Modular stand unit, combined stand and construction method thereof

A modular and combined technology, applied in the direction of podium, building, building structure, etc., can solve the problems that it is difficult to meet the requirements of large venues, affect the mood of the audience watching the performance, and increase the visual distance of the auditorium. Convenience, reduced transportation costs, and the effect of increasing the number of seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

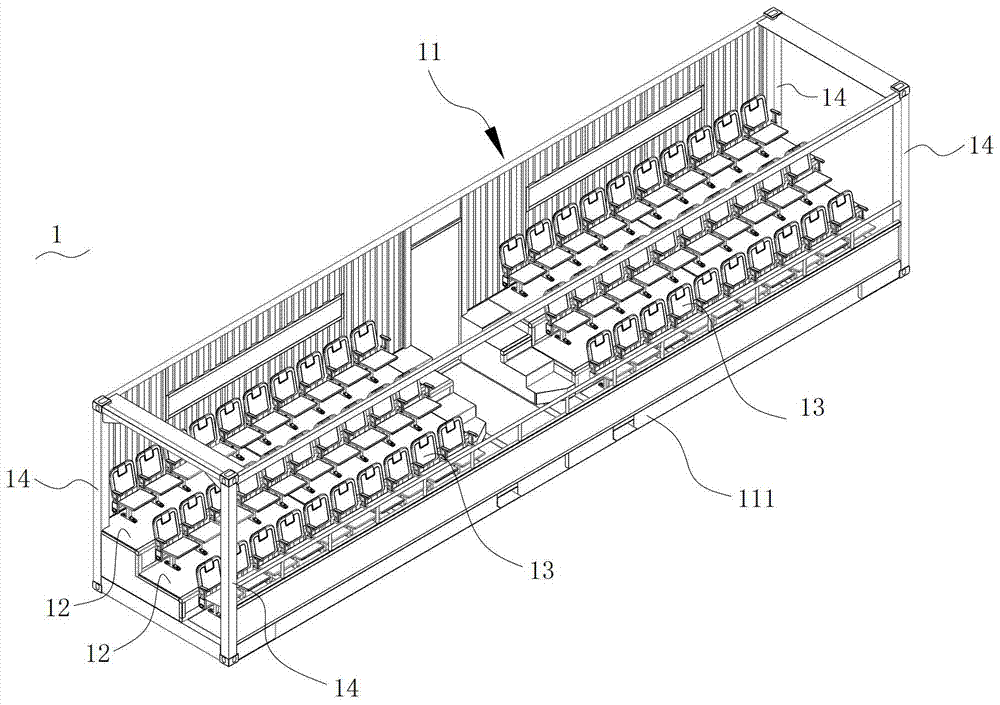

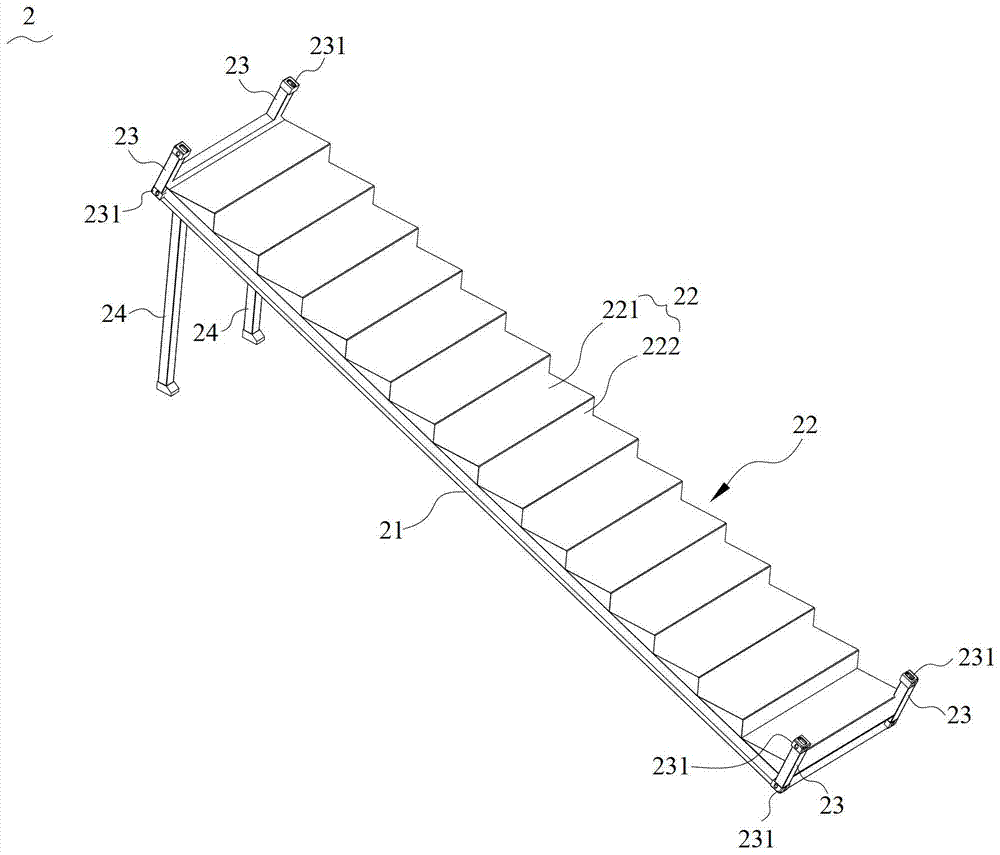

[0044] Modular Stand Unit

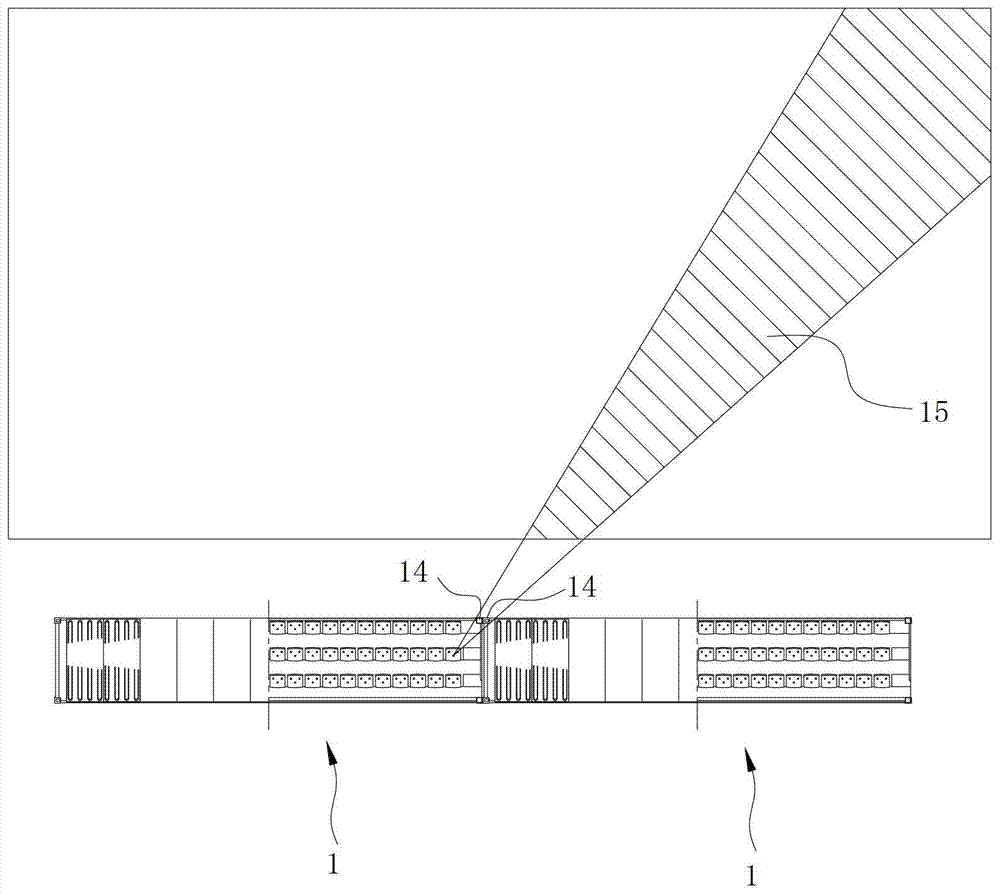

[0045] The modular stand unit of the present invention is roughly divided into three types according to the setting of the seats, one image 3 is the seatless modular grandstand unit shown, a Figure 4 Modular grandstand unit with partial seating shown, there is also a version for Figure 5 Full seat modular grandstand unit shown.

[0046] refer to image 3 , the seatless modular stand unit 2 includes: a chassis 21 and a multi-ladder step 22 arranged on the upper surface of the chassis 21, a plurality of supports 23 arranged on the chassis 21, and a pair of One end and a leg 24 that can be folded relative to the chassis 21 .

[0047] refer to Figure 4 In addition to the underframe 21, steps 22, supports 23 and leg 24 structures of the modular stand unit 2 without seats, the modular stand unit 2a of this part of the seats also includes a plurality of Seat 25 (in other embodiments, seat 25 also can be directly arranged on the chassis 21), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com