Patents

Literature

142 results about "Volume bragg grating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

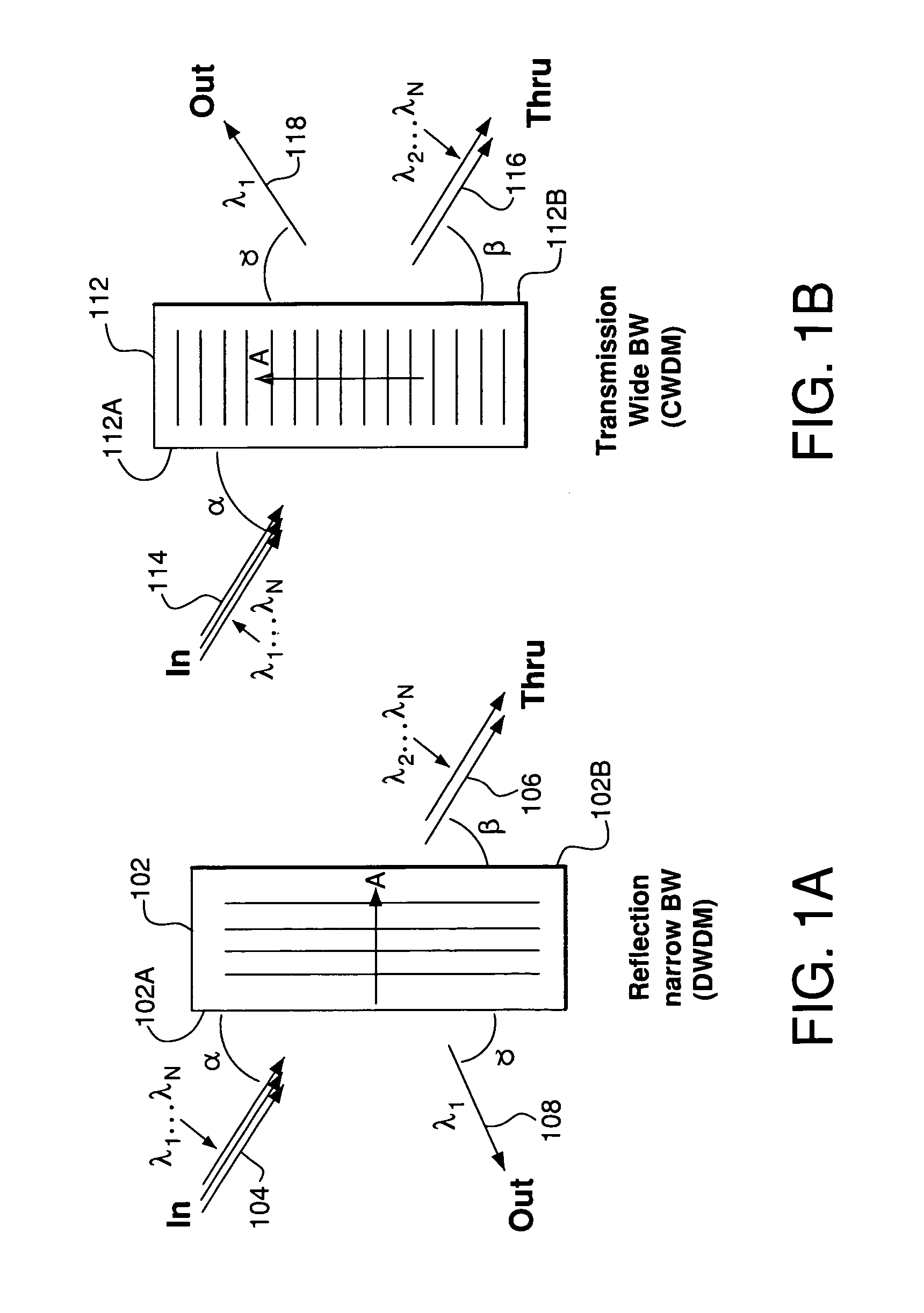

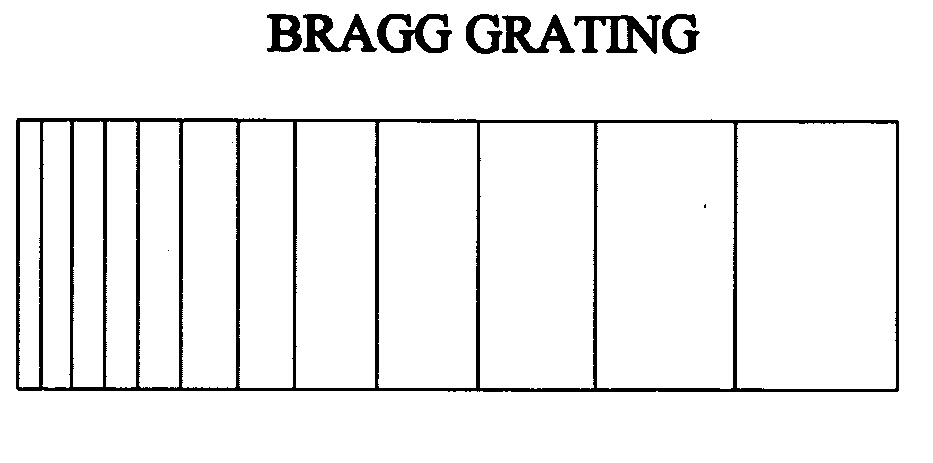

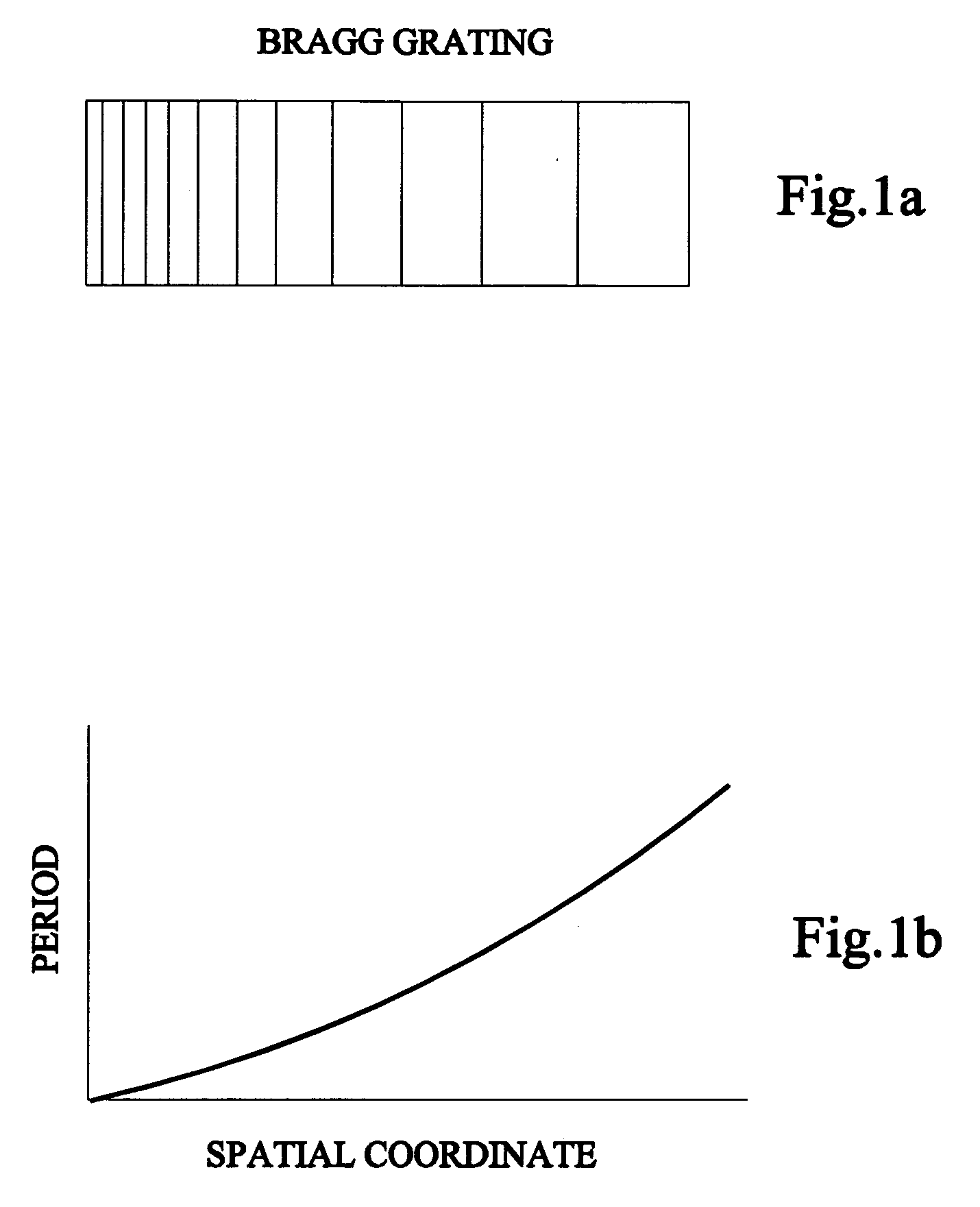

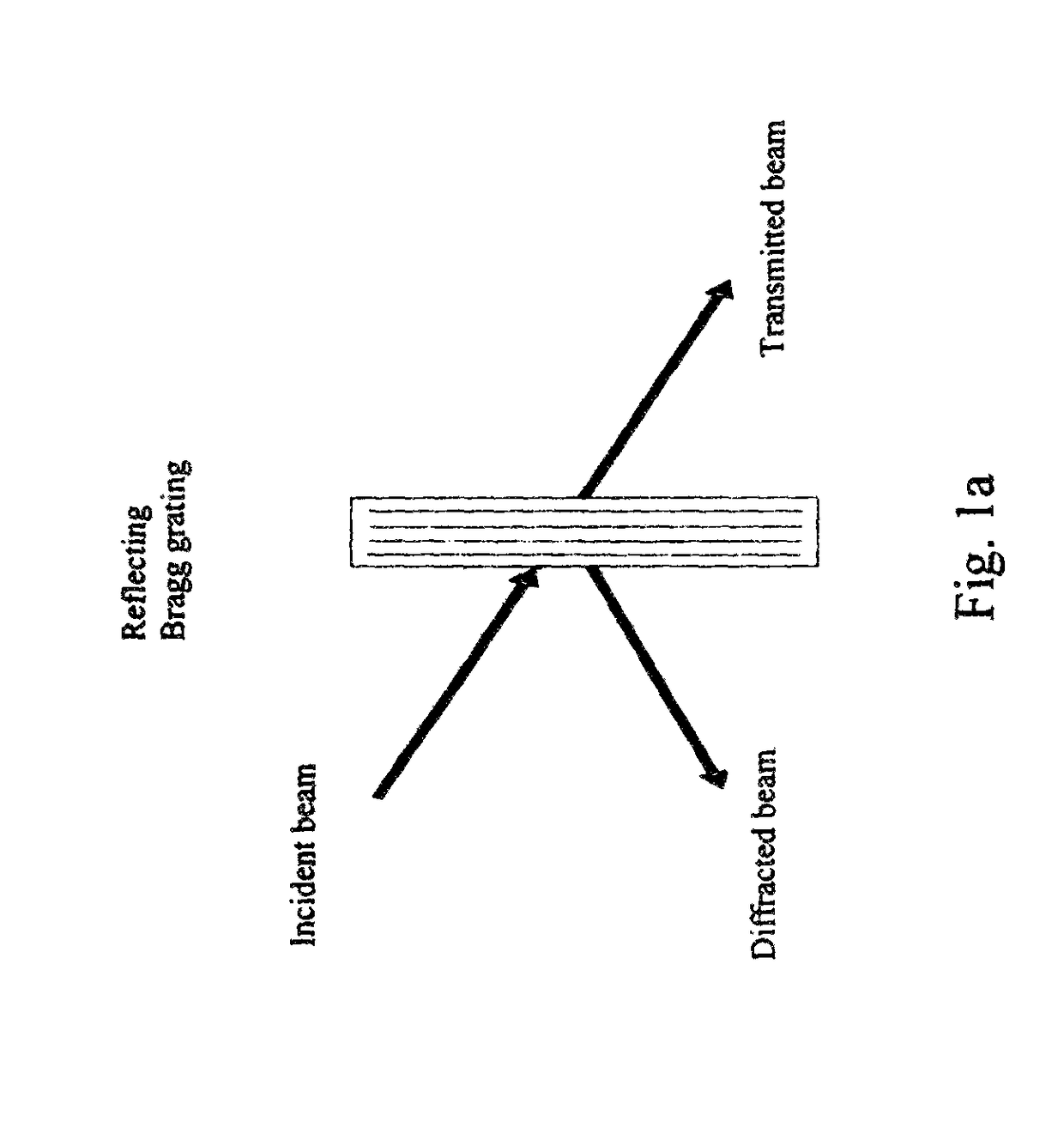

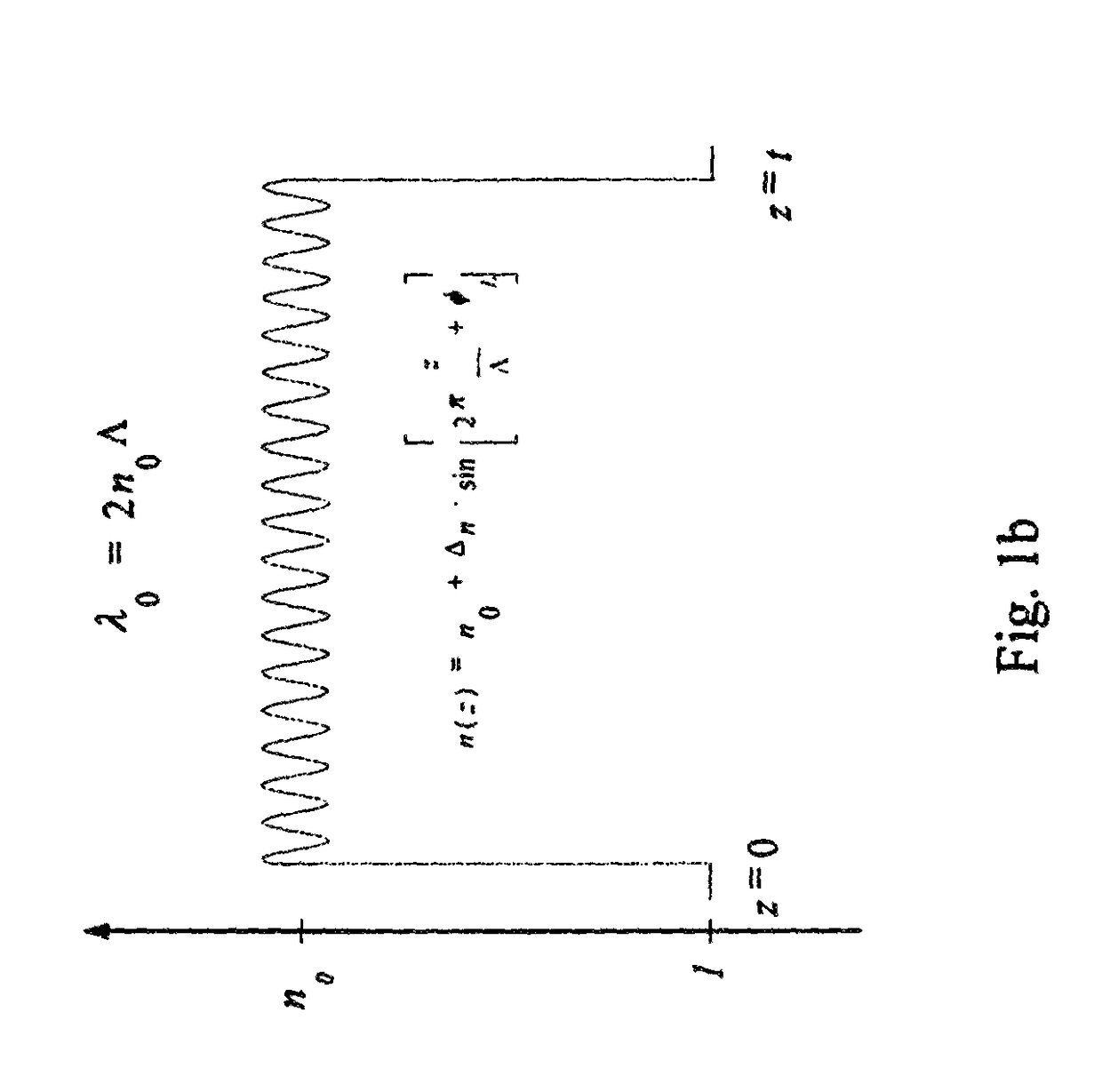

Volume Bragg gratings (also called volume holographic gratings) are Bragg gratings which are written inside some transparent material, e.g. in the form of a cube or a parallelepiped – in contrast to diffraction gratings made on the surface of an optical element or fiber Bragg gratings, where the grating is written into the core of an optical fiber.

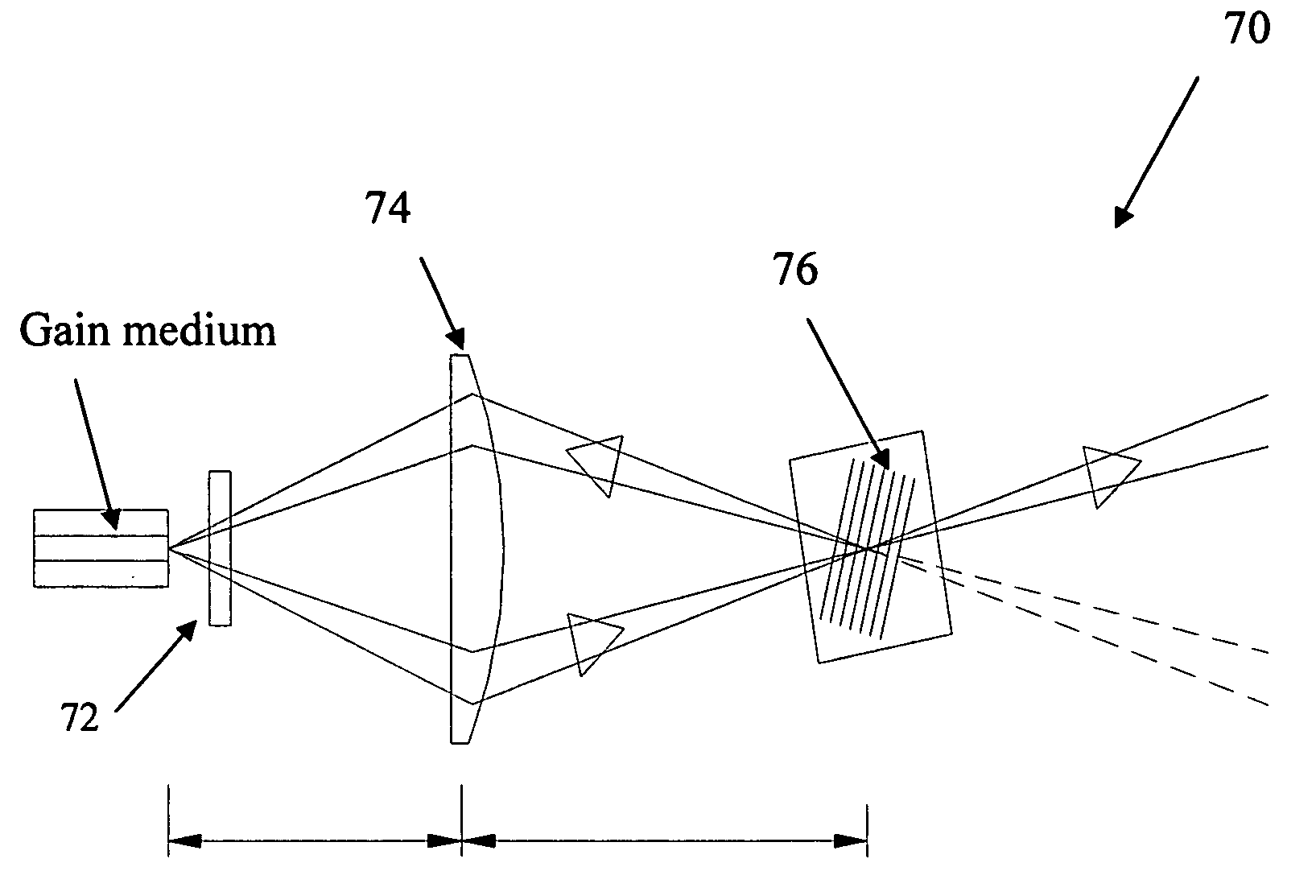

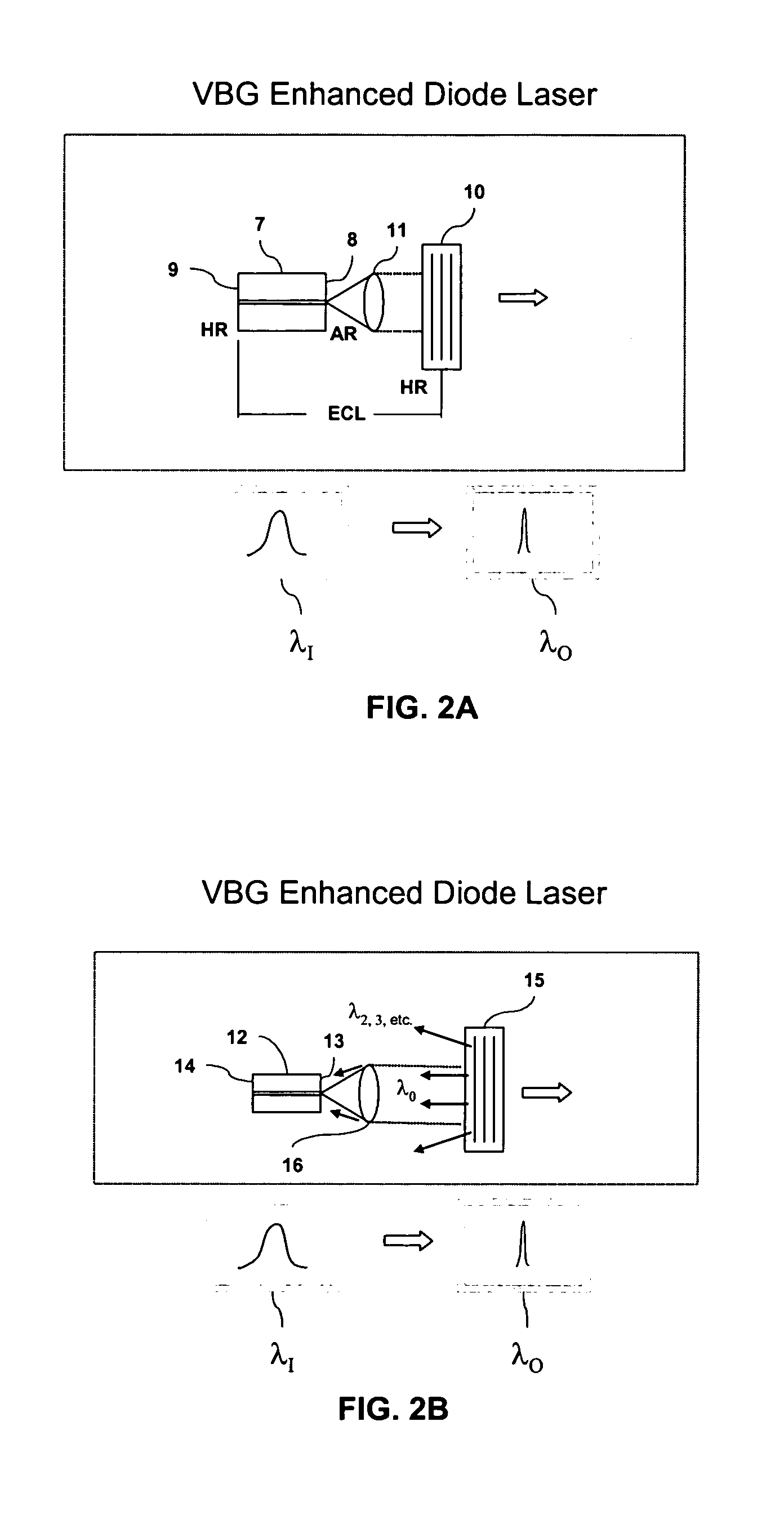

Use of volume Bragg gratings for the conditioning of laser emission characteristics

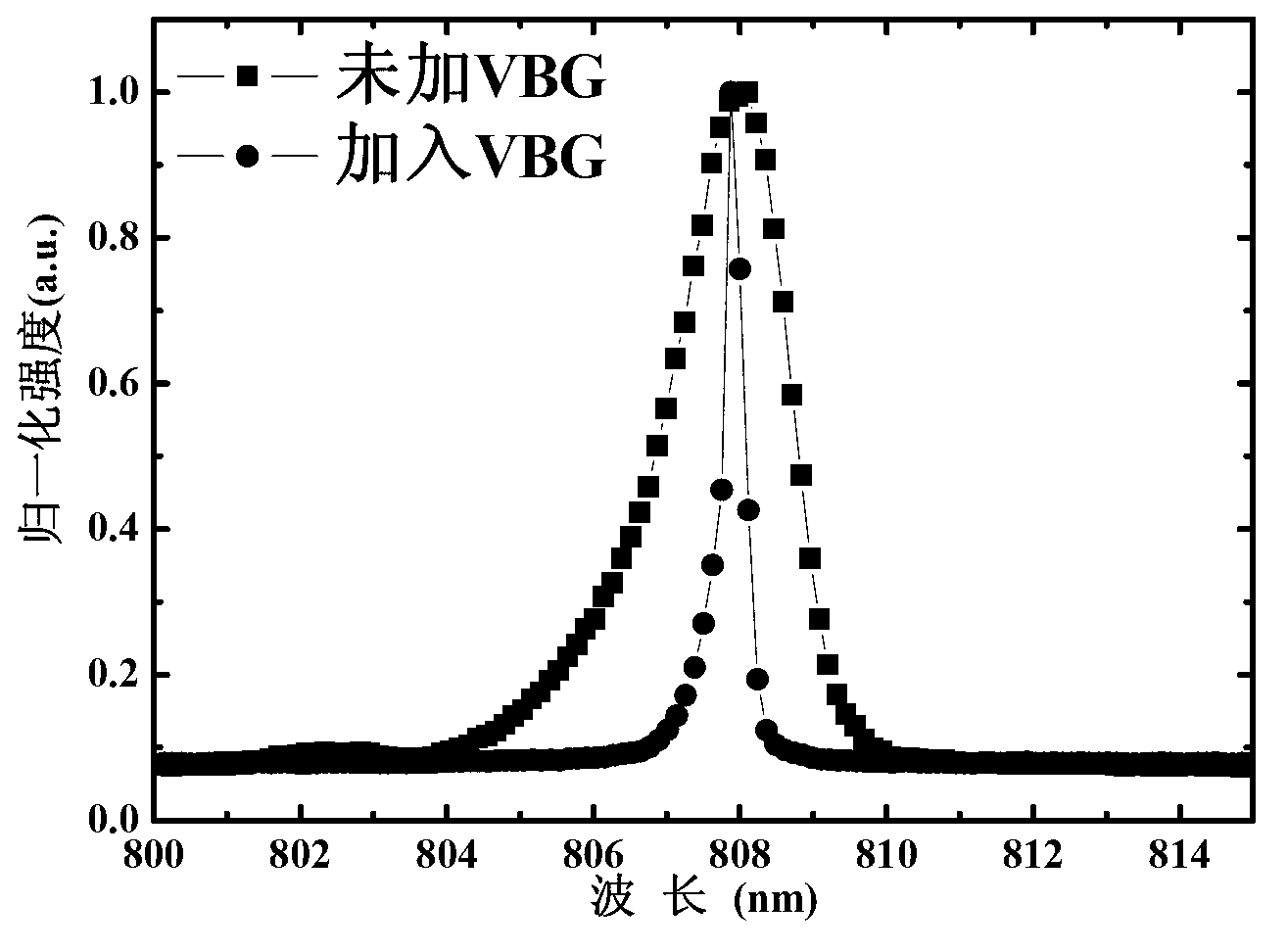

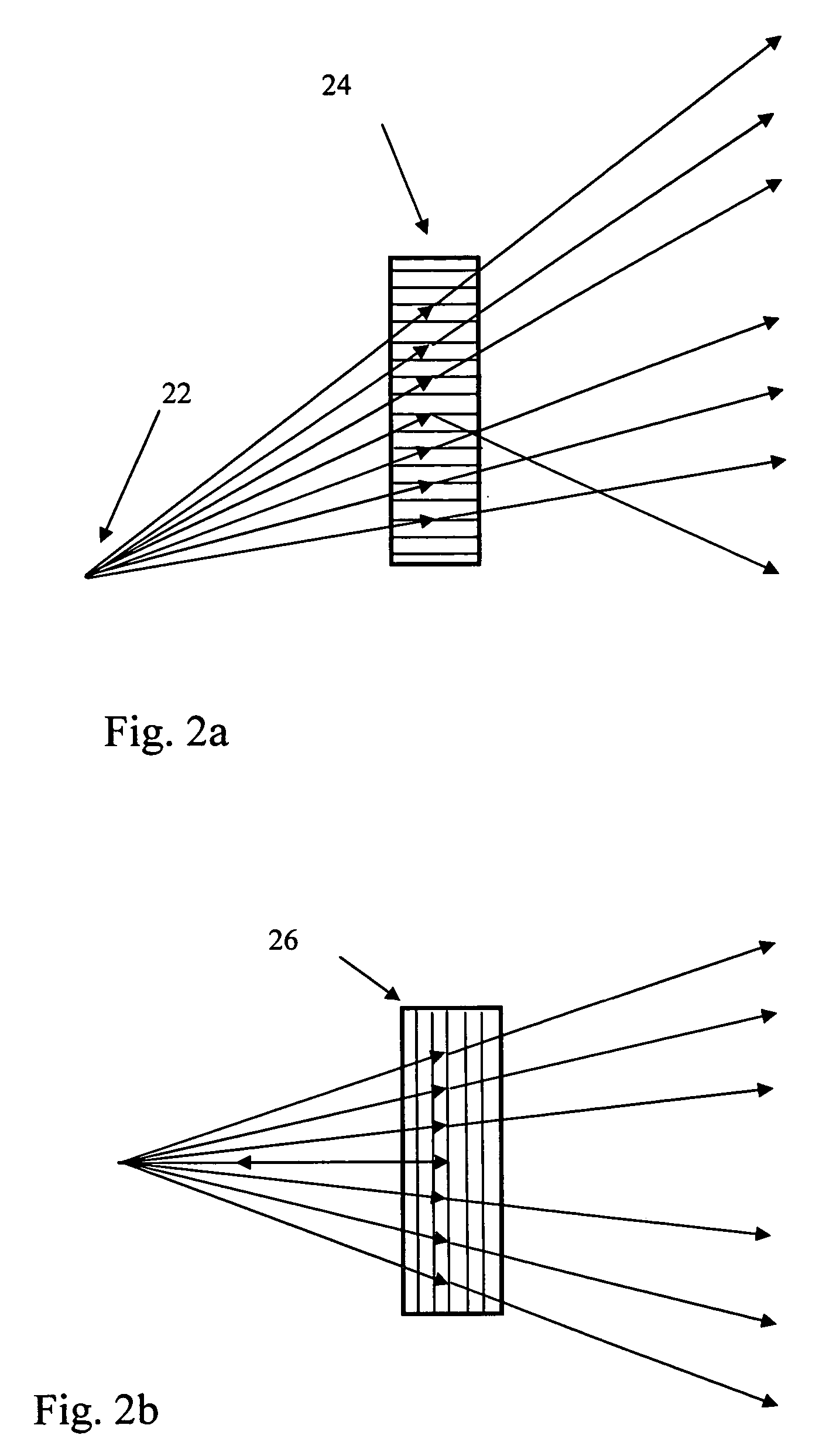

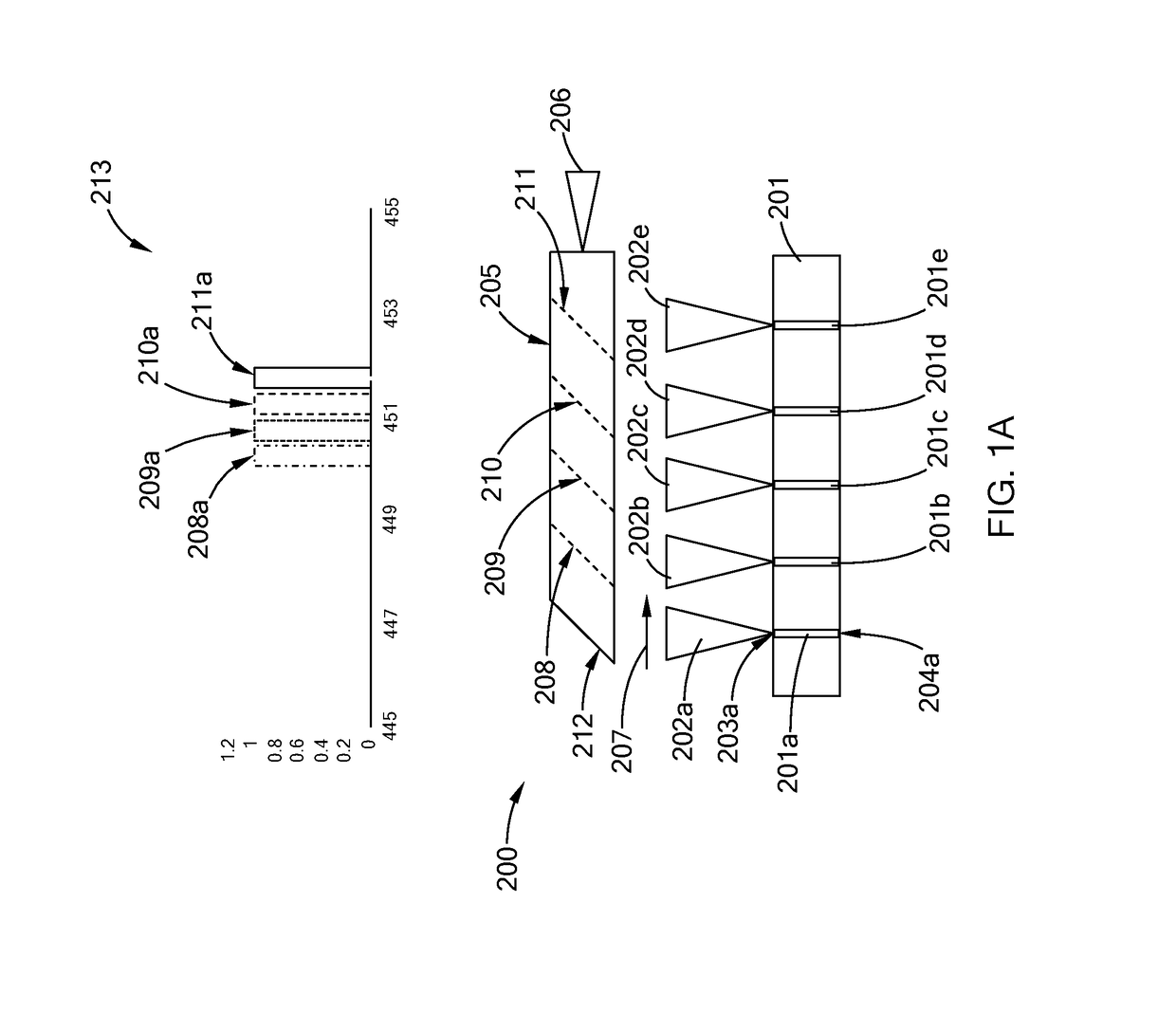

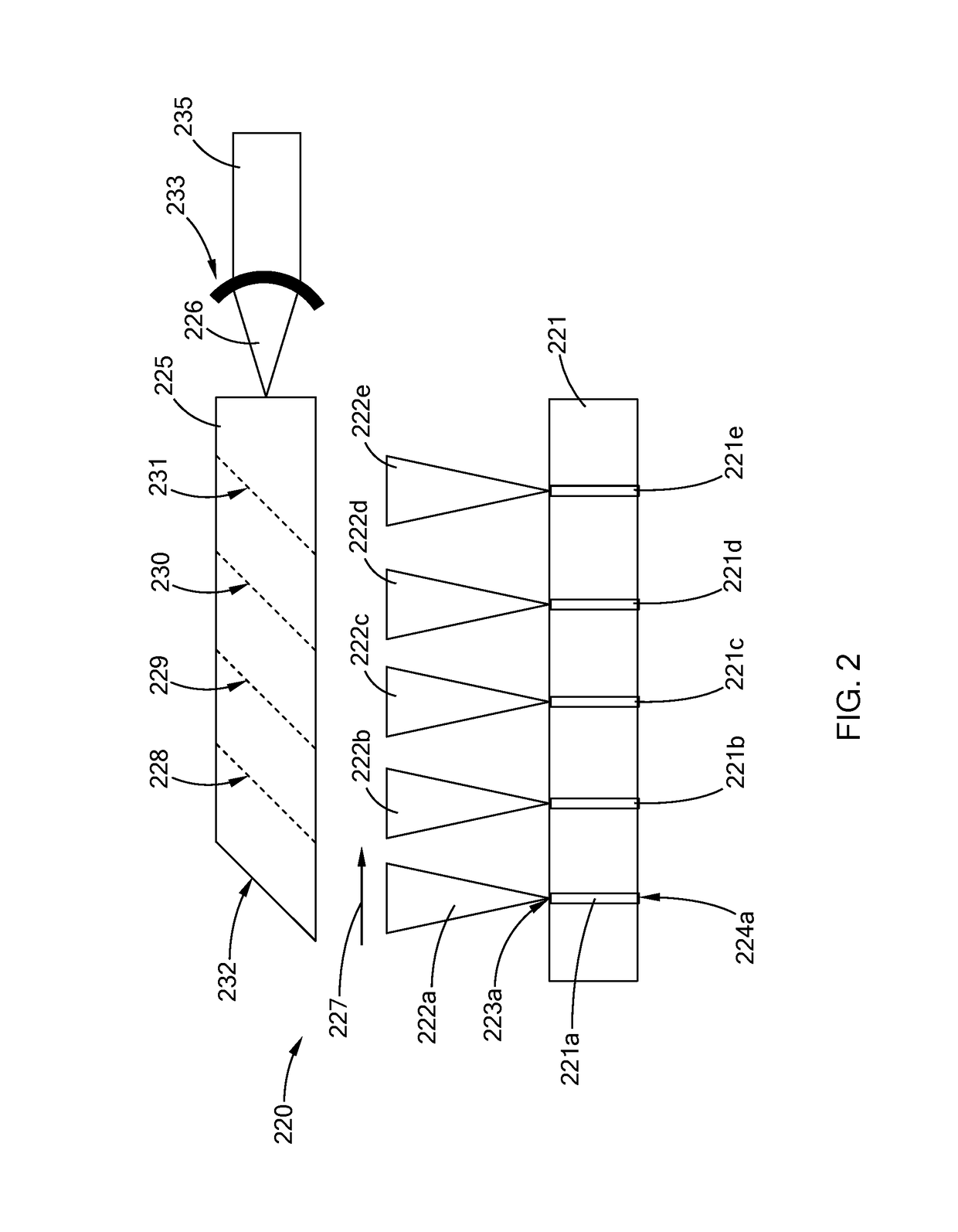

ActiveUS20050018743A1High damage thresholdLarge clear apertureLaser optical resonator constructionSemiconductor laser arrangementsGratingLight emitting device

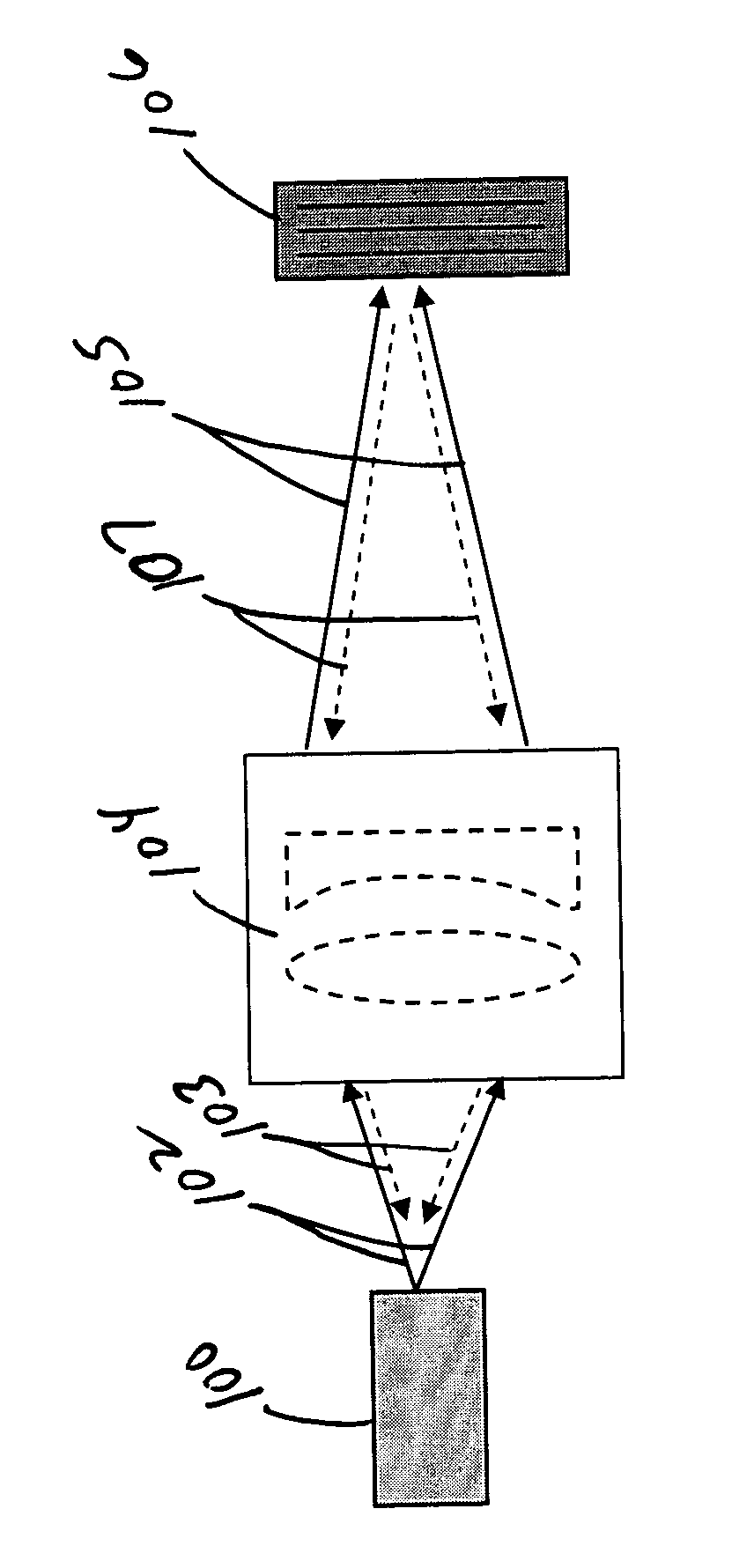

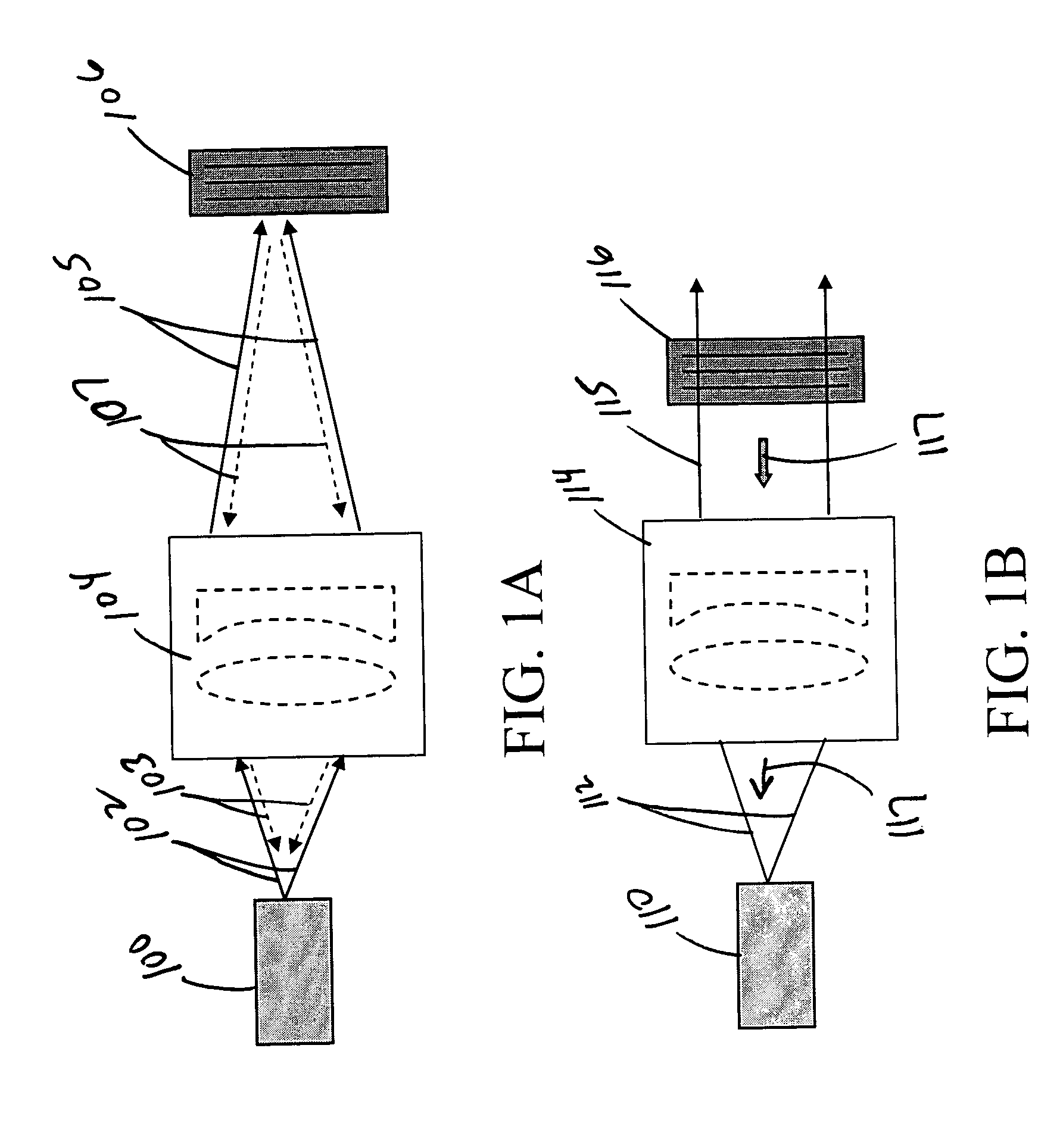

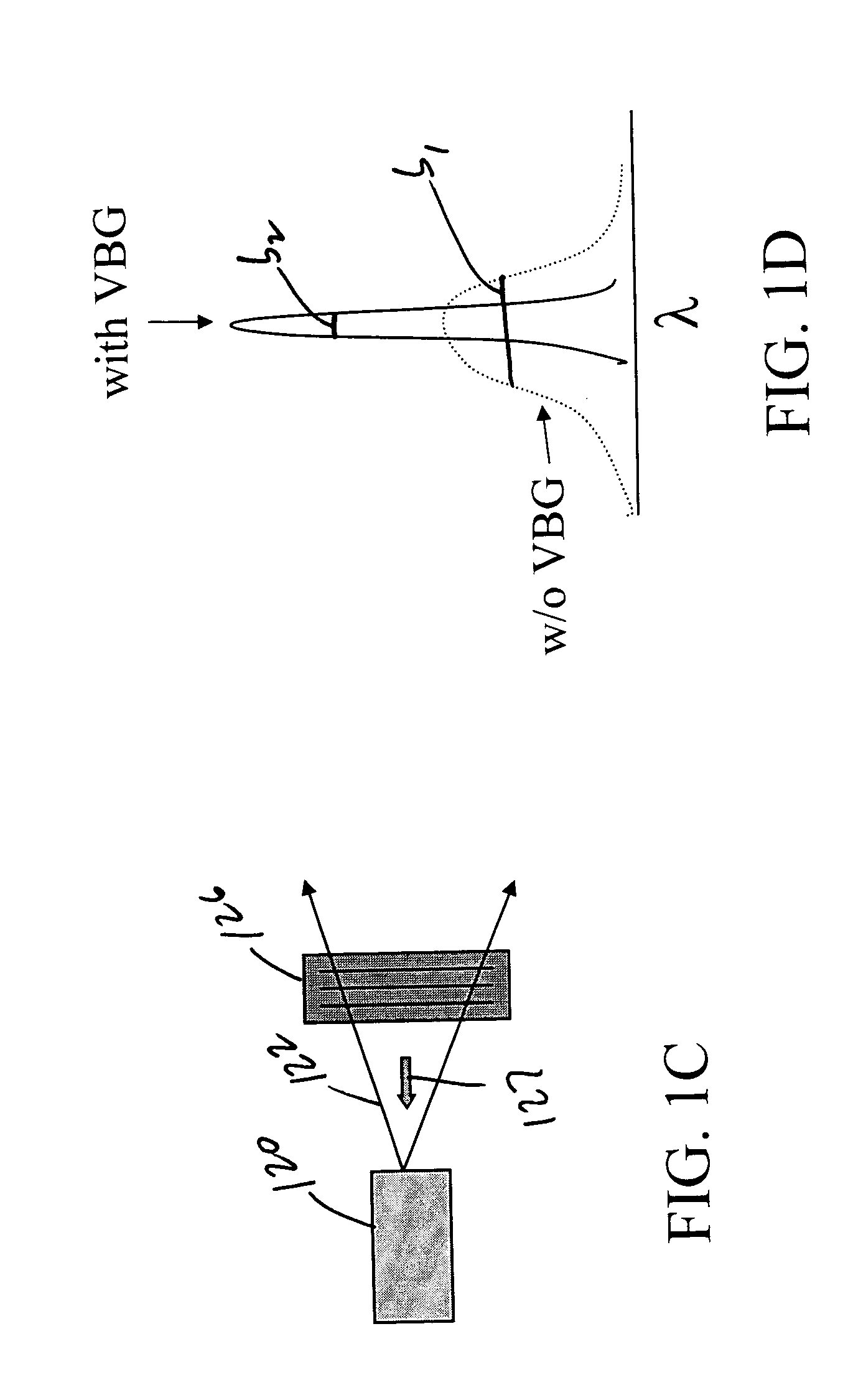

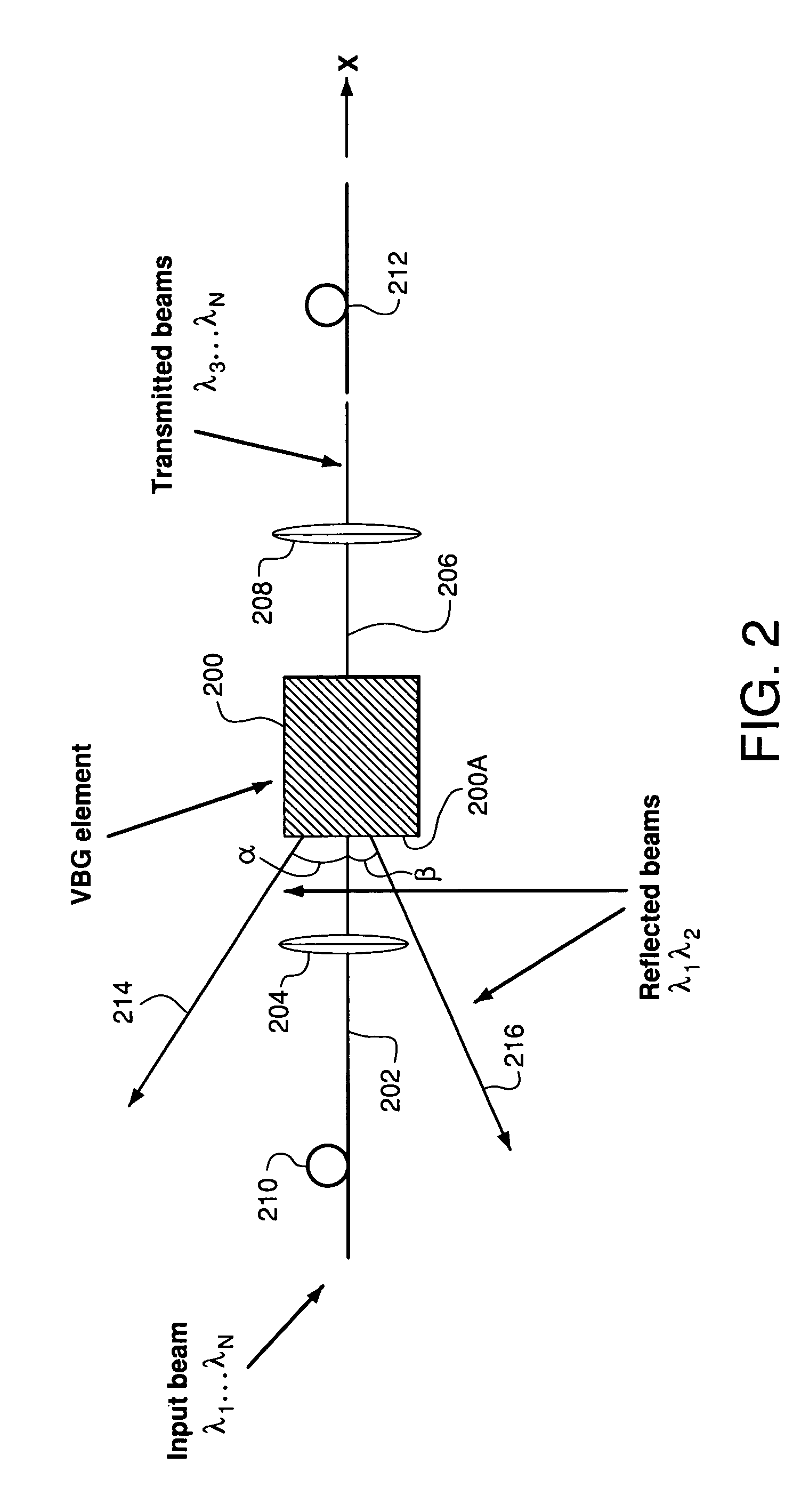

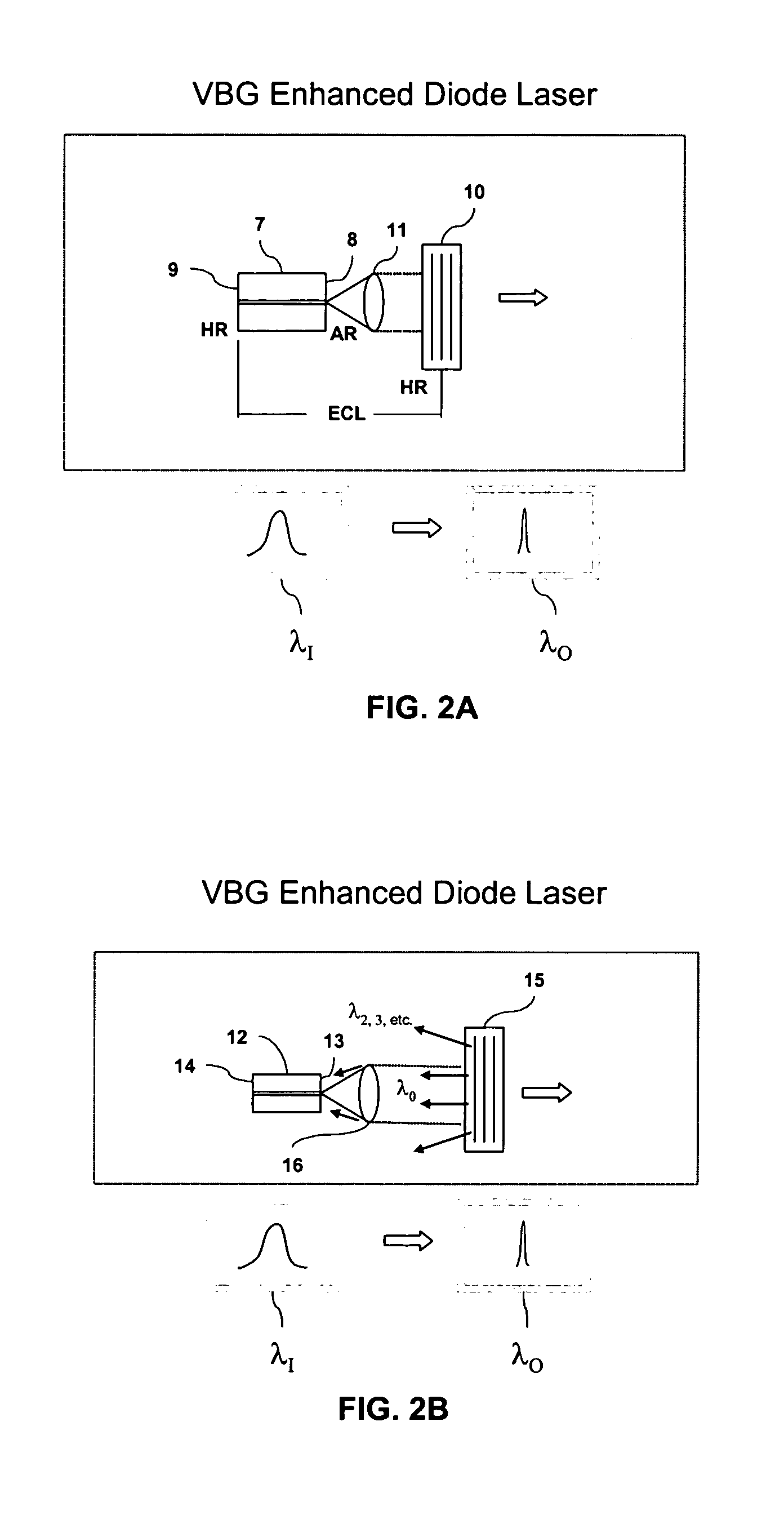

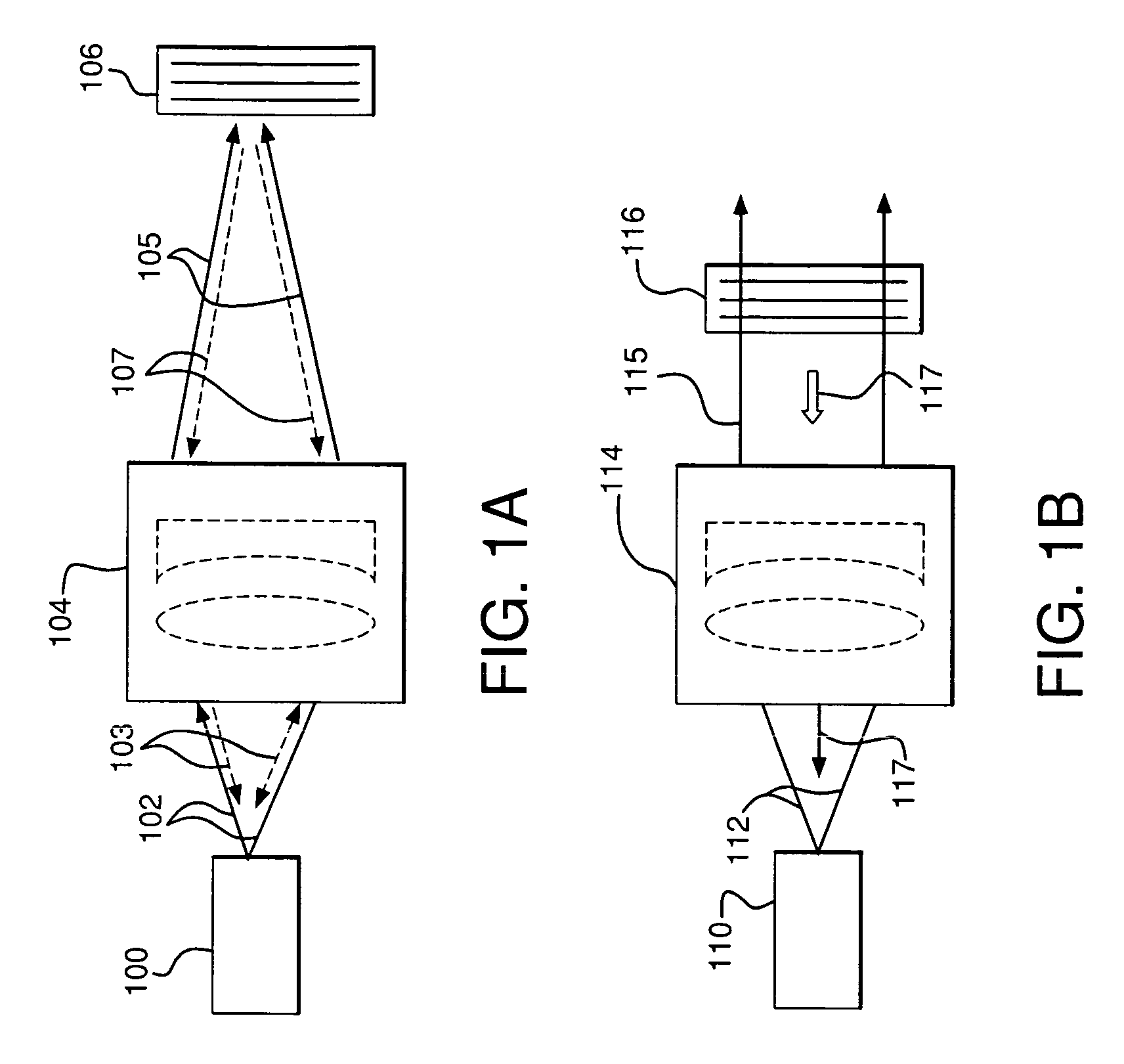

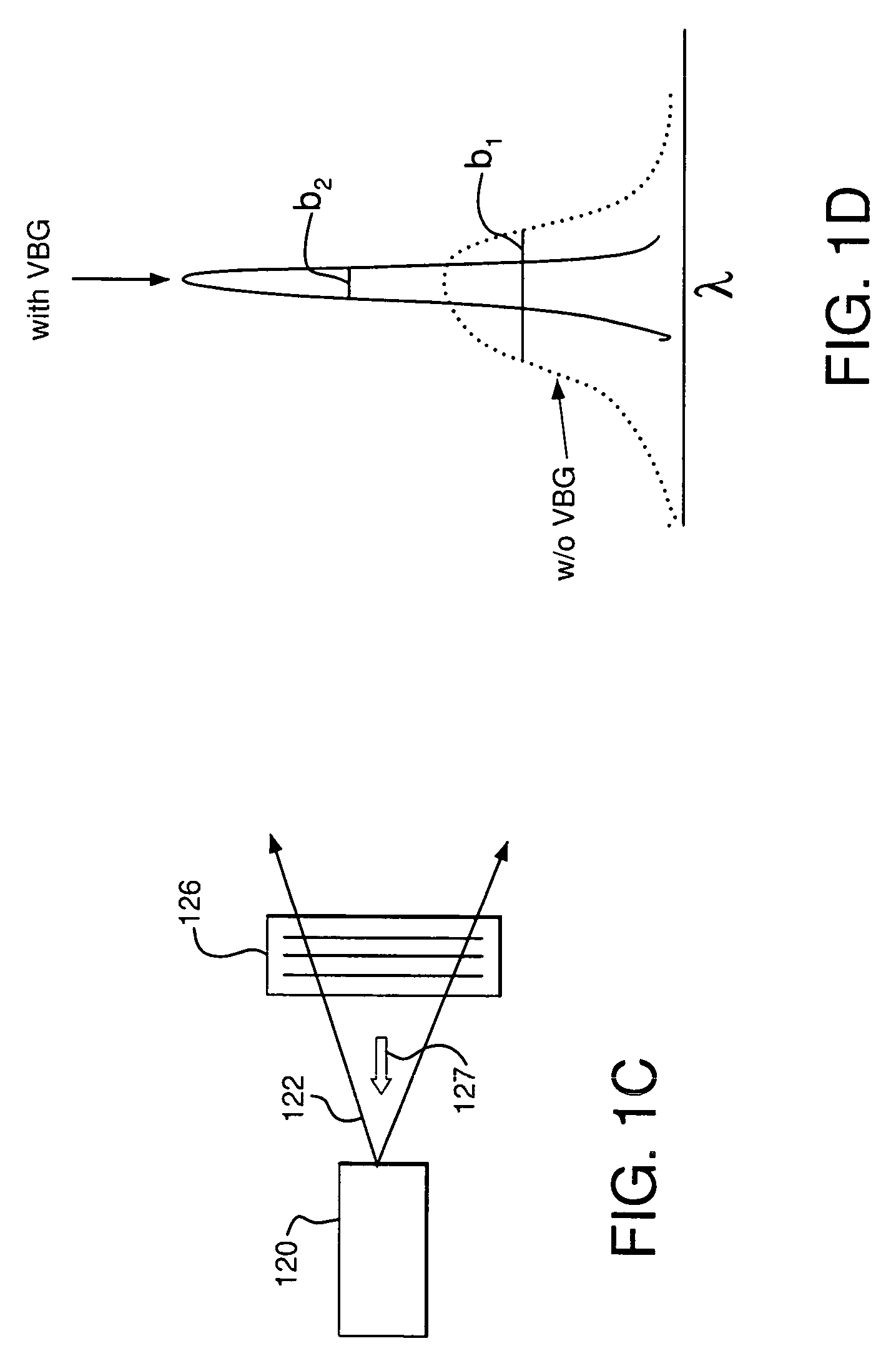

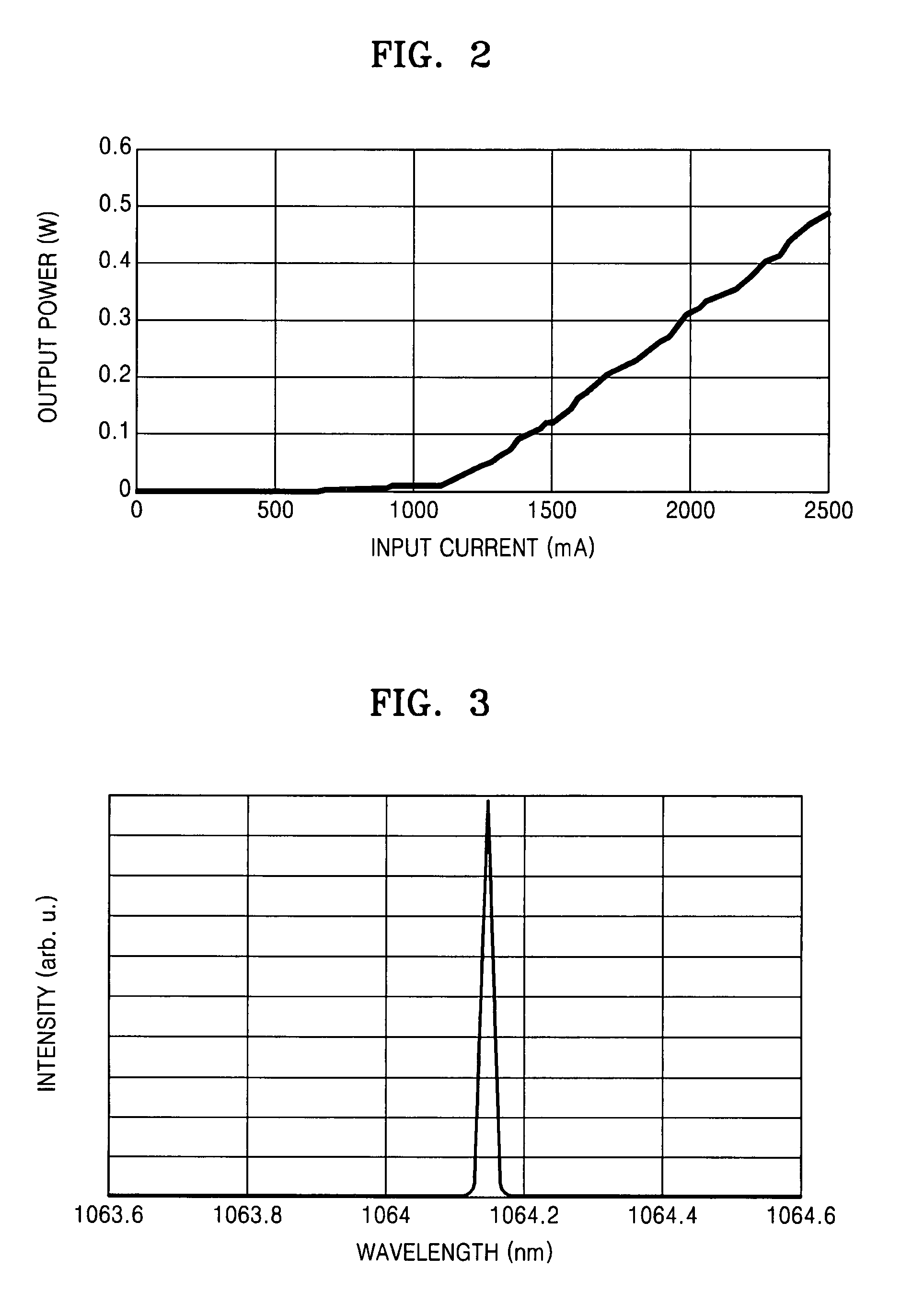

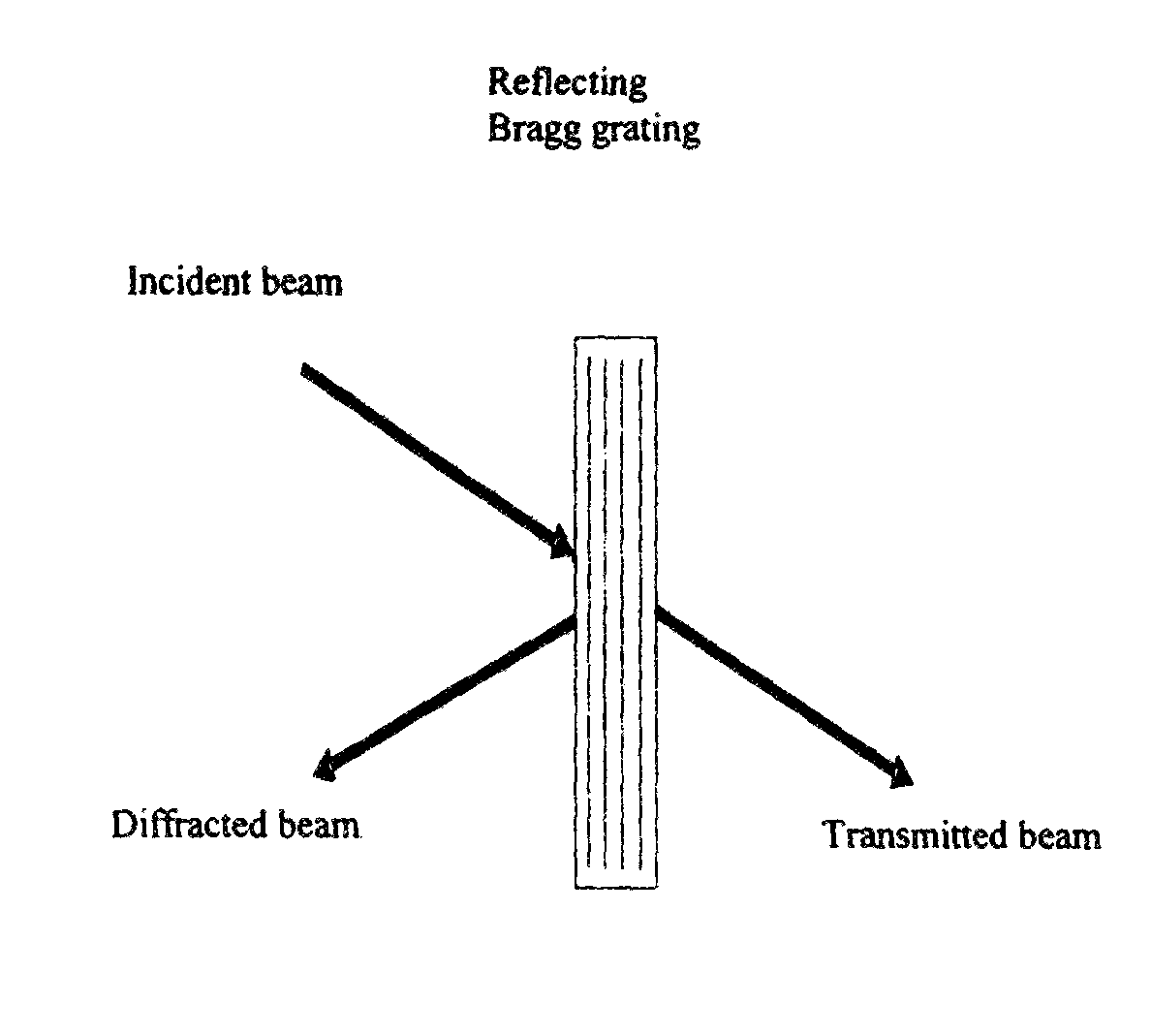

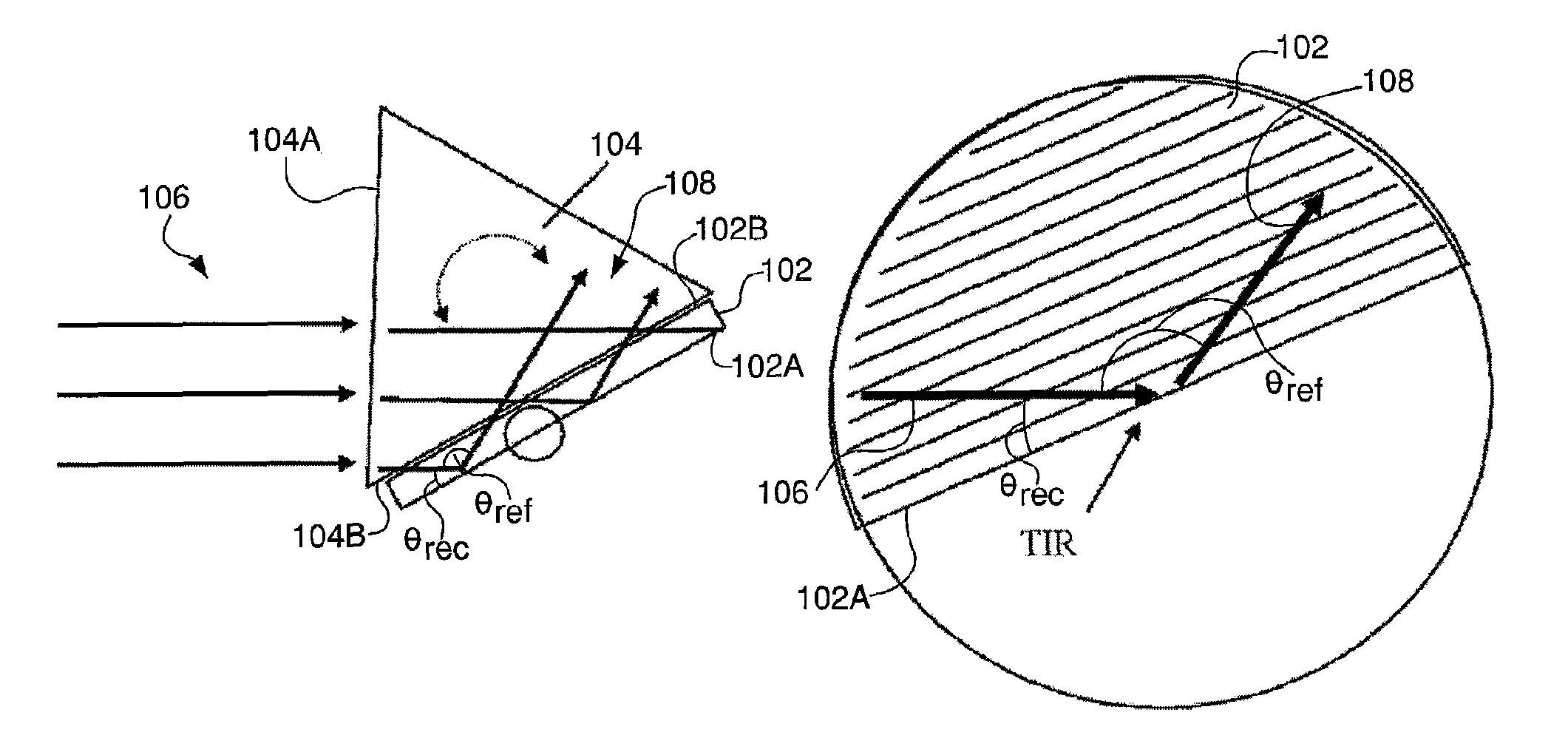

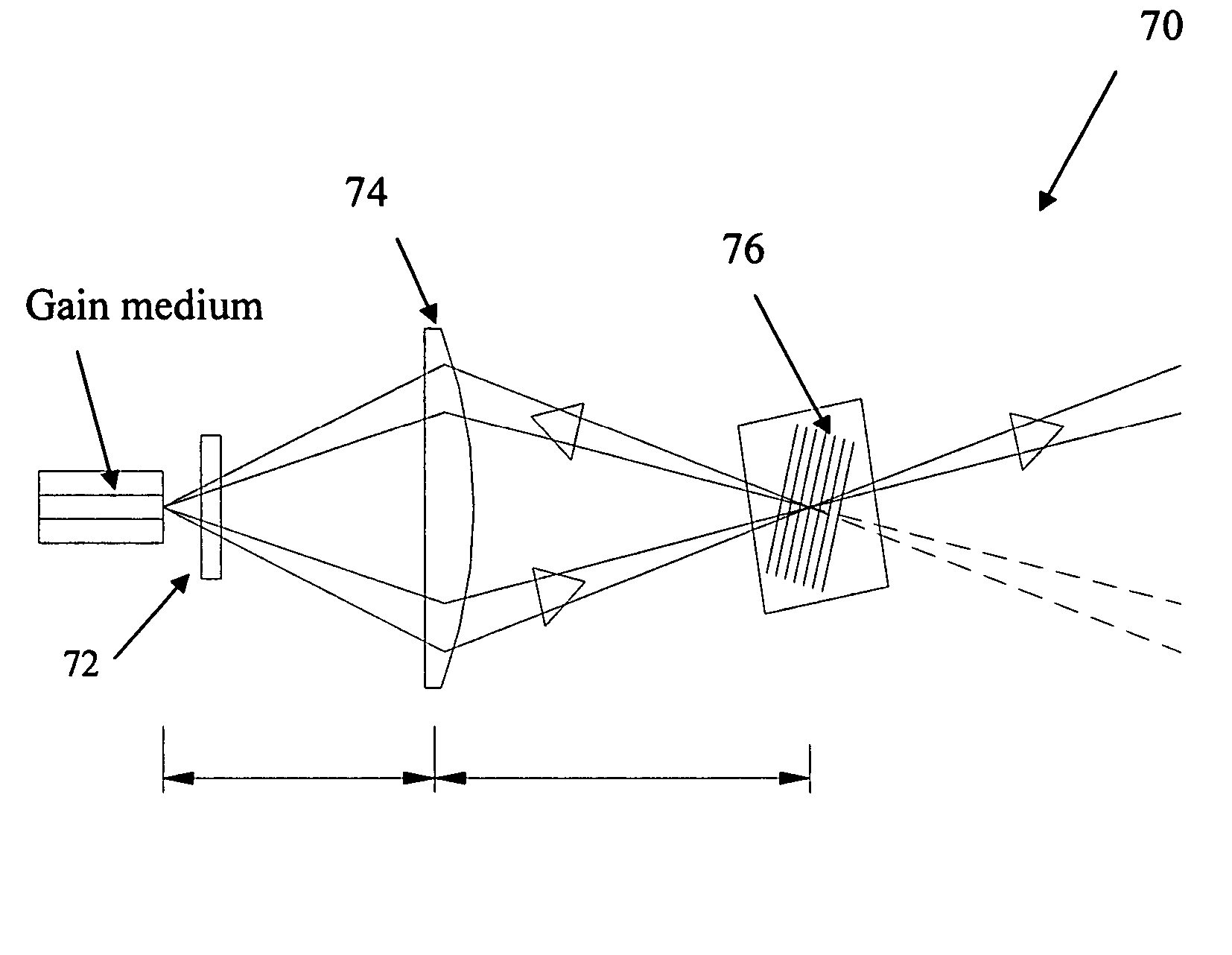

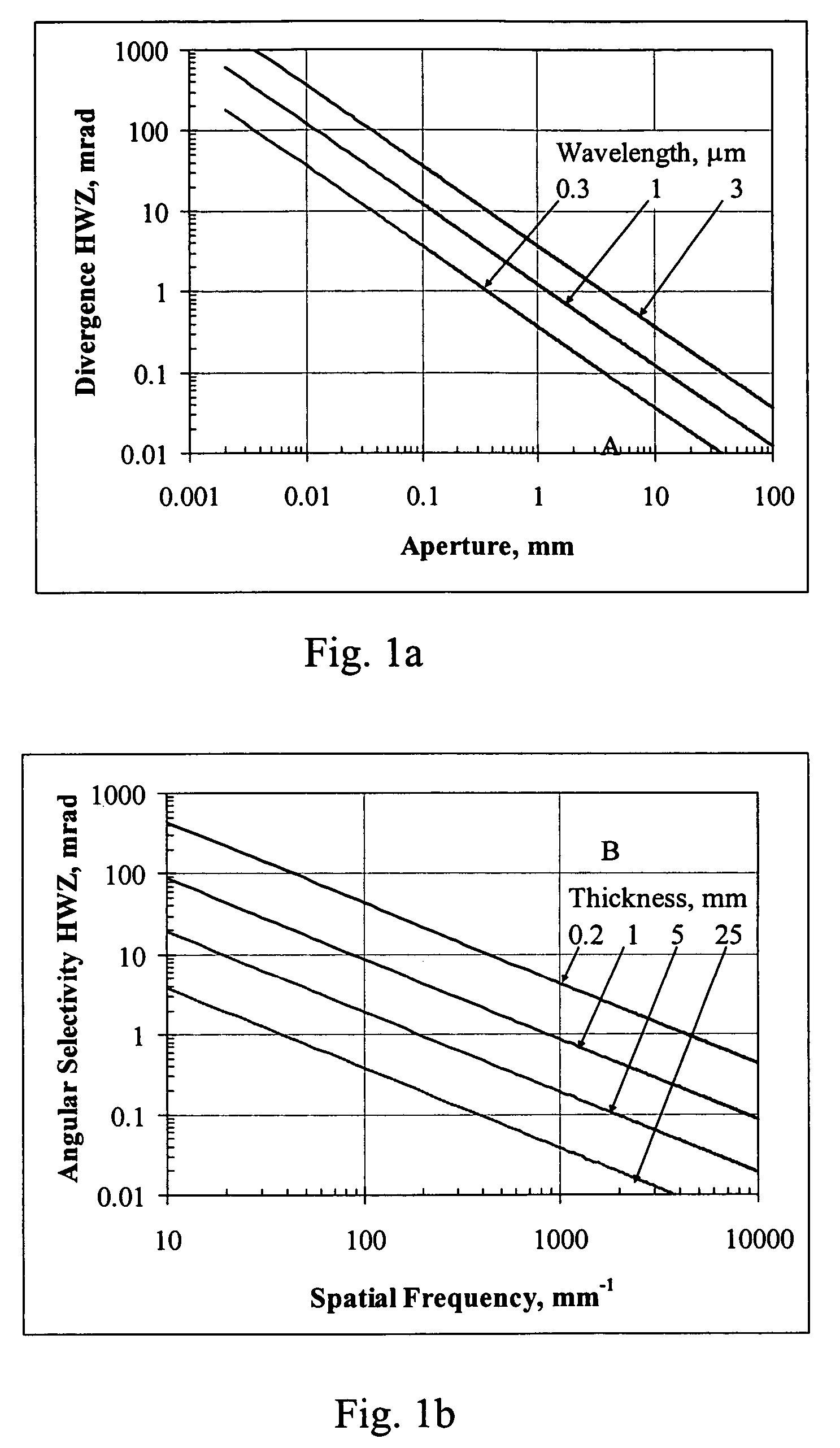

Apparatus and methods for altering one or more spectral, spatial, or temporal characteristics of a light-emitting device are disclosed. Generally, such apparatus may include a volume Bragg grating (VBG) element that receives input light generated by a light-emitting device, conditions one or more characteristics of the input light, and causes the light-emitting device to generate light having the one or more characteristics of the conditioned light.

Owner:NECSEL INTPROP

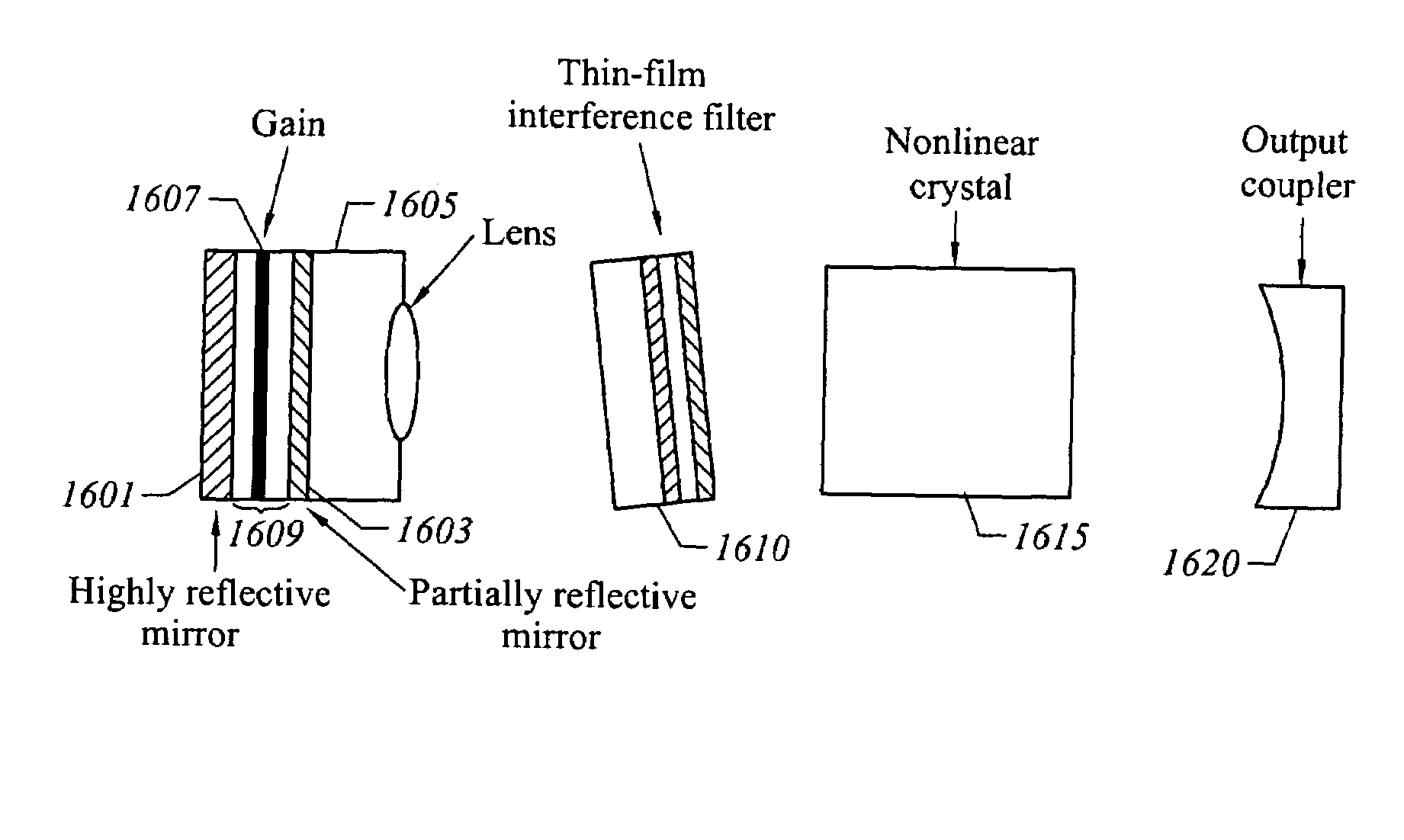

Frequency stabilized vertical extended cavity surface emitting lasers

ActiveUS20060280219A1ProjectorsOptical resonator shape and constructionFrequency stabilizationGrating

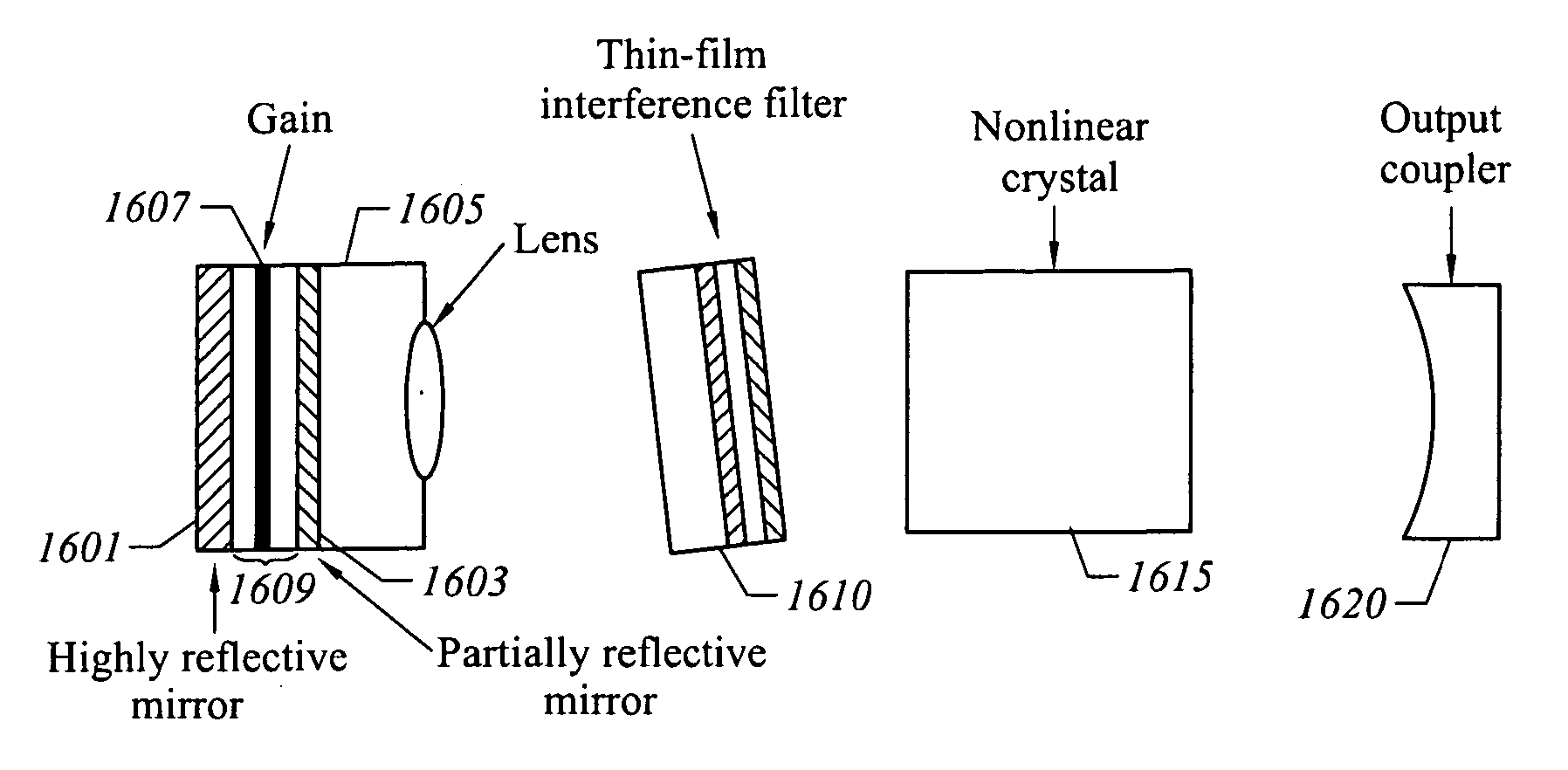

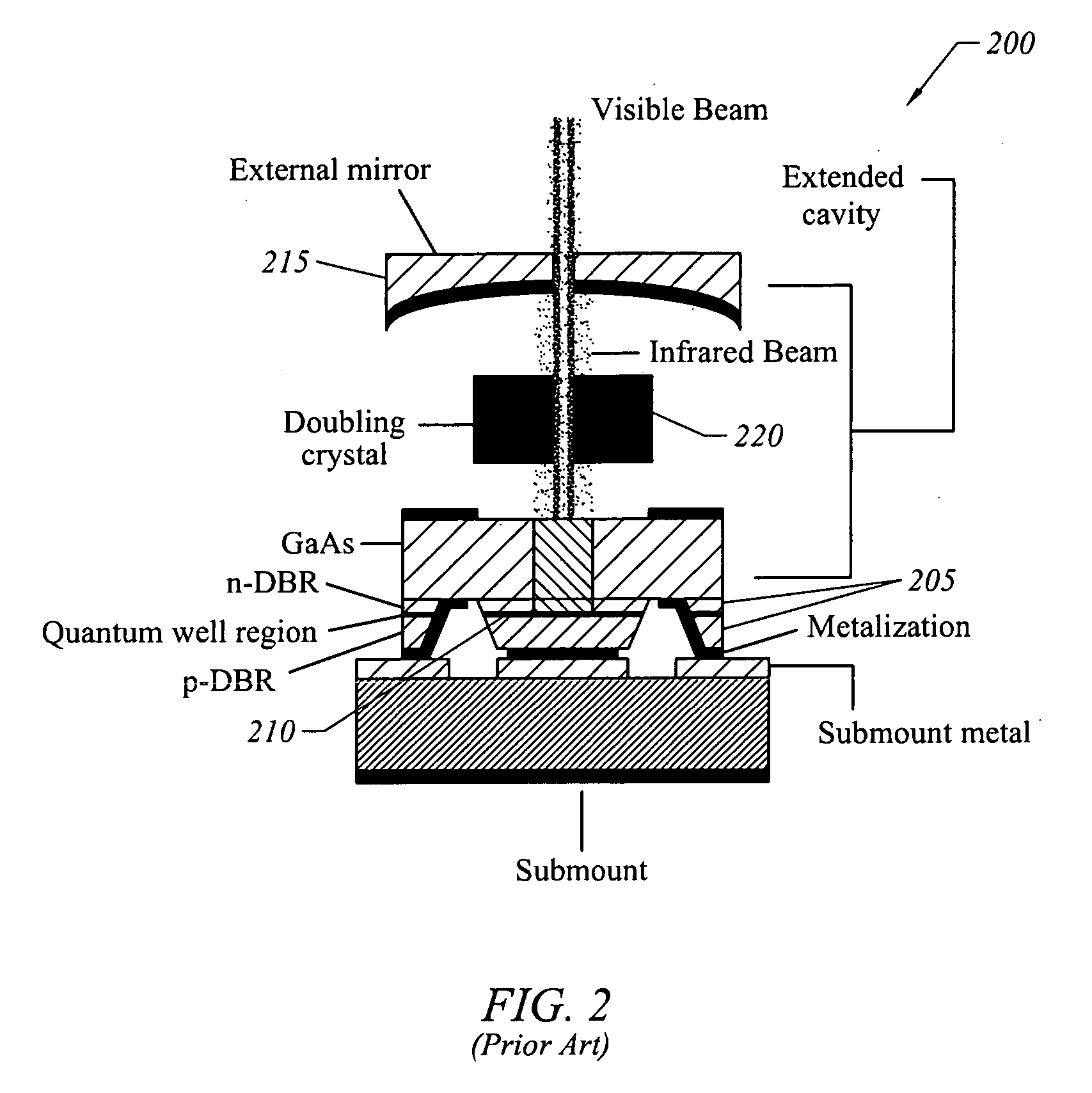

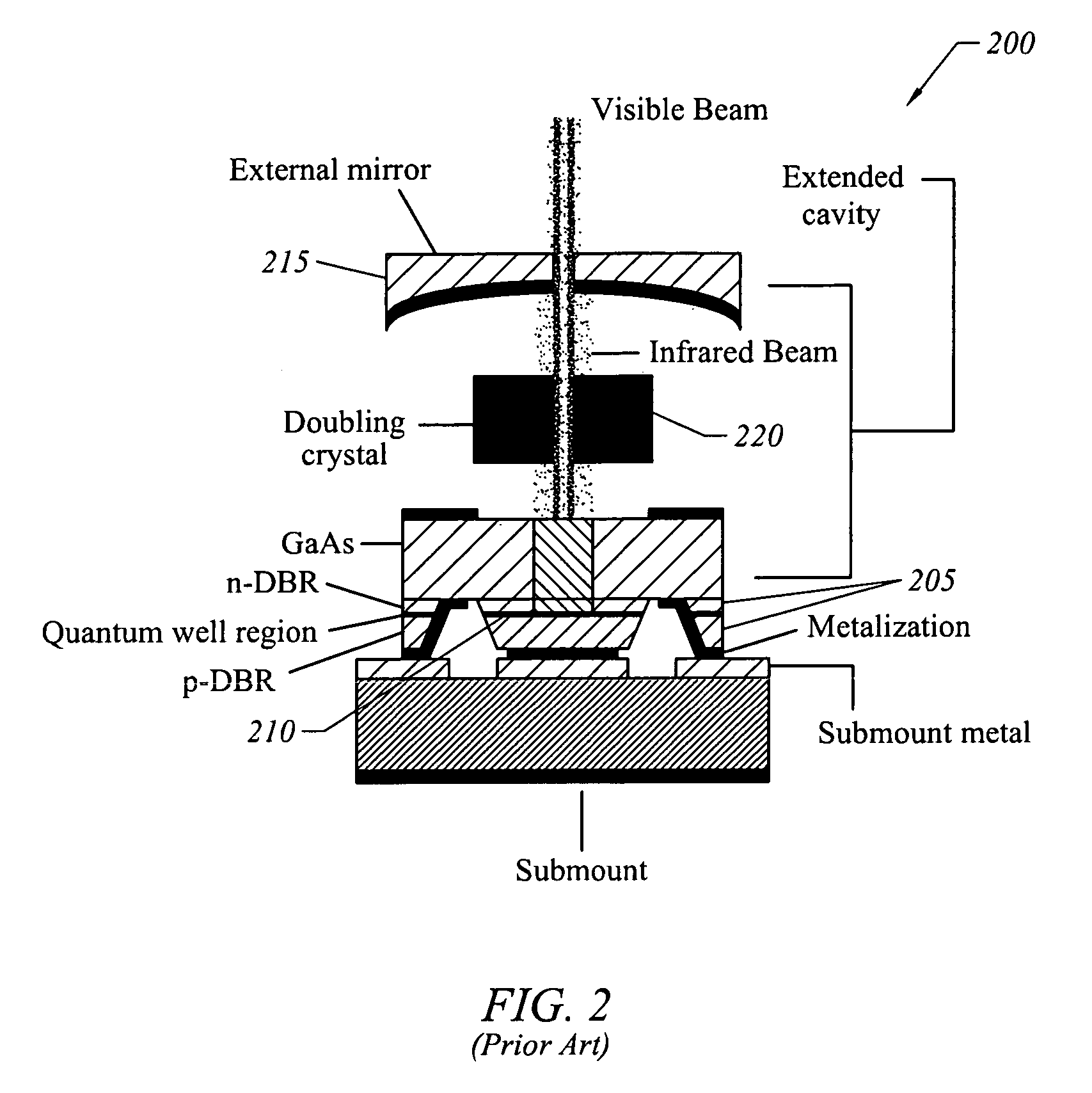

A vertical extended cavity surface emitting laser (VECSEL) includes intra-cavity frequency doubling. Conventional frequency control elements, such as etalons, are replaced with thin film interference filters or volume Bragg gratings.

Owner:NECSEL INTPROP +1

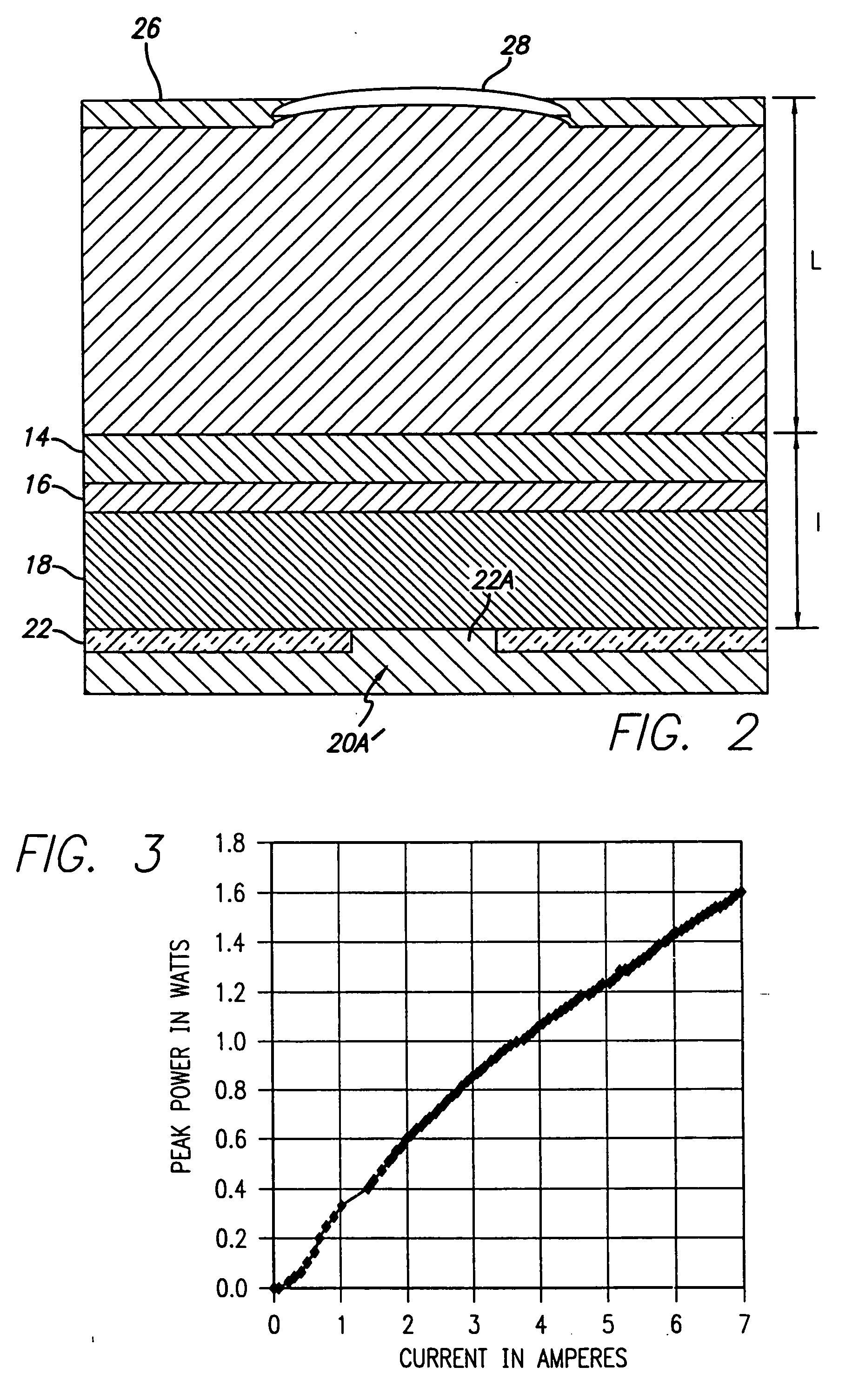

Coupled cavity high power semiconductor laser

InactiveUS20060029120A1Maximize circulating fundamental laser powerConvenient registrationOptical resonator shape and constructionSemiconductor lasersFundamental frequencyPartial reflection

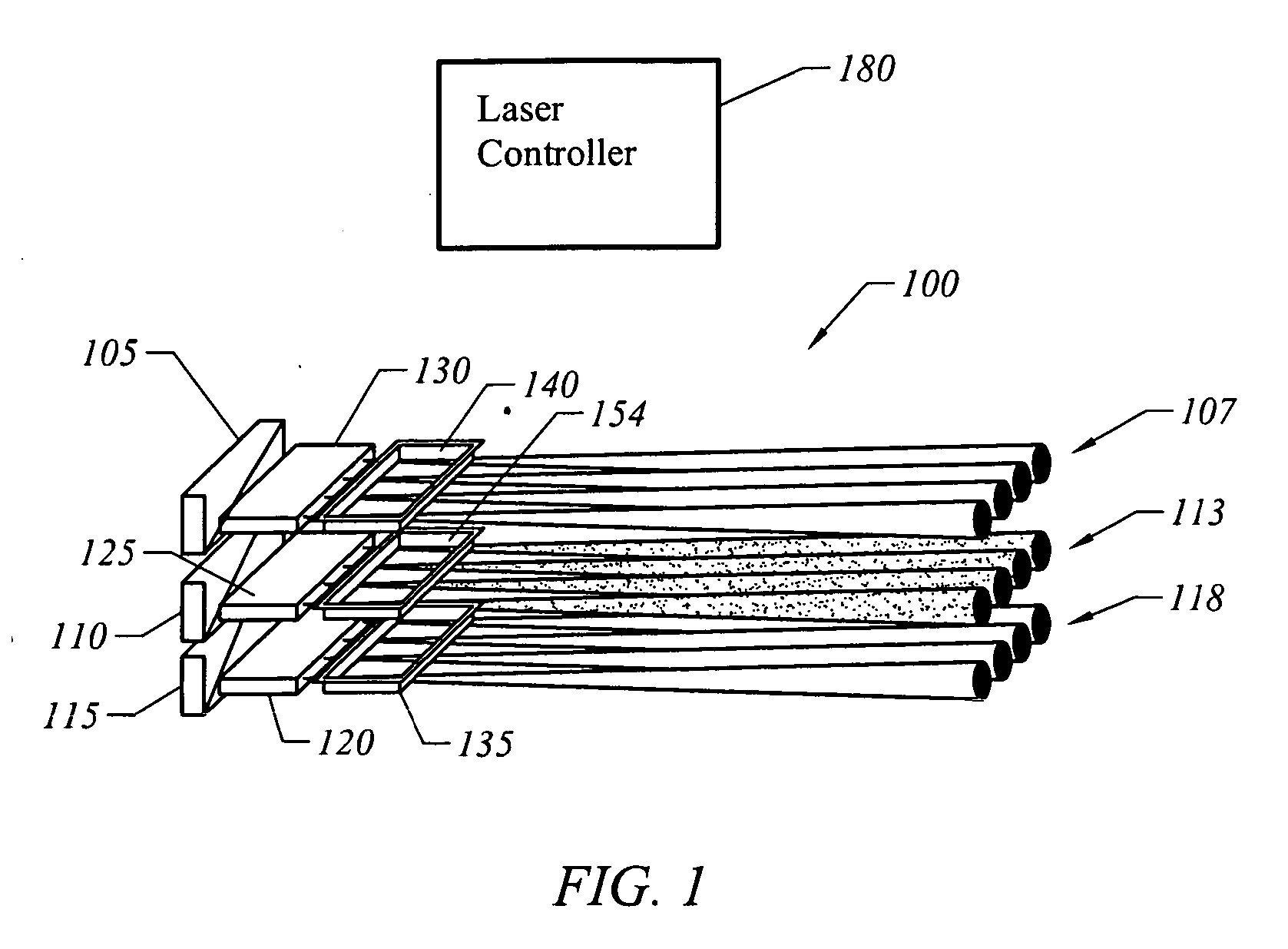

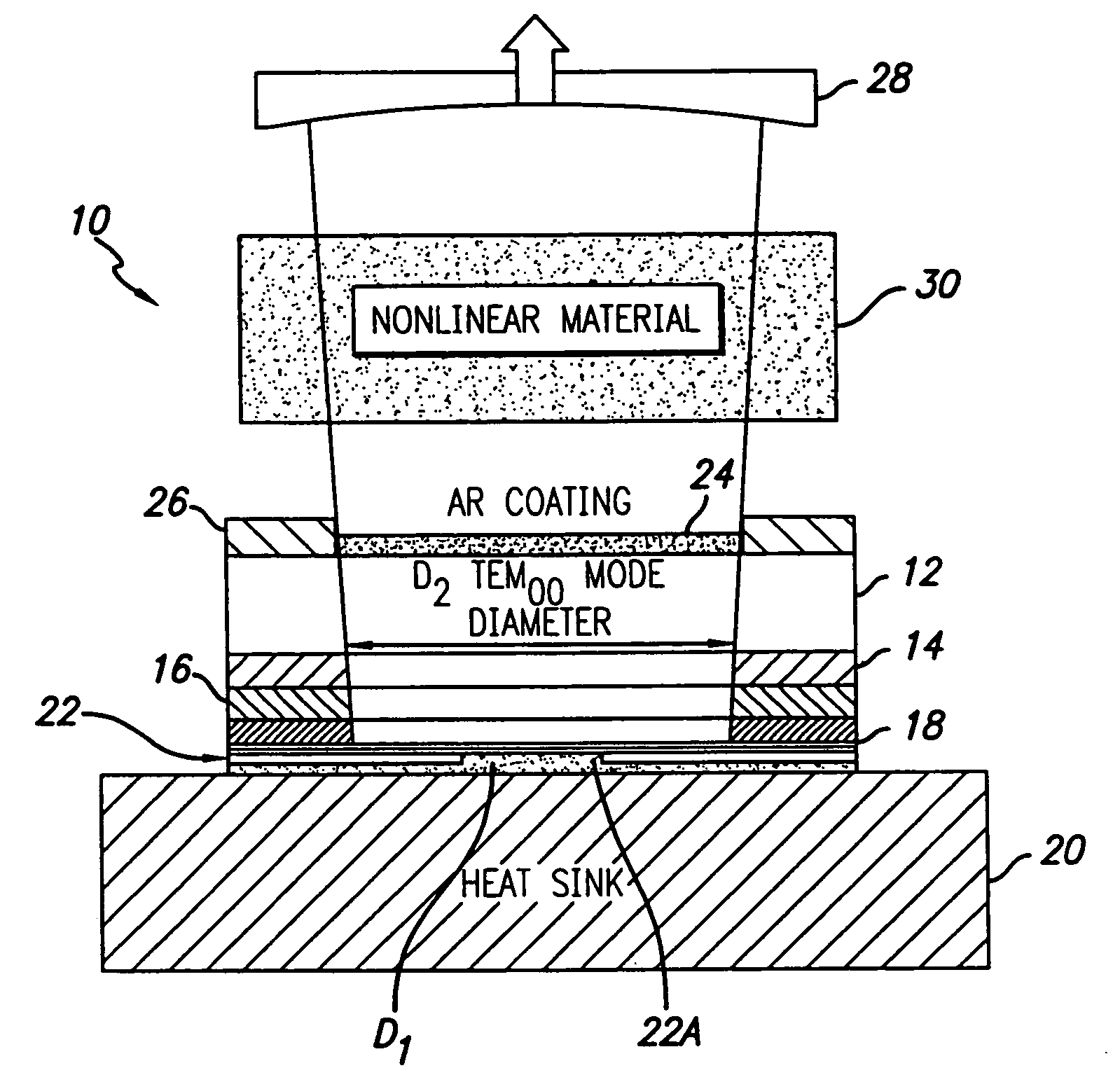

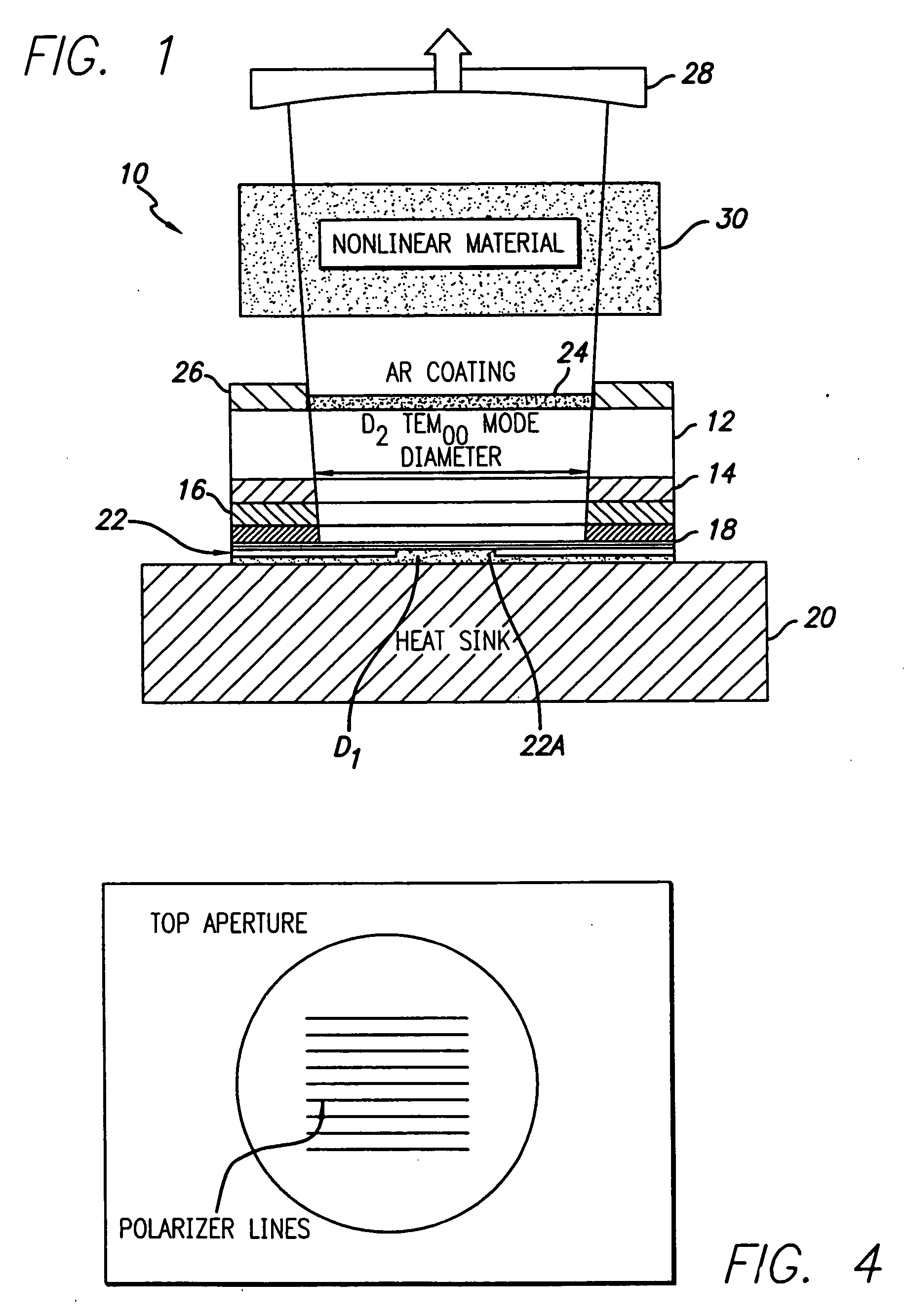

An active gain region sandwiched between a 100% reflective bottom Bragg mirror and an intermediate partially reflecting Bragg mirror is formed on a lower surface of a supporting substrate, to thereby provide the first (“active”) resonator cavity of a high power coupled cavity surface emitting laser device. The reflectivity of the intermediate mirror is kept low enough so that laser oscillation within the active gain region will not occur. The substrate is entirely outside the active cavity but is contained within a second (“passive”) resonator cavity defined by the intermediate mirror and a partially reflecting output mirror, where it is subjected to only a fraction of the light intensity that is circulating in the gain region. In one embodiment, non-linear optical material inside each passive cavity of an array converts an IR fundamental wavelength of each laser device to a corresponding visible harmonic wavelength, and the external output cavity mirror comprises a Volume Bragg grating (VBG) or other similar optical component that is substantially reflective at the fundamental frequency and substantially transmissive at the harmonic frequency. The VBG used in an array of such devices may be either flat, which simplifies registration and alignment during manufacture, or may be configured to narrow the IR spectrum fed back into the active resonant cavity and to shape the spatial mode distribution inside the cavity, thereby reducing the size of the mode and compensating for any deformations in the semiconductor array.

Owner:ARASOR ACQUISITION +1

Fiber optic devices having volume Bragg grating elements

Owner:NECSEL INTPROP

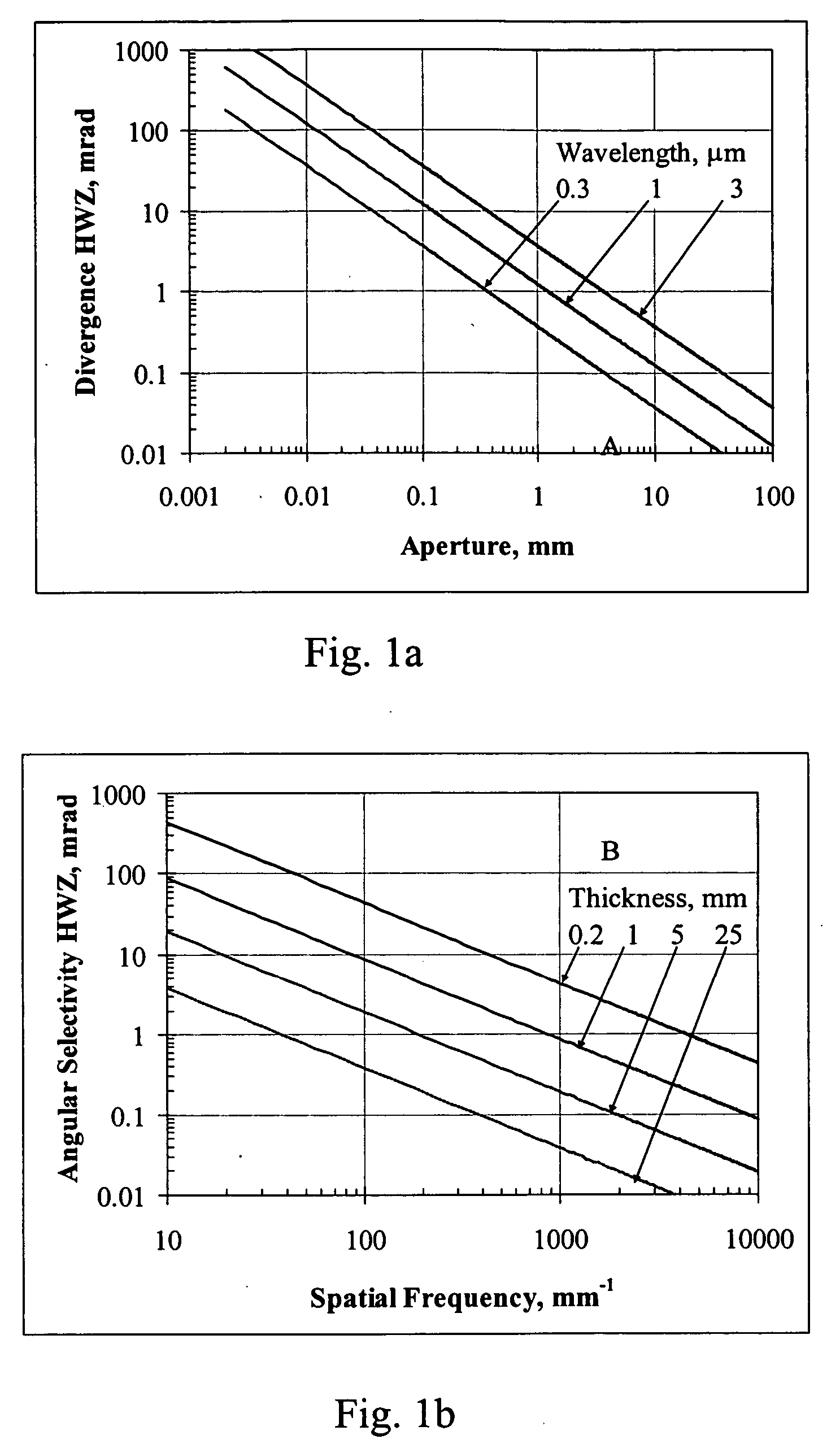

Volume bragg lasers based on high efficiency diffractive elements in photo-thermo-refractive glass

InactiveUS20050207466A1Increase brightnessImprove efficiencyLaser optical resonator constructionSemiconductor laser arrangementsCouplingMechanical stability

A volume Bragg laser including a resonator comprising photo-thermo-refractive (PTR) volume diffractive elements that can be used in a laser emitting window of transparency of PTR glass to provide control of the lasers spectral and angular parameters, and methods, devices, apparatus and systems related thereto. The high efficiency volume Bragg gratings recorded in photo-thermo-refractive (PTR) glass preferably has an absolute diffraction efficiency exceeding approximately 95% in transmitting and reflecting modes is used for selection of a transverse and longitudinal mode for thermal, optical and mechanical stabilization of the volume Bragg lasers and coherent coupling of different lasers. Robustness, compactness, thermal and laser stability along with the ability to place several elements in the same space allows the use of sophisticated optical system according to the invention in fields of military lasers, optical communications, data storage and processing, and the like.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

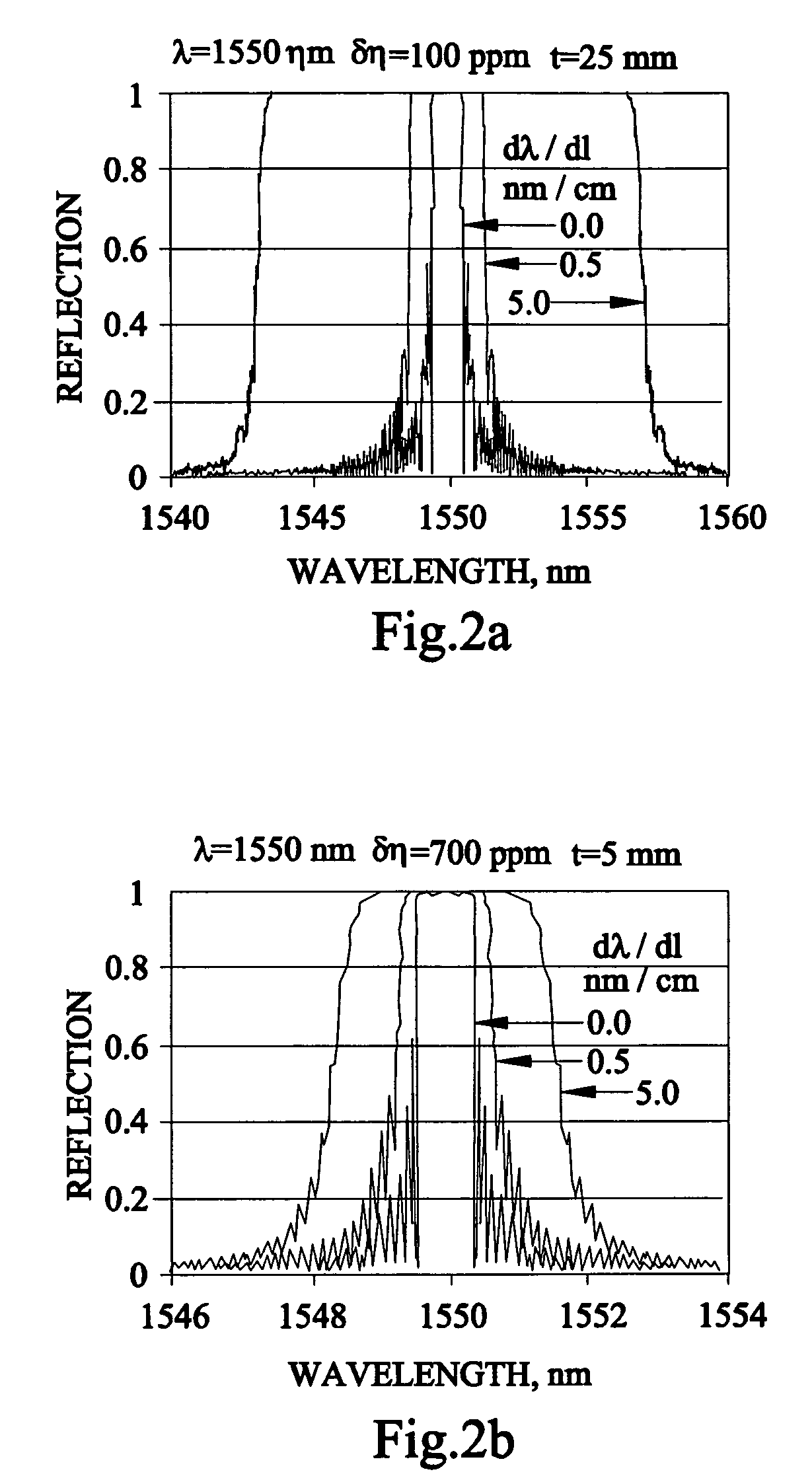

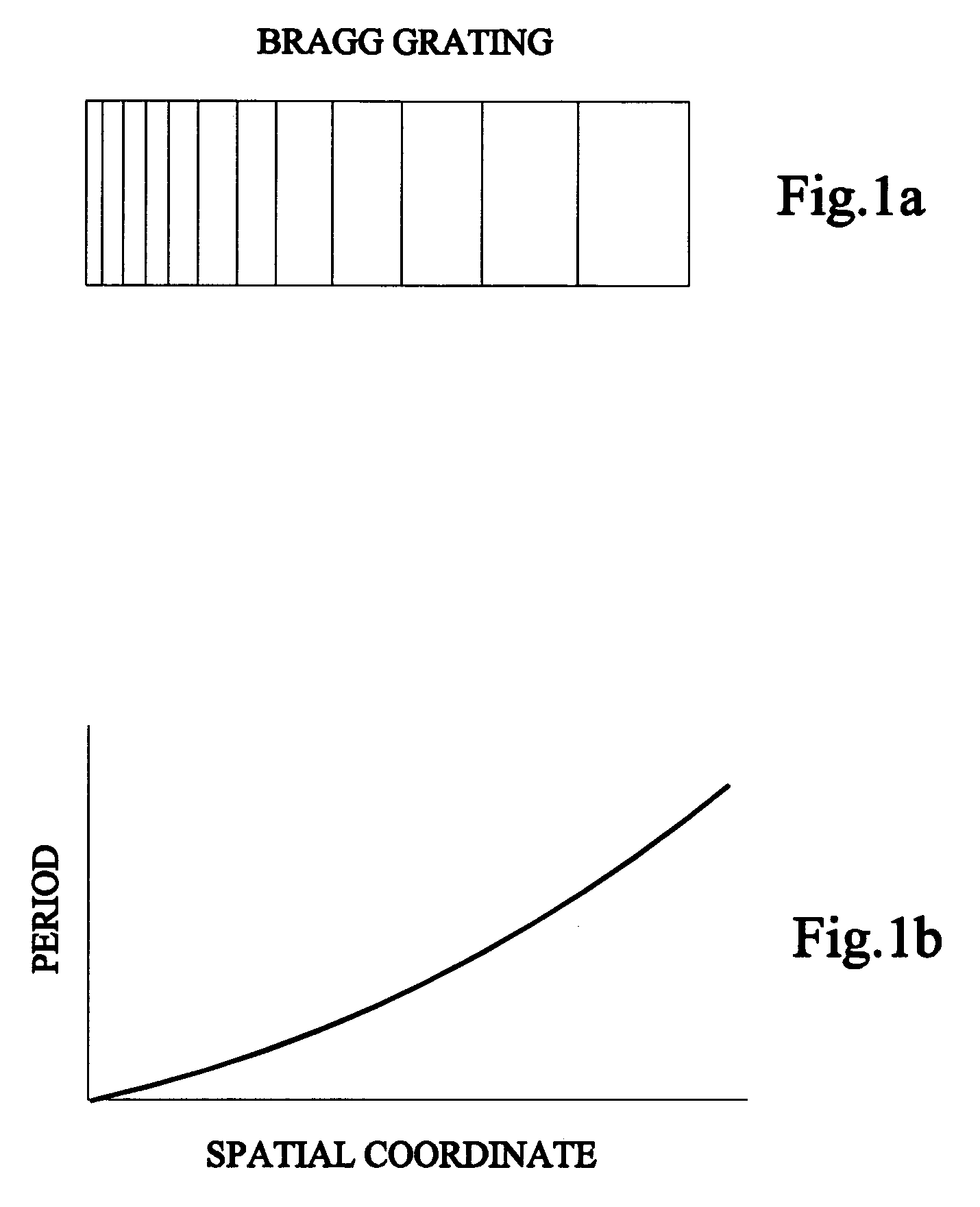

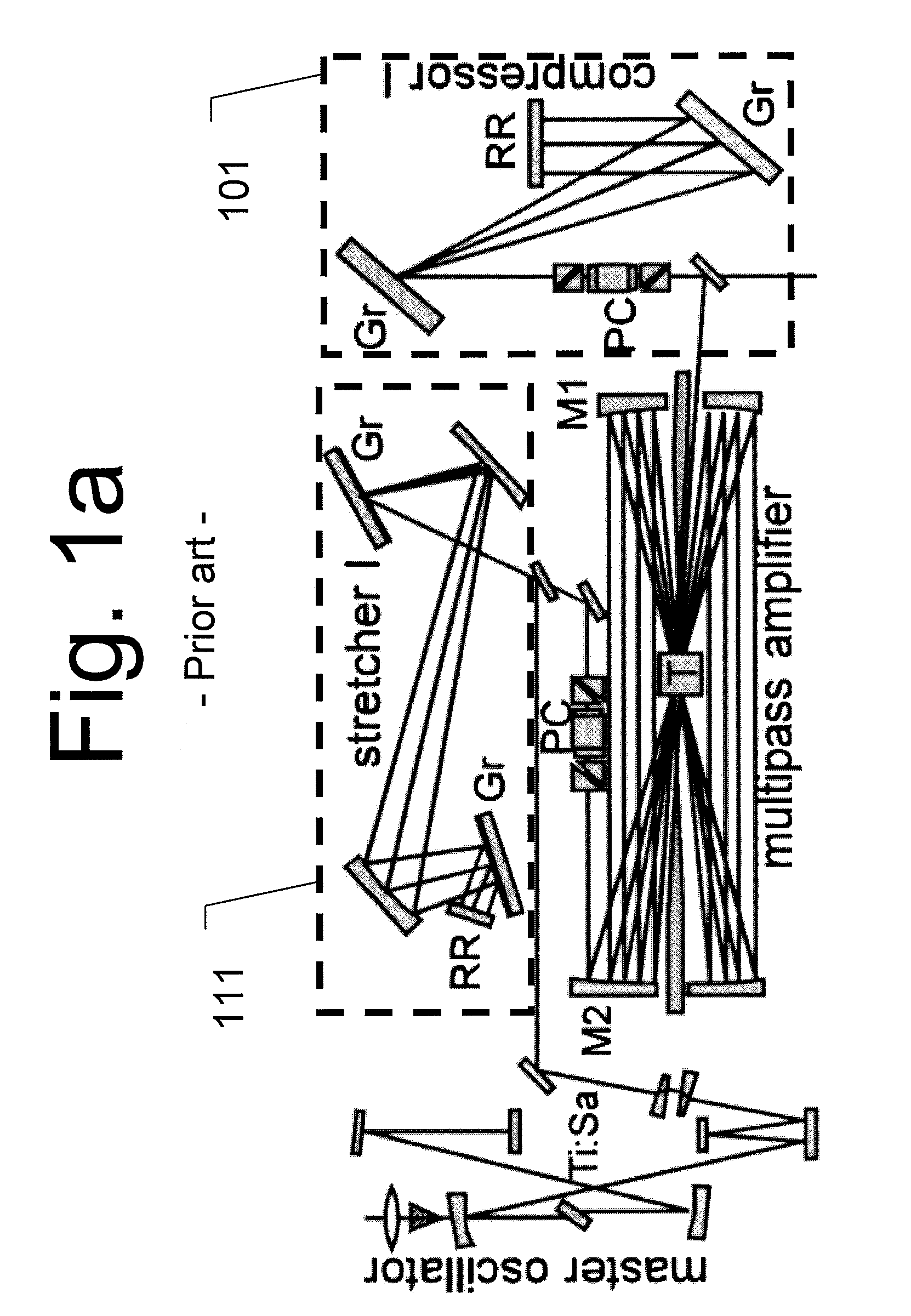

Stretching and compression of laser pulses by means of high efficiency volume diffractive gratings with variable periods in photo-thermo-refractive glass

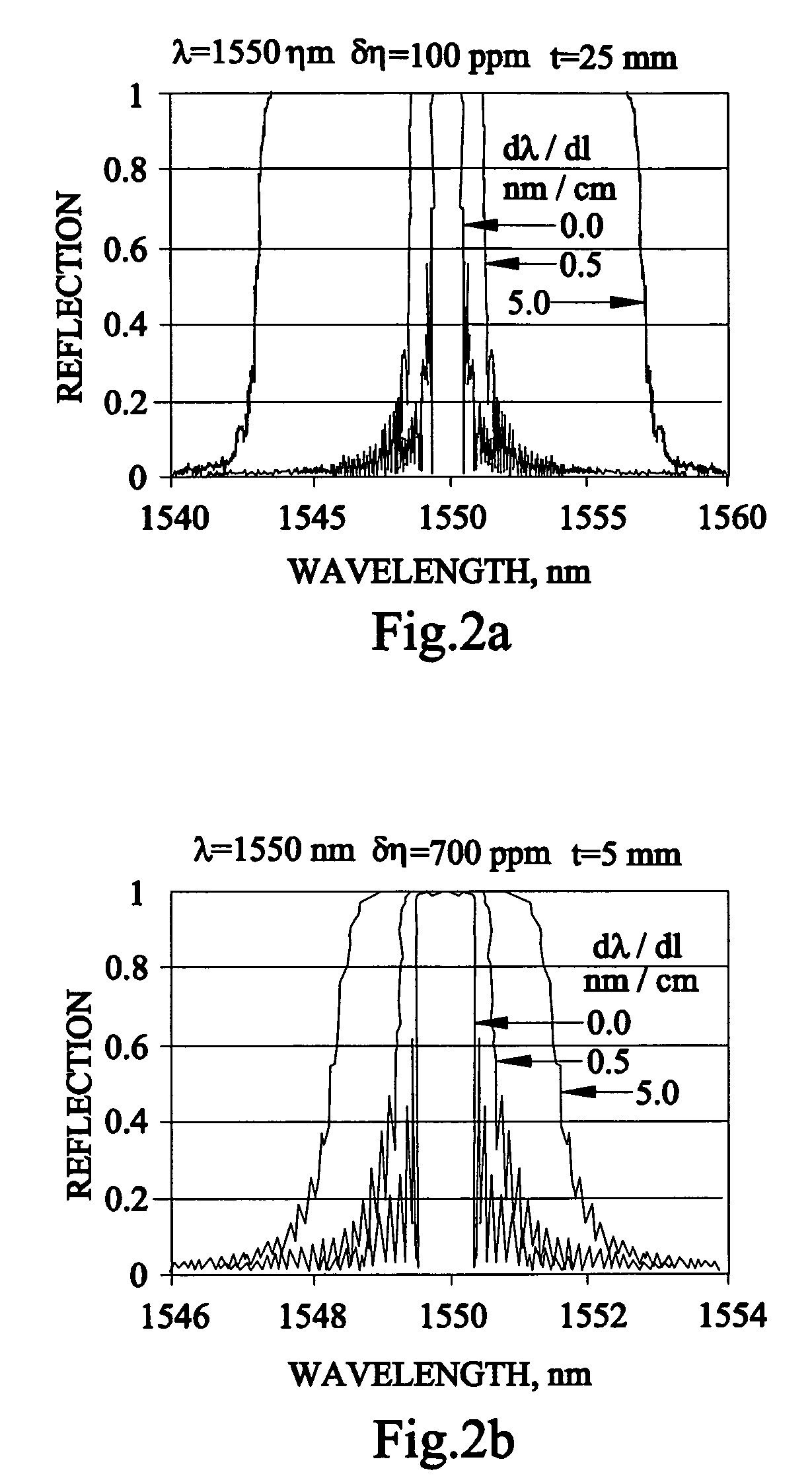

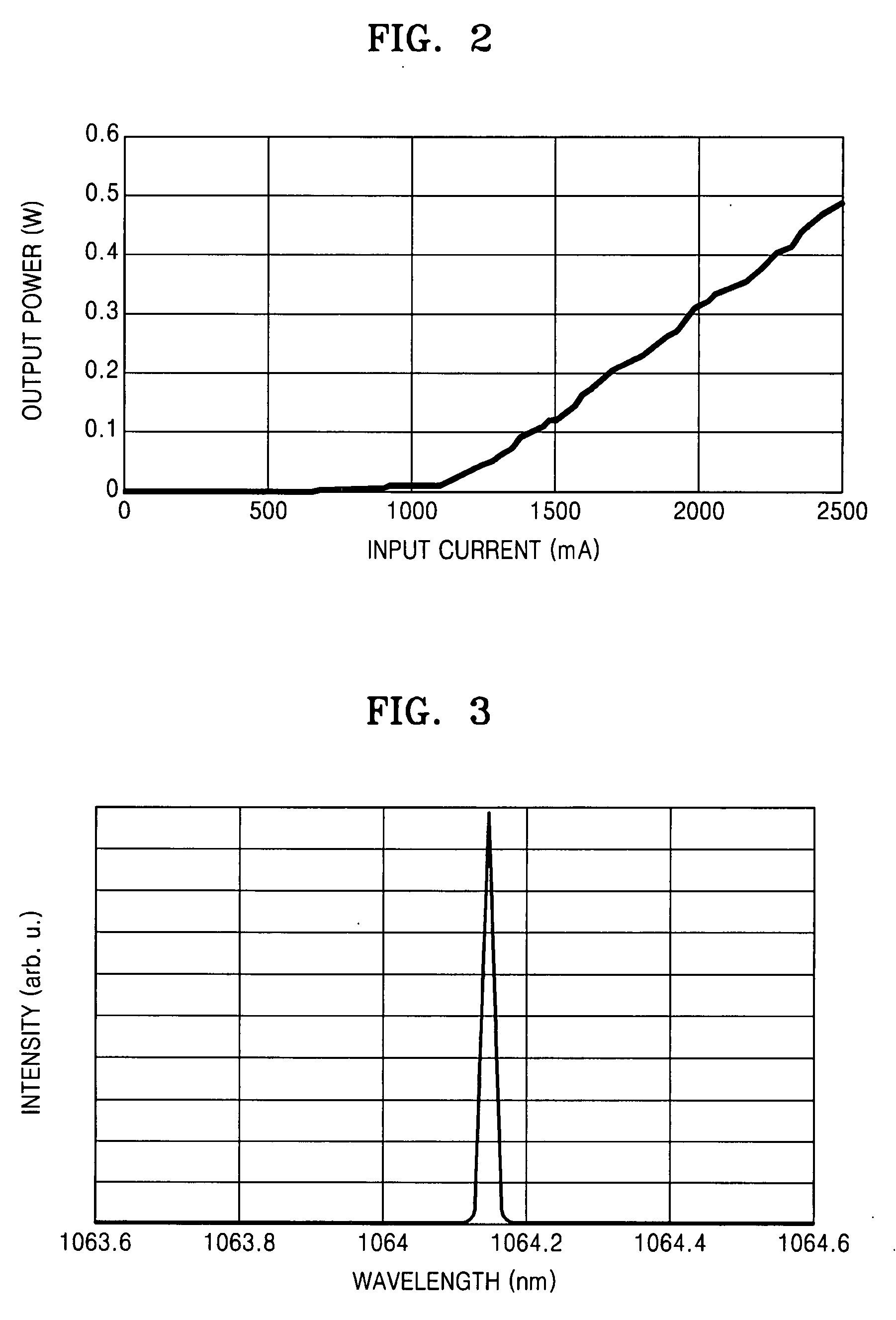

InactiveUS20060221449A1Eliminate significant beam distortionImprove efficiencyLaser using scattering effectsPhotomechanical apparatusUltrashort laserVolume bragg grating

High efficiency reflective volume Bragg gratings with chirped gratings recorded in photo-thermo-refractive glass having an absolute diffraction efficiency exceeding 95% in transmitting and reflecting modes are used to stretch and / or compress ultrashort laser pulses with high efficiency. Robustness, compactness, thermal and laser stability along with placement of multiple elements in the same space provides femtosecond laser system with high efficiency of stretching and re-compression of femtosecond pulses.

Owner:UNIV OF MICHIGAN THE +1

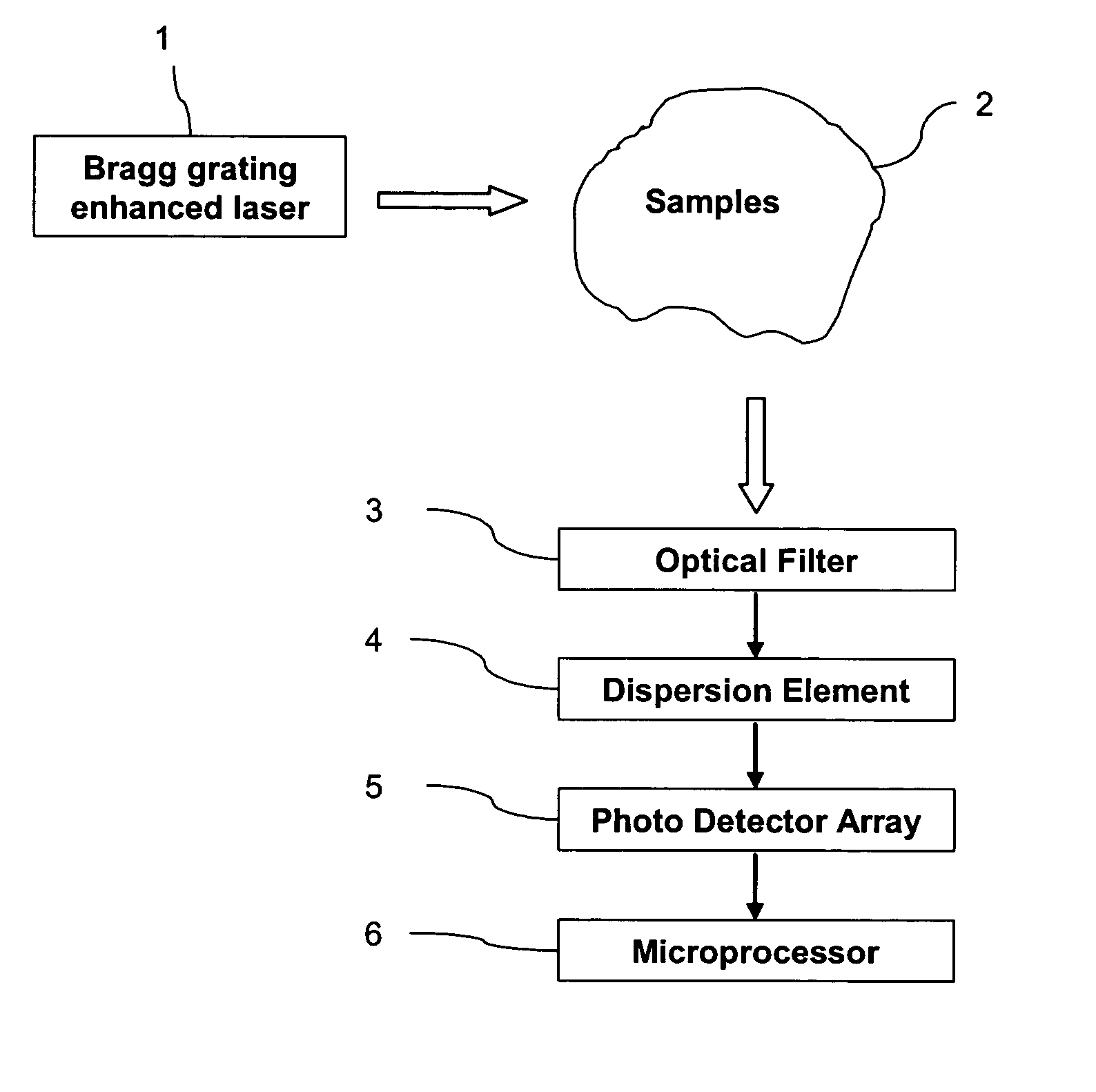

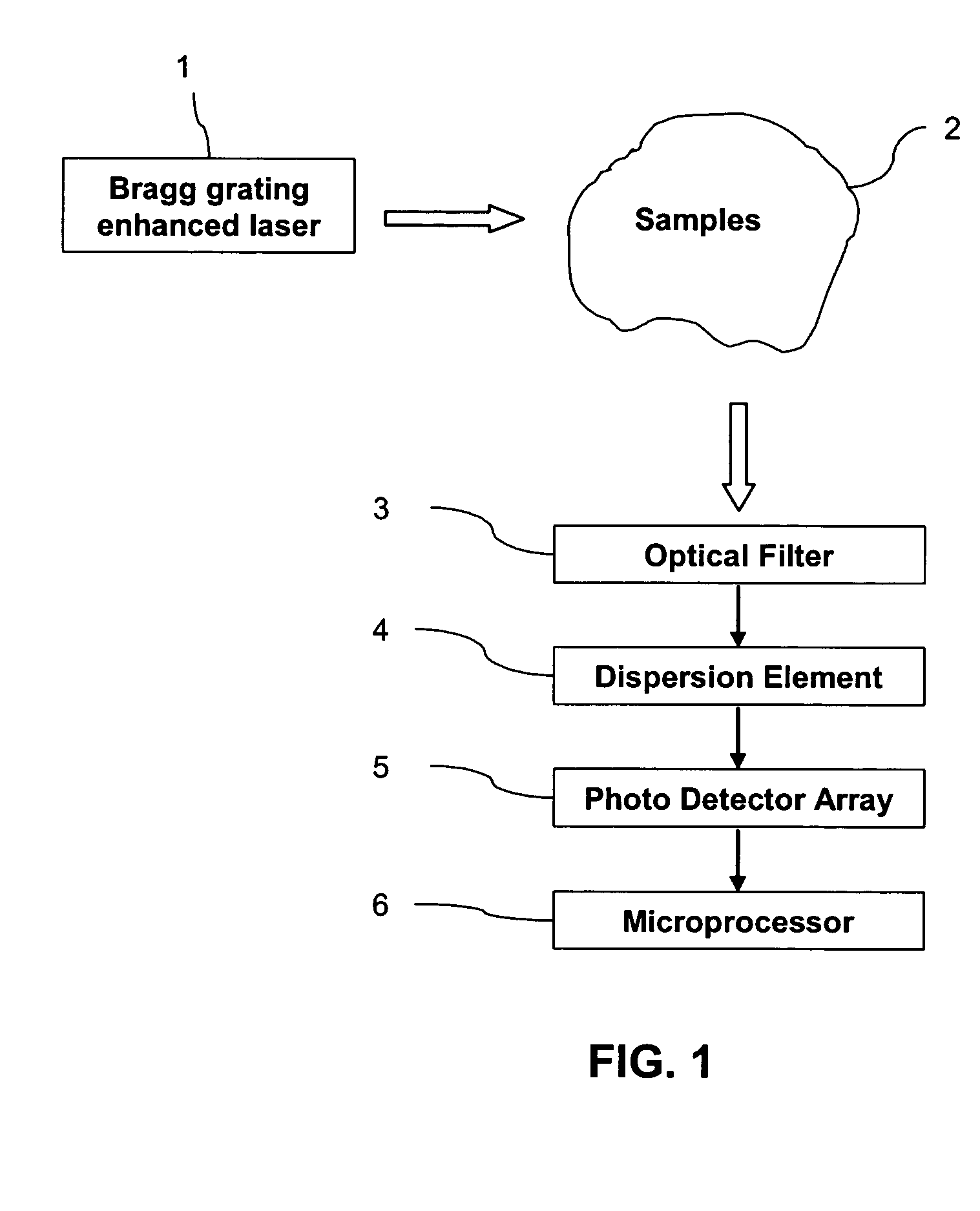

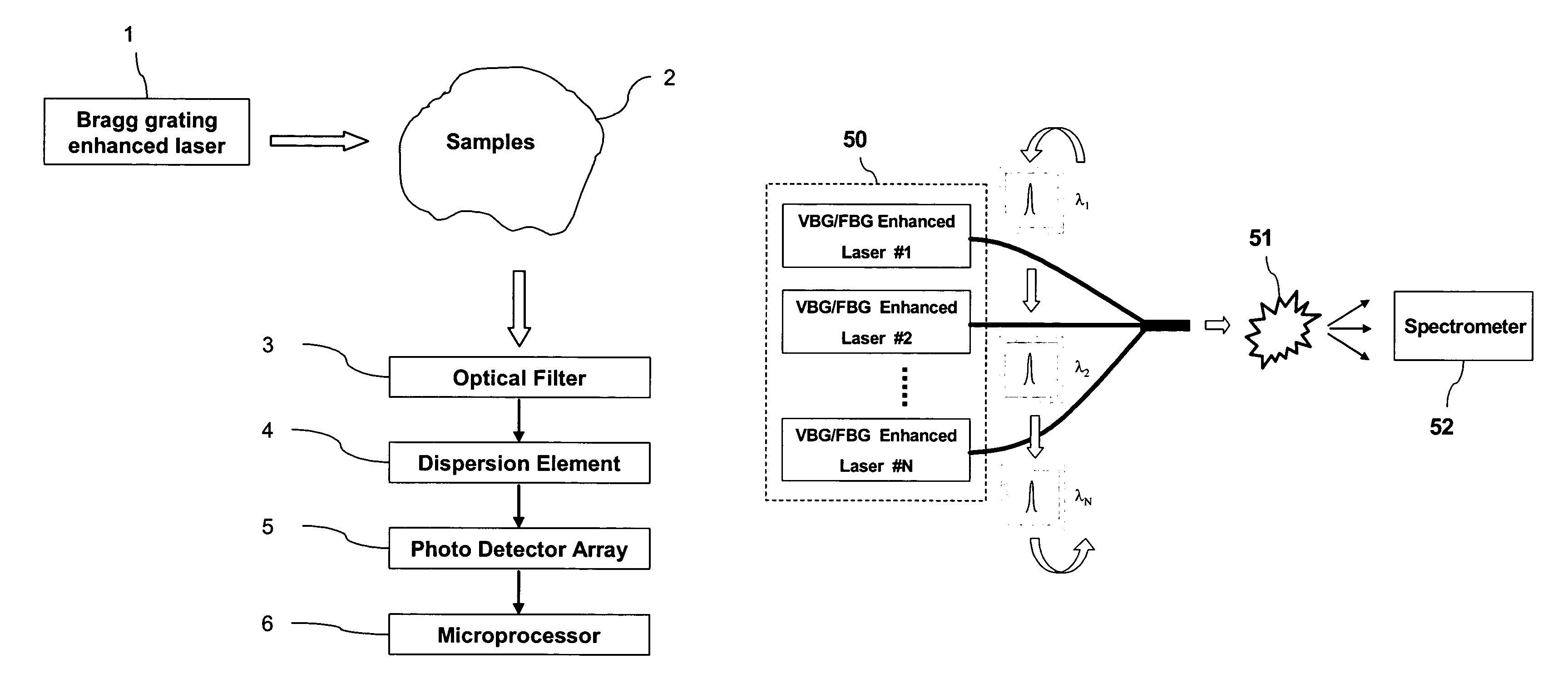

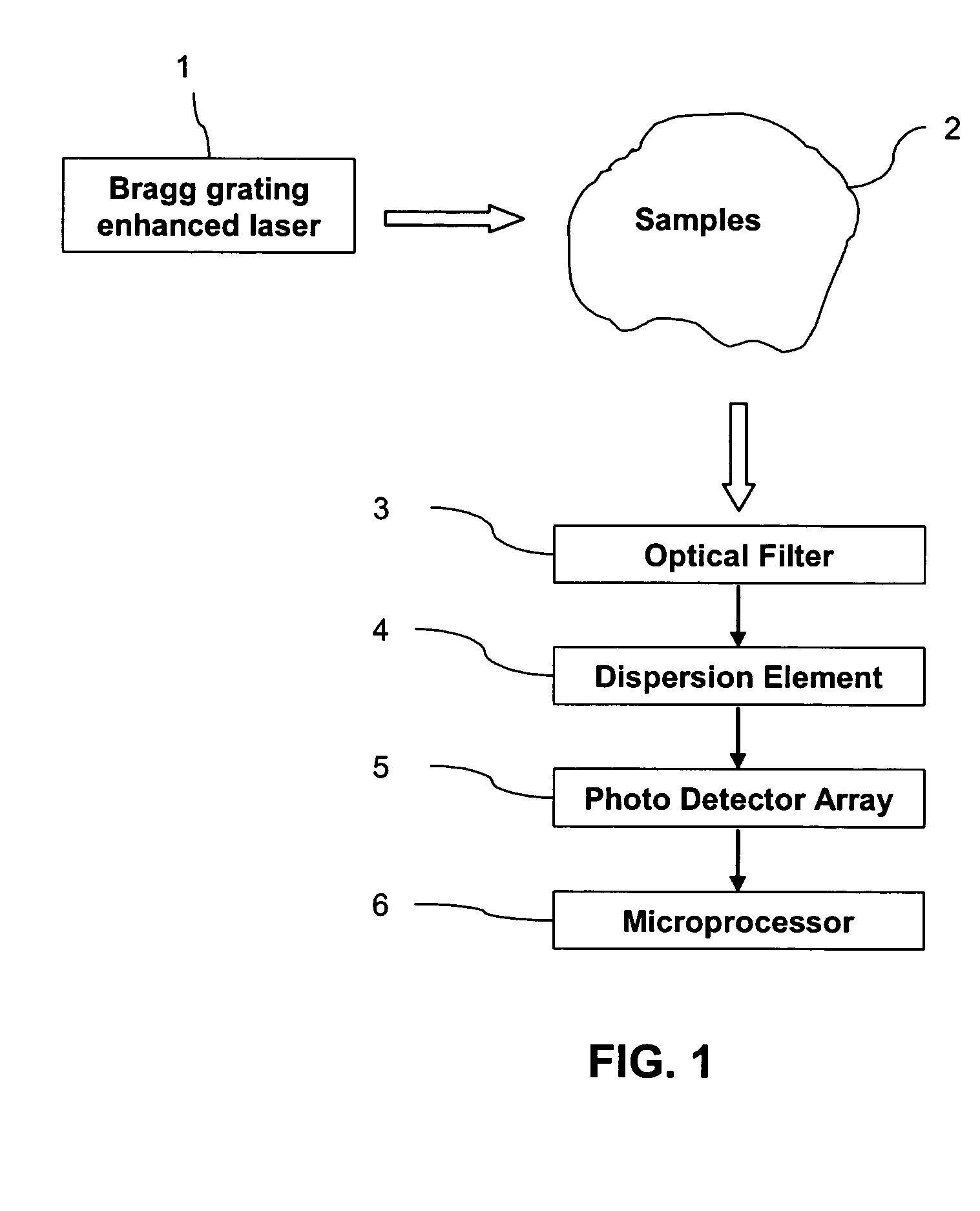

Spectroscopic apparatus using spectrum narrowed and stabilized laser with Bragg grating

An apparatus for measuring properties of physical matters by means of Raman spectroscopy including a laser element, a wavelength dispersion element, an array or single element detector, and a control and data processing unit. The laser element, which is used to excite Raman scattering, is spectrum narrowed and stabilized by attachment of a Bragg grating device. The grating can be either a volume Bragg grating (VBG) written inside a glass substrate or a fiber Bragg grating (FBG) written inside an optical fiber. A laser element can be provided with a wavelength modulation capability for fluorescence background suppression.

Owner:METROHM SPECTRO INC

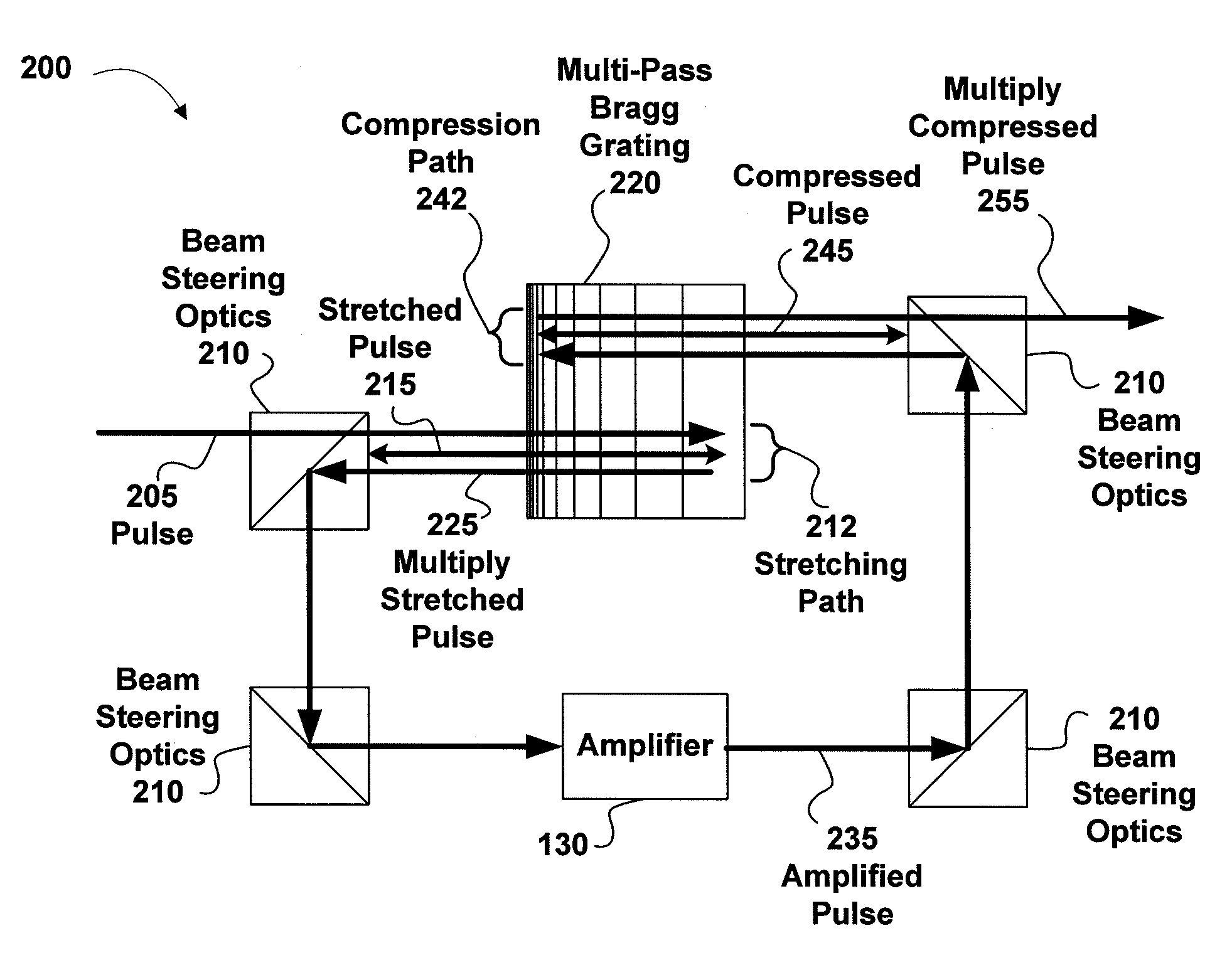

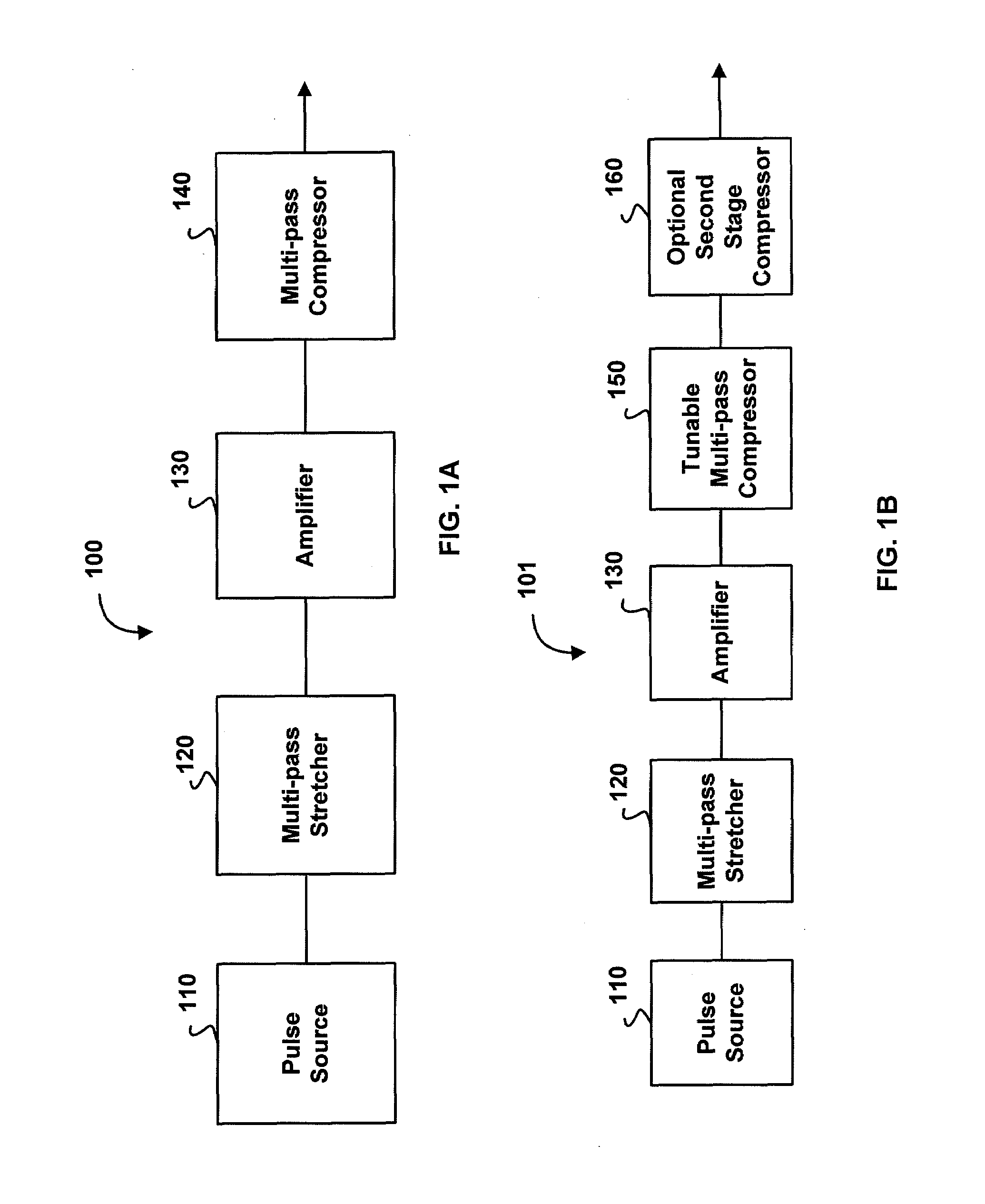

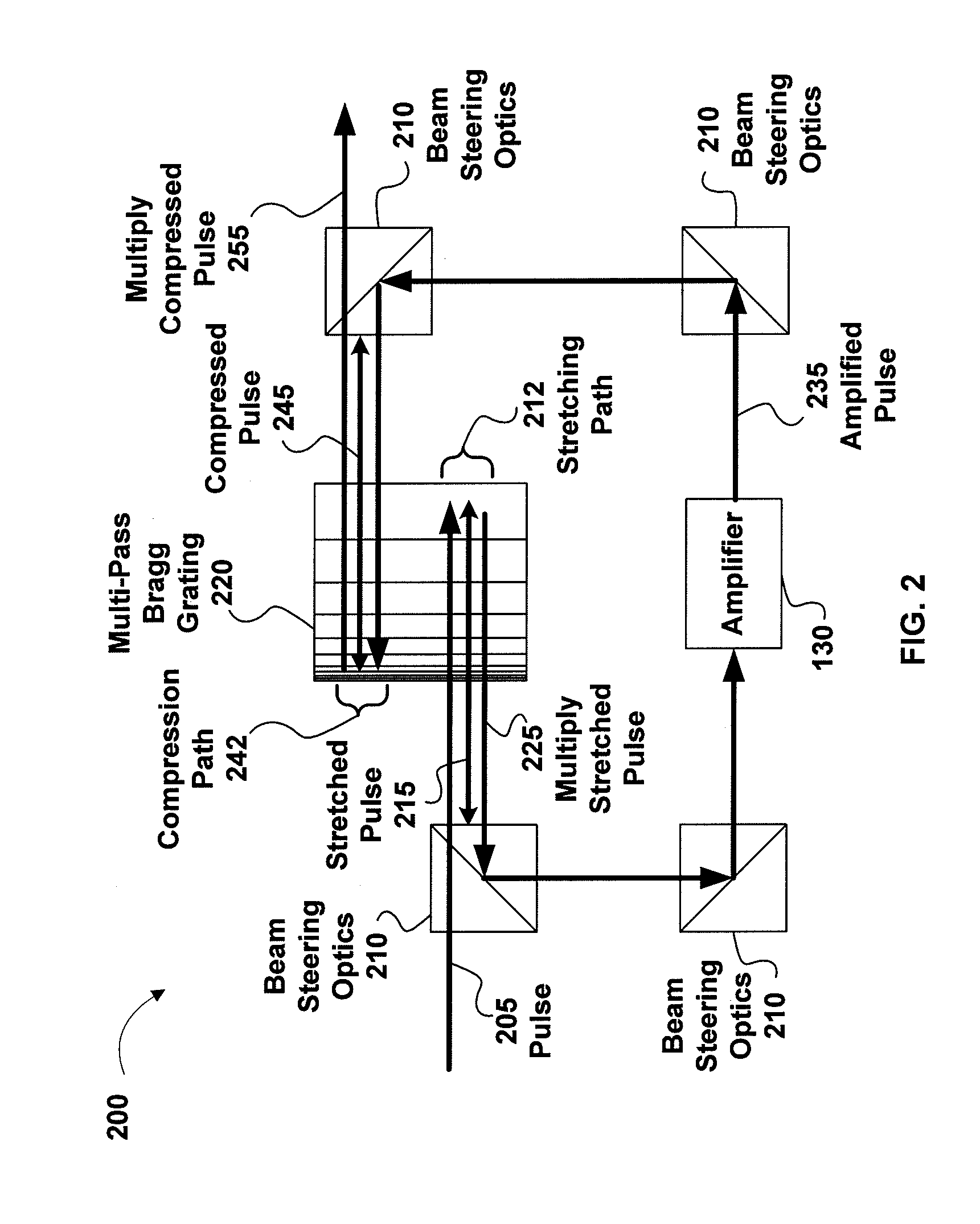

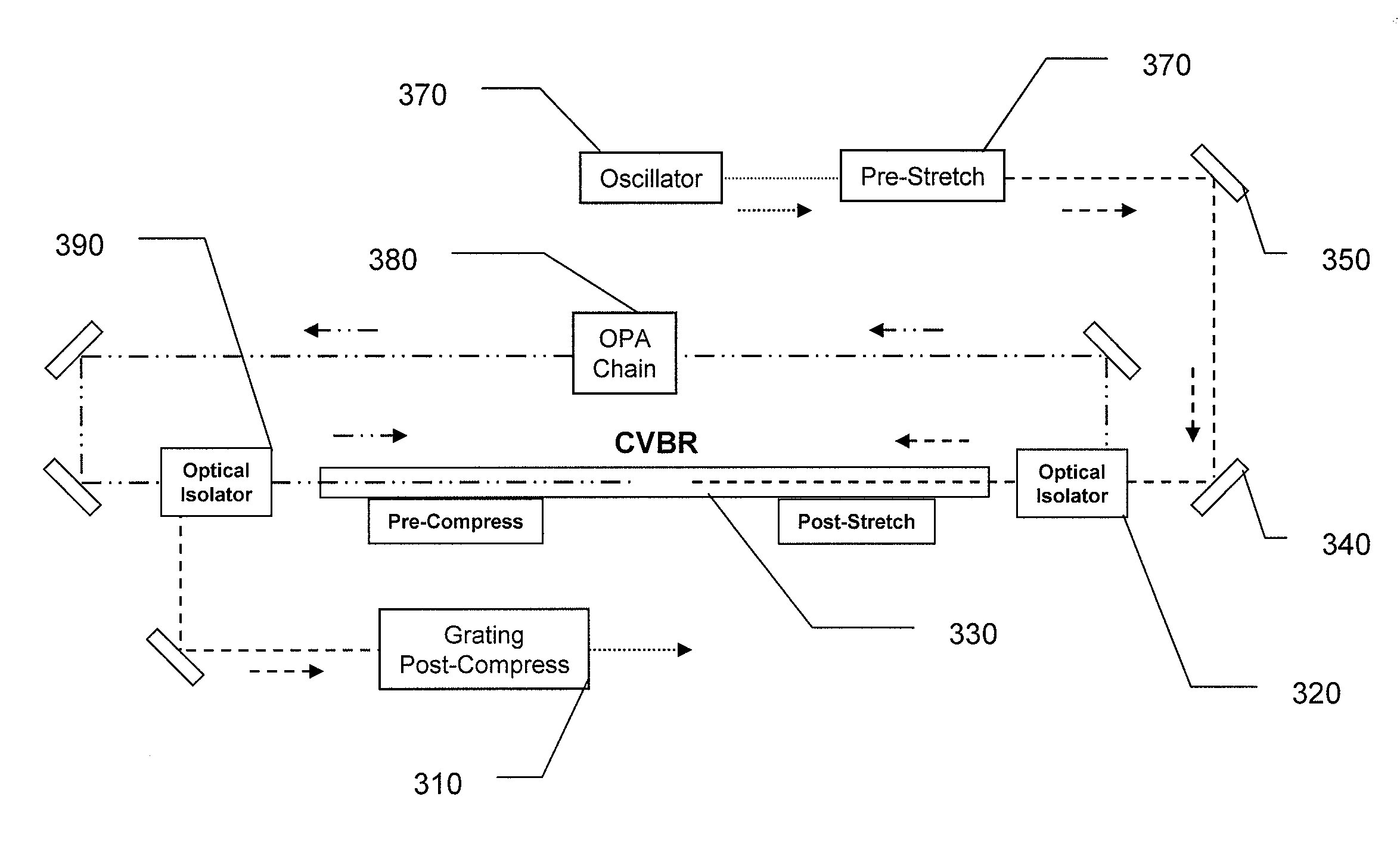

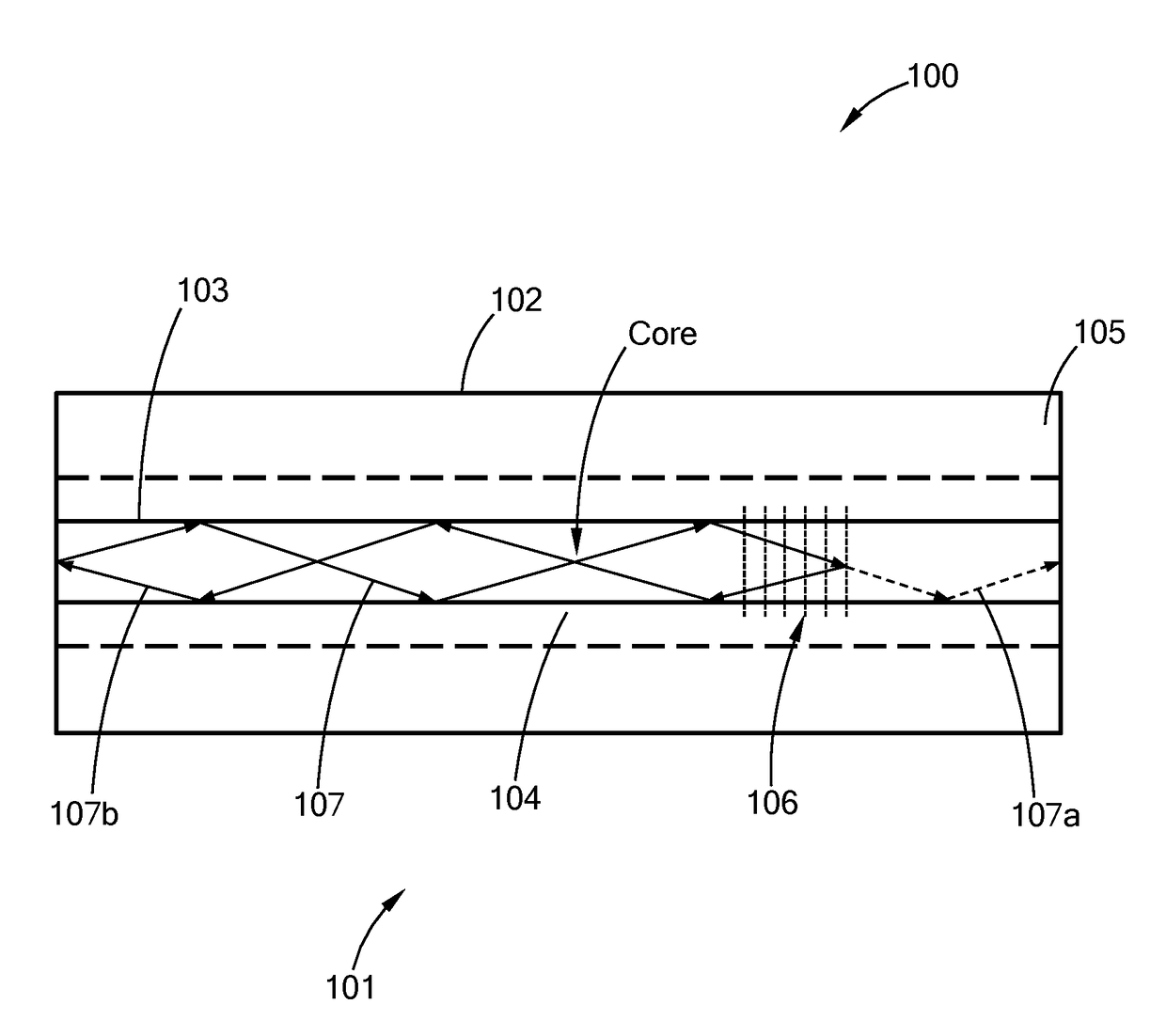

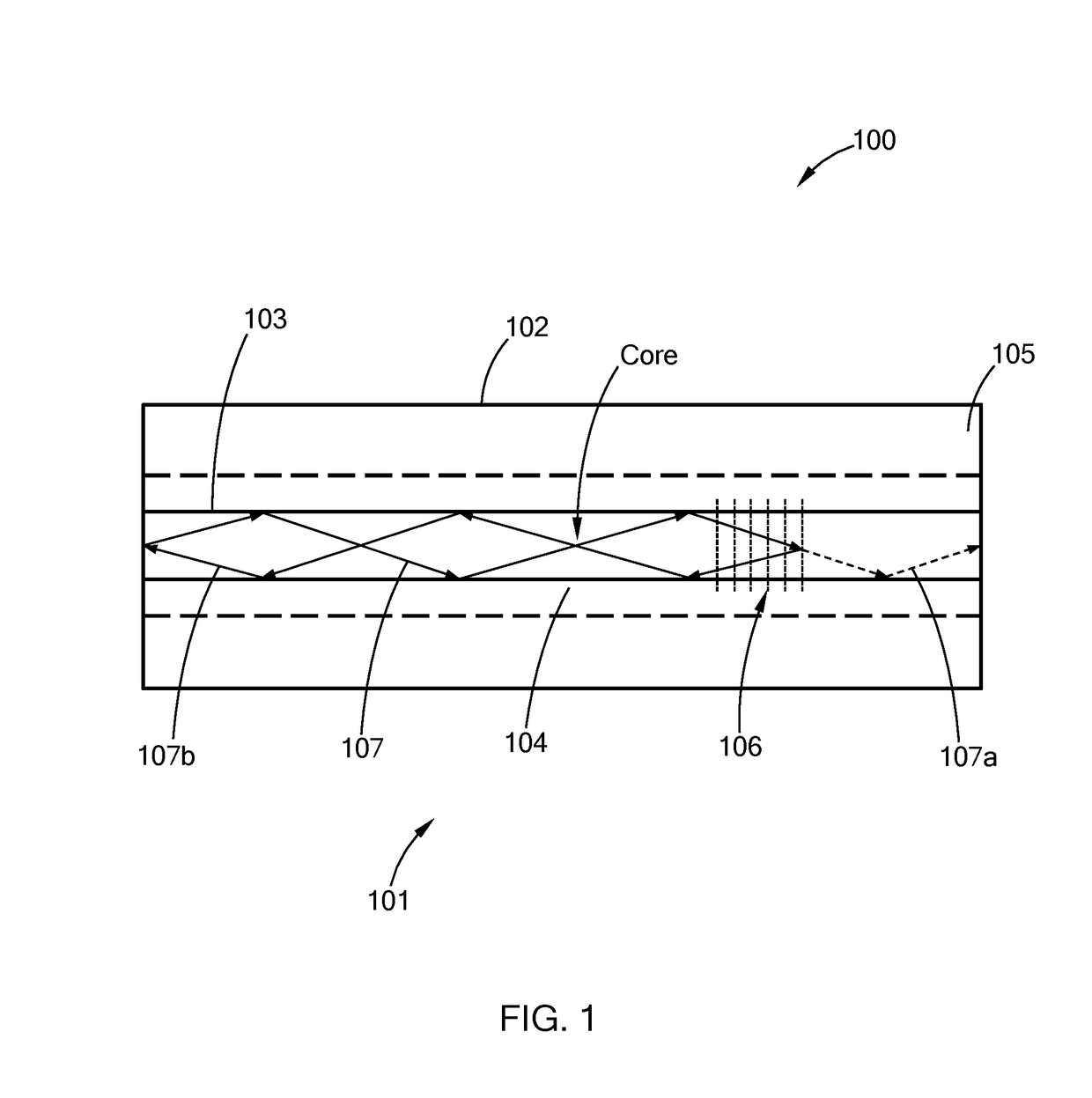

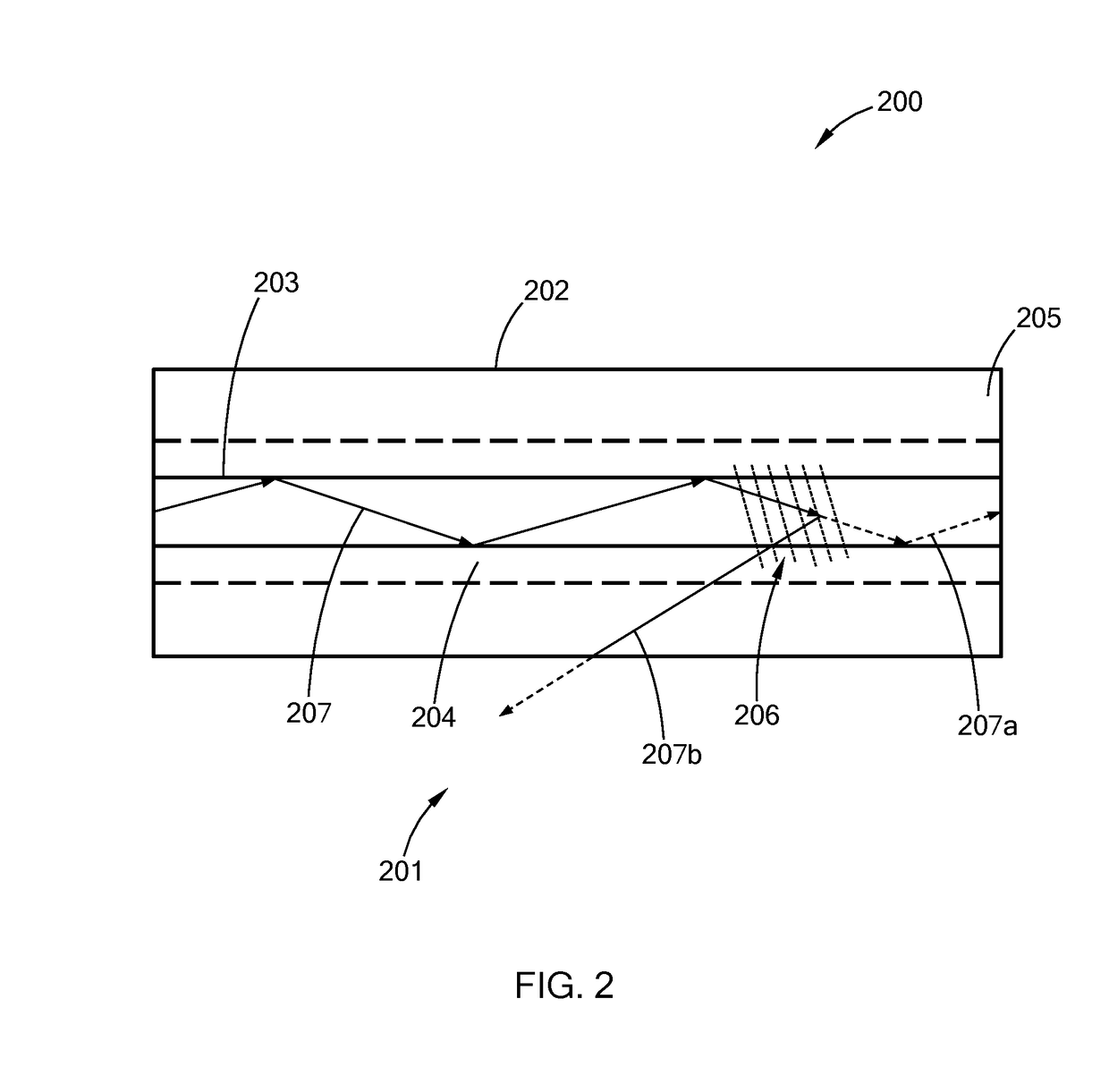

Pulse stretcher and compressor including a multi-pass Bragg grating

A chirped pulse amplification (CPA) system and method is described wherein the pulse is stretched using multiple passes through a Bragg grating or compressed using multiple passes through a Bragg grating. A switch may be used to control the number of passes through the Bragg grating, thus, tuning the compressed or the stretched pulse width. The pulse may be directed through an amplifier between the multiple passes through the Bragg grating to apply amplification to the stretched pulse multiple times. The Bragg grating may include a fiber Bragg grating, a volume Bragg grating, or a Bragg waveguide.

Owner:COHERENT INC

Spectroscopic apparatus using spectrum narrowed and stabilized laser with Bragg grating

An apparatus for measuring properties of physical matters by means of Raman spectroscopy including a laser element, a wavelength dispersion element, an array or single element detector, and a control and data processing unit. The laser element, which is used to excite Raman scattering, is spectrum narrowed and stabilized by attachment of a Bragg grating device. The grating can be either a volume Bragg grating (VBG) written inside a glass substrate or a fiber Bragg grating (FBG) written inside an optical fiber. A laser element can be provided with a wavelength modulation capability for fluorescence background suppression.

Owner:METROHM SPECTRO INC

Frequency stabilized vertical extended cavity surface emitting lasers

Owner:NECSEL INTPROP +1

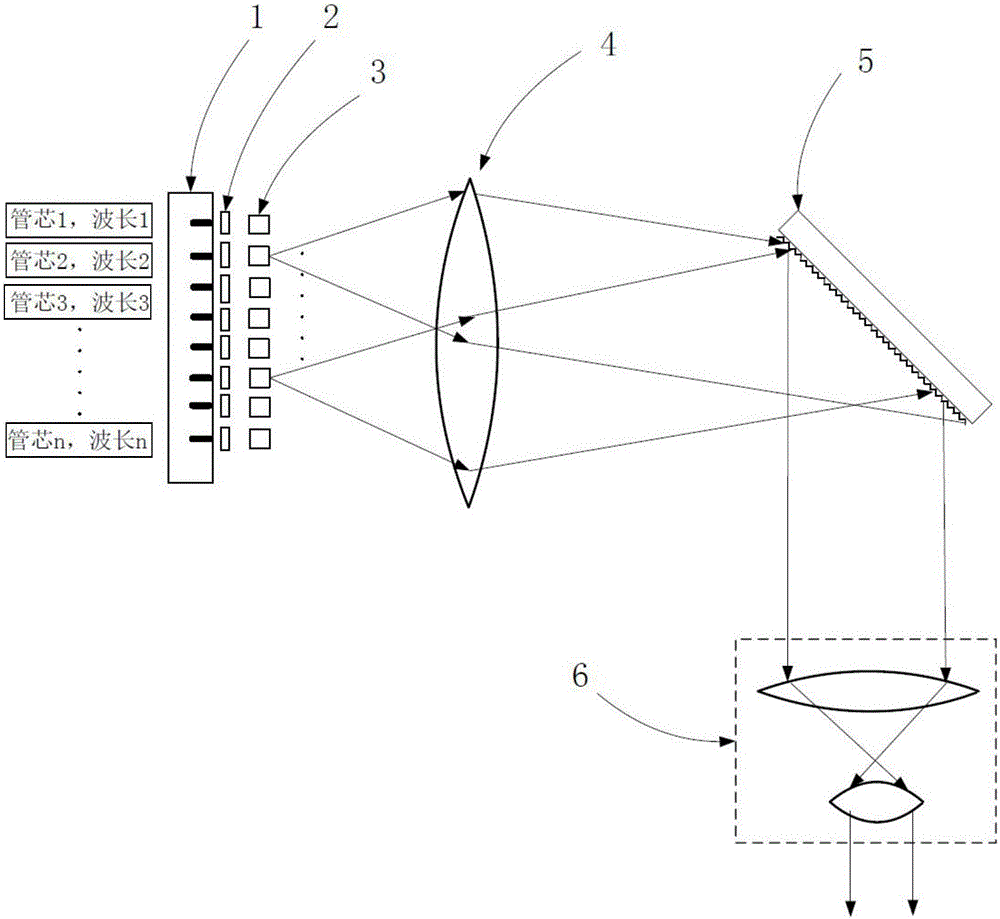

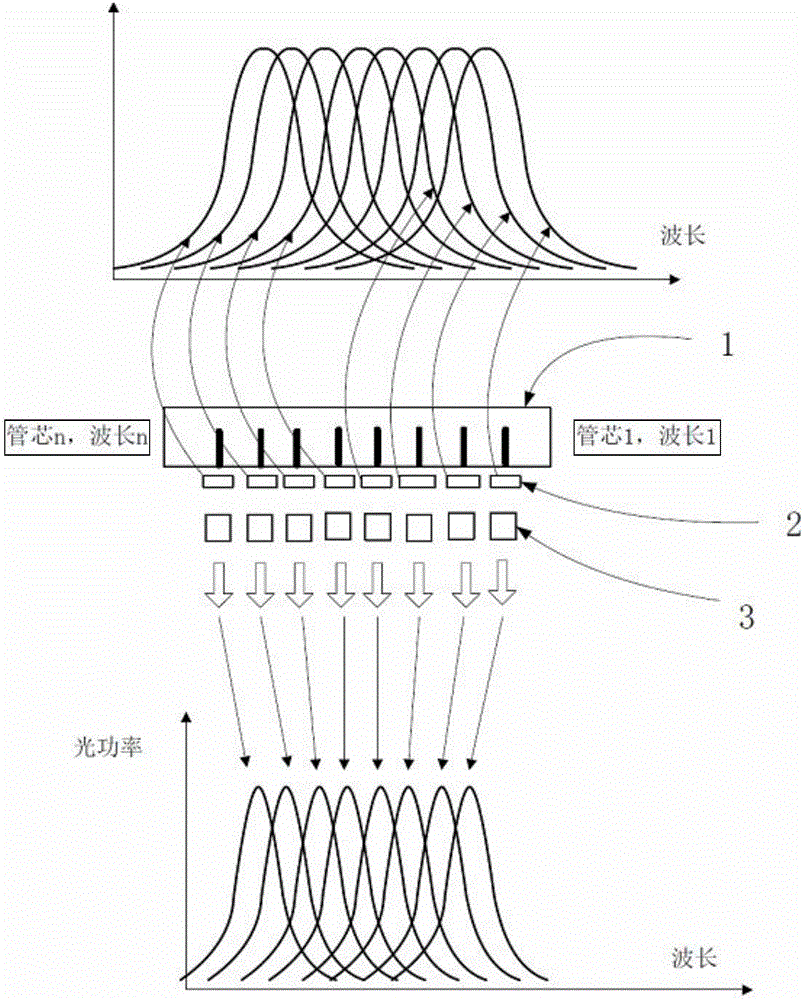

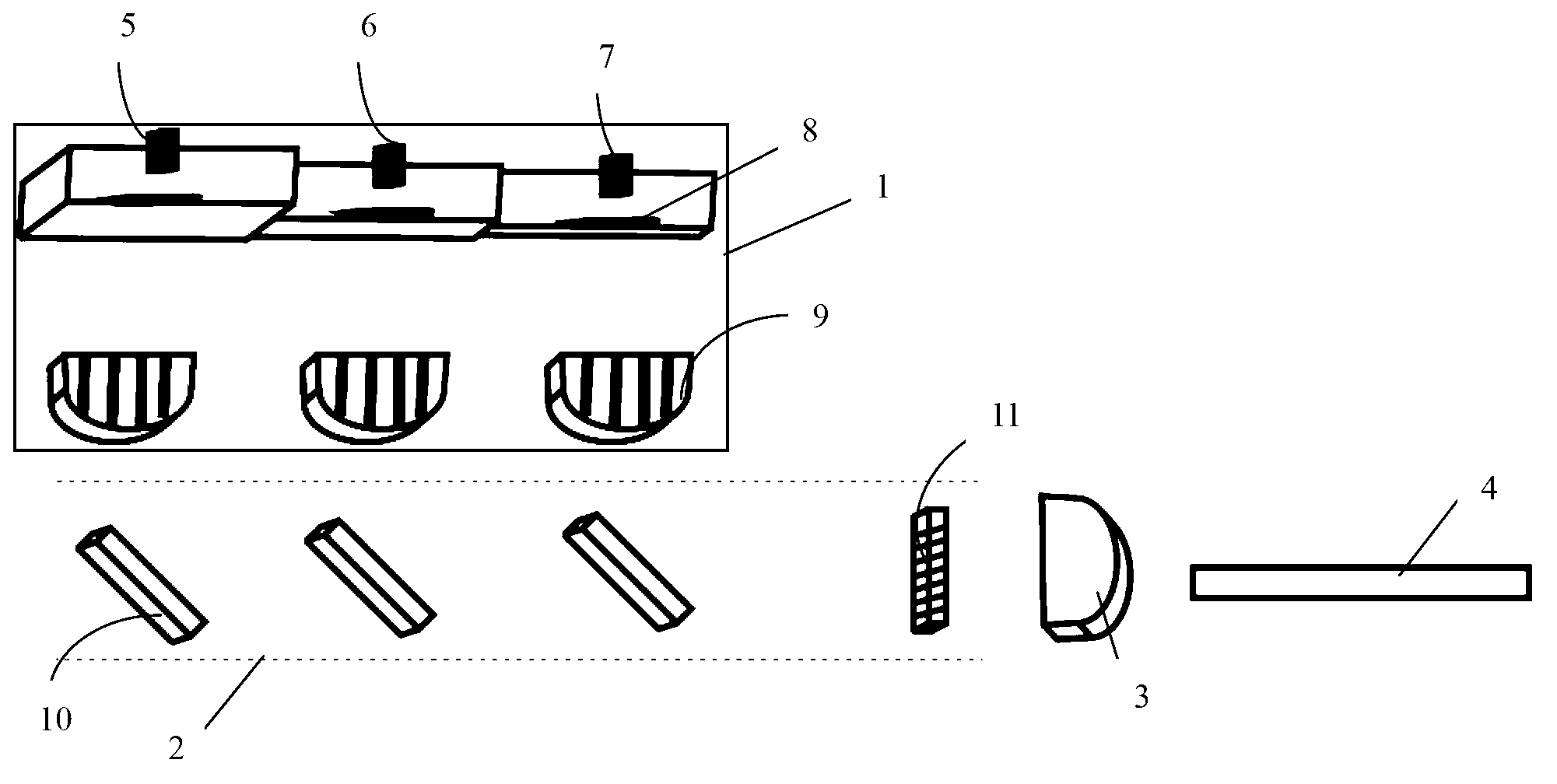

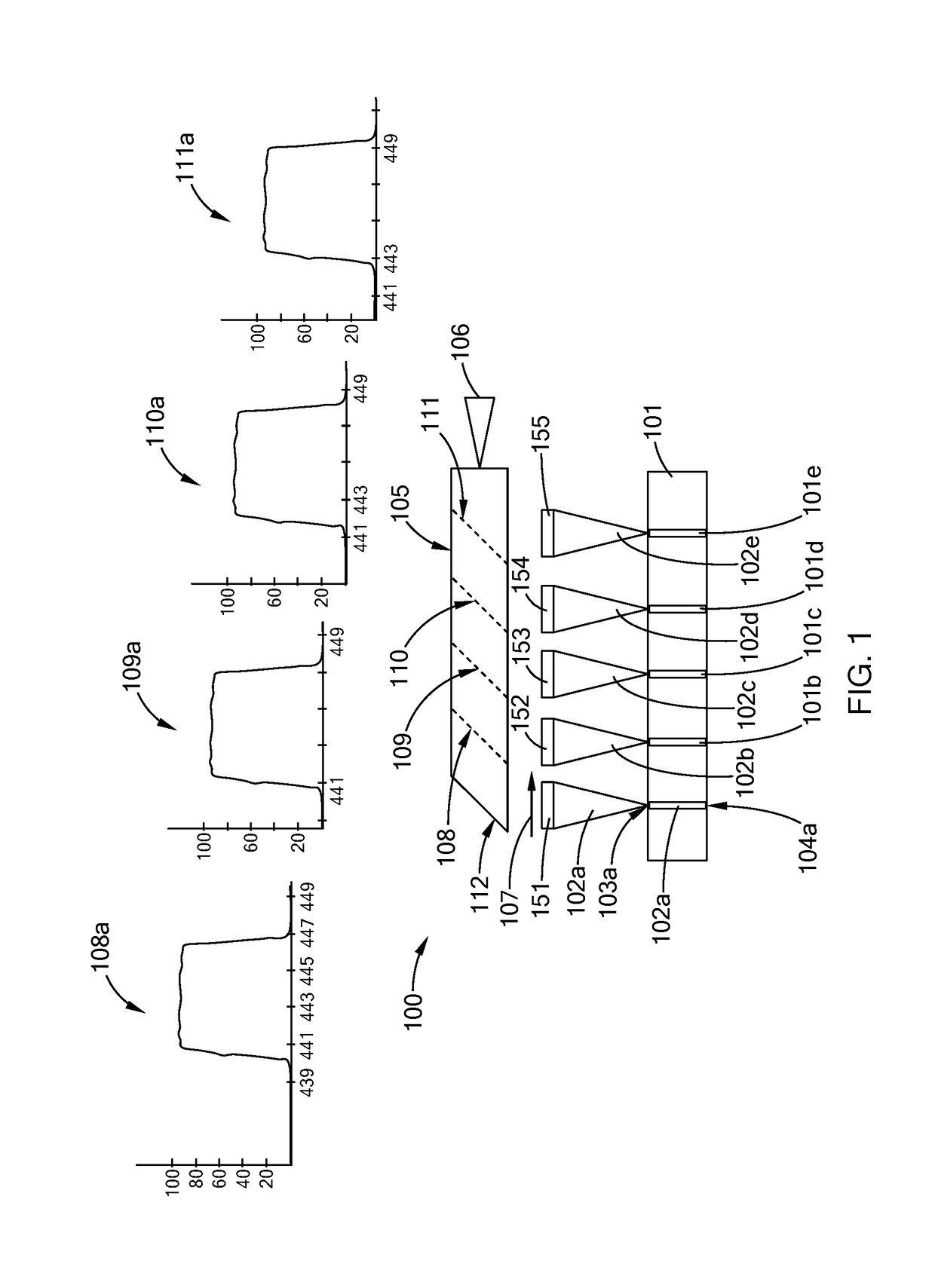

Multi-grating structure-based semiconductor laser beam combination device and beam combination method

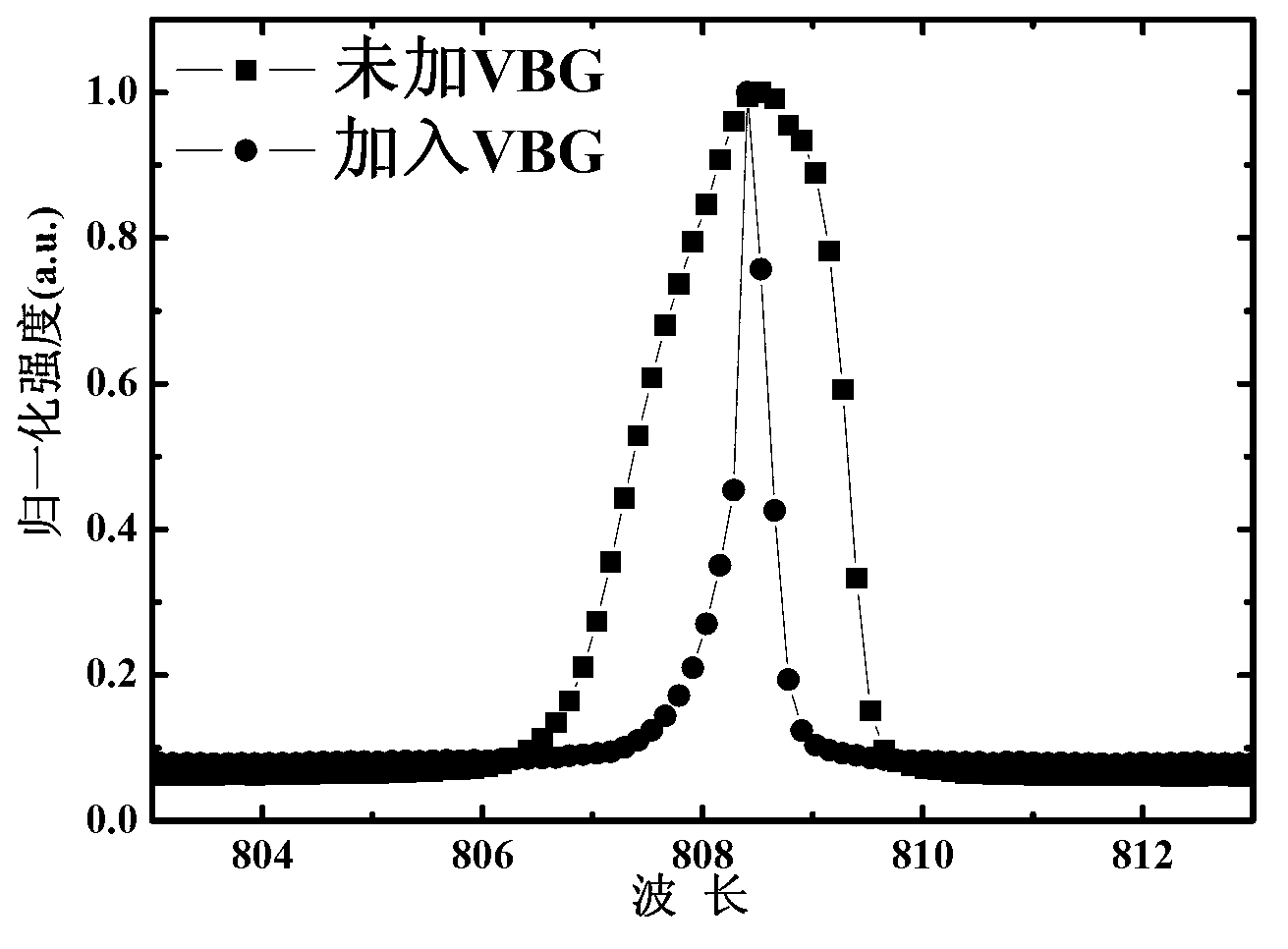

InactiveCN105428996ASimple structureImprove structural stabilitySemiconductor laser arrangementsLaser output parameters controlResonant cavityLight beam

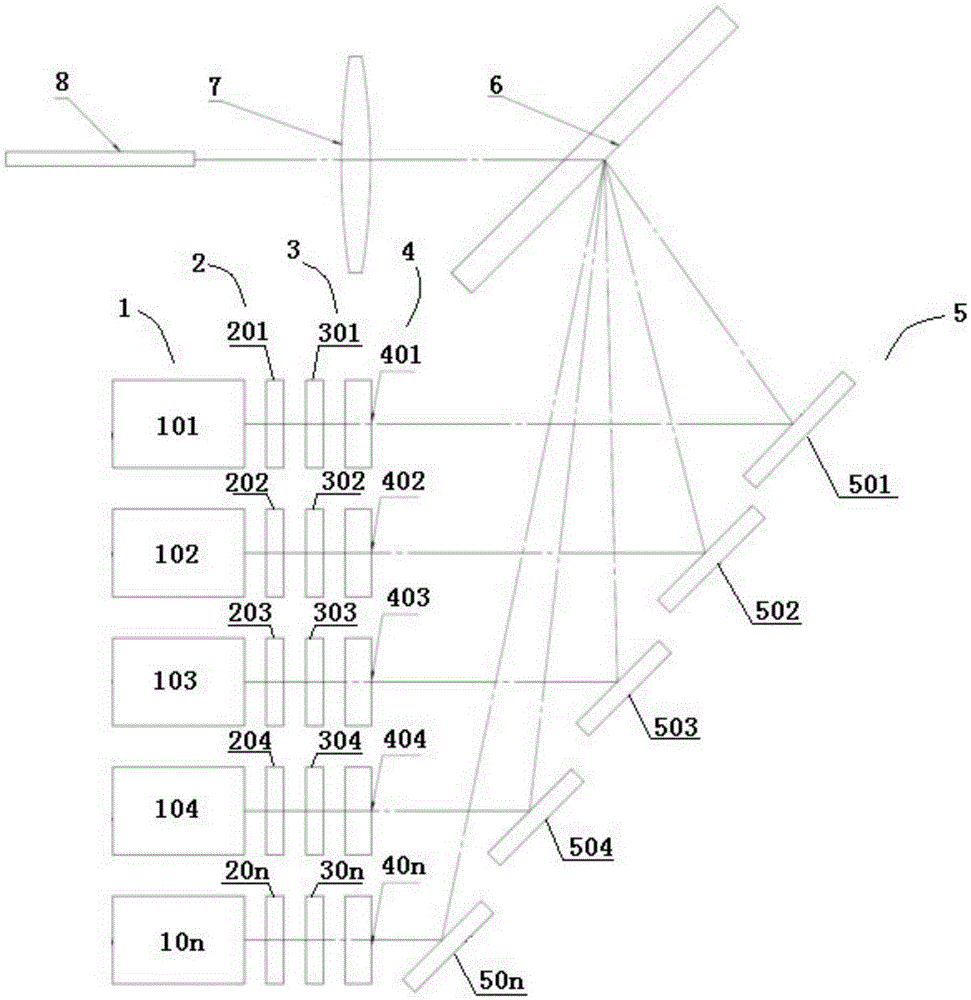

The invention discloses a multi-grating structure-based semiconductor laser beam combination device and beam combination method, relates to the field of semiconductor lasers and aims at solving the problem that existing device and method are poor in quality of semiconductor laser-combined beams. A semiconductor laser group in the device sends out combined beams which are the same in outgoing direction; the combined beams enter a volume Bragg grating group after the actions of a fast-axis collimating lens group and a slow-axis collimating lens group; one part of beams are reflected to corresponding semiconductor lasers to achieve locking of output wavelengths of the semiconductor laser group; the other part of beams enter corresponding reflectors, enter diffraction gratings for overlapping at different incident angles after being reflected through a reflector group, and are diffracted at the same diffraction angle; and outgoing beams of the semiconductor laser group are combined into one beam for outputting, and are coupled to a multi-mode optical fiber through a focus lens. A feedback resonant cavity is short in length; the structural stability is relatively high; assembly and adjustment are simple; and output powers of the semiconductor lasers are greatly improved under the premise of keeping relatively good beam quality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Volume Bragg grating laser mirror device

InactiveUS20080187019A1Improve featuresSimple designOptical resonator shape and constructionActive medium shape and constructionLength waveLaser

A volume Bragg grating (VBG) has a narrow wavelength. The wavelength is changed by changing an angle of the VBG or a temperature of the VBG. Thus, the present invention has a narrow wavelength, a bright laser, a simple system and an adjustable reflection for a wide application to laser systems.

Owner:NAT CENT UNIV

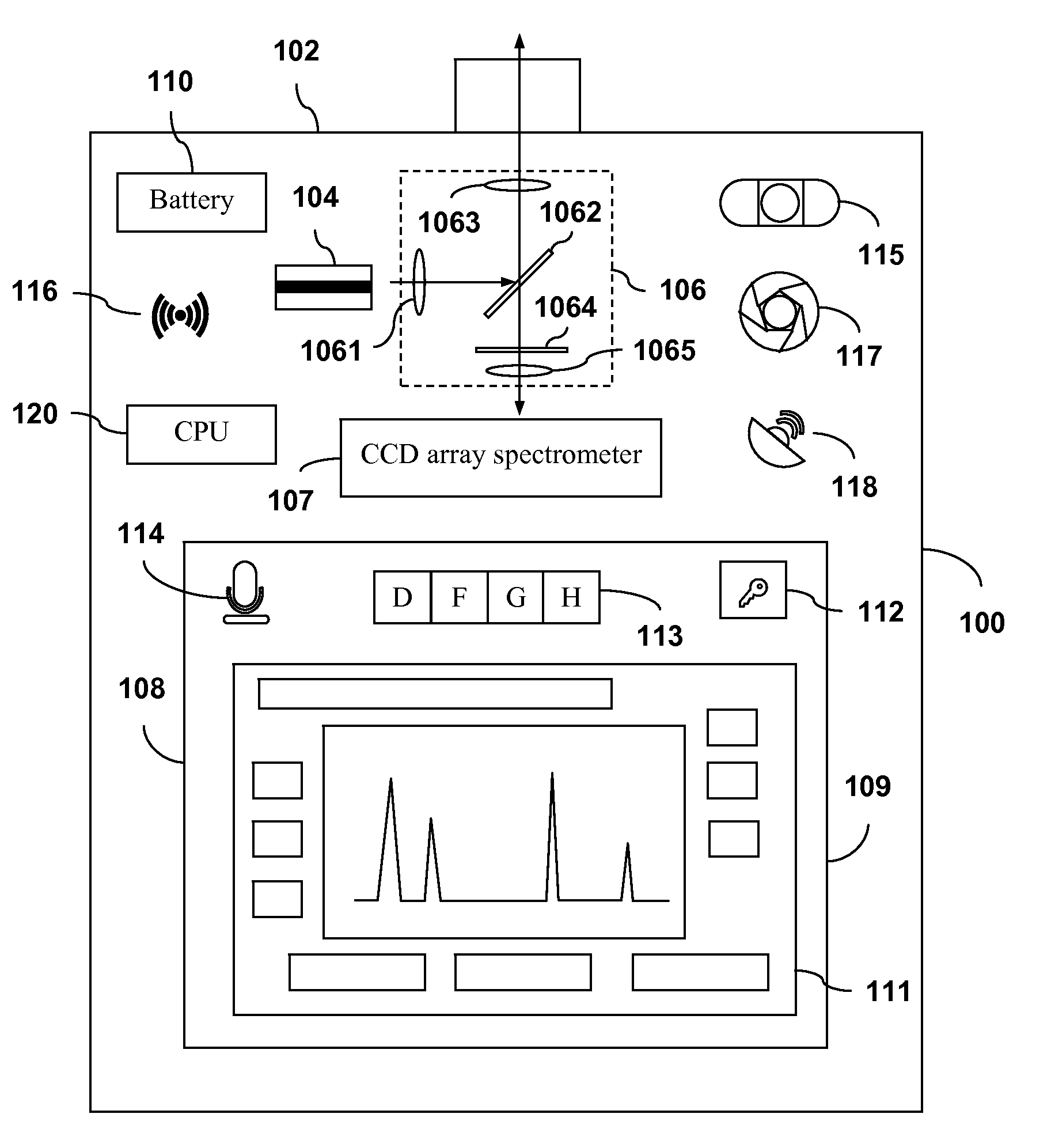

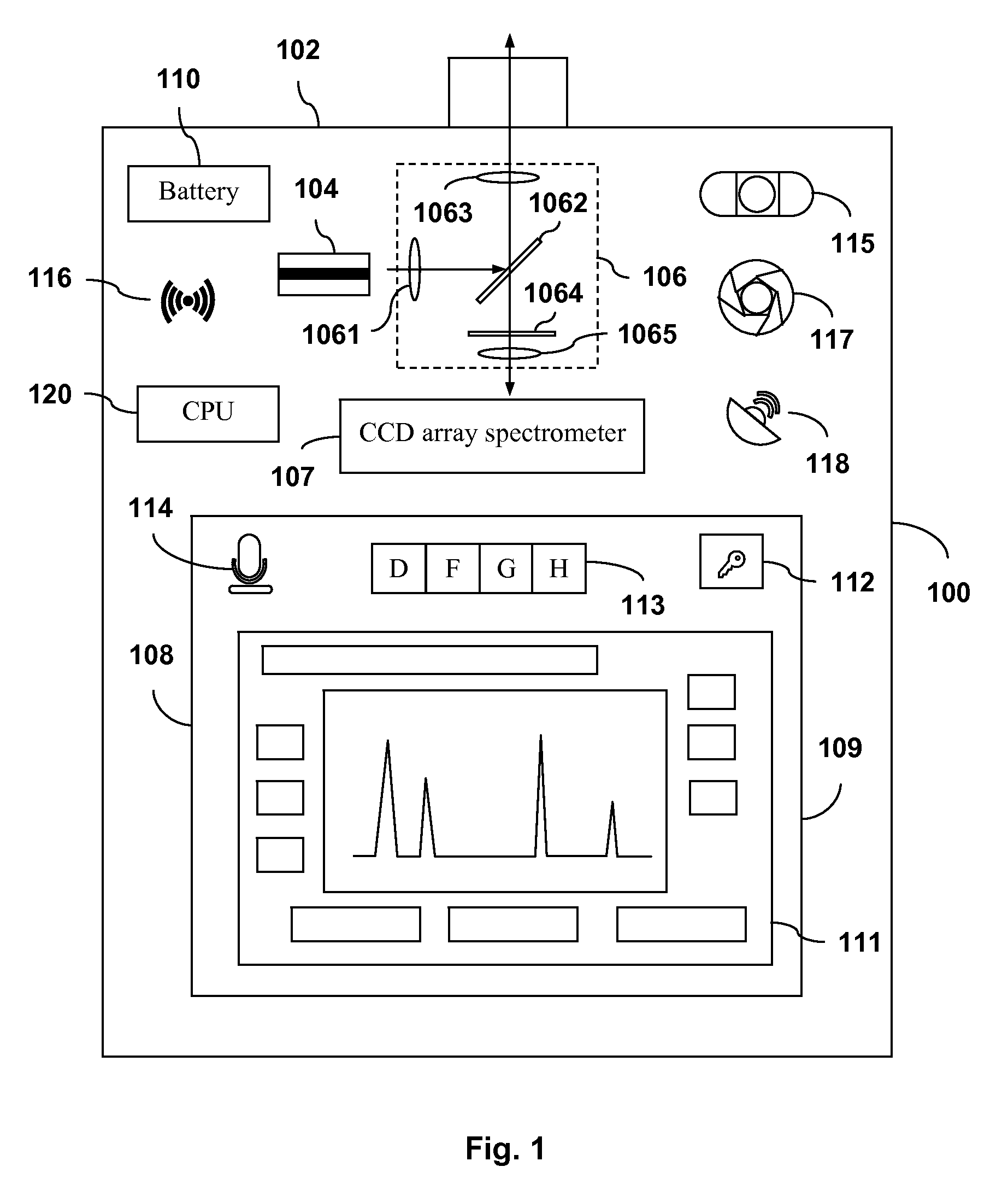

Handheld Raman spectrometer

ActiveUS8699020B1Increase brightnessEasy to useRadiation pyrometryRaman scatteringGratingDisplay device

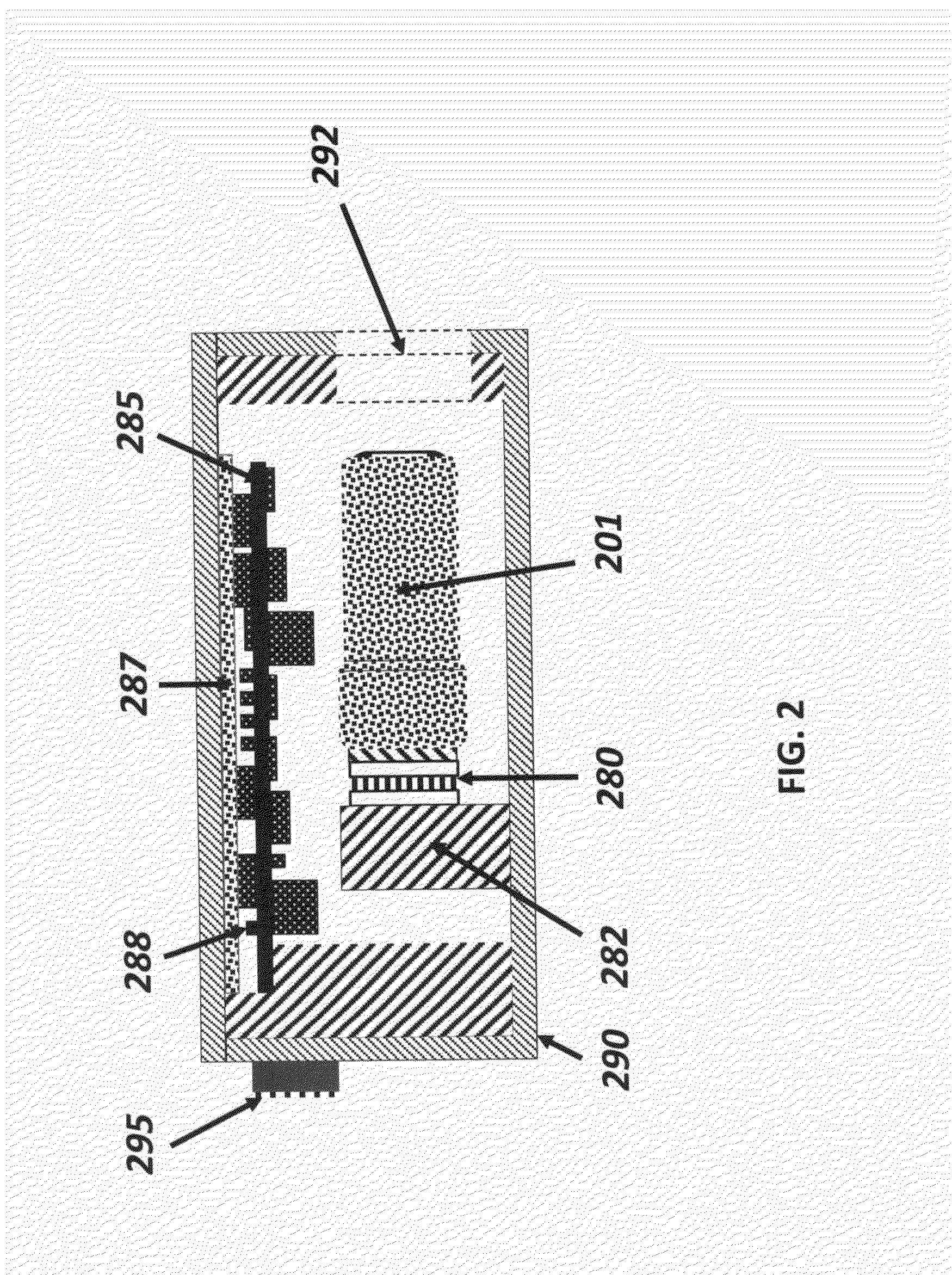

This invention discloses a handheld Raman spectrometer. The handheld Raman spectrometer comprises: (i) a handheld enclosure; (ii) a volume Bragg grating stabilized laser mounted in the handheld enclosure for producing laser light; (iii) a Raman probe for delivering the laser light to a subject to produce Raman scattered light from the subject and collecting the Raman scattered light; (iv) a spectrometer mounted in the handheld enclosure for measuring the Raman scattered light and obtaining a Raman spectrum; (v) a high brightness display mounted in the handheld enclosure for displaying the obtained Raman spectrum; (vi) a multi-touch screen mounted on top of the high brightness display for receiving user inputs; (vii) a central processing unit mounted in the handheld enclosure for processing user inputs and controlling operation of the handheld Raman spectrometer; and (viii) a user interface based on the high brightness display, the multi-touch screen, and the central processing unit, the user interface is programmed to be capable to respond to user inputs incurring at least two points of contact with the multi-touch screen.

Owner:METROHM SPECTRO INC

Stretching and compression of laser pulses by means of high efficiency volume diffractive gratings with variable periods in photo-thermo-refractive glass

InactiveUS7424185B2High damage thresholdIncrease powerLaser using scattering effectsPhotomechanical apparatusFemto second laserUltrashort laser

High efficiency reflective volume Bragg gratings with chirped gratings recorded in photo-thermo-refractive glass having an absolute diffraction efficiency exceeding 95% in transmitting and reflecting modes are used to stretch and / or compress ultrashort laser pulses with high efficiency. Robustness, compactness, thermal and laser stability along with placement of multiple elements in the same space provides femtosecond laser system with high efficiency of stretching and re-compression of femtosecond pulses.

Owner:RGT UNIV OF MICHIGAN +1

Apparatus and methods for altering a characteristic of light-emitting device

ActiveUS20060251143A1High damage thresholdLarge clear apertureLaser optical resonator constructionSemiconductor laser arrangementsGratingLight emitting device

Apparatus and methods for altering one or more spectral, spatial, or temporal characteristics of a light-emitting device are disclosed. Generally, such apparatus may include a volume Bragg grating (VBG) element that receives input light generated by a light-emitting device, conditions one or more characteristics of the input light, and causes the light-emitting device to generate light having the one or more characteristics of the conditioned light.

Owner:NECSEL INTPROP

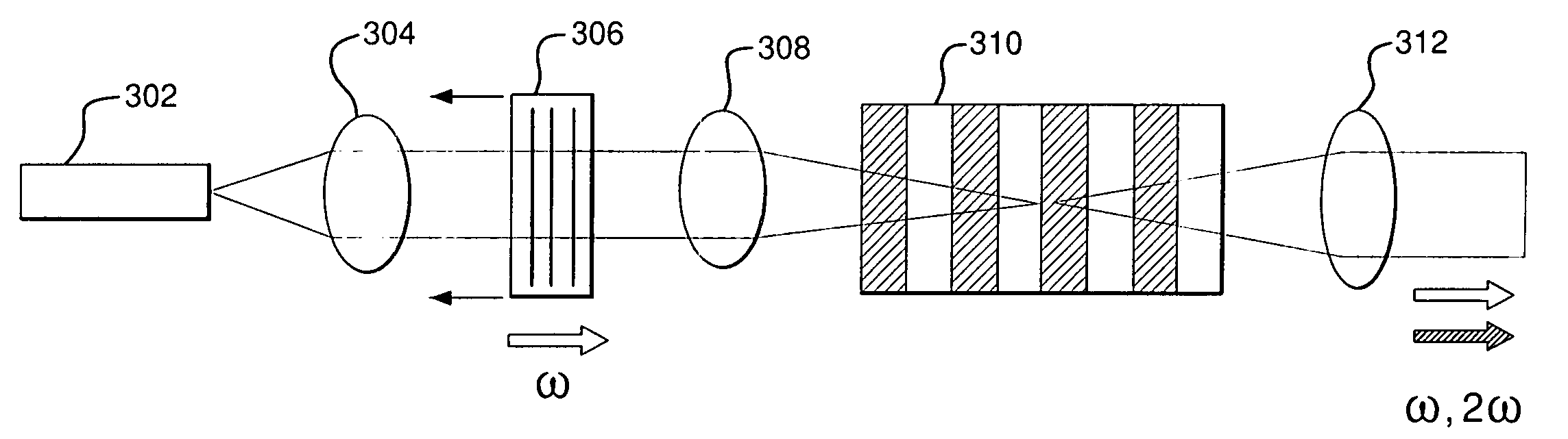

Laser module allowing direct light modulation and laser display employing the same

ActiveUS20080031289A1Laser detailsSemiconductor laser optical deviceExternal cavity laserDisplay device

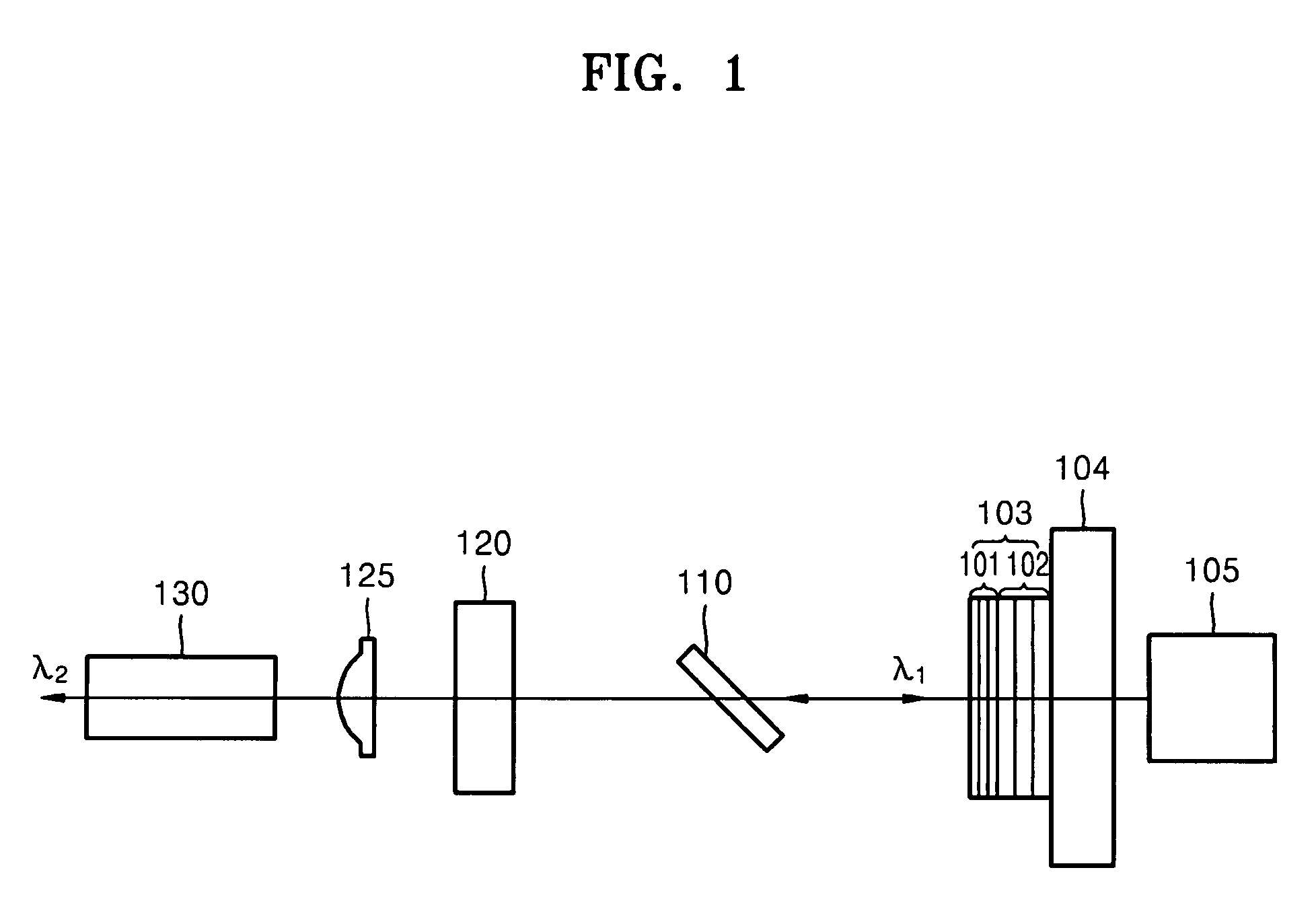

Provided are a laser module allowing direct light modulation and a laser display employing the laser module. The laser module may include a semiconductor chip, a Volume Bragg Grating (VBG), a pump laser and a non-linear optical element. The semiconductor chip includes an active layer generating light of primary wavelength and a reflective layer providing the generated light to a cavity and reflecting the light within the cavity. The VBG may output light repeatedly reflected between the reflective layer and the VBG. The non-linear optical element disposed outside a cavity between the semiconductor chip and the VBG may convert the light of a first wavelength emitted from the active layer into light of a second wavelength different from the first wavelength. The laser module having the above-mentioned construction uses an external cavity laser and a non-linear optical element to achieve direct light modulation.

Owner:SAMSUNG ELECTRONICS CO LTD

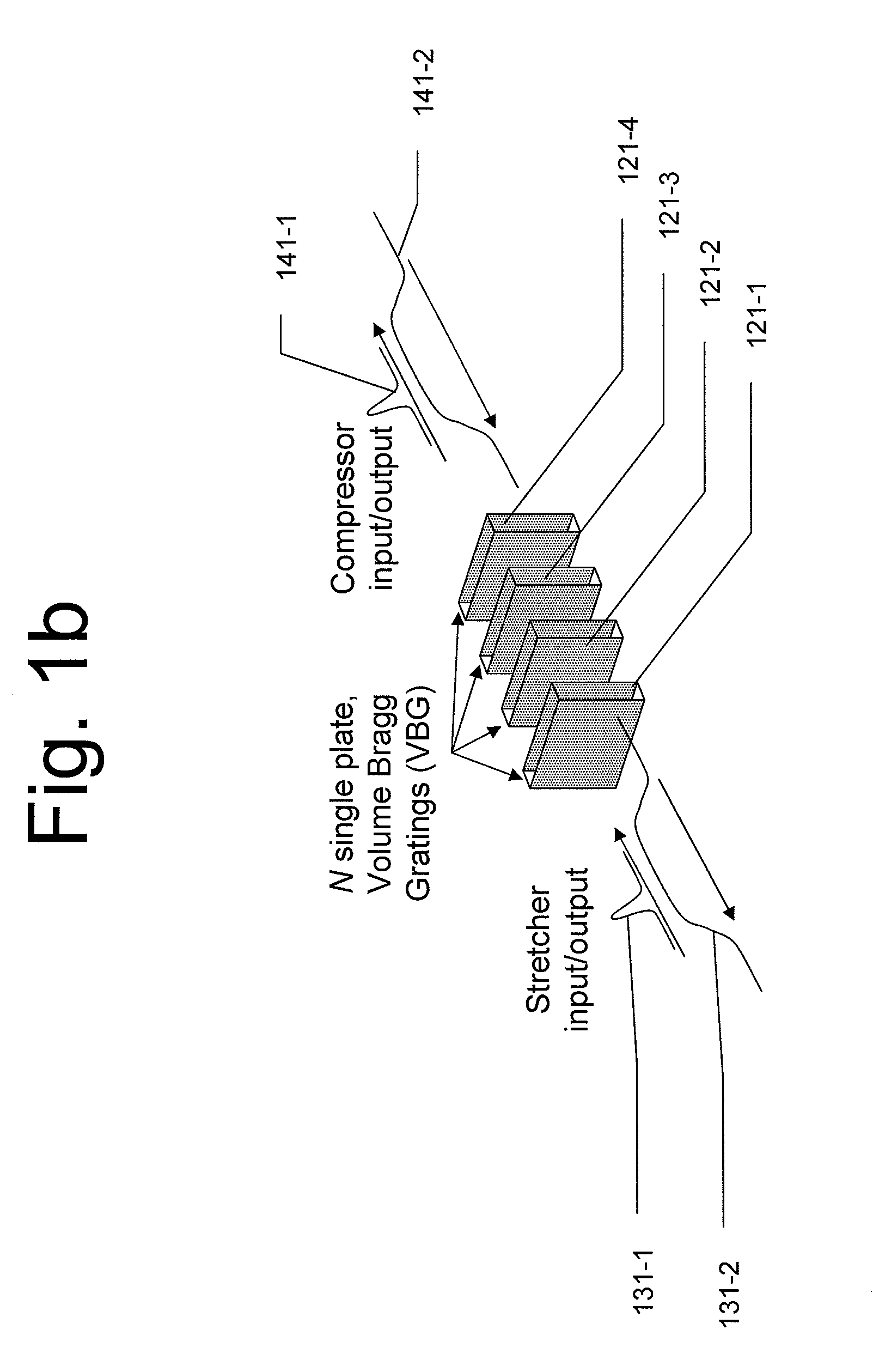

Multi-plate composite volume bragg gratings, systems and methods of use thereof

InactiveUS20110038390A1Increase powerLarge stretch factorLaser detailsDiffraction gratingsGratingChirped pulse amplification

Variations of composite volume Bragg grating devices and methods for creating same are disclosed. Also, variations of chirped pulse amplification laser systems, and system portions, that make use of a composite volume Bragg grating device for pulse stretching and / or compression are disclosed.

Owner:LOCKHEED MARTIN CORP

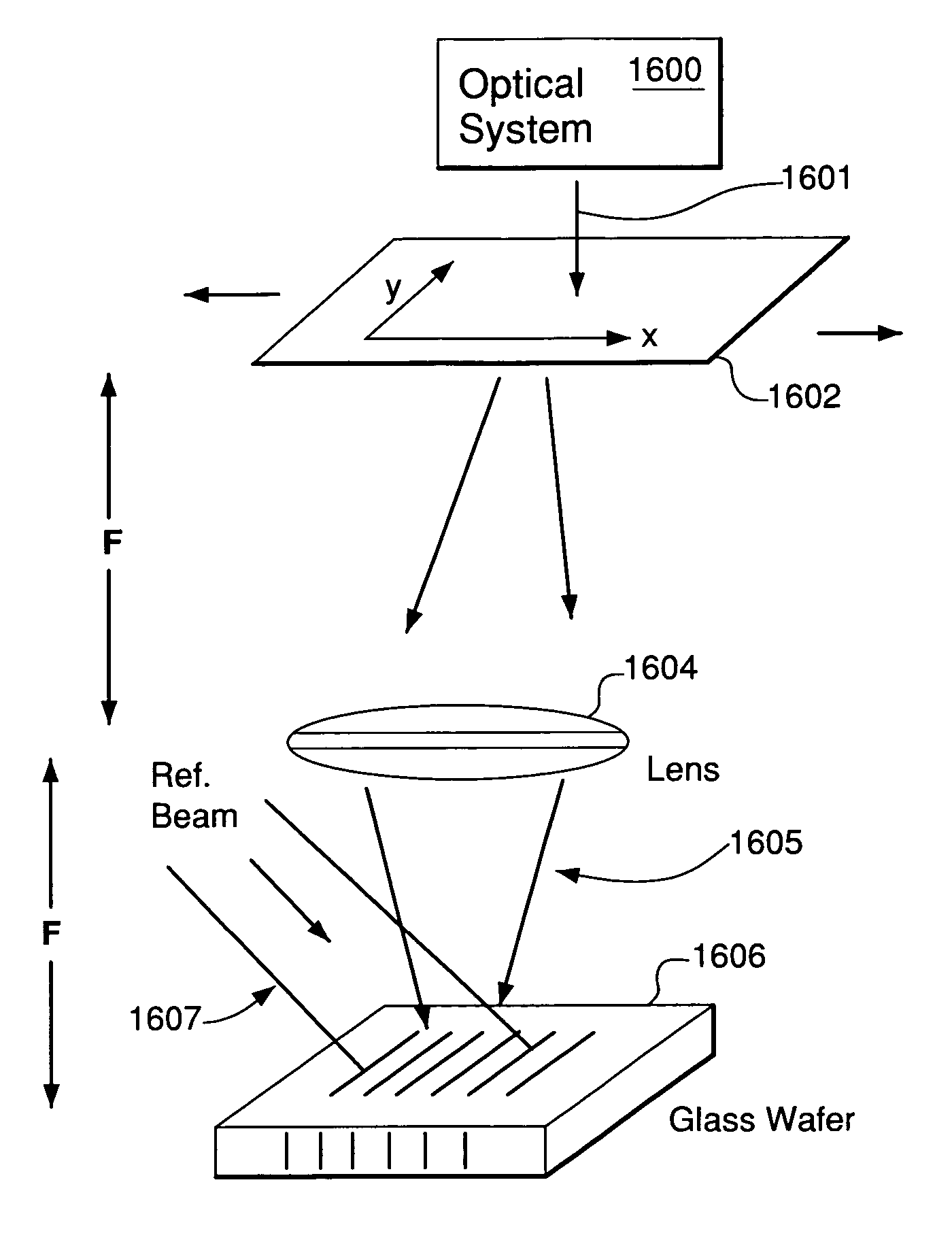

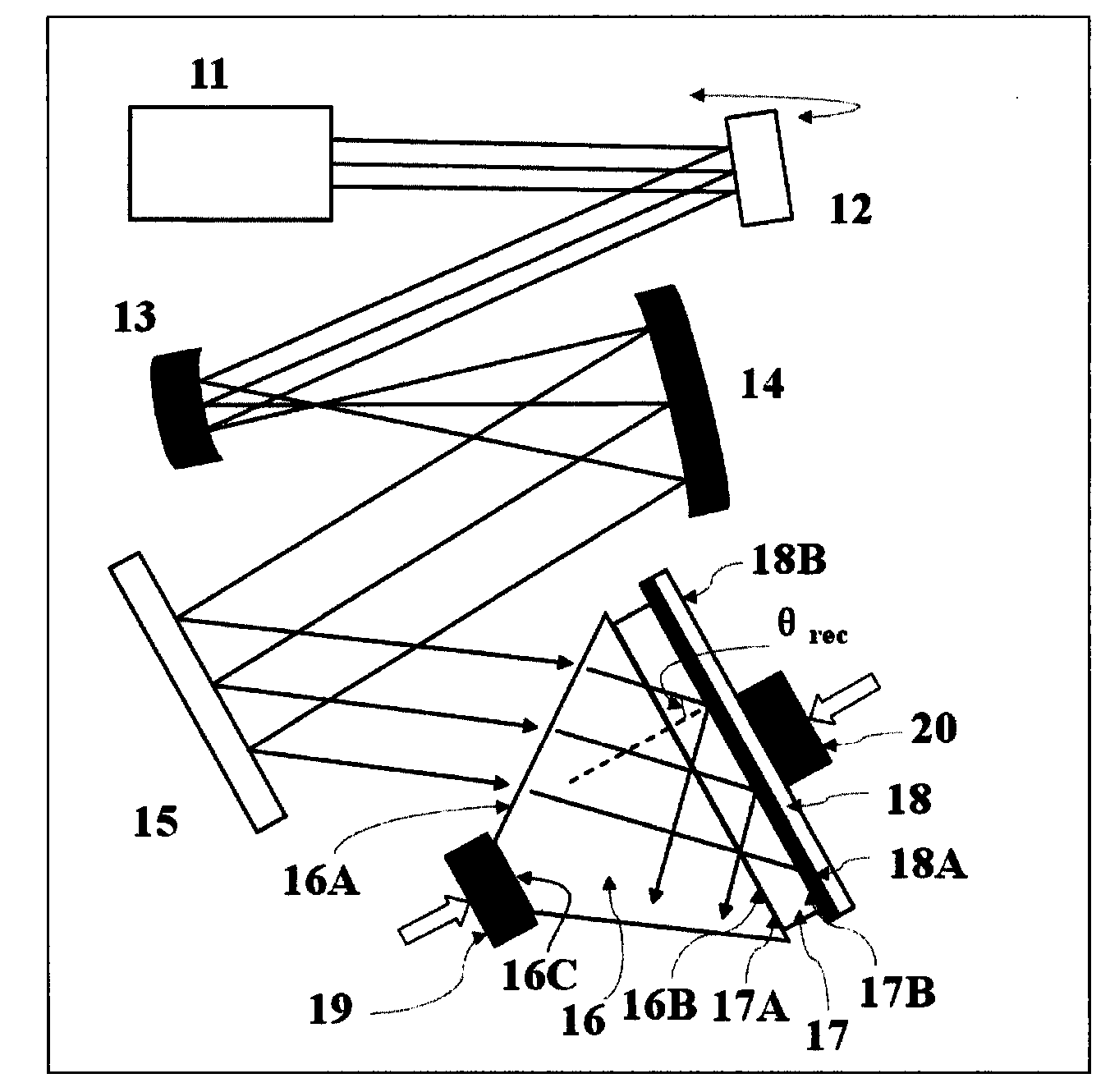

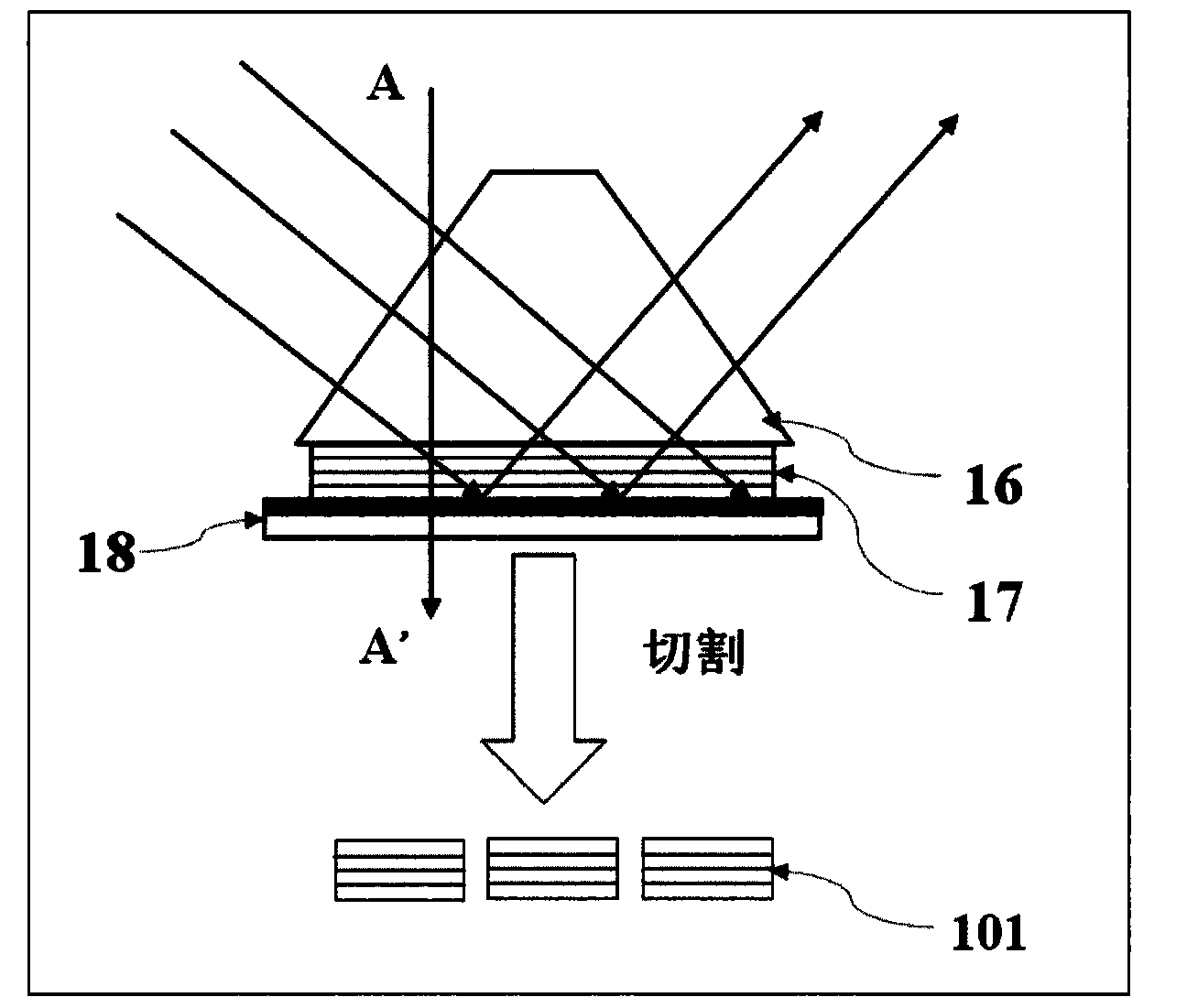

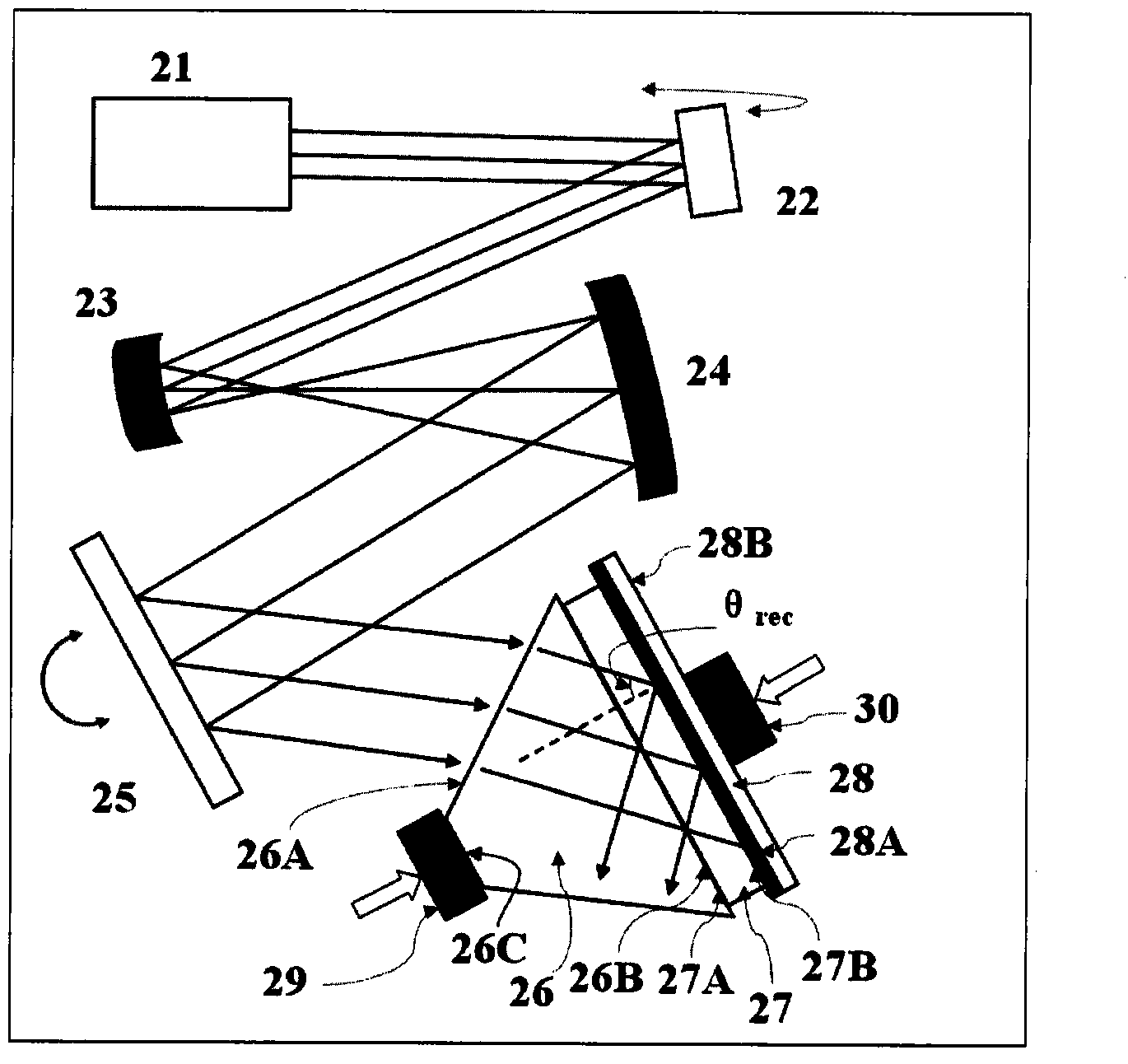

Method for manufacturing multi-wavelength volume bragg gratings

ActiveCN104133267AEasy to fixThe production process is simple and practicalCladded optical fibrePhotomechanical apparatusGratingUltraviolet lights

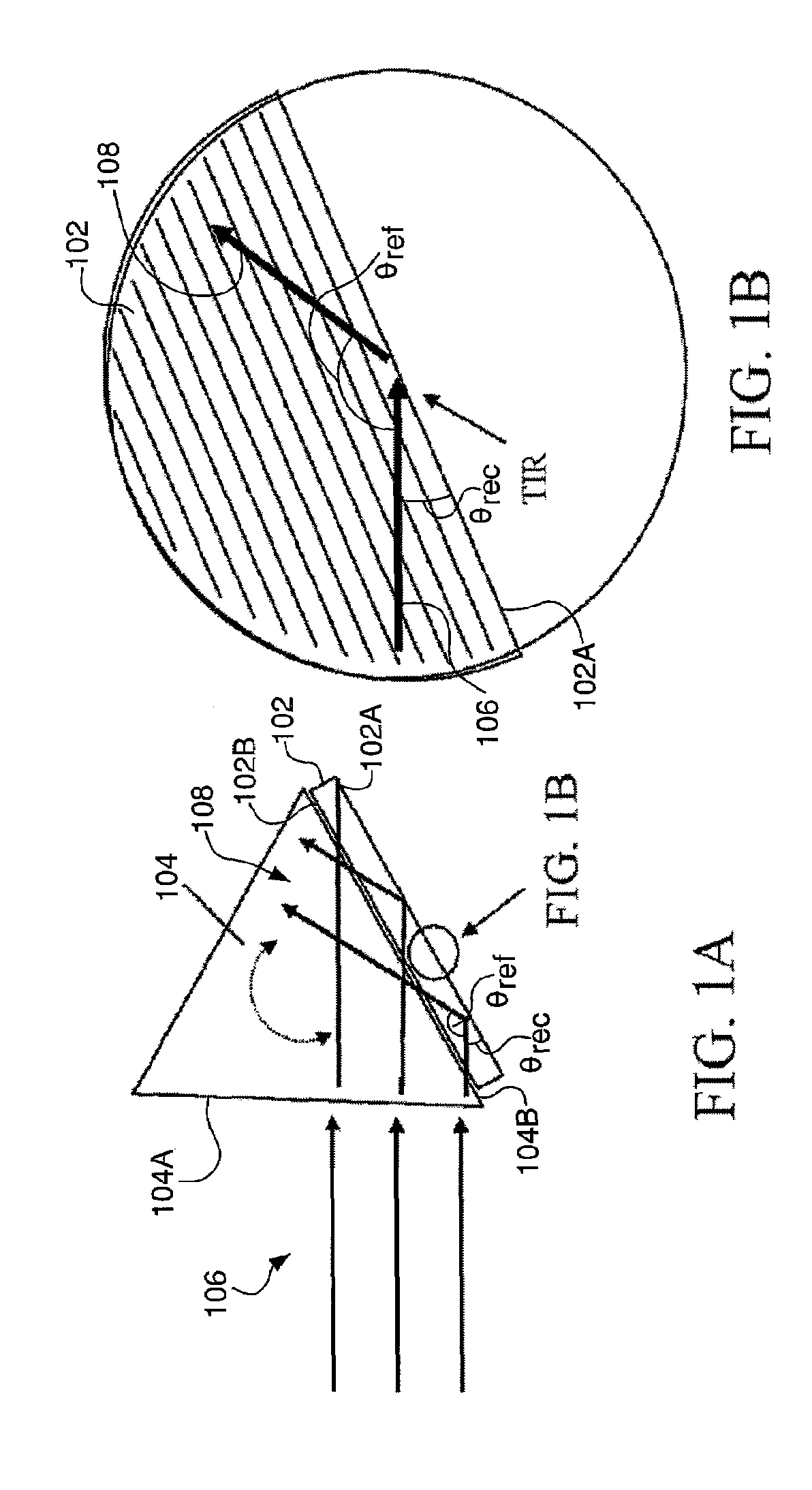

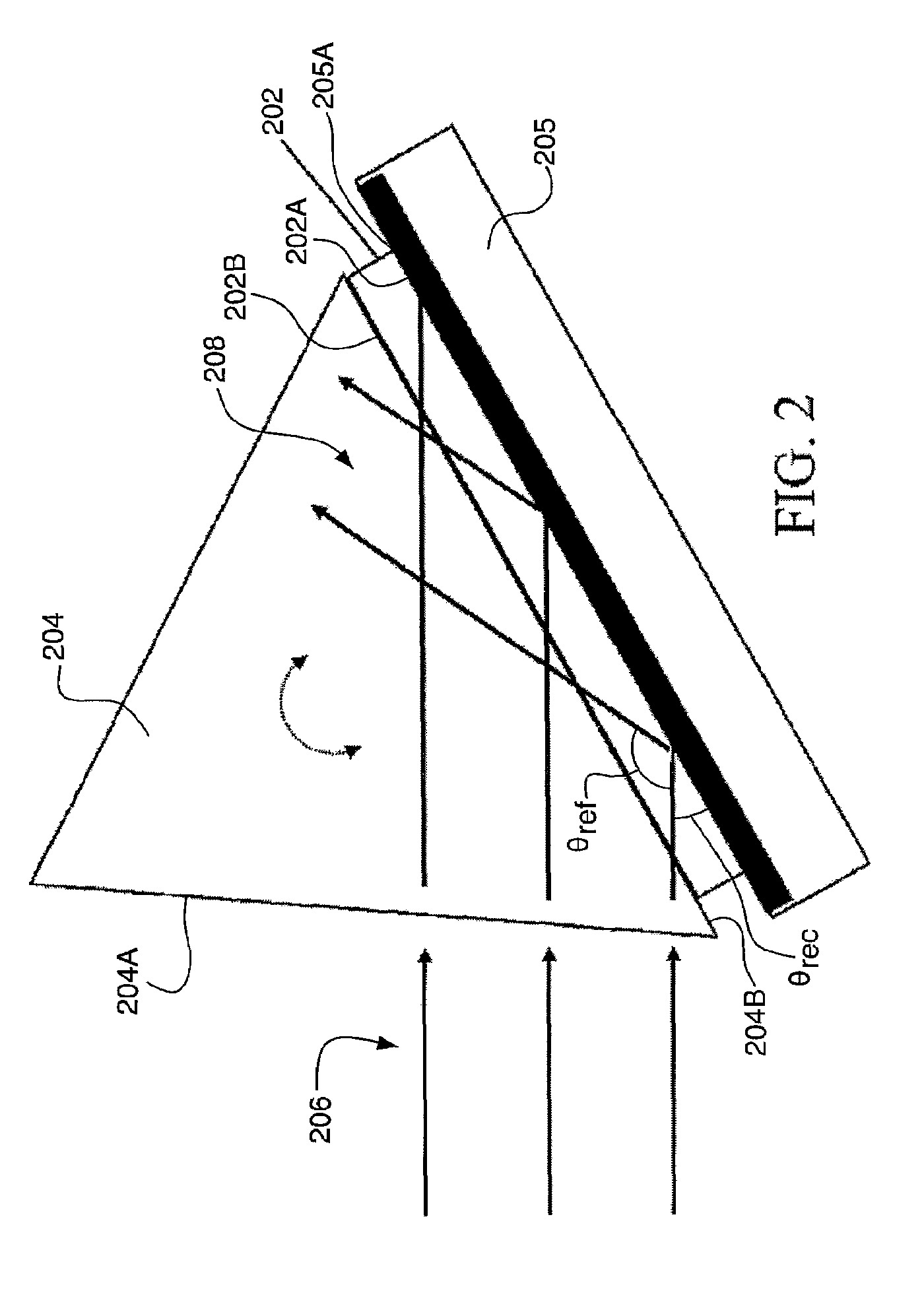

The invention relates to a method for manufacturing multi-wavelength VBGs. The method particularly includes the steps that an ultraviolet light passes through a trapezoid prism to irradiate photosensitive dielectric PTR glass; incoming recording light is reflected through an auxiliary optical flat or the PTR glass, the reflected recording light and the incoming recording light are intervened in the PTR glass to form standing waves; the wavelength of a tuning laser source or a rotary laser reflection element enables the incoming angle of the recording light to be changed, and exposure in different periods is achieved; heat processing and cutting are carried out on the PTR glass obtained after exposure, and the multi-wavelength VBGs are finally obtained. The method for manufacturing the multi-wavelength VBGs is concise and practical, continuous tuning of the VBG working wavelength can be achieved under the condition that a recording device is kept unchanged; the clear aperture of the manufactured VBGs is not limited by sample absorption or other kinds of performance of materials; incoming of only one beam of recording light is needed, so that the recoding device is greatly simplified, and the large-amount efficient manufacturing of the VBGs is facilitated.

Owner:林安英 +1

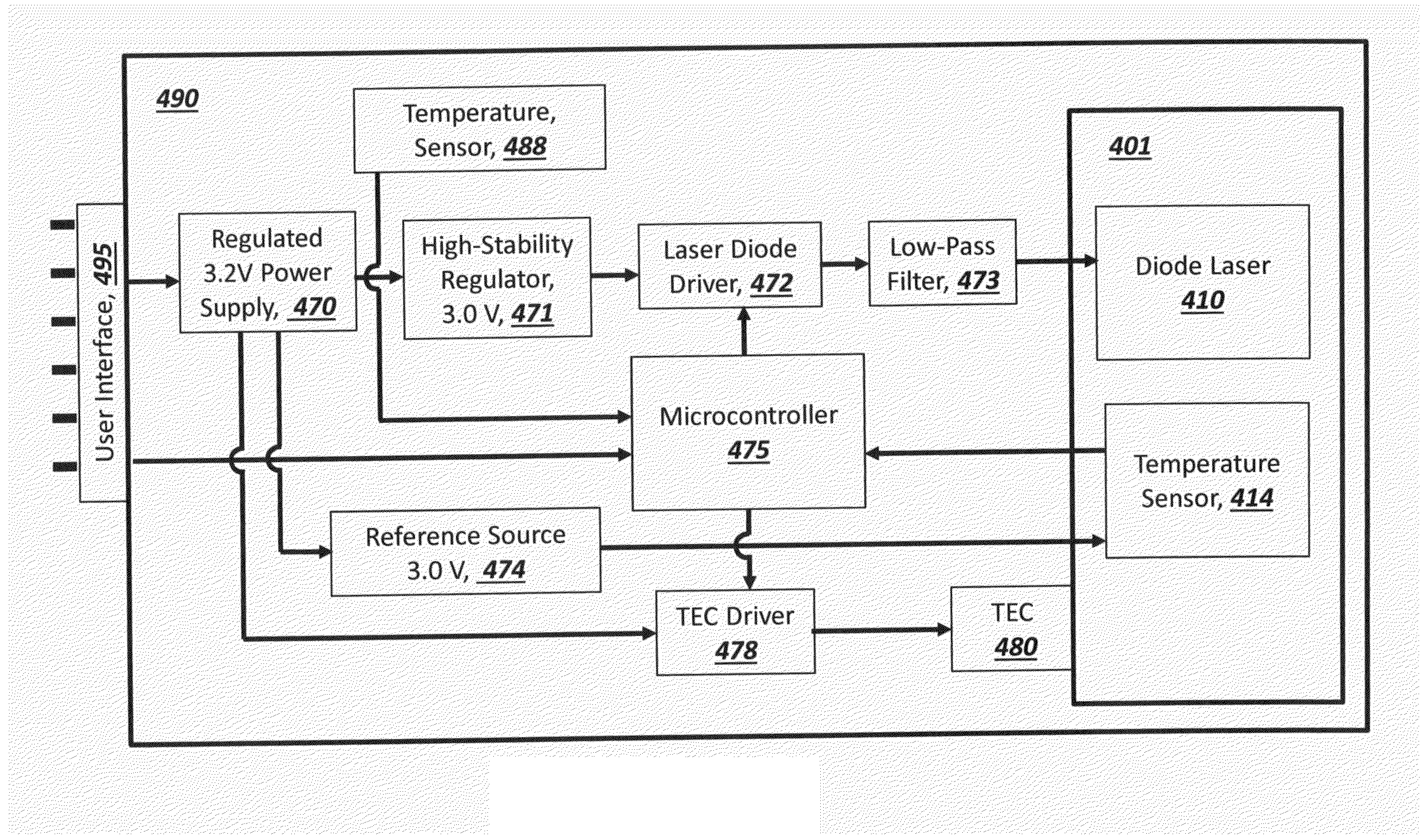

Wavelength-Stabilized Diode Laser

ActiveUS20140072004A1Improved wavelength stabilityReduced wavelength driftSemiconductor lasersLaser cooling arrangementsThermoelectric coolingBillionth

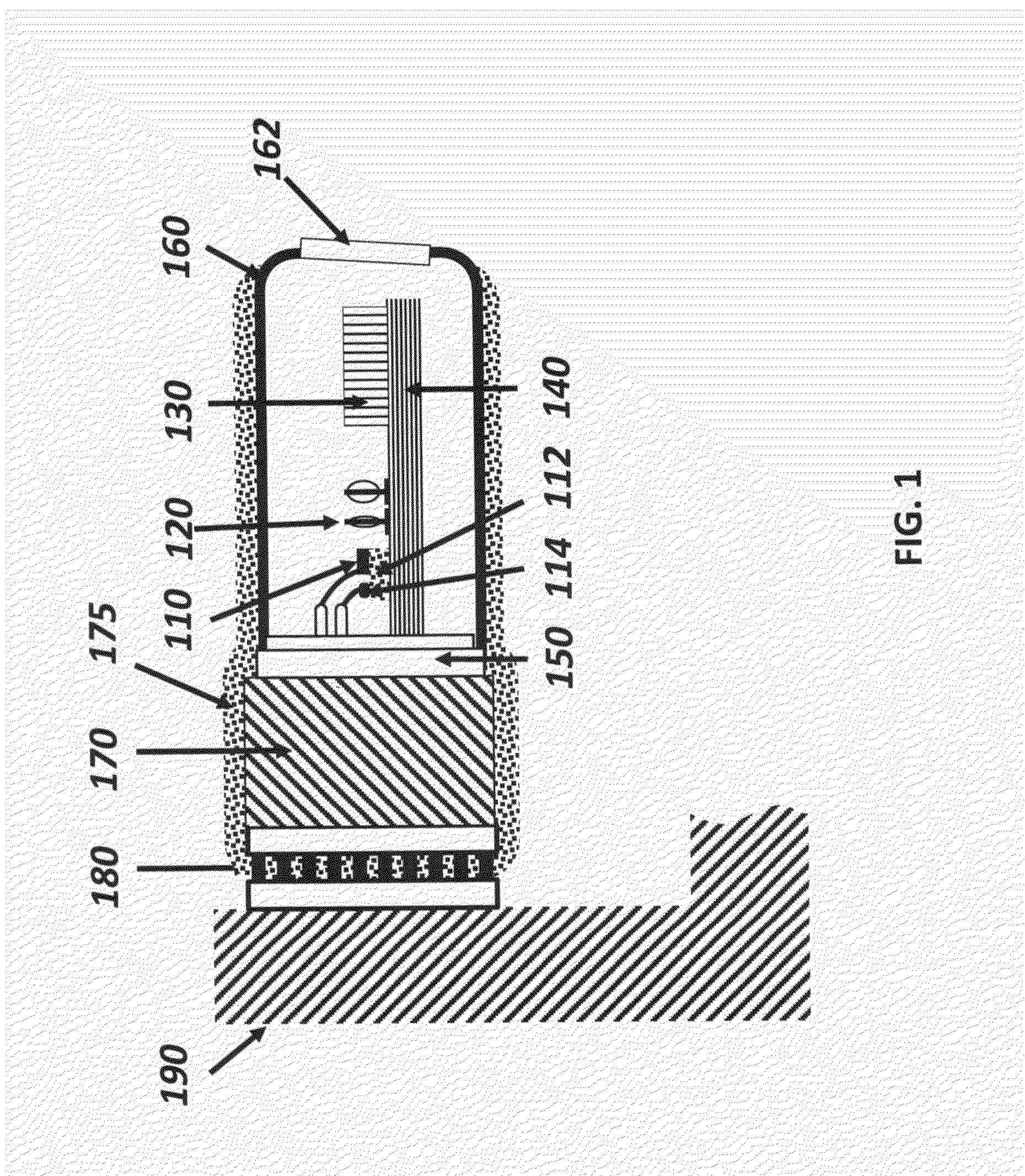

A hybrid external cavity laser (HECL) system comprises a diode laser, collection and collimation optics, and a volume Bragg grating, emits radiation at a single wavelength with a short-term wavelength stability in the order of at least one part in a billion The wavelength stability is achieved by use of a thermal management system, comprising inner and outer housings, each containing a temperature sensor, and electronic circuitry that monitors the temperatures and controls both the laser diode current and a thermoelectric cooler based on temperatures determined from said temperature sensors. The laser system is packaged in a compact enclosure that minimizes waste heat, facilitating use in applications that have heretofore employed stable, single-frequency lasers, including He—Ne lasers.

Owner:INNOVATIVE PHOTONIC SOLUTIONS INC

Laser module allowing direct light modulation and laser display employing the same

Provided are a laser module allowing direct light modulation and a laser display employing the laser module. The laser module may include a semiconductor chip, a Volume Bragg Grating (VBG), a pump laser and a non-linear optical element. The semiconductor chip includes an active layer generating light of primary wavelength and a reflective layer providing the generated light to a cavity and reflecting the light within the cavity. The VBG may output light repeatedly reflected between the reflective layer and the VBG. The non-linear optical element disposed outside a cavity between the semiconductor chip and the VBG may convert the light of a first wavelength emitted from the active layer into light of a second wavelength different from the first wavelength. The laser module having the above-mentioned construction uses an external cavity laser and a non-linear optical element to achieve direct light modulation.

Owner:SAMSUNG ELECTRONICS CO LTD

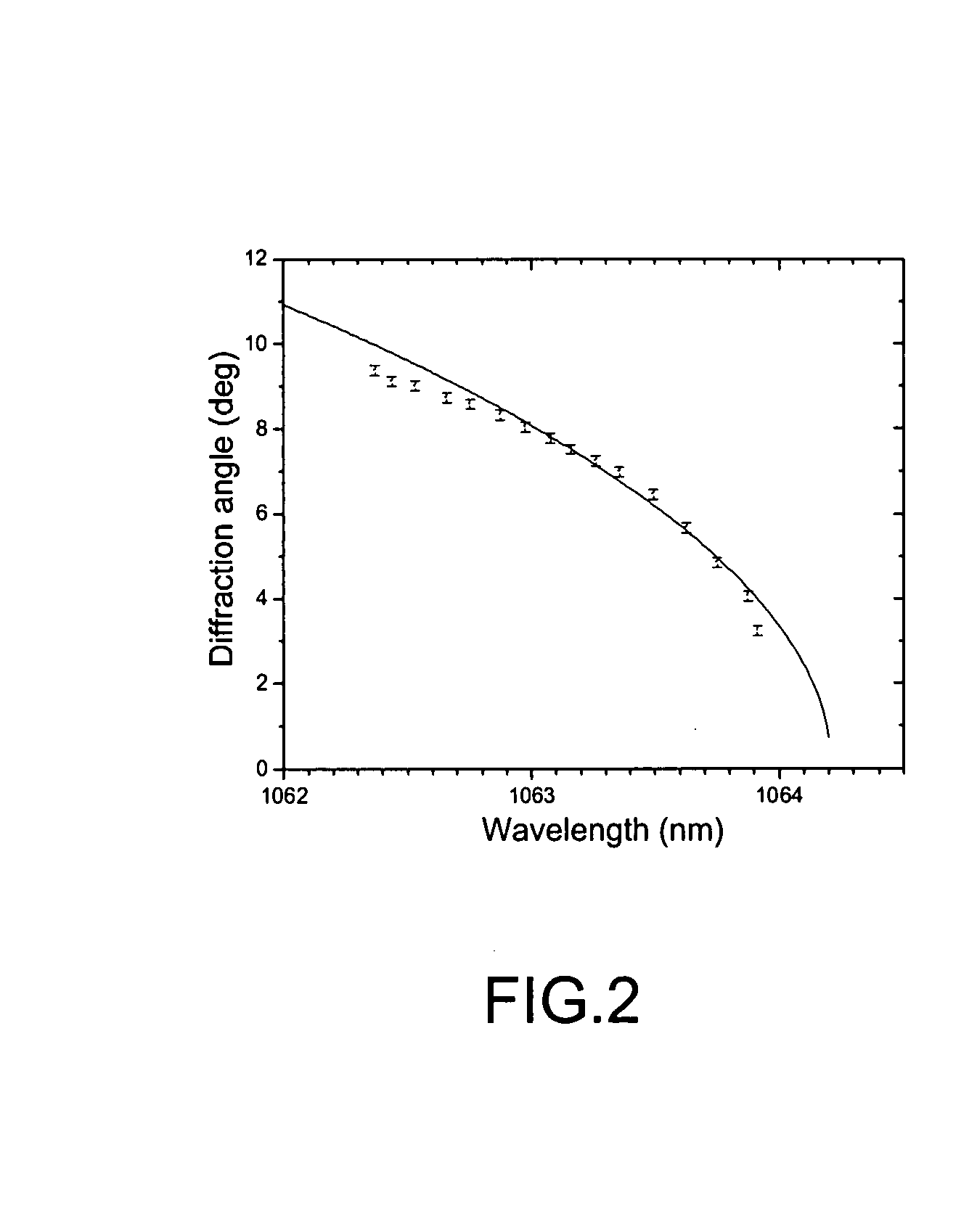

Volume Moiré Bragg gratings in a photosensitive material

Complex spectral and angular diffractive optical elements in photosensitive materials based on Moiré pattern are proposed and demonstrated. The process is based on the recording of multiple volume Bragg gratings with controlled difference of the periods in the same volume of photosensitive material. Filters with ultra-narrow bandpass in the range of a few picometers to a few tens of picometers or apodized diffractive optical elements across large aperture are demonstrated. Several methods to fabricating such Moiré Bragg gratings are proposed. Experimental demonstration of a Moiré ultra-narrowband diffractive optical element in PTR glass is performed.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

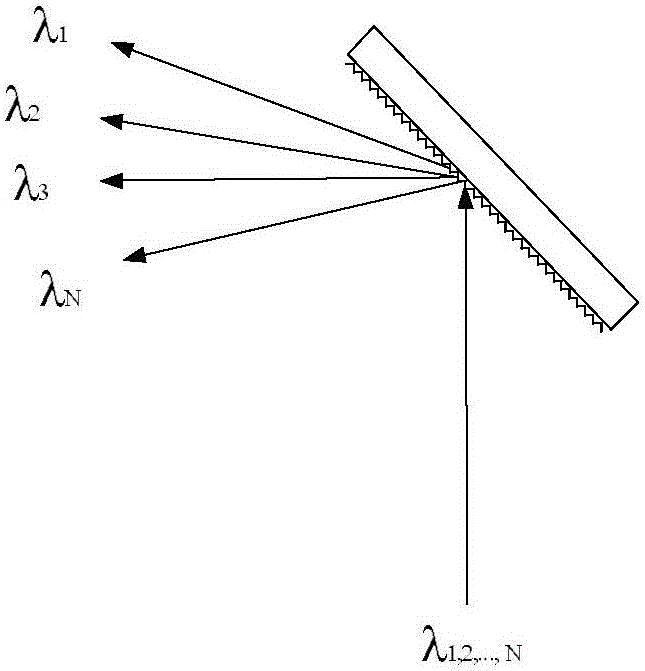

Multi-wavelength laser beam combination system

InactiveCN105892067AEasy to operateWork won't breakLaser optical resonator constructionSemiconductor laser arrangementsGratingLaser beams

The invention discloses a multi-wavelength laser beam combination system, comprising tube cores (1) of a plurality of semiconductor lasers, and a fast axis collimation lens (2), a volume Bragg grating (VBG) (3), a fast-slow axis collimation lens (4), a holographic grating (5) and a beam transforming lens set (6) arranged on an output light path of the semiconductor laser tube cores. The system is characterized in that the fast-slow axis collimation lens (4) is placed on the back of the volume Bragg grating (3), so that laser beams from the semiconductor laser tube cores are diffracted to the same direction on +1-level diffraction fringes to realize semiconductor laser beam combination of the multiple tube cores (1). The beam combination technology improves the wavelength stability of each semiconductor laser tube core, and also improves the working stability of the whole system. The beam combination technology provides a new method and path for realizing a high-brightness and high-power direct semiconductor laser system.

Owner:WUHU ANRUI LASER TECH CO LTD

Methods for manufacturing volume Bragg grating elements

Owner:NECSEL INTPROP

Raman Spectroscopic Apparatus Utilizing Self-Aligned Non-Dispersive External Cavity Laser

InactiveUS20100315631A1Improved Spectral StabilityHigh spectral brightnessRadiation pyrometryRaman scatteringExternal cavity laserGrating

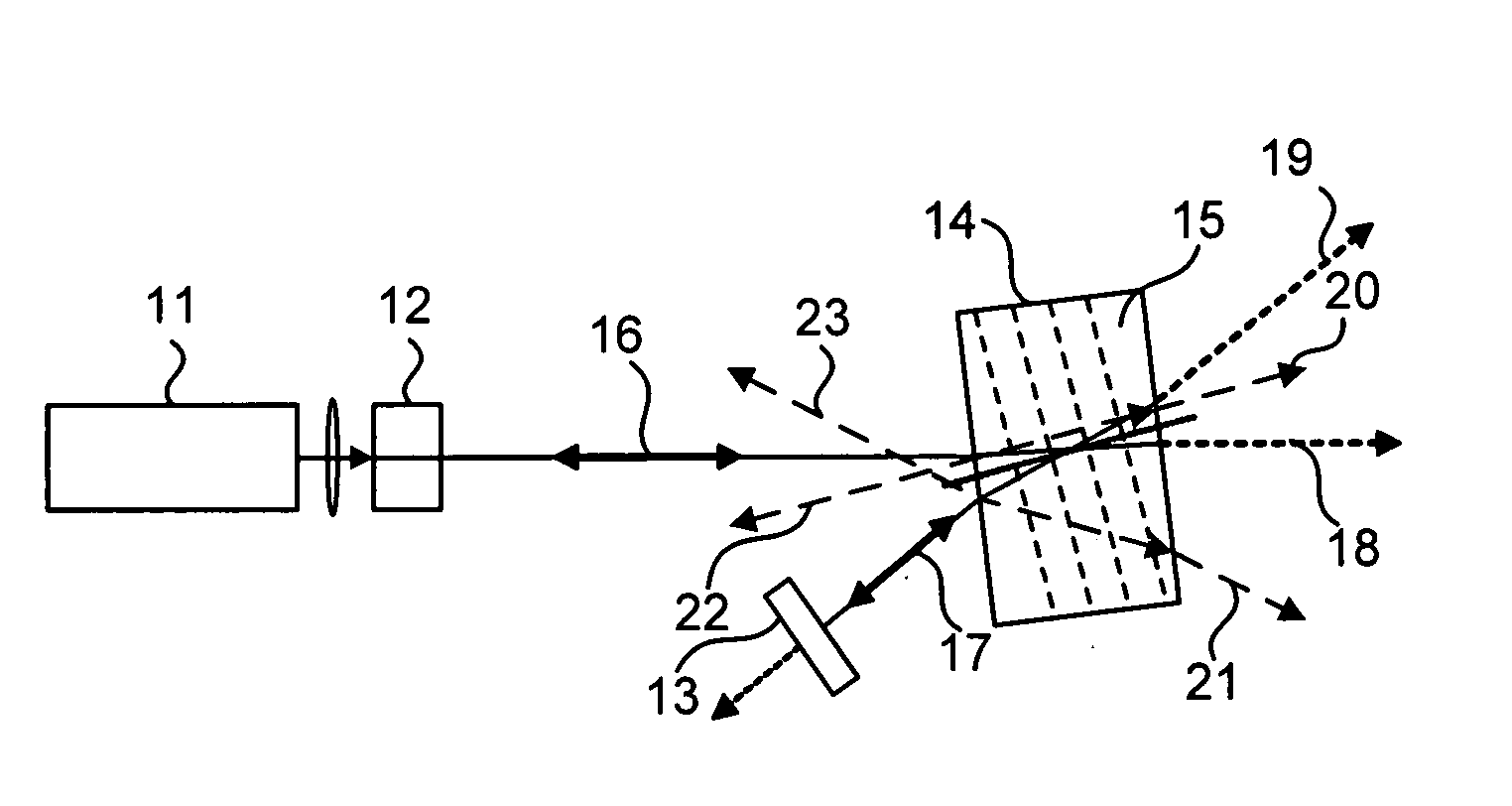

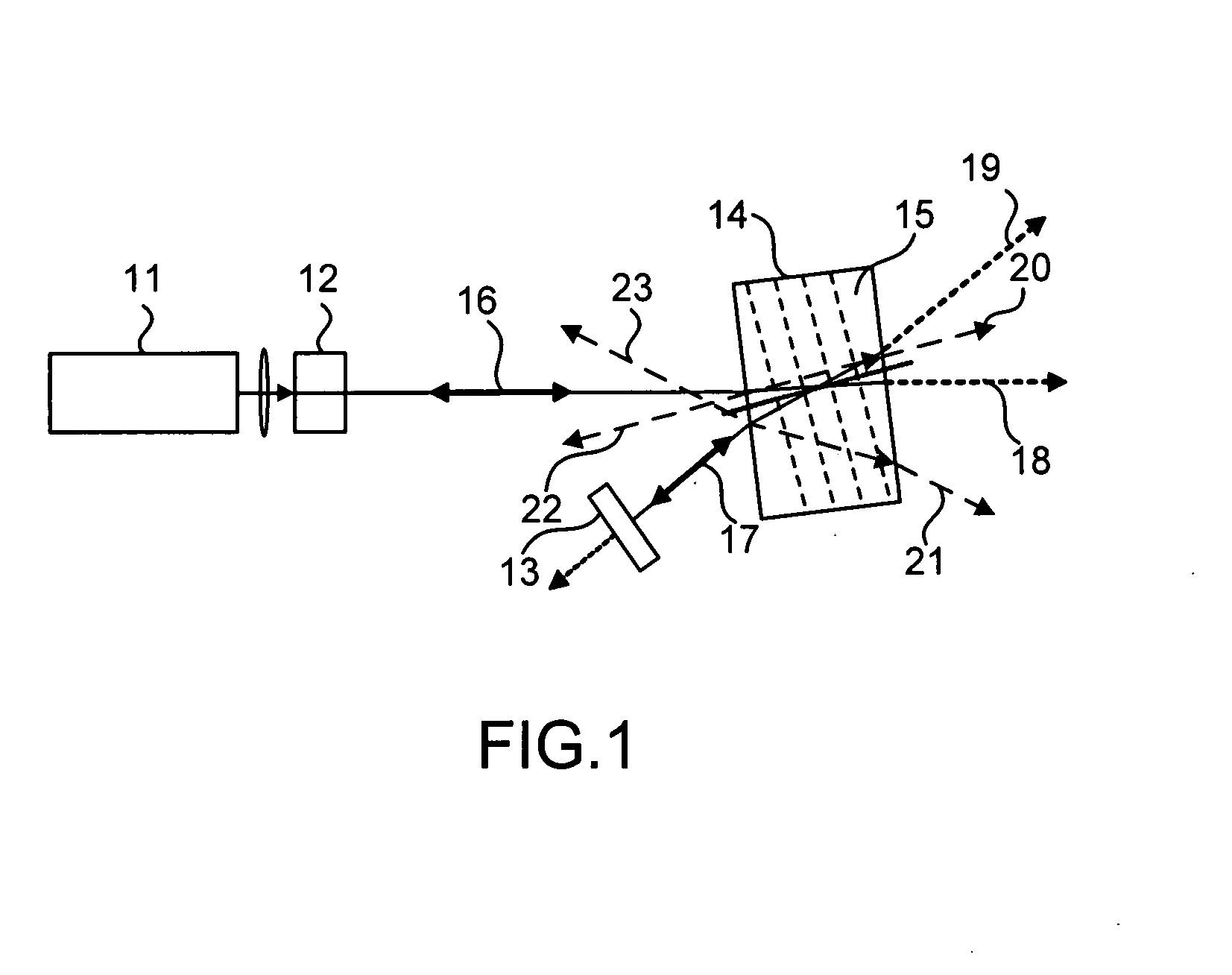

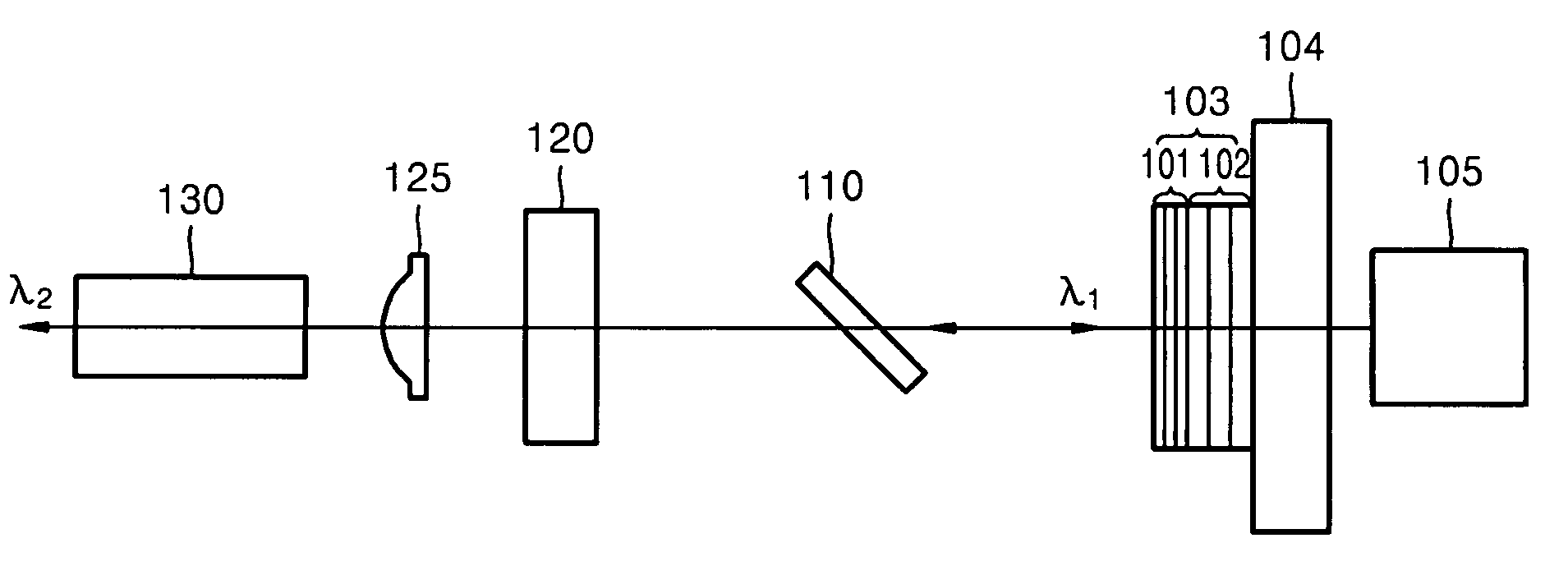

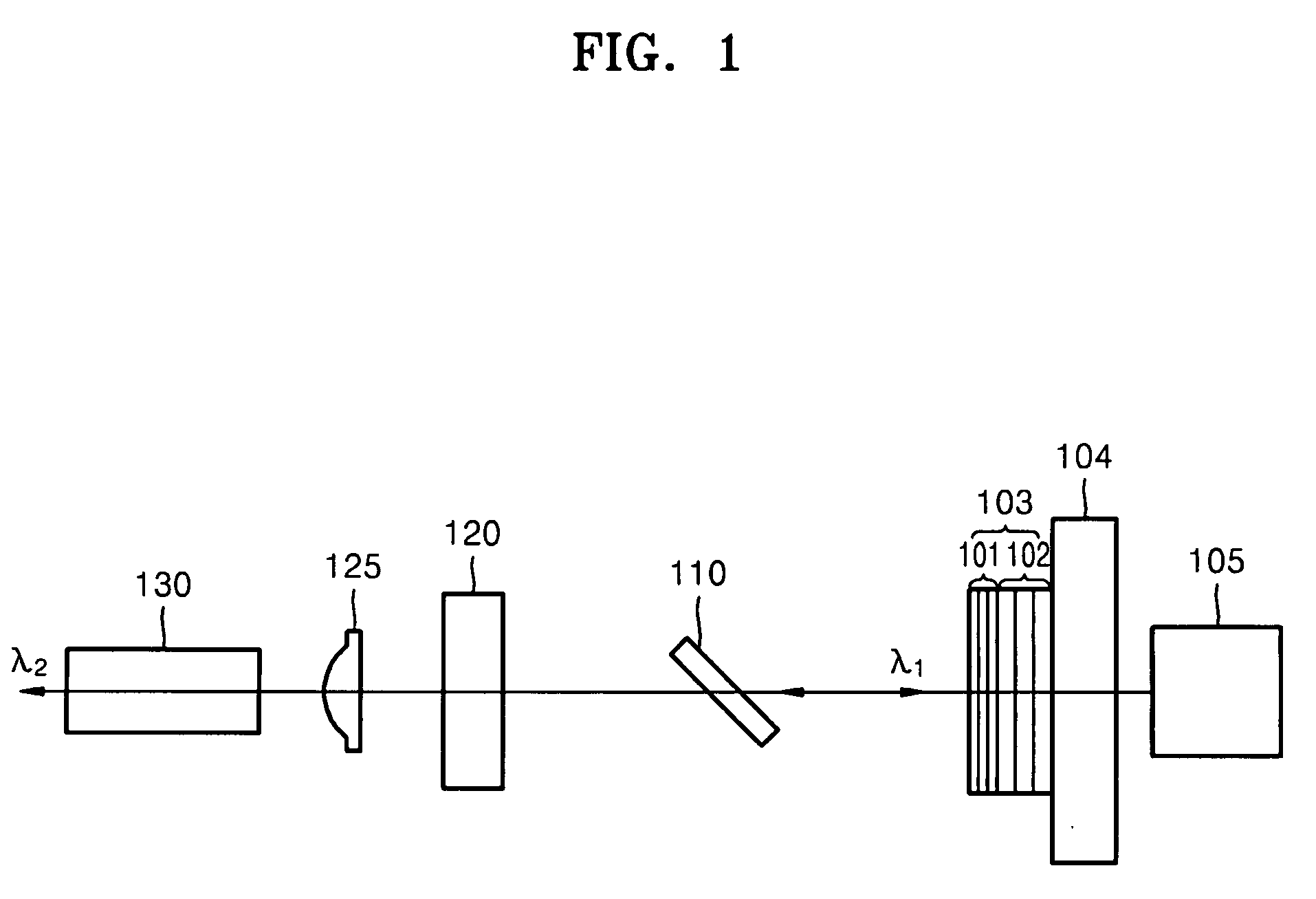

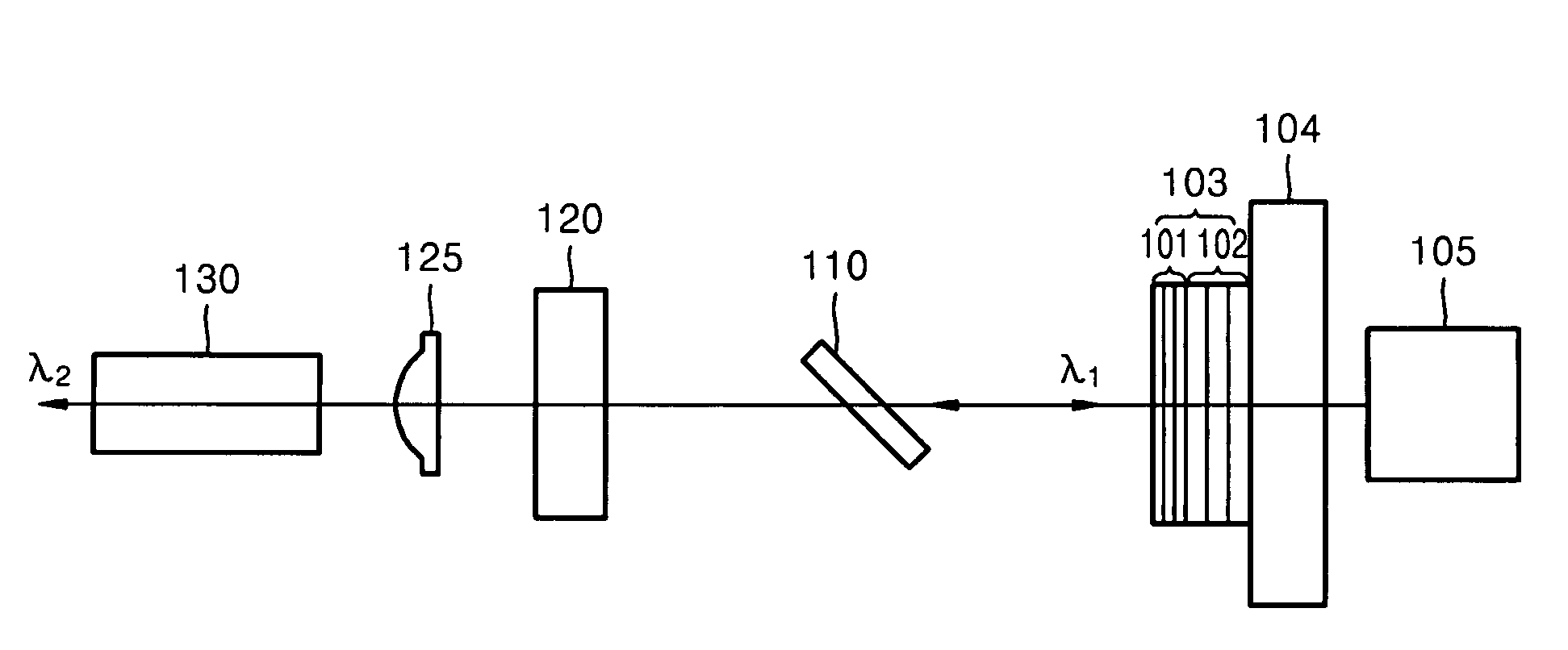

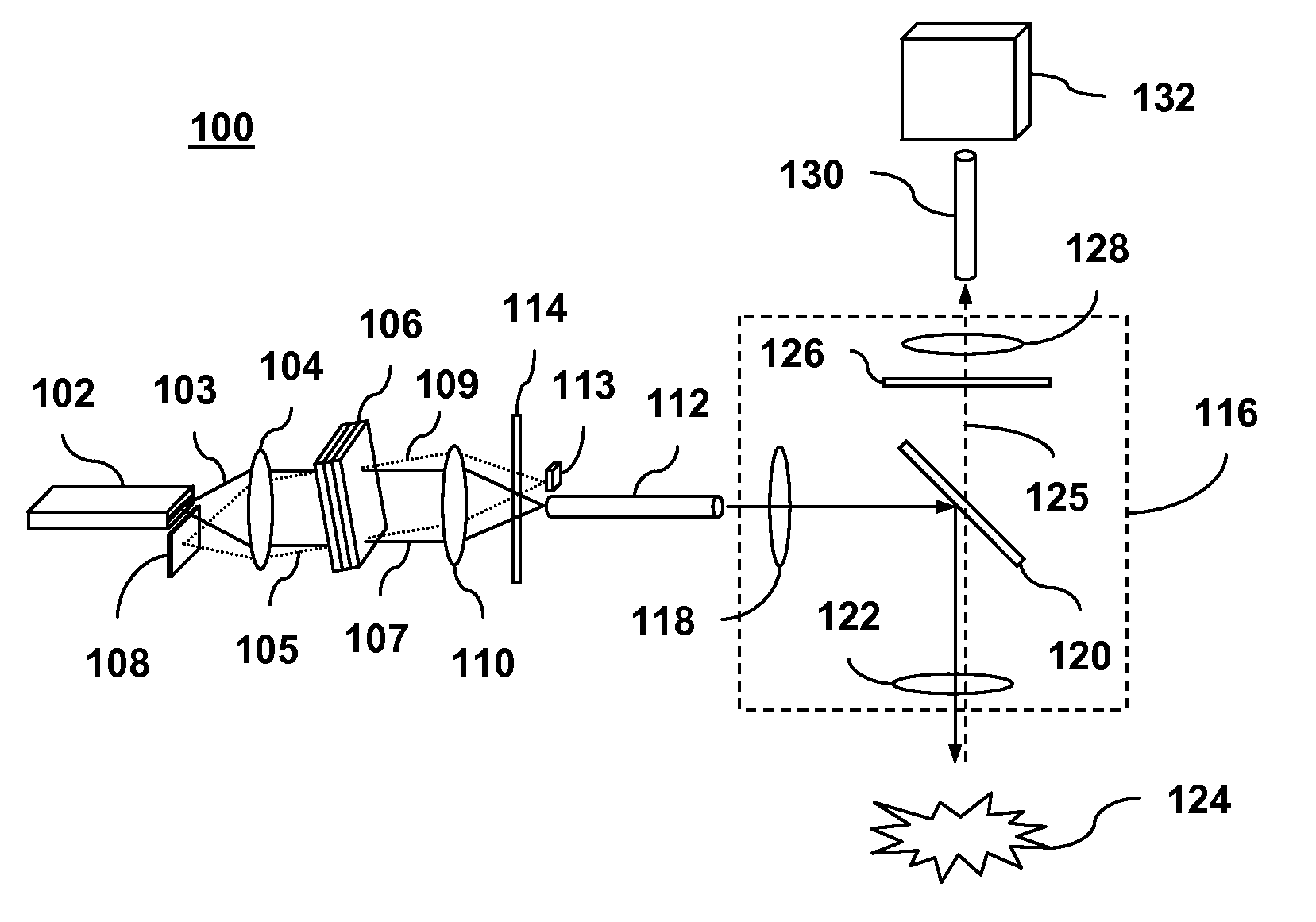

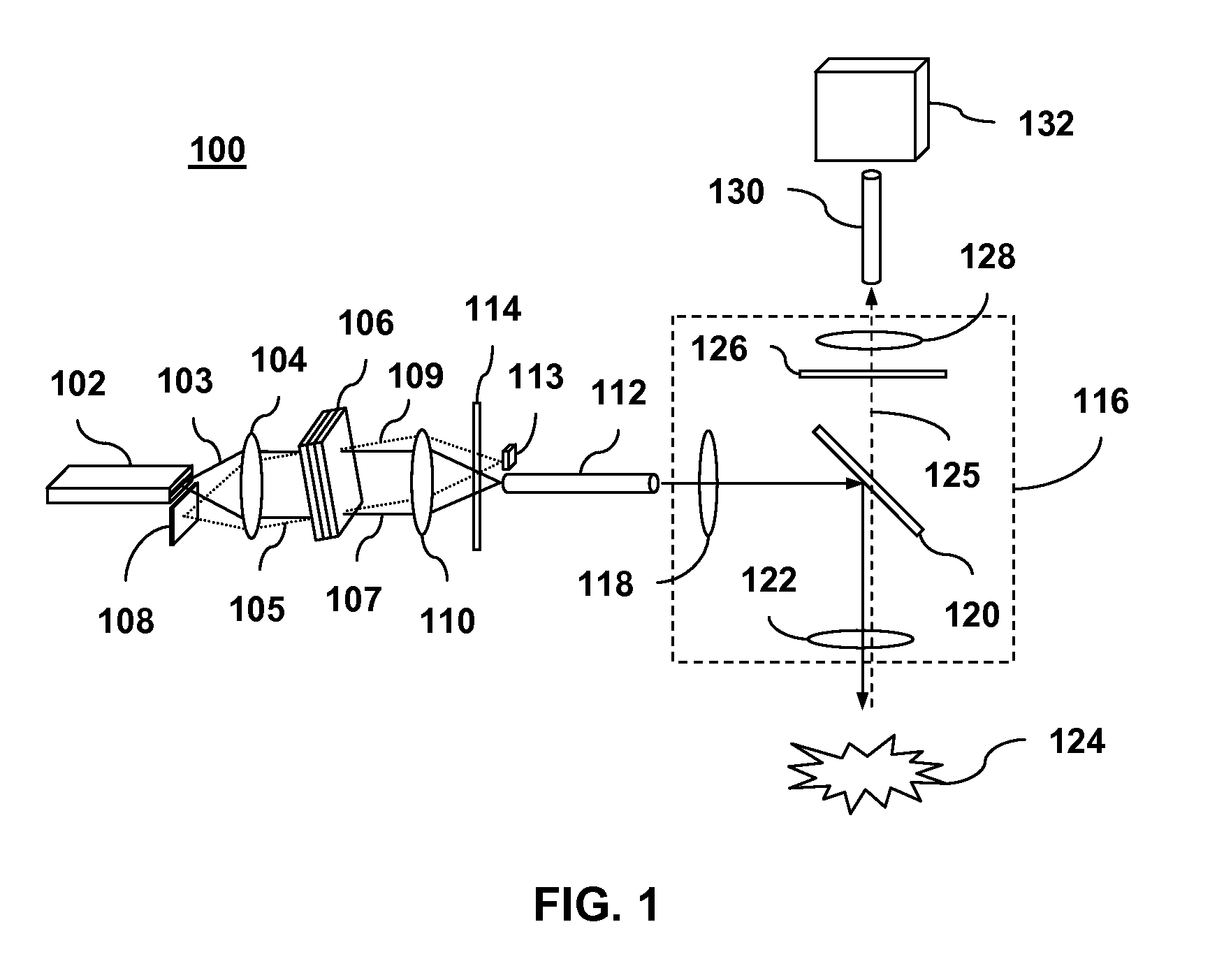

A Raman spectroscopic apparatus utilizing a self-aligned non-dispersive external cavity laser as the excitation light source. The output spectrum of the laser is narrowed and stabilized by a volume Bragg grating to provide high spectral brightness. A high throughput optical system is used for Raman scattering signal excitation and extraction, which takes full advantage of the high spectral brightness of the laser source.

Owner:BWT PROPERTY

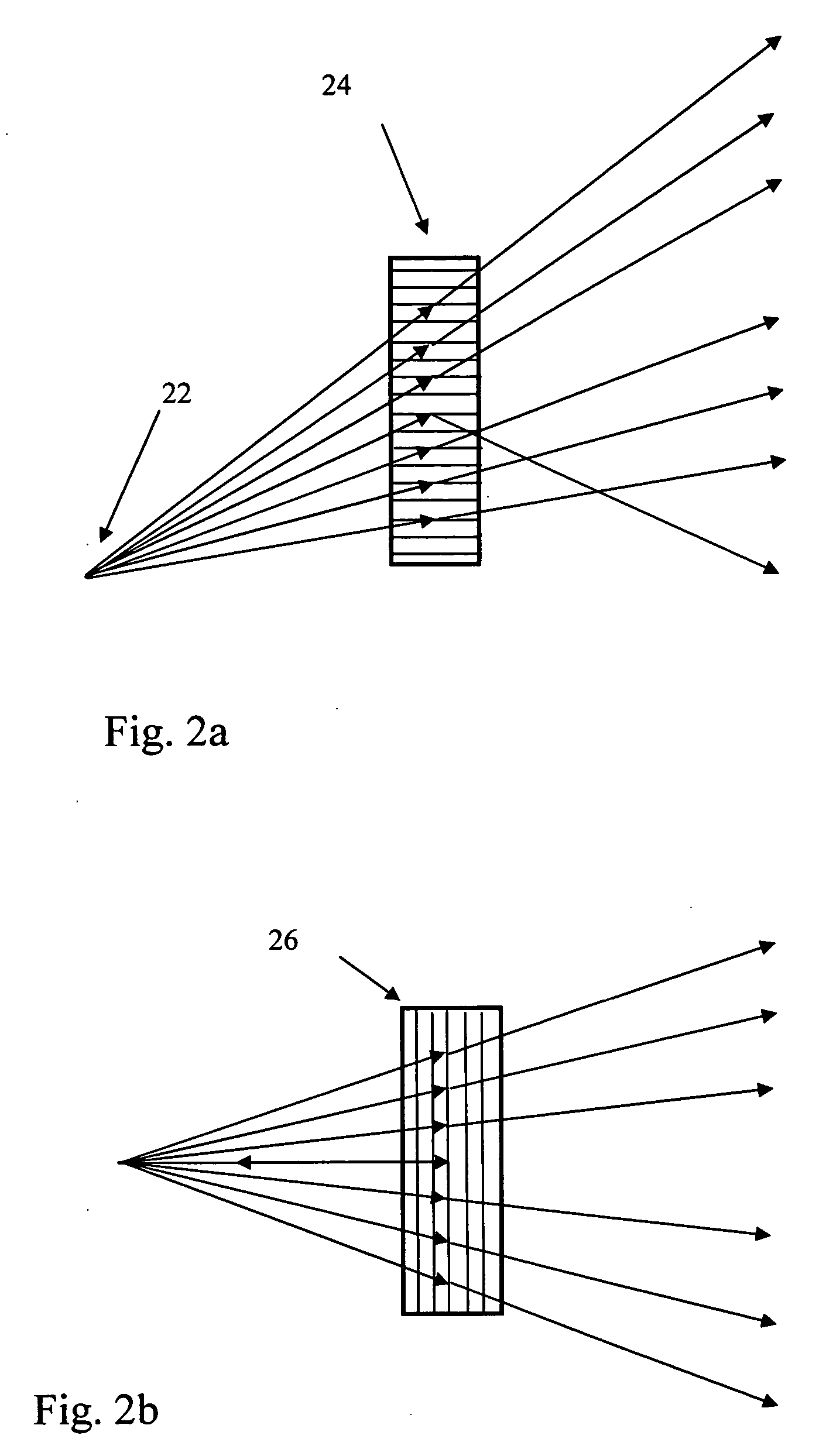

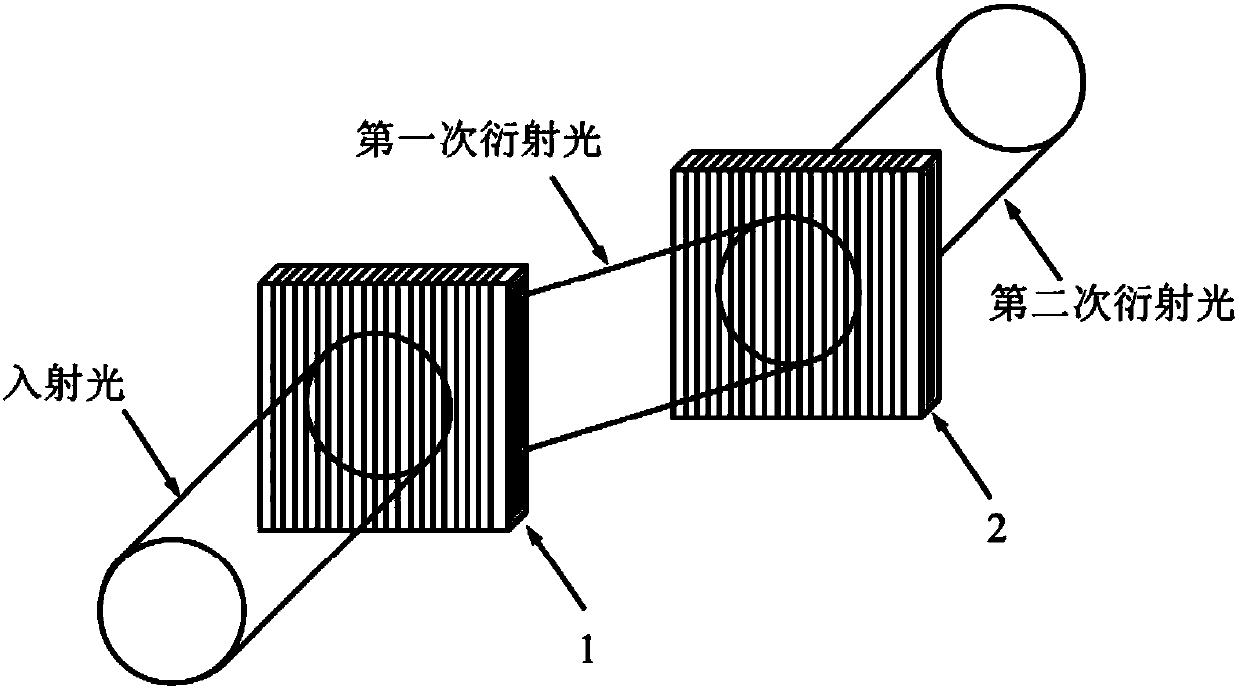

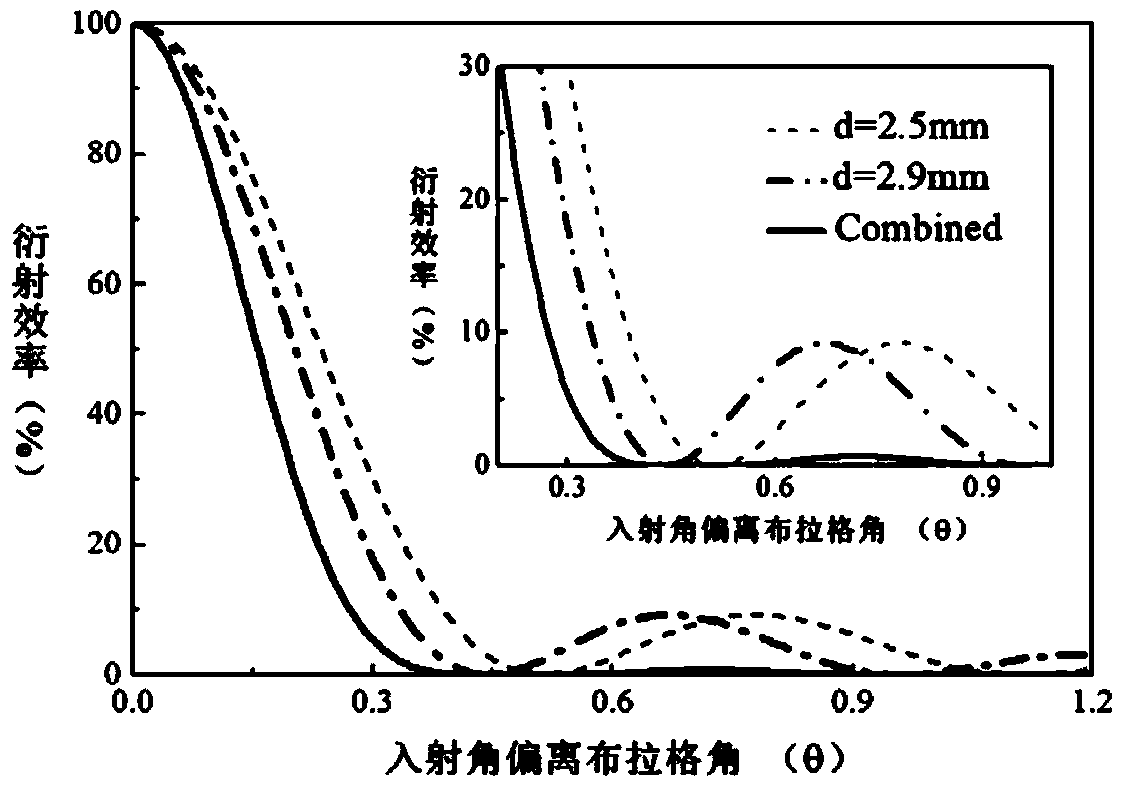

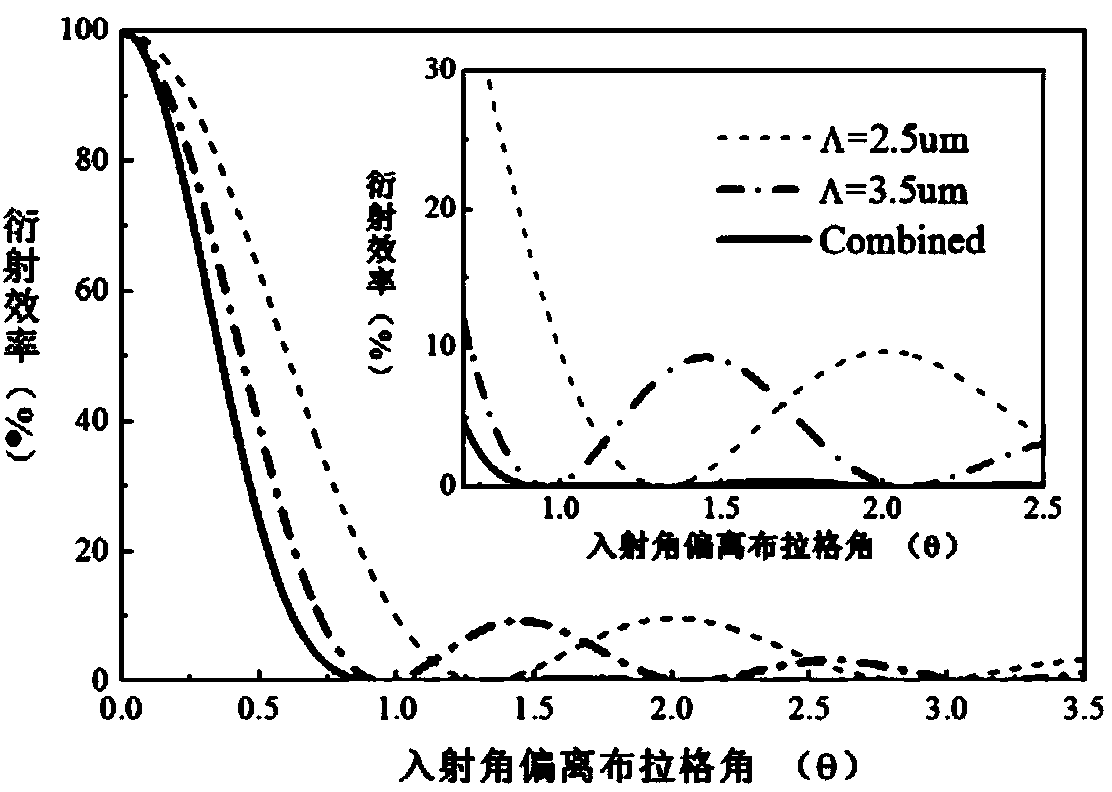

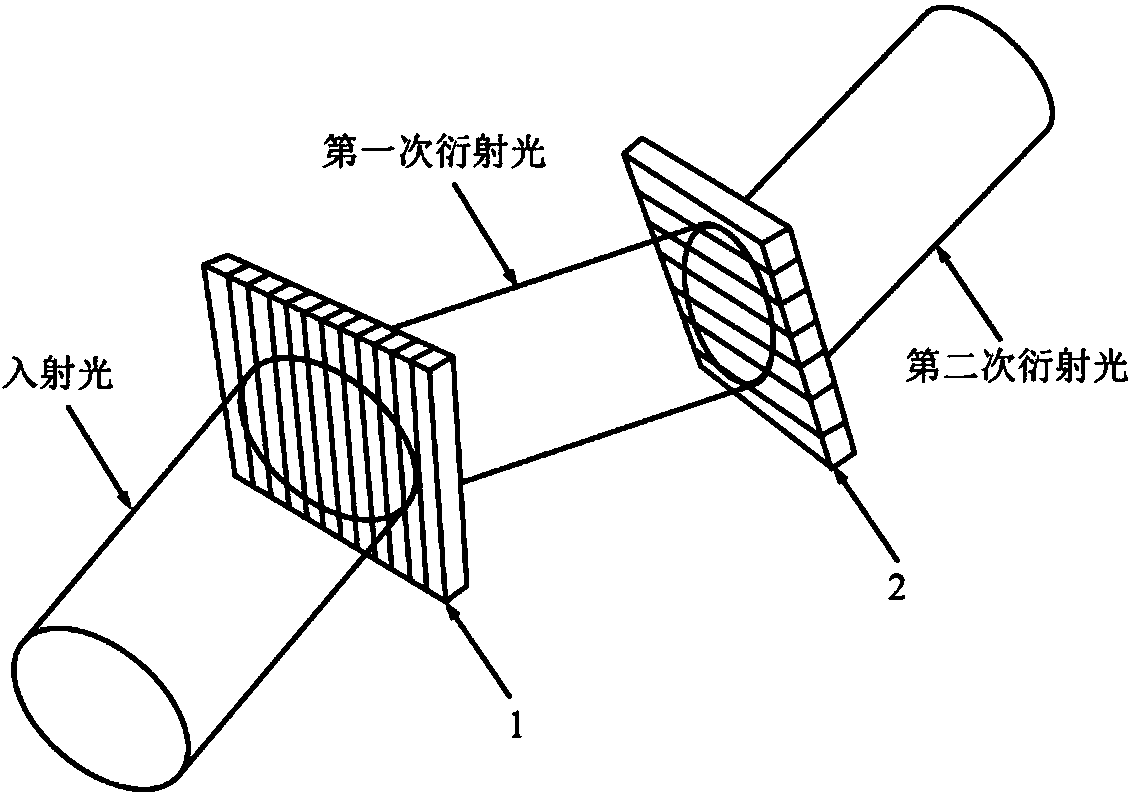

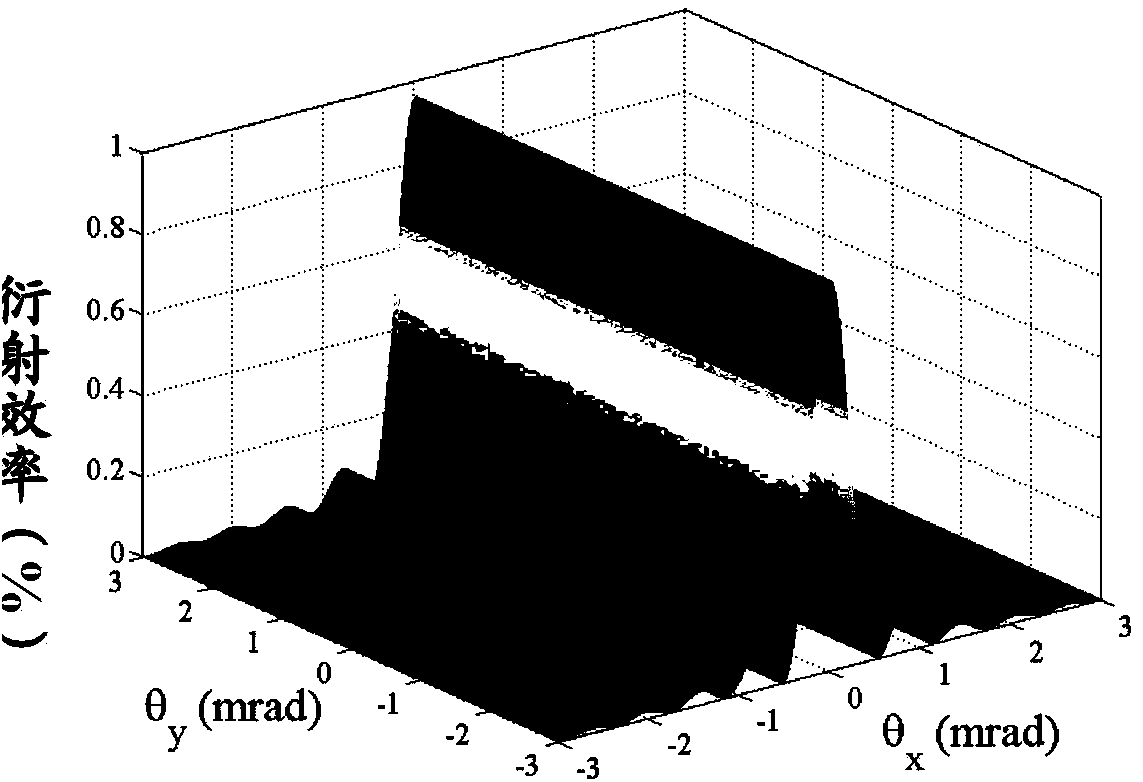

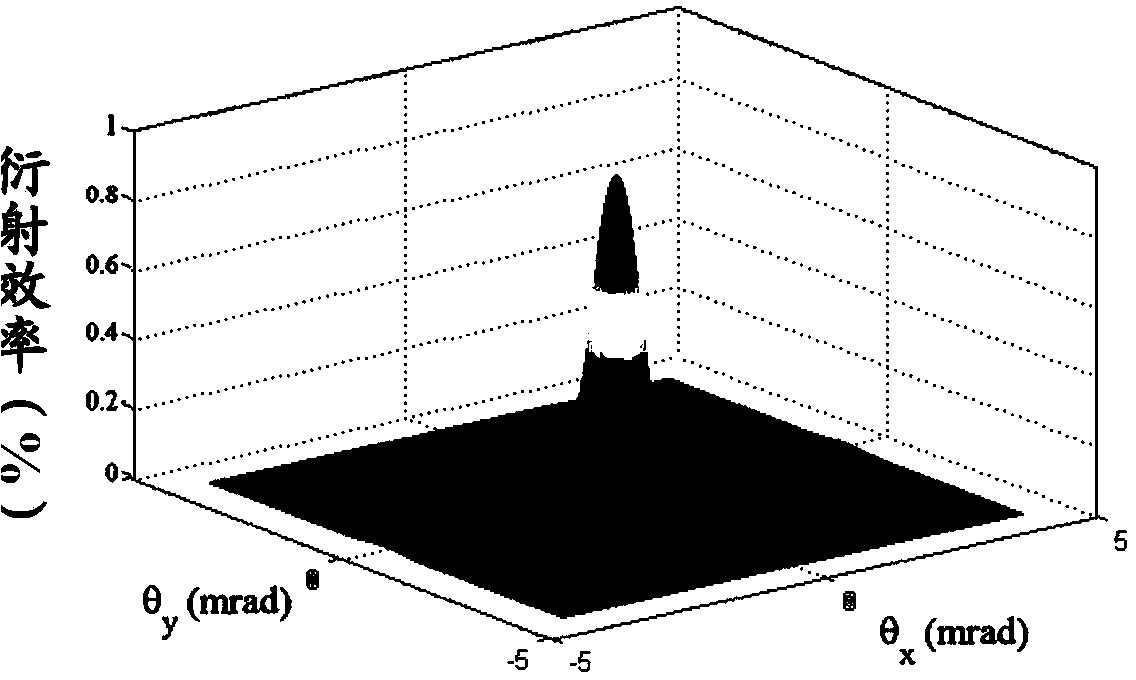

Sidelobe-free angle-selection laser filter

InactiveCN103592713AAchieve purificationSpatial frequency component purificationOptical filtersGratingSide lobe

The invention discloses a sidehole-free angle-selection laser filter. The filter comprises a first volume Bragg grating for diffracting incident light for the first time and a second volume Bragg grating for diffracting diffracted light from the first volume Bragg grating for the second time, wherein vectors of the first and second volume Bragg gratings are parallel, and a large diffraction level of the first volume Bragg grating corresponds to the diffraction zero value of the second volume Bragg grating. The sidehole-free angle-selection laser filter of the invention can effectively overcome the sidehole defect of a common angle-selecting laser filter, and can realize space filtering in a higher quality; the structure is compact; and low-pass filtering can be excellently carried on different spectral components, and bearable laser power is higher.

Owner:SUZHOU UNIV

Coupling device and method for narrow spectral high-power semiconductor laser

InactiveCN103078253AEasy to adjustImprove stabilityLaser optical resonator constructionSemiconductor laser arrangementsLight beamSemiconductor

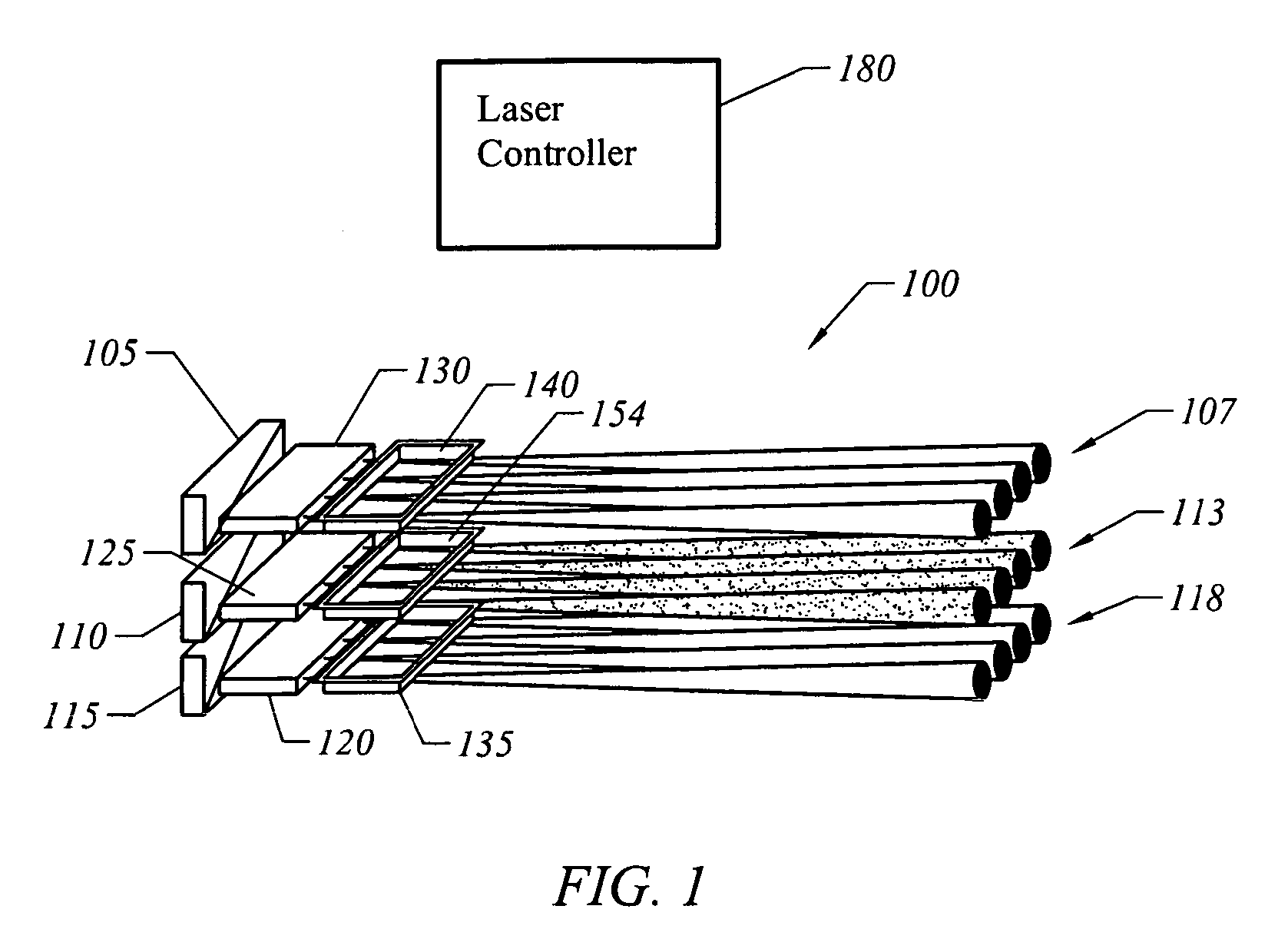

The invention relates to a coupling device and method for a narrow spectral high-power semiconductor laser. The device is characterized by comprising a semiconductor laser system, a light beam backtrack feedback system, a focusing lens and output optical fiber; the semiconductor layer system consists of a plurality of semiconductor lasers which are provided with fast axis collimation lenses or a plurality of semiconductor lasers which are provided with fast axis and slow axis collimation lenses; the light beam backtrack feedback system comprises a reflective lens group which is arranged in sequence along the laser emission direction and a transmission-type volume bragg grating (VBG) of which position is adjustable; and the focusing lenses is arranged on the output end surface of the transmission-type volume bragg grating so as to focus the light transmitted and output by the transmission-type volume bragg grating, the optical fiber is arranged at the output end of the focusing lens so as to perform optical fiber coupling on the light which is output by the focusing lens. The device and the method provided by the invention have the advantage that the power is expandable.

Owner:FOCUSLIGHT TECH

Volume bragg lasers based on high efficiency diffractive elements in photo-thermo-refractive glass

InactiveUS7394842B2Increase brightnessImprove efficiencyLaser optical resonator constructionSemiconductor laser arrangementsCouplingOptical communication

A volume Bragg laser including a resonator comprising photo-thermo-refractive (PTR) volume diffractive elements that can be used in a laser emitting window of transparency of PTR glass to provide control of the lasers spectral and angular parameters, and methods, devices, apparatus and systems related thereto. The high efficiency volume Bragg gratings recorded in photo-thermo-refractive (PTR) glass preferably has an absolute diffraction efficiency exceeding approximately 95% in transmitting and reflecting modes is used for selection of a transverse and longitudinal mode for thermal, optical and mechanical stabilization of the volume Bragg lasers and coherent coupling of different lasers. Robustness, compactness, thermal and laser stability along with the ability to place several elements in the same space allows the use of sophisticated optical system according to the invention in fields of military lasers, optical communications, data storage and processing, and the like.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Two-dimensional angle selecting laser filter

The invention discloses a two-dimensional angle selecting laser filter. The two-dimensional angle selecting laser filter comprises a first volume Bragg grating for performing first-time diffraction on incident light and a second volume Bragg grating for performing second-time diffraction on the diffracted light emerging from the first volume Bragg grating, wherein grating vectors of the first volume Bragg grating and the second volume Bragg grating are mutually orthogonal. The two-dimensional angle selecting laser filter is completely different from a traditional spatial filter provided with a lens and a pin hole, and the high-quality spatial filtering is directly achieved in a laser transmission near field. The two-dimensional angle selecting laser filter is compact in structure, has excellent lowpass filtering capacity on spectral components and is high in bearable laser power.

Owner:SUZHOU UNIV

Monolithic visible wavelength fiber laser

ActiveUS20170343729A1Improve conversion efficiencyReduce reflectivityLaser detailsCladded optical fibreGratingFemto second laser

Fiber laser having a monolithic laser resonator having laser affected zones for providing laser beams having wavelengths below 800 nm and from between 400 nm to 800 nm. Methods of using femtosecond lasers to form fiber Bragg gratings, volume Bragg gratings, space gratings, and laser beam delivery patterns for changing the index of refraction within optical fibers.

Owner:NUBURU INC

Very Dense Wavelength Beam Combined Laser System

ActiveUS20180375296A1Sufficient powerImprove performanceLaser optical resonator constructionSemiconductor laser arrangementsGratingRaman amplifiers

Apparatus, systems and methods to spectrally beam combine a group of diode lasers in an external cavity arrangement. A dichroic beam combiner or volume Bragg grating beam combiner is placed in an external cavity to force each of the diode lasers or groups of diode lasers to oscillate at a wavelength determined by the passband of the beam combiner. In embodiments the combination of a large number of laser diodes in a sufficiently narrow bandwidth to produce a high brightness laser source that has many applications including as to pump a Raman laser or Raman amplifier.

Owner:NUBURU INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com