Patents

Literature

32results about How to "Guaranteed design strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

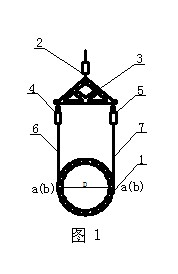

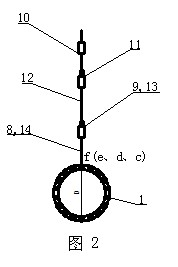

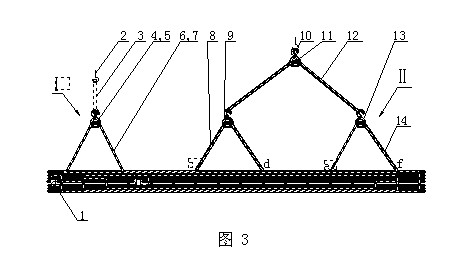

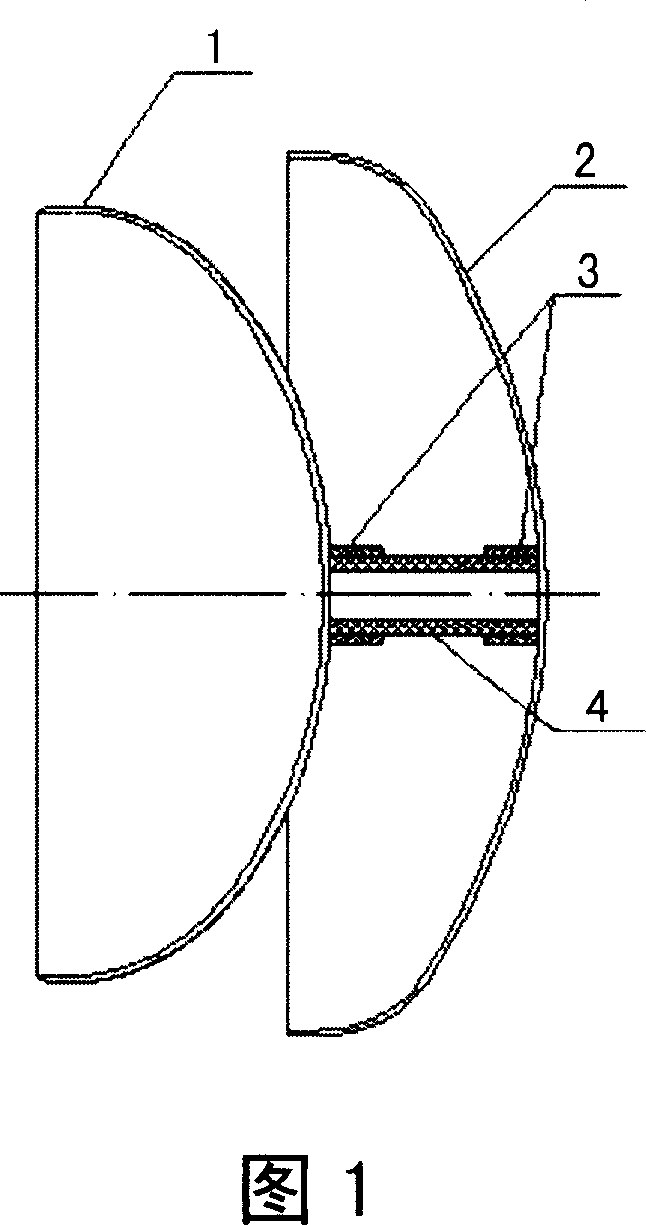

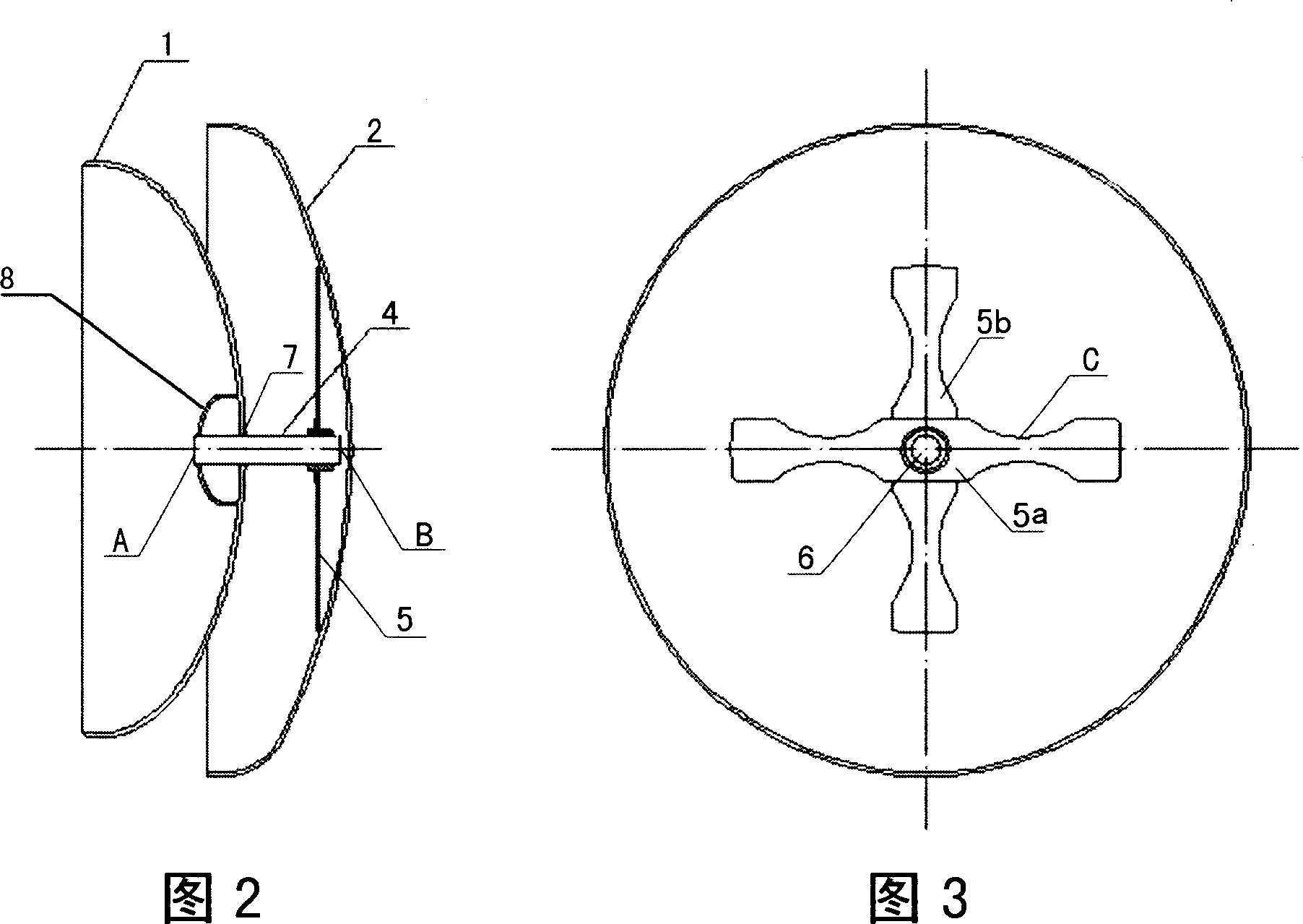

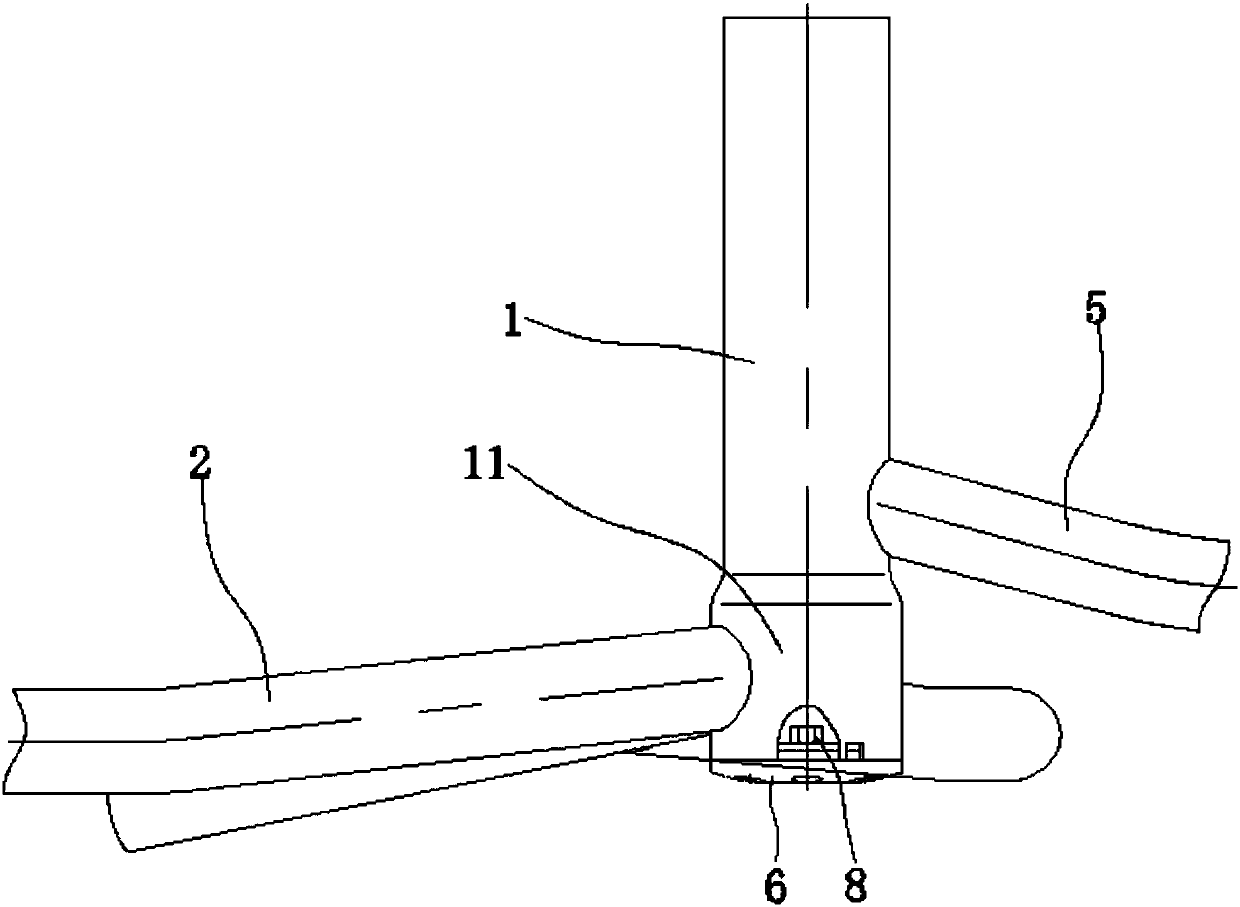

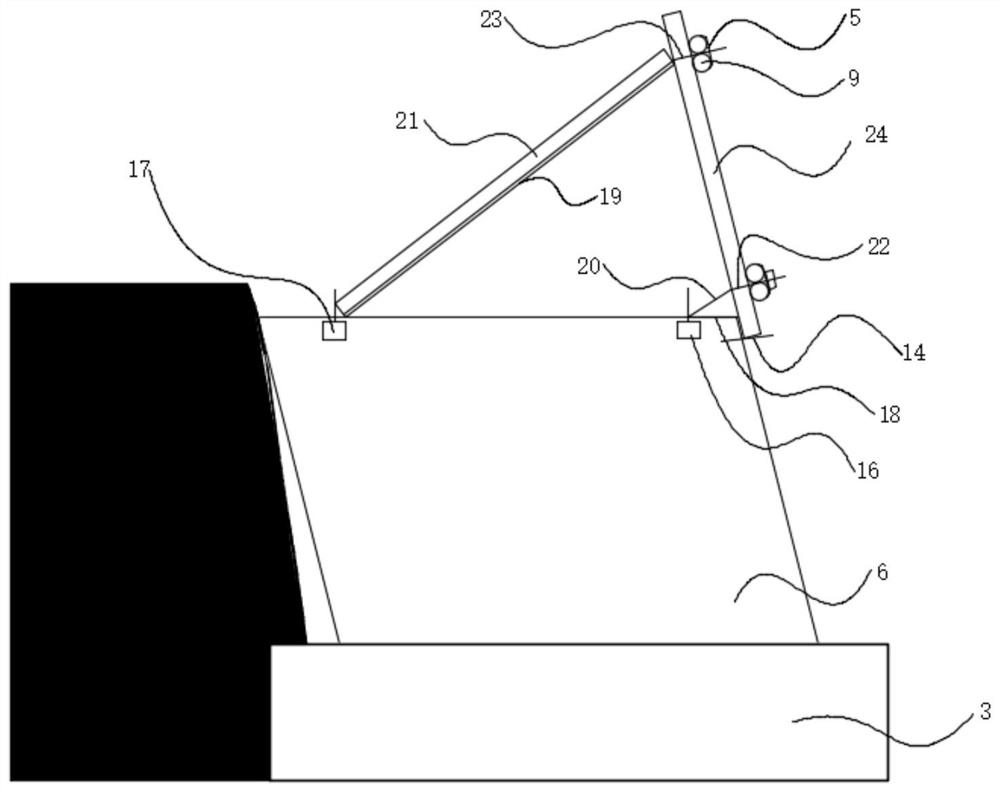

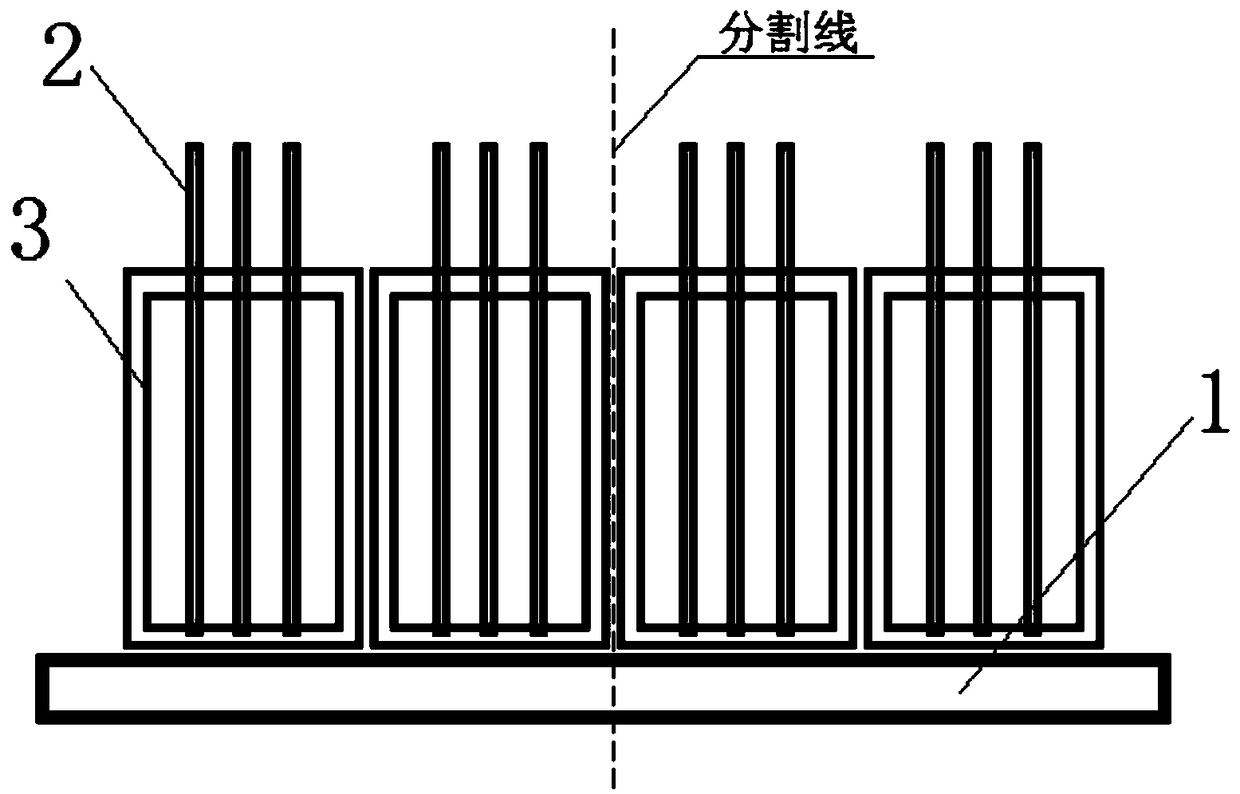

Hoisting method of steel reinforcement cage

ActiveCN102070071AAvoid deformationGuaranteed design strengthLoad-engaging elementsBulkheads/pilesRebarMechanical engineering

The invention relates to a hoisting method of a steel reinforcement cage. The method comprises the following steps of: 1) preparing for hoisting, namely preparing a hoisting machine which is provided with a main hoisting hook and an auxiliary hoisting hook and manufacturing a main hoisting component, an auxiliary hoisting component and the like; 2) setting hoisting points, namely setting main hoisting points at the two ends of the horizontal diameter of a horizontal steel reinforcement cage and setting an auxiliary hoisting point on a steel reinforcement cage at the upper end of the vertical diameter of the horizontal steel reinforcement cage, and connecting the main and auxiliary hoisting components with corresponding main and auxiliary hoisting points; and 3) hoisting, namely hoisting the main and auxiliary hoisting hooks at the same time, always keeping the distance of between 0.5 and 1.0 meter between the steel reinforcement cage and the ground by using the auxiliary hoisting hookafter the steel reinforcement cage leaves the ground, continually hoisting the main hoisting hook upwards, gradually erecting the steel reinforcement cage until the steel reinforcement cage is vertical to the ground, rotating the hoisting machine, aligning the steel reinforcement cage with a drill hole and putting the steel reinforcement cage into the drill hole. The hoisting method has the advantages that: the steel reinforcement cage is not deformed easily, reinforcement is not required during hoisting and working efficiency is high; construction cost is low; and design intensity of the steel reinforcement cage is ensured, potential safety hazard is not left easily and construction quality is ensured.

Owner:CHEM IND GEOTECHN ENG

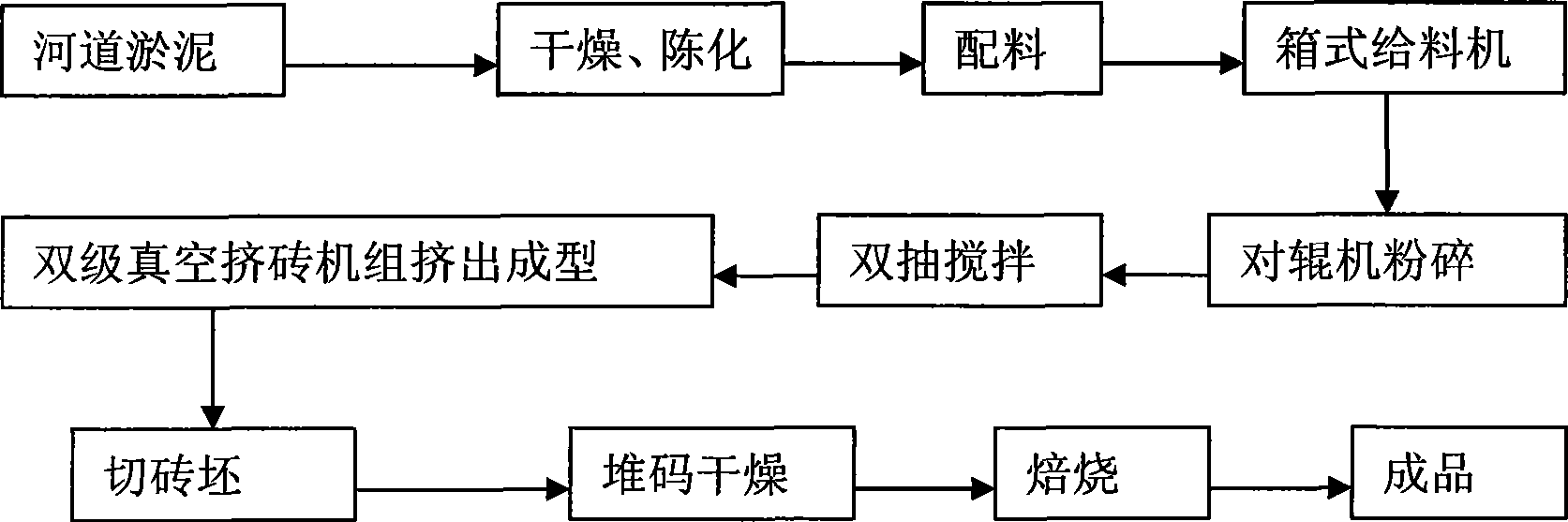

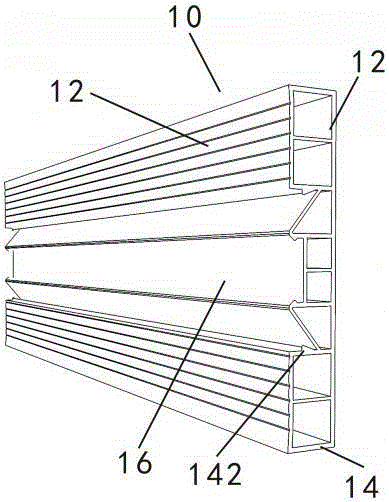

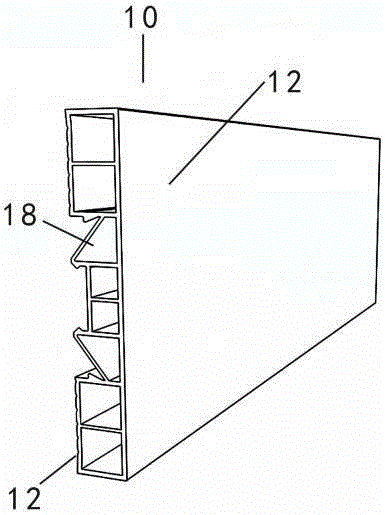

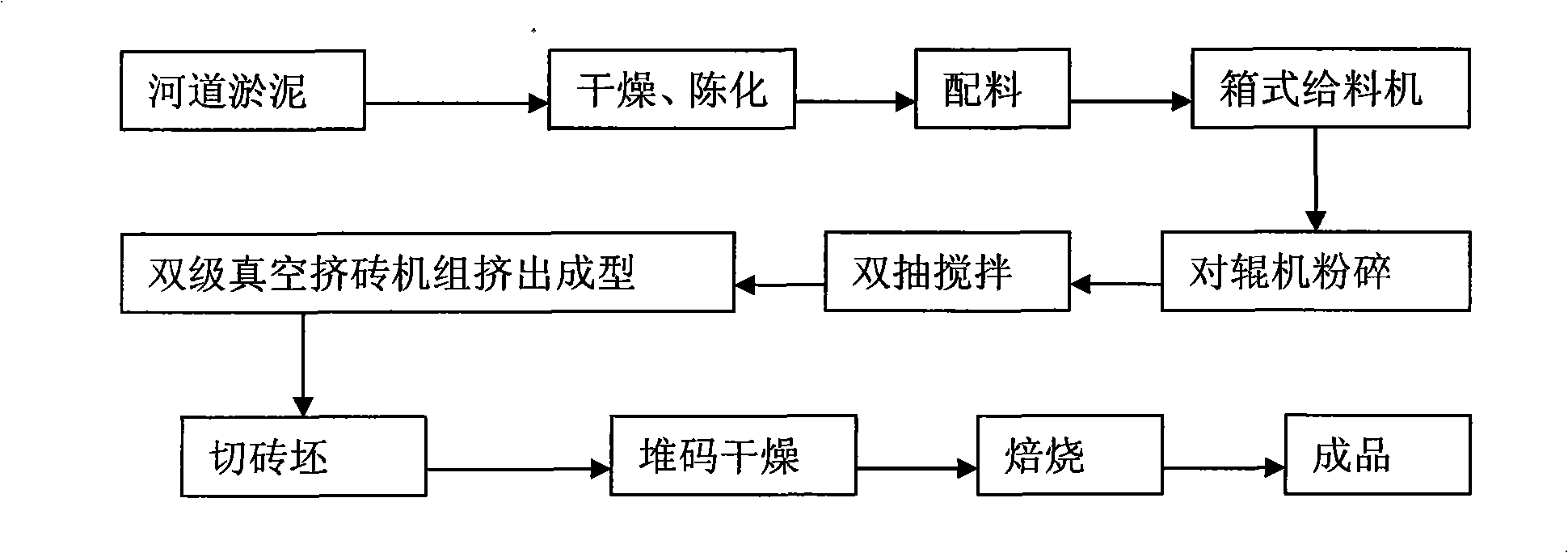

Riverway sludge self-heat preserving sintering porous brick and production method thereof

The invention relates to a heat-insulating wall body material for a building, and discloses a riverway sludge self heat-insulating sintered porous brick and preparation thereof. The riverway sludge self heat-insulating sintered porous brick comprises the following raw materials in percentage by mass: 30 to 50 percent of riverway sludge, 20 to 40 percent of riverway sludge dry powder, 20 to 30 percent of cinder and 1 to 8 percent of microporous forming materials. The riverway sludge self heat-insulating sintered porous brick has superior self heat-insulating property, and can realize building energy conservation by more than 50 percent in the aspect of enclosure of a common building structure.

Owner:上海鑫晶山淤泥研发有限公司

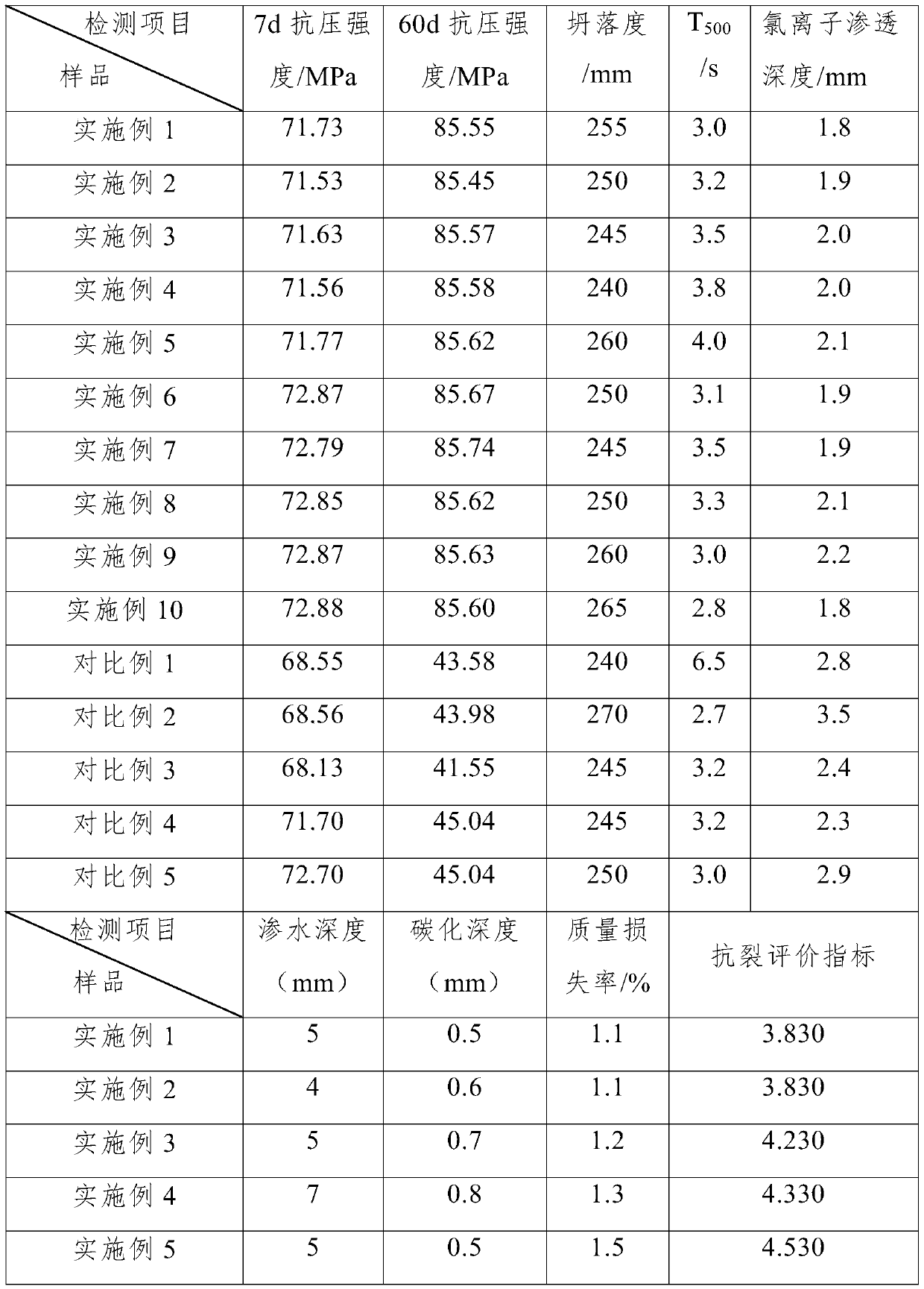

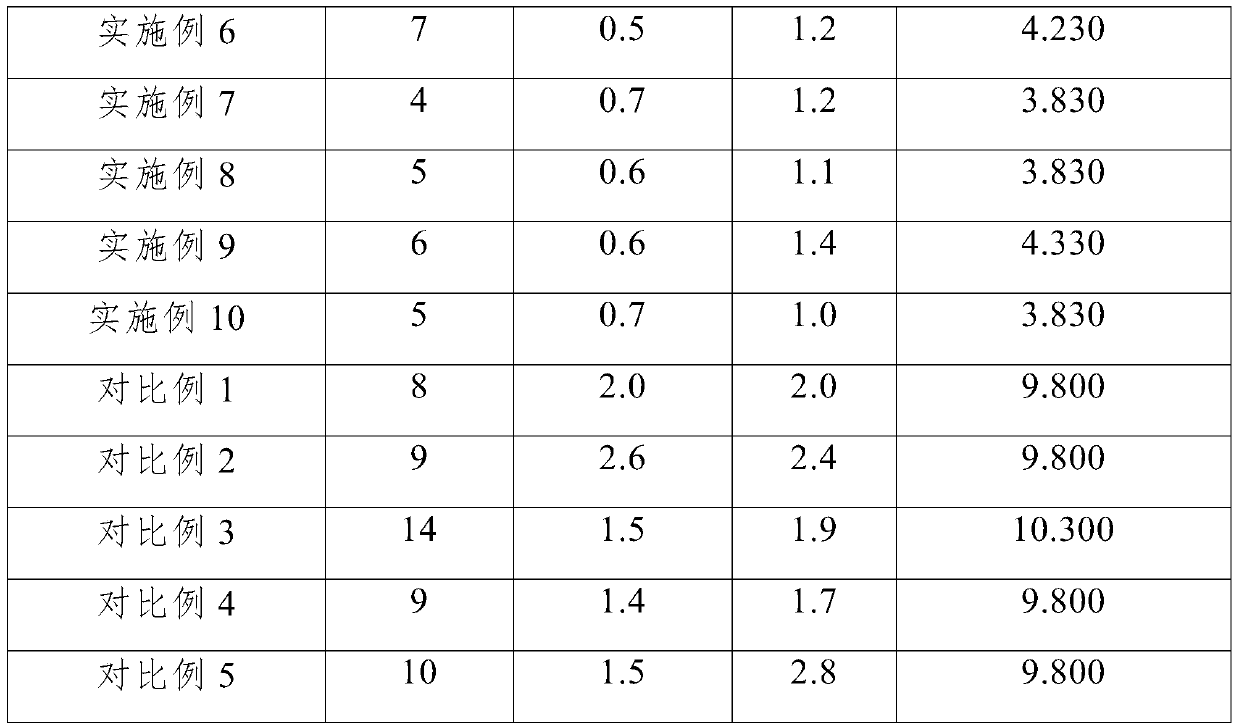

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Concrete for plant growth

The invention relates to a vegetation-growing concrete which is produced by stirring with water, concrete, coarse aggregate and addition agents in the proportion of 1:2.8-3.3:12-18:0.01-0.03, the gauge number of the concrete is more than 425 #, and the grain size of the coarse aggregate is between 2cm to 4cm. Using the new proportioning of concrete composition materials and the new construction method to produce the big pore in the concrete, meanwhile, neutralizing the strong alkalinity of the concrete by the addition agents and using the exclusive seeds of plants to make sure the plants growing in the concrete or across the concrete.

Owner:毛鑫

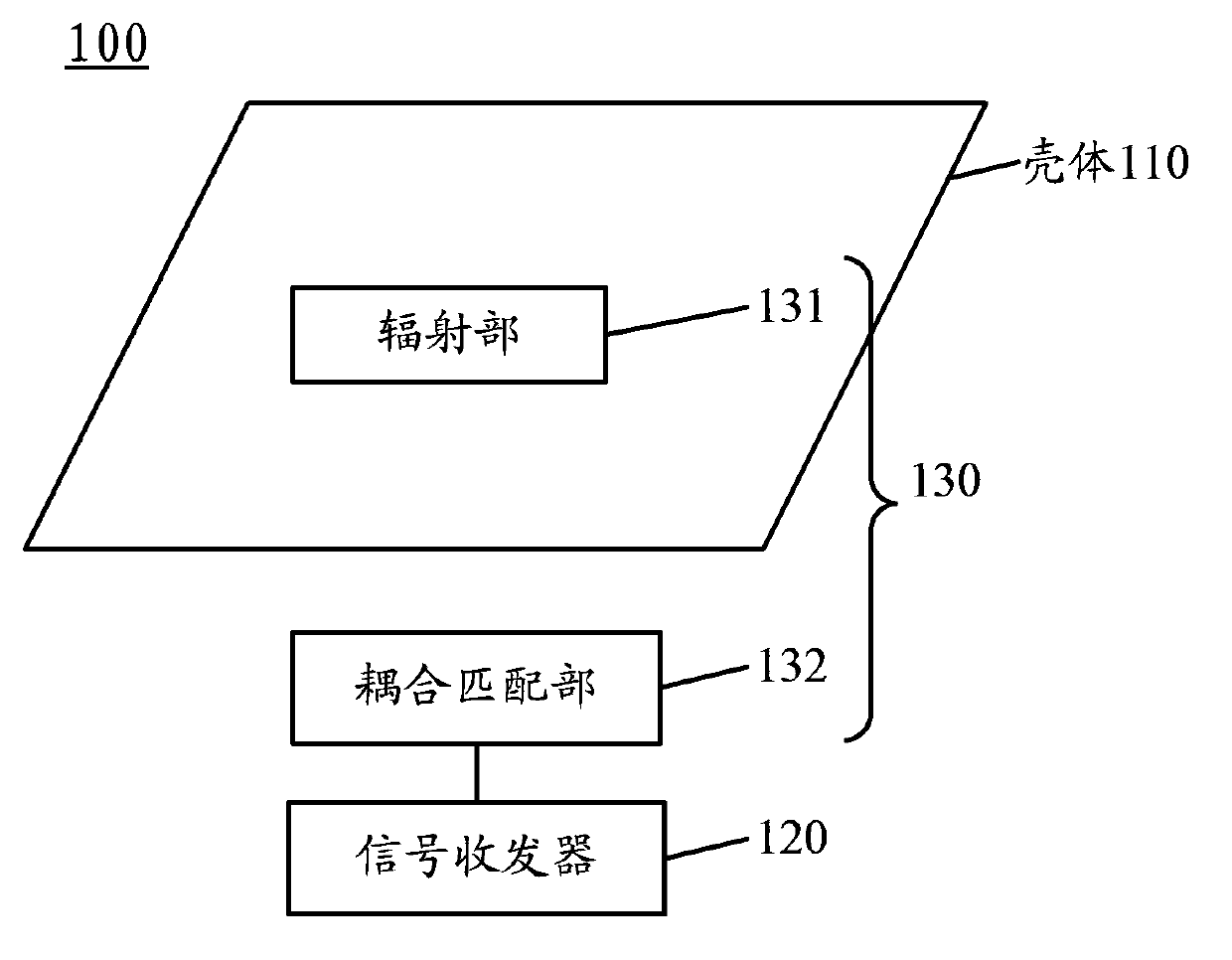

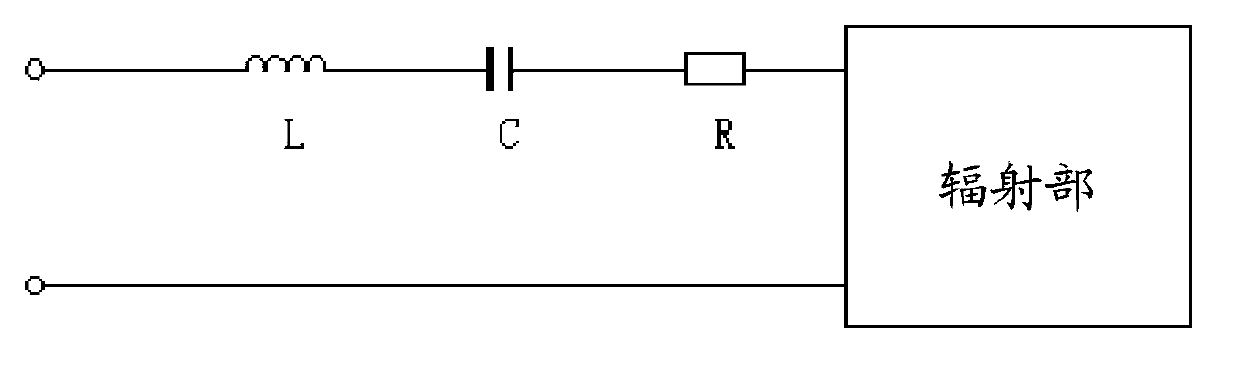

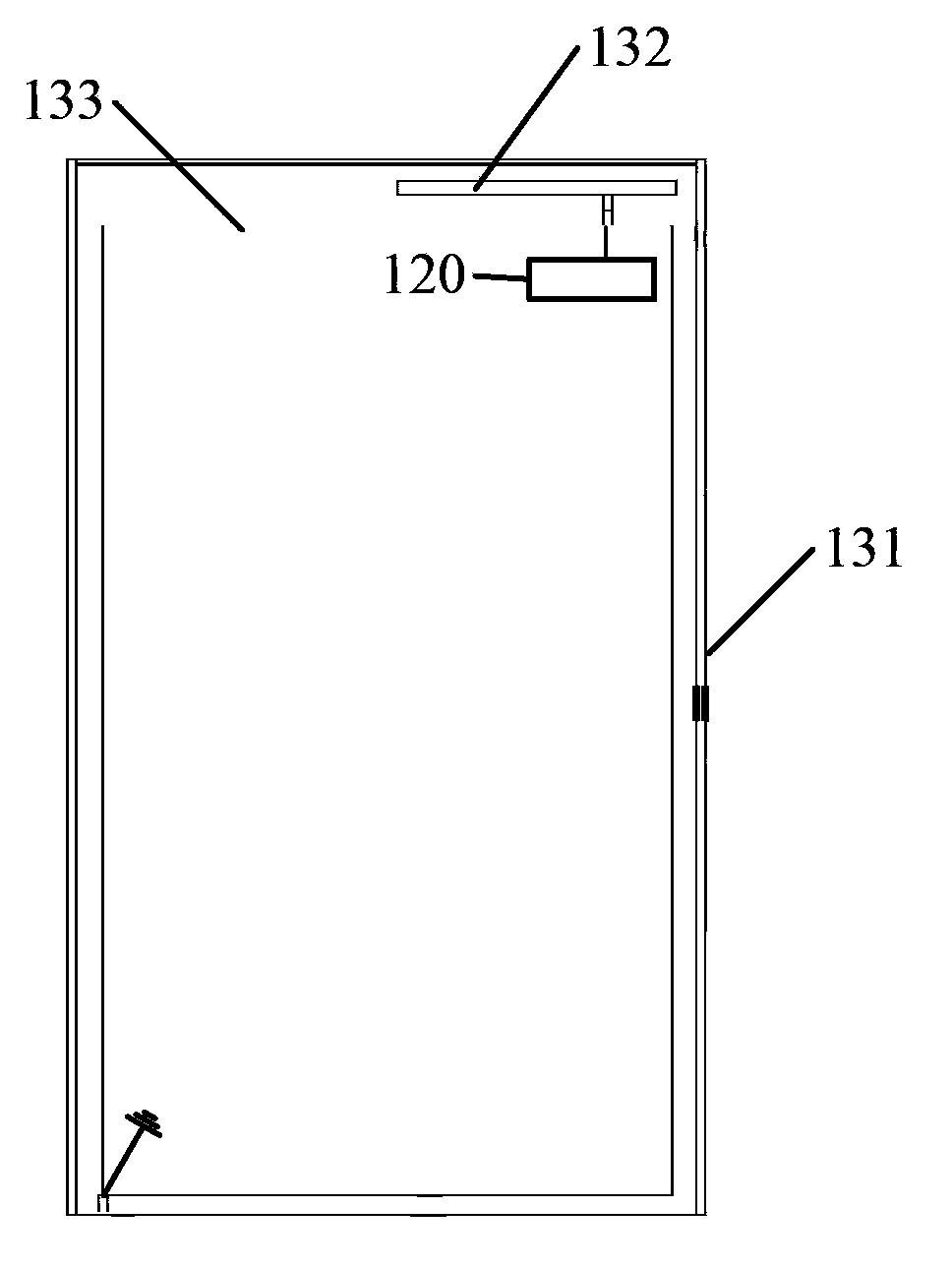

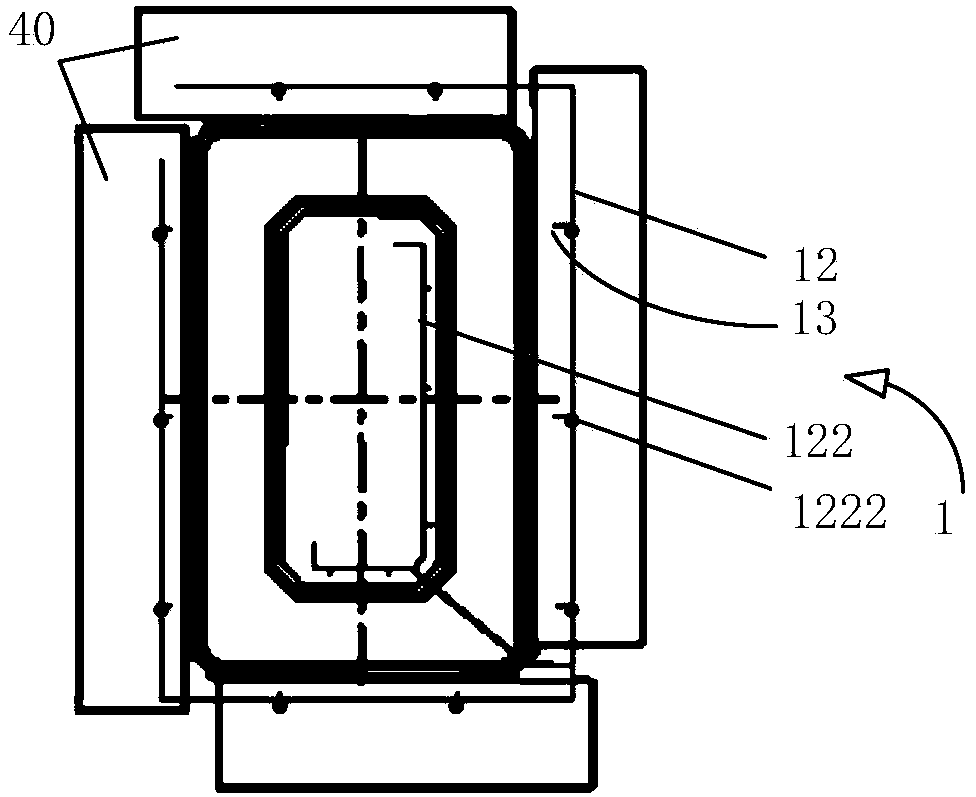

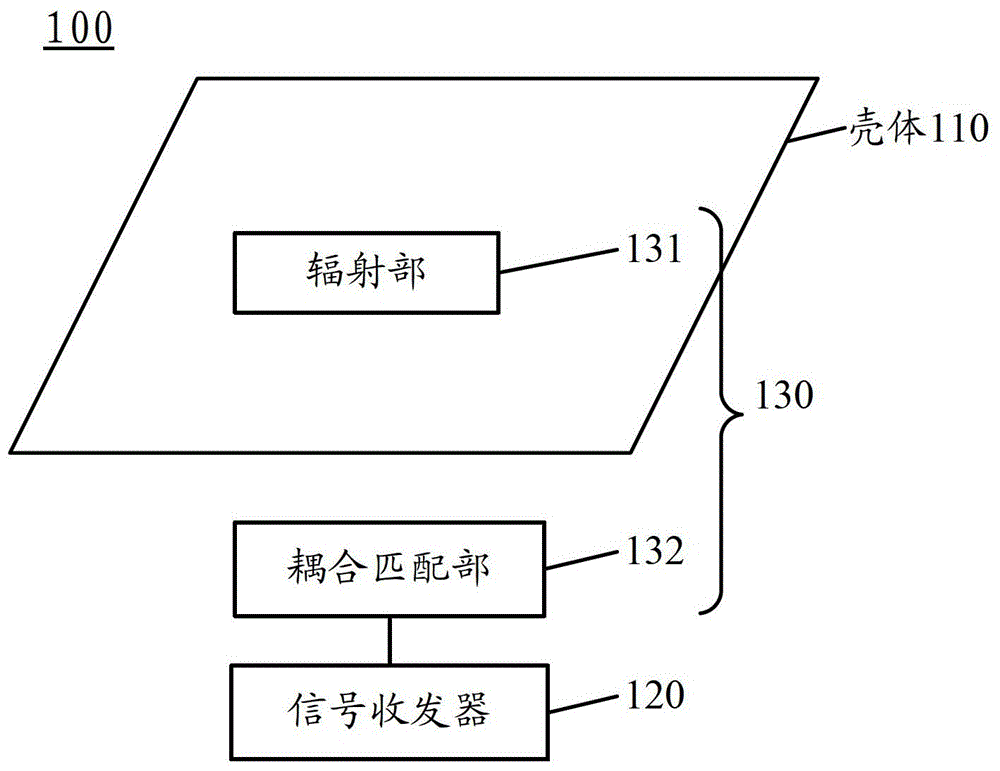

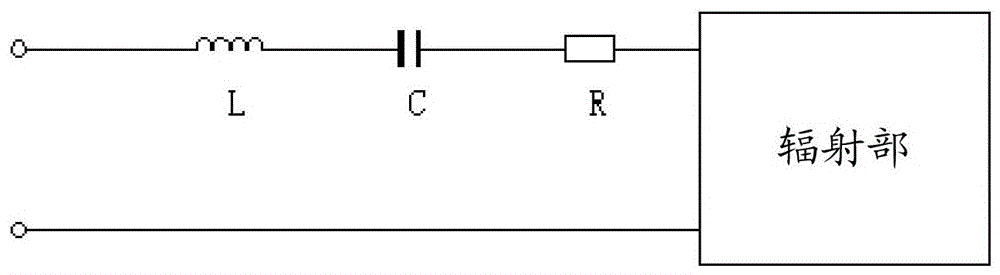

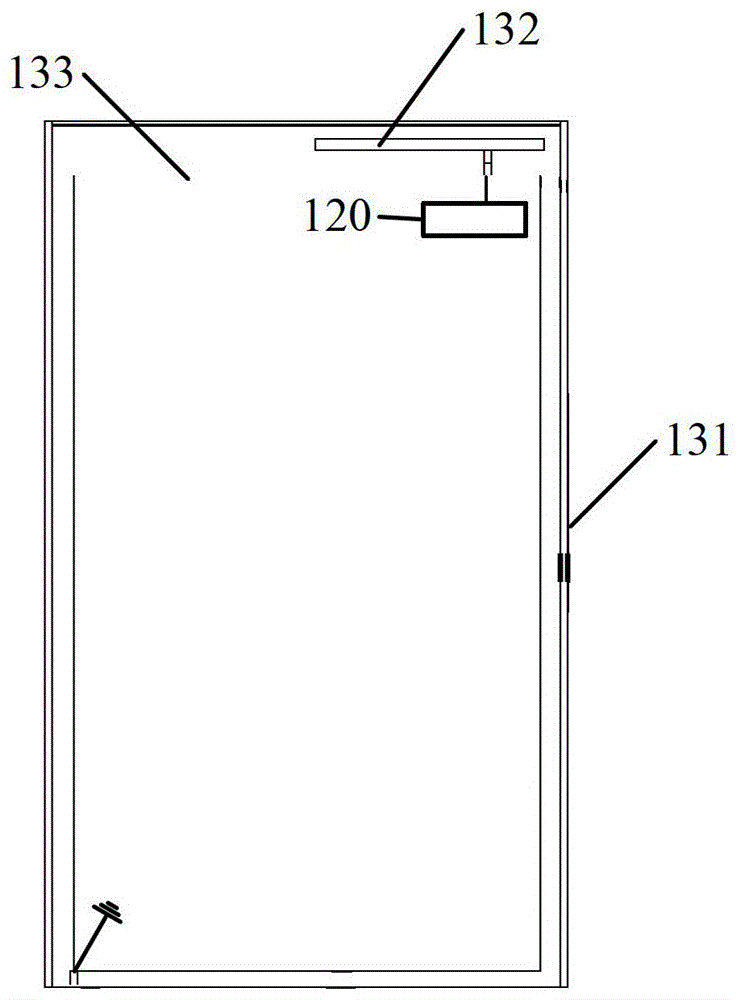

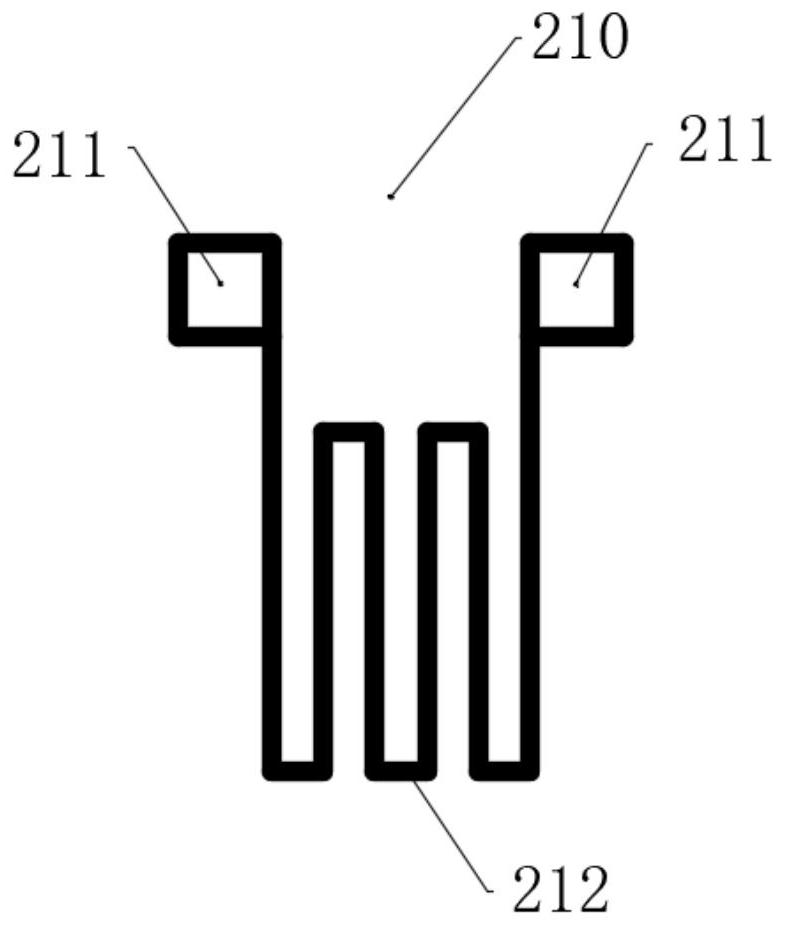

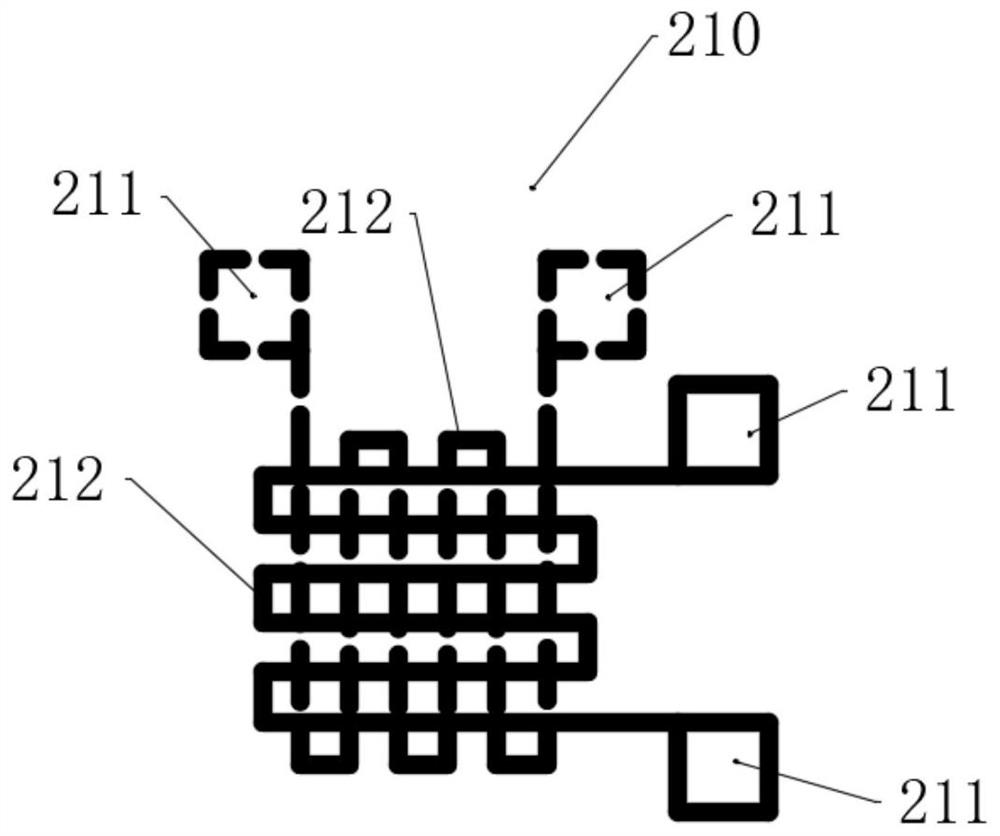

Electronic device, antenna and method for forming antenna

ActiveCN103872452AGuaranteed design strengthGuaranteed structural strengthAntenna equipments with additional functionsTransceiverElectrical conductor

The invention provides an electronic device, an antenna and a method for forming the antenna. The electronic device comprises a shell, a signal transceiver and the antenna, wherein the shell comprises a conductor zone manufactured by a conducting material; the antenna comprises an irradiation part and a coupling and matching part; the irradiation part is formed by utilizing the conductor zone and is used for irradiating and receiving signals; the coupling and matching part is coupled to the irradiation part, is connected to the signal transceiver and is used for feeding signals between the irradiation part and the signal transceiver and exciting the irradiation part to irradiate and receive the signals in specified frequency bandwidth. In each technical scheme of the embodiment, the antenna has a good antenna performance while the appearance design and the structure strength of the electronic device are ensured.

Owner:LENOVO (BEIJING) CO LTD

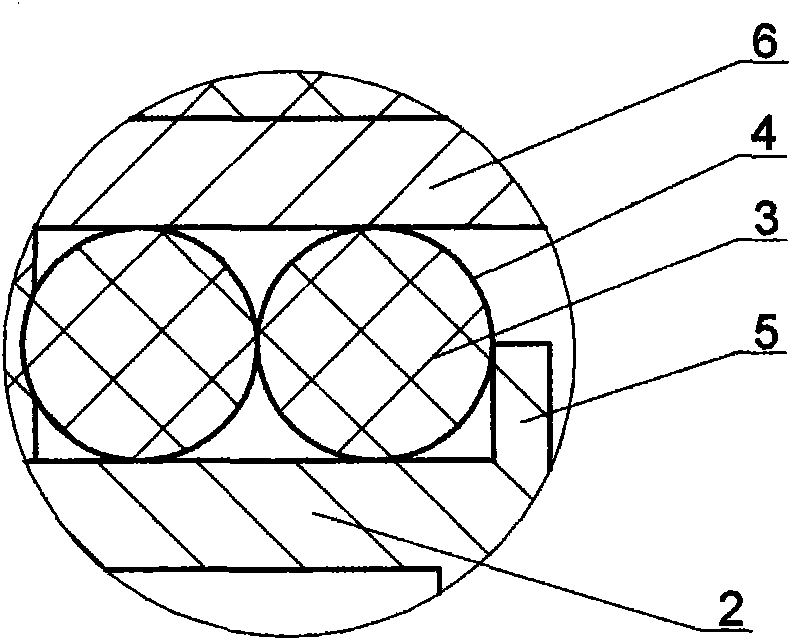

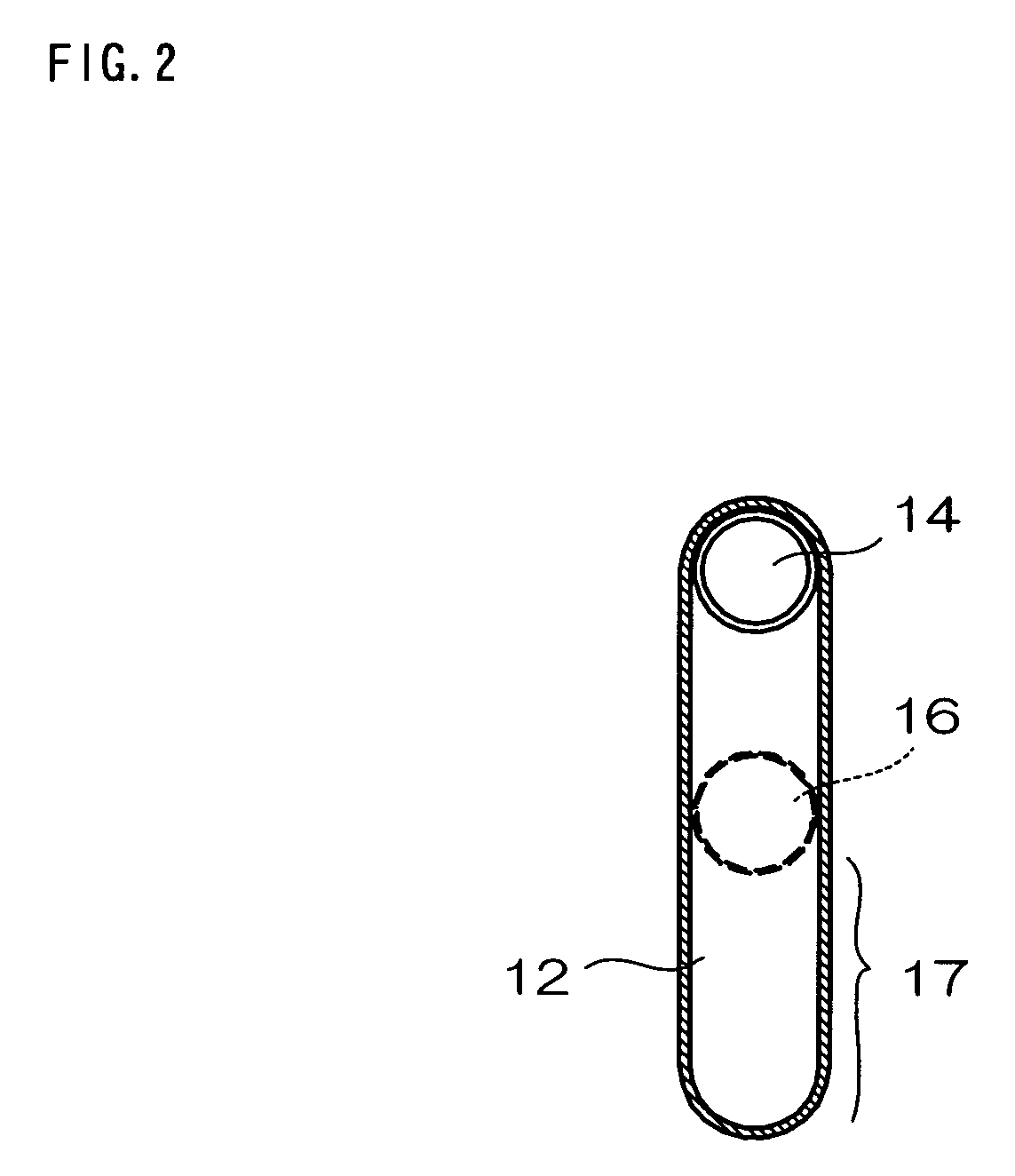

Supporting structure

InactiveCN1963282AGuaranteed design strengthImprove wear resistanceContainer filling methodsContainer discharging methodsThermal insulationEngineering

A supporting structure for a low temperature thermal insulation air bottle between the inner container and the outside housing of the said air bottle, comprises a supporting pipe that sticks to the No.1 end of the inner sealer of the said inner container, a pipe cover that is located at the inner side of the inner sealer and fastens the No.1 end of the said supporting pipe to the inside of the said inner sealer, a support bracket that is set at the inside of the outside sealer of the said outside housing with inserting holes on it, with the No.2 end of the said supporting pipe inserted into the inserting holes of the said support bracket. The invention can not only improves the supporting strength but also reduce the transmission of heat.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

Large-volume concrete pumping construction method under high-temperature condition

InactiveCN110670592AReduce heat of hydrationReduce dosageFoundation engineeringProcess engineeringConcrete pump

The invention provides a large-volume concrete pumping construction method under a high-temperature condition. The method comprises the following steps that the temperature of raw materials is controlled, so that the temperature of a machine outlet is reduced to be within a specified temperature range; the raw materials are selected, the matching ratio is optimized, and hydration heat is reduced;a reasonable concrete transportation and pouring mode is selected to reduce the pouring temperature; and the surface temperature of the concrete is lowered by using a concrete surface flowing water curing method. After the construction method is adopted, under the condition that the temperature of the outside environment is high, the temperature of large-volume concrete can be well controlled, andthe requirements for concrete storage temperature and in-bin temperature are met.

Owner:SINOHYDRO BUREAU 5

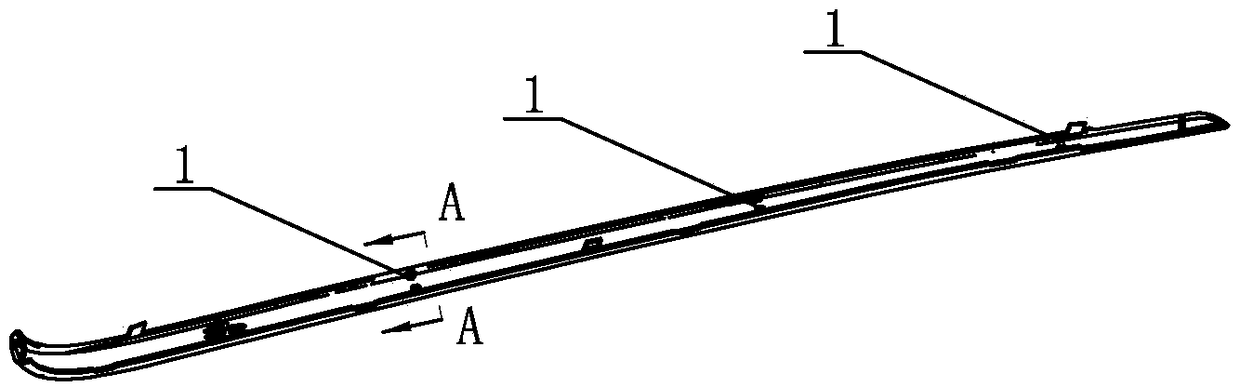

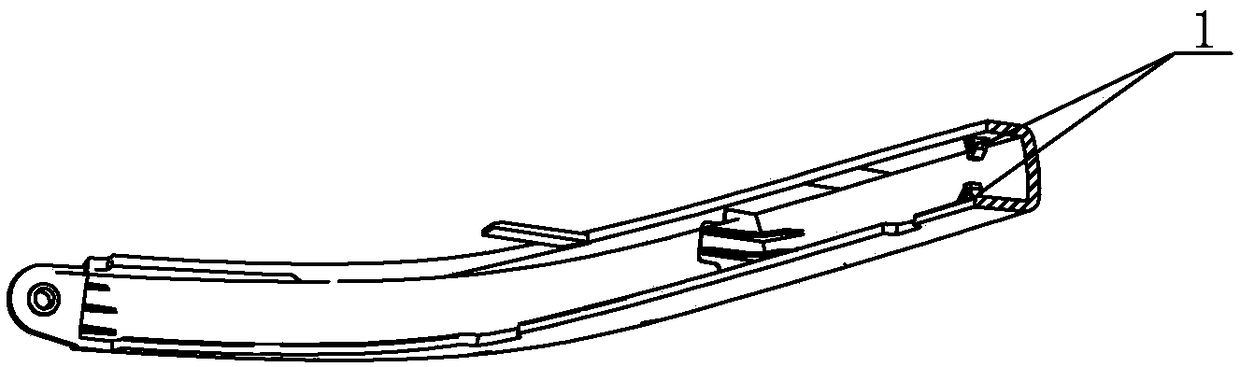

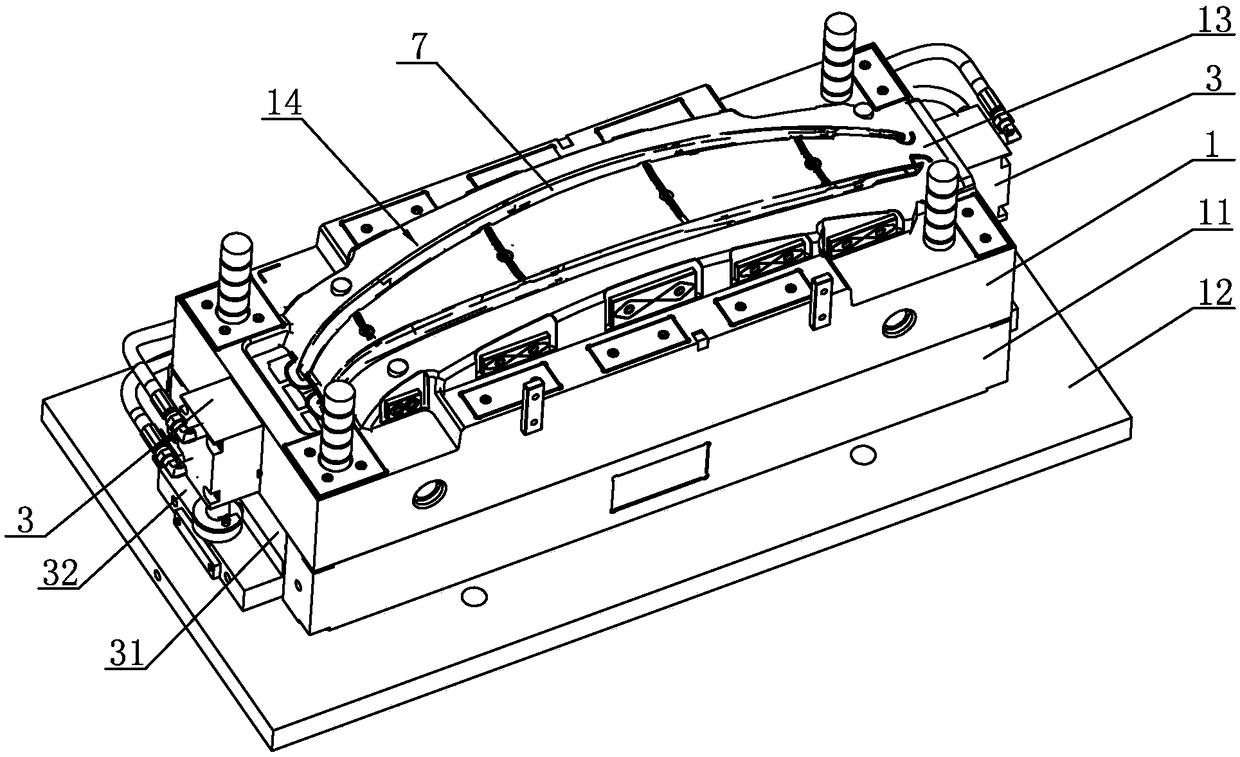

Injection mold for automobile trims

Owner:NINGBO SWELL IND CO LTD

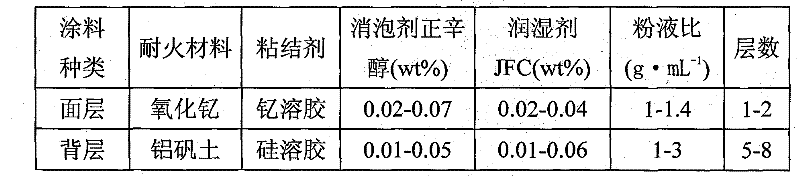

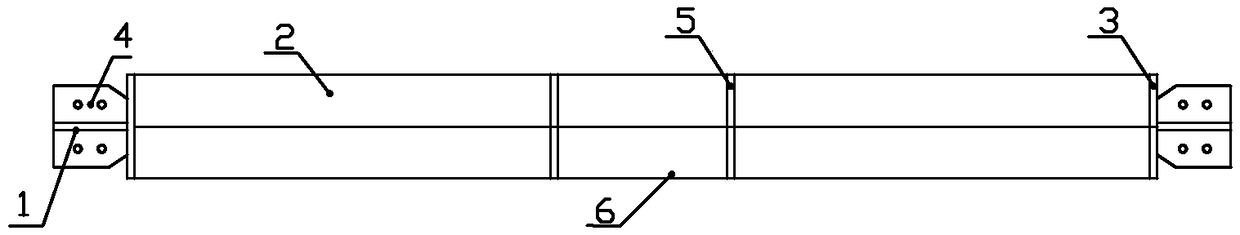

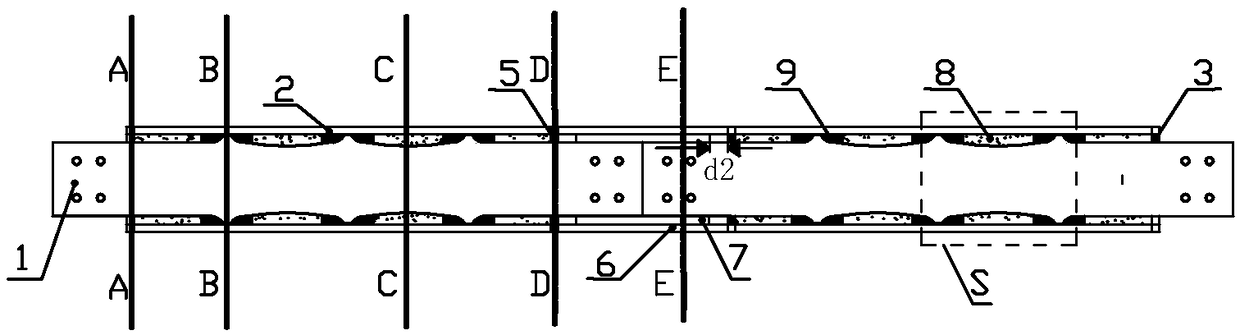

High-temperature resistant corrugated expansion joint

InactiveCN101655177AGuaranteed design strengthMeet the use requirementsPipeline expansion-compensationInorganic material artificial filamentsEngineeringUltimate tensile strength

The invention discloses a high-temperature resistant corrugated expansion joint which comprises a left connecting pipe, a corrugated pipe and a right connecting pipe which are sequentially connected in a seal way, wherein the inner wall of the left connecting pipe is fixedly connected with a flow guide cylinder opened to the right, and the inner wall of the right connecting pipe is fixedly connected with an accessory flow guide cylinder opened to the left; the inner diameter of the accessory flow guide cylinder with less length is larger than the outer diameter of the flow guide cylinder, andthe accessory flow guide cylinder and the flow guide cylinder are coaxial and are partially sleeved. A heat insulation material sleeved by a metal mesh is arranged in a clearance between the outer wall surfaces of the flow guide cylinder and the accessory flow guide cylinder and the inner walls of the left connecting pipe, the corrugated pipe and the right connecting pipe to form a heat insulationstructure. A heat insulation material sleeved by a metal mesh is also arranged between sleeving sections of the flow guide cylinder and the accessory flow guide cylinder to form a seal structure which can relatively move axially. The heat insulation structure is arranged in the high-temperature resistant corrugated expansion joint, and the corrugated pipe still maintains enough structural strength without the influence of medium temperature, normally plays a role of absorption or compensation and ensures the safe running of the configured pipeline.

Owner:JIANGSU XINFANGYUAN ELECTRIC EQUIP MFG

Guide rail cleaning device for escalator or automatic pavement

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

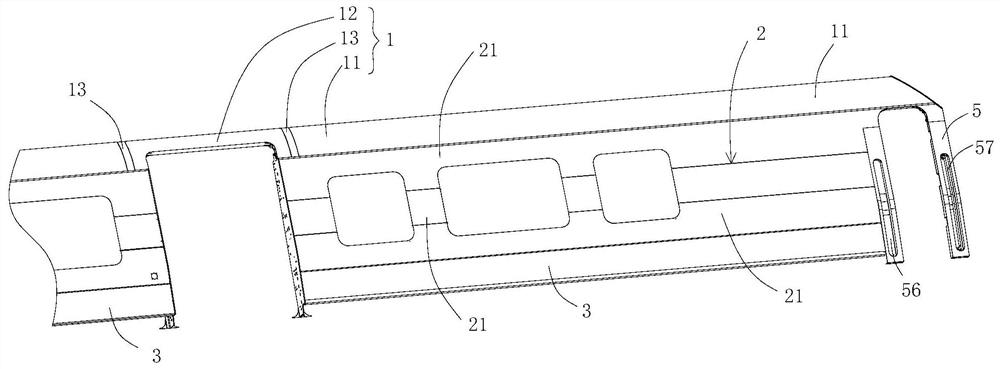

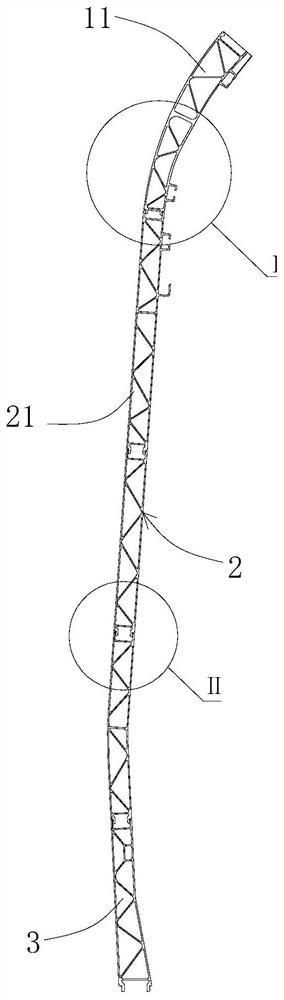

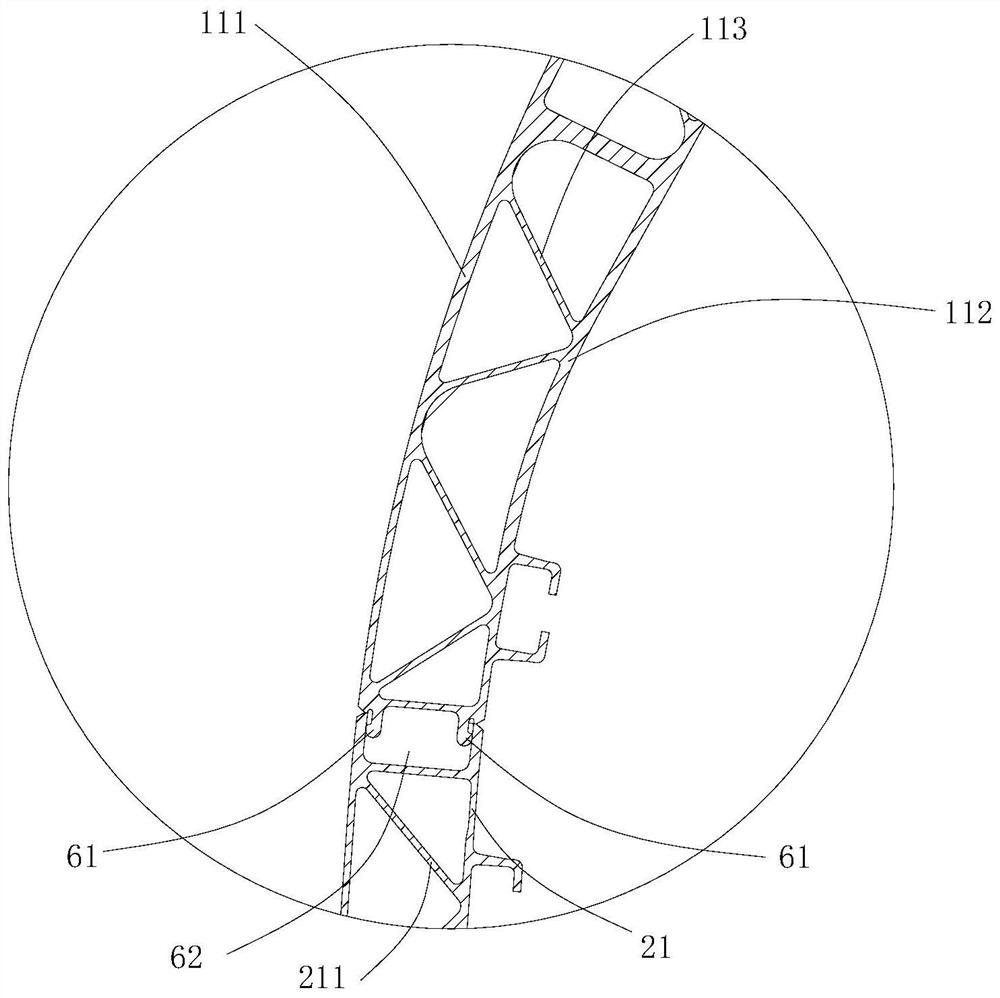

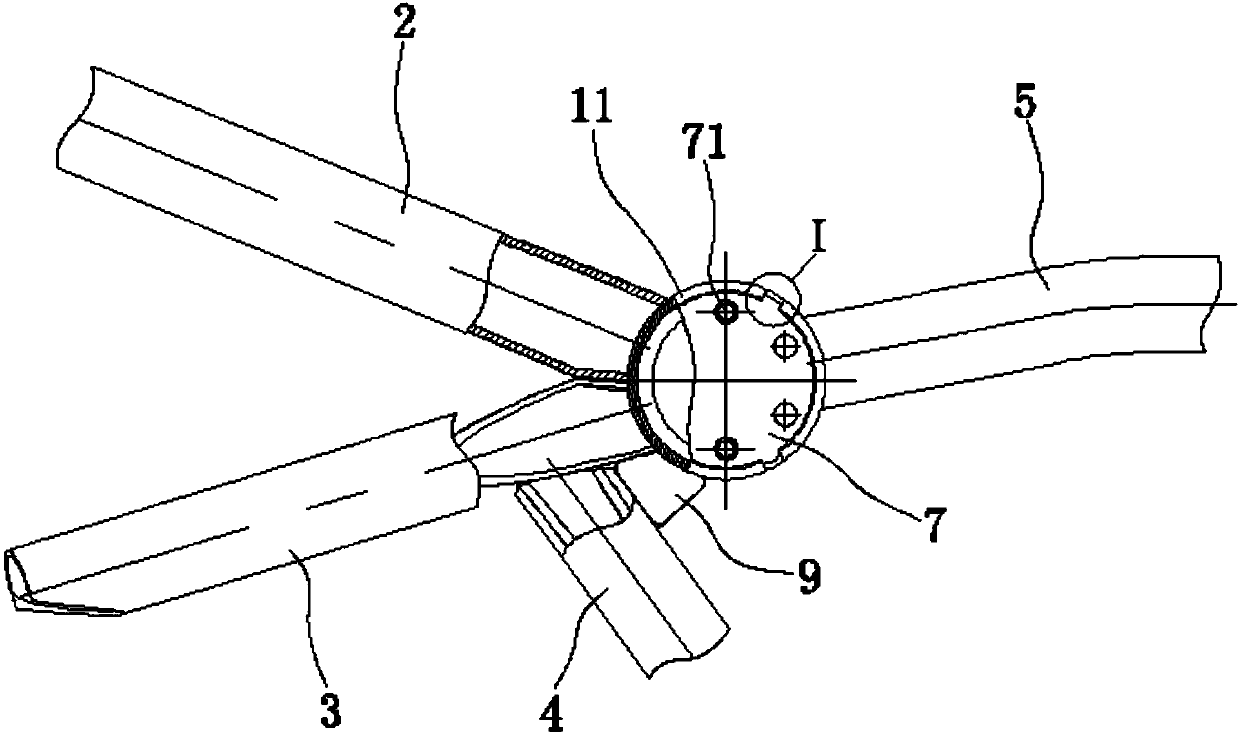

Lightweight side wall structure and railway vehicle

ActiveCN113771894AImprove structural stabilityGuaranteed StrengthRailway transportAxle-box lubricationWall plateCar door

The invention provides a light-weight side wall structure and a railway vehicle. The light-weight side wall structure comprises an upper profile, a middle profile and a lower profile, wherein the upper section bar is arranged close to the roof; the middle section bar is connected to the lower part of the upper section bar and is connected with the upper section bar in an inserting and welding manner; the lower section bar is connected to the lower part of the middle section bar and is connected with the middle section bar in an inserting and welding manner; the thickness of the inner wall plate on the side, adjacent to the automobile door, of the upper profile is larger than that of the inner wall plate on the side away from the automobile door. According to the lightweight side wall structure provided by the invention, the whole side wall is arranged in a form of combining the upper section bar, the middle section bar and the lower section bar; therefore, the rigidity and the strength of the area which needs to be set to be high-strength above the automobile door are improved by increasing the thickness of the inner side plate, close to the automobile door part, of the upper sectional material, whereas for other parts, the thickness of the plate is smaller. On the premise that the strength of the vehicle body is guaranteed, the weight of the vehicle body is reduced conveniently, and light-weight design can be achieved easily.

Owner:CRRC TANGSHAN CO LTD

Motorcycle frame middle connecting structure

PendingCN107856794AEasy to shapeGuaranteed design strengthMotorcyclesCycle framesVehicle frameIndustrial engineering

The invention discloses a motorcycle frame middle connecting structure which comprises a left and right connecting pipe, a front left main pipe, a left supporting pipe, a lower connecting pipe and a rear left main pipe. The lower connecting pipe is welded to the left supporting pipe. The rear left main pipe is welded to the left and right connecting pipe. The left end of the left and right connecting pipe integrally extends leftwards, and a large-diameter section is formed through pipe expansion. Both the front left main pipe and the left supporting pipe are welded to the large-diameter section. The motorcycle frame middle connecting structure is ingenious in design, simple and easy to transform, the shape of a single part is simplified, the structure is more convenient to manufacture, production cost is further reduced, the improved structure makes the middle portion of a motorcycle frame stressed more reasonably, and the design strength of the original motorcycle frame can be guaranteed.

Owner:力帆科技(集团)股份有限公司

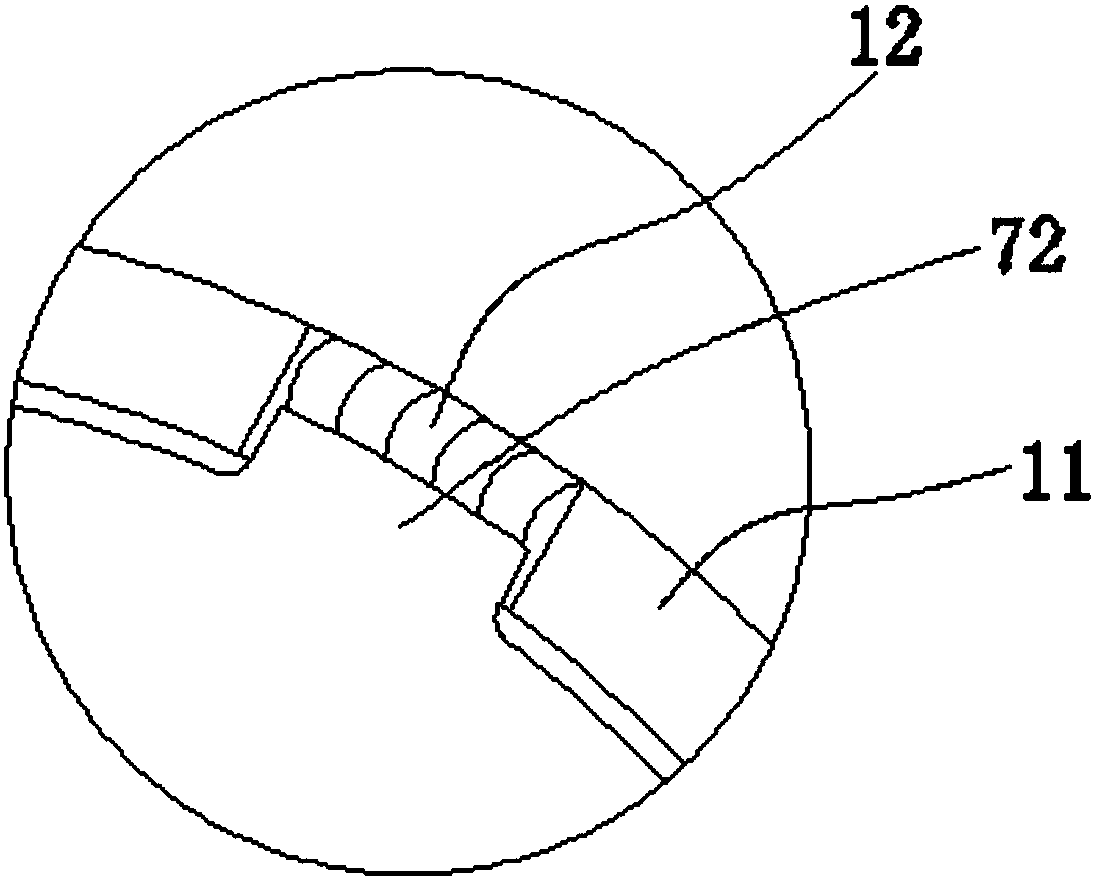

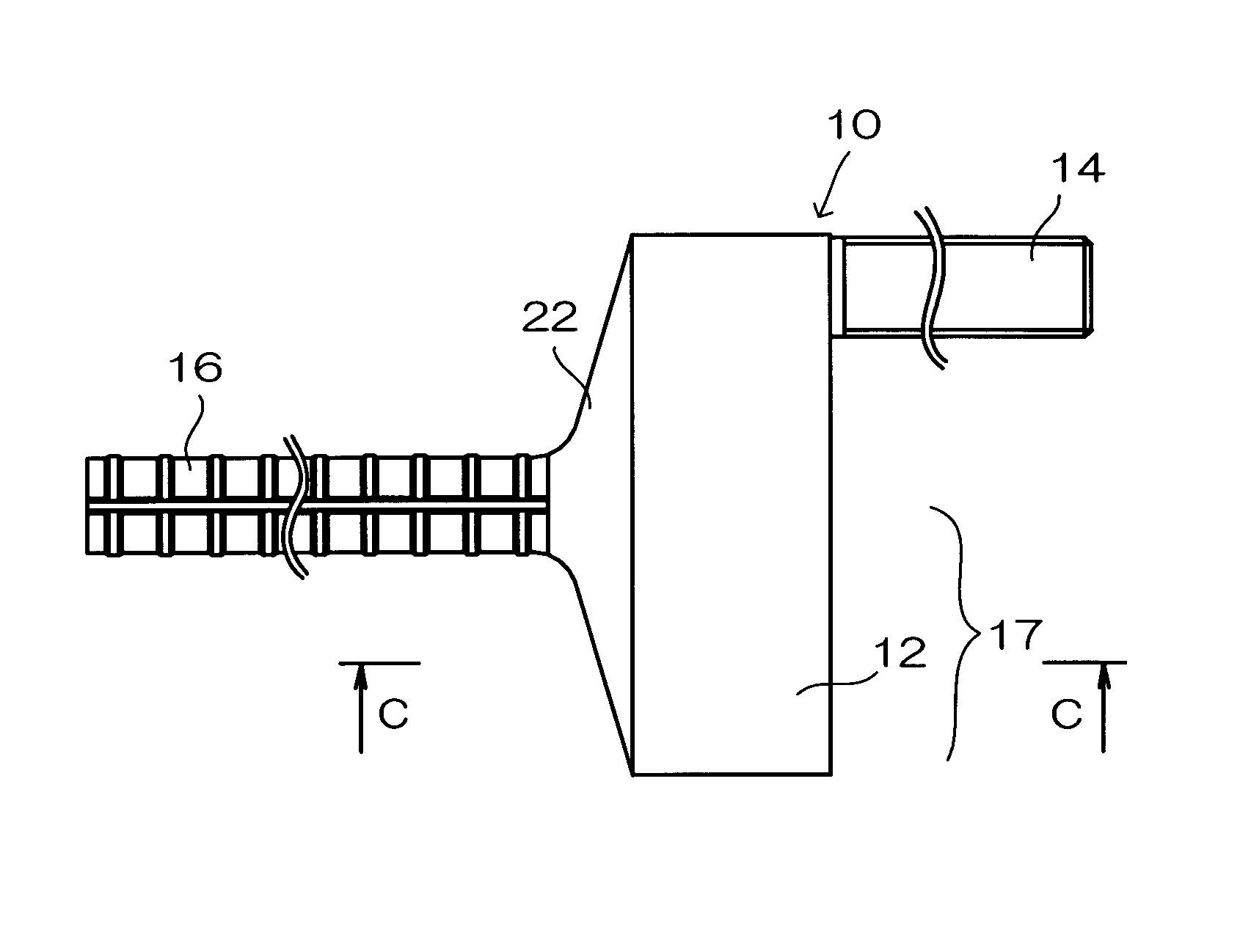

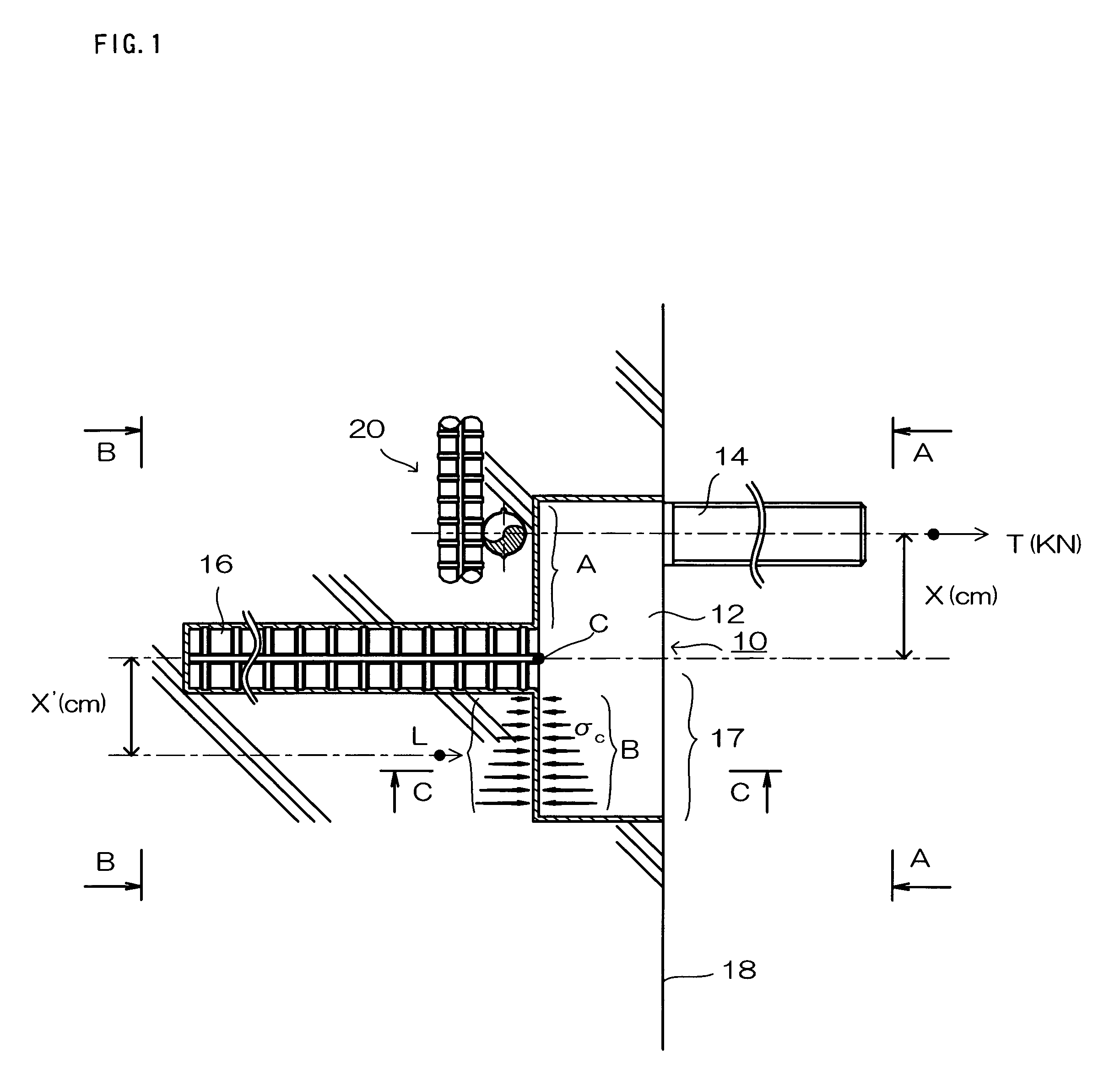

Composite anchor bolt and method for installation

ActiveUS8087211B2Reduces the bending momentIncreased adhesion areaConstruction materialBuilding repairsBending momentAnchor bolt

A post-construction composite anchor bolt is provided having great resistance to a bending moment, even when the reinforcement covering margin is small, and reduces the transformation force caused by the bending moment acting on the joining point between the connecting part and the second anchor bolt, even if the size of the anchor bolt is increased. A post construction anchor bolt in the concrete frame comprising: a first anchor bolt installed projecting outside of a concrete frame; and a second anchor bolt which is eccentrically positioned to the axis of said first anchor bolt and is installed embedded in the concrete frame, and a connecting part which links said first anchor bolt and said second anchor bolt, and is installed embedded in the concrete frame together with said second anchor bolt. Said connecting part is formed to have a portion projecting in the opposite direction to the first anchor bolt, and thus reduces the bending moment which is exerted locally on the connecting part due to the load on said first anchor bolt.

Owner:SUEHIRO SYST CO LTD

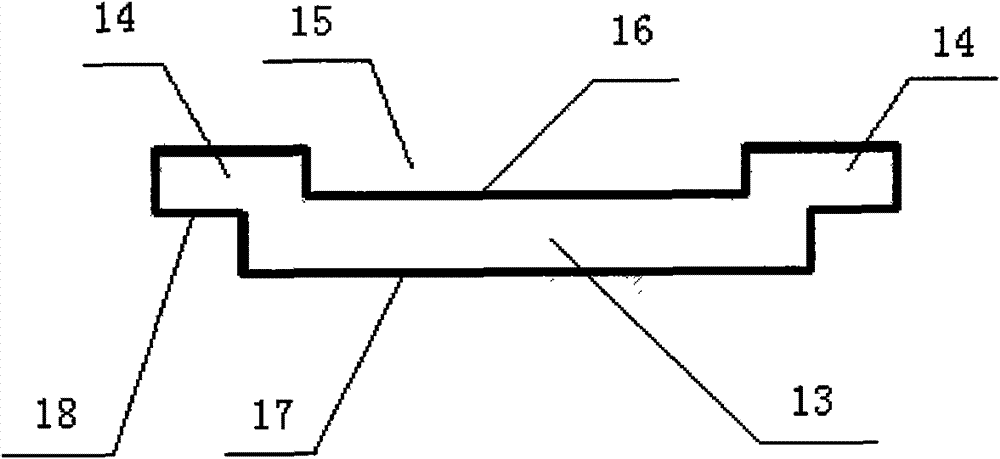

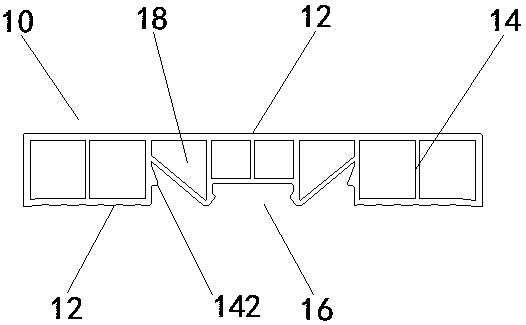

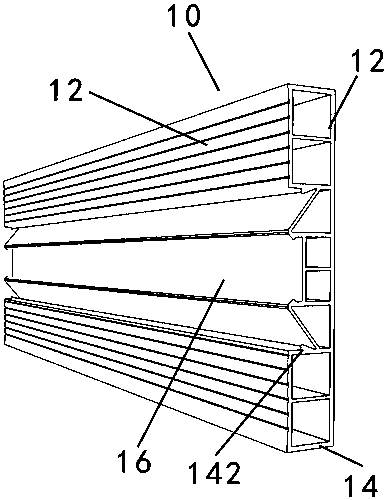

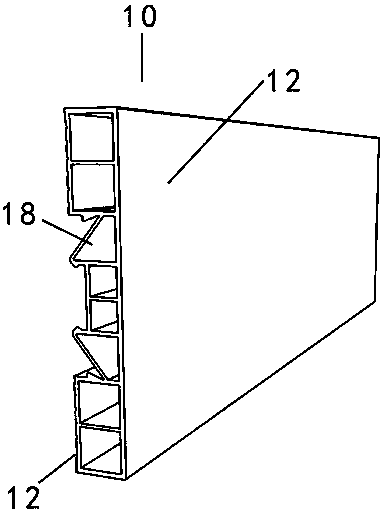

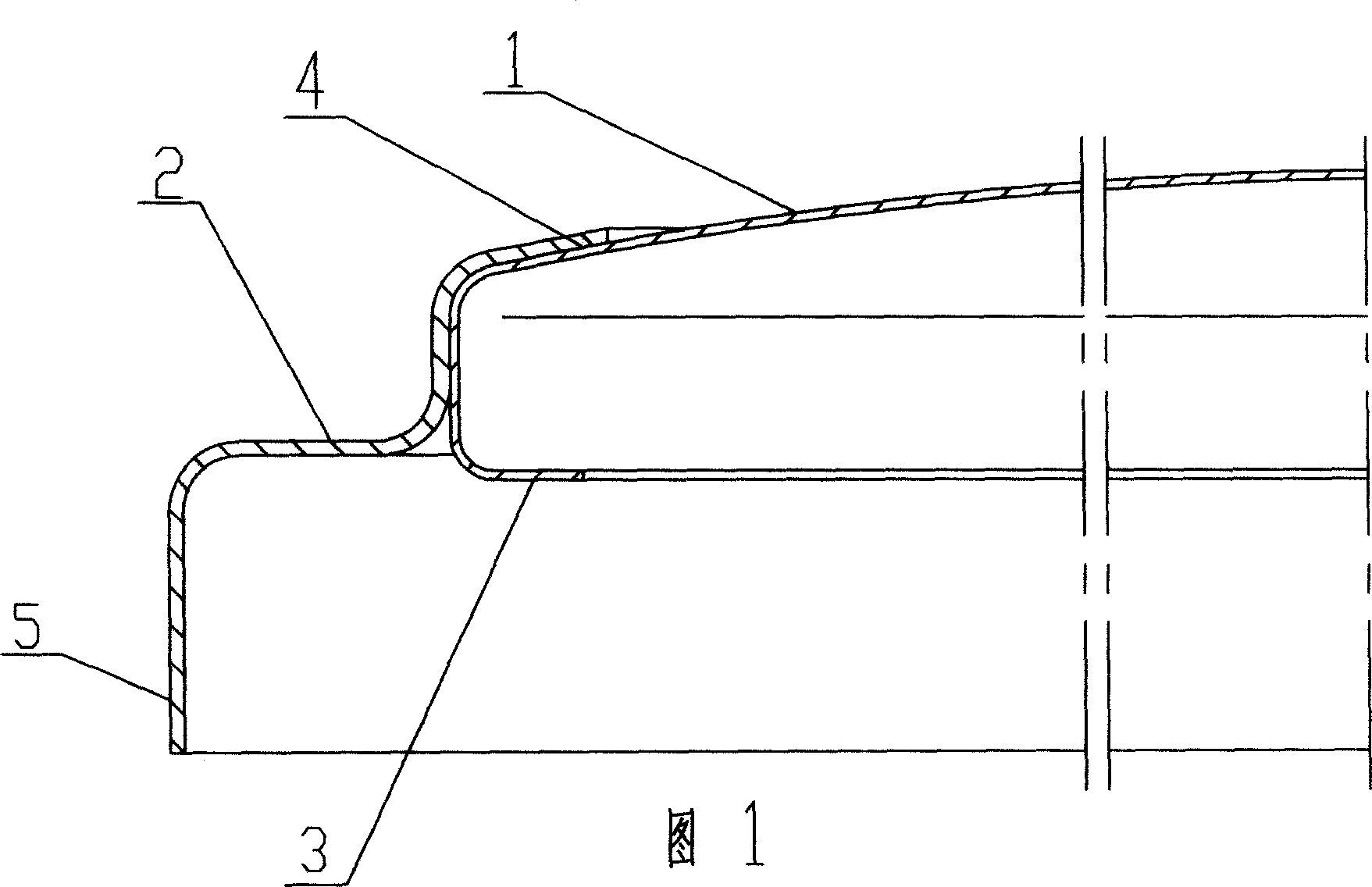

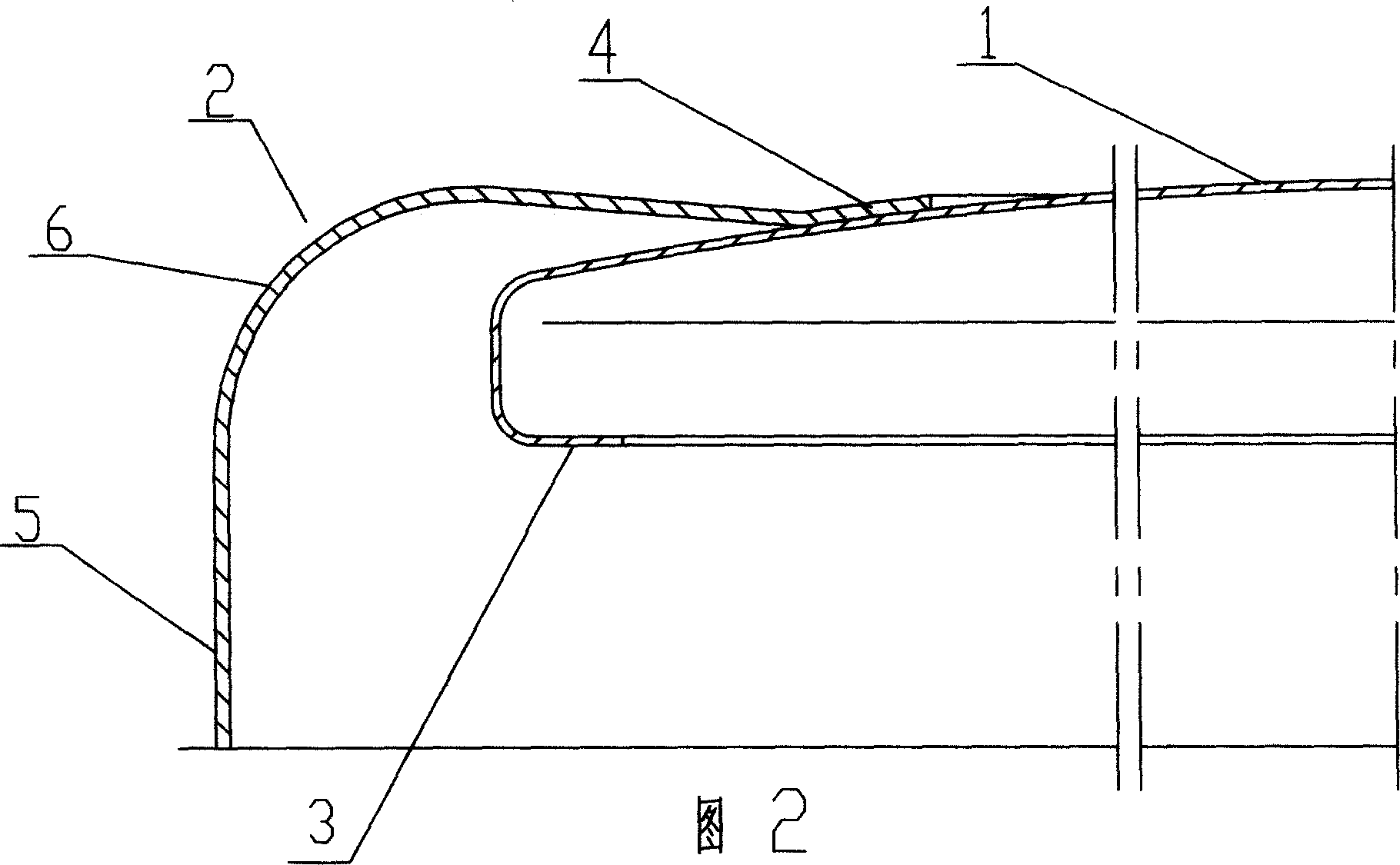

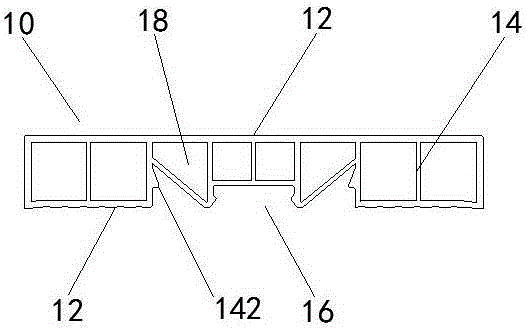

Moldings, closures and molding components

ActiveCN105421727BGuaranteed design strengthQuick checkBuilding constructionsStructural engineeringMechanical engineering

The invention relates to the field of building decoration, in particular to a decorative moulding, a closing component and a decorative moulding assembly formed by the decorative moulding and the closing component. The decorative moulding comprises at least one panel. At least two first reinforcing ribs are arranged at one side of each panel. Buckles are arranged on the opposite face of every two adjacent first reinforcing ribs. The closing component comprises a closing component body which is a panel with the hollow center. At least two locking arms are arranged at one side of the closing component body oppositely. The distance between every two locking arms corresponds to the distance between every two adjacent first reinforcing ribs. A buckle head is arranged at one end, away from the closing component body, of each locking arm. The buckle heads and the buckles are mutually matched and locked closely. In this way, it can be ensured that terminals such as a circuit inserting board and a switch can be installed on the decorative moulding fast. Attractiveness of the decorative moulding can be ensured to the maximum, and the decorative moulding can be connected or disassembled fast.

Owner:嘉兴天美环保集成墙面有限公司

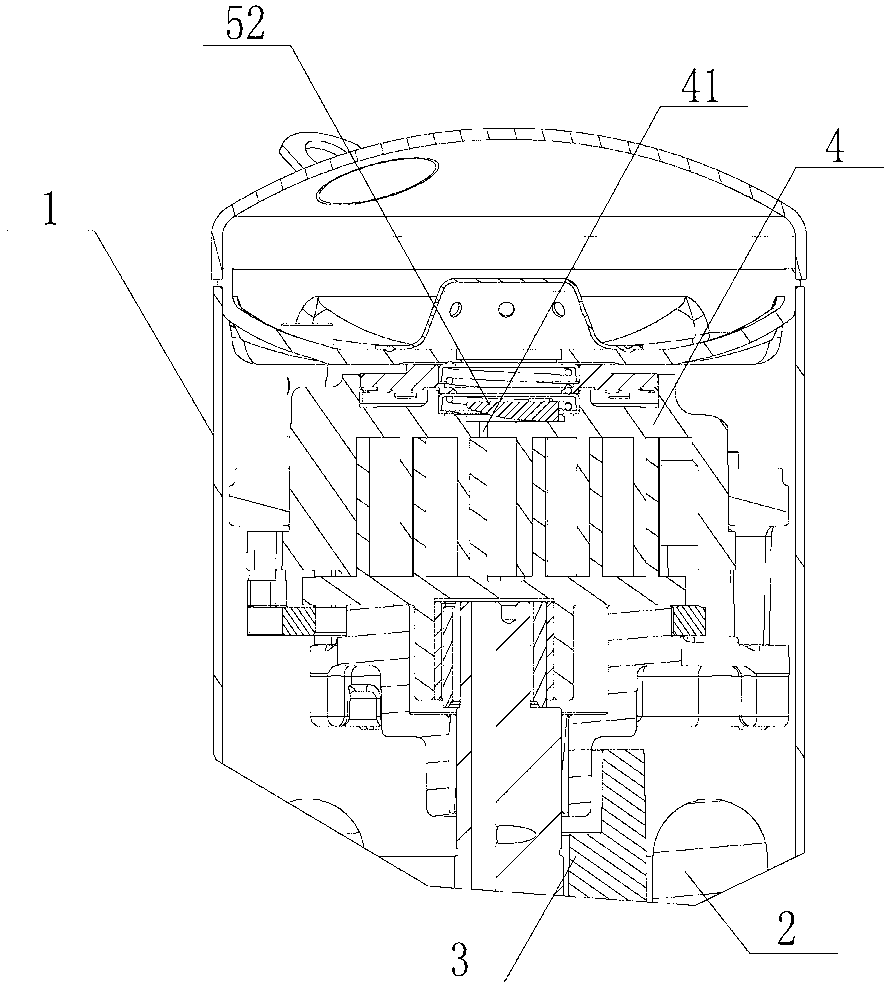

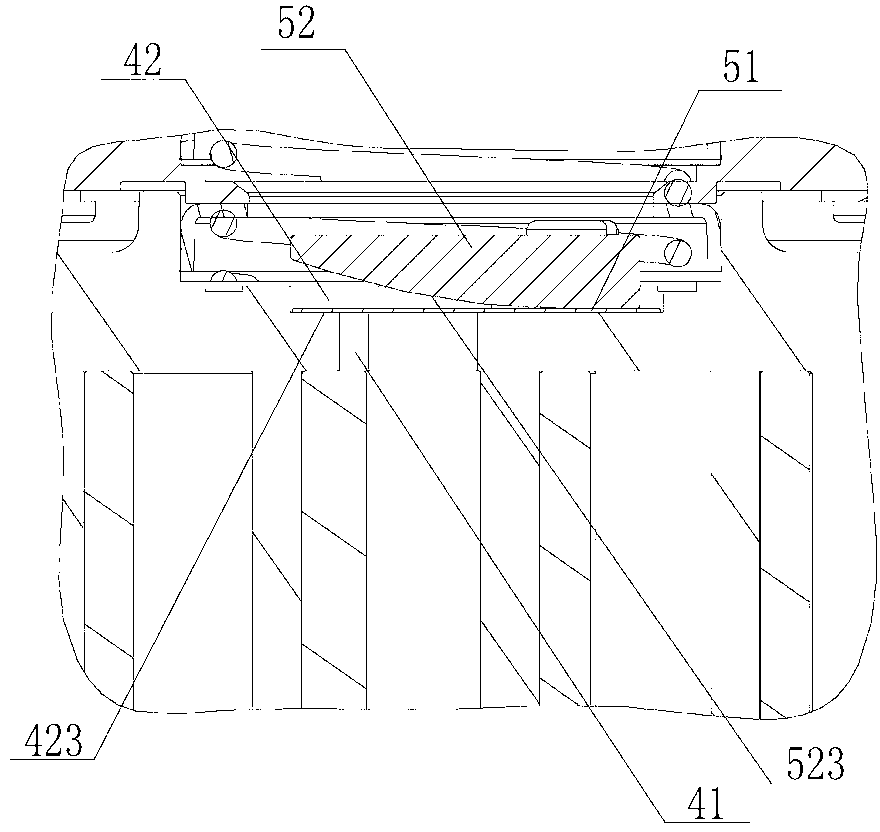

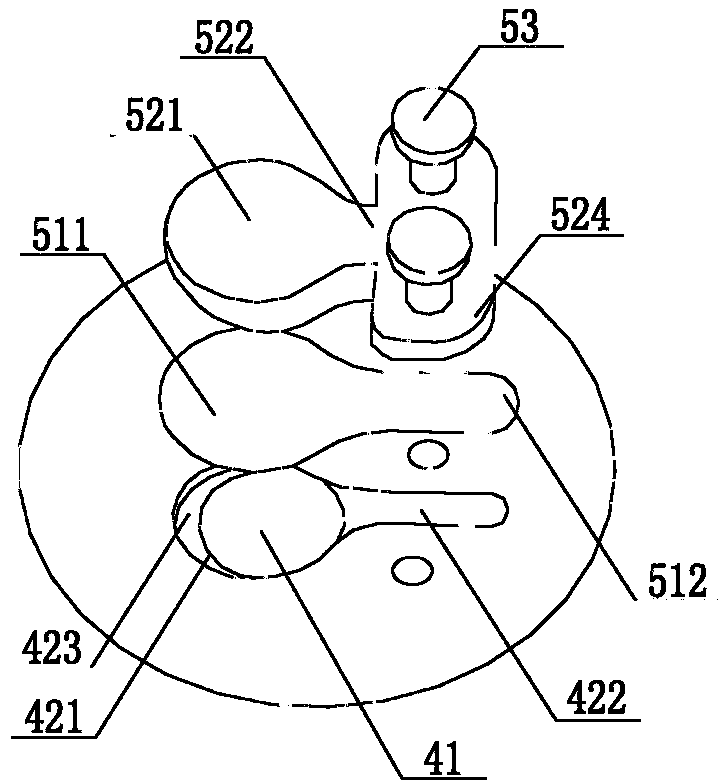

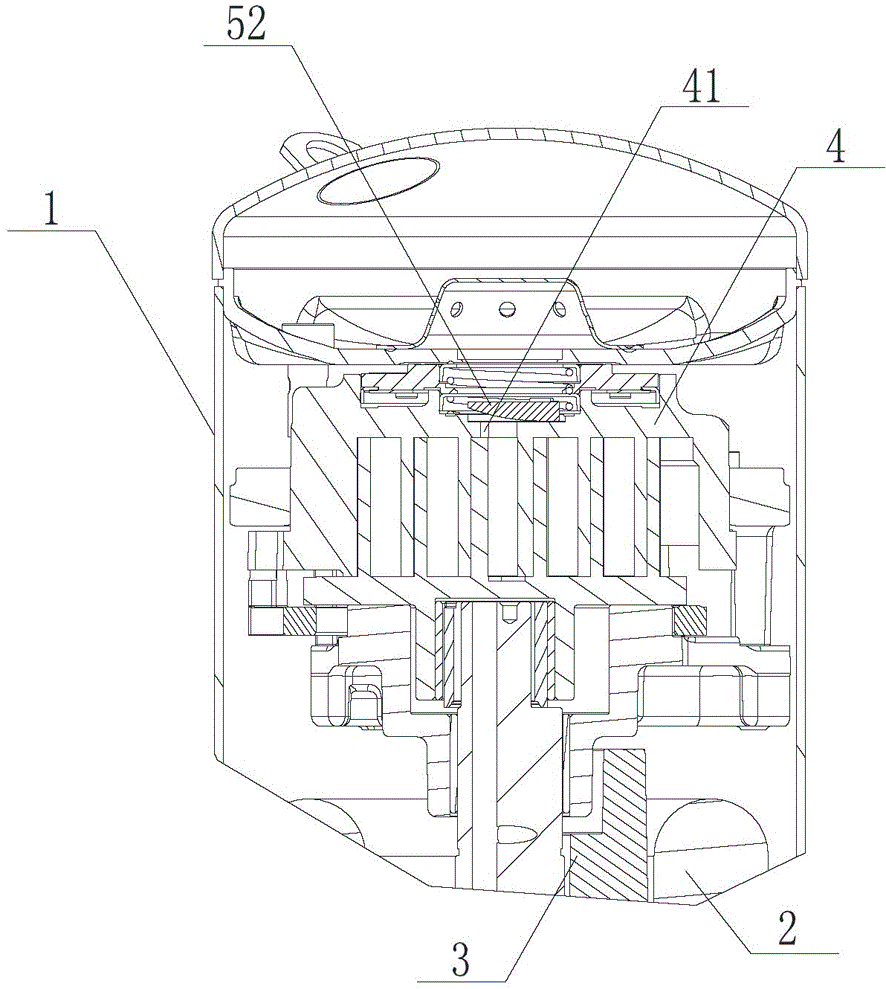

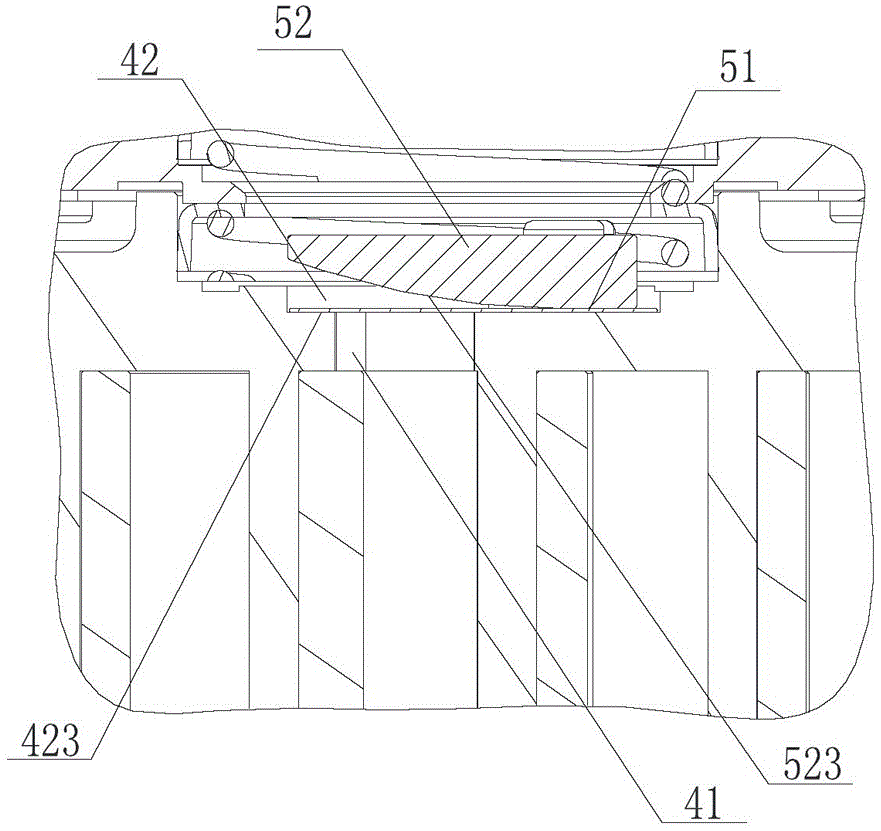

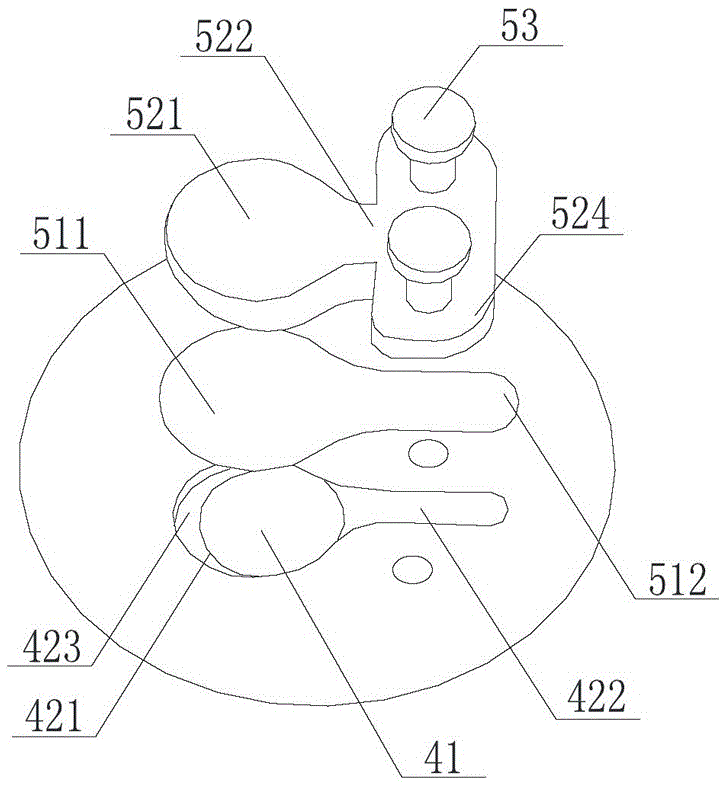

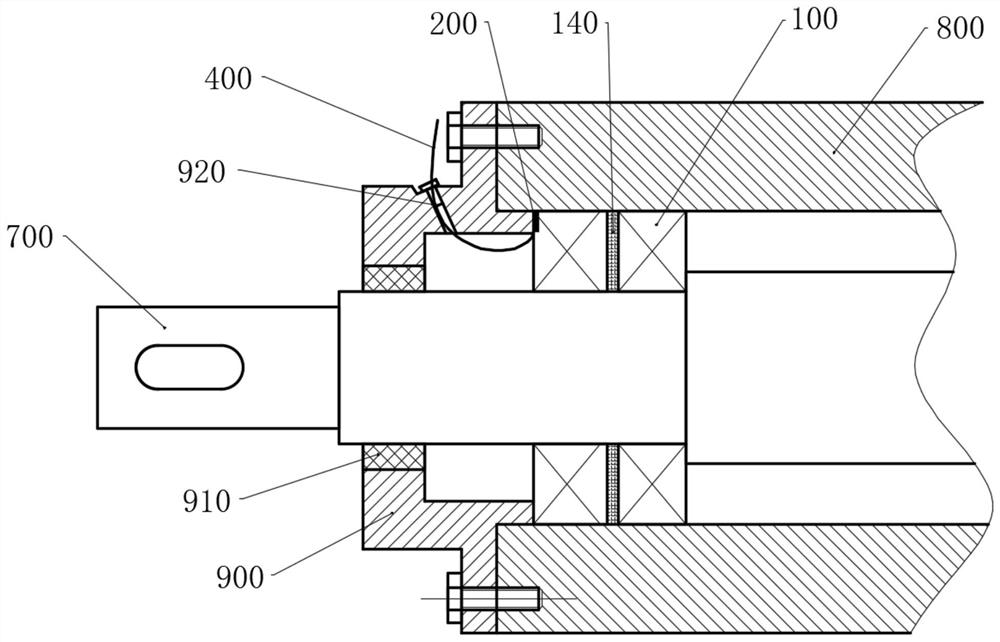

Scroll compressor with novel exhaust port structure and exhaust valve component

ActiveCN103267017AReduce volumeSmall volumeRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

The invention discloses a scroll compressor with a novel exhaust port structure and an exhaust valve component. The scroll compressor comprises a shell, an air inlet pipe, an air outlet pipe, a motor, a rotor shaft component and a scroll plate component, wherein an exhaust port is formed in the scroll plate component; a groove is formed in the upper surface of the scroll plate component positioned at the periphery of the exhaust port; the groove is formed towards the bottom of the exhaust port; a valve plate which covers the exhaust port and is in a long strip type is laid in the groove; one end of the valve plate is fixedly connected with the upper surface of the scroll plate component; a limiting plate with an arc-shaped lower surface is arranged on the valve plate; and when the exhaust port starts and stops exhausting air, the other end of the valve plate swings up and down between the upper surface of the scroll plate component and the arc-shaped lower surface. According to the scroll compressor, the exhaust port structure and the exhaust valve component are optimized, and the clearance volume is reduced to the greatest degree, so that at high compression ratio, the operating efficiency of the compressor is improved, the shutdown response speed of the compressor is increased, and the manufacturing cost and the using cost are reduced.

Owner:SUZHOU INVOTECH SCROLL TECH

Manufacturing method of environment-resistant electric connector shell made of titanium alloy

InactiveCN101572362BIncrease profitReduce manufacturing costContact member cases/bases manufactureCoupling device detailsElectricityInvestment casting

The invention provides an environment-resistant electric connector shell made of a titanium alloy and a manufacturing method thereof, which relates to an electric connector shell and the manufacturingmethod thereof and solves the problem that the existing electric connector shell can not be applied to harsh environment. The electric connector shell is made of titanium alloy material which contains 87.5 to 99.8 wt% of titanium, and one or a plurality of combinations of Ni, Pd, Ta, Mo, Ru, Zr, V and Sn as balance. The electric connector shell can be manufactured by adopting a powder metallurgymethod, and titanium and other elemental metal powders are mixed and then are added to a mould; powder blank is prepared by pressurization, and then pressure sintering or non-pressurized sintering iscarried out by adopting a vacuum sintering furnace; finally, finish machining is carried out according to the shape of the electric connector shell. The electric connector shell can also be manufactured by a precision investment casting method, and the titanium alloy is smelted and cast on a centrifugal titanium casting machine; subsequently, sandblasting and hot isostatic pressing treatment are carried out on a casting, and then the finish machining is carried out according to the shape of the electric connector shell so as to obtain the electric connector shell which is made of titanium alloy and is qualified.

Owner:HARBIN INST OF TECH +1

High tower steam curing system

The invention provides a steam curing system for a high tower. The steam curing system for the high tower comprises a heat supply module and a heat preservation module, wherein the heat supply module comprises a steam generation unit and a steam conveying unit connected with the steam generation unit, and the steam conveying unit comprises a main pipeline extending to a high position from a low position, a branched pipeline which intersects and communicates with the main pipeline, and a steam outlet pipeline which intersects and communicates with the branched pipeline; and the heat preservation module is composed of a plurality of cloth-shaped heat preservation units and used for covering the area through which the branched pipeline passes. Through the scheme, construction of tower columns in winter or under low-temperature conditions can be achieved.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

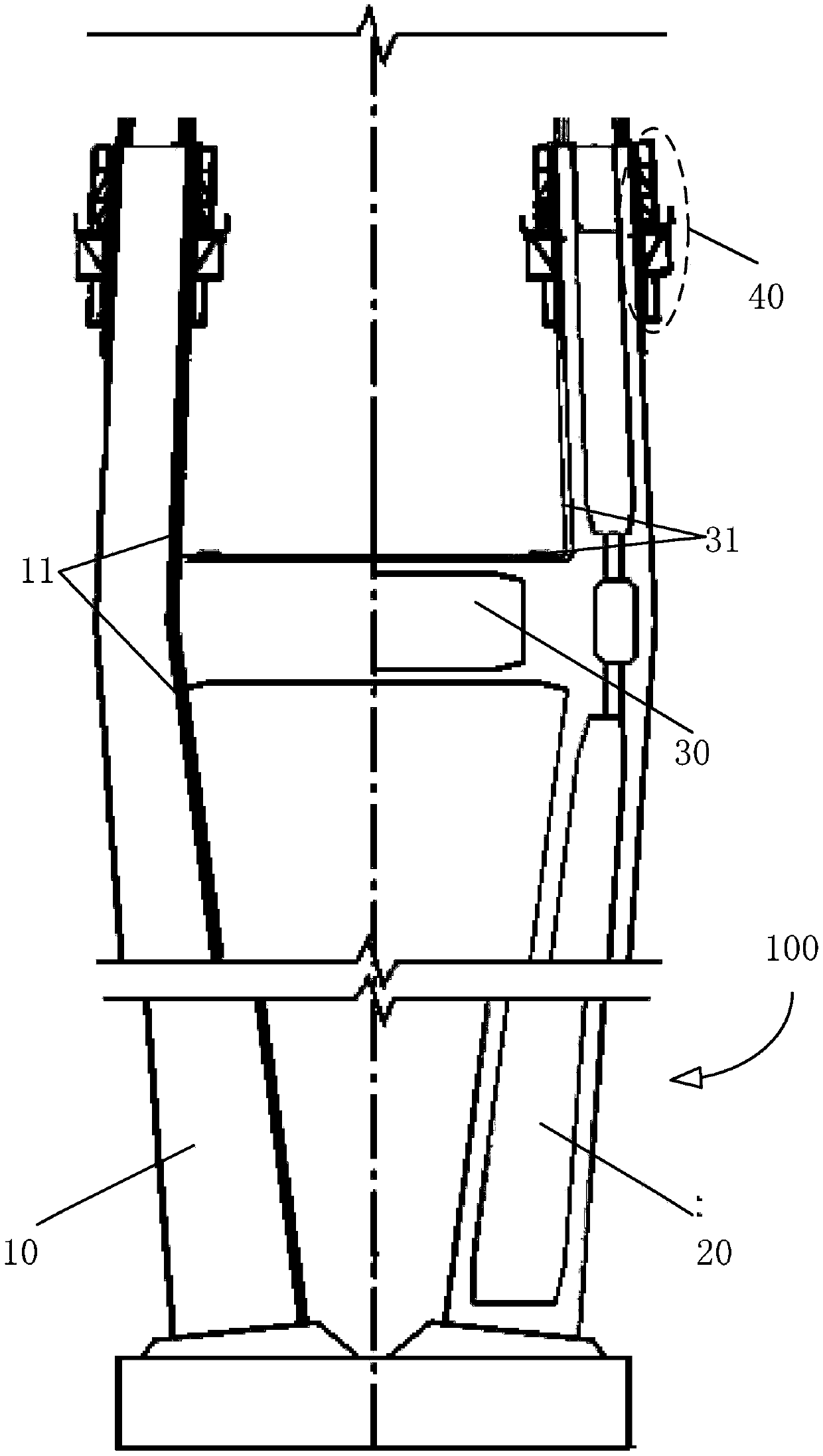

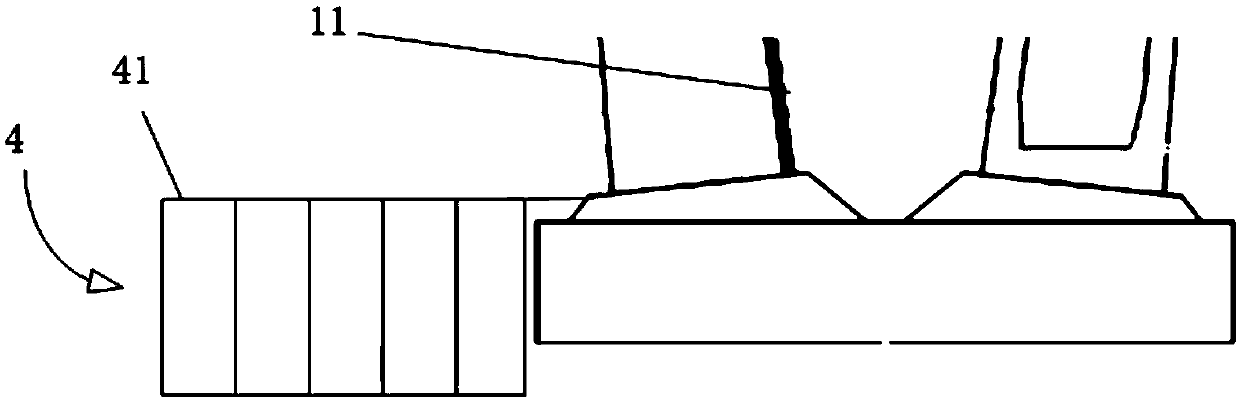

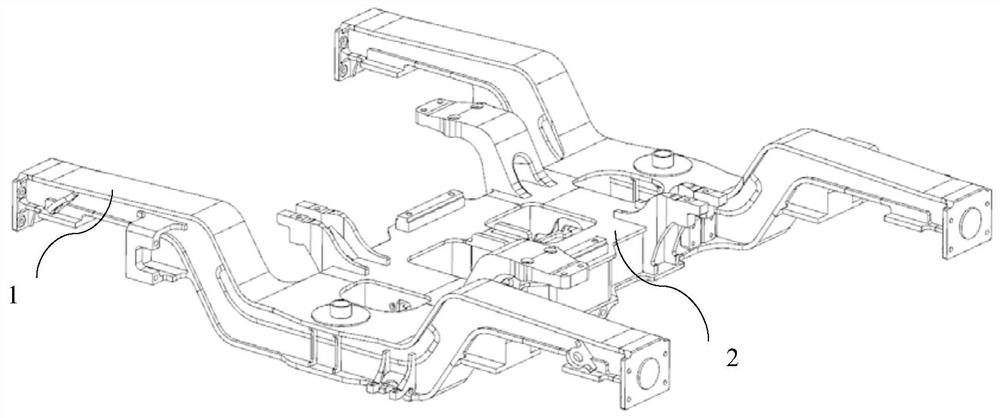

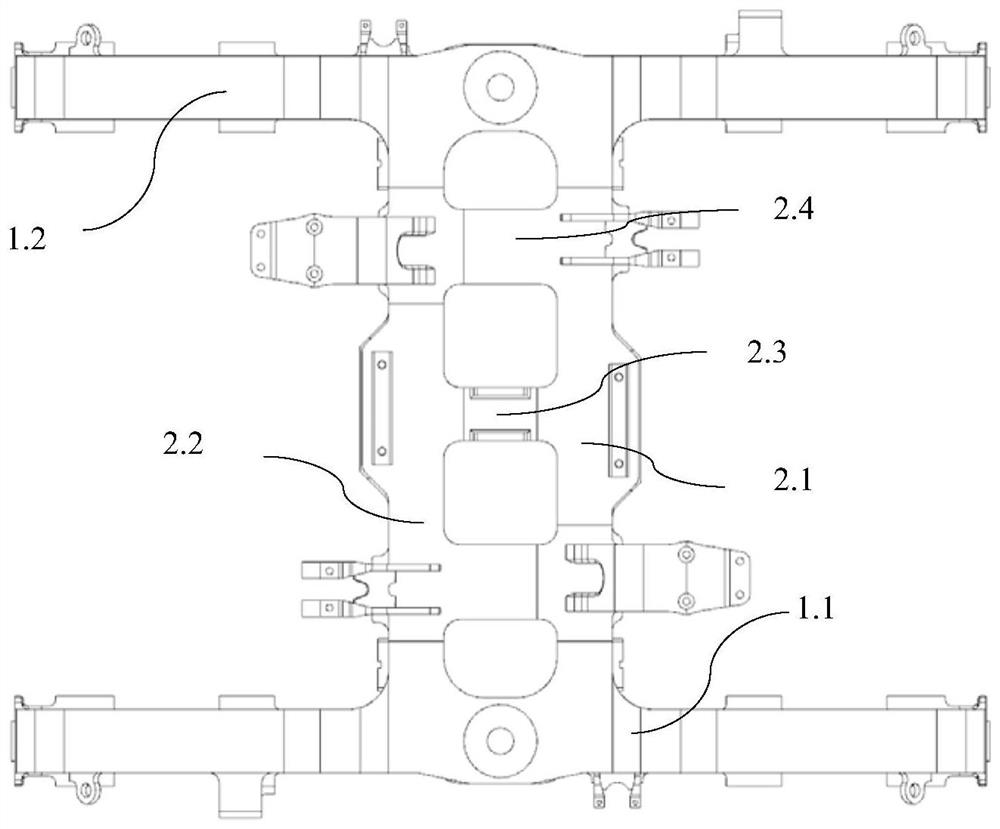

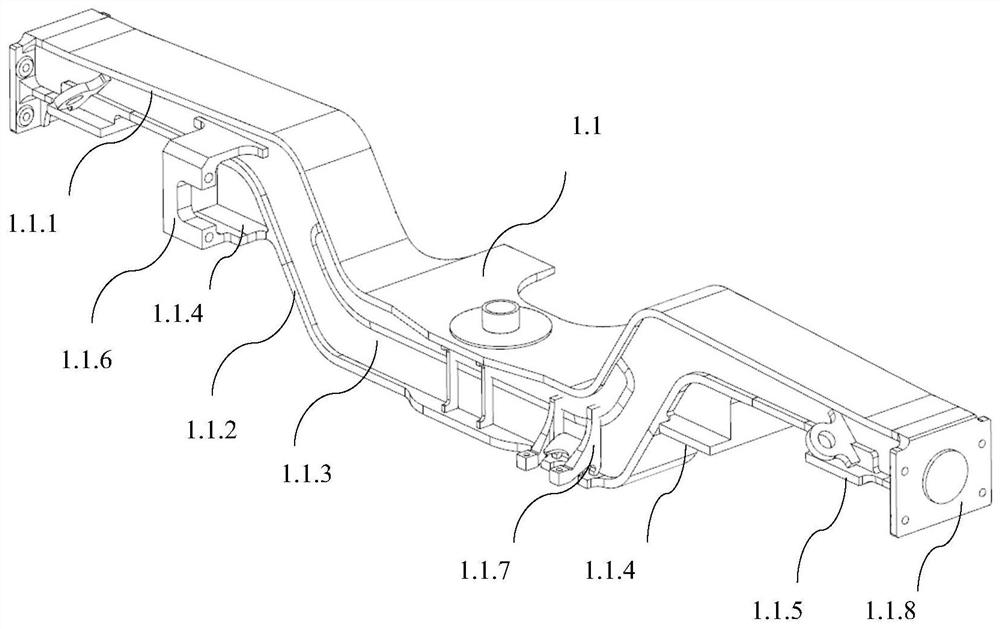

A motor vehicle frame of a light rail vehicle

The invention provides a bullet train framework of a light rail vehicle. The bullet train framework of the light rail vehicle comprises side beams and a cross beam, wherein the cross beam is of a boxtype beam structure, and the cross beam comprises a first cross beam and a second cross beam which are arranged at intervals; the first cross beam and the second cross beam are formed by installing and welding cross beam upper cover plates, cross beam lower cover plates, cross beam inner vertical plates and cross beam outer vertical plates correspondingly; a plurality of mounting bases are arranged on the first cross beam and the second cross beam correspondingly, the plurality of mounting bases are integrated with the first cross beam or the second cross beam through a structure of butt jointof at least one surface and hinged connection of multiple surfaces, and the positions of the plurality of mounting bases on the first cross beam and the positions of the mounting bases on the secondcross beam are rotationally symmetric about the central axis of a transverse framework; and the middle parts of the side beams are flush with the upper plane and the lower plane of the cross beam. Compared with the prior art, the bullet train framework of the light rail vehicle can ensure that the design strength meets the use requirements, and meanwhile, also has good manufacturability and good quality measuring degree.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

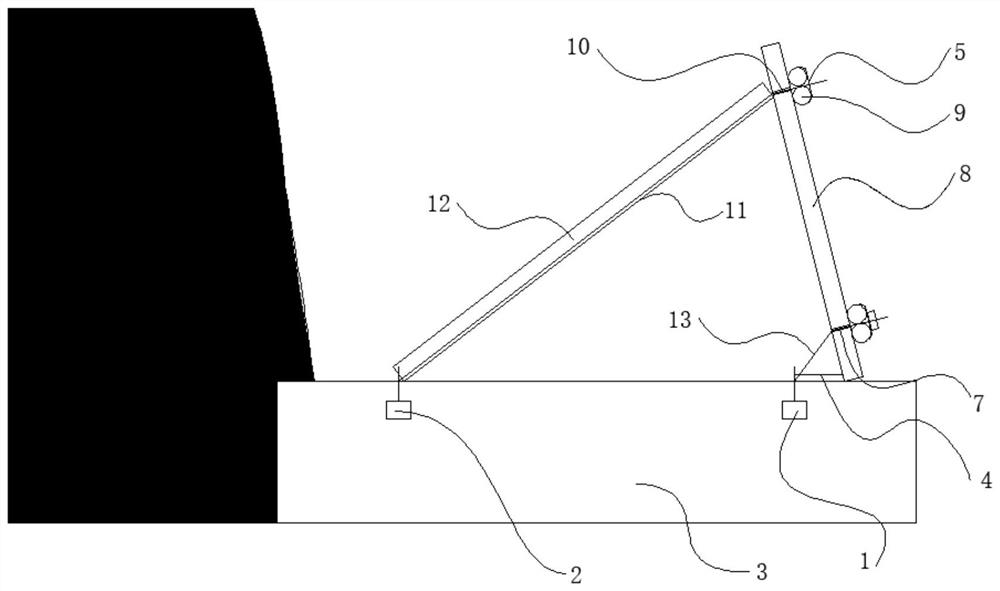

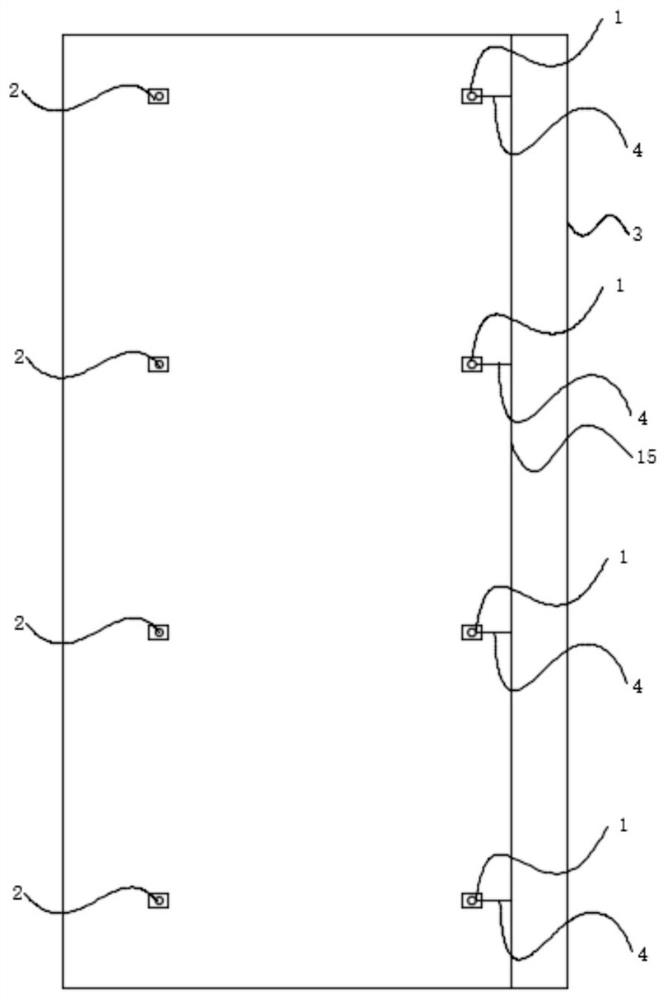

Inclined retaining wall single-side formwork reinforcing construction device and method

PendingCN113152513AGuaranteed StrengthEnsure safetyArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

The invention discloses an inclined retaining wall single-side formwork reinforcing construction device and method. The device comprises a plurality of first-layer reinforcing devices and a plurality of second-layer reinforcing devices; and each first-layer reinforcing device comprises a first base layer, a plurality of first ground anchors, a plurality of second ground anchors, a plurality of first supporting systems, a plurality of first opposite-pulling systems and a plurality of first formworks. The problems that an existing common retaining wall is difficult to construct, a single-side formwork and a mountain cannot be oppositely pulled are solved; the formwork can be reinforced under the condition that the safety of constructors is guaranteed through the design of supporting mechanisms and opposite-pulling mechanisms, and the strength of the retaining wall can be guaranteed under different construction conditions through the design of multiple layers of the reinforcing devices; and the problems of membrane expansion, slurry leakage and linear unevenness in the construction process can be effectively prevented, and the standard of design strength is guaranteed.

Owner:CCCC TUNNEL ENG +1

Scroll compressor with new exhaust port structure and exhaust valve assembly

ActiveCN103267017BReduce volumeSmall volumeRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

Owner:SUZHOU INVOTECH SCROLL TECH

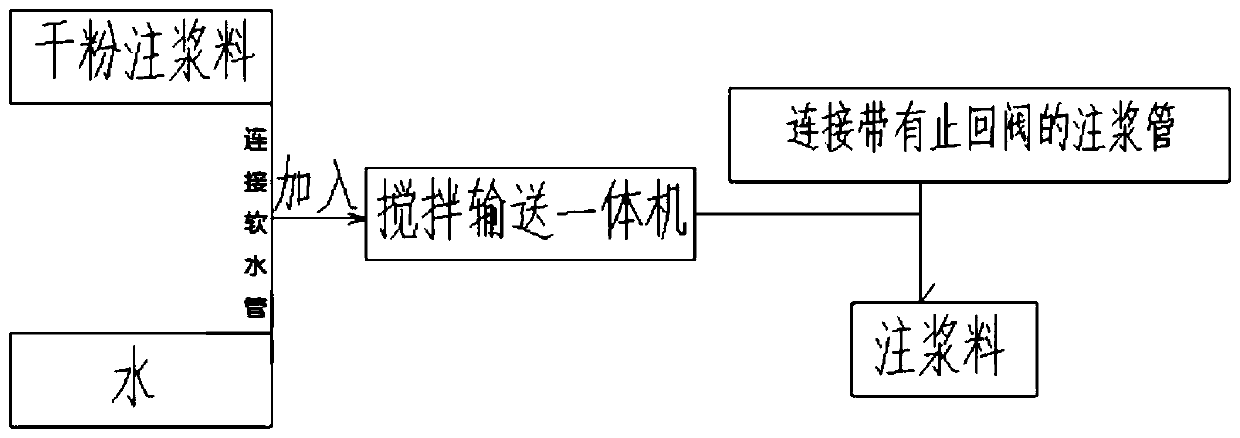

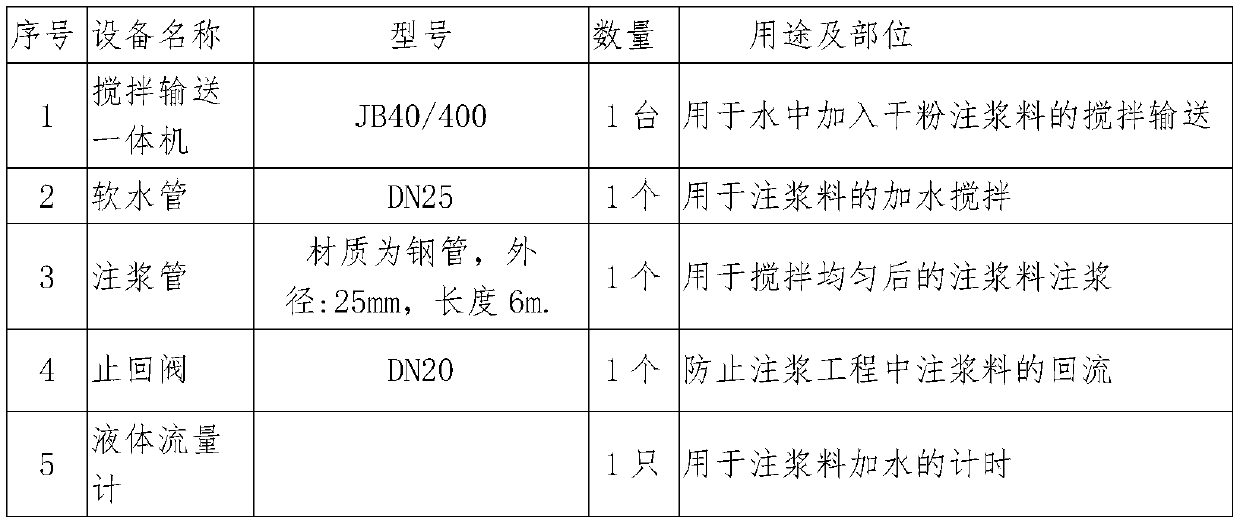

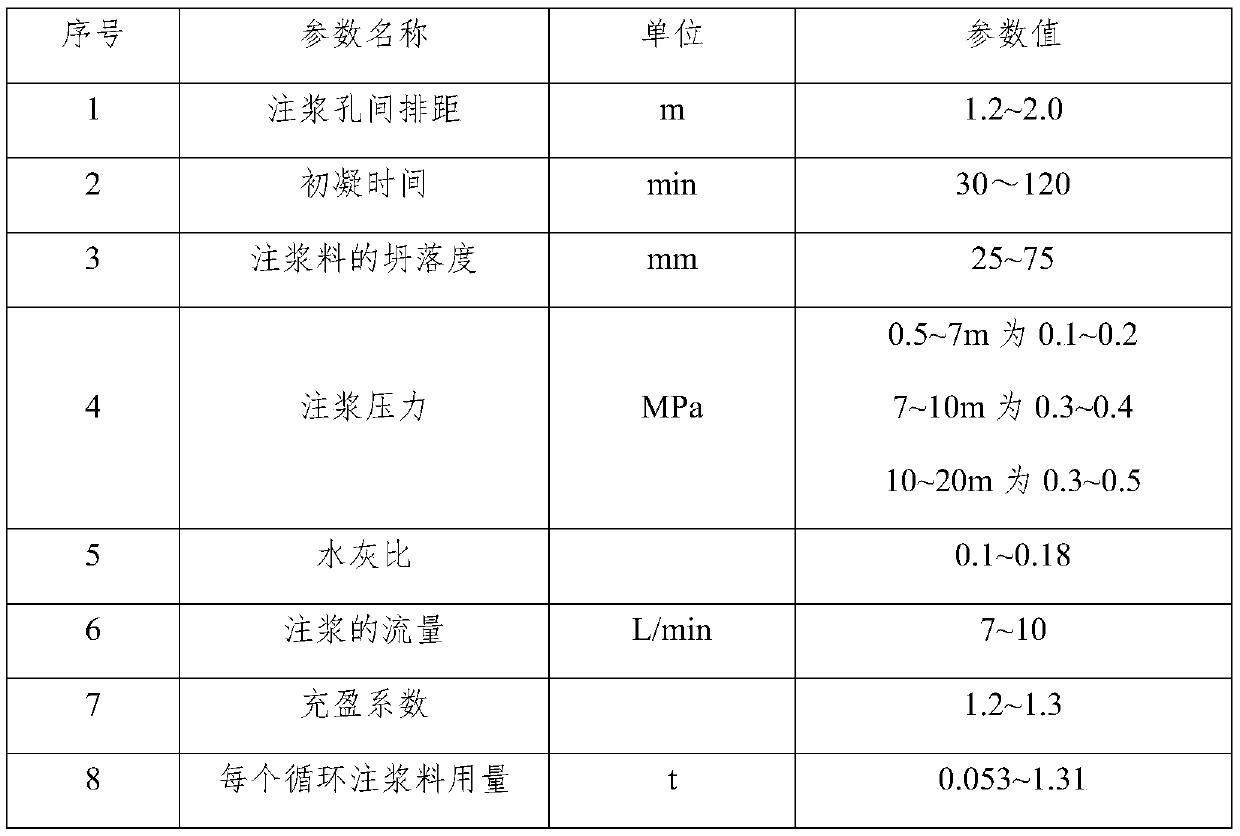

A kind of preparation method of grouting material

A preparation method for a grouting material, wherein 80-12 parts of magnesium phosphate cement, 4-15 parts of an additive, 10-15 parts of an admixture and 50-100 parts of an aggregate are used as a grouting material; by means of reasonable proportional design, the amount of magnesium phosphate cement may be effectively reduced so that the powder content in the aggregate is controlled and costs are reduced. The grouting material is suitable for geological conditions in which engineering is complex, such as tunnel engineering, slope treatment engineering, mining engineering, and urban underground spaces, and the effect of the grouting material on surrounding rock reinforcement and anti-seepage and plugging in the geological conditions in which engineering is complex is improved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Electronic device, antenna, and method for forming antenna

ActiveCN103872452BGuaranteed design strengthGuaranteed structural strengthAntenna equipments with additional functionsElectrical conductorTransceiver

The present invention provides an electronic device, an antenna, and a method for forming an antenna. The electronic device includes: a housing including a conductor area made of conductive material; a signal transceiver; an antenna including: a radiation portion formed using the conductor area for radiating and receiving signals; a coupling matching portion, coupled to the radiating portion and connected to the signal transceiver for feeding a signal between the radiating portion and the signal transceiver and energizing the radiating portion to radiate and receive signals of a specific frequency bandwidth . In the technical solutions according to various embodiments of the present invention, the antenna can have good antenna performance while ensuring the appearance design and structural strength of the electronic device.

Owner:LENOVO (BEIJING) LTD

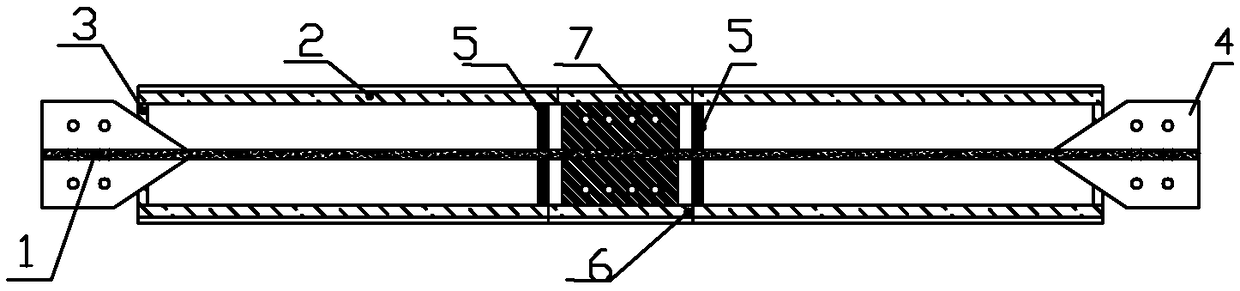

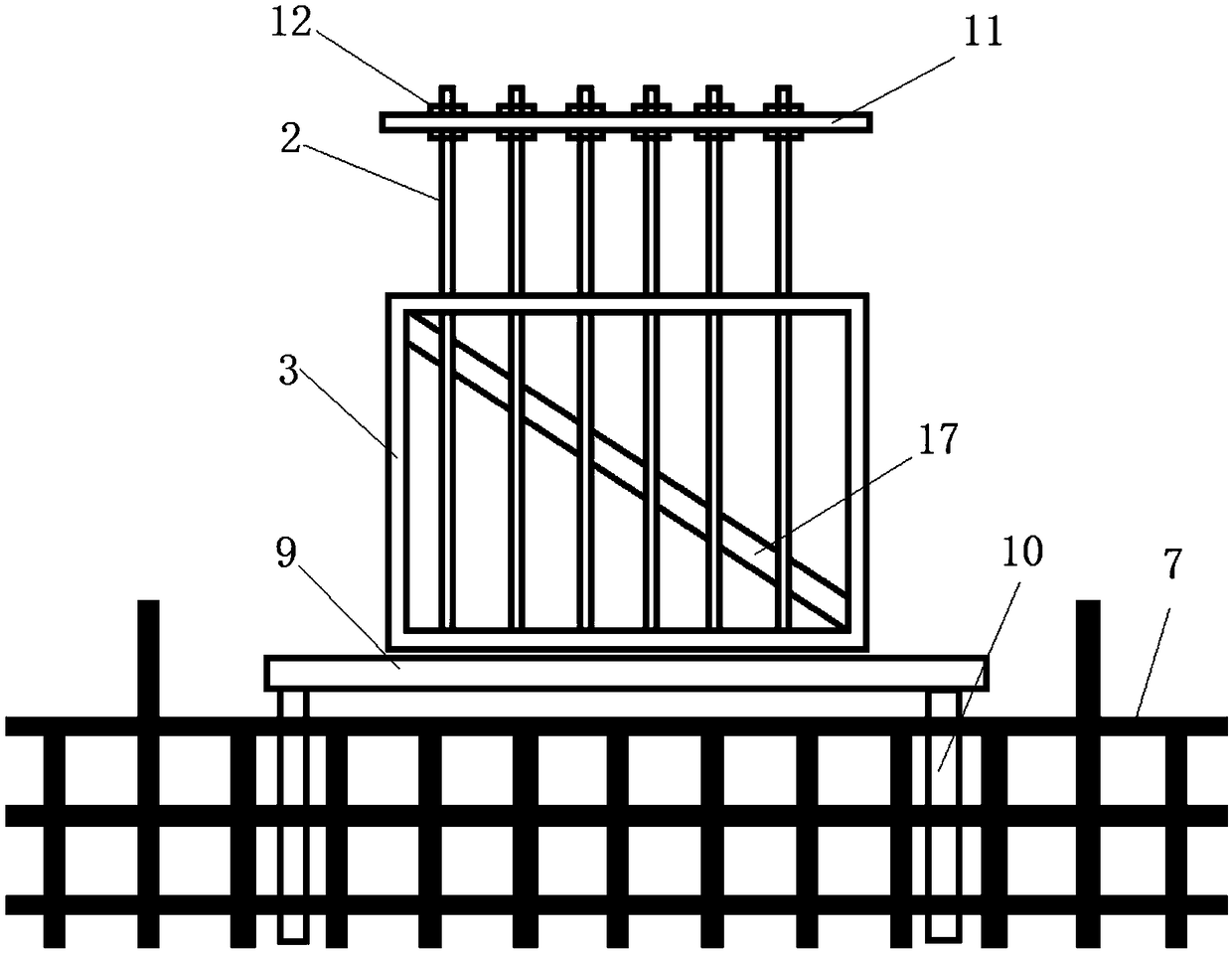

Assembled large-scale buckling-restrained bracing member

PendingCN109184312AEfficient deliveryDissipate energyProtective buildings/sheltersShock proofingStress concentrationResidual deformation

The invention discloses an assembled large-scale buckling-restrained bracing member, which comprises sub buckling-restrained braces and connection nodes. The sub buckling-restrained braces are dividedinto end sub buckling-resistant braces and middle sub buckling-restrained braces according to the setting position and the cover plate type. The connection nodes are used to connect the sub buckling-restrained braces. The connection sections between the sub buckling-restrained braces are strengthened by splicing angle steel, which ensures effective transmission of the axial force and enables eachsub buckling-restrained brace to yield and dissipate energy. Energy dissipating inner cores are connected by bolts, so that the adverse effects caused by stress concentration, welding residual stressand welding residual deformation caused by welding are avoided, the design strength of the linear inner cores is guaranteed, and the low-cycle fatigue performance is improved. Meanwhile, the assembled large-scale buckling-restrained bracing member can be designed, manufactured and assembled in sections, is convenient to transport, and breaks through the limitation of plate and section steel specifications.

Owner:HUAQIAO UNIVERSITY

Complex pressure cooker cover

InactiveCN101032372AIncrease profitMeet design strength requirementsCooking-vessel lids/coversPressure-cookersPressure cooking

The present invention discloses one technological scheme for composite pressure cooker cover, and belongs to the field of cooker technology. The composite pressure cooker cover includes one central cover and one toothed ring, and the toothed ring includes one inside ring connected to the central cover and one outer ring with a connecting mechanism. The present invention has the cooker cover stress considered, and possesses high material utilization and lowered production cost.

Owner:王永光

Mega column anchor bolt construction method

ActiveCN109252674AGuaranteed design strengthReduce pressureGirdersJoistsField conditionsArchitectural engineering

The invention relates to the field of building construction, in particular to a mega column anchor bolt construction method, mainly including: pre-assembling anchor bolts via a support, grouping according to field conditions, transporting in bulk to a mounting site, measuring, assembling in a whole, performing position correction on the anchor bolts via a positioning socket plate so as to completemega column anchor bolt construction. Therefore, the problem with mounting construction and positioning adjusting process of mega column anchor bolts is solved.

Owner:北京市机械施工集团有限公司 +1

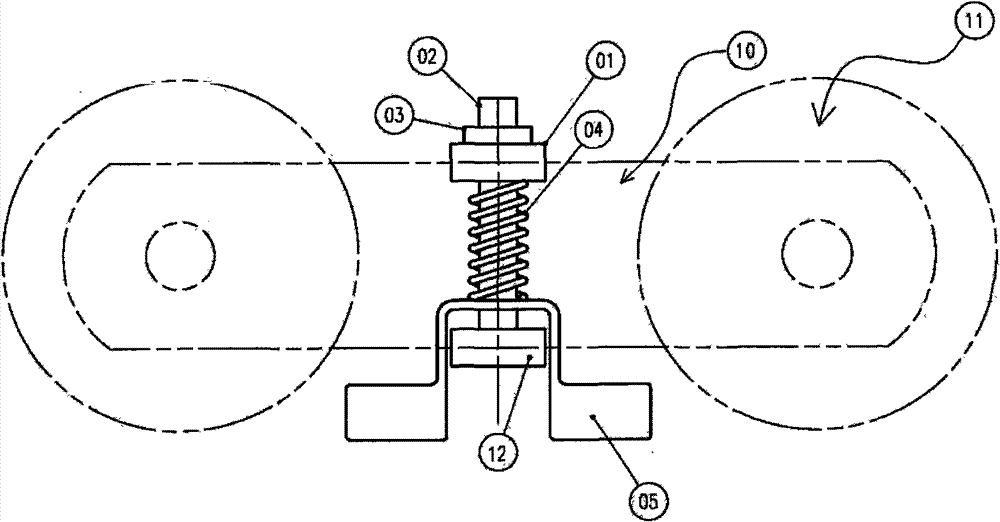

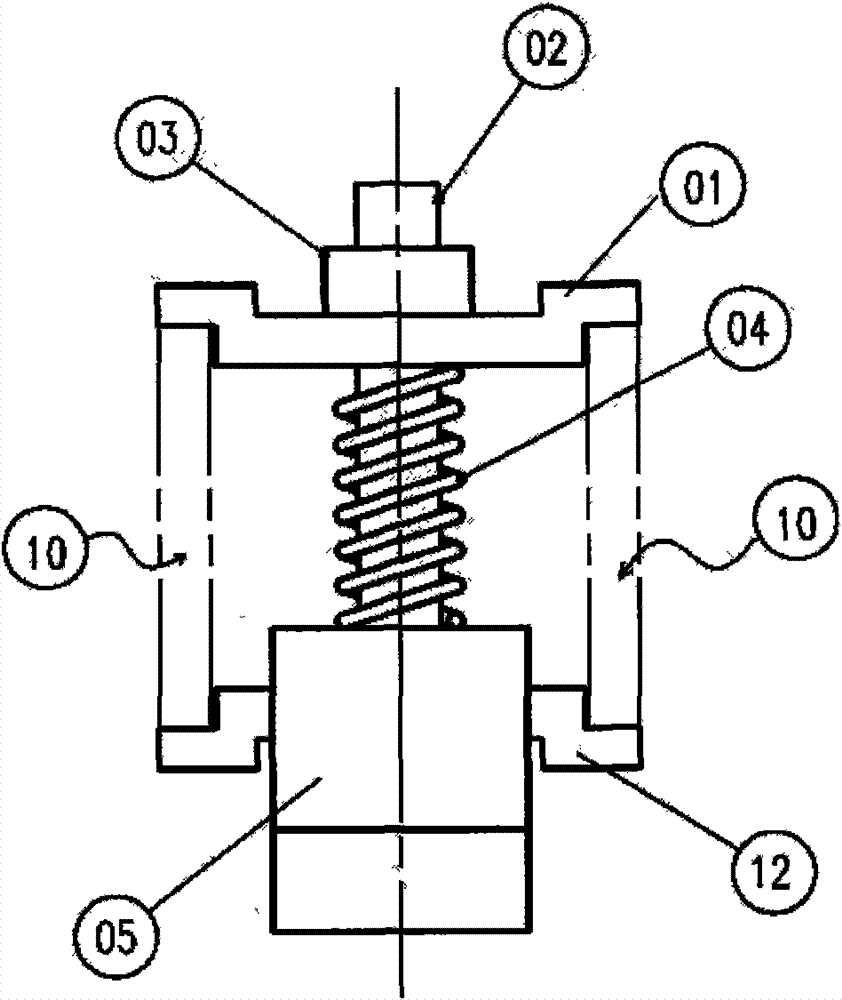

Bearing structure

PendingCN113898667AGuaranteed design strengthReduce lossRolling contact bearingsBearing assemblyPhysicsEngineering

The invention relates to a bearing structure which comprises a bearing main body, a signal processor, a signal emitter and a power supply. The bearing main body comprises a bearing inner ring and a bearing outer ring, and the bearing inner ring and the bearing outer ring are relatively rotatably assembled through a bearing retainer; at least one sensitive coating is formed on at least one part area of at least one side wall of the bearing outer ring; a sensitive groove is formed in the sensitive coating, and the sensitive groove is configured for generating corresponding resistance change with temperature change, and the signal processor is arranged on the bearing outer ring; the signal processor is electrically connected with the sensitive groove, and the signal transmitter is arranged on the bearing outer ring; and the signal transmitter is electrically connected with the signal processor, and the power supply is arranged on the bearing outer ring. According to the bearing structure, the sensitive coating capable of acquiring temperature information in real time is integrated on the outer ring of the bearing, the working state of the bearing structure can be monitored in situ at a short distance, the real measured value of the bearing is acquired, and the loss caused by signal transmission is reduced.

Owner:北京石墨烯技术研究院有限公司

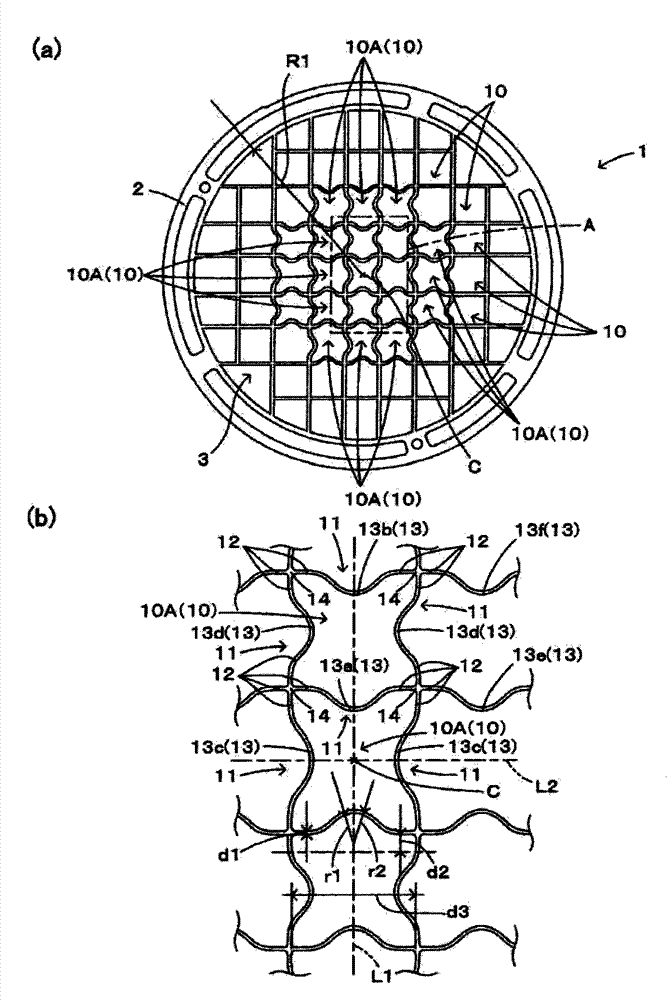

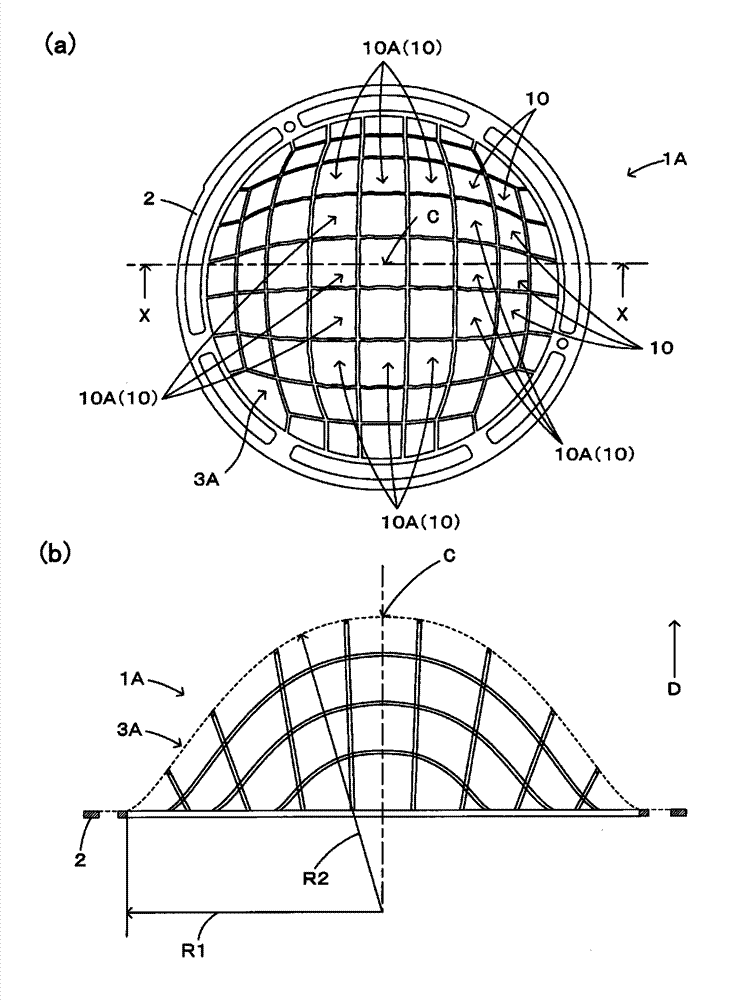

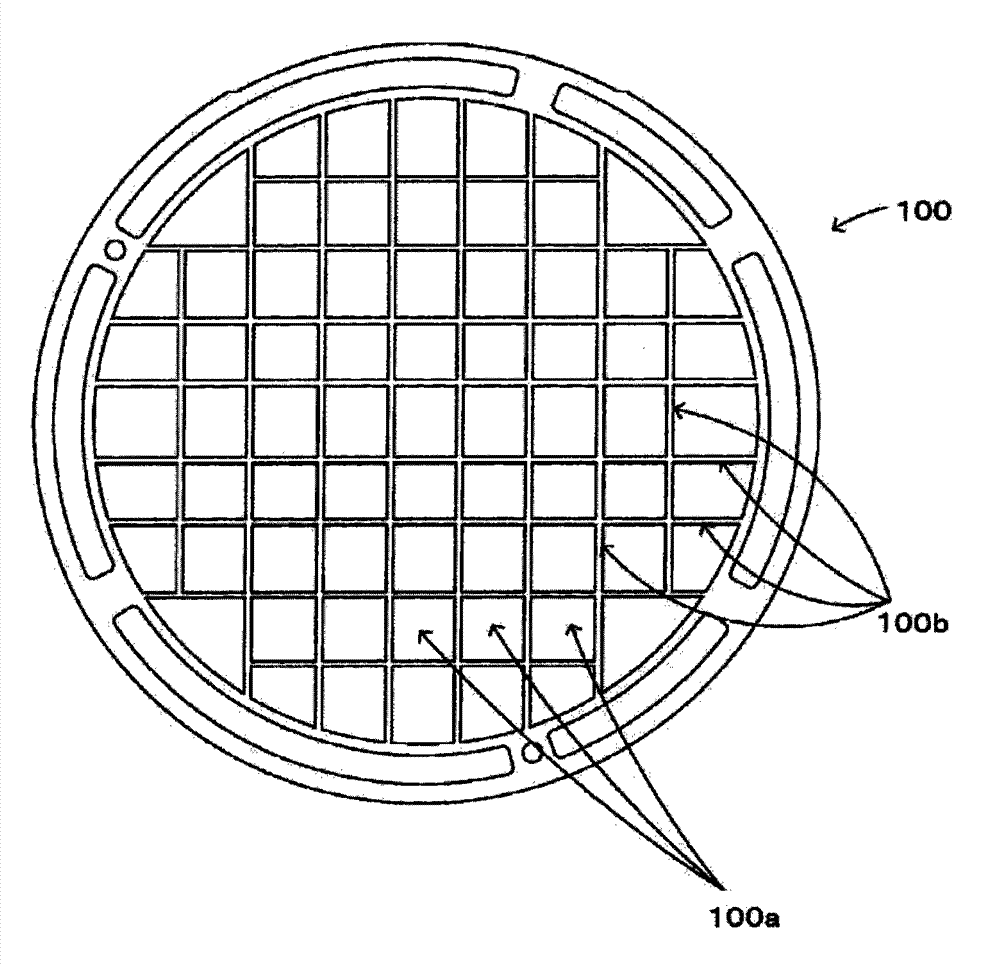

Method for machining metal plate and mesh member produced by means of said machining method

ActiveCN104718032AImplement deep drawingEfficient processingMembrane filtersStationary filtering element filtersMachiningDome shape

This method for machining a metal plate machines into a dome shape a mesh body (1) that is made from a metal plate and at which a plurality of lattice-shaped through holes (10) have been formed, and is characterized in that when forming a mesh body provided with a plurality of sides (11) configuring the through holes by machining the metal plate, an extension allowance section (13) is formed curving in the plane-region direction at the sides of the machined region at which the mesh body is pressed in a drawing-machining, and the mesh body is machined in the dome shape by drawing-machining from one side to another side.

Owner:UCHIYAMA MFG

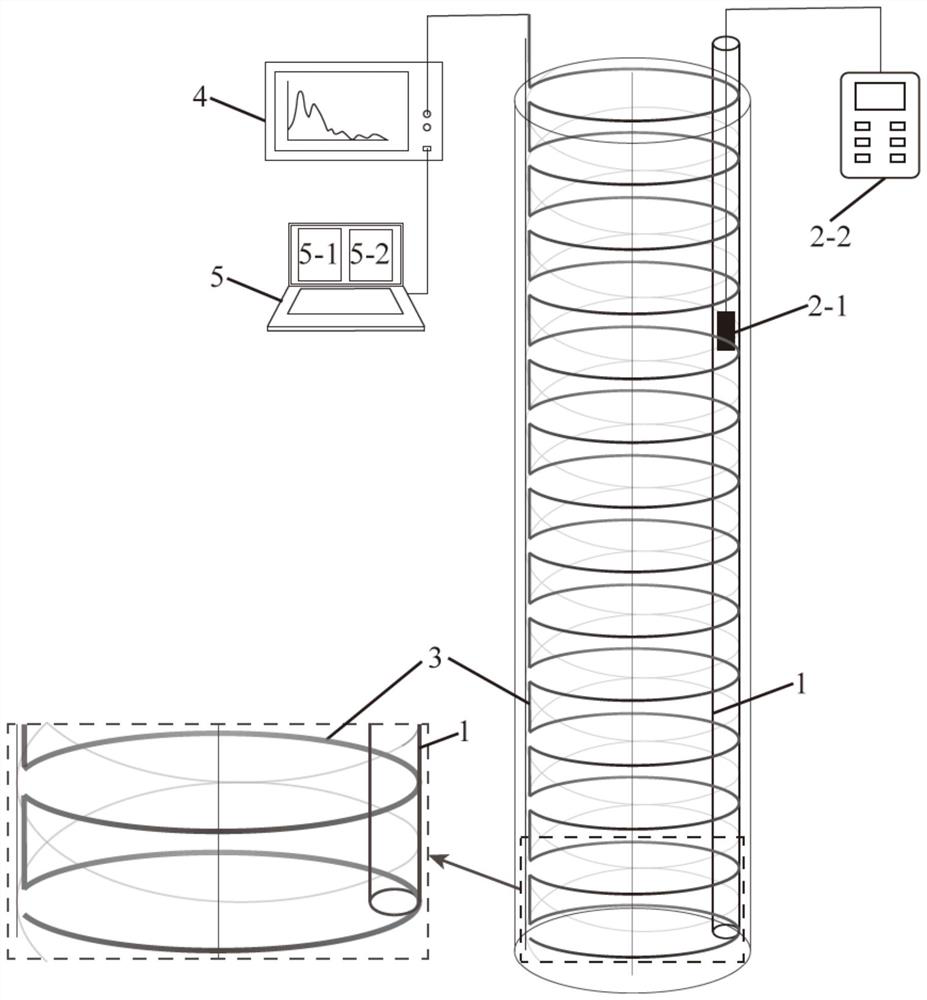

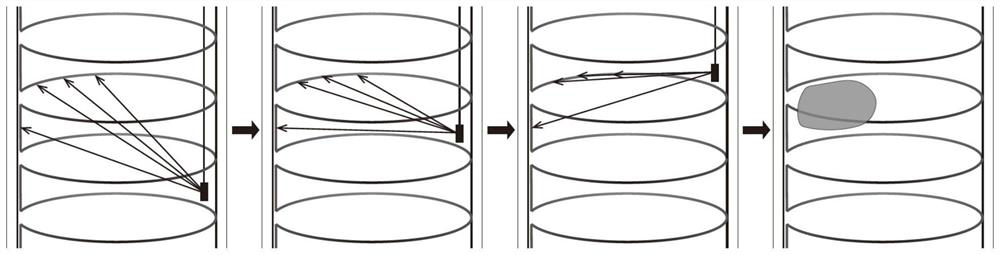

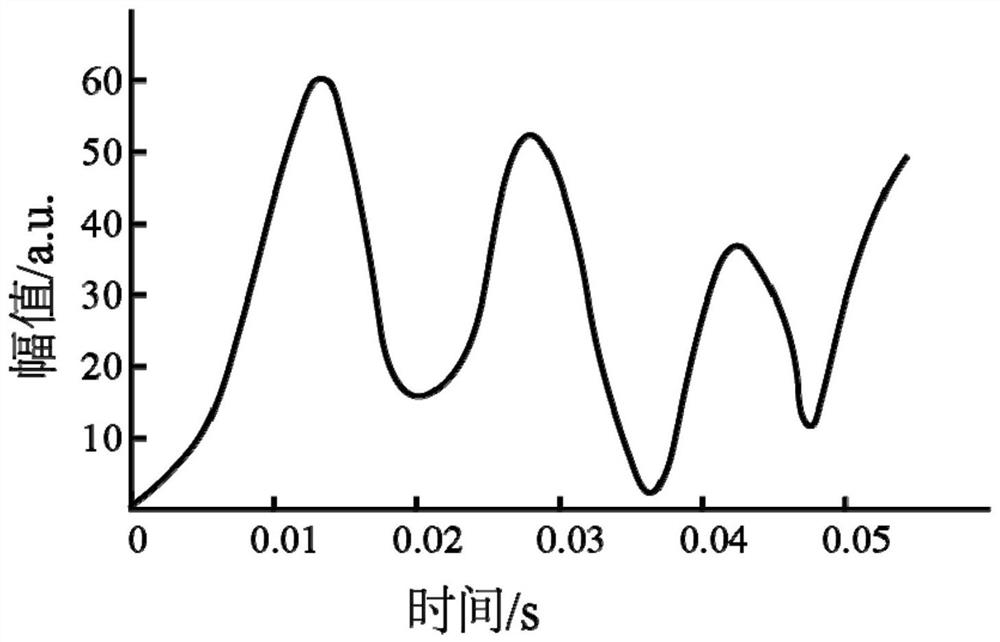

Cast-in-place pile integrity optical fiber ultrasonic detection device and detection method thereof

PendingCN114441645AGuaranteed design strengthReduce integrity detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

The invention relates to the technical field of cast-in-place concrete pile body defect detection, in particular to a cast-in-place pile integrity optical fiber ultrasonic detection device and a detection method thereof. An ultrasonic transmitting unit comprises at least one sounding pipe, an ultrasonic transmitting transducer and a controller; the data acquisition unit comprises a sensing optical cable and a distributed sound wave sensing demodulator; the data analysis unit comprises a cast-in-place pile integrity evaluation module; the sensing optical cable is wound on a reinforcement cage, the sounding pipe is fixed to one side of the reinforcement cage, the ultrasonic transmitting transducer is arranged in the sounding pipe in a liftable mode and electrically connected to the controller, and the sensing optical cable is electrically connected to the cast-in-place pile integrity evaluation module through the distributed sound wave sensing demodulator. The defect that a traditional sensor is not prone to survive in the cast-in-place concrete pile is overcome, and the detection cost is reduced.

Owner:NANJING UNIV

Decorative moulding, closing component and decorative moulding assembly

ActiveCN105421727AGuaranteed design strengthQuick checkBuilding constructionsEngineeringStructural engineering

The invention relates to the field of building decoration, in particular to a decorative moulding, a closing component and a decorative moulding assembly formed by the decorative moulding and the closing component. The decorative moulding comprises at least one panel. At least two first reinforcing ribs are arranged at one side of each panel. Buckles are arranged on the opposite face of every two adjacent first reinforcing ribs. The closing component comprises a closing component body which is a panel with the hollow center. At least two locking arms are arranged at one side of the closing component body oppositely. The distance between every two locking arms corresponds to the distance between every two adjacent first reinforcing ribs. A buckle head is arranged at one end, away from the closing component body, of each locking arm. The buckle heads and the buckles are mutually matched and locked closely. In this way, it can be ensured that terminals such as a circuit inserting board and a switch can be installed on the decorative moulding fast. Attractiveness of the decorative moulding can be ensured to the maximum, and the decorative moulding can be connected or disassembled fast.

Owner:嘉兴天美环保集成墙面有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com