Riverway sludge self-heat preserving sintering porous brick and production method thereof

A technology of river silt and self-insulation, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of poor insulation performance, unrealistic silt, low content of river sludge, etc., achieve good self-insulation performance, and save land resources , the effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

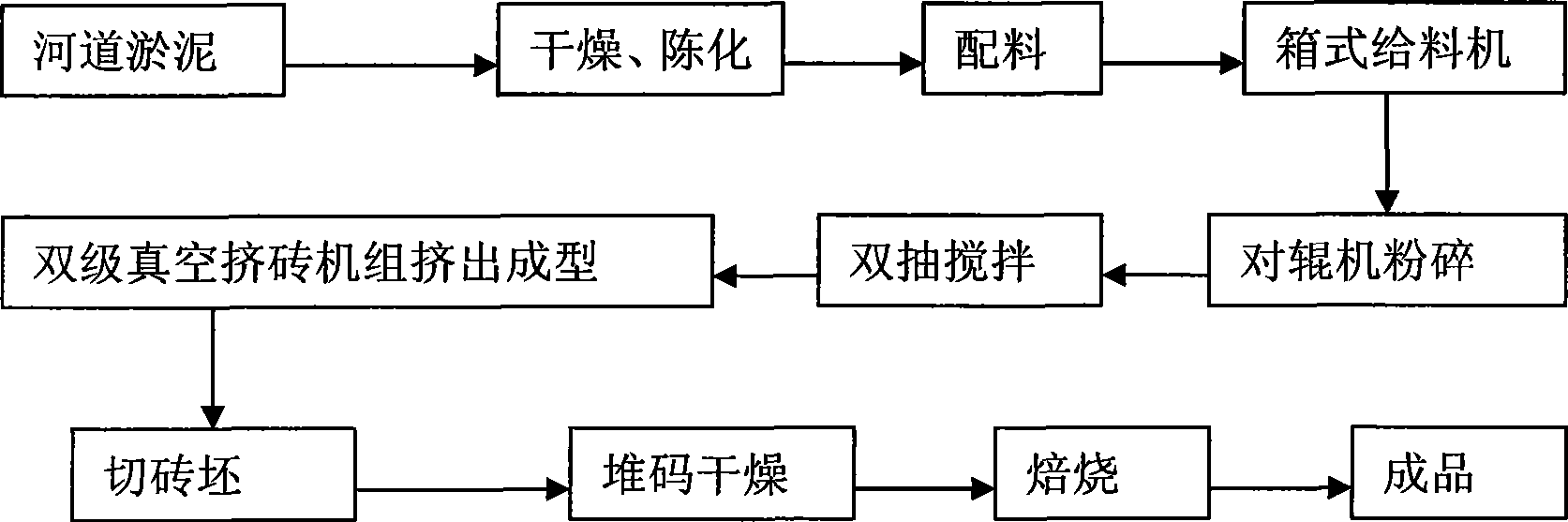

[0025] The river silt sintered porous brick is made by mixing river silt, river silt dry powder, cinder, and microporous forming agent, making billets, drying and firing. The mass ratio of river silt, river silt dry powder, coal slag, and wood chip microporous forming agent is 50%: 29%: 20%: 1%. The preparation process is as figure 1 As shown, mix the aged and dried river silt, cinder, and sawdust, add appropriate amount of water, fully stir, roll, and vacuum-extrude the adobe. The rectangular through holes on the adobe are longitudinally arranged in an orderly manner. The through-holes in adjacent columns are staggered from each other, and the width of the hole is about 15mm; the thickness of the hole wall is 15mm. After sintering at a high temperature of 950°C, a 90×115×240mm self-insulating sintered brick is made, and its thermal conductivity is 0.28W / (m K), and the heat transfer coefficient of a 240mm wall made of self-insulating bricks is 1.34W / (m 2 · K).

Embodiment 2

[0027] The river silt sintered porous brick is made by mixing river silt, river silt dry powder, cinder, and microporous forming agent, making billets, drying and firing. The mass ratio of river silt, river silt dry powder, coal slag, and straw microporous forming agent is 50%: 28%: 20%: 2%. Mix the aged and dried river silt, cinder, and microporous forming agent, add appropriate amount of water, fully stir, roll, and vacuum-extrude the adobe. The rectangular through holes on the adobe are longitudinally and orderly arranged. Adjacent through-holes are staggered from each other, with a width of about 22mm and a wall thickness of 15mm. After sintering at a high temperature of 1000°C, a 90×115×240mm self-insulating sintered brick is made, and its thermal conductivity is 0.24W / (m K), and the heat transfer coefficient of a 240mm wall made of self-insulating bricks is 1.01W / (m 2 · K).

Embodiment example 3

[0029] The river silt sintered porous brick is made by mixing river silt, river silt dry powder, cinder and microporous forming agent, making billets, drying and firing, and the mass ratio of river silt, river silt dry powder, coal slag and microporous forming agent is 45 %: 29%: 22%: 4%. Mix the aged and dried river silt, cinder, and microporous forming agent, add appropriate amount of water, fully stir, roll, and vacuum-extrude the adobe. The rectangular through holes on the adobe are longitudinally and orderly arranged. Adjacent through-holes are staggered from each other, and the width of the hole is about 20mm; the thickness of the hole wall is 12mm. Sintered at a high temperature of 1050°C to make 90×115×240mm self-insulating sintered bricks, the thermal conductivity is 0.20W / (m K), and the heat transfer coefficient of a 240mm wall made of self-insulating bricks is 0.85W / (m 2 · K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com