Complex pressure cooker cover

A compound and pressure technology, applied in the field of kitchen utensils, can solve the problems of low utilization rate of pot lid materials, difficulty in taking into account food hygiene and material strength, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

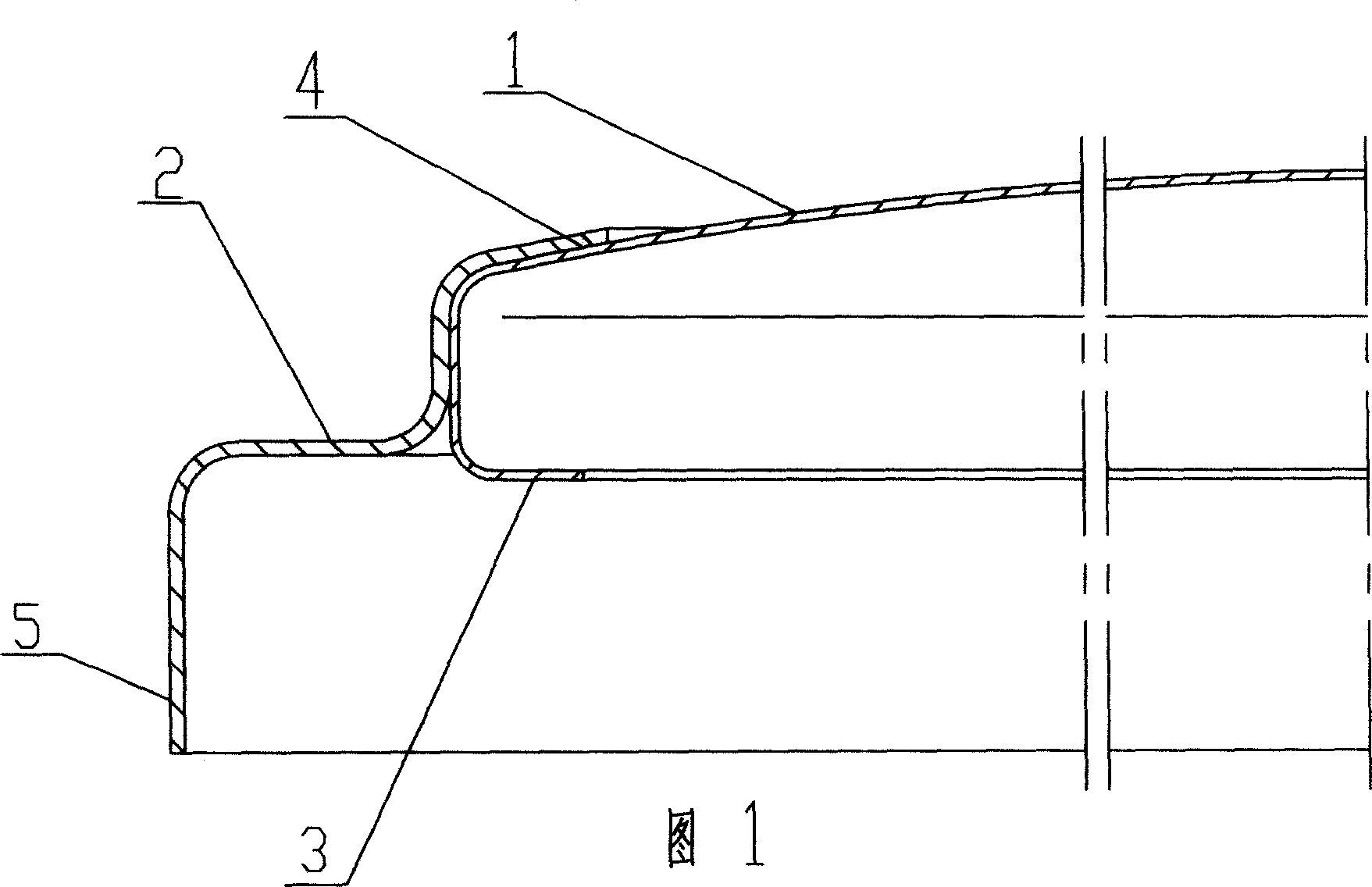

[0016] Embodiment 1 Referring to Fig. 1, take the inner pot diameter of 22cm and the maximum working pressure of 100kPa as an example: the center cover 1 is made of high-quality, corrosion-resistant, stainless steel plate that meets food hygiene requirements, such as SUS304, etc., and its thickness can be determined according to the diameter of the inner pot. The size, that is, the size of the force is determined. When the caliber of the inner pot is 22cm, a material with a thickness of about 0.6mm can be selected for use. Compared with the thickness of about 1.2 mm commonly used in the prior art, the space for material saving is large. In order to make the center cover 1 have a better force bearing capacity, it can be designed as an upper convex circle. The outer edge 3 of the center cover is turned inward to form a hanging ring, which can meet the needs of hanging the sealing ring, so that the hanging ring in the prior art can be omitted, and the purpose of saving materials...

Embodiment 2

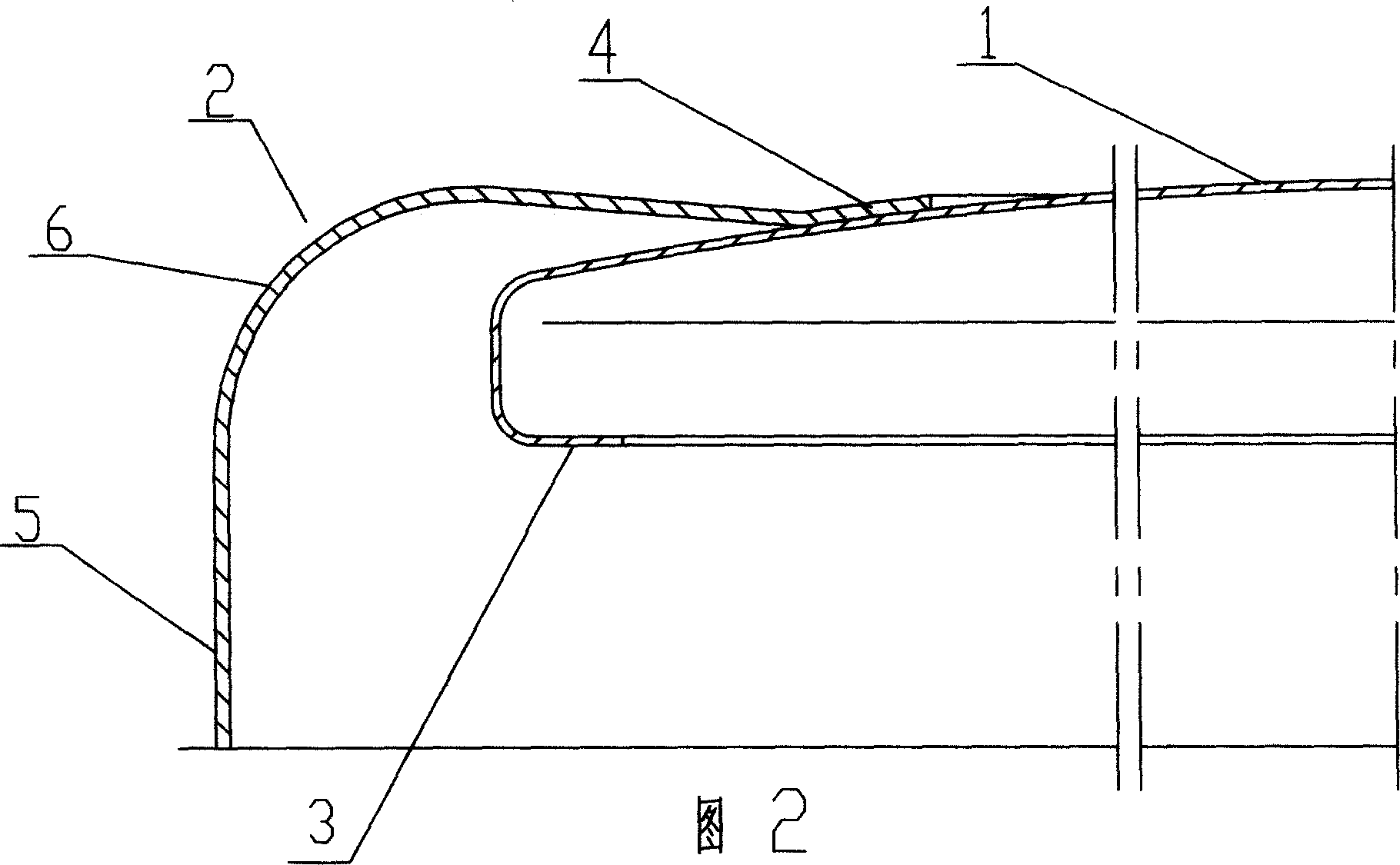

[0020] Embodiment 2 is referring to Fig. 2, is the embodiment of elastic composite pressure cooker cover. Still taking the inner diameter of the pot of 22cm and the maximum working pressure of 100kPa as an example: the transition part between the outer side 5 of the lid ring and the inner side 4 of the lid ring is designed as a circular arc transition 6 according to the requirements of the elastic composite pressure cooker lid. The transition 6 is the part that produces elastic deformation after being stressed, that is, the arc transition 6 between the maximum diameter of the capping ring 2 and its minimum diameter. The R dimension of the circular arc transition 6 in Fig. 2 can be selected at about 16mm, in order to obtain enough elastic displacement, can select the radius difference between the inner side 4 of the appropriate denture ring and the outer side 5 of the denture ring, this difference and the elasticity The amount of displacement is proportional, and the radius dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com