Double-light-source yarn flaw detection method

A detection method and defect detection technology, which is applied in the direction of optical defect/defect detection, measuring device, and material analysis through optical means, can solve the problems of high cost, complex circuit system, and susceptibility to environmental influence, and achieve environmental impact The effect of small size and long system life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

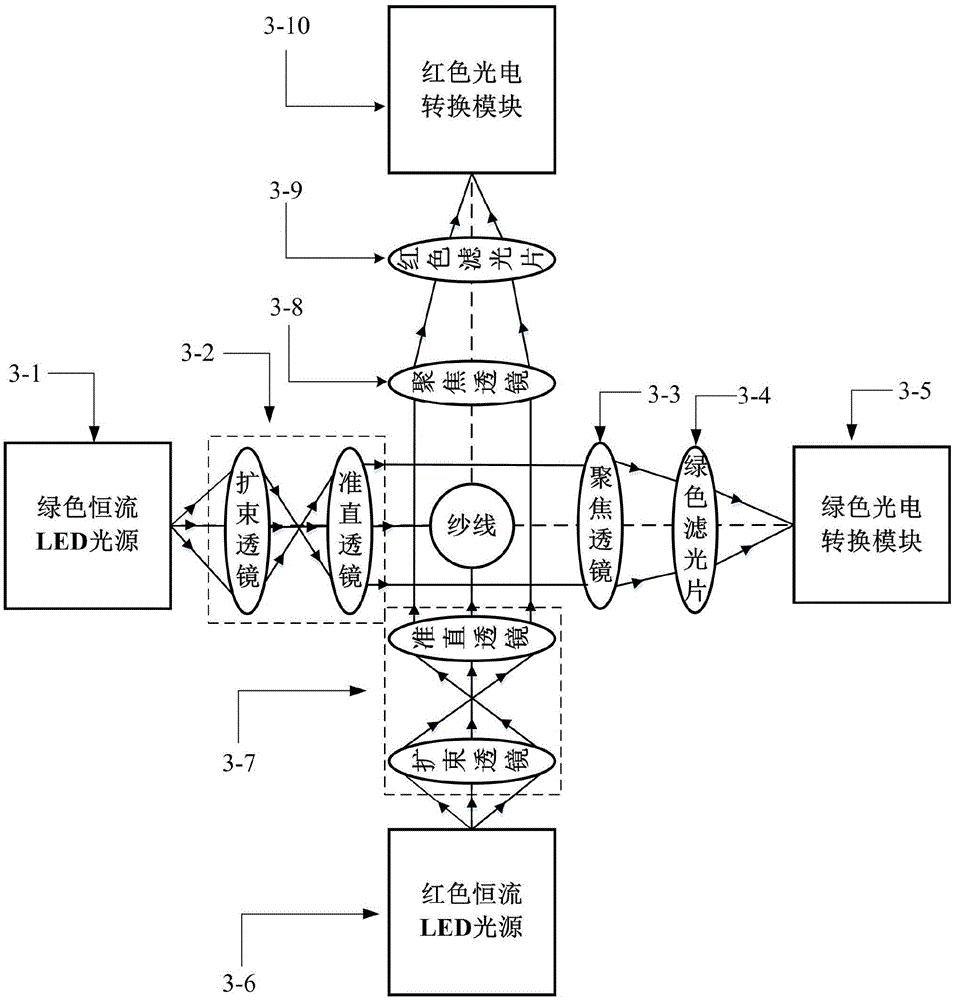

[0050] Example: In the yarn defect photoelectric detection system, the LED light signal passes through the beam expander lens and the collimator lens in turn to irradiate the yarn vertically, and then the light signal passes through the focusing lens and the green light filter once and then focuses on the photoelectric conversion module. The same wavelength of 555nm is used for the light source and the optical filter, and the total amount of light intensity absorbed by the photoelectric conversion part of the red light and the green light is 0.01lx when there is no yarn; the photoelectric conversion coefficient of the system h=2v / lx; The λ shading ratio coefficient is 1; the illumination width y is 2cm; therefore the K=100v / m; the standard diameter d 0 =0.5cm; said yarn horizontal direction diameter d 1 =0.7cm, vertical diameter d 2 =0.3cm; the voltage U obtained by the red photoelectric conversion system R =hE 0 -Kd 1 =0.013V, the voltage U obtained by the green photoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com