Diameter-expanding and bend-pressing forming core head for short radius elbows

A technology with short radius and bending radius, which is applied in the field of forming cores of expanding push-bending short-radius elbows, can solve the problems of not being able to obtain finished products, tearing, and thinning, and achieve high practical value, wide application range, and use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

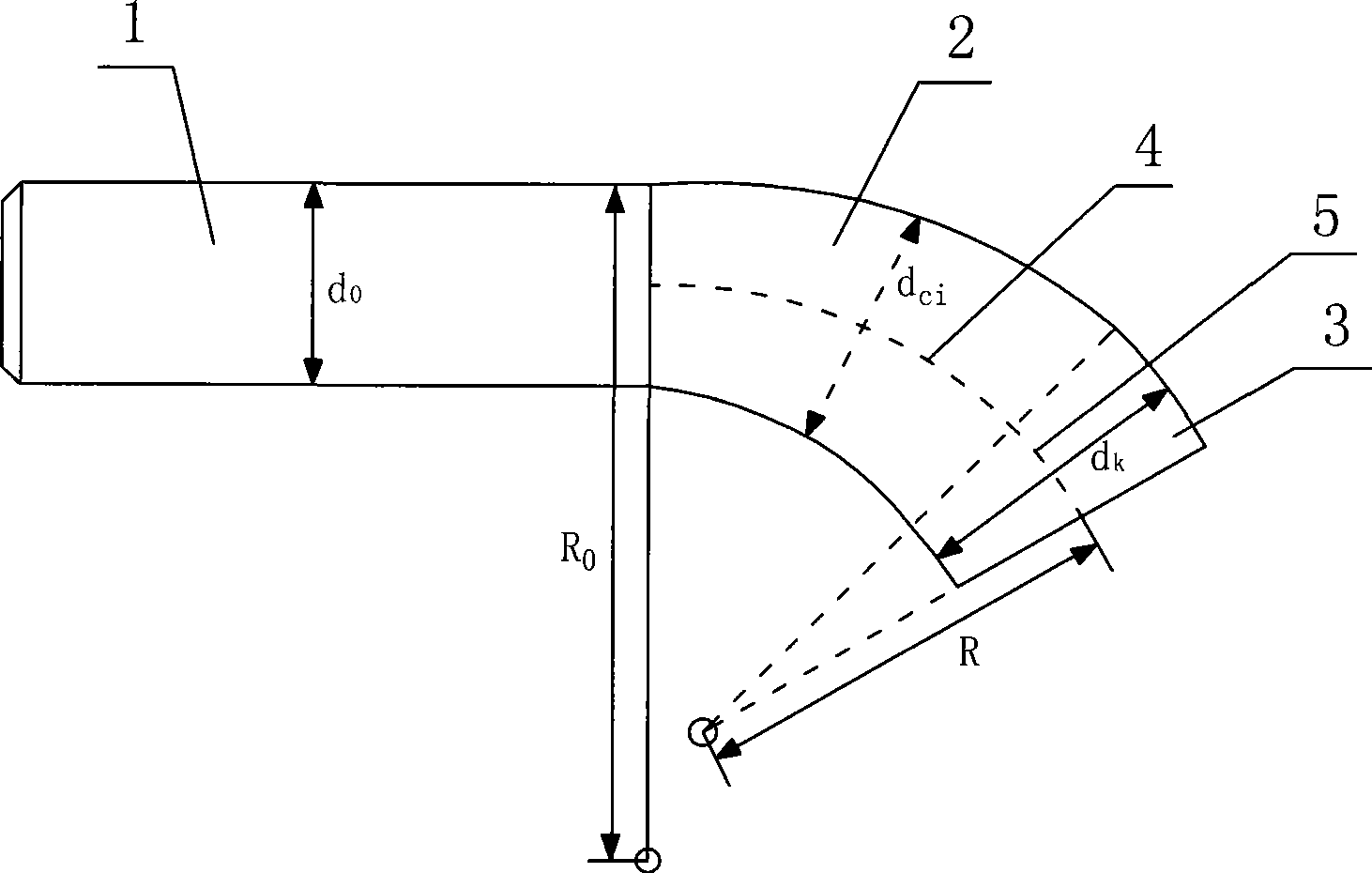

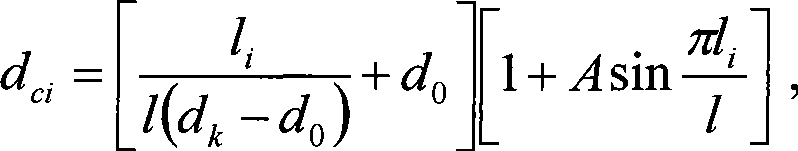

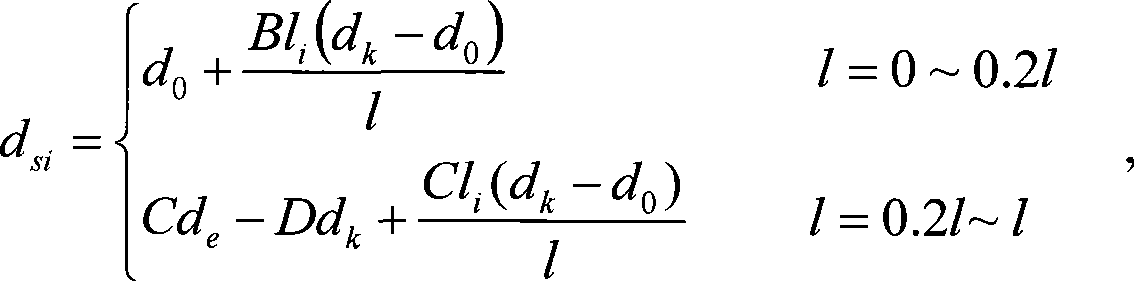

[0030] In this embodiment, the Ti-3Al-2.5V titanium alloy is formed into a short-radius (R=102mm) elbow with a diameter of Φ108×5mm×90°, that is, the size of the short-radius elbow to be produced is Φ108× 5mm×90°, its bending radius R=102mm. Firstly, according to the principle of diameter expansion and push bending method, it is calculated that the tube blank of Φ70×5mm should be selected. The selected tube blank is Ti-3Al-2.5V titanium alloy and its yield strength is 515MPa. The extension section 1 of the croissor mandrel mold that produces the above-mentioned short-radius elbow is a straight section whose diameter is Φ60mm and length is 180mm. The radius of the base circle of the central arc-4 of the deformation section 2 is 73 mm, and the initial bending radius R 0 =214mm, the end bending radius R=102mm, the starting diameter d of the croissant core mold 0 =60mm, the termination diameter d of the croissant core mold k =98mm, the total length l=214mm of the central arc-4,...

Embodiment 3

[0034] In this embodiment, the expanded diameter push-bends TA2 pure titanium into a short-radius (R=508mm) elbow of Φ508mm×15mm×90°, that is, the size of the finished short-radius elbow to be produced is Φ508mm×15mm×90° and other Bending radius R=508mm. Firstly, according to the principle of diameter expansion push bending method, it is calculated that the tube blank of Φ323.9×15mm should be selected. The selected tube blank is TA2 titanium alloy and its yield strength is 320MPa. The extension section 1 of the croissor mandrel mold for producing the above-mentioned short radius elbow is a straight section with a diameter of Φ293mm and a length of 800mm. The radius of the base circle of the central arc-4 of the deformation section 2 is 233 mm, and the initial bending radius R 0 =813mm, ending bending radius R=508mm, starting diameter d of the croissant mandrel mold 0 =293mm, the termination diameter d of the croissant core mold k =478mm, the total length l=864mm of the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com