Patents

Literature

62 results about "Vertical diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

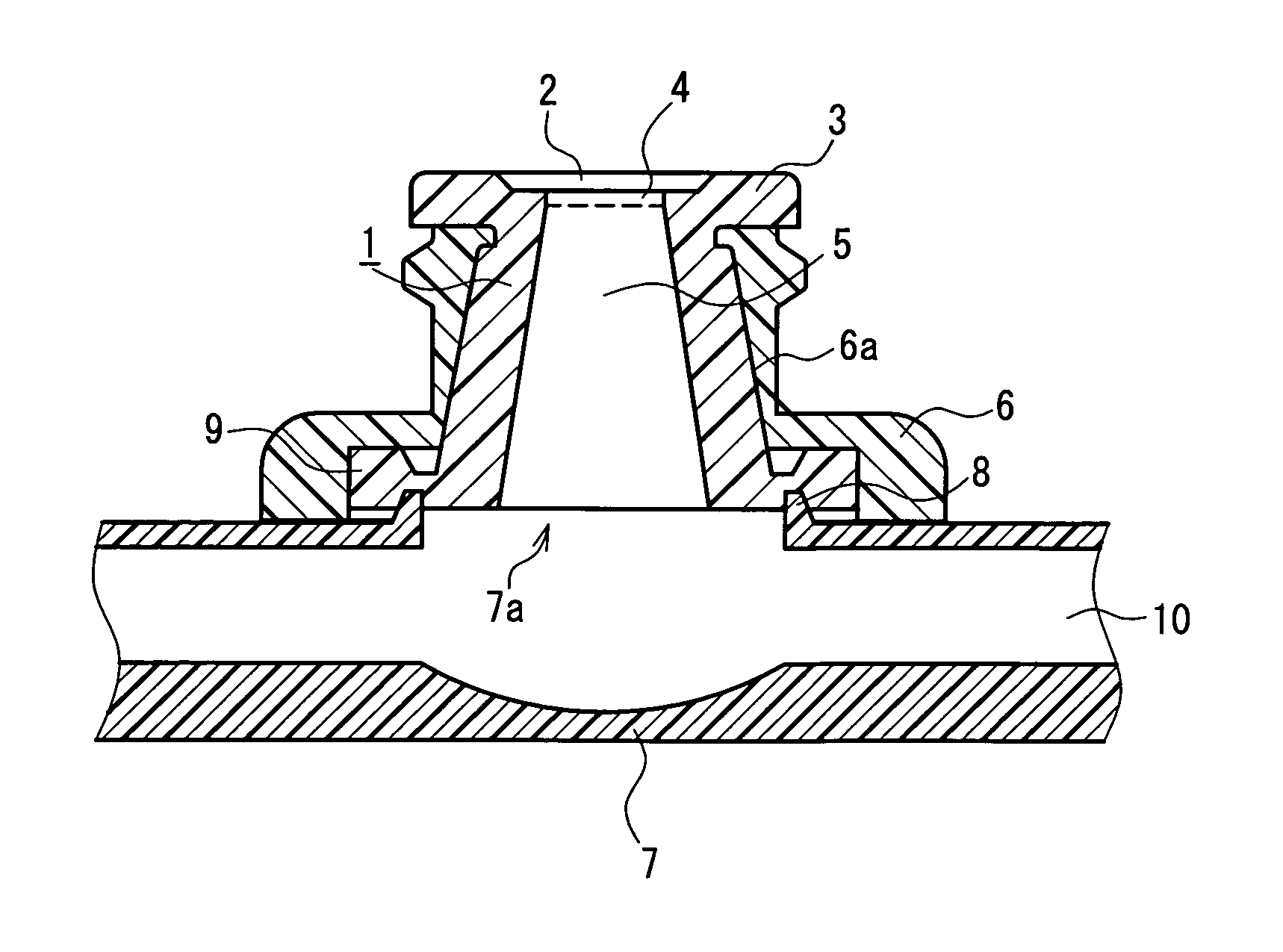

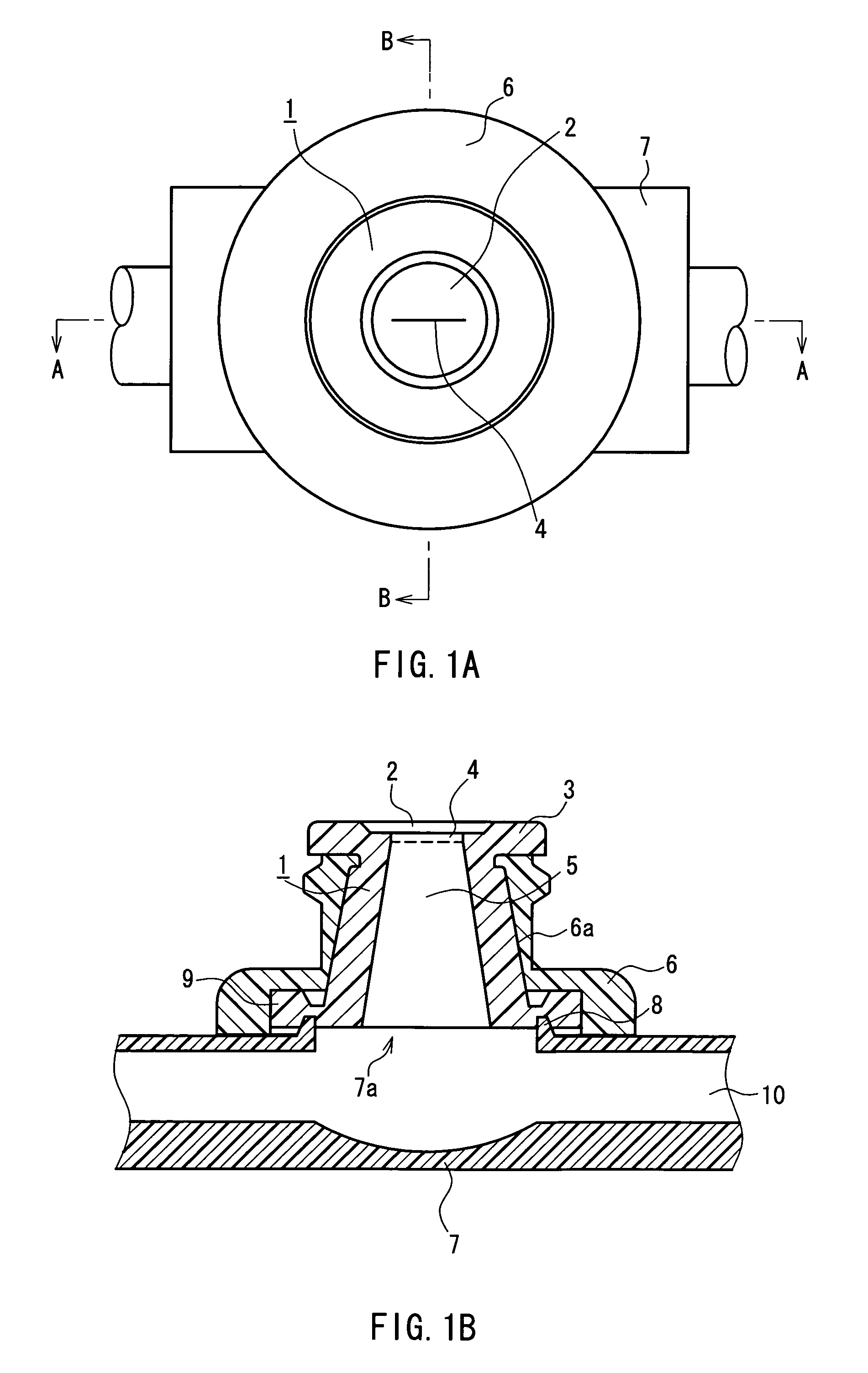

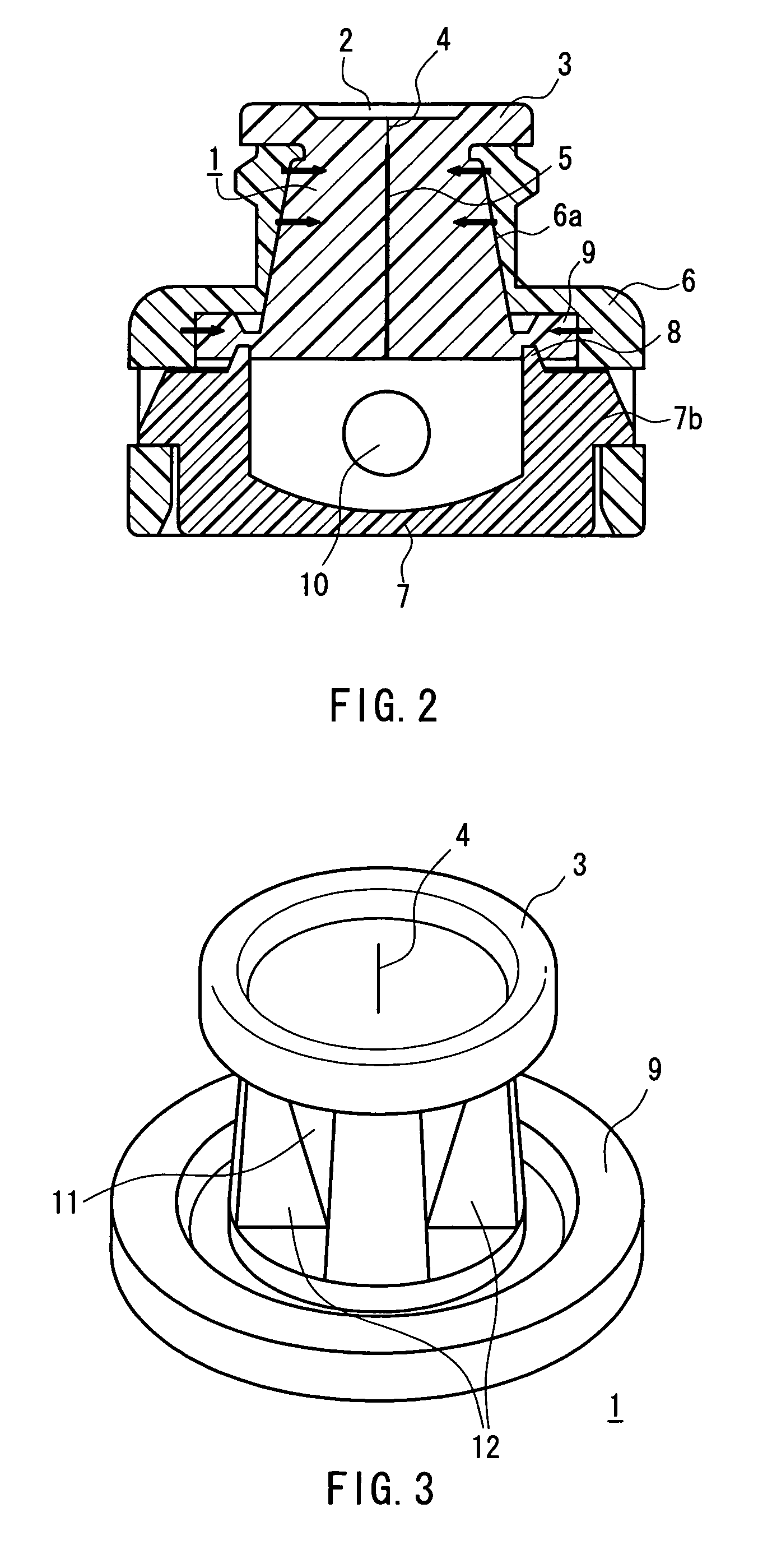

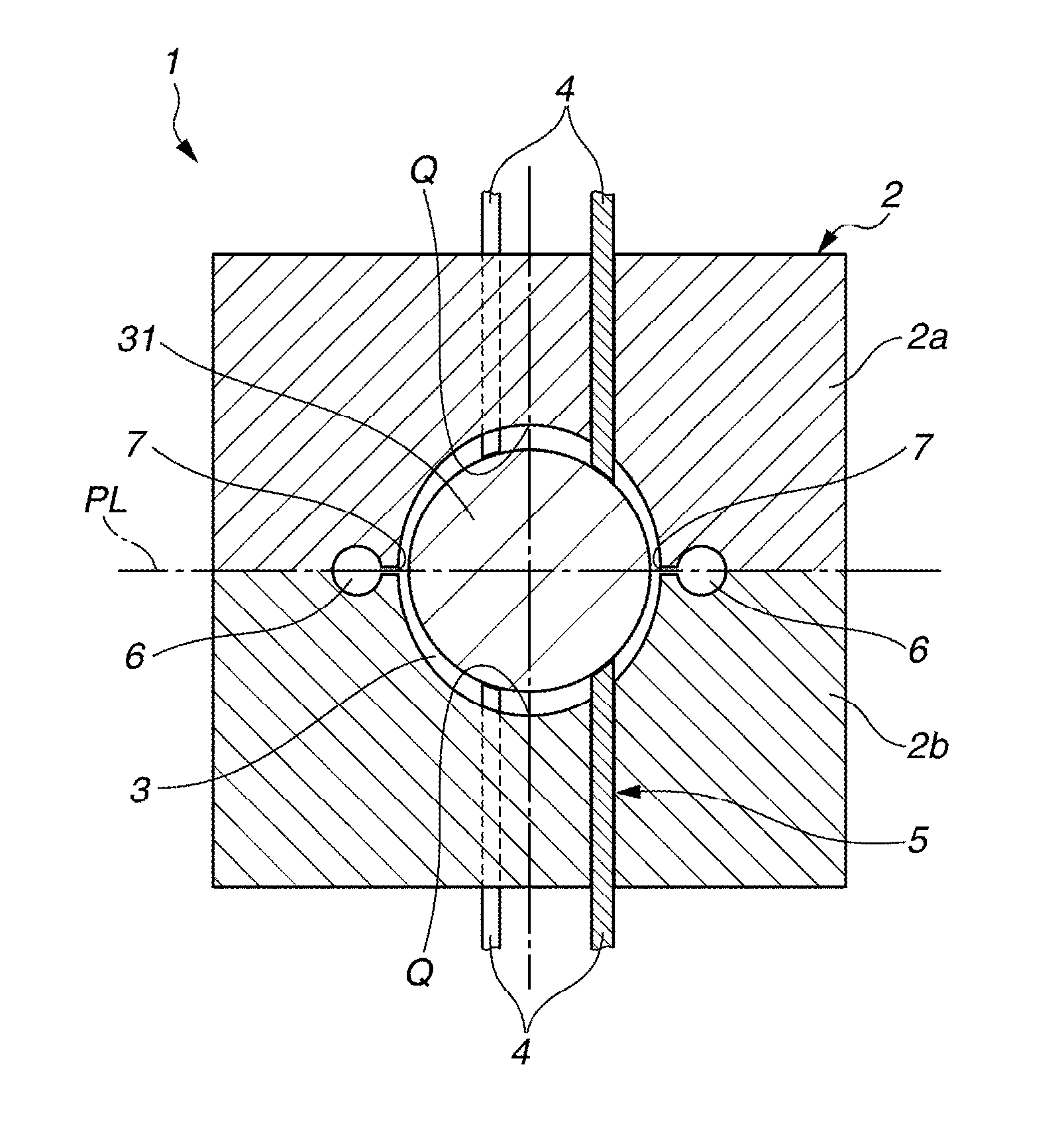

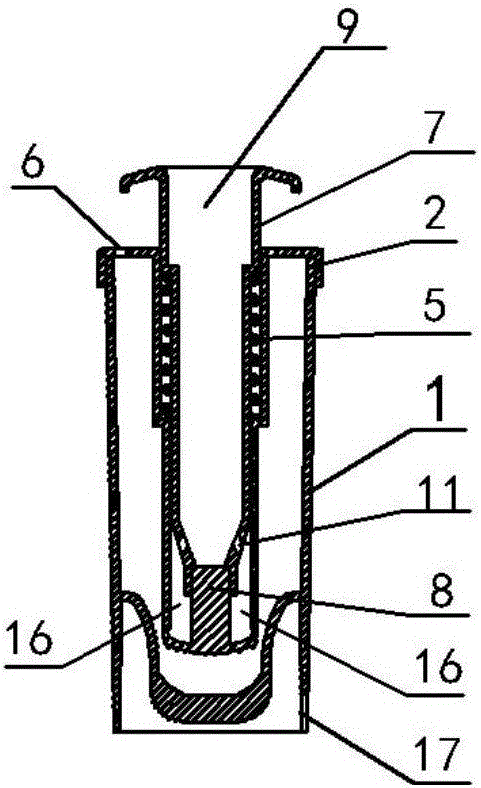

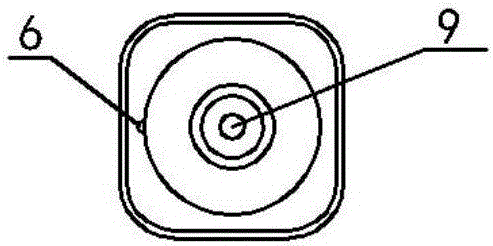

Needleless port

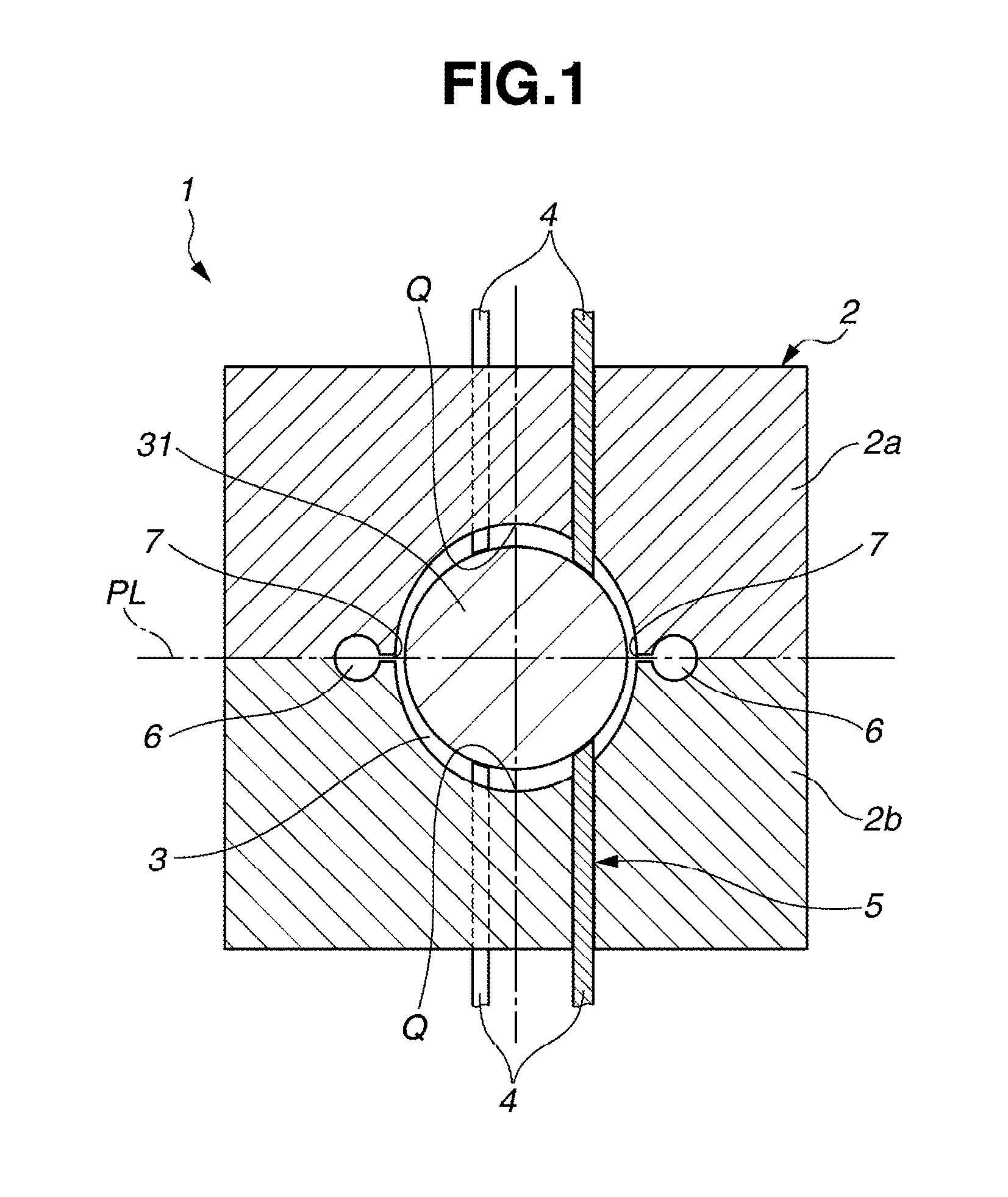

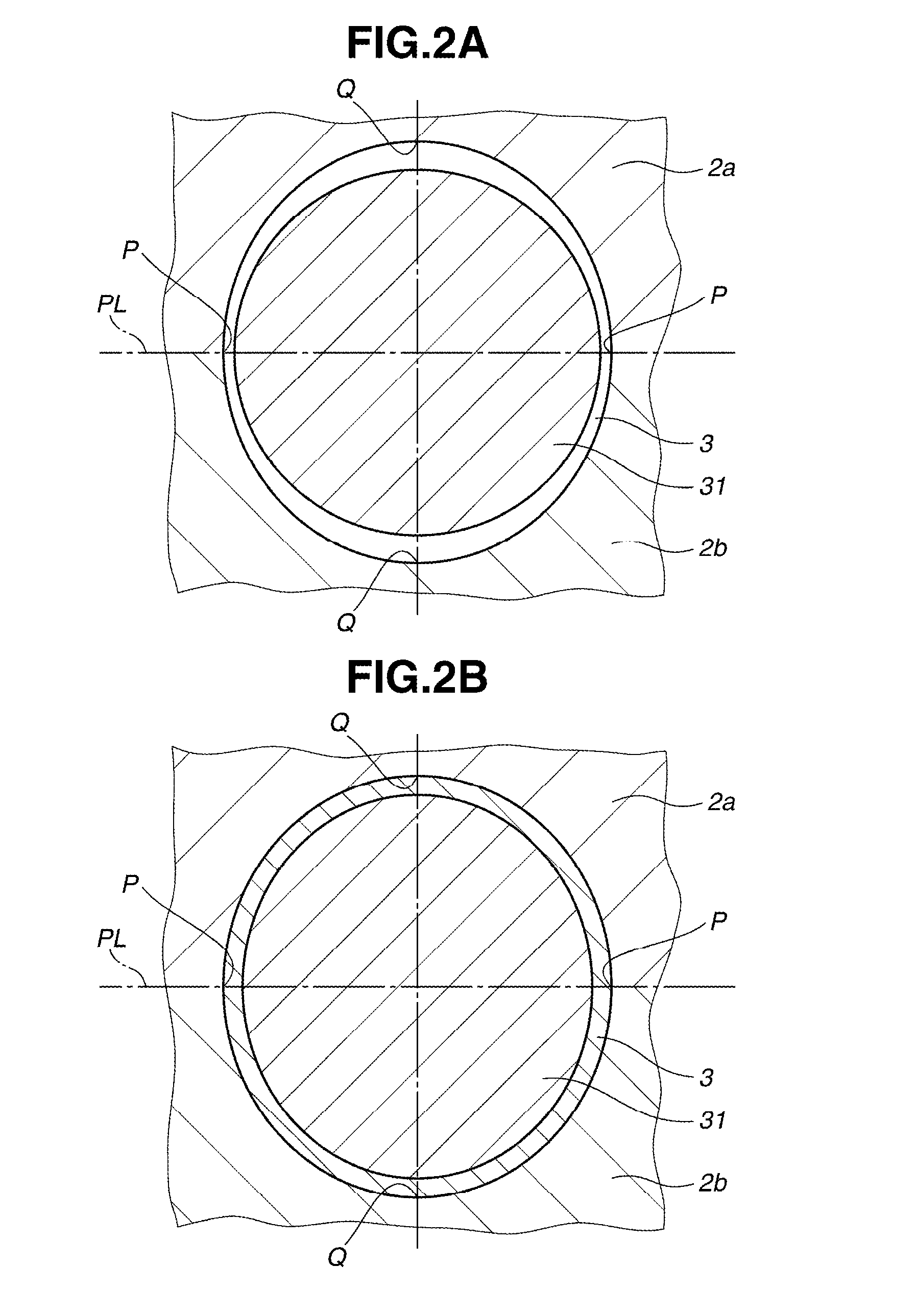

A septum (1) is held in the cavity of a cover (6) and mounted on a pedestal (7) forming part of a flow channel, and comprises a main body having a through passageway and compression ribs formed in the sides thereof. In the main body, the vertical diameter of the cross section orthogonal to the through passageway is longer than the transverse diameter, and the through passageway includes a vertical diameter direction slit (4) formed in the vicinity of the outer end surface of the main body, and a hole (5) that is formed in a region extending from the slit to the inner end surface of the main body and whose cross section is spindle-shaped having a longer axis extending in the vertical diameter direction. The compression ribs are formed in the opposite sides of the main body in the transverse diameter direction, and the cavity of the cover is of circular cross section whose diameter is shorter than the outer surface spacing between the compression ribs. With the septum mounted, a space is defined between part of the surface of the main body and the inner wall surface of the cover. Further, the hole is closed by a compressive force acting on the septum from the inner wall surface of the cover through the compression ribs. The through passageway in the septum hardly forms a dead space that would cause a residual liquid therein, and the slit in the septum surface hardly opens even at the time of pressurization.

Owner:JMS CO LTD

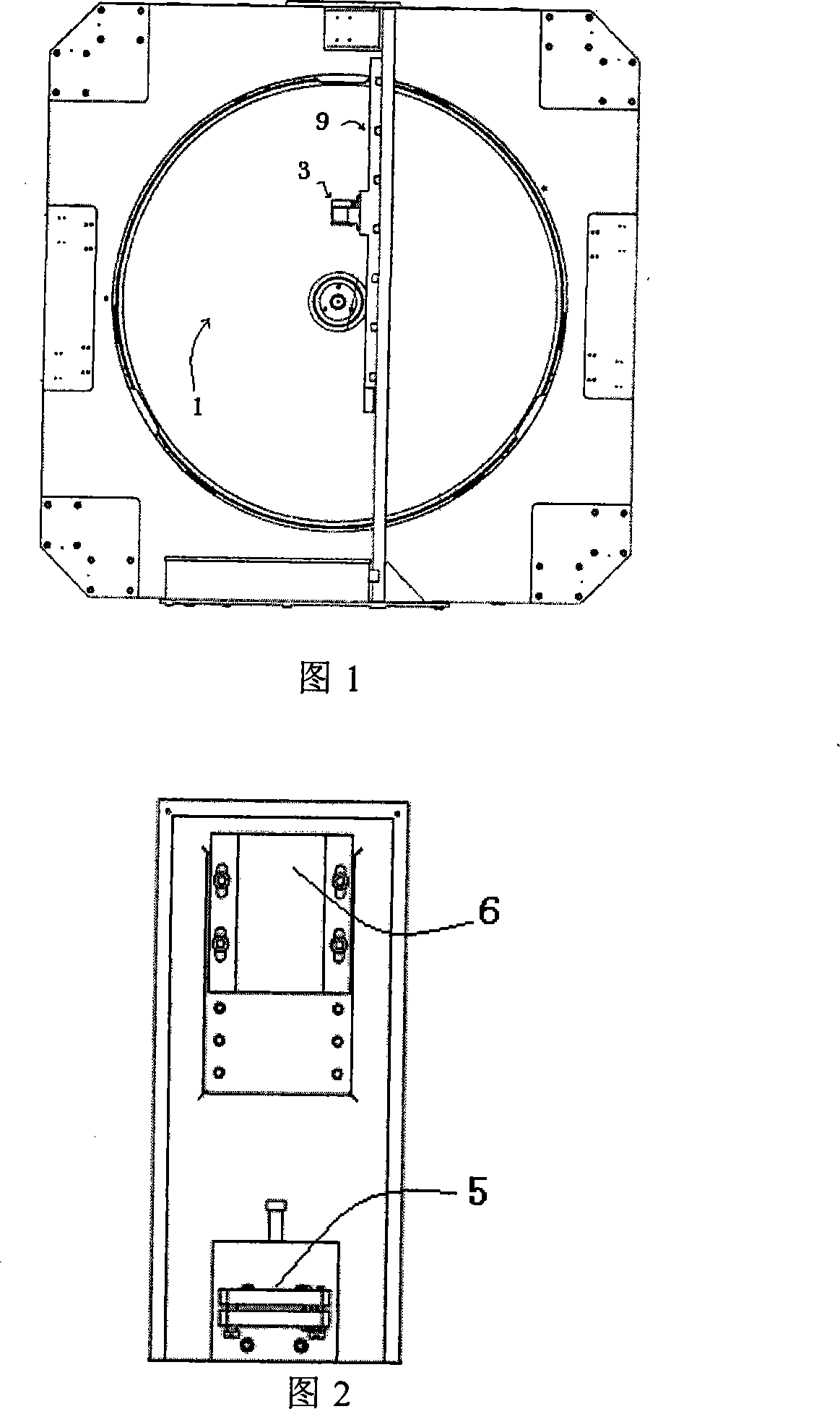

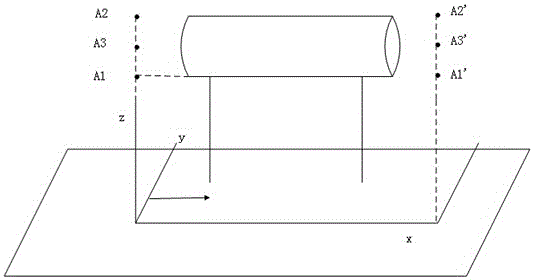

Device for detecting large-sized perspective glass primary and secondary mirror spacing

InactiveCN101236073AImplement pan scanSolve the problem of adjusting the distance between primary and secondary mirrorsUsing optical meansTelescopesOptical axisEngineering

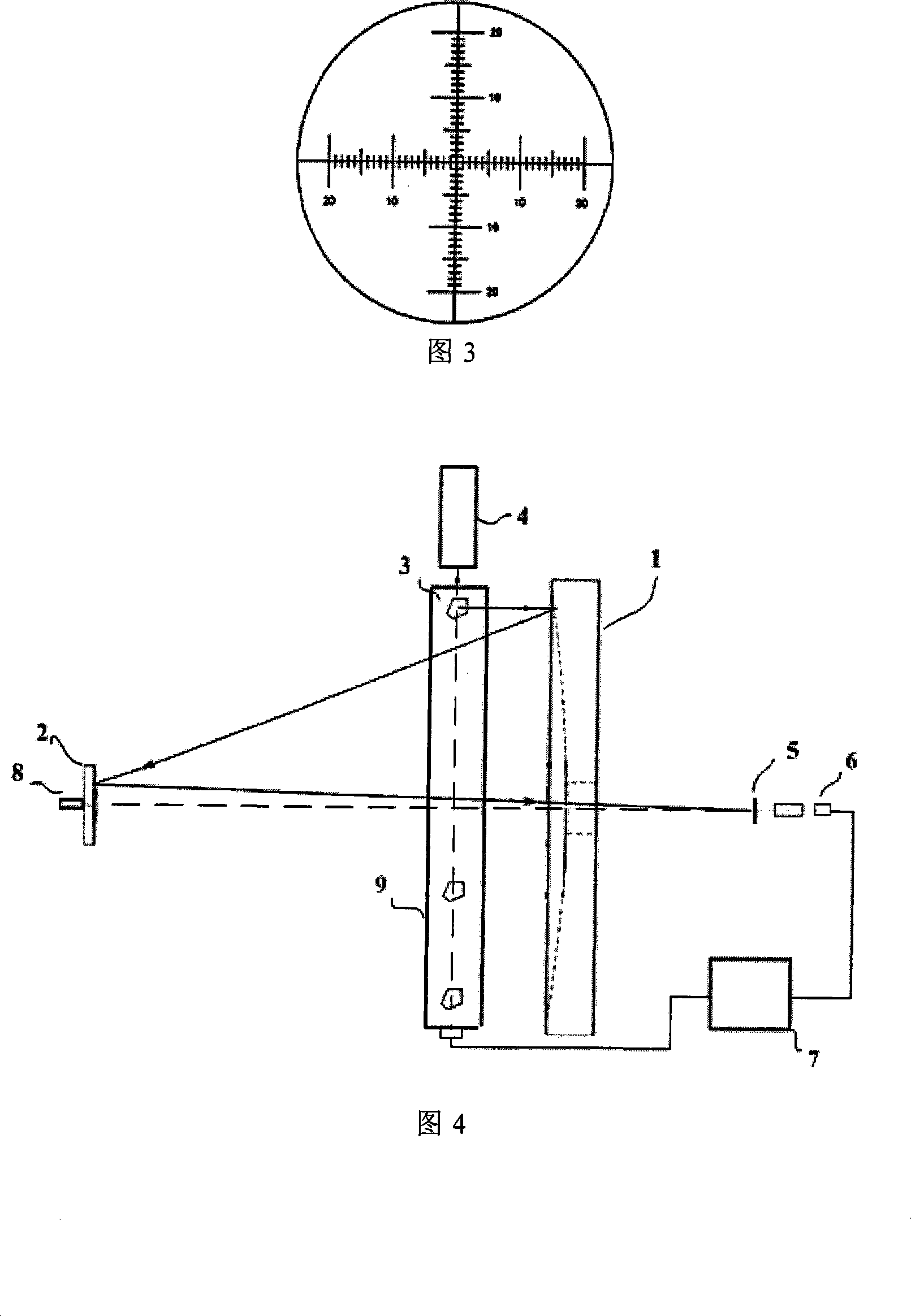

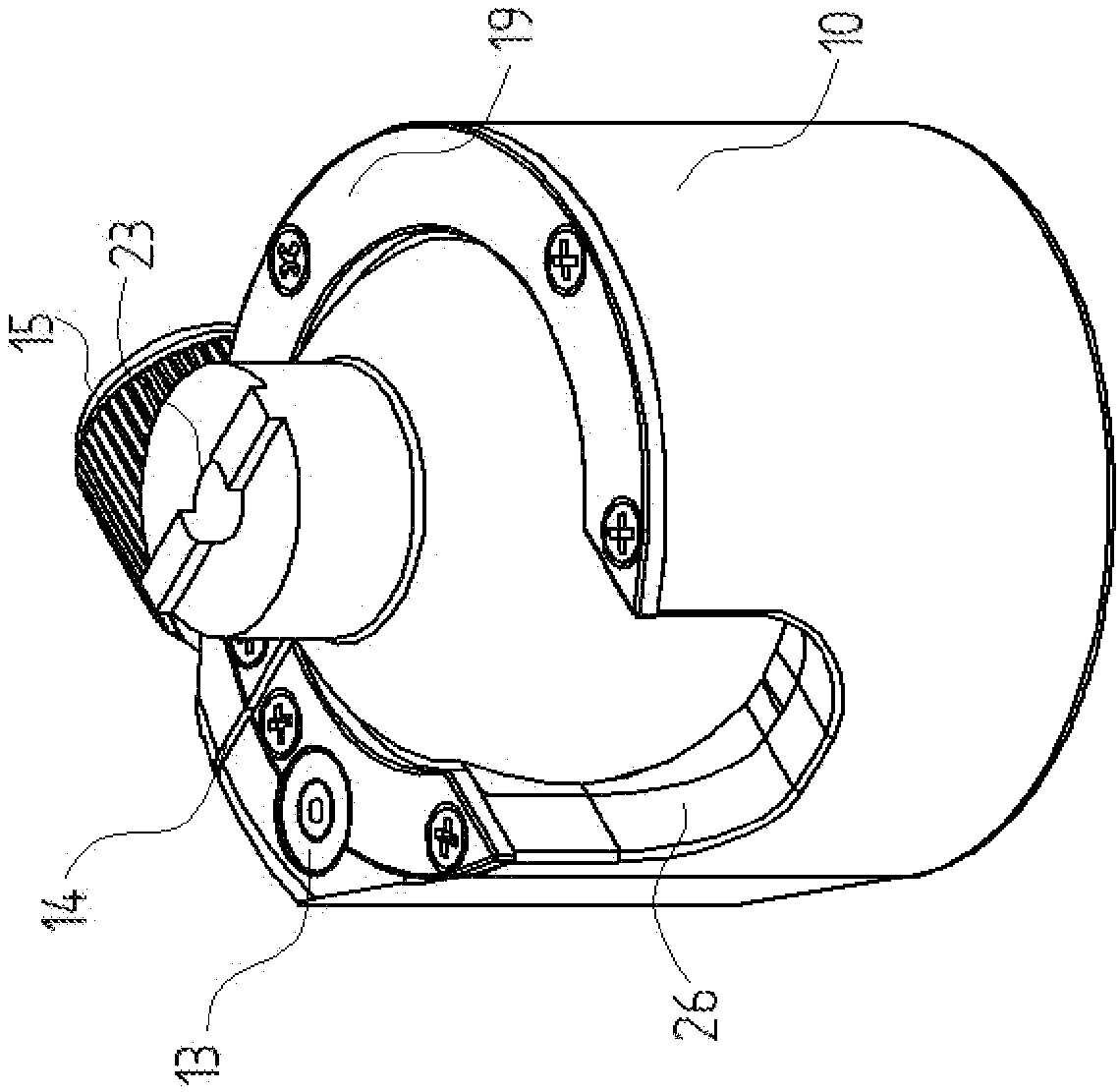

An apparatus for detecting spacing between a primary mirror and a secondary mirror, which comprises an auto-collimator, a pentaprism, a guide rail, a reticle, a CCD detection system and a monitoring computer, wherein the guide rail is arranged in parallel direction of vertical diameter of the primary mirror, the pentaprism is arranged at the guide rail and can be translated along the vertical direction, parallel rays emitted from the auto-collimator is turned 90 degrees via the pentaprism and then via telescope optical system to converge at primary optical axis, the reticle is arranged at Cassegrain focus, the CCD detection system is employed for image-forming of the parallel rays convergent point and the reticle, the monitoring computer is capable of calculating the centre of mass of the images detected by CCD detection system and obtaining a group of image points position, while another group of image points position can be obtained by moving the pentaprism, radial scanning of the primary mirror can be achieved by continue moving, and a movement path of the centre of mass of image points can be obtained, thereby spacing error between the primary mirror and the secondary mirror is obtained via processing of the monitoring computer. The apparatus achieves auto-detecting of the spacing between the primary mirror and the secondary mirror of the telescope, increasing the detecting accuracy, thereby providing important guarantee for later system adjusting of large telescope.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

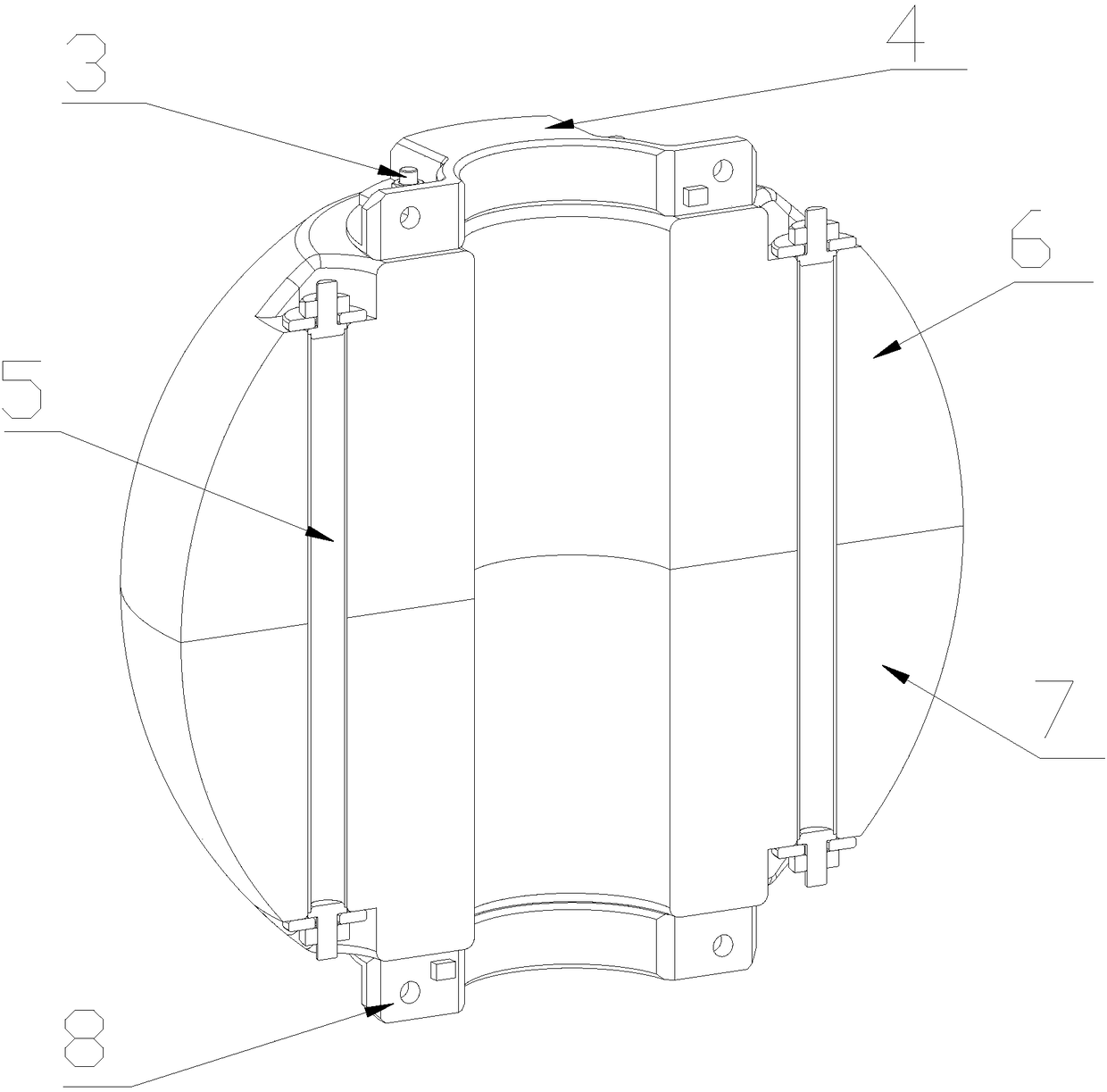

Spherical head assembly for attaching optical and/or electronic device to stander

ActiveCN108474512ASolve the problem of the adjustment of the base planeResolve adjustmentsStands/trestlesPivotal connectionsCouplingEngineering

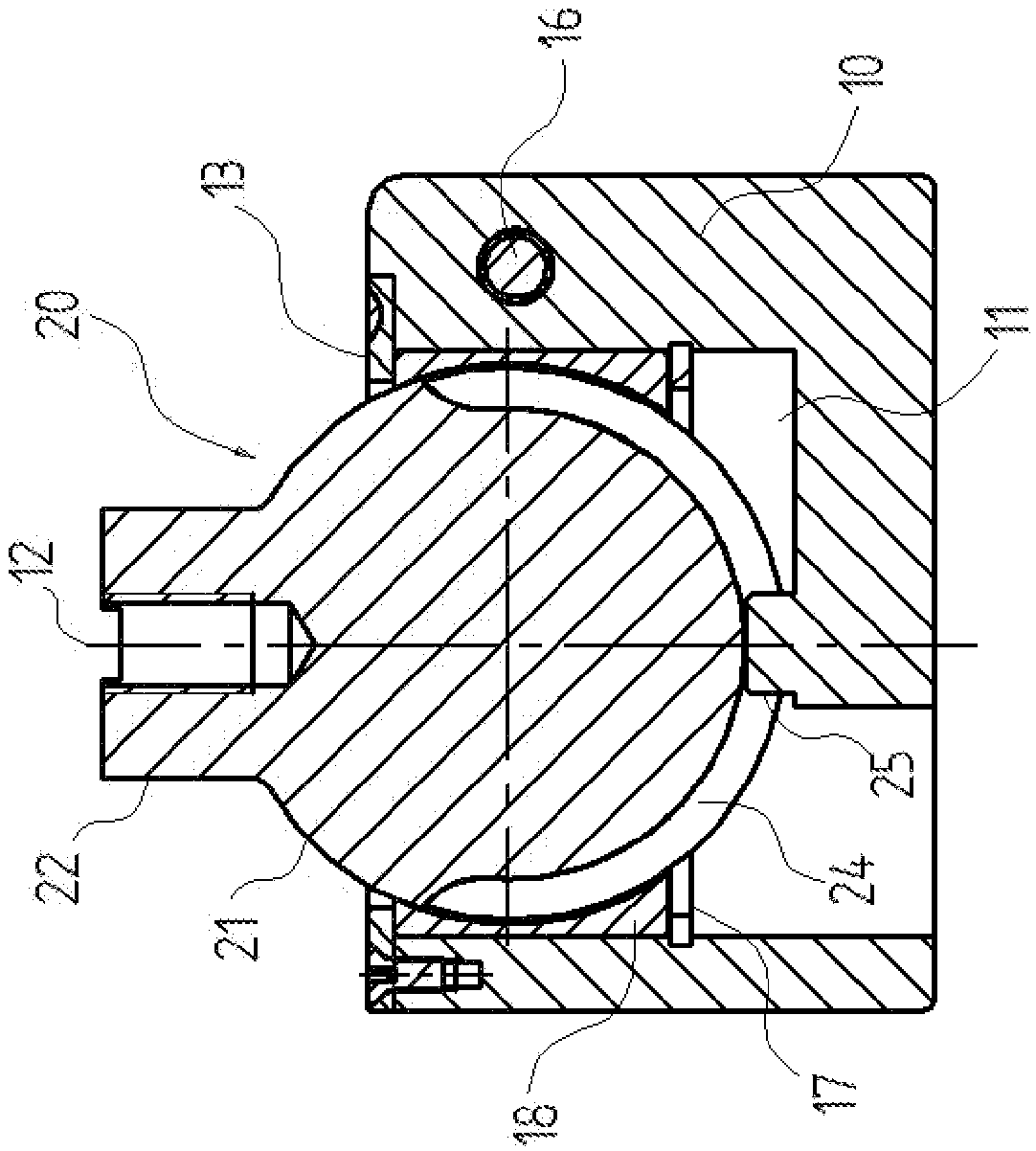

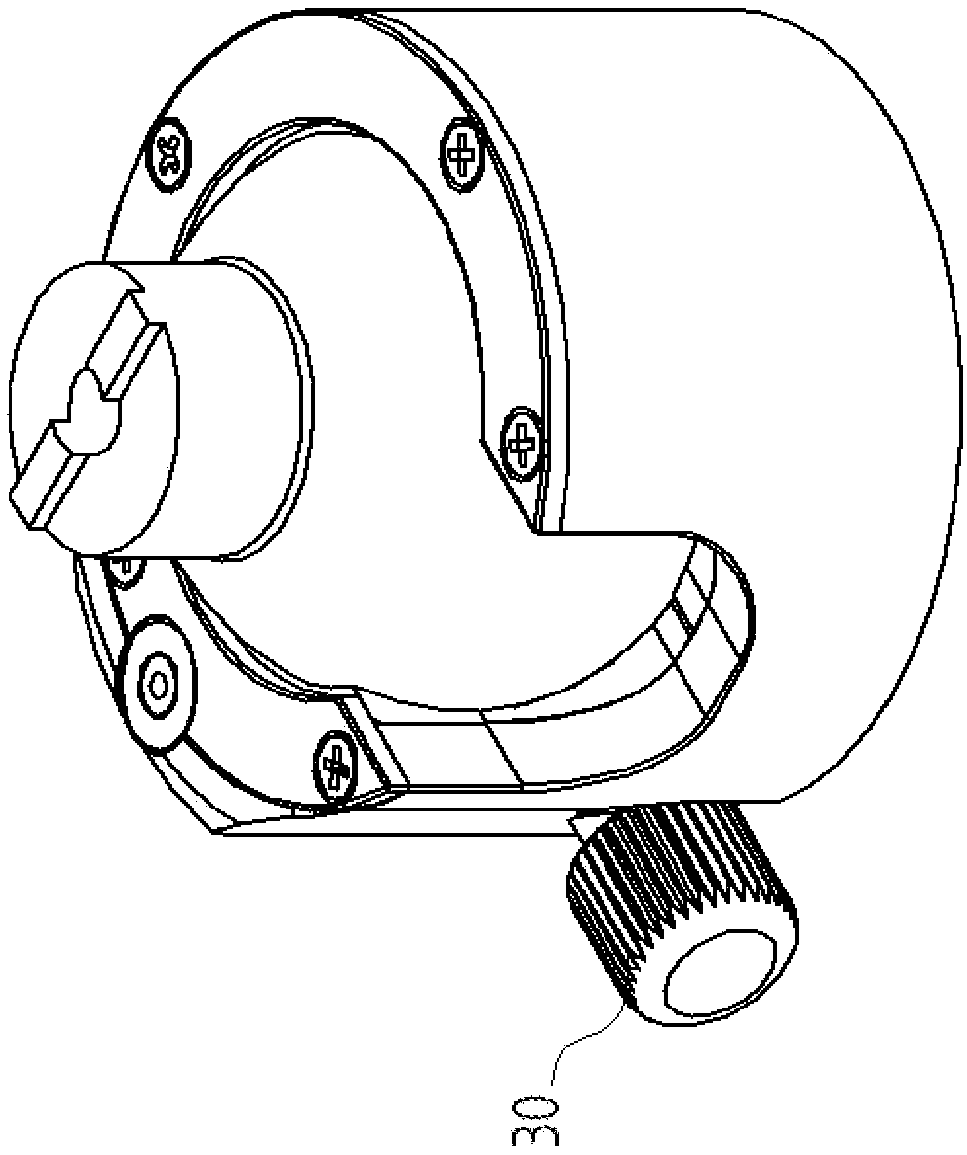

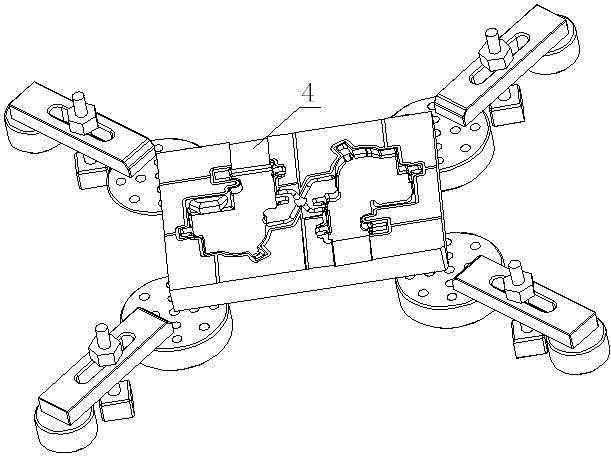

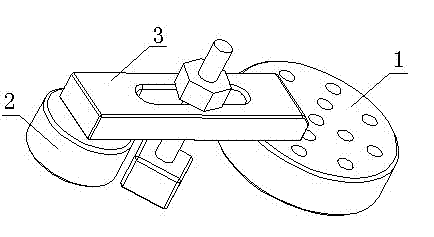

Spherical head assembly for attaching an optical and / or electronic device to a stander with an adjustability in at least two degrees of freedom, which has a first part that can be releasably connectedto the stander and a second part which is provided with a support element for the releasable connection of the device to be held thereby, and one of the two parts is a spherical head (20, 100) that has a body (21, 99) which has at least in part a spherical shape, and the other part comprises a cavity formed as a spherical segment which encircles the spherical head (20, 100) at least in part and is fitted thereto, and comprises an adjusting means for coupling the two parts together and releasing the same coupling, and in the initial position of intended use the held device is adjusted in horizontal or almost horizontal position. In the second part a groove (24, 108) is provided that has a vertical central plane and extends along the largest diameter of the spherical segment, and on the first part a circularly symmetrical stud (25, 103) is provided at a position that corresponds to the vertical diameter of the spherical segment and the stud (25, 103) can be fitted in the groove (24, 108), and in the fitted position the stud (25, 103) allows the displacement of the two parts along the groove (24, 108), and the stud (25, 103) allows the turning of the two coupled spherical fitted segments around the vertical axis of the stud (25, 103) at each of the adjusted positions, and the adjusting means is arranged on that one of the two parts which has the spherically shaped cavity, and when the position of two parts are fixed the adjusting means presses the cavity to the spherical body (21, 99).

Owner:巴拉兹卡门 +1

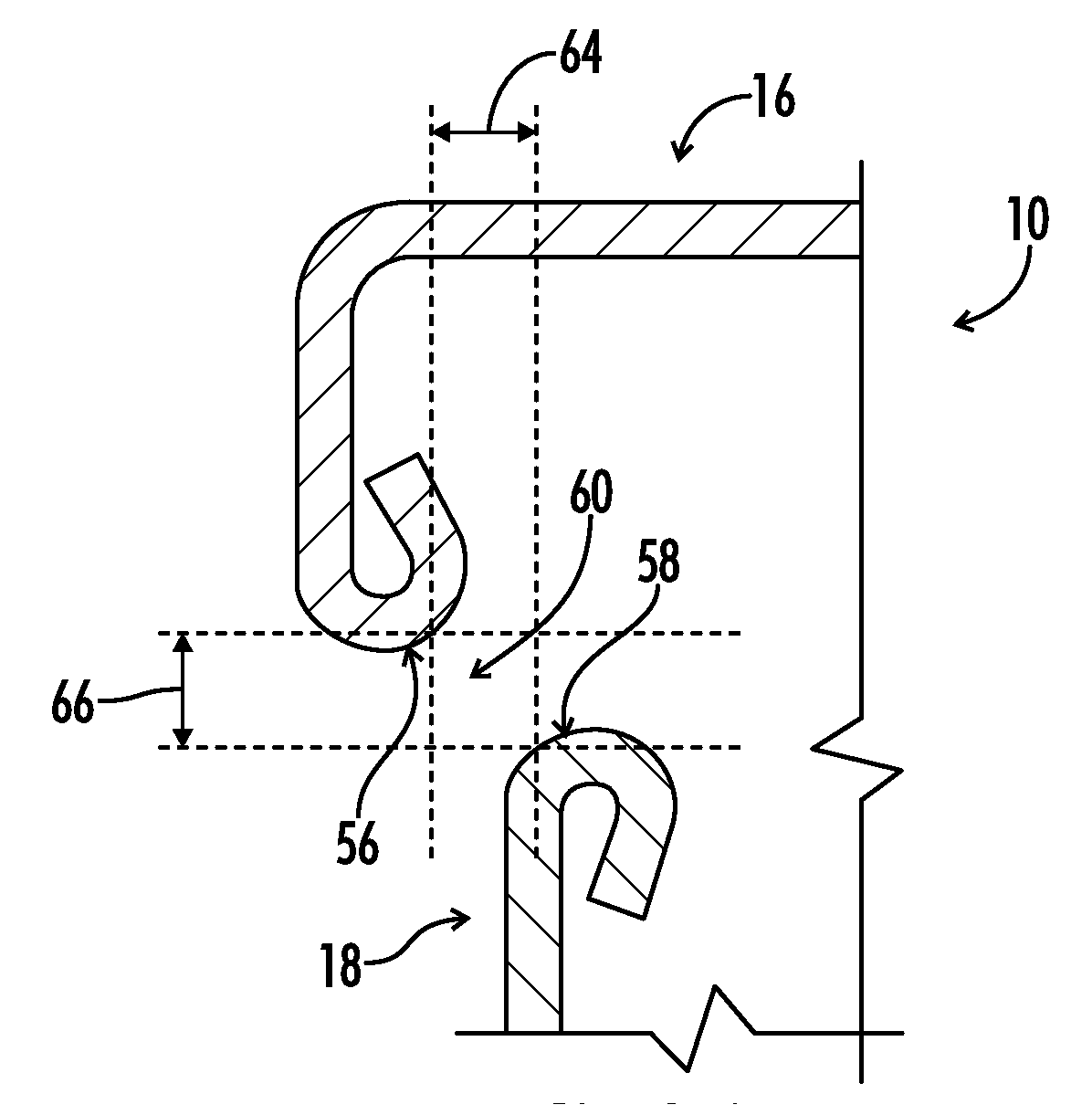

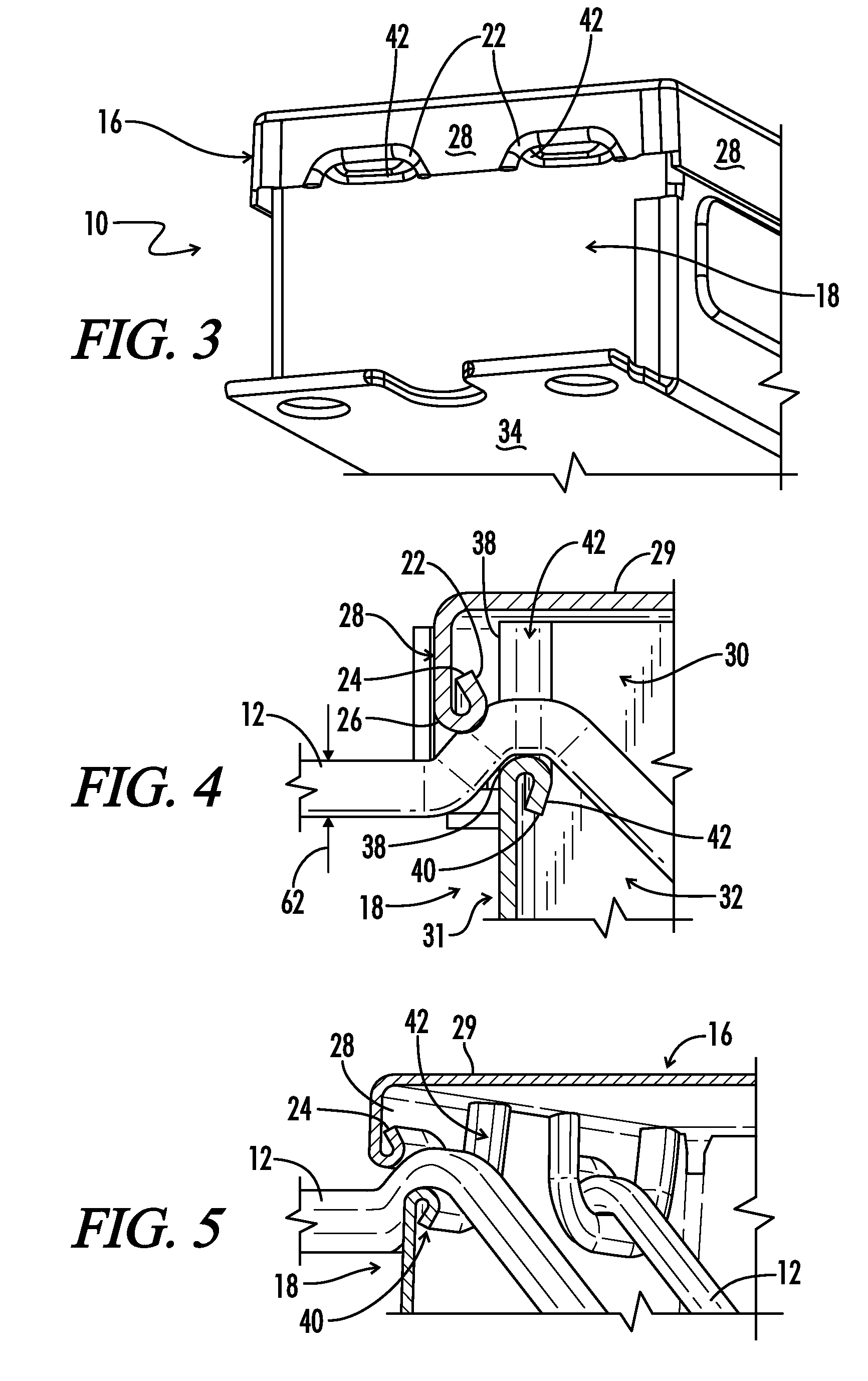

Ballast housing having rolled edge lead wire exit

A ballast housing having a rolled edge lead wire exit for providing protection and strain relief to lead wires extending out from the housing. Grommets are not required in order to provide protection and strain relief to lead wires exiting the housing. The housing includes a lead wire opening having rolled upper and lower edges. The housing includes a lid including the rolled upper edge and a can including the rolled lower edge. The rolled upper edge is vertically aligned with the rolled lower edge but horizontally misaligned with the rolled lower edge. As a result, the rolled upper edge is positioned away from the rolled lower edge a distance that is horizontally shorter than the diameter of the lead wire. Additionally, the lead wire opening has a vertical diameter that is shorter than the diameter of the lead wire.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

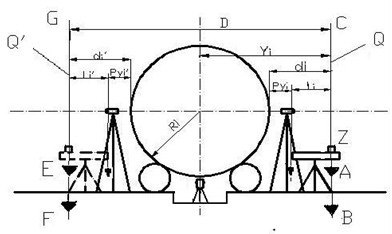

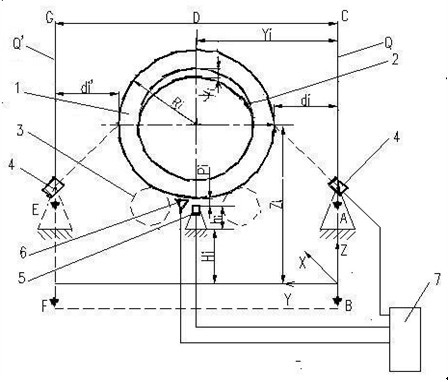

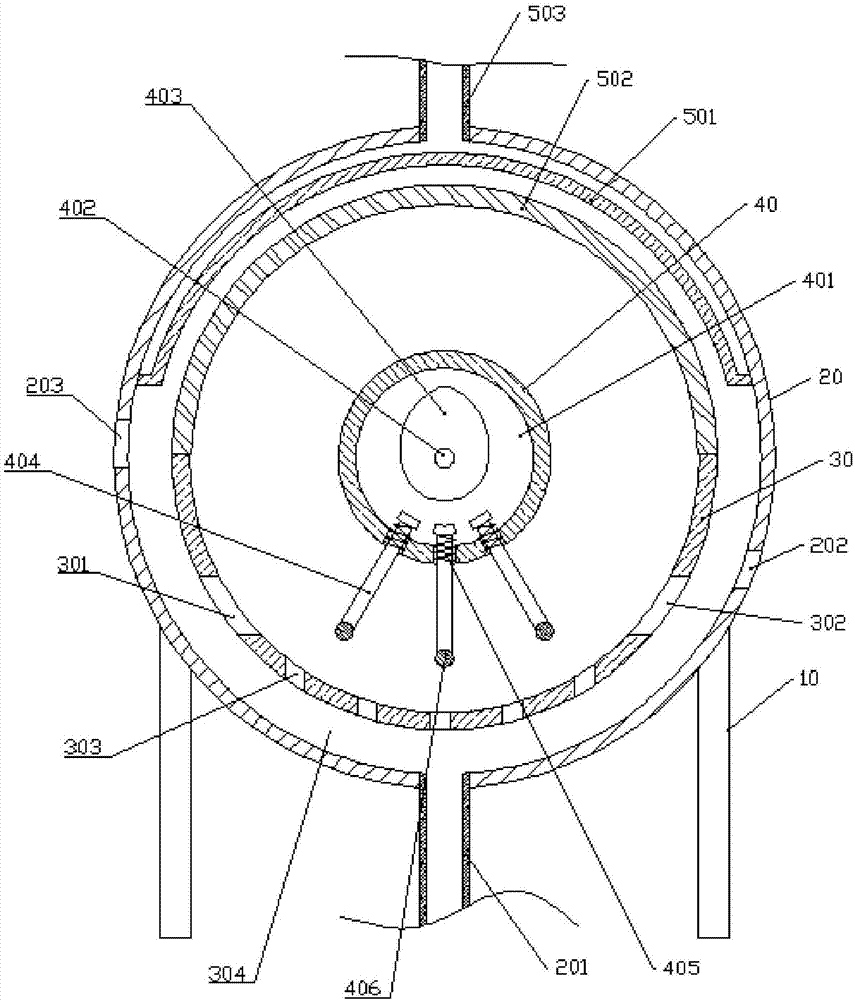

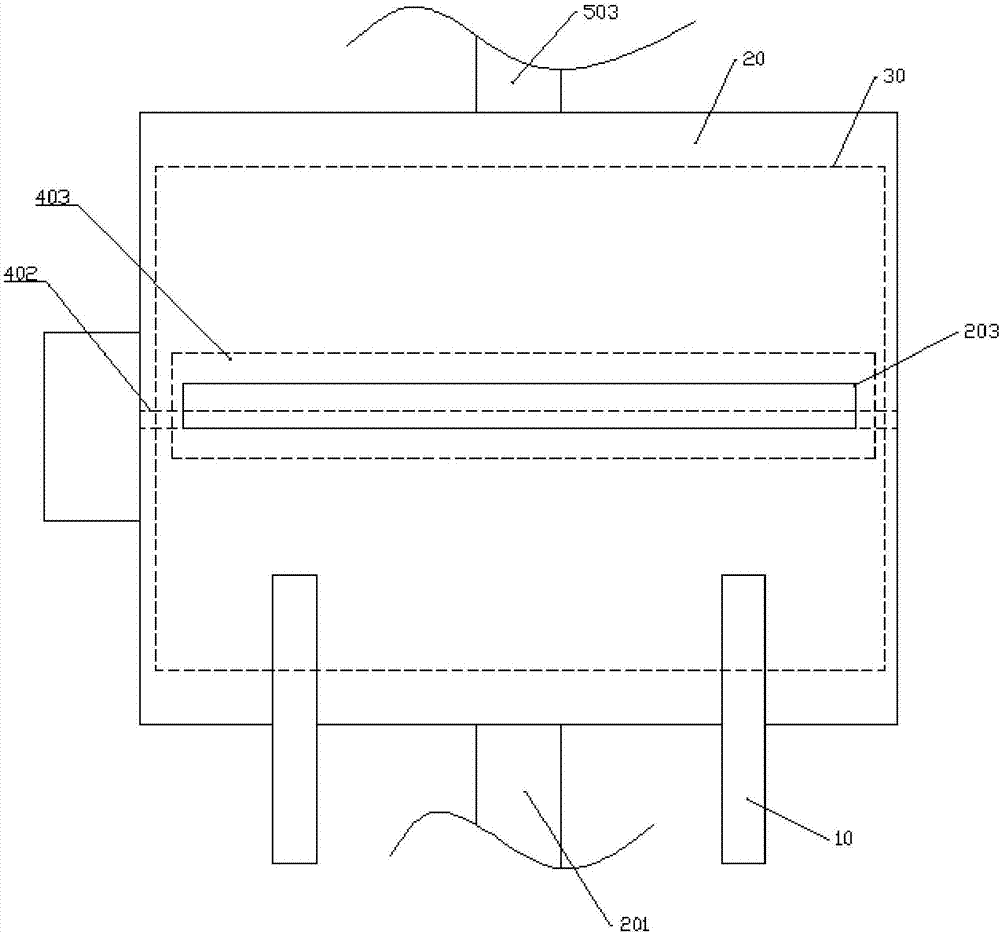

Detecting and monitoring method and measuring system for dynamic axis and bending of rotary kiln tube

ActiveCN102654396AGuaranteed ranging accuracyMeasurement operation safetyMeasurement devicesVertical planeShortest distance

The invention discloses a detecting and monitoring method and a measuring system for a dynamic axis and bending of a rotary kiln tube, wherein the system comprises an instrument for distance measurement and angle measurement, a short-distance measurer, a tube position sensor and a microcomputer system. A coordinate system and two parallel vertical planes are established at both sides of a rotary kiln; at the two vertical planes away from the kiln, the instrument for the distance measurement and the angle measurement can be used for directly measuring horizontal distances from each point on a horizontal diameter line of each kiln body to the two vertical planes, and measuring the height difference from each point on a vertical diameter line of the kiln body to the coordinate system; and the distance measurement accuracy is not greater than + / -1mm. According to the method and the system, the operation of the measurement system is performed on the ground, and the operation is safe and fast, the influence on the measurement caused by factors such as vibration and high temperature of the rotary kiln and artificial reading error can be avoided completely, and the measurement accuracy of a central point and the bending of a rotary kiln tube can be ensured not to be greater than 1.5mm; and the measurement process is obviously simplified and the measurement efficiency is greatly improved.

Owner:WUHAN UNIV OF TECH

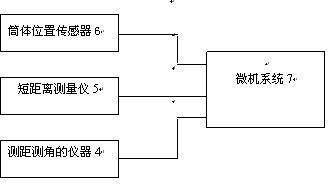

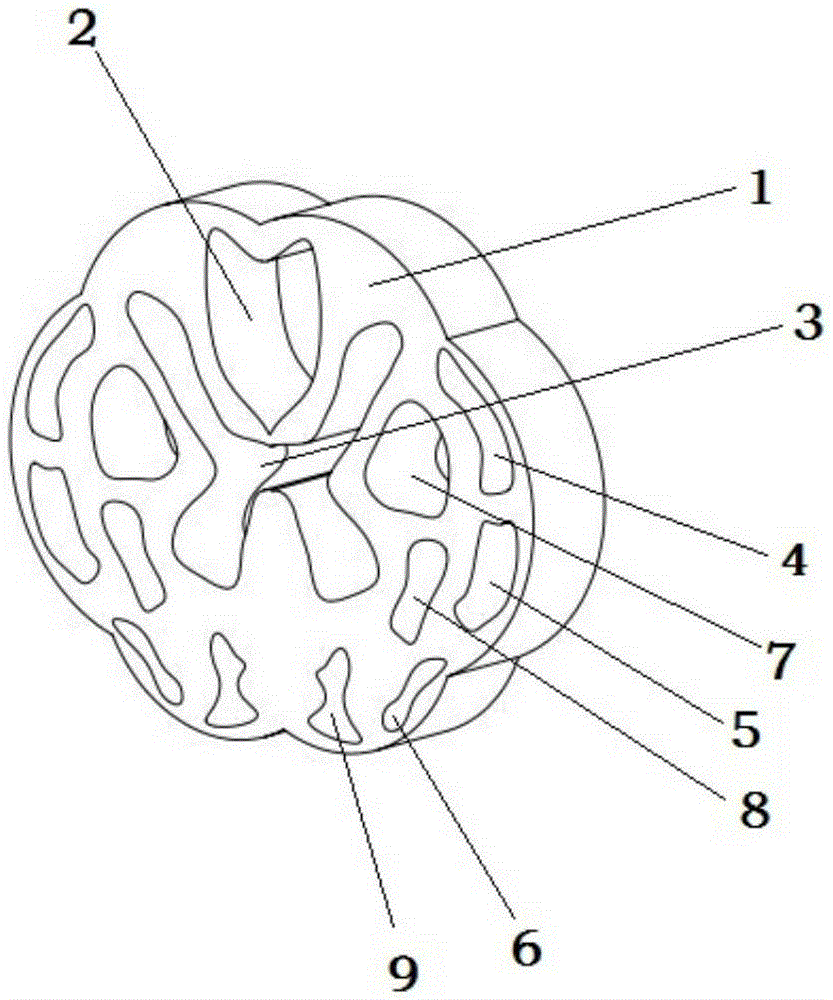

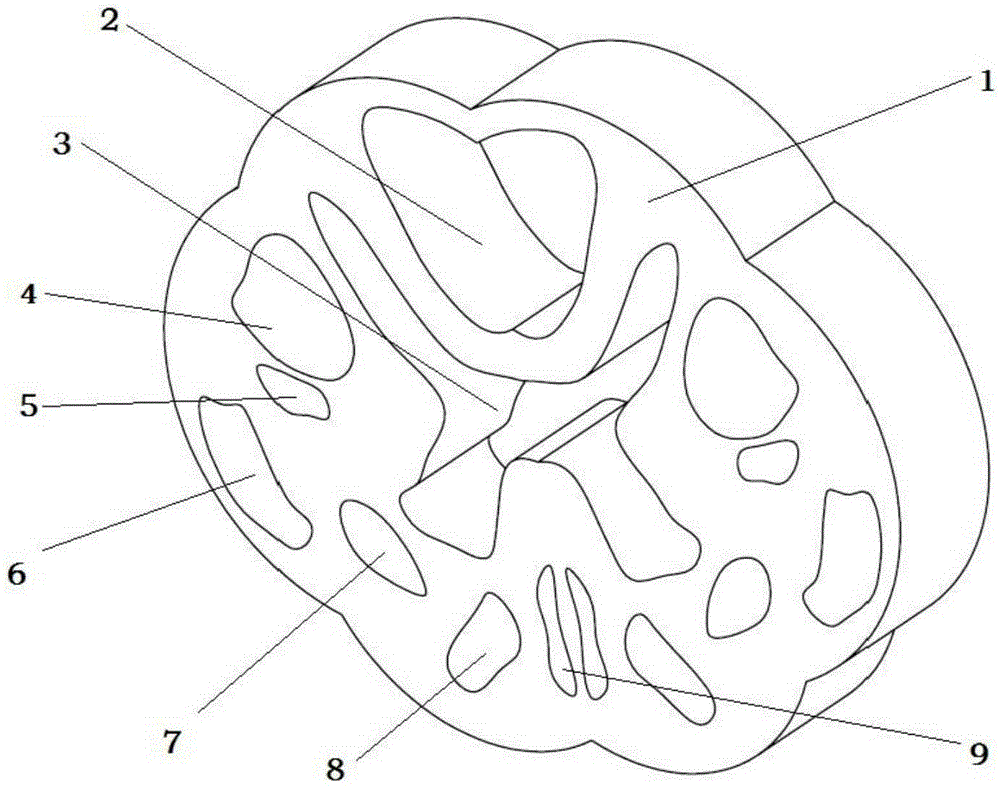

Beagle spinal cord orientation channel stent and production method thereof

InactiveCN105342731APromotes directional growthPromote regenerationStentsProsthesisTractus corticospinalis lateralisDirect Pyramidal Tract

The invention provides a beagle spinal cord orientation channel stent which comprises a stent body. A hollow area for growing fasciculus gracilis, fasciculus cuneatus, tractus spinothalamicus, tractus corticospinalis lateralis, fasciculus cerebellospinalis, tractus spinothalamicus lateralis, tractus spinotectalis, tractus spinothalamicus anterior, direct pyramidal tract and grey matter is arranged inside the stent body. The stent body is 8-15mm in vertical diameter, 6-10mm in transverse diameter and 0.1-1.0mm in wall thickness. The beagle spinal cord orientation channel stent based on the three-dimensional printing technology has the advantages that the precision and structure problems in the prior art can be solved, and the beagle spinal cord orientation channel stent is applicable to treatment and researches of spinal cord injuries.

Owner:THE CHINESE PEOPLES ARMED POLICE LOGISTICS INST AFFILIATED HOSPITAL

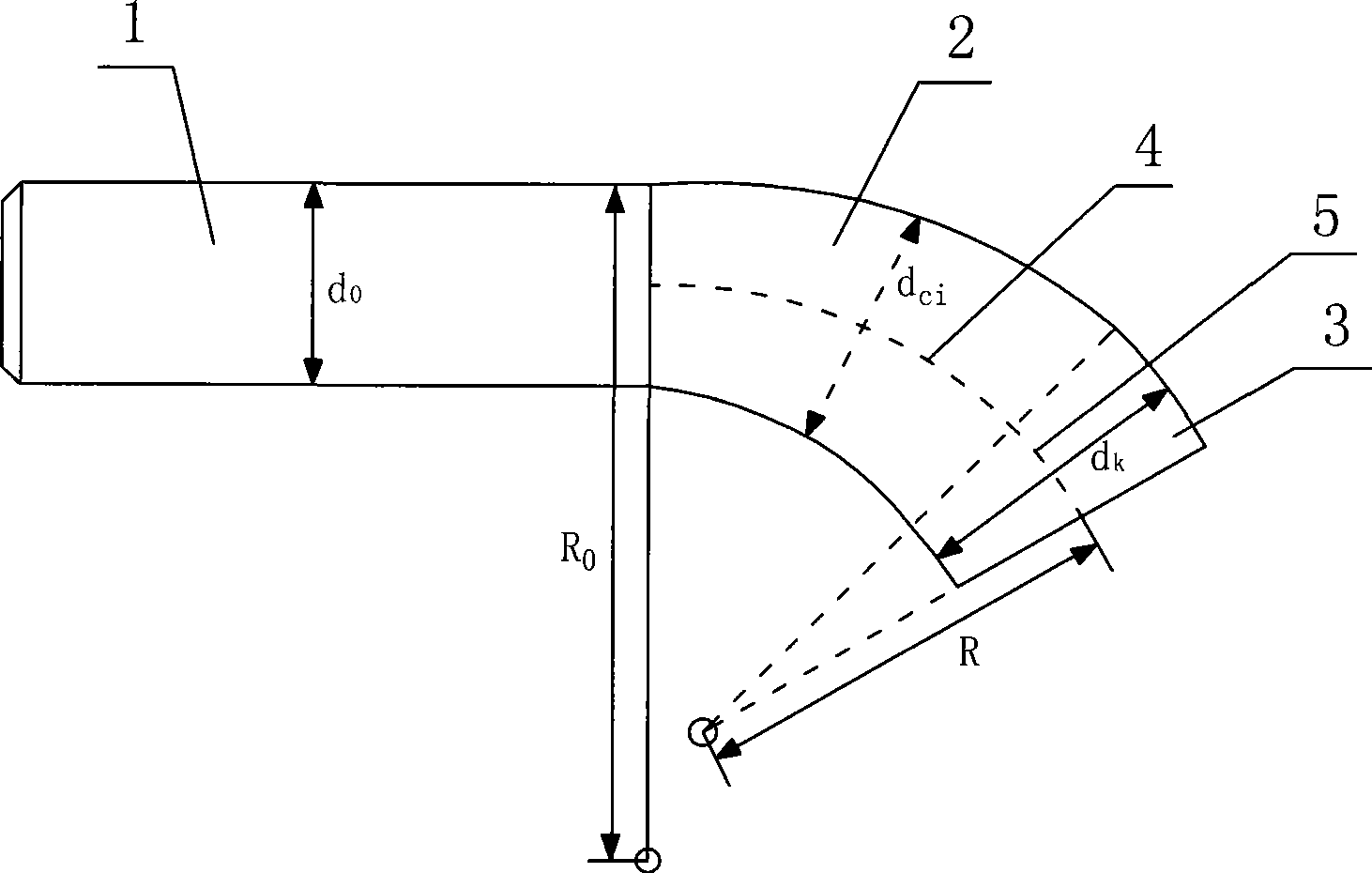

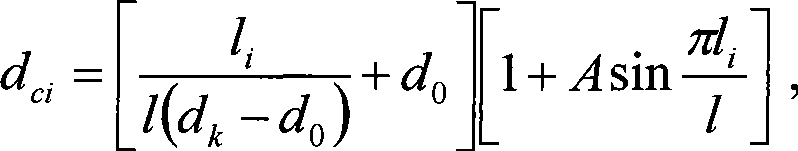

Diameter-expanding and bend-pressing forming core head for short radius elbows

The invention discloses a diameter-expanding and bend-pressing forming core head for short radius elbows, which is formed by sequentially connecting an extension section, a deformation section and a shaping section from front to back, wherein the three sections are sequentially connected to form an arietiform core head mold with a smooth external surface. A central arc line of the deformation section is an involute, the bending radius of the involute transitions continuously and smoothly from an initial bending radius R0 to the final bending radius from front to back. A cross section, vertical to the central arc line, of the deformation section is an elliptic cross section, and the vertical diameter and the horizontal diameter of the elliptic cross section both vary with the arc length li of a central arc line 1 from front to back. The extension section is a straight section. A central arc line 2 of the shaping section is a circular arc, and the cross section, vertical to the central arc line 2, of the shaping section is a circular cross section. The core head can conveniently make high-precision high-quality metal elbows including high-quality short-radius elbows of general specifications as well as heavy-calibre thin-wall short-radius elbows.

Owner:西安秦钛智造科技有限公司

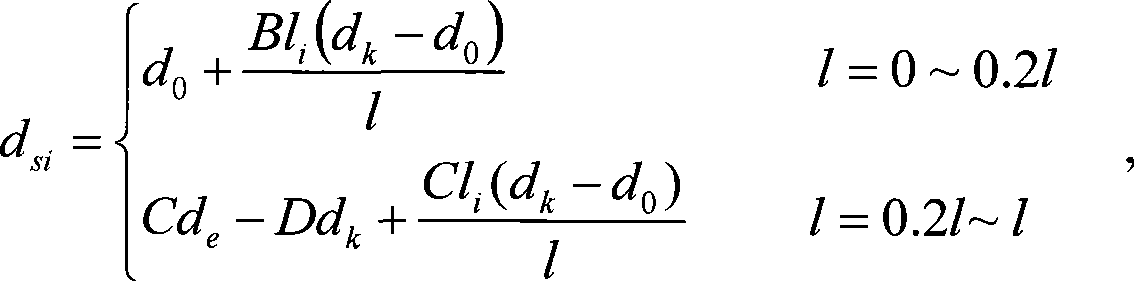

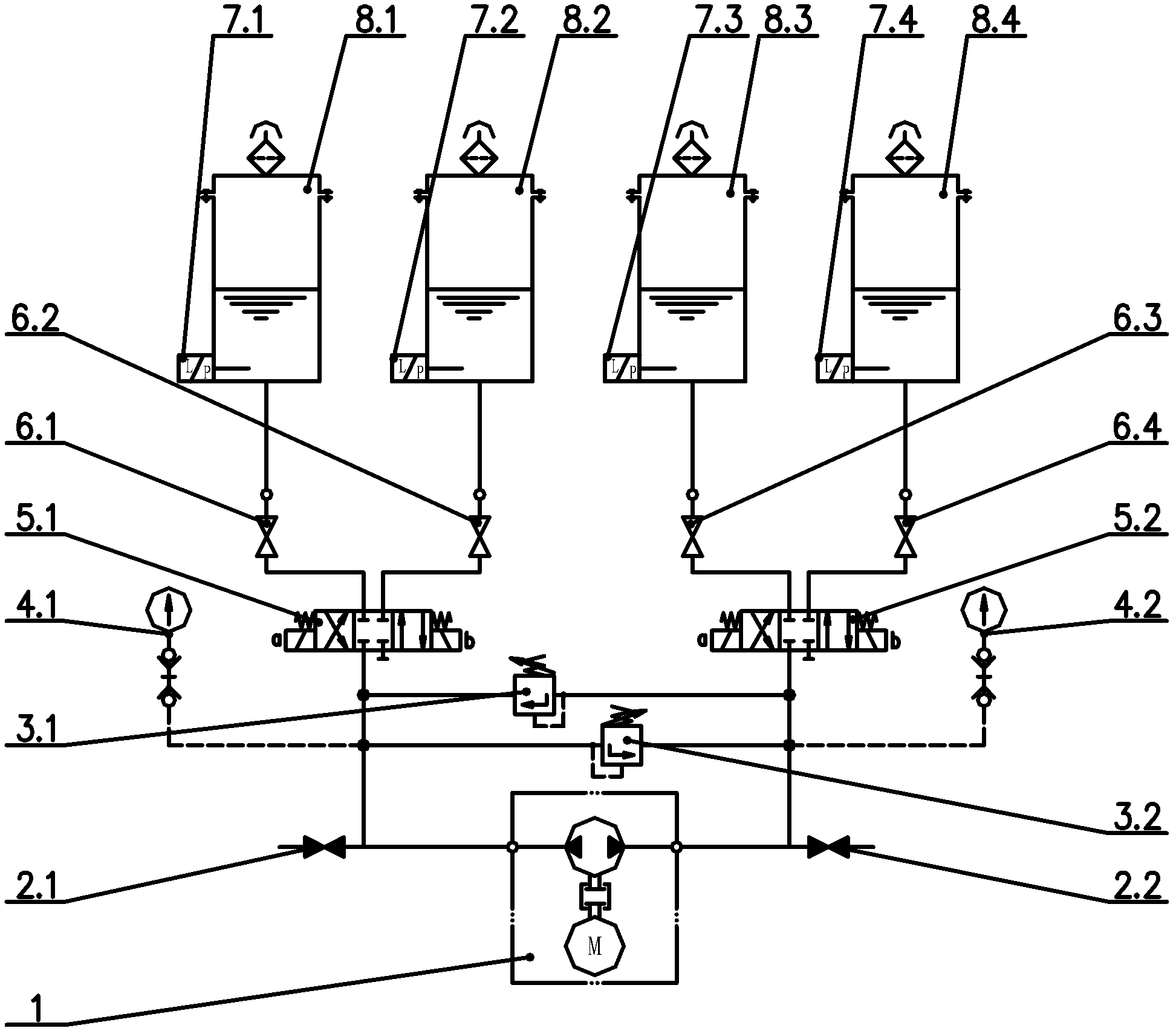

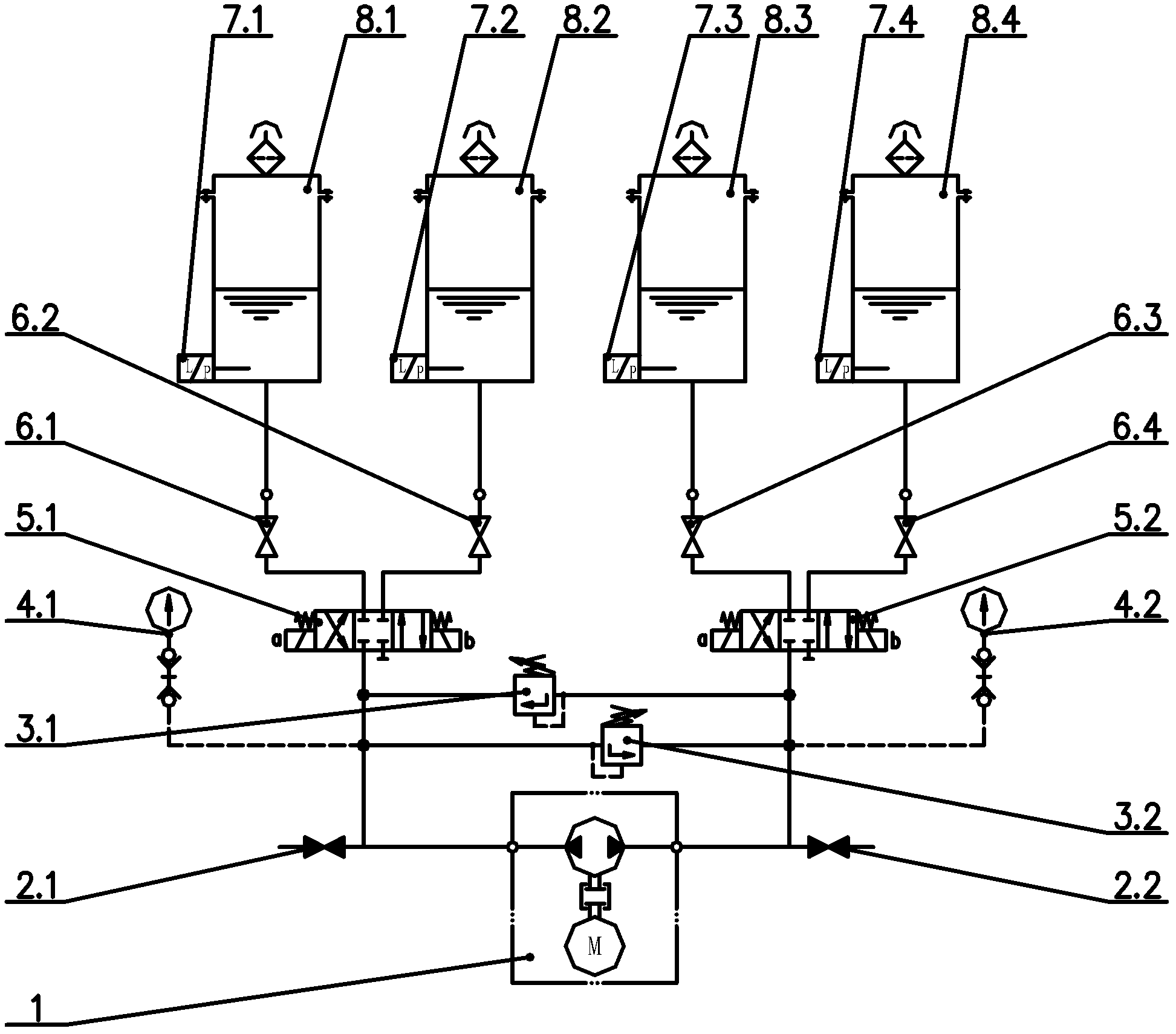

Automatic leveling device of gas holder piston

The invention relates to an automatic leveling device of a gas holder piston. Four same weight boxes and four same horizontal detectors are respectively and symmetrically distributed on a round piston along the circumference uniformly, and each weight box and the corresponding horizontal detector are positioned on the same radius. The device is characterized in that each weight box is filled with fluids, and a liquid position meter is equipped on each weight box; the horizontal detectors are piston horizontal detectors, and are used for detecting the titling degrees along two mutually vertical diameter directions for the piston; the device also comprises a liquid level adjusting system which can convey fluids in a weight box at the downward tilting part to a weight box at the upward tilting part according to the detection result so as to implement the piston leveling. The titling problem of the piston can be automatically, accurately, rapidly and safely solved by using the device.

Owner:WISDRI ENG & RES INC LTD

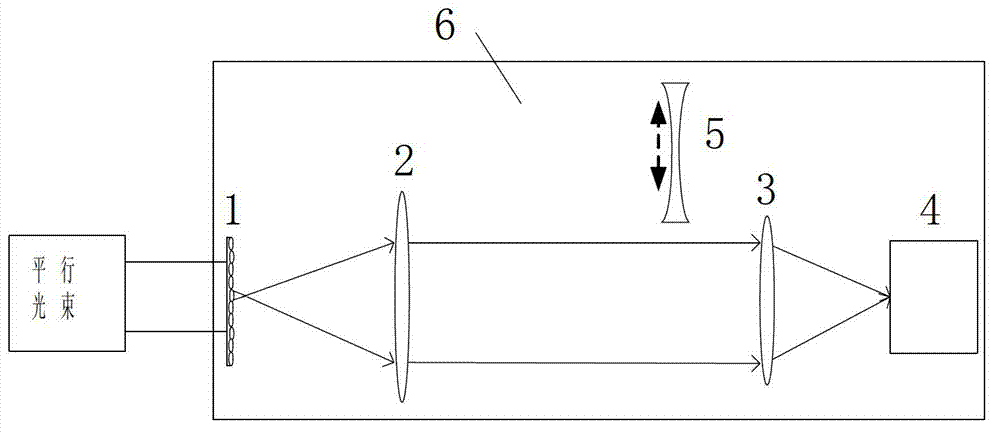

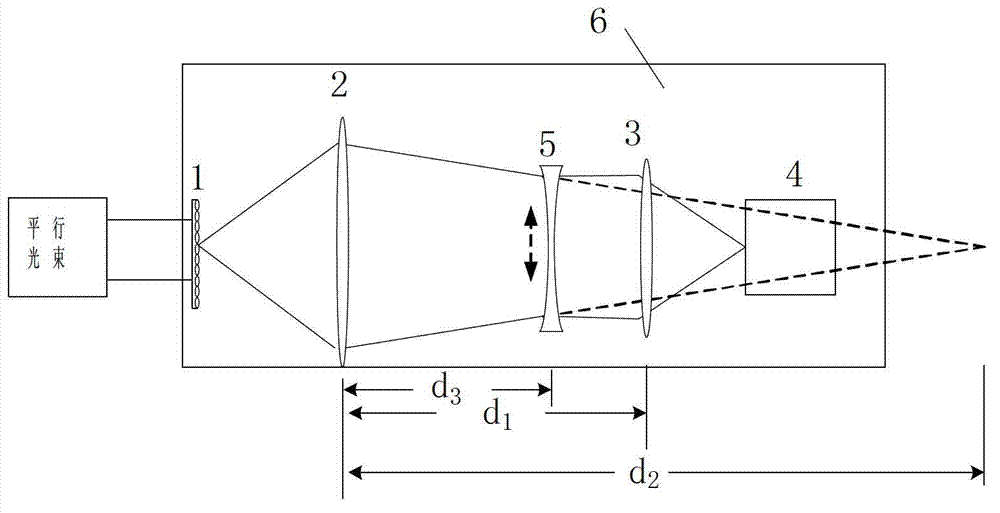

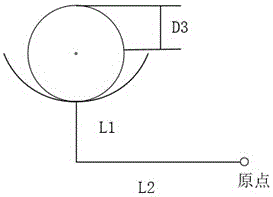

Hartman wave front detector with aperture alignment function

ActiveCN102778299APrecise alignmentOptical measurementsMountingsVisual field lossPhotovoltaic detectors

The invention provides a Hartman wave front detector with an aperture alignment function. The Hartman wave front detector is characterized by consisting of a traditional Hartman wave front detector, a switching concave lens and a micromovement table, wherein the whole device is fixedly arranged on the micromovement table; the micromovement table can perform two-dimensional translation, pitching, torsional pendulum and rotation on the section of an optical axis so as to adjust the optical axis of the Hartman detector; the switching concave lens is fixedly arranged on an insertion plate; during aperture alignment, the insertion plate is inserted into a slot of a switching lens cone, so that the switching concave lens is switched into the light path of a switching lens as shown in the figure, and thus an image of a light spot array on a photodetector is switched into a real image of a microlens array; while the morphology of the microlens array in the photodetector is monitored, the micromovement table is adjusted, until the end points of a vertical diameter and a horizontal diameter of a visual field have complete microlenses, aperture alignment is finished; and after aperture alignment is finished, the insertion plate is pulled up, so that the switching concave lens is moved out of the light path of the switching lens, so that the traditional Hartman wave front detector is recovered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

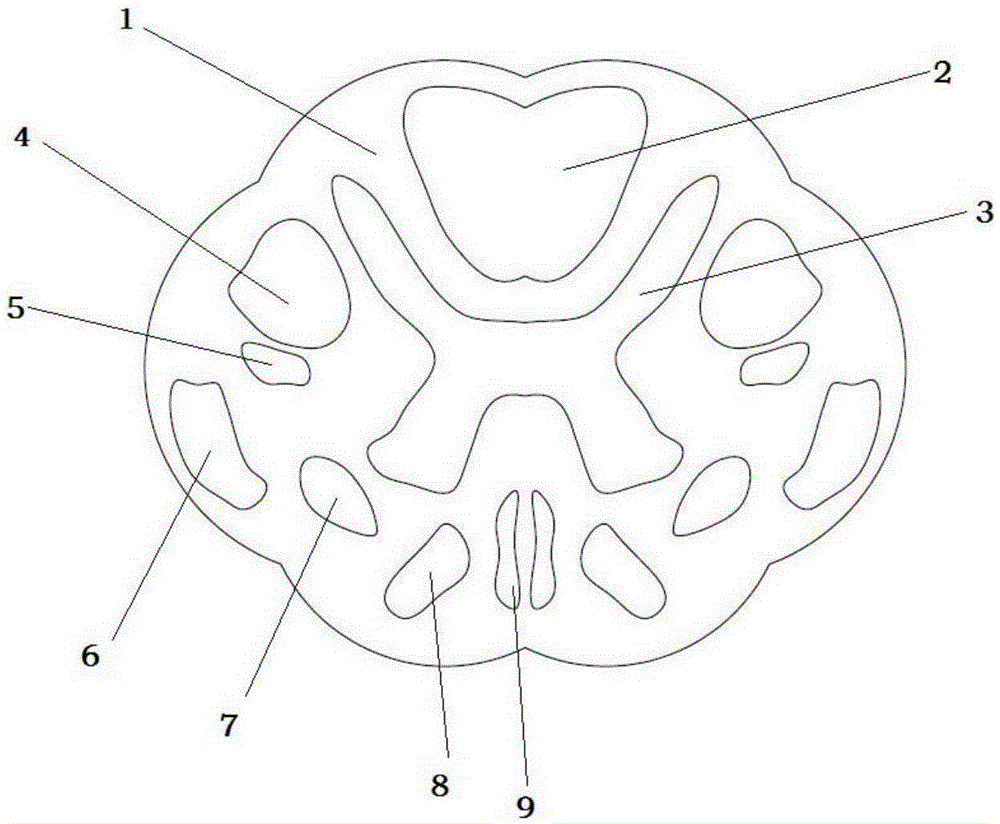

High-simulation collagen spinal cord stent for people and preparation method thereof

InactiveCN105380728AAccurate printingNon-destructive propertiesAdditive manufacturing apparatusTissue regenerationAnatomical structuresReticulospinal tract

The invention provides a high-simulation collagen spinal cord stent for people. The stent comprises a stent body, and the stent body is internally provided with hollow regions used for growing spinal grey matter, fasciculus gracilis, fasciculus cuneatus, tractuscorticospinalislateralis, tractusrubrospinalis, a reticulospinal tract, a lateral spinothalamic tract, a spinotectal tract, a reticulospinal tract, a direct pyramidal tract and a central canal. The vertical diameter of the stent body is 1.2-1.8 cm, the transverse diameter of the stent body is 1.4-1.8 cm, and the height of the stent body is 2.0 mm-8 cm. The stent body is made of collagen. According to the high-simulation collagen spinal cord stent for people, the main anatomical structure and the spatial relationship of thoracolumbar horizontal spinal segment white and grey matter of people are established, the stent is used for improving nerve directional and orderly connection after spinal cord injury, and rapid repair is promoted after spinal cord injury of people.

Owner:THE CHINESE PEOPLES ARMED POLICE LOGISTICS INST AFFILIATED HOSPITAL

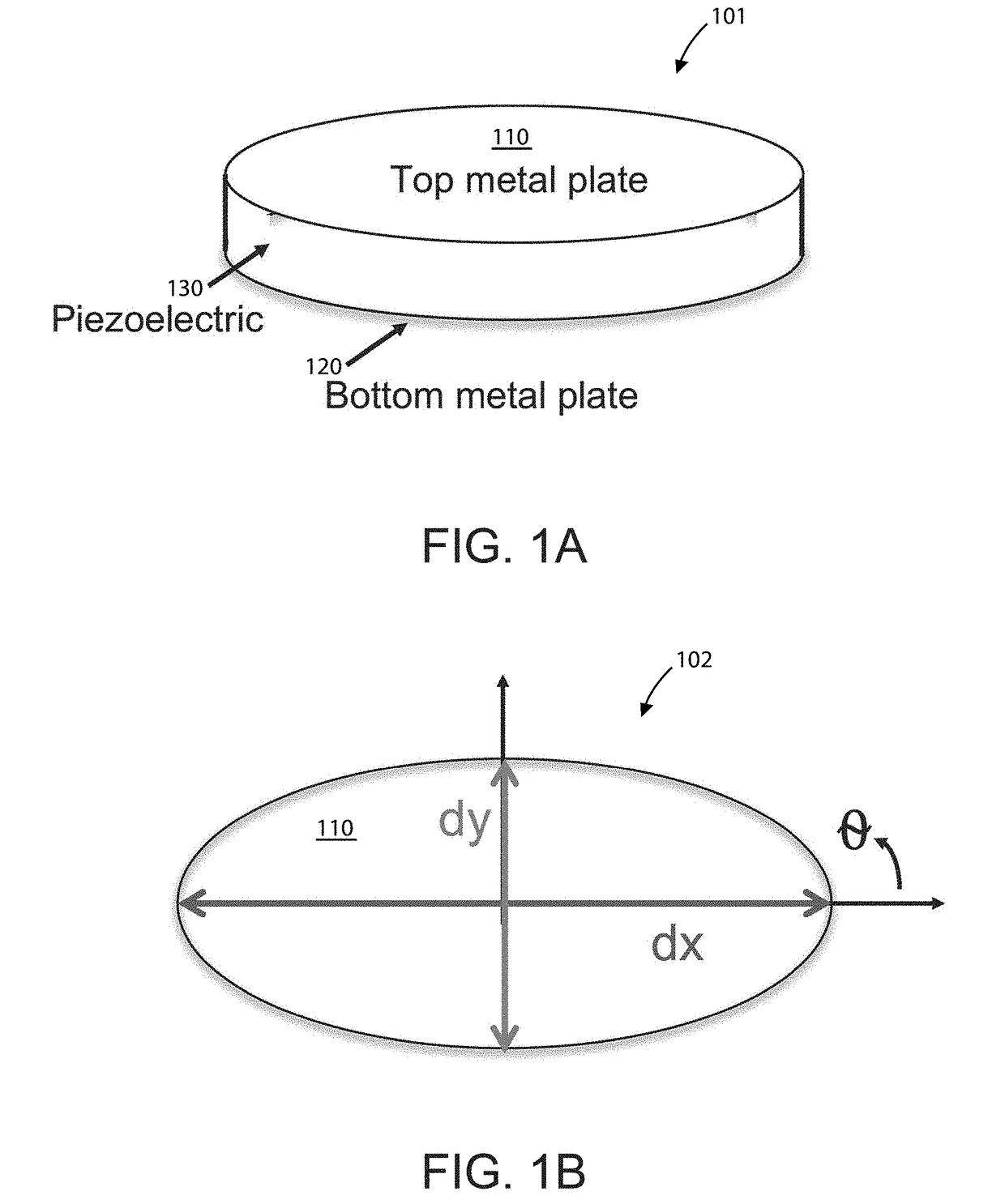

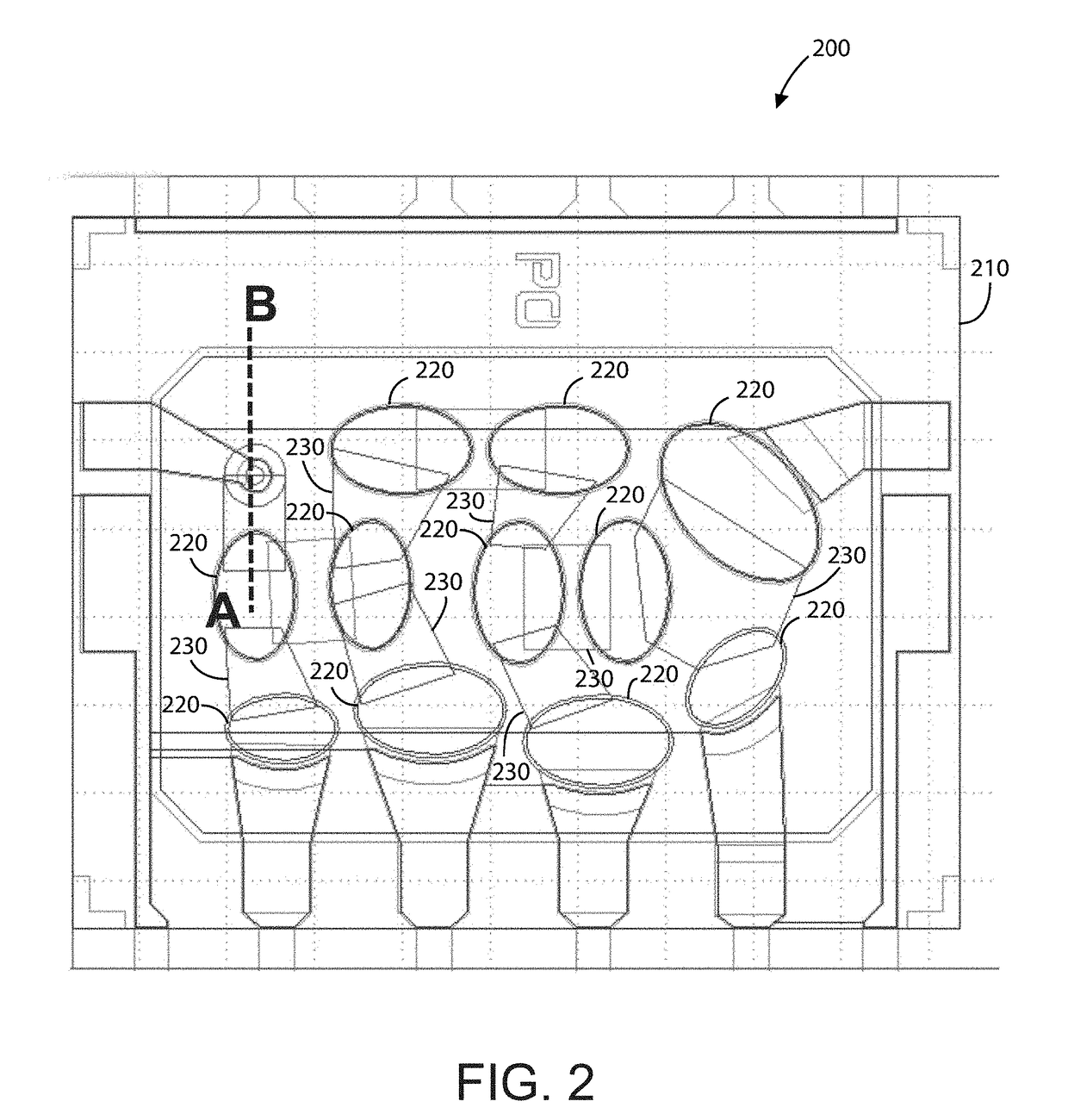

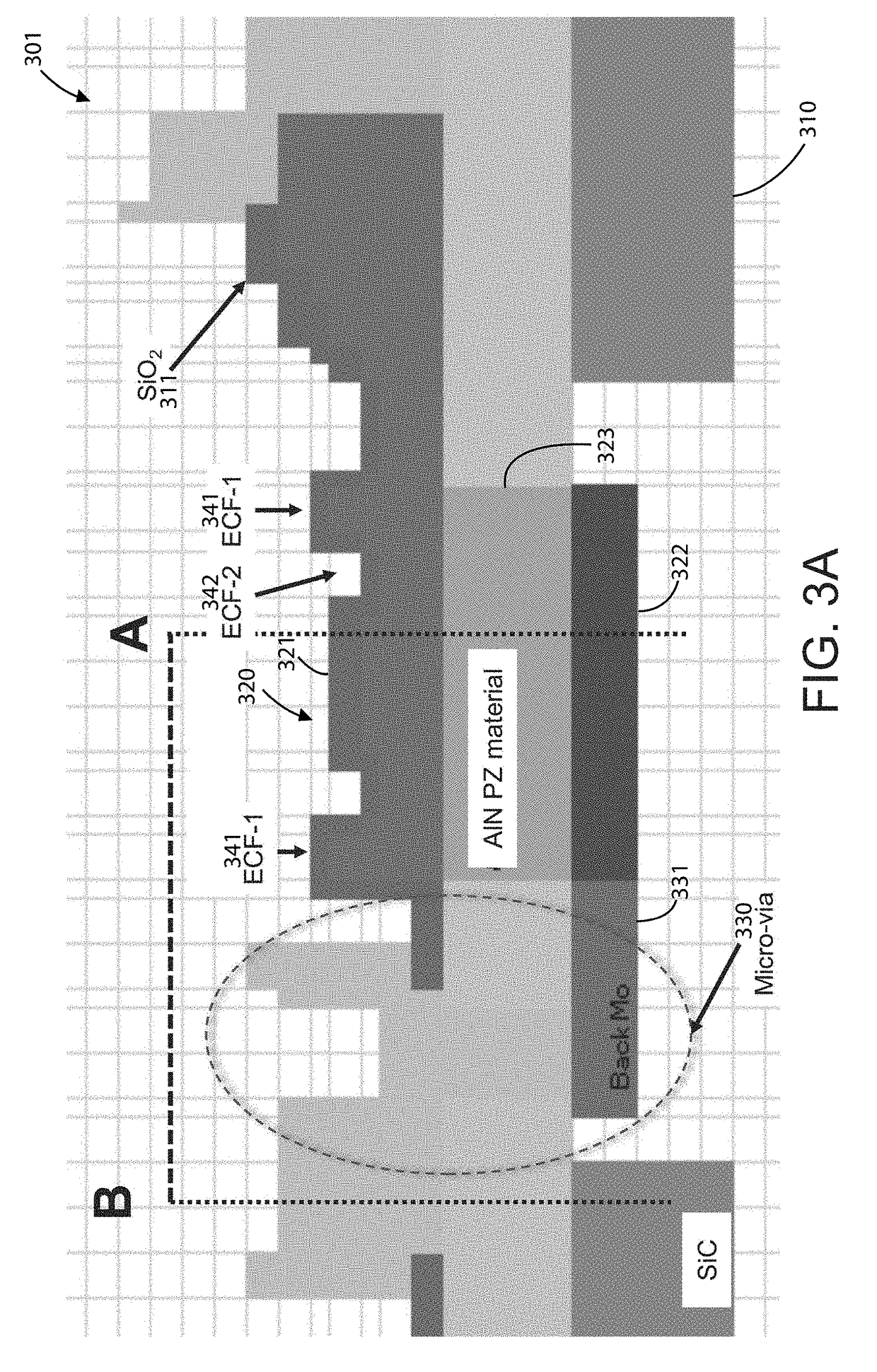

Elliptical structure for bulk acoustic wave resonator

ActiveUS20190044493A1Simple and cost-effectiveImprove insertion lossImpedence networksEllipseCoupling

An elliptical-shaped resonator device. The device includes a bottom metal plate, a piezoelectric layer overlying the bottom metal plate, and a top metal plate overlying the piezoelectric layer. The top metal plate, the piezoelectric layer, and the bottom metal plate are characterized by an elliptical shape having a horizontal diameter (dx) and a vertical diameter (dy), which can be represented as ellipse ratio R=dx / dy. Using the elliptical structure, the resulting bulk acoustic wave resonator (BAWR) can exhibit equivalent or improved insertion loss, higher coupling coefficient, and higher quality factor compared to conventional polygon-shaped resonators.

Owner:AKOUSTIS INC

Automatic pipeline roundness value detection method

ActiveCN106152968AReduce distractionsHigh precisionUsing optical meansImaging processingVertical diameter

The invention provides an automatic pipeline roundness value detection method. According to the detection method, a horizontal distance between an image acquisition device and a pipeline end surface is adjusted to make a smallest distance from an acquired outer edge in a pipeline end surface diameter direction to an acquired image frame be smaller than or equal to 5% of length of the image frame parallel with the distance direction; after the horizontal distance is adjusted, images of the pipeline end surface are acquired, and the acquired images are sent to an image processing system; the acquired pipeline end surface images are processed through the image processing system to extract end surface edges, and roundness of each end surface is acquired. According to a method in the prior art, gray processing on shot images is carried out to extract end surface edges, a horizontal diameter and a vertical diameter of a pipeline are calculated according to pixels, and the detection method is different from the manual measurement method in the prior art; according to the detection method provided by the invention, an optimal horizontal acquisition distance of the image acquisition device and the acquired pipeline end surface is determined, the images of the pipeline end surface are acquired at the optimal acquisition distance, and reduction of interference and improvement of accuracy can be realized.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

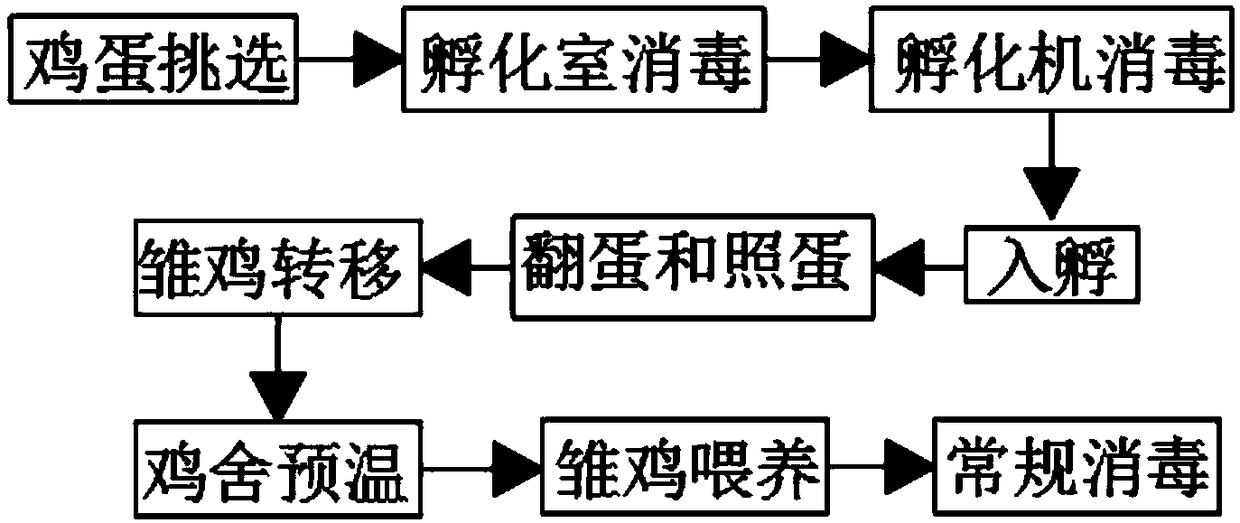

Method for high effective incubation and high quality breeding of ephedra chickens

InactiveCN109287565APremium useImprove hatching effectAnimal husbandryMortality rateCultural methods

The invention provides a method for high effective incubation and high quality breeding of ephedra chickens. The method includes the following steps that egg selection is performed, wherein medium-sized and normal-shape eggs are selected, wherein the weight of each egg is 45-50 g, and the ratio of the horizontal diameter to vertical diameter of each egg is 0.72-0.75; disinfection of an incubator is performed, wherein the selected eggs are placed in the incubator, and the eggs per cubic meter are fumigated and disinfected with a mixture of 15 g of potassium permanganate and 30 ml of formalin. According to the method for high effective incubation and high quality breeding of ephedra chickens, a good hatching condition can be created, the hatching effect of the chickens is thus improved, thesurvival rate of the chickens can be improved, high quality breeding of the chickens can be achieved and facilitate the later growth of the chickens, and the mortality rate of the chickens can be reduced. Moreover, through strict control over the hatching condition and the breeding condition, the breeding method is more effective, the resources can be reasonably used, waste of the resources is reduced, the cost of farmers is thus reduced, and the income of the farmers is improved.

Owner:六安市叶集区王大娘生态养殖专业合作社

Air-seat interface observation key technology-data real-time water surface relay communication float

PendingCN108545147AReduce horizontal flow resistanceReduce volumeMeasurement devicesWaterborne vesselsVertical stabilityMarine engineering

Owner:OCEAN UNIV OF CHINA

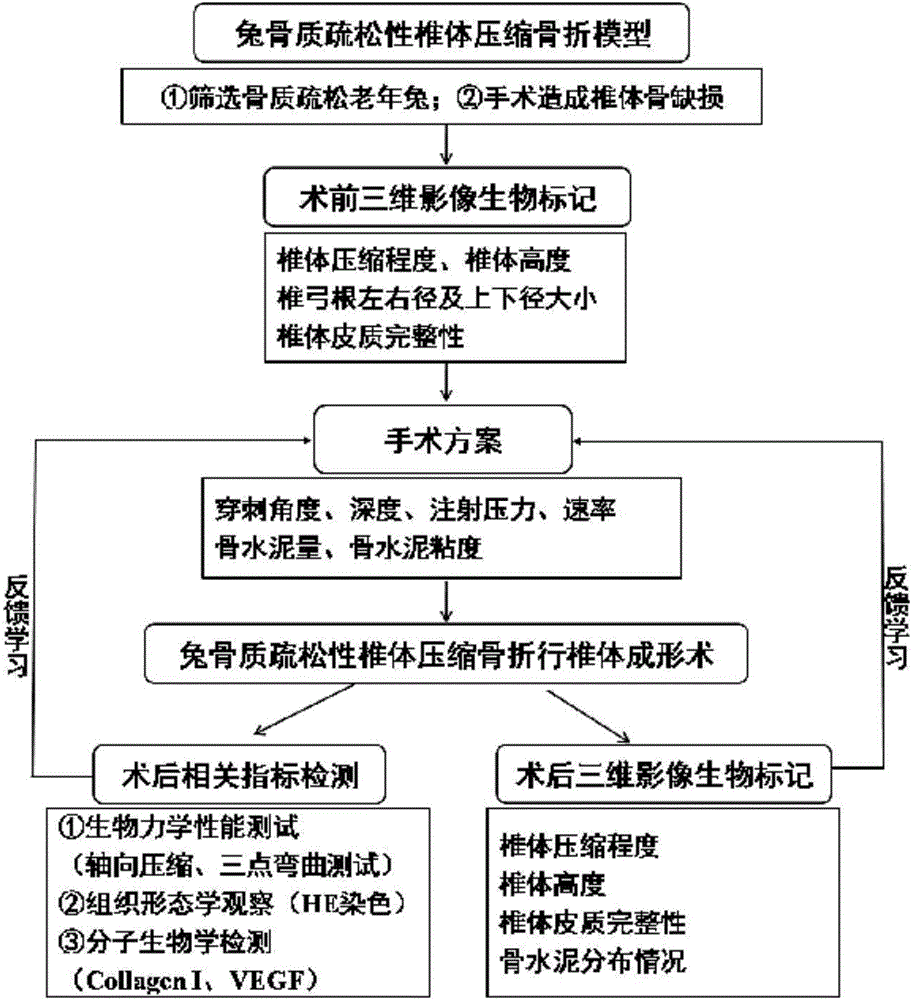

Imaging biomarker for guiding percutaneous vertebroplasty and application of imaging biomarker for guiding percutaneous vertebroplasty

InactiveCN106420051AReduce exposureReduce serious complicationsMedical imagingComputerised tomographsVertebral heightImaging biomarker

The invention relates to a marker in medicine and application of the marker, in particular to an imaging biomarker for guiding percutaneous vertebroplasty and application of the imaging biomarker for guiding percutaneous vertebroplasty. The imaging biomarker comprises a preoperative imaging biomarker and a postoperative imaging biomarker, wherein the preoperative imaging biomarker involves vertebral compression degree, a vertebral height, a vertebral pedicle transversal diameter, a vertebral pedicle vertical diameter and vertebral cortex integrity, and the postoperative imaging biomarker involves vertebral compression degree, a vertebral height, vertebral cortex integrity and bone cement distribution conditions. The imaging biomarker provides quantitative bases for operation plans and lays a firm foundation for precise standardized vertebroplasty plans.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Raisin processing technology

InactiveCN104814400AQuality improvementSweet and mellow tasteFood preparationCold storageSodium hydroxide

The present invention belongs to the technical field of food processing, in particular to a raisin processing technology. The raisin processing technology consists of the following steps: choosing seedless fully mature grapes as raw materials, removing fruit granules with vertical diameter of less than 13 mm and damaged skins and rotting fruit granules after harvesting grapes, putting the grapes into sodium hydroxide solution with concentration of 1.5%-4.0% to soak for 1-5 seconds, putting the grapes into a baking dish to bake at a temperature of 35-40 DEG C for 4-5 hours, cold storing the baked grapes in a cold storage room at a temperature of 2-3 DEG C for 10-12 hours, repeating the baking and cold storing for 10-12 times, artificially air-drying the grapes treated in the above steps at a temperature of 10-15 DEG C for 30-35 days with artificial air-drying wind speed of 2 m / s and air-drying humidity of 25%-30%, stacking the air-dried grapes for 7-14 days to enable the grapes to be evenly dried, and finally removing fruit stems to obtain the raisins. The raisins prepared by the present invention have excellent quality, are semi-transparent, do not change color, taste sweet, fresh and mellow, and contain no other impurities.

Owner:HEFEI FENGSHENGYUAN AGRI SCI & TECH CO LTD

Cloth boiling and dyeing device

ActiveCN107988749AEasy to dipKeep it straightTextile treatment containersSucessive textile treatmentsEngineeringWater pipe

The invention relates to the field of cloth processing, in particular to a cloth boiling and dyeing device. The device includes an outer cylinder, a water inlet pipe, an inner cylinder, a fixing shaft, a first electric heat wire and an air outlet pipe; the outer cylinder and the inner cylinder are sequentially, coaxially and fixedly installed on the fixing shaft from outside to inside, and the outer cylinder and the inner cylinder form a dye cavity; the outer wall of the outer cylinder is fixedly connected with a machine frame, the upper end of the water inlet pipe is communicated with the lower side of the outer cylinder, the side face of the inner cylinder is provided with a first inlet and a first outlet which are communicated with the inner cylinder, and the first inlet and the first outlet are formed in the two sides of the vertical diameter of the cross section of the inner cylinder; the outer cylinder is provided with a second outlet near the first outlet, the outer cylinder isprovided with the second outlet near the first inlet, the first electric heat wire is fixedly installed on the inner wall of the upper side of the outer cylinder, the air outlet pipe is communicated with the upper side of the outer cylinder, and the air outlet pipe is communicated with the air inlet pipe. According to the scheme, the situation that cloth generates wrinkles in the dyeing process can be avoided.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

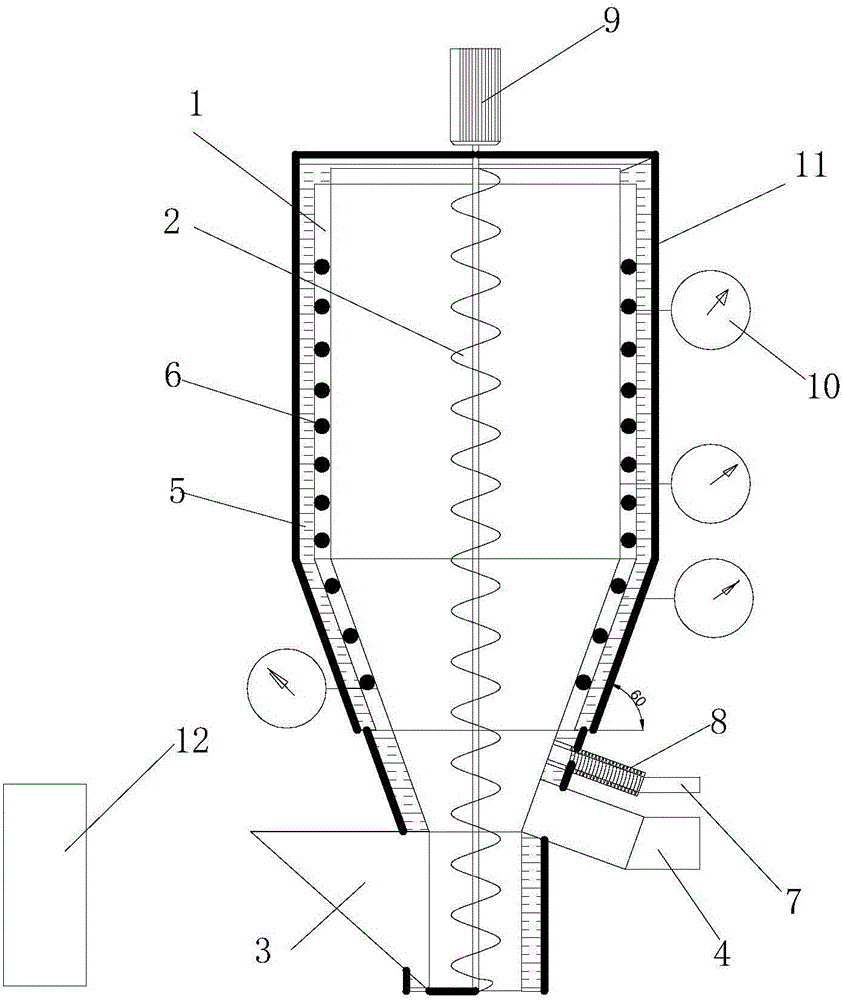

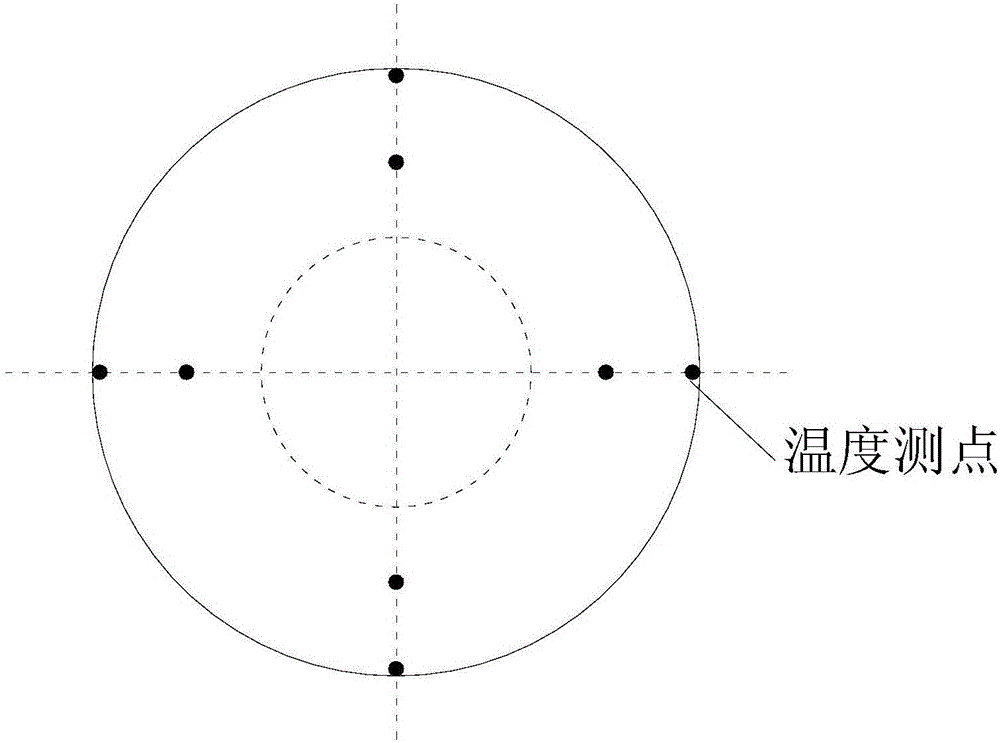

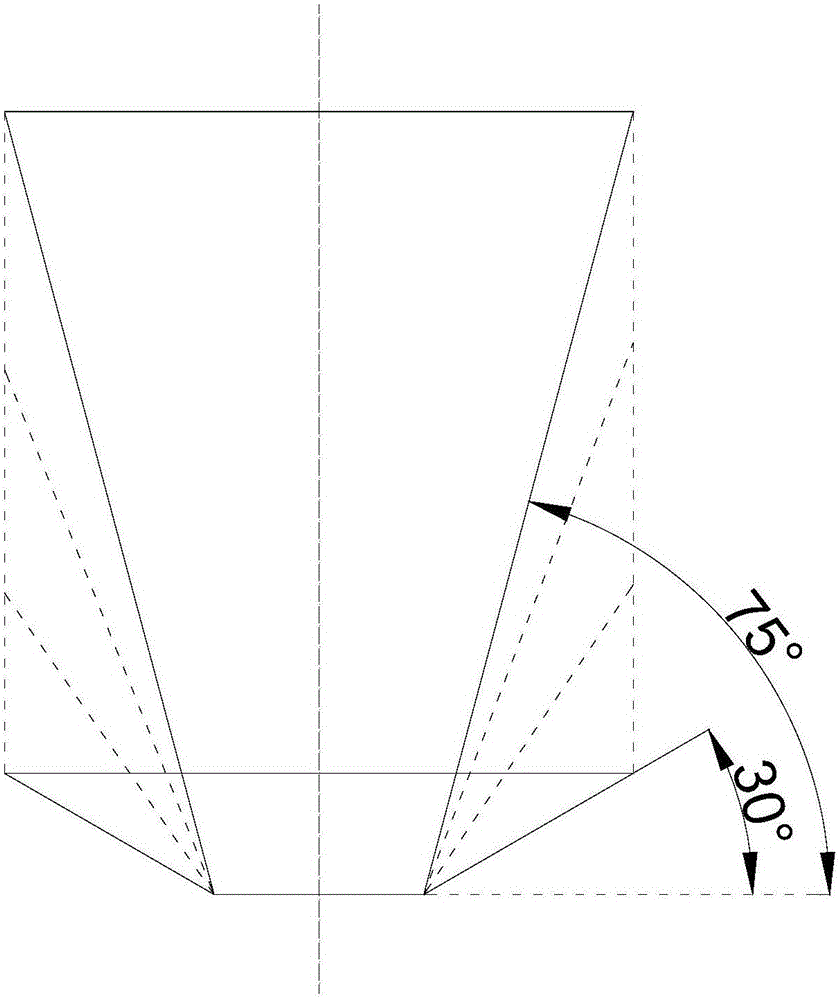

Composite heating fast fermentation device of organic fertilizer

InactiveCN106631222AExpand sourceEasy to passBio-organic fraction processingExcrement fertilisersEngineeringOxygen

The invention relates to a composite heating fast fermentation device of an organic fertilizer. The composite heating fast fermentation device comprises a tube body and a spiral stirrer, wherein the tube body is provided with a material feeding opening and a material discharging opening. The composite heating fast fermentation device is characterized in that the tube body is a vertical diameter change tube body; a heating sandwich sleeve is arranged on the outer wall of the tube body; a sandwich heater is arranged on the heating sandwich sleeve; the material feeding opening and the material discharging opening of the tube body are formed in the bottom of the tube body; a ventilation pipeline communicating with an inner cavity of the tube body is arranged on the lower part side wall of the tube body; a heating air pipe is arranged on the ventilation pipeline. The composite heating fast fermentation device has the beneficial effects that a composite heating mode is used; the heat resource is increased; through hot air input into the inside, and the heating sandwich sleeve of the tube body, heating is simultaneously performed, so that the heat transfer can be accelerated; the heat efficiency is higher; in addition, during the hot air introduction into the tube body, the hot air per se has kinetic energy, so that the materials can be further promoted to be uniformly mixed; the hot air heating is used; during the heating, additional oxygen can be provided for fermentation thalli; the fermentation process is accelerated.

Owner:TIANJIN ENVIRONMENTAL PROTECTION TECHNICAL DEV CENT DESIGNING INST

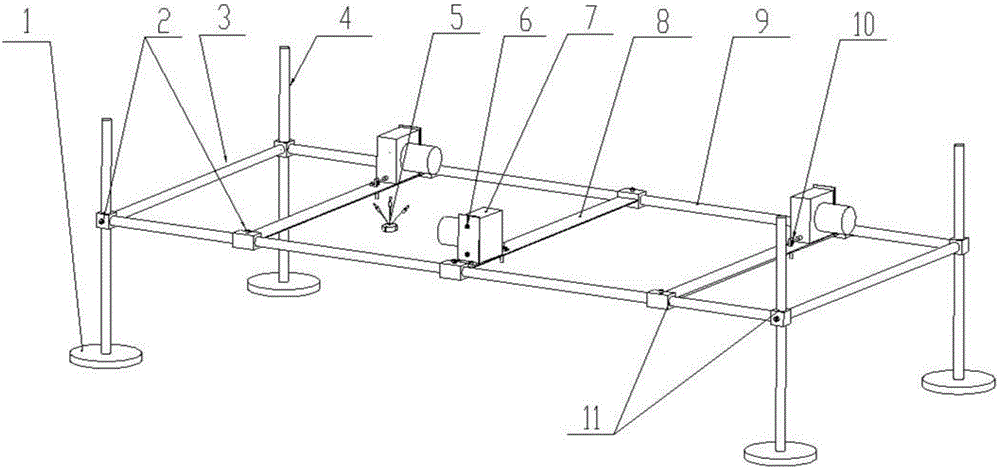

Novel dieless test device and method for curved surface ship plate forming

InactiveCN105698735ASave crafting materialsSimple structureMeasurement devicesMagnetic measurementsDigital analysis

The invention discloses a novel dieless test device and a method for curved surface ship plate forming. The device comprises a frame mechanism and a measurement mechanism, wherein the frame mechanism comprises cross bars and longitudinal slipways mutually connected into a frame structure through thread; three cross supports are fixedly arranged between the longitudinal slipways equidistantly; each cross support is fixedly provided with a pull rope displacement sensor and a guide roller structure; the measurement mechanism comprises magnetic measurement heads and fixed length lines; the upper end of each fixed length line is connected with a connection buckle at the measurement head end; a connection buckle at a sensor end is in matched connection with the connection buckle at the measurement head end and quick assembly and disassembly are realized; and the magnetic measurement heads are provided with channels in two mutually-vertical diameter directions. The structure is simple, disassembly and movement can be carried out randomly, the mounting is convenient, and repeated use is realized; and in addition, through digital analysis by the software, the hull plate forming precision condition can be quickly measured and analyzed, and subjective test errors brought by manual measurement can be avoided.

Owner:WUHAN UNIV OF TECH +1

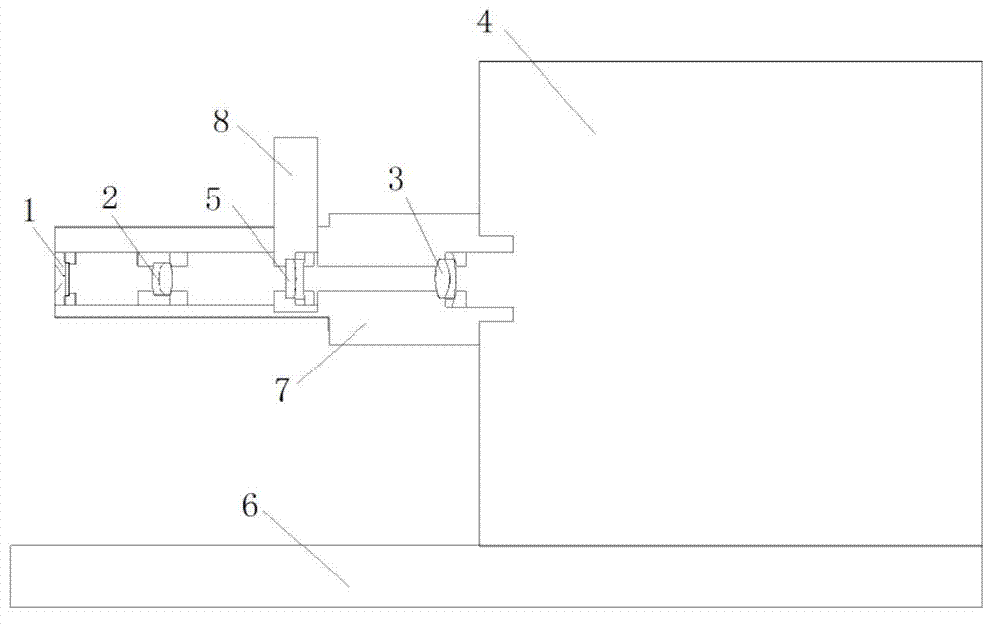

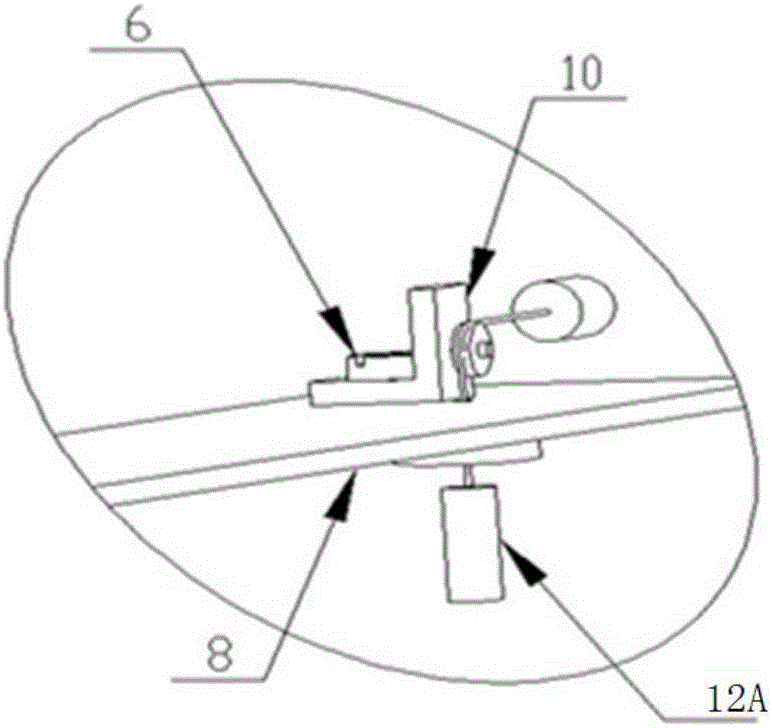

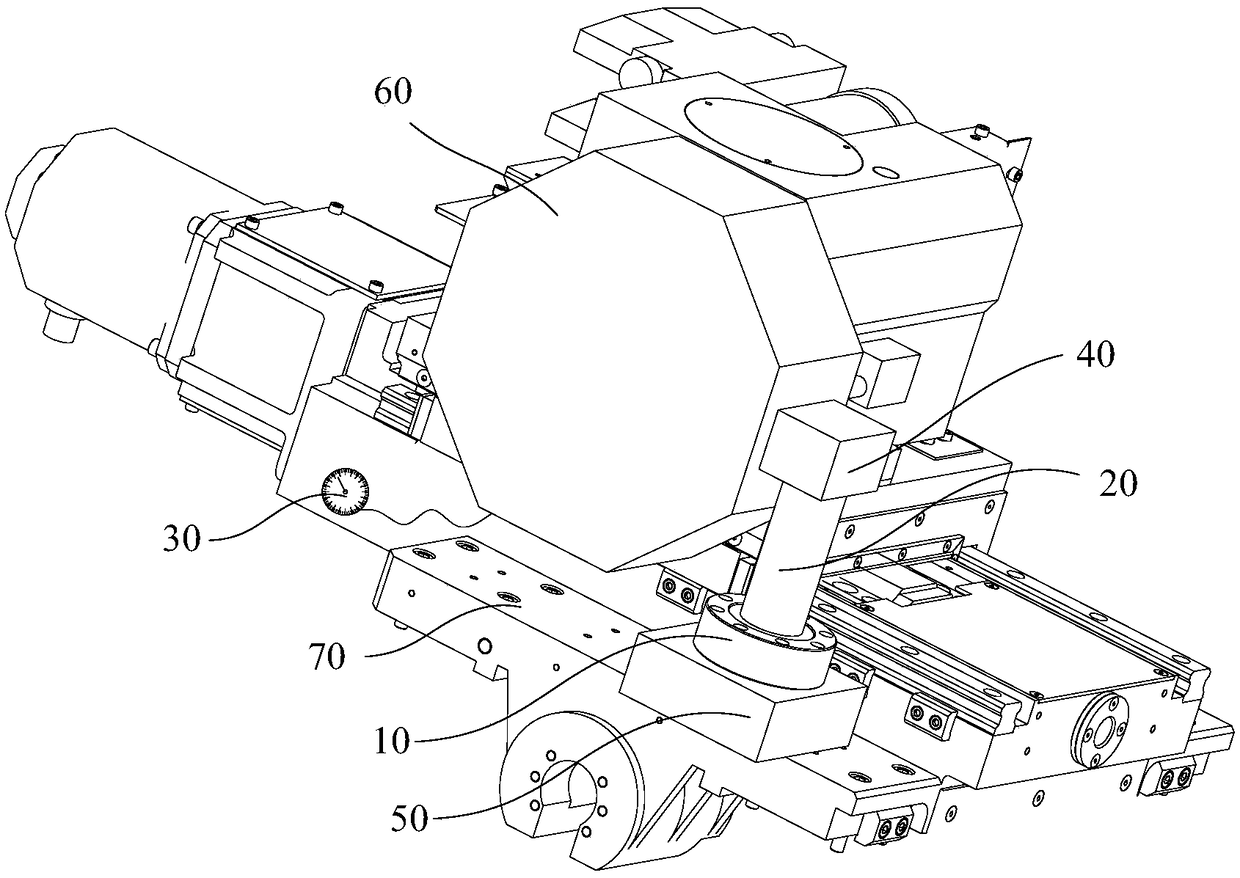

Static stiffness measuring device for vertical diameter direction of lathe tool holder and measuring method thereof

InactiveCN109186899AMeet the needs of accurately measuring the static stiffness of the lathe tool holder in the vertical directionReduce the possibility of misjudgmentElasticity measurementMeasuring instrumentEngineering

The invention discloses a static stiffness measuring device for the vertical diameter direction of a lathe tool holder and a measuring method thereof. The static stiffness measuring device for the vertical diameter direction of the lathe tool holder comprises a force sensor, a force applying element and a displacement measuring instrument. The force sensor has opposite upper and lower ends, and the lower end of the force sensor is fixedly disposed. The upper end of the force sensor is connected to the lower end of the force applying element, and the upper end of the force applying element is connected to the side surface of the lathe tool holder. The lathe tool holder is set fixedly. The force applying element is used for applying a load to a vertical direction of the side surface of the lathe tool holder. The force sensor is used for acquiring applied load data The displacement measuring instrument is used for measuring the vertical diameter deformation amount of the lathe tool holder. The static stiffness measuring device for the vertical diameter direction of the lathe tool holder can reduce the possibility of misjudgment of the static stiffness value of the vertical diameter direction of the lathe tool holder.

Owner:NEWAY CNC EQUIP SUZHOU

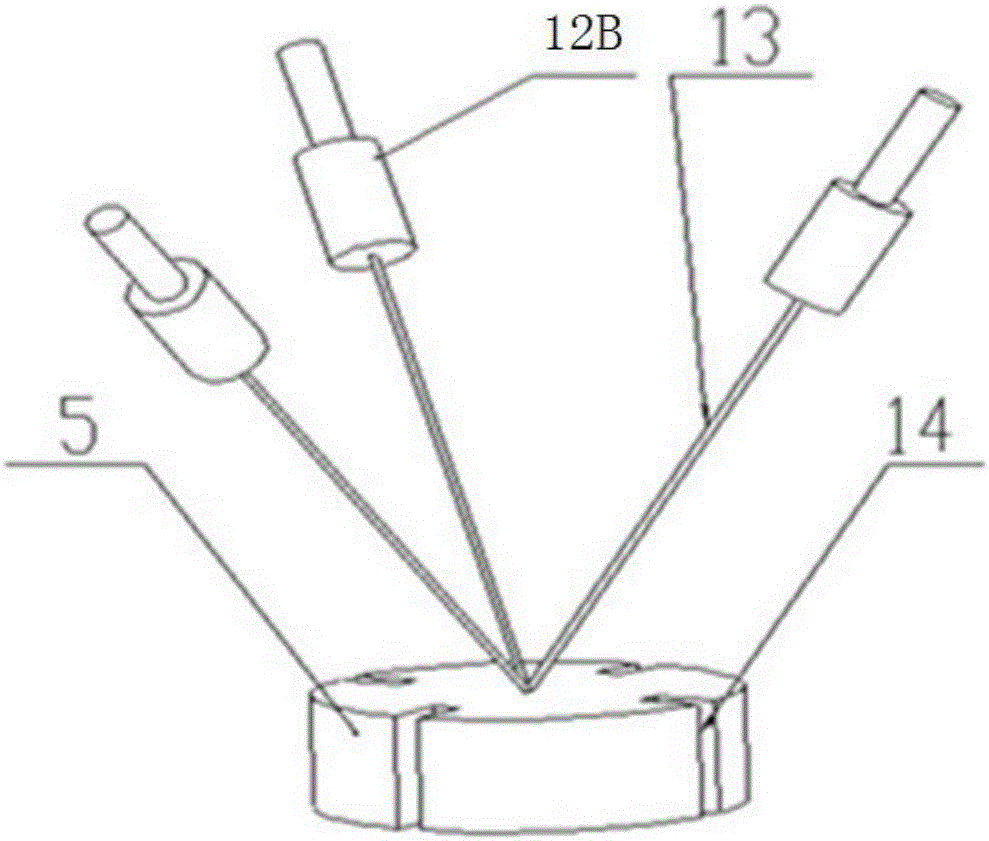

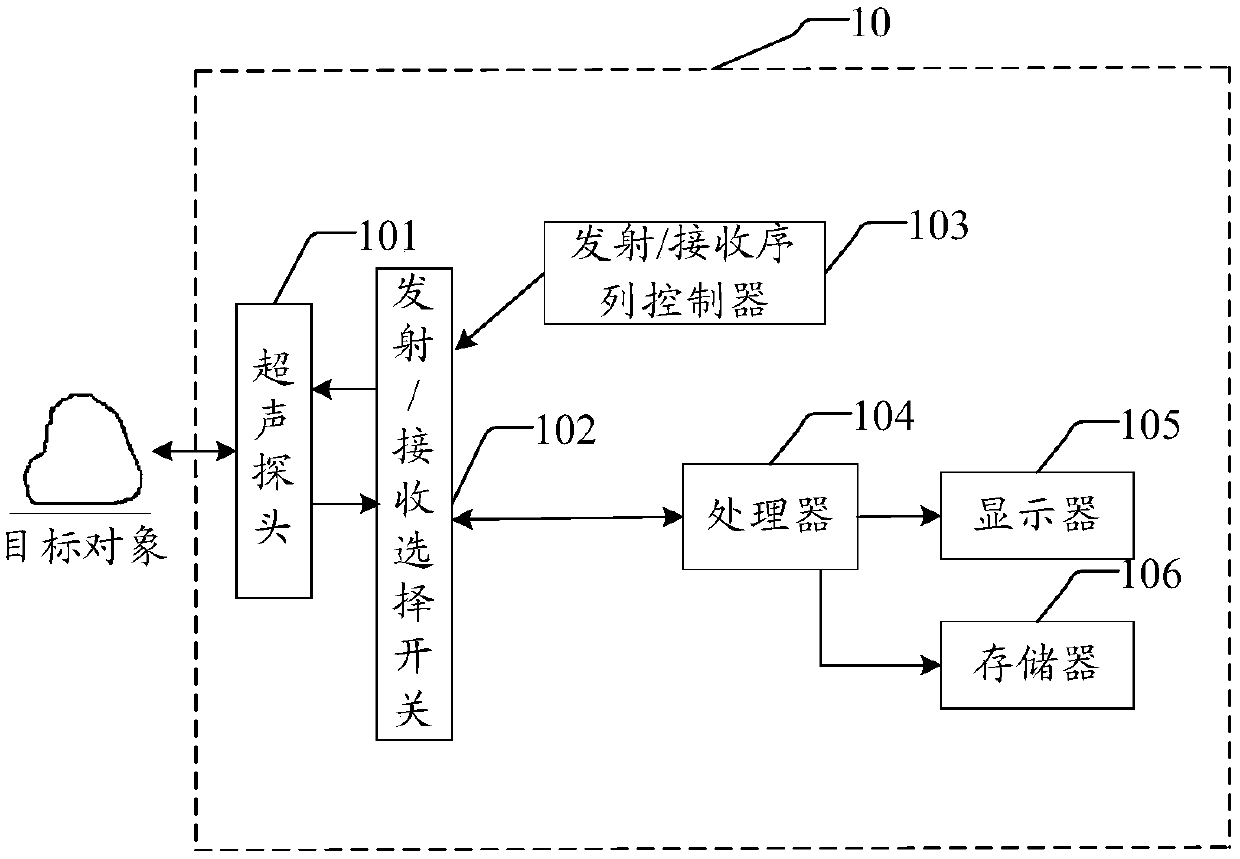

Measurement method of amniotic fluid index, ultrasonic imaging equipment and storage medium

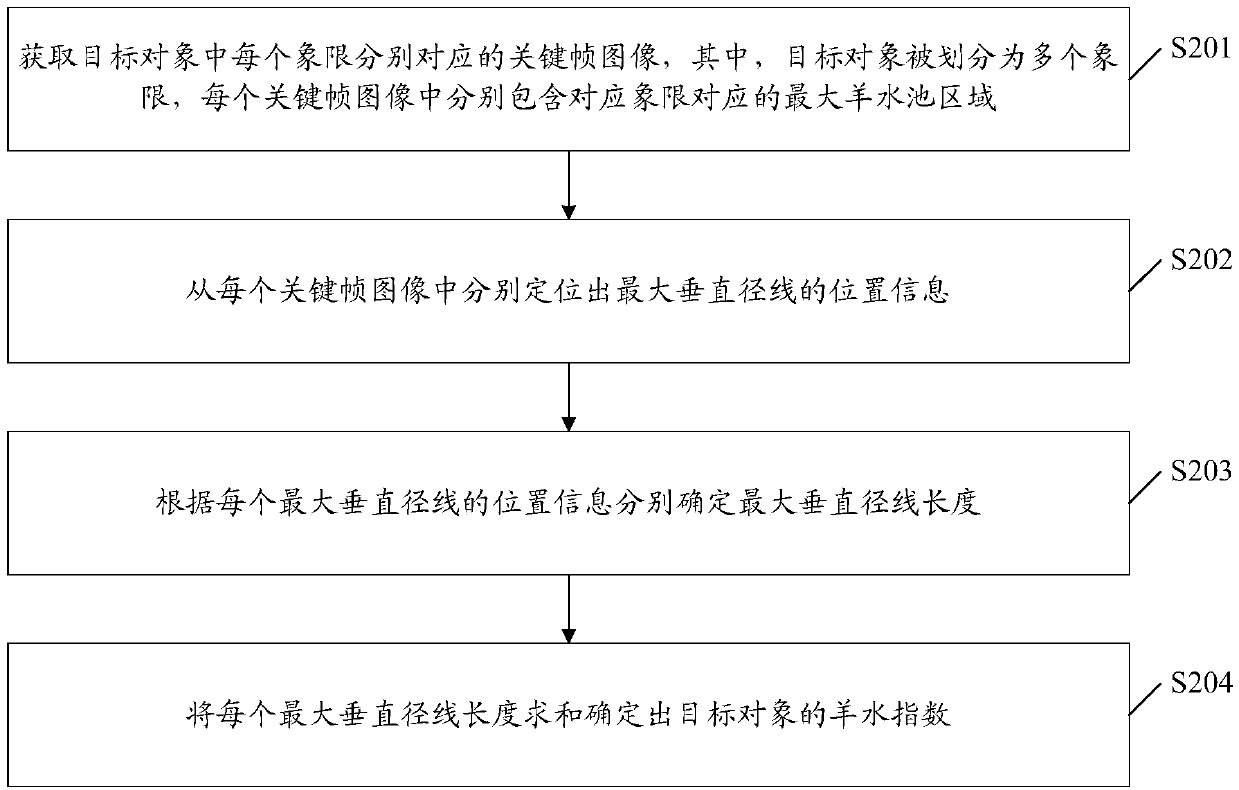

PendingCN109636843AImprove measurement efficiencyImprove measurement accuracyImage enhancementImage analysisUltrasound imagingSonification

The embodiment of the invention discloses a measurement method of an amniotic fluid index, which comprises the following steps that: obtaining a key frame image corresponding to each quadrant in a target object, the target object being divided into a plurality of quadrants, each key frame image comprising a maximum amniotic fluid pool area corresponding to the corresponding quadrant; Positioning position information of a maximum vertical diameter line from each key frame image; Determining the maximum vertical diameter line length according to the position information of each maximum verticaldiameter line; And summing the maximum vertical diameter line lengths to determine the amniotic fluid index of the target object.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

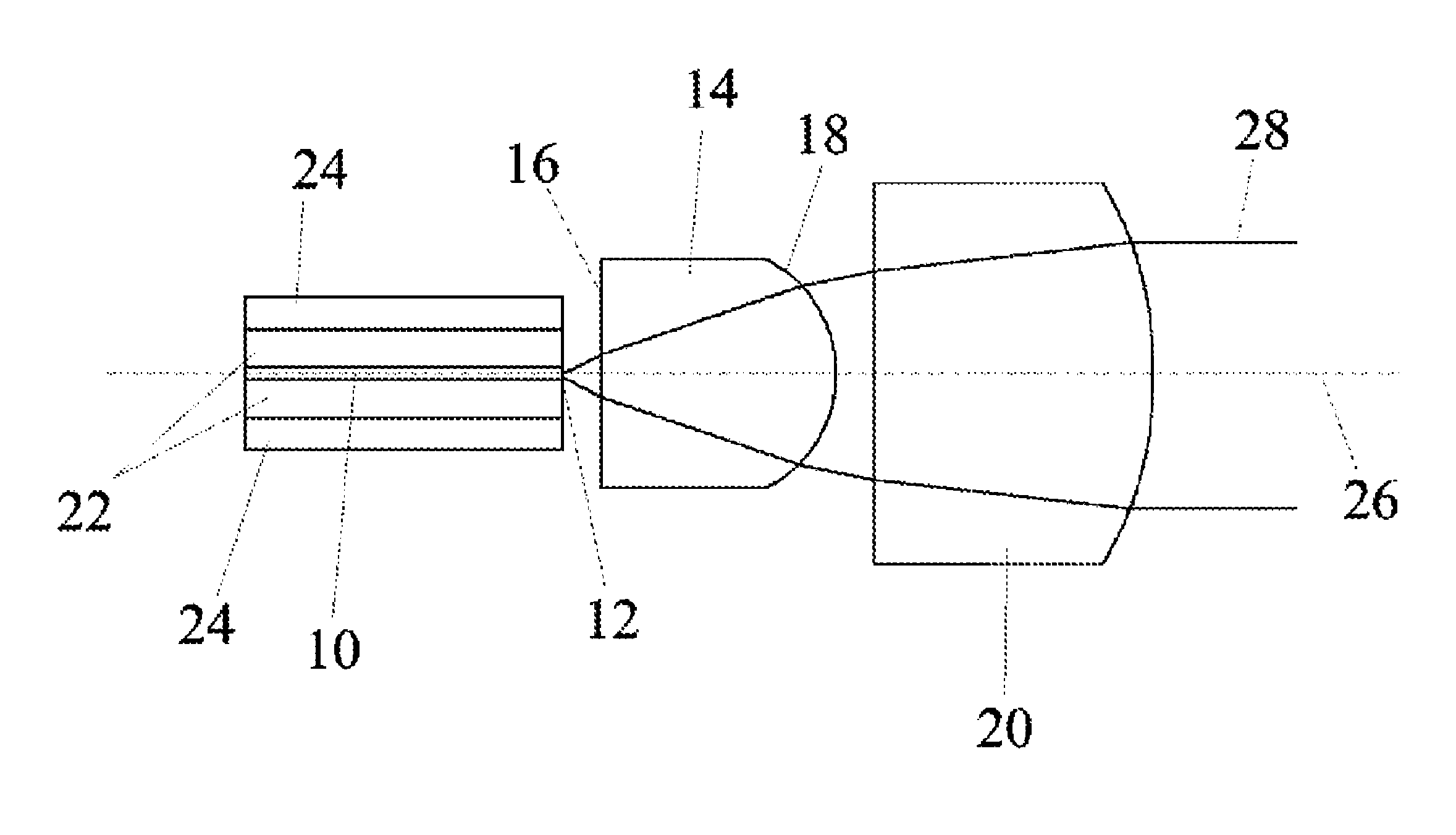

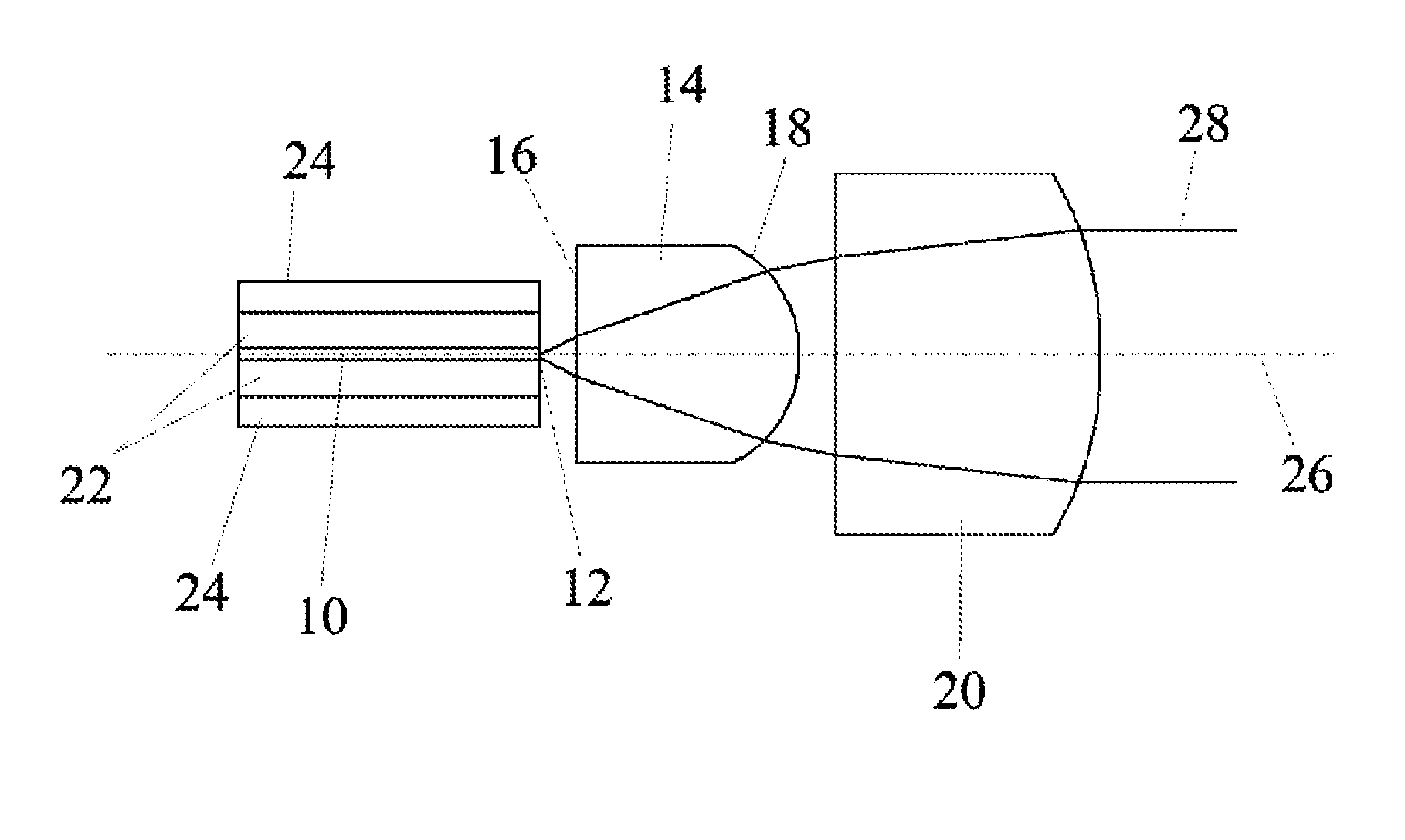

Diode laser

ActiveUS8867586B2Small beam diameterLow noise operationLaser optical resonator constructionOptical resonator shape and constructionGratingWavelength

A diode laser is provided with wavelength stabilization and vertical collimation of the emitted radiation, which allows a small distance of the volume Bragg grating from the emitting surface, a small vertical diameter of the collimated beam and also compensation for manufacturing tolerances affecting the shape of the grating and the lens. The diode laser comprises an external frequency-selective element for wavelength stabilization of the laser radiation, wherein the external frequency-selective element comprises an entry surface facing the exit facet and an exit surface facing away from the exit facet and is designed as a volume Bragg grating; and wherein the external frequency-selective element is designed in such a manner that the divergence of the radiation emitting from the exit facet is reduced during passage through the external frequency-selective element.

Owner:FERDINAND BRAUN INST GGMBH LEIBNIZ INST FUR HOCHSTFREQUENZTECHNIK

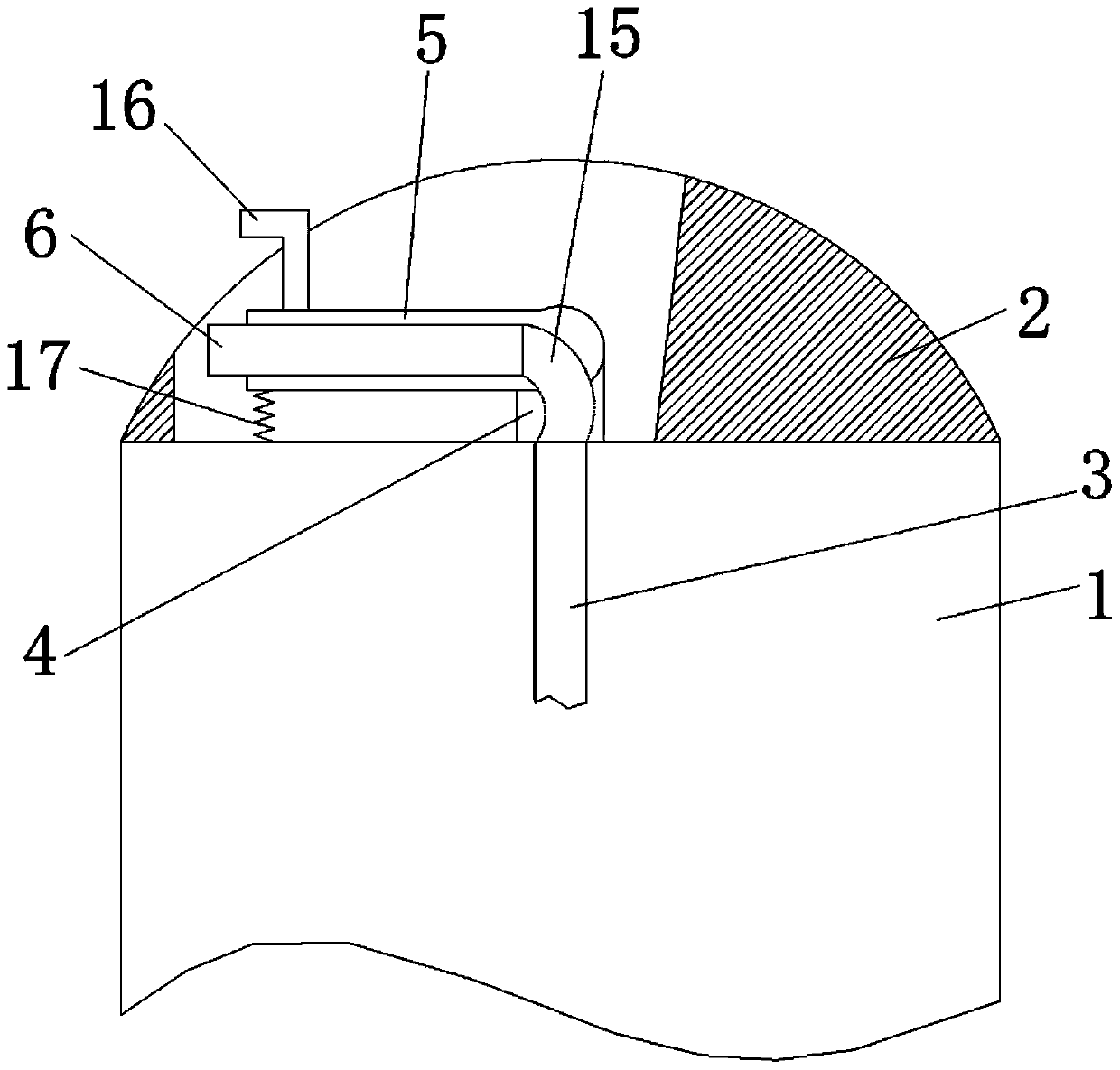

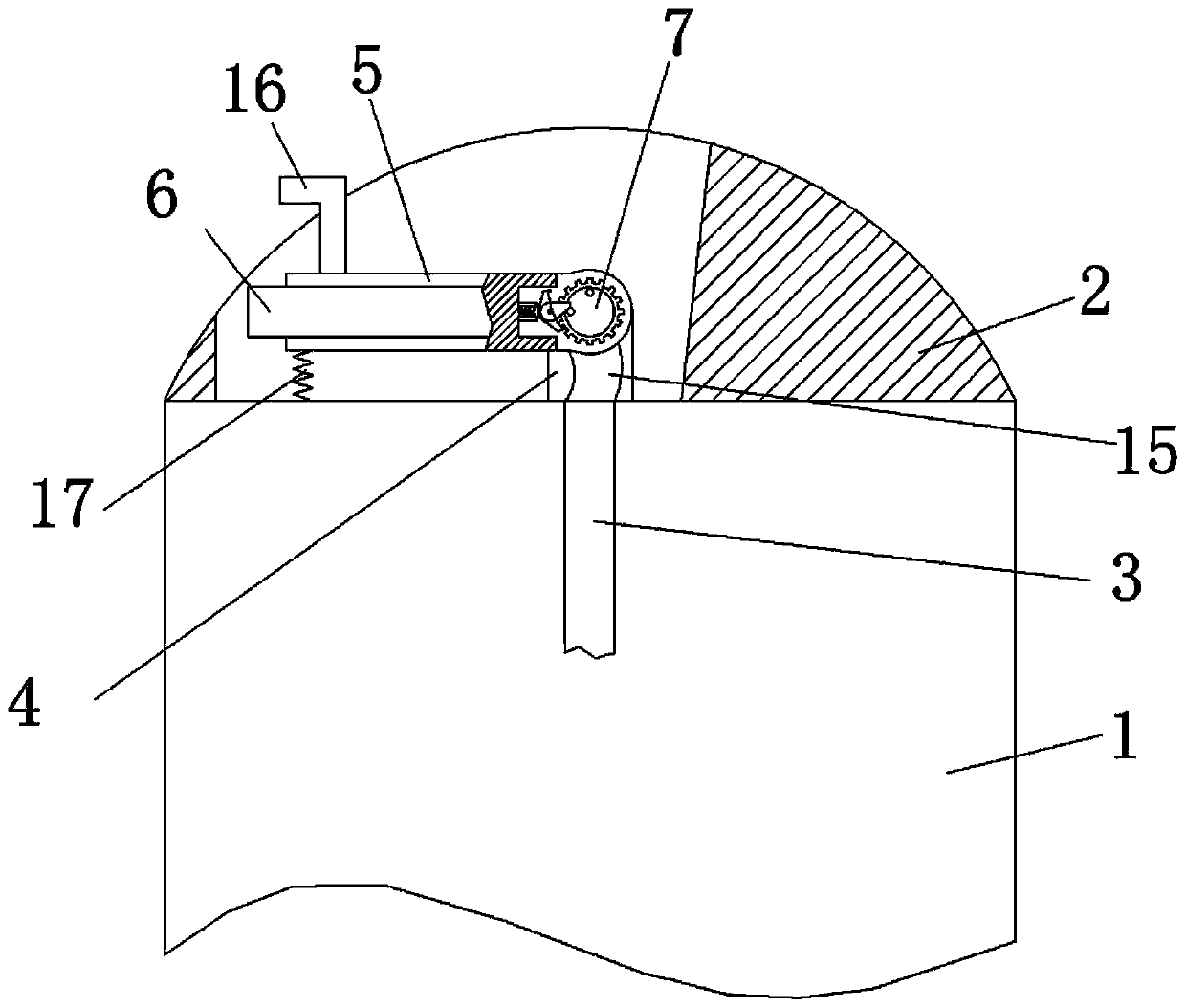

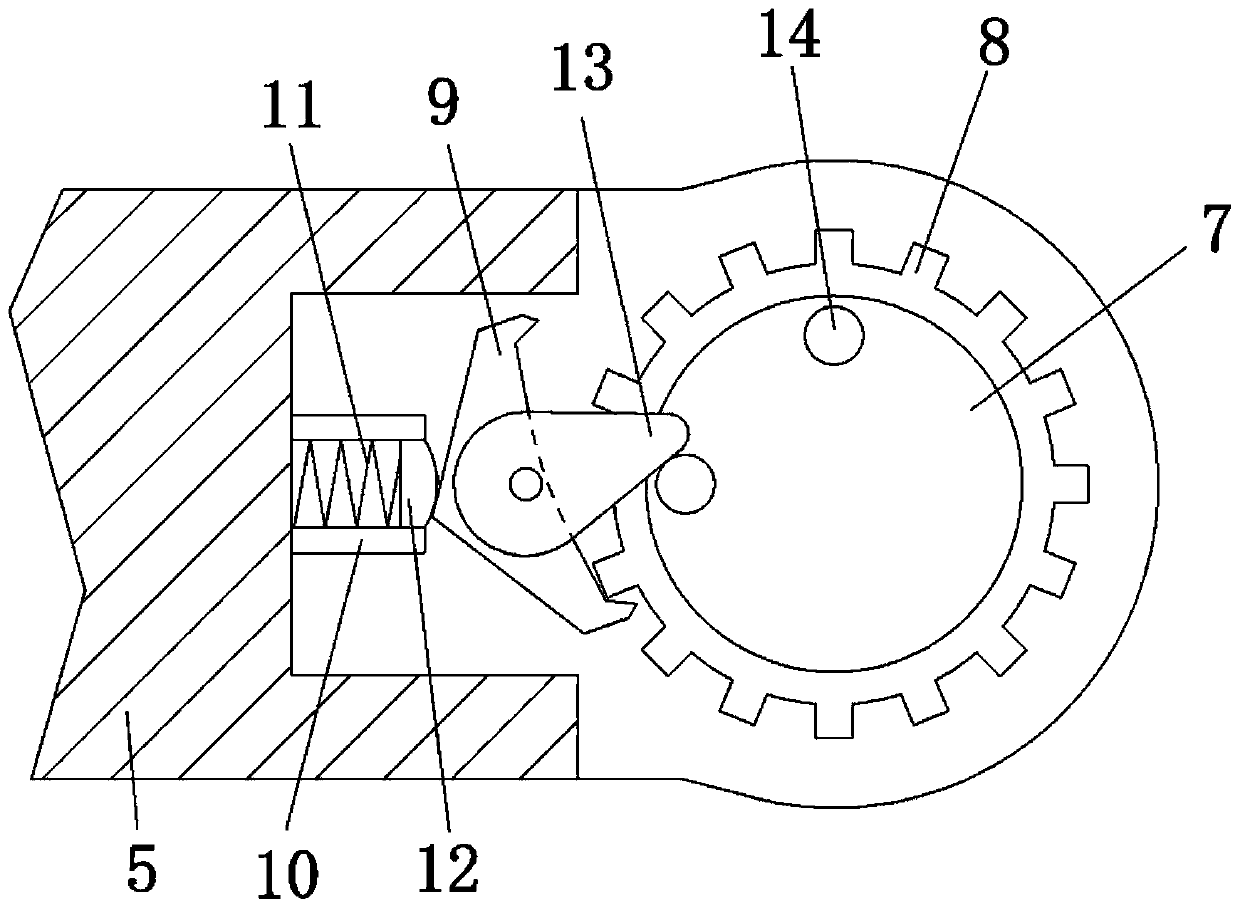

Cup cover with folding type straw and using method thereof

The invention provides a cup cover with a folding type straw. The cup cover comprises a cup cover body, wherein the cup cover body is internally provided with the straw and a rotating part; the strawcan be folded to be horizontally placed through the rotating part or can be unfolded to be vertically placed; the cup cover body is provided with a fixed seat; the rotating part comprises a rotating plate, a central shaft, a ratchet wheel, a shifting fork, a shifting block and two fixed columns; the central shaft is arranged on the fixed seat; a slot is formed in the surface of the rotating plate,and the rotating plate is rotationally connected to the central shaft through the slot; the ratchet wheel is fixedly arranged on the surface of the central shaft in a sleeving way; the shifting forkand the shifting block are coaxially fixed; the shifting fork comprises two symmetric pawls which can limit the ratchet wheel from two directions; the two fixed columns are both arranged on the end surface of the central shaft and can block the rotating shifting block; one fixed column is located on the left end of the maximum horizontal diameter position of the end surface of the central shaft, and the other fixed column is located on the upper end of the maximum vertical diameter position of the end surface of the central shaft; the straw is fixedly arranged on the rotating plate; the rotating part also comprises a push-pull rod which is fixedly arranged on the rotating plate. The cup cover provided by the invention is capable of relatively conveniently folding or unfolding the straw.

Owner:林杨洋

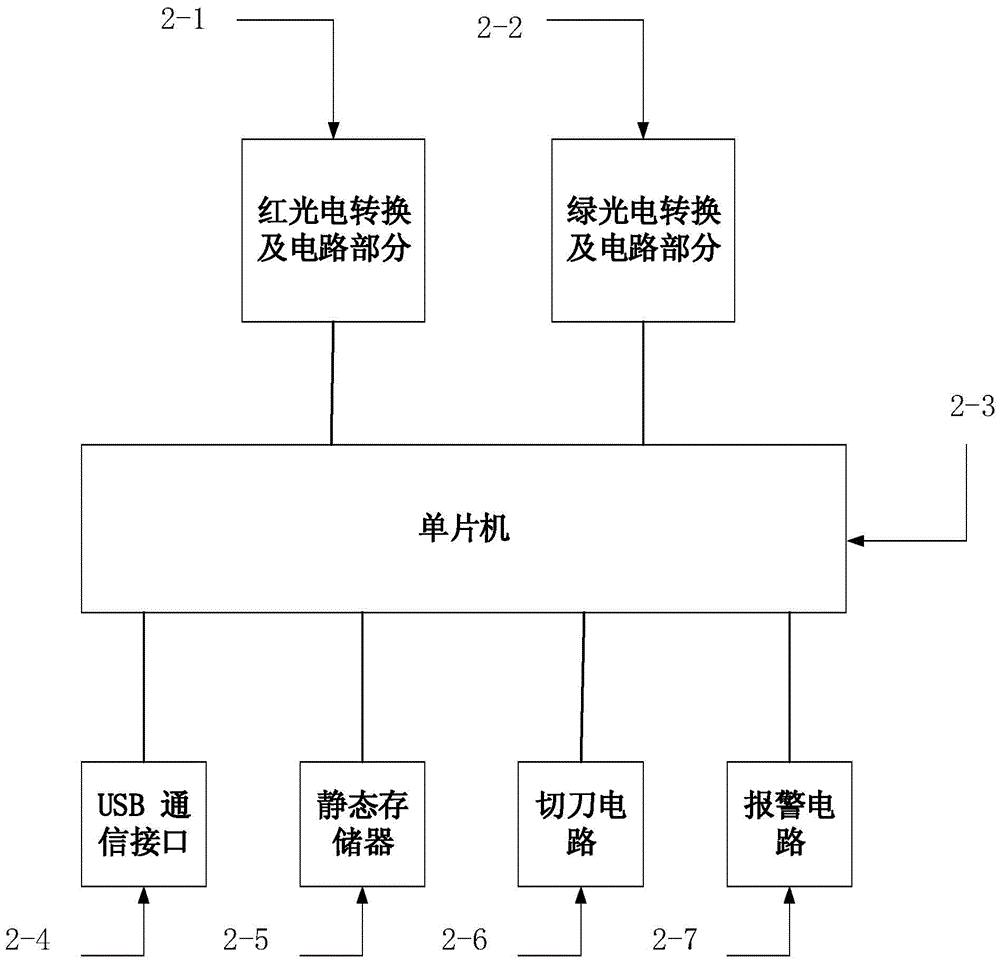

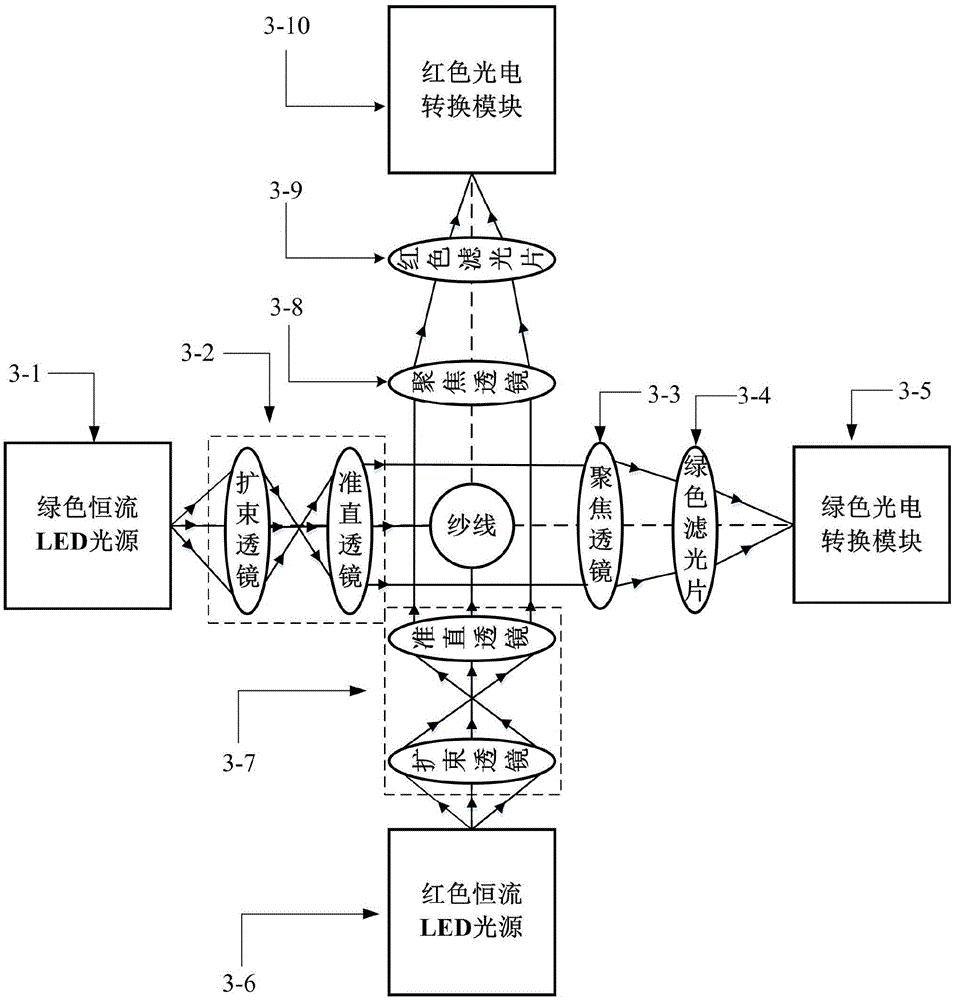

Double-light-source yarn flaw detection method

InactiveCN105675618ASolve the problem of not being able to detect flat yarn defectsTroubleshoot flat blemishesOptically investigating flaws/contaminationYarnOptical axis

A double light source detection method for yarn defect detection, the detection system for realizing the detection method includes a first light source detection unit and a second light source detection unit, the light colors of the first light source and the second light source are different, and the first light source detection The detection optical axes of the unit and the second light source detection unit are perpendicular to the moving direction of the yarn to be detected, while the detection optical axes of the first light source detection unit and the second light source detection unit are orthogonal; the double light source detection method includes the following steps: 1) Calculate Output voltage U of the first light source detection unit R and the second light source detection unit output voltage U G , the standard diameter set by the detection yarn is d 0 , calculate the standard voltage U0 in yarn detection; 2) Calculate the voltage output △ U of the diameter change in the horizontal direction of the yarn R and the voltage output △U of the diameter change in the vertical direction of the yarn G ;3) by ΔU R and ΔU G Determine the type of defect. The invention has low cost, simple system, and can simultaneously detect yarn thickness defects and flat defects.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

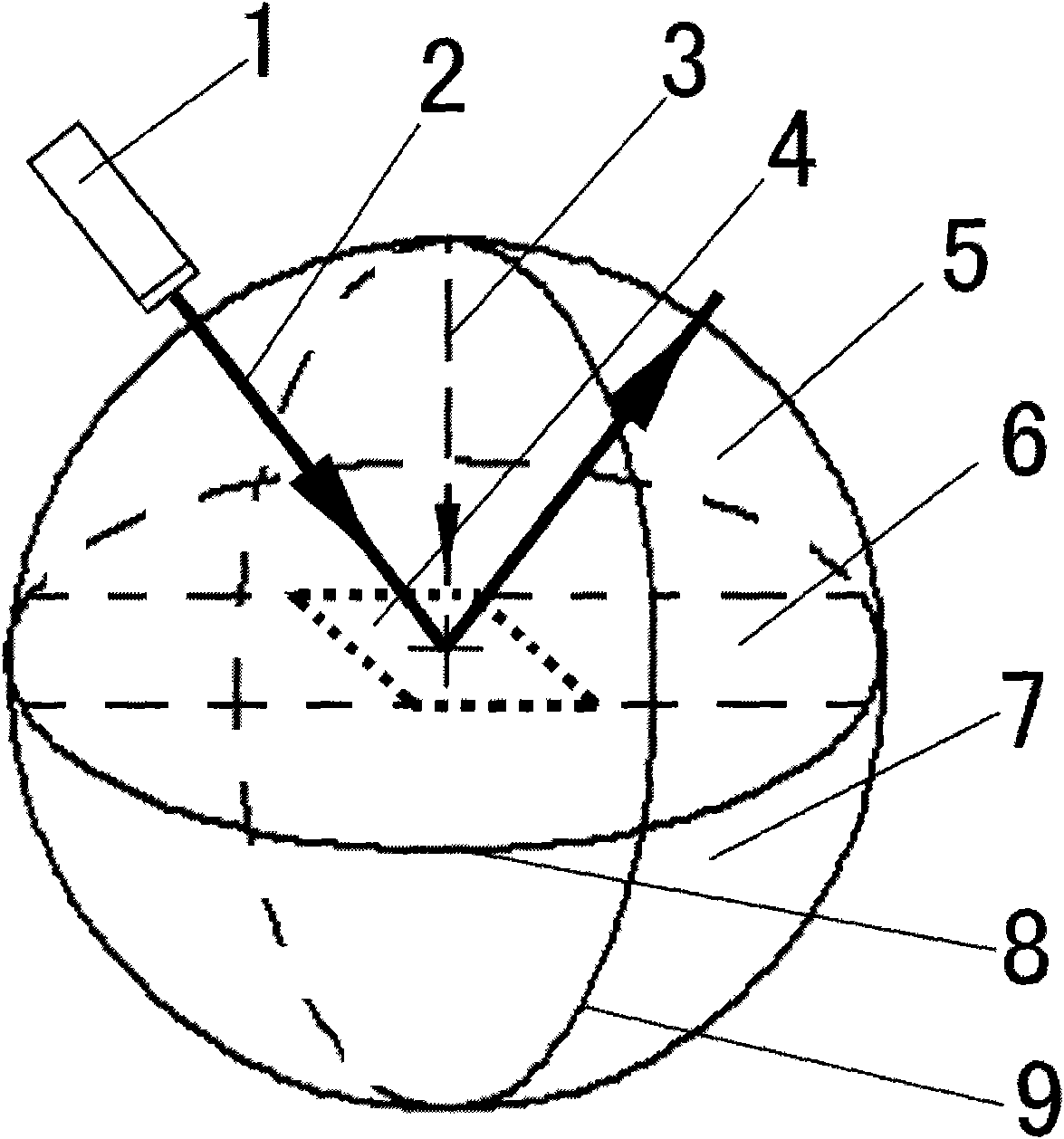

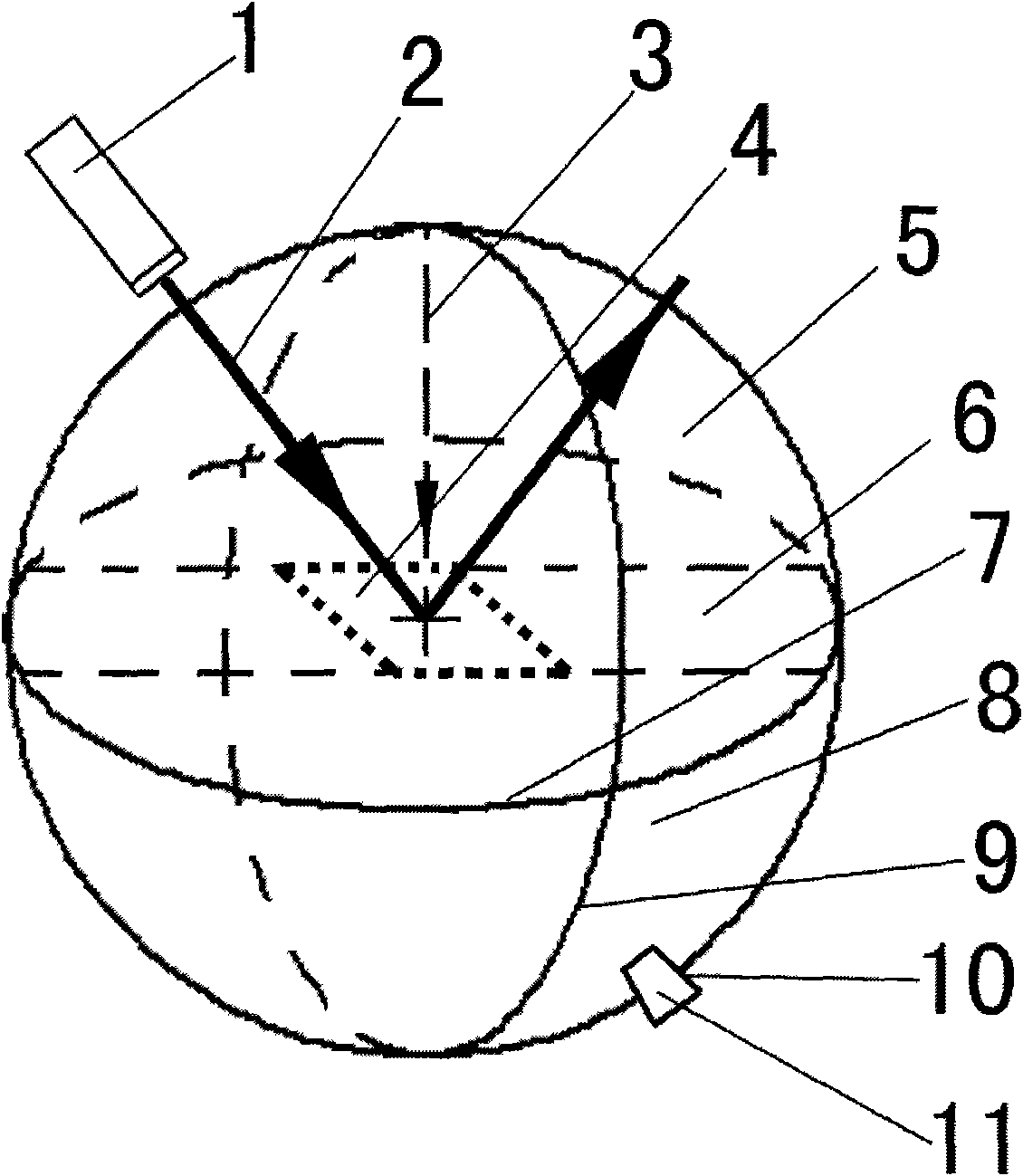

Light reflection and refraction experimental instrument

The invention relates to a light reflection and refraction experimental instrument. The instrument is a transparent hollow sphere with holes; a plurality of vertical circles are marked on the surface of the sphere; the vertical circles are formed in a way that a vertical surface passing through the sphere centre are tangent to the surface of the sphere; the vertical diameters of the plurality of vertical rings are all coincided with the vertical diameter of the hollow sphere; a plurality of horizontal circles are marked on the sphere surface; the horizontal circles are formed in a way that a horizontal surface is tangent to the sphere surface in the process of moving upwards and downwards; degrees for indicating sizes of incident angles, reflective angles and refractive angles are marked on the horizontal circles. The invention has the following beneficial effects that the students can independently learn the real connotation of ''three lines on the same plane'' by means of the vertical circles in a vivid and direct three-dimensional form without mechanically imaging the ''three lines on the same plane'' by the explanation of teachers from an indirect angle, and therefore, the students can easily understand the connotation of ''three lines on the same plane''; and the angle size can be read from the horizontal circles, so that the invention successfully enables the experiment to be transferred from the replication experiment to the Investigation experiment.

Owner:雷海平

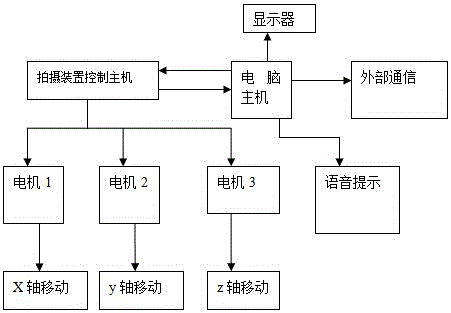

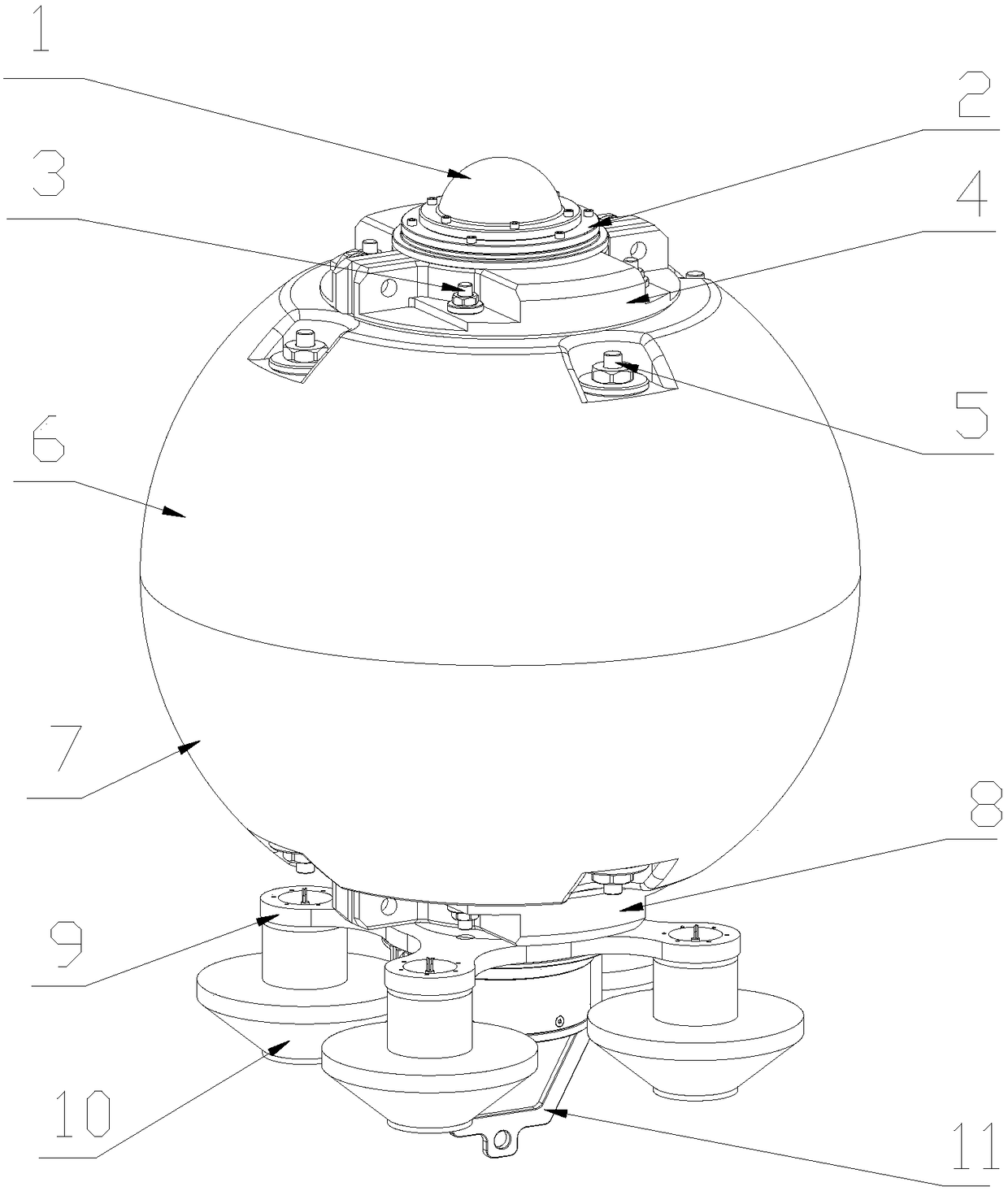

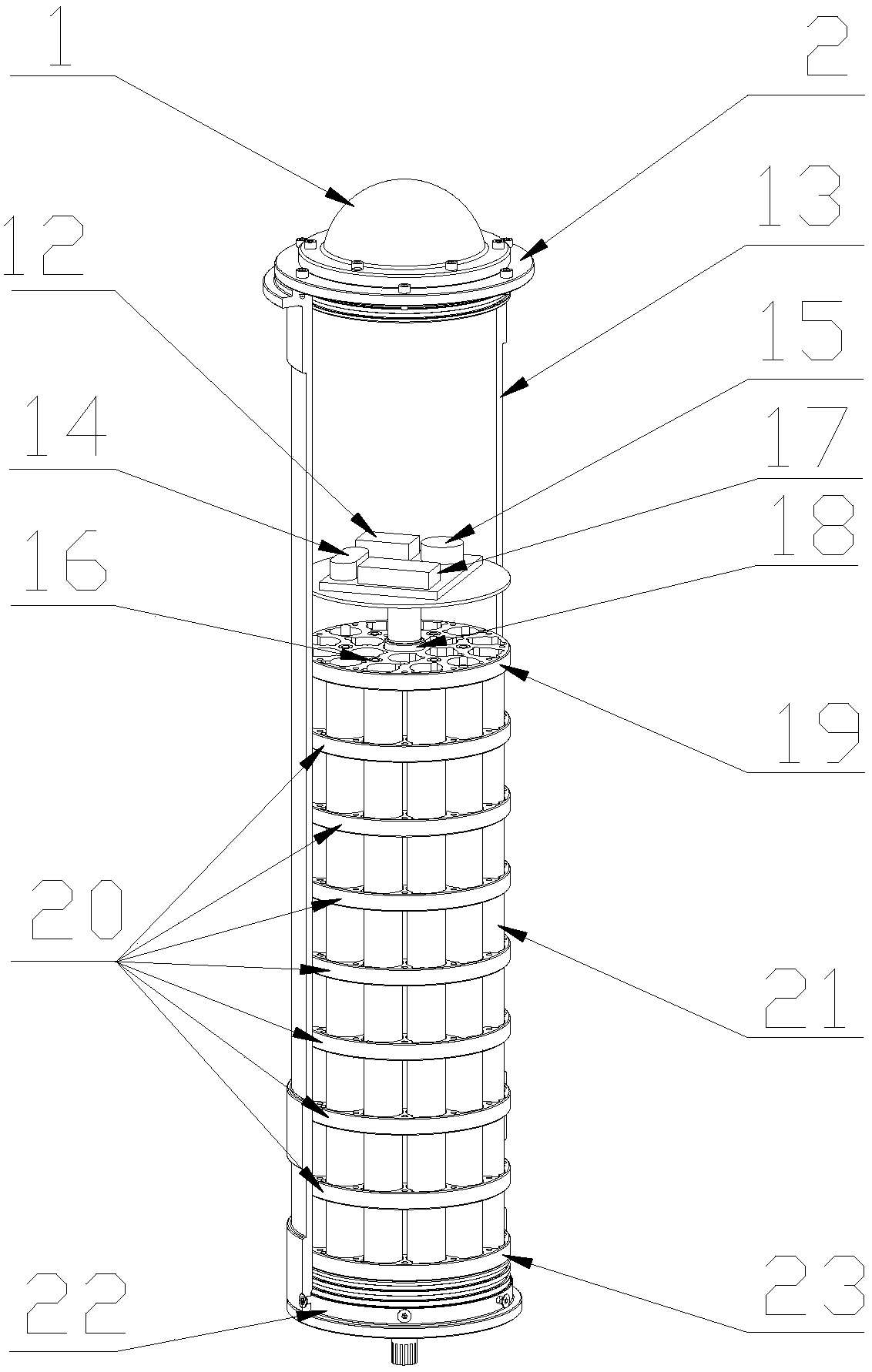

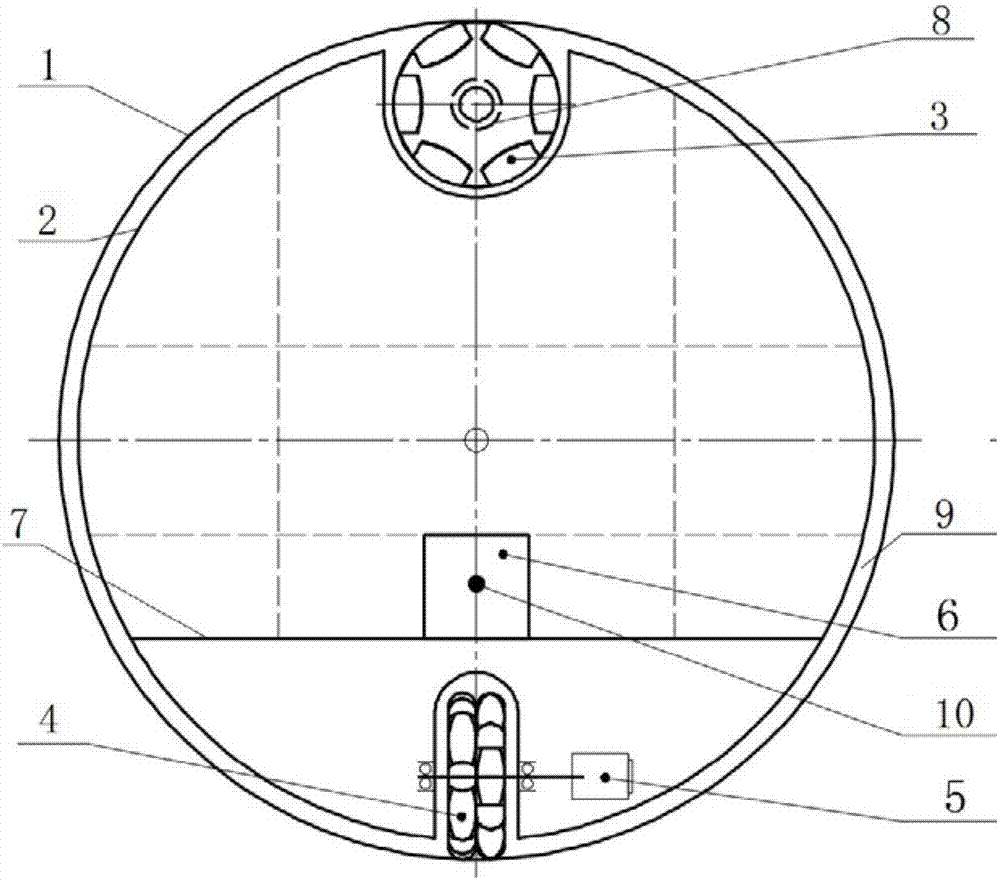

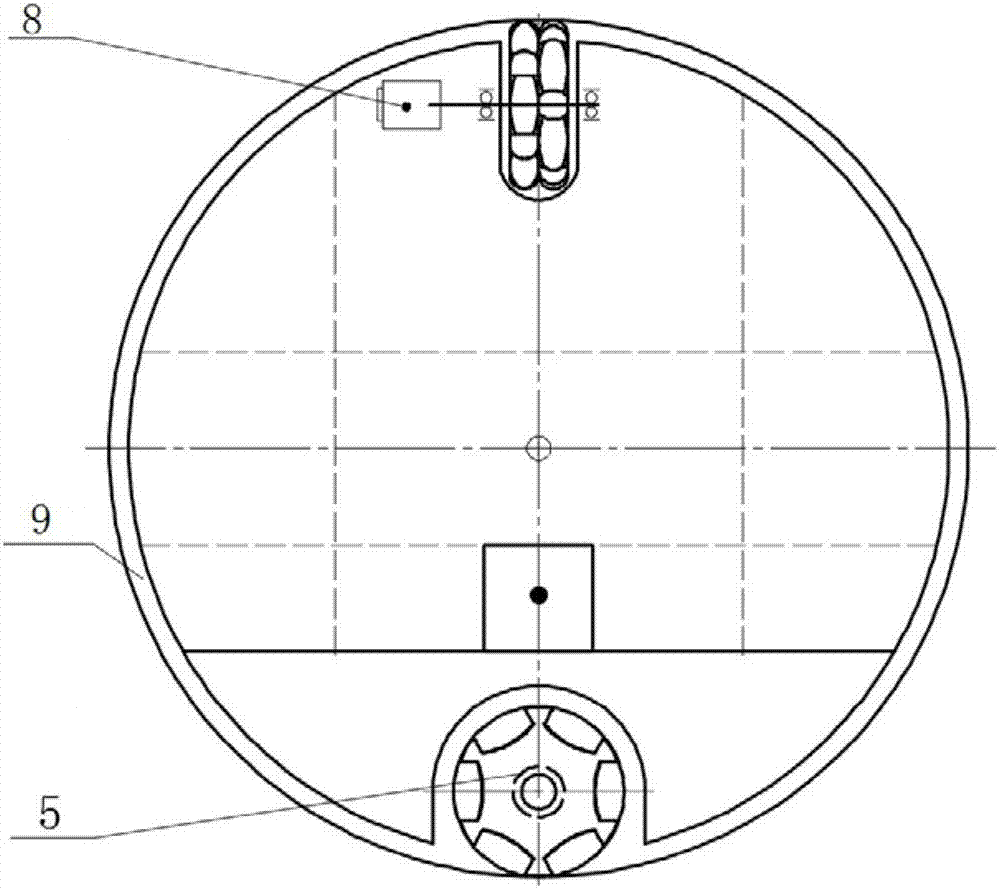

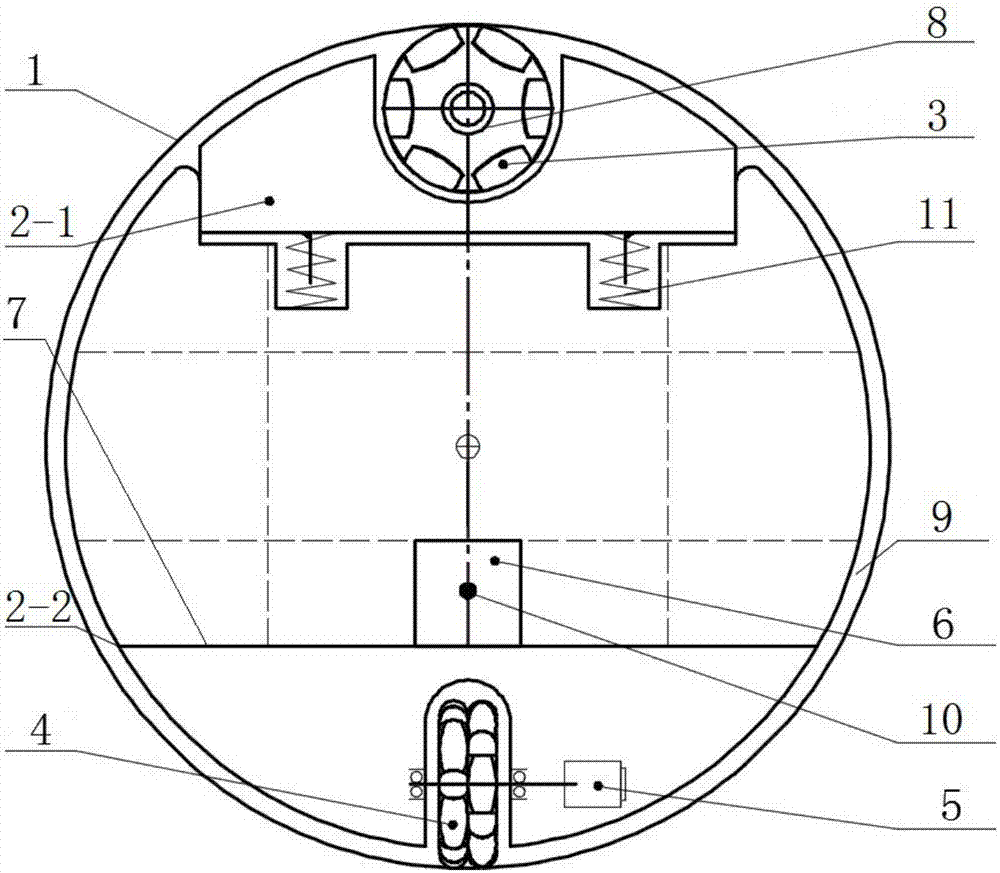

Spherical robot driven by orthogonal-position double omnidirectional wheels

The invention relates to a spherical robot driven by orthogonal-position double omnidirectional wheels. The two omnidirectional wheels driven independently are arranged at the two ends of the maximal vertical diameter in a spherical shell in an orthogonal mode, and omnidirectional movement of the spherical robot is achieved by utilizing the friction force generated by the pressure of the omnidirectional wheels and the inner surface of the spherical shell. According to the spherical robot driven by the orthogonal-position double omnidirectional wheels, the structure is simple, accurate control is easy to achieve, manufacturing of high-precision parts is not needed, and the engineering cost is reduced.

Owner:BEIJING JIAOTONG UNIV

Mold for injection-molding a golf ball, and golf ball manufactuing method

ActiveUS20140175699A1Molding stabilityEasily and reliably obtainFood shapingDomestic articlesEngineeringGolf Ball

The invention provides a mold for injection-molding a golf ball, which mold has a cavity inner wall with a vertical diameter connecting both poles in a vertical direction thereof that is longer than a horizontal diameter connecting both poles in a horizontal direction thereof. A method of manufacturing golf balls using such a mold is also provided. The use of this mold eliminates molding problems that arise when molding the outermost cover layer of a golf ball, enabling the cover to be stably molded and also making it possible to easily and reliably obtain golf balls of high symmetry in which a cover of uniform thickness has been formed.

Owner:BRIDGESTONE SPORTS

Device for fixing die and die core

InactiveCN103111882AGuaranteed accuracyIngenious designPositioning apparatusMetal-working holdersMechanical engineeringVertical diameter

The invention relates to a device for fixing a die and a die core. The device for fixing the die and the die core comprises a base, a fixing block and a press block, wherein the upper surface and the lower surface of the base are flat surfaces, via holes are evenly distributed along two vertical diameters and using a center as a base point on the base, the height of the fixing block is same as the height of the base, the fixing block and the base are respectively fixed on two ends of the press block by using screws, and an oblong via hole is formed in the center of the press block. The device for fixing the die and the die core is skilled in design, stable in working, compact in structure, convenient to machine, and easy to replace due to the fact that various elements of the device for fixing the die and the die core form series, so that accuracy and machine cost of machining the die and the die core can be ensured.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

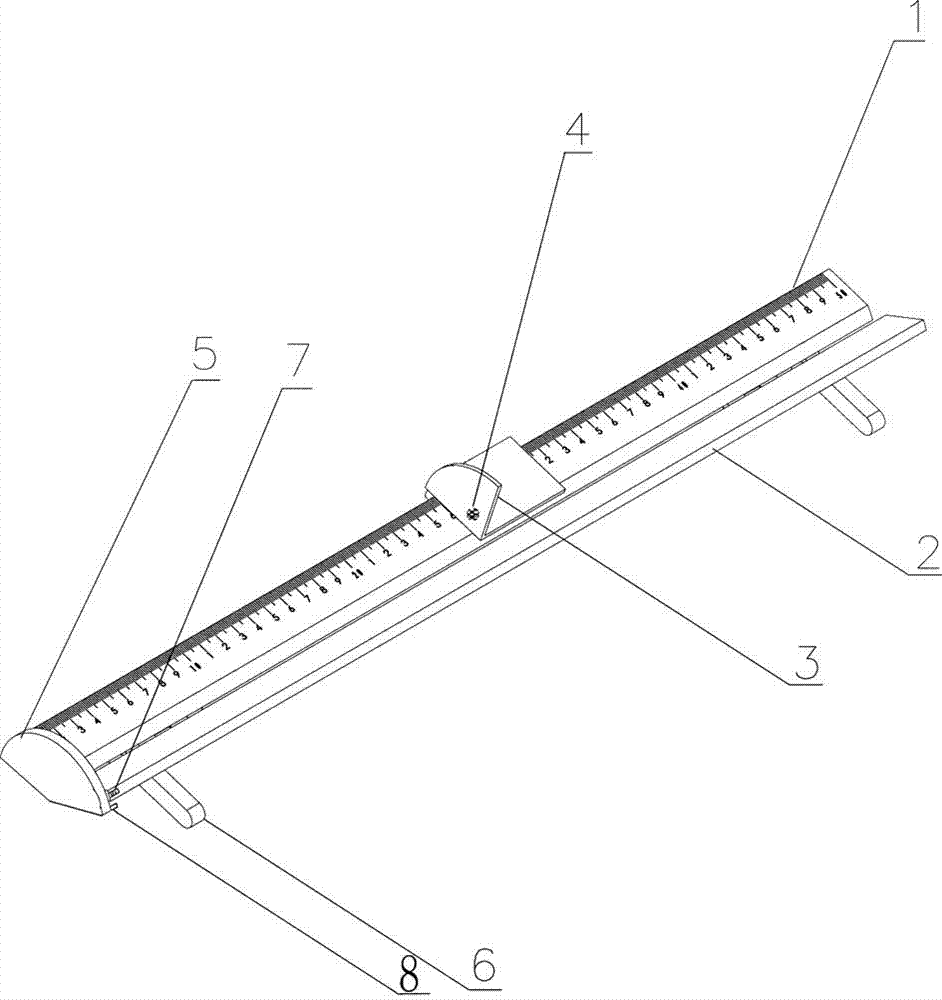

Multi-functional fruit grain size measurement scale

InactiveCN107478117AAccurate measurementEasy to calculateMeasurement arrangements for variableRulers for direct readingSize measurementEngineering

The present invention provides a multi-functional fruit grain size measurement scale. The scale comprises a fixed scale and a scale movable board, the fixed scale is provided with measurement scales, the fixed scale is hinged with the scale movable board, a magnetic vertical baffle is fixedly arranged at one end of the fixed scale, one end of the scale movable board is provided with a movable board locking magnet, the vertical baffle and the movable board locking magnet are located at the same end, and a vernier is sleeved on the fixed scale. The multi-functional fruit grain size measurement scale can perform order arrangement of fruit grains and perform one accurate measurement of a plurality of fruit grains, the angle of a V-shaped slot can be changed when the transverse diameters and the vertical diameters of fruit grains are needed to measure so as to facilitate integrated regulation of the directions of the fruit grains, the structure is simple, the measurement speed is fast, and the efficiency is high.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

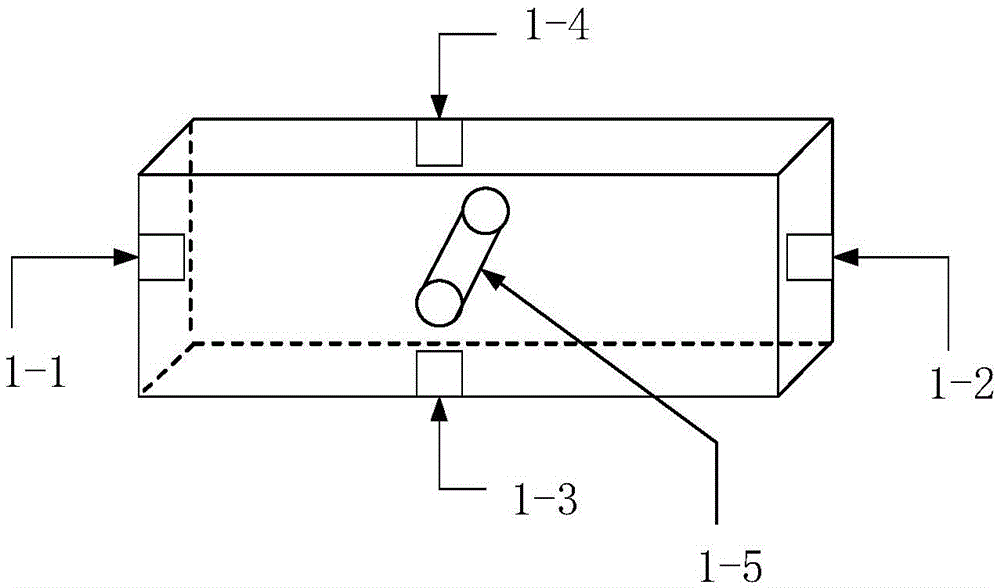

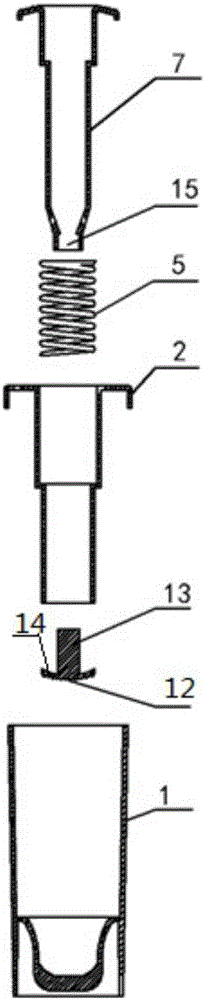

Disposable quantitative sampling box

PendingCN106644555AAvoid bad consequencesGuaranteed basic quantitativeWithdrawing sample devicesEngineeringVertical diameter

The invention discloses a disposable quantitative sampling box. The disposable quantitative sampling box comprises a container box with a variable-diameter lower end and a liftable sampling spoon and is characterized in that the container box is made of transparent materials, the liftable sampling spoon comprises a spoon handle and a sample spoon head, a positioning opening is formed in the bottom of the container box and used for positioning an instrument placed into the container box, a box cover matched with the container box is arranged on the opening of the container box, a cylindrical hollow hole for mounting the liftable sampling spoon is formed in the box cover, and a spring can be placed into a space formed by clamp positions, formed by the vertical diameter variation of the inner diameter of the hole, in the box cover. The disposable quantitative sampling box has the advantages that sampling, sample diluting and even mixing are performed in the disposable quantitative sampling box, the disposable quantitative sampling box has incomparable superiority as compared with original excrement sample collecting, placing and final sample sterilizing, operation is facilitated, and negative effects caused by inappropriate processing and sterilizing of an excrement sample can be prevented effectively.

Owner:济南继德生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com