shape of a prestressed concrete slab (beam) required to be subjected to cast-in-place on a building object in sequence. In the cast-in-place prestressed slab (beam) mould, because a pretensioned prestressed reinforcing steel bar can be fixed by the grooves (holes) of the prestressed bars formed on the frame, the pretensioned prestressed reinforcing steel bar can be added in the construction of the cast-in-place prestressed slab (beam). The weight of the slab (beam) with the same strength can be greatly reduced. Therefore, the cast-in-place prestressed slab (beam) manufactured by the cast-in-place prestressed slab (beam) mould has the advantages of good integrity, light self-body and low cost.

Owner:张军

Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

ActiveCN103725327BFully contactedAdequate responseGranular/pulverulent flues gasificationPositive pressureSlag

The invention discloses a gasification entrained-flow bed coal powder gasification furnace and a gasification method of micro-positive pressure air. At present, a normal-pressure fixed bed gasification furnace is commonly applied in an industrial fuel gas preparation industry and an efficient powdered coal entrained-flow bed gasification technology has some difficulties on preparing industrial fuel gas under the condition that the micro-positive pressure air is used as a gasifying agent. The gasification entrained-flow bed coal powder gasification furnace is characterized in that a gasification furnace body is provided with at least one row of wall surface burners; each row of the wall surface burners comprise a plurality of wall surface burners which are arranged along the peripheral direction of the gasification furnace body at intervals; the gasification agent which is sprayed into the gasification furnace by all the wall surface burners accounts for 80%-97% of the use amount of all the gasification agent; a furnace bottom nozzle is arranged below the bottom face of a gasification furnace slag opening; the gasification agent which is sprayed into the gasification furnace by the furnace bottom nozzle accounts for 3%-20% of the use amount of all the gasification agent. According to the gasification furnace, the gasification intensity of a unit volume is high; the quantity of in-furnace coal powder falling into a dreg tank is effectively reduced; the gasification entrained-flow bed coal powder gasification furnace is very suitable for producing the industrial fuel gas by taking the micro-positive pressure air as the gasification agent.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

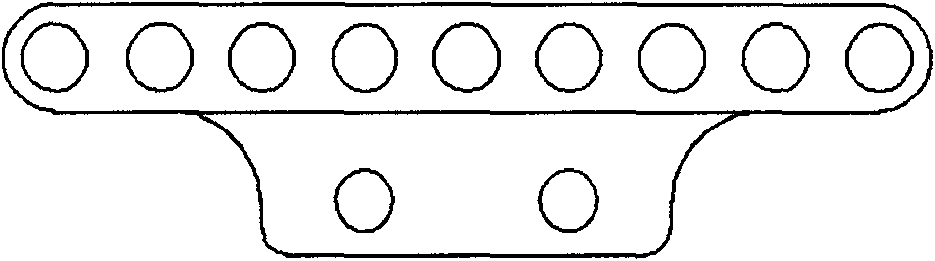

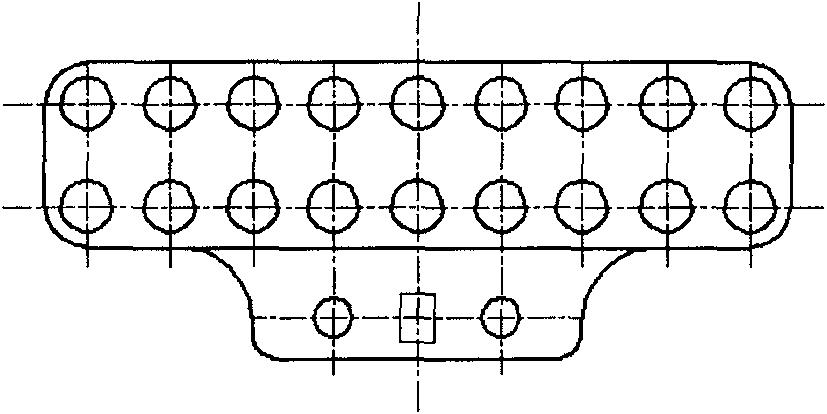

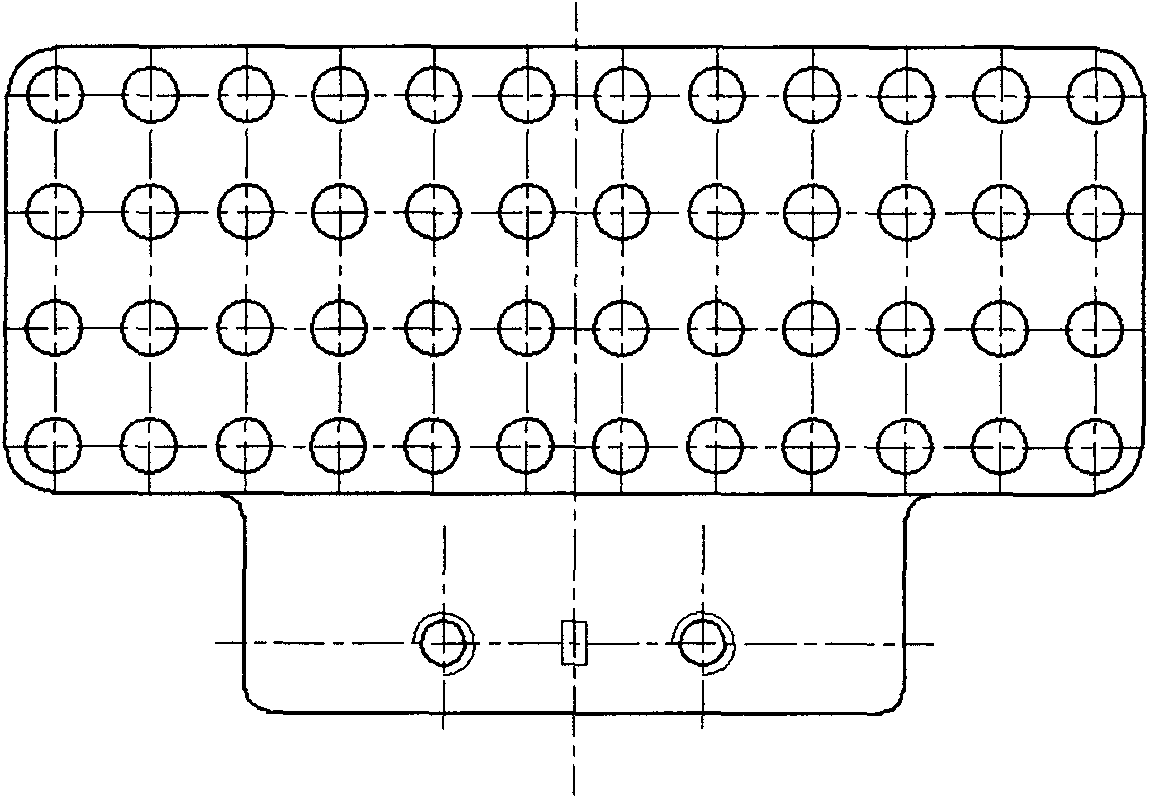

Capsule filling machine

ActiveCN101632623BIncrease the number of rowsAchieve dischargeCapsule deliveryBiomedical engineering

The invention relates to a capsule filling machine belonging to the field of pharmaceutical machinery and comprising a capsule filling machine module which is used for placing capsules and is provided with three rows or more than three rows of capsule filling holes. The invention increases the number of filled capsules during each processing period by increasing the number of the rows of the capsule filling holes, thereby further increasing the production speed; in addition, the invention realizes the waste rejection and the discharging of the capsules by a capsule waste rejecting mechanism and a capsule discharging mechanism.

Owner:BEIJING HANLIN HANGYU TECH DEV

Anti-theft lock cylinder for flat cross key

InactiveCN104948019BIncrease the number of rowsIncreased theoretical key volumeCylinder locksEngineeringMechanical engineering

The invention relates to an anti-theft lock core for a flat cross key. There are four cylindrical holes at both ends of the cylinder, and an axial pin is inserted in each cylindrical hole; an axial pin reset spring is placed at one end of the axial pin; The radial cylindrical hole is provided with a radial pin in the first hole, an engineering bead is arranged at one end of the radial pin, a radial sliding pin is arranged at the other end of the engineering bead, and a radial pin return spring is arranged at the other end of the radially sliding pin; Radial pins are also arranged in the second hole and the third hole, one end of the radial pin has a radial slide pin, and the other end of the radial slide pin is provided with a radial pin return spring; in the fourth hole, there is a positioning bead for positioning. There is a radial marble return spring at one end of the ball. Owing to adopting the cylinder-shaped cylinder lock blocking cylinder formed by stamping, the size is consistent during mass production, the structure is simple, and the cost is low.

Owner:王崇钢

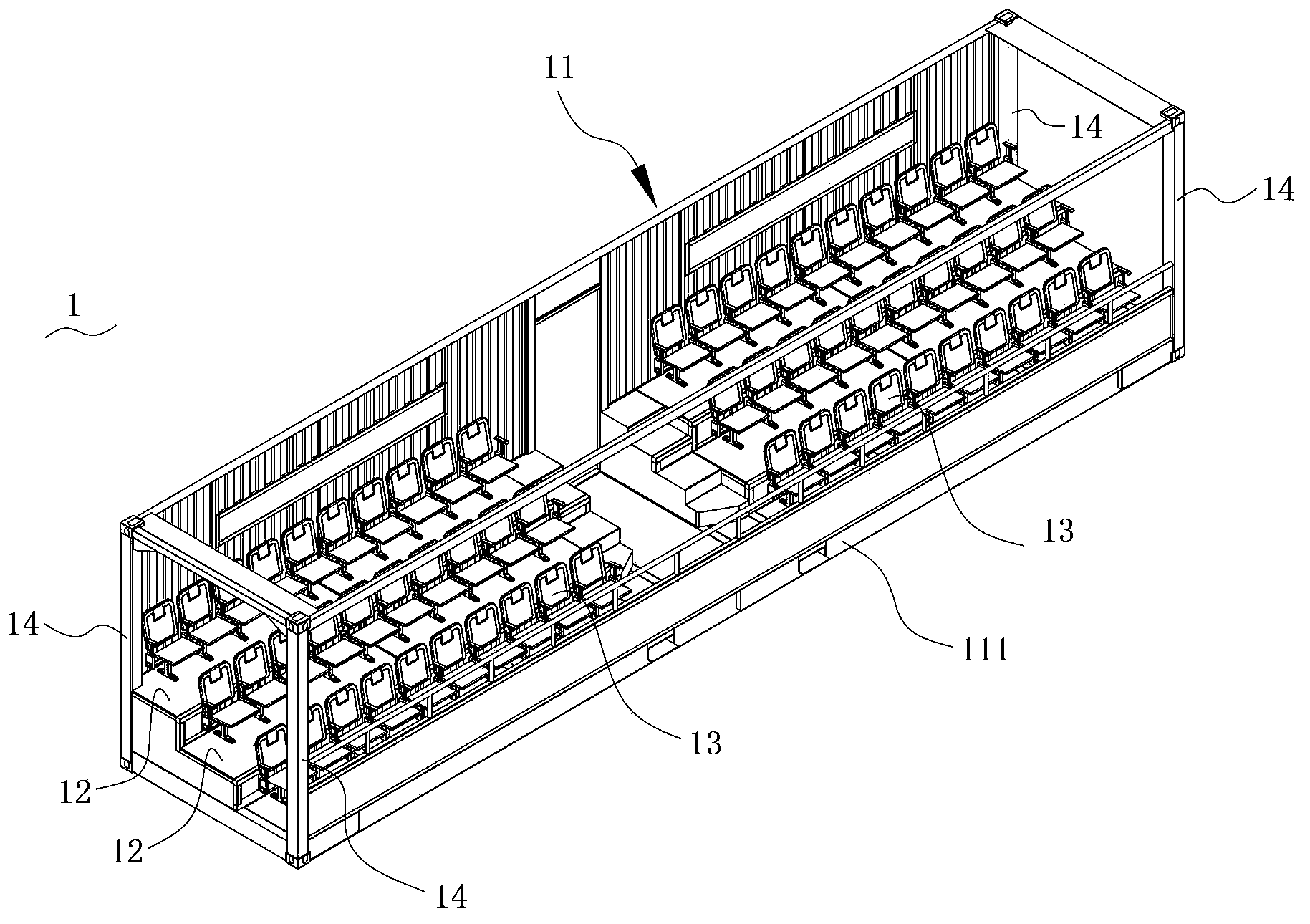

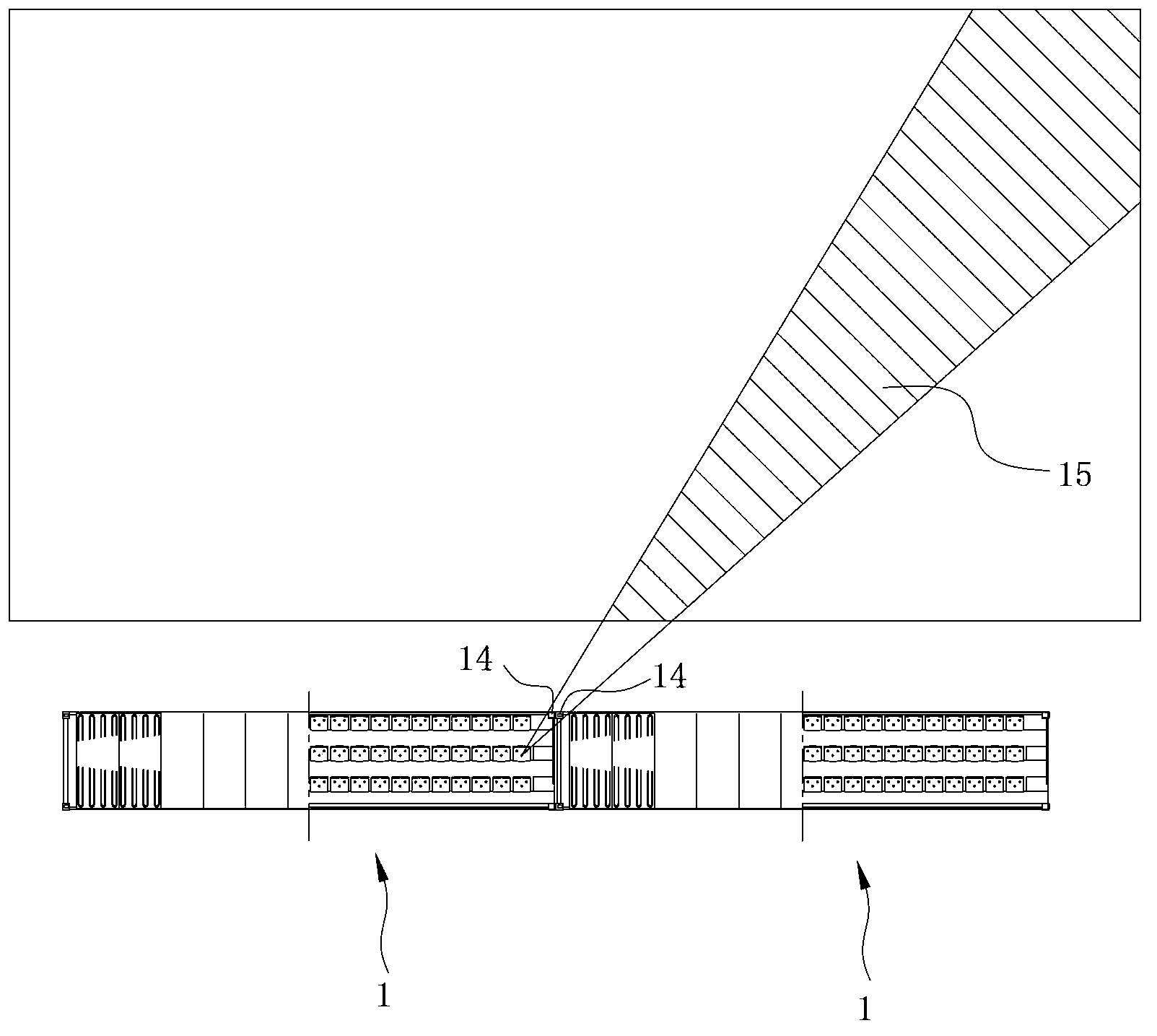

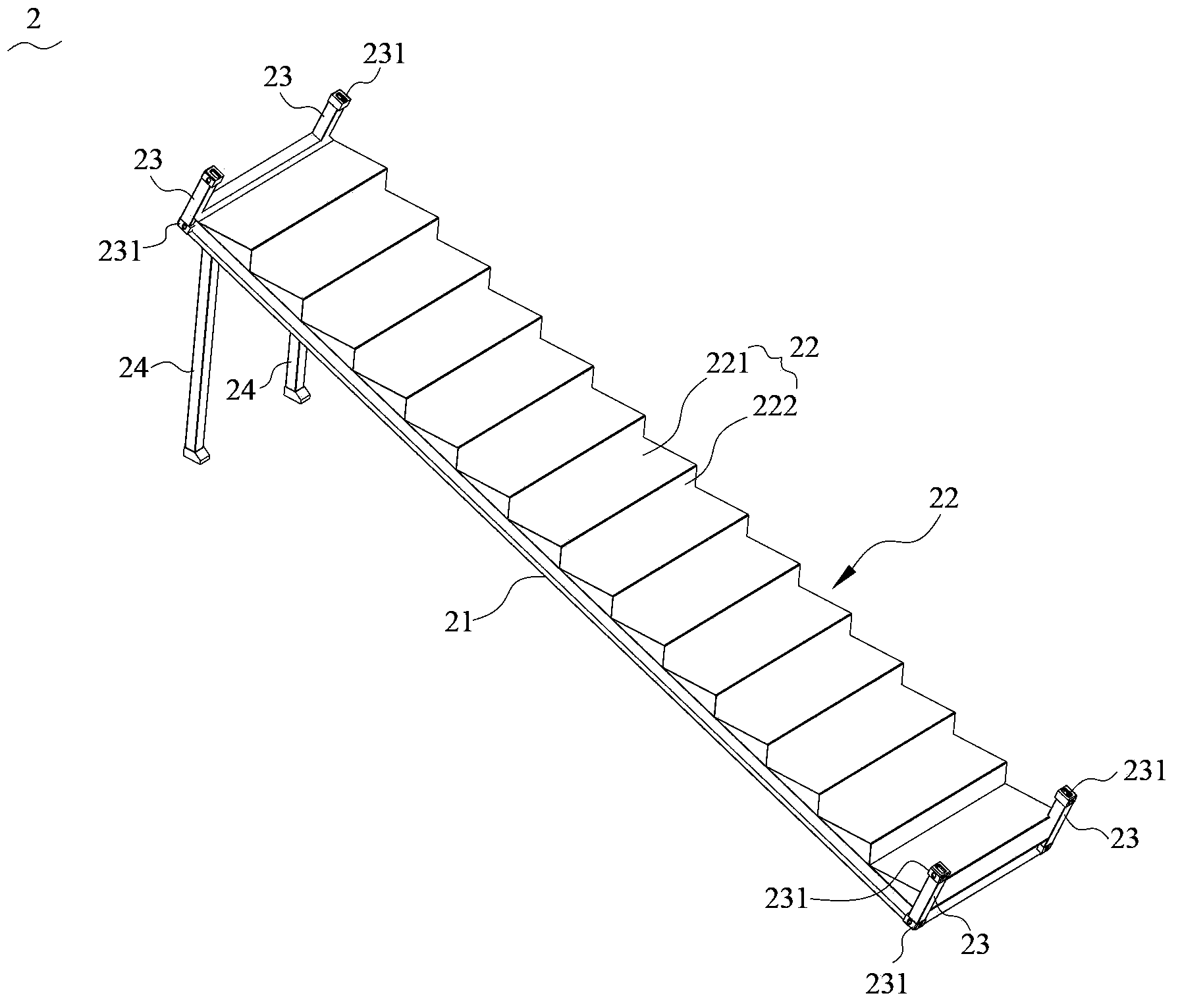

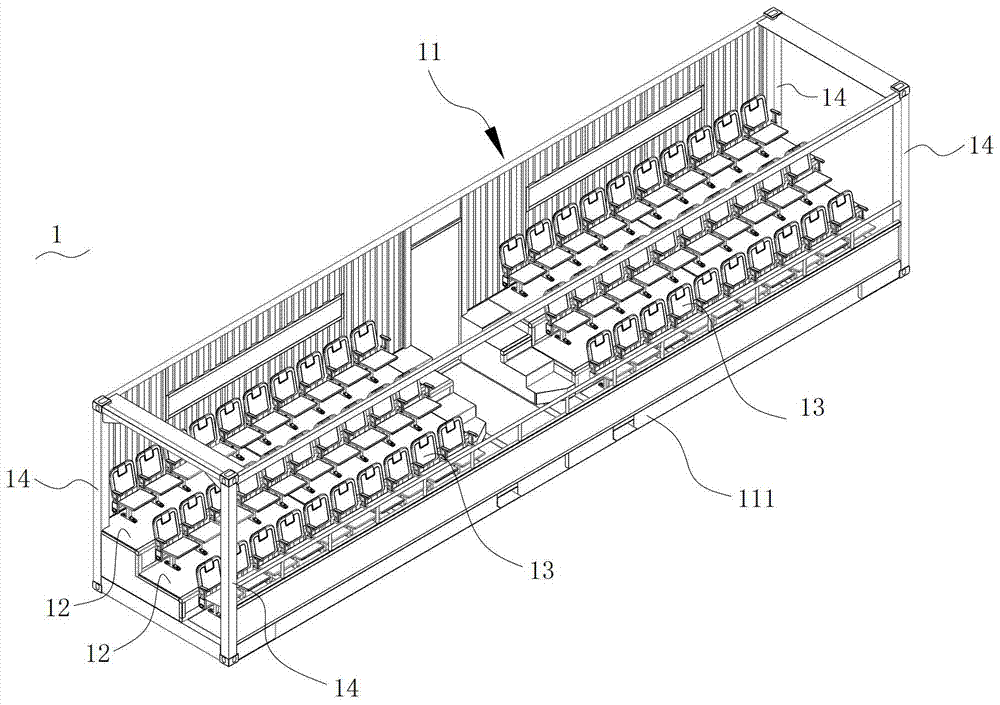

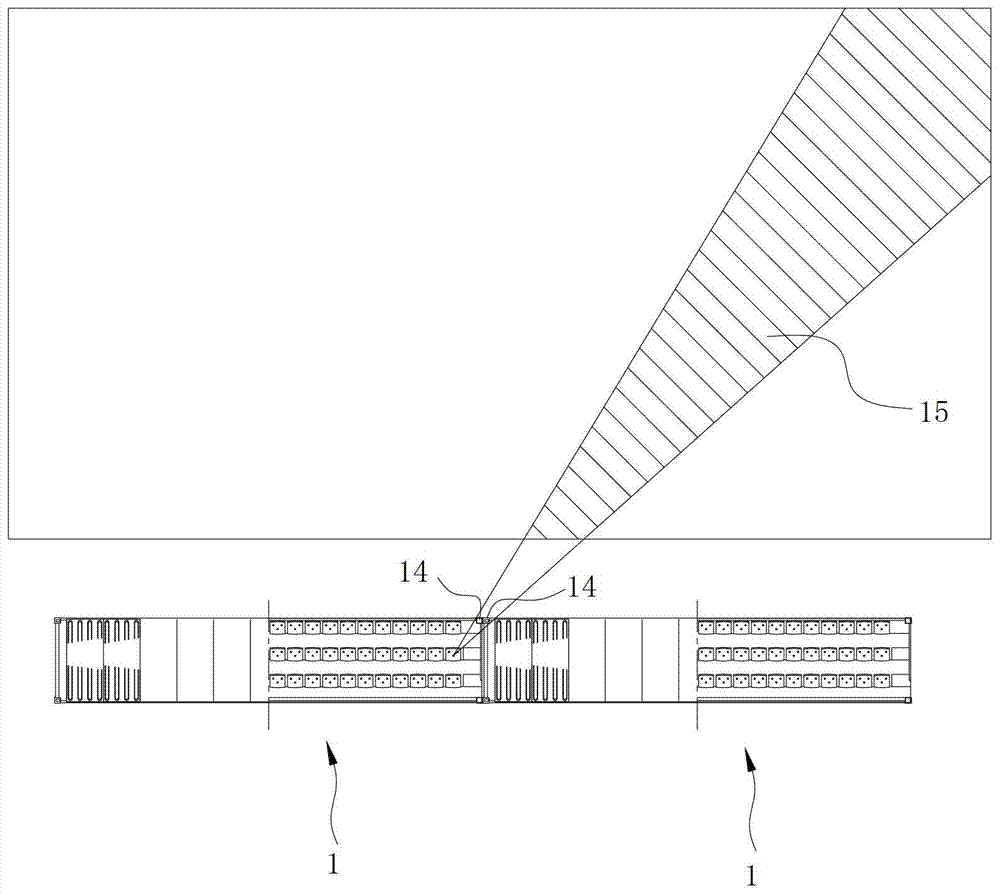

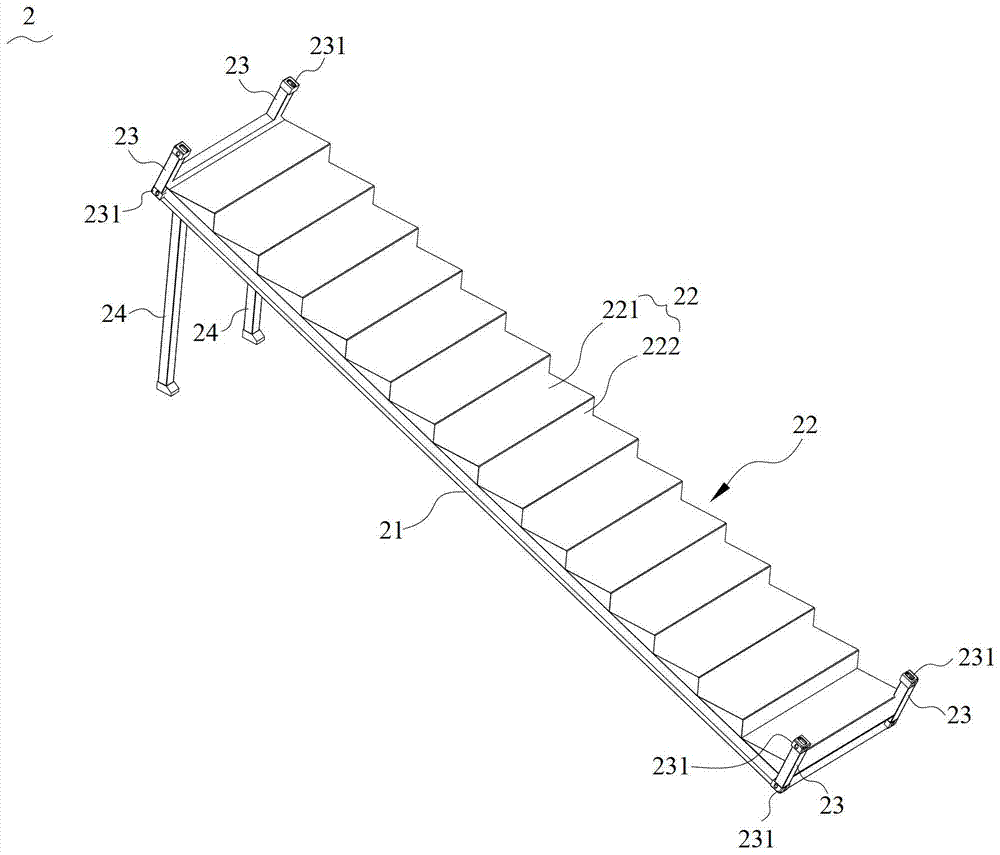

Modular stand unit, combined stand and construction method of combined stand

InactiveCN104110144AIncrease profitImprove comfortGrandstandsBuilding constructionsMechanical engineeringIndustrial engineering

Disclosed are a modular stand unit, a combined stand and a construction method of the combined stand. The modular stand unit comprises a strip underframe and multiple stair steps arranged on the upper surface of the underframe. The length-width ratio of the underframe is greater than or equal to two, all the stair steps extend along the width direction of the underframe and are arranged sequentially along the length direction of the underframe, and working surfaces of the steps are parallel to one another and incline relative to the underframe. The combined modular stand comprises at least two modular stand units, all the modular stand units are arranged together side by side along the length direction, two ends of each modular stand unit in the length direction are in an inclined state that one end is higher than the other end, and the inclination angle satisfies the condition that stairs on the modular stand units are parallel to the horizontal plane. The modular stand unit is simple in structure, high in space utilization rate, low in manufacturing cost and convenient to transport, the large combined stand can be constructed easily, sight block is avoided, and use requirements of the large-scale stand are met.

Owner:DALIAN CIMC SPECIAL LOGISTICS EQUIP CO LTD

An automatic and rapid test tube cap removal robot and cap removal method

ActiveCN106272368BReduce the numberTime-consuming and laborious to solveProgramme-controlled manipulatorGripping headsBlood collectionEngineering

The invention relates to an automatic fast test tube cover taking robot and a cover taking method. The robot comprises a base, wherein an X-axis mechanical arm for controlling movements in front and back directions is arranged on the base, a Z-axis mechanical arm for controlling up and down movements is vertically arranged on the X-axis mechanical arm, a Y-axis mechanical arm for controlling left and right movements is vertically arranged on the Z-axis mechanical arm, and a cover taking mechanical hand is arranged on the Y-axis mechanical arm; and a mechanical arm rotation driving mechanism is arranged at one end of the cover taking mechanical hand, and a cover taking mechanism is arranged at the other end. The automatic fast test tube cover taking robot can automatically complete a cover taking task of a blood collection test tube, can adapt to blood collection test tubes and test tube racks in different specifications, and can recover test tube covers.

Owner:CHINA THREE GORGES UNIV

Modular stand unit, combined stand and construction method thereof

InactiveCN104110144BIncrease the number of seatsIncrease profitBuilding constructionsGrandstandsModular unitEngineering

A modular stand unit, a combined stand and a construction method thereof. The modular stand unit includes: a strip-shaped underframe and multiple steps arranged on the upper surface of the underframe. The aspect ratio of the underframe is greater than or equal to two. Each ladder step extends along the width direction of the base frame and is arranged sequentially along the length direction of the base frame, and the working surfaces of each step are parallel to each other and inclined relative to the base frame. The combined modular stand includes: at least two modular stand units, each modular stand unit is arranged side by side in the length direction, and the two ends of the length direction of each modular stand unit are high at one end and low at the other end The tilting posture, the tilting angle is based on the fact that the stairs on the modular stand unit are parallel to the horizontal plane. The modularized stand unit of the present invention has the advantages of simple structure, high space utilization rate, low manufacturing cost, convenient transportation, and can be easily built into a large-scale combined stand without any line of sight blocking, meeting the use requirements of large-scale stands.

Owner:DALIAN CIMC SPECIAL LOGISTICS EQUIP CO LTD

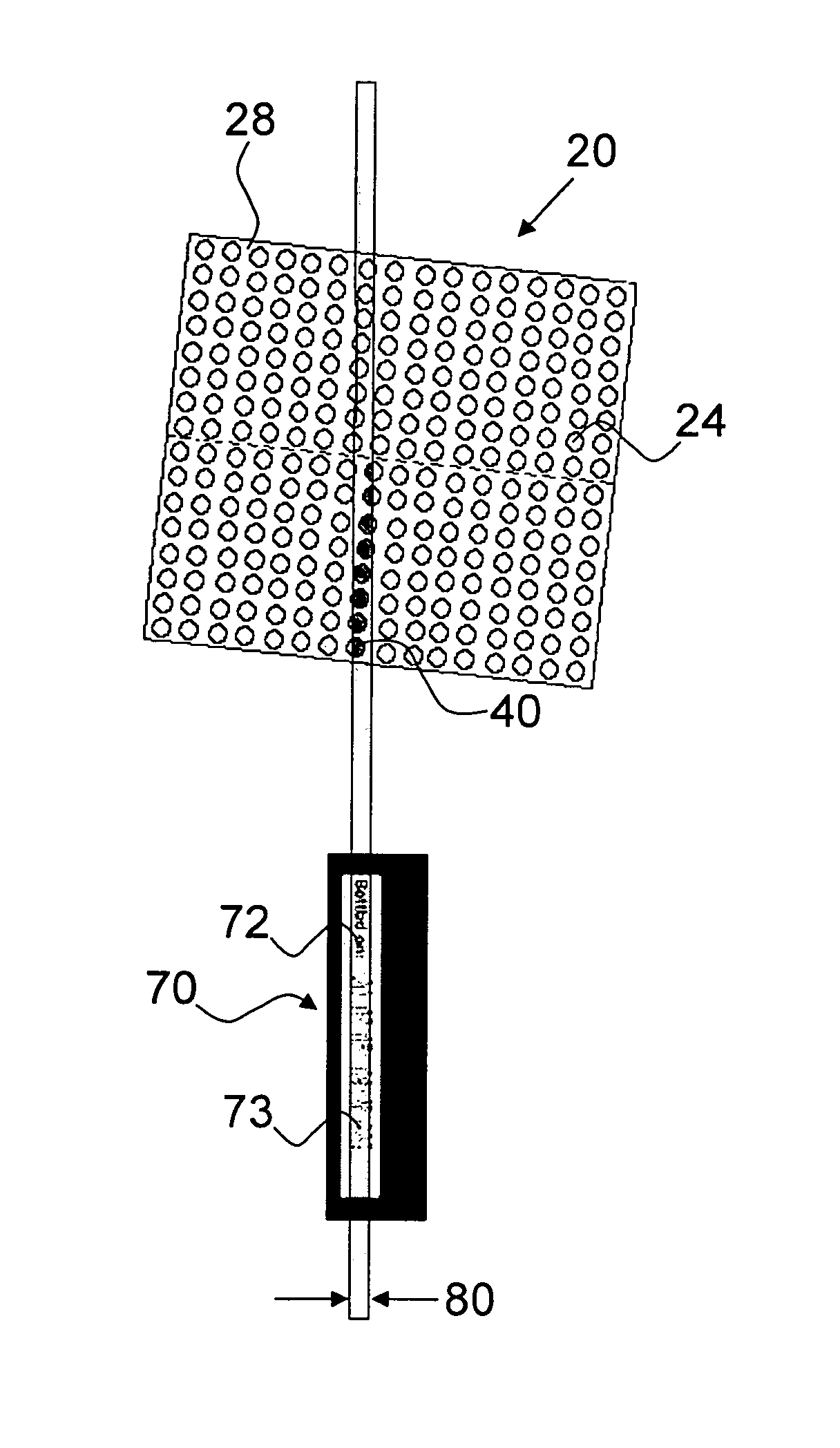

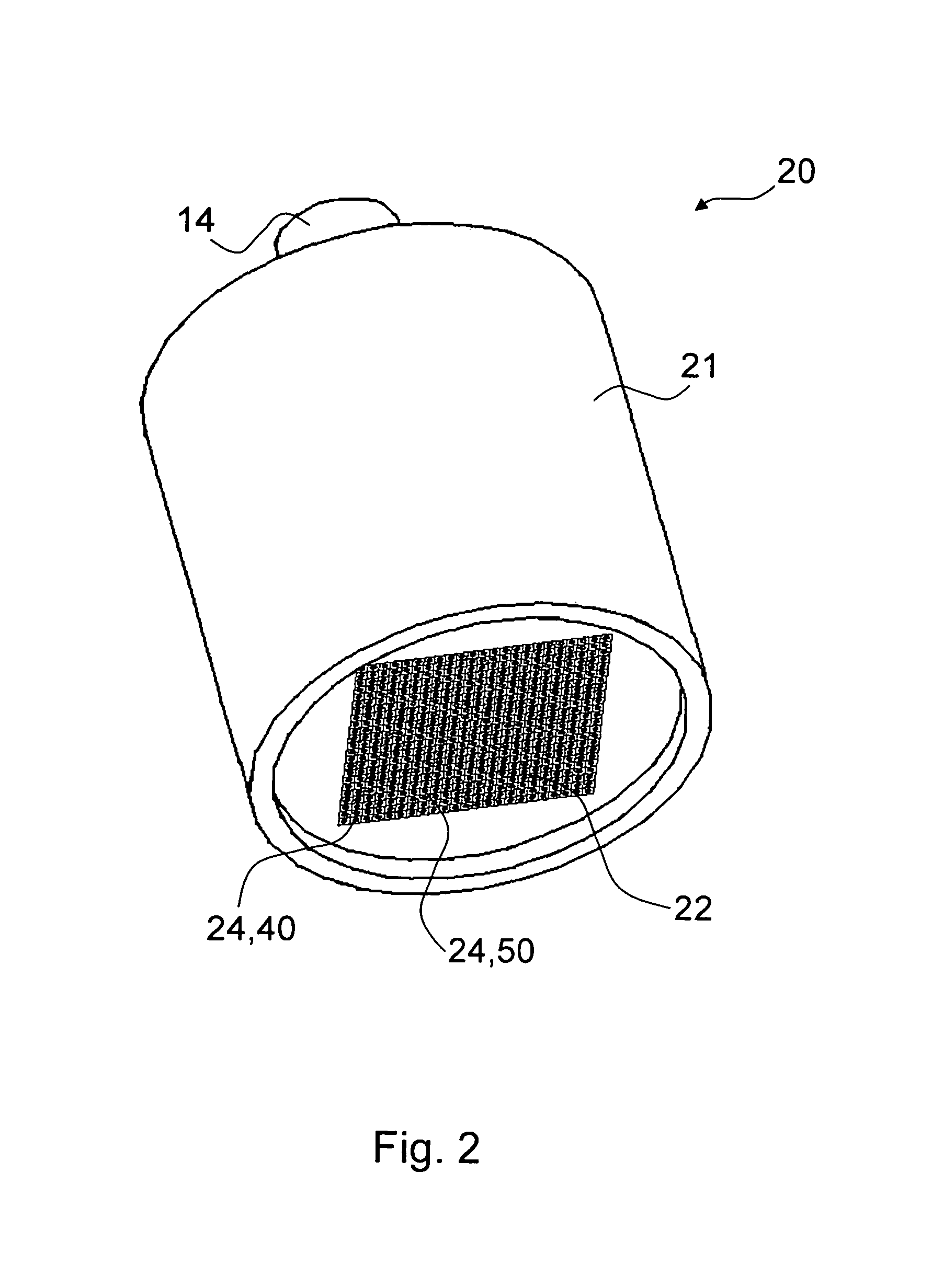

Method for applying a marking on an object and marking apparatus

ActiveUS9102168B2Improve marking qualityHigh resolutionRecording apparatusOther printing apparatusComputer science

Owner:ALLTEC ANGEWANDTE LASER LICHT TECH GMBH

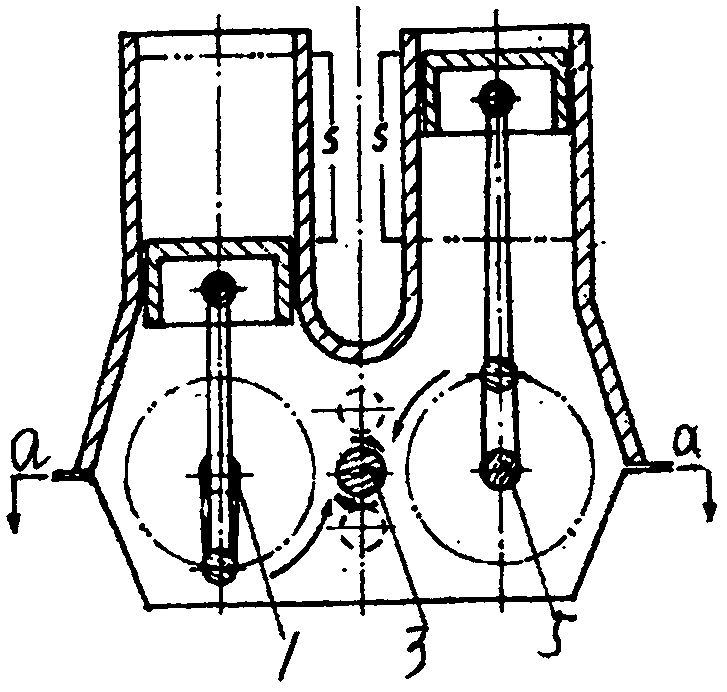

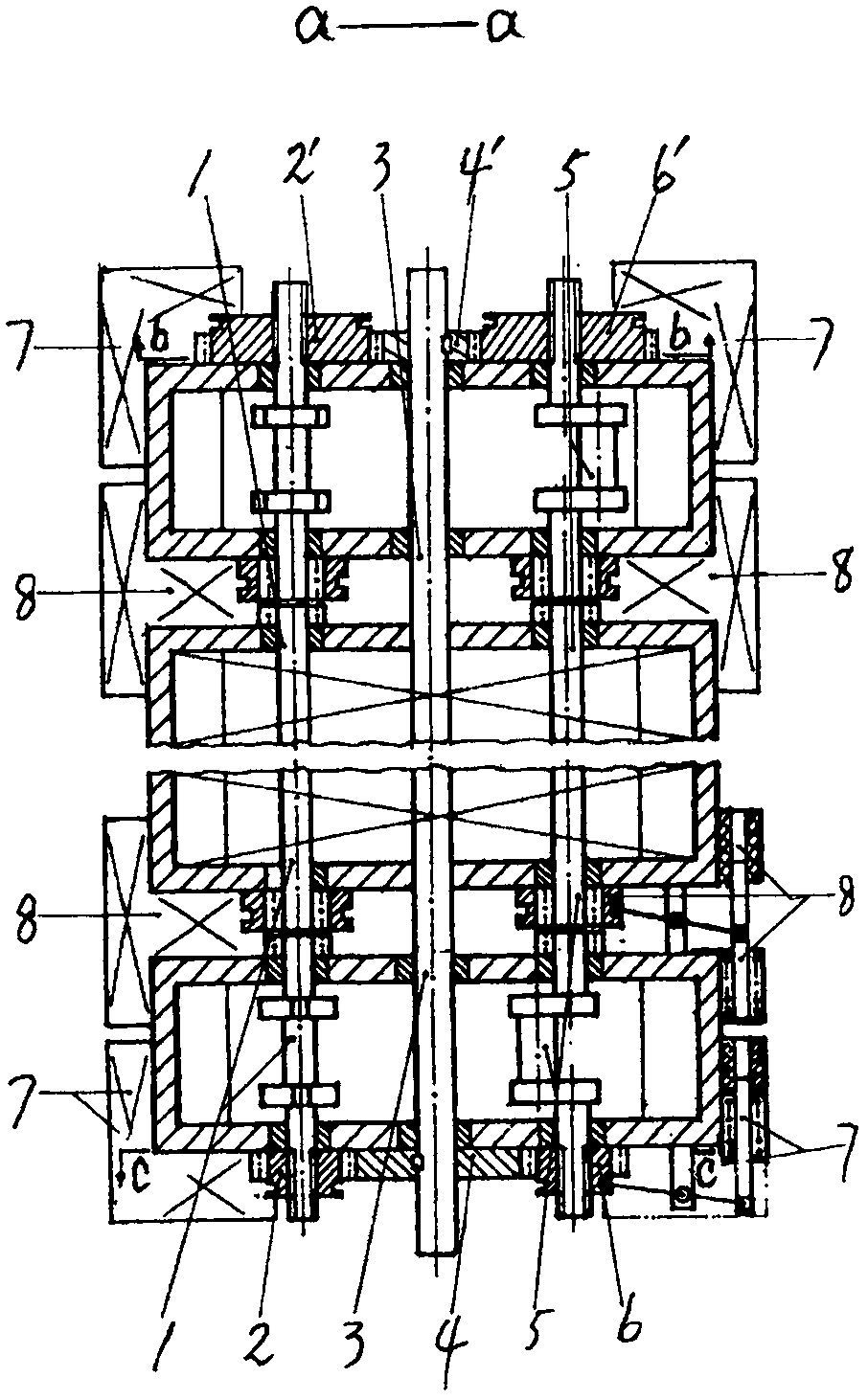

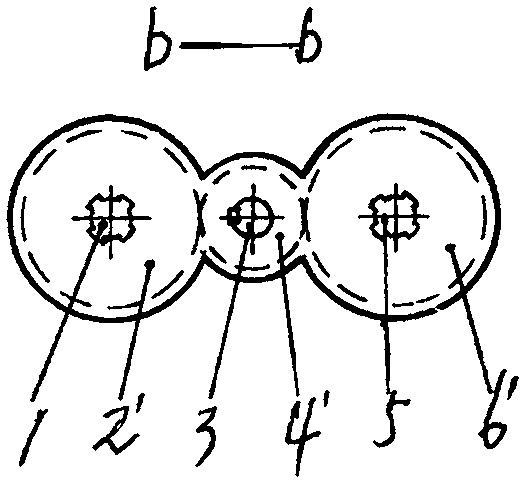

Piston reciprocating tank engine

ActiveCN109296455ASimple structureEasy to manufactureInternal combustion piston enginesGear wheelDiameter ratio

The invention discloses a piston reciprocating tank engine. The piston reciprocating tank engine is formed by connecting a plurality of rows of U-shaped cylinders in series, wherein each U-shaped cylinder is formed by connecting two L-shaped cylinders perpendicularly and in parallel. The engine rated speed output by an output shaft (3) to the outside can be changed by changing the reference diameter ratio of crank gears (2 and 6) of each gear set to an output shaft gear (4). Clutch mechanisms (7) are arranged on the outer sides of the crank gears of the front and back gear sets, and clutch mechanisms (8) are arranged between axially adjacent crank sections, and a working cylinder can be stopped or linked according to the requirement of a working condition. Therefore, the advantages that the L-shaped engine cylinders and cranks are simple in structure, easy to manufacture and maintain, low in manufacturing cost, good in stability performance and high in thermal efficiency are achieved,and the advantages that a V-shaped engine body is short and convenient to arrange are also achieved; particularly, the engine rated speed, the number of the cylinders and the power can be directly adjusted, a deceleration or a speed change gear is omitted, and starting is convenient; and when a certain working cylinder breaks down or is damaged, the working cylinder can be disengaged and stops running while the engine can still continue to operate.

Owner:肖光宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com