Hoisting method of steel reinforcement cage

A technology for hoisting and reinforcing steel cages, which is used in transportation and packaging, load hanging components, sheet pile walls, etc., can solve problems such as insufficient guarantee of hoisting without deformation, insufficient rigidity of steel bars, and potential safety hazards, so as to save reinforcement. The effect of settlement time, high work efficiency, and not easy safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

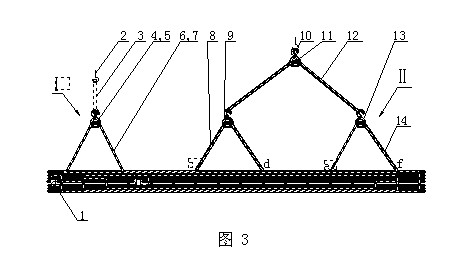

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

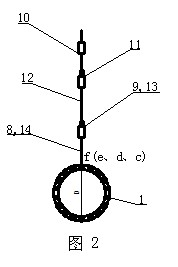

[0028] The reinforcing cage of the present embodiment has a diameter of 0.5m, a cage length of 33.6m, and a reinforcing cage of an aspect ratio of 67.2. No special reinforcement is required for the hoisting reinforcing cage, and it is placed flat on a platform on the ground. The hoisting device adopts a hoist (not shown) with main and auxiliary hoisting hooks and specially provided main hoisting assembly I and auxiliary hoisting assembly II.

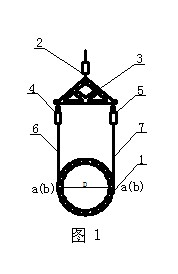

[0029] The main lifting components such as figure 1 , mainly be made up of lifting beam 3 and two groups of lifting pulleys 4,5 spanning wire rope 6,7 on it, mention lifting beam 3 two ends and connect one group of lifting pulleys 4,5 respectively. The lifting beam 3 is an isosceles triangular steel member, which is cut from a single piece of steel plate, without a welded part, so as to ensure a stronger tensile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com