Coupling device and method for narrow spectral high-power semiconductor laser

A coupling device and semiconductor technology, which is applied in the coupling of semiconductor laser devices, laser devices, and optical waveguides, can solve the problems of inability to realize single-tube semiconductor laser feedback and simultaneous inability to achieve convenient adjustment, high electro-optical conversion efficiency, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

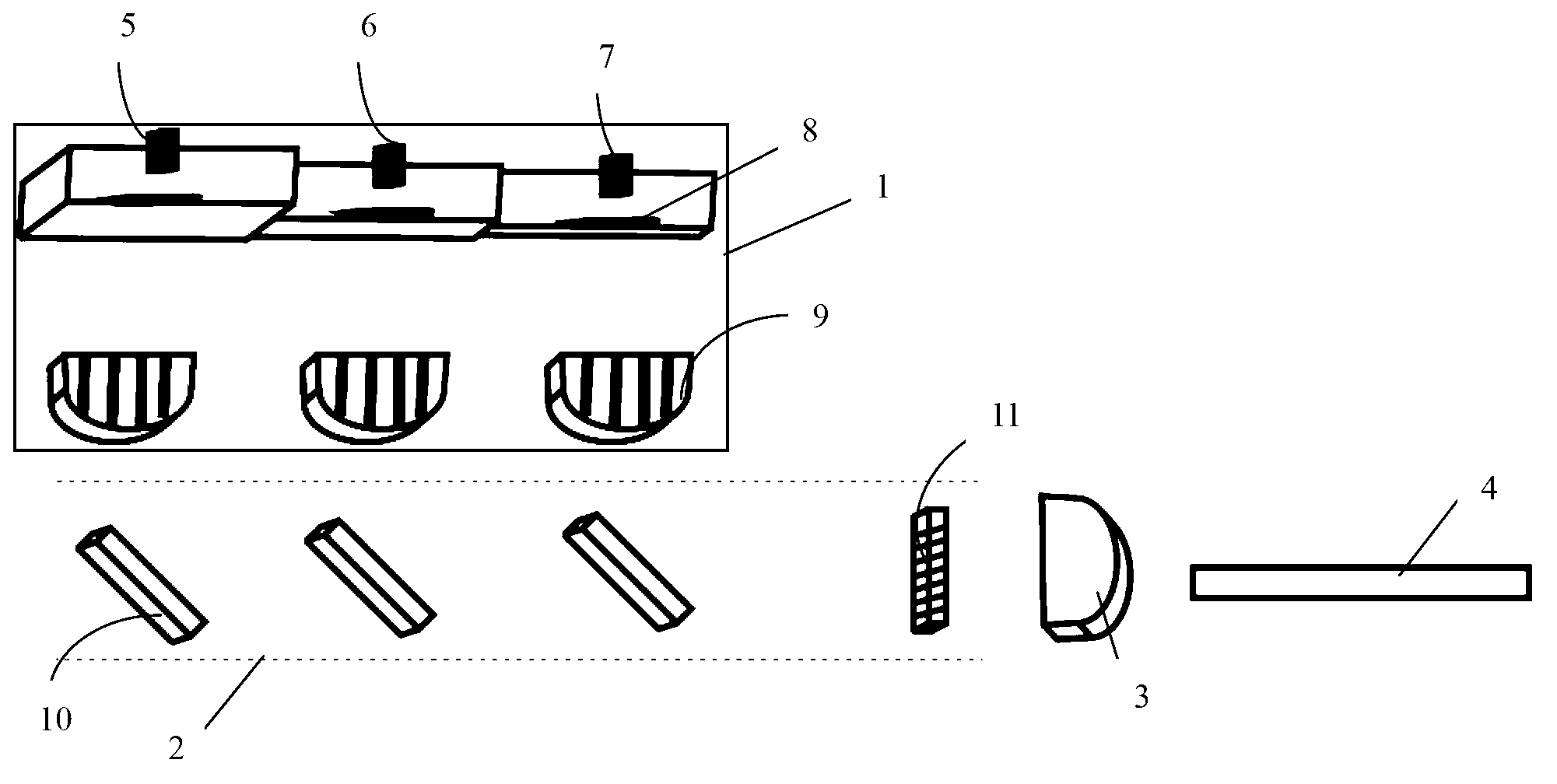

[0025] like figure 1 As shown, wherein, 1 is a semiconductor laser system, including semiconductor lasers 5, 6, 7 and fast axis collimating mirrors 8 and slow axis collimating mirrors 9 installed in front of semiconductor lasers 5, 6, 7; semiconductor lasers 5, 6, 7 is a multi-light-emitting unit laser with a light-emitting wavelength of 808nm, which is a laser with three light-emitting units;

[0026] A fast-axis collimator mirror 8 and a slow-axis collimator mirror 9 are arranged at the light-emitting surface ends of the semiconductor laser 5, semiconductor laser 6, and semiconductor laser 7 respectively; the multi-beam original path feedback system 2 is placed at the light-emitting end of the semiconductor laser system 1, and the multi-beam The original feedback system 2 includes: a reflector 10, a transmissive volume Bragg grating 11 (VBG); Returned along the original path, part of the light directly passes through the transmissive volume Bragg grating 11 , and the transm...

Embodiment 2

[0034] The basic structure of the system is the same as that of Embodiment 1. Among them, the discrete lasers 5, 6, and 7 are single-tube lasers with an emission wavelength of 808nm;

[0035] A fast-axis collimator mirror 8 and a slow-axis collimator mirror 9 are arranged at the light-emitting surface ends of the semiconductor laser 5, semiconductor laser 6, and semiconductor laser 7 respectively; the multi-beam original path feedback system 2 is placed at the light-emitting end of the semiconductor laser system 1, and the multi-beam The original feedback system 2 includes: a reflector 10, a transmissive volume Bragg grating 11 (VBG); Returned along the original path, part of the light directly passes through the transmissive volume Bragg grating 11 , and the transmitted light is coupled into the optical fiber 4 through the focusing lens 3 .

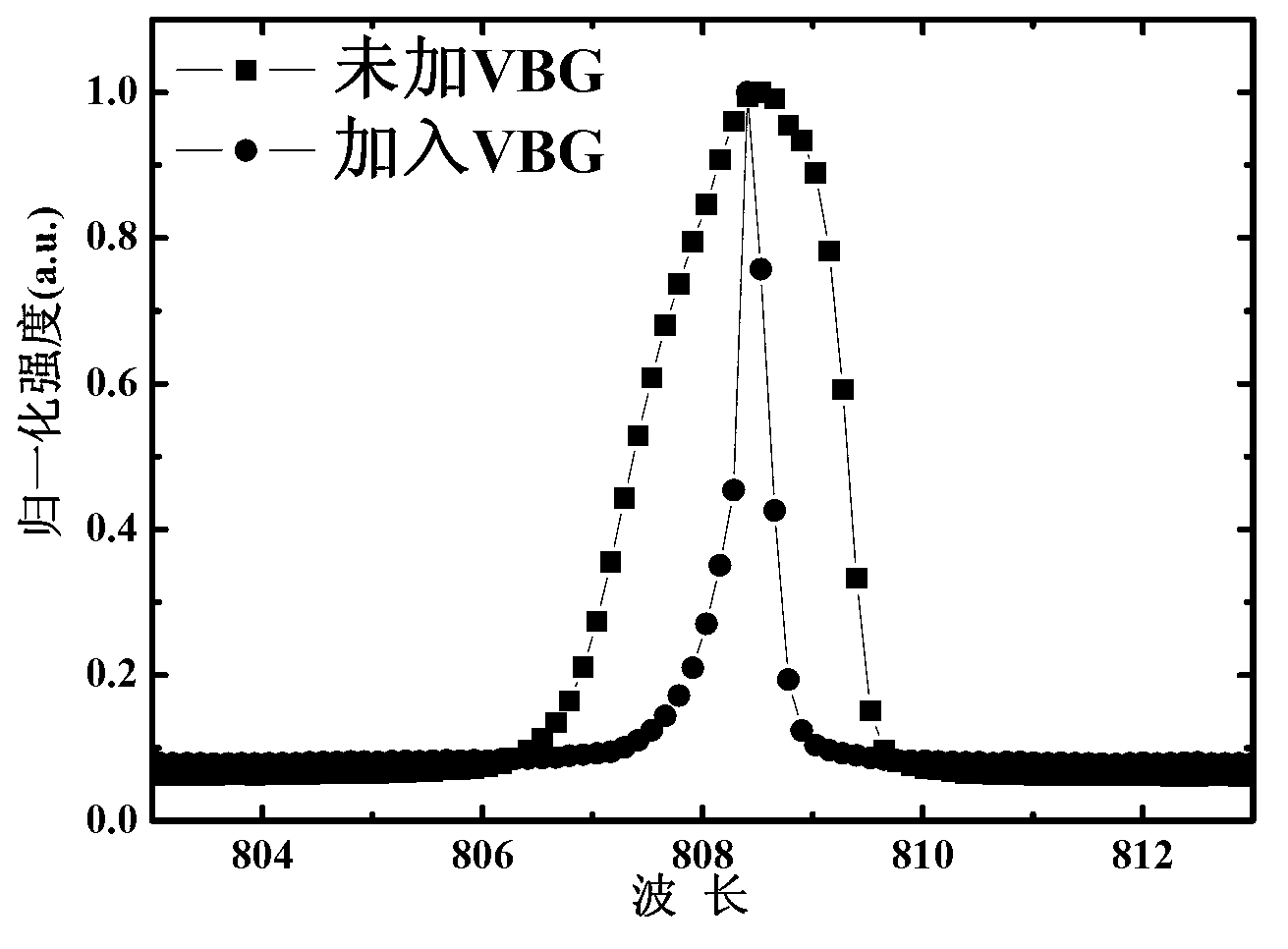

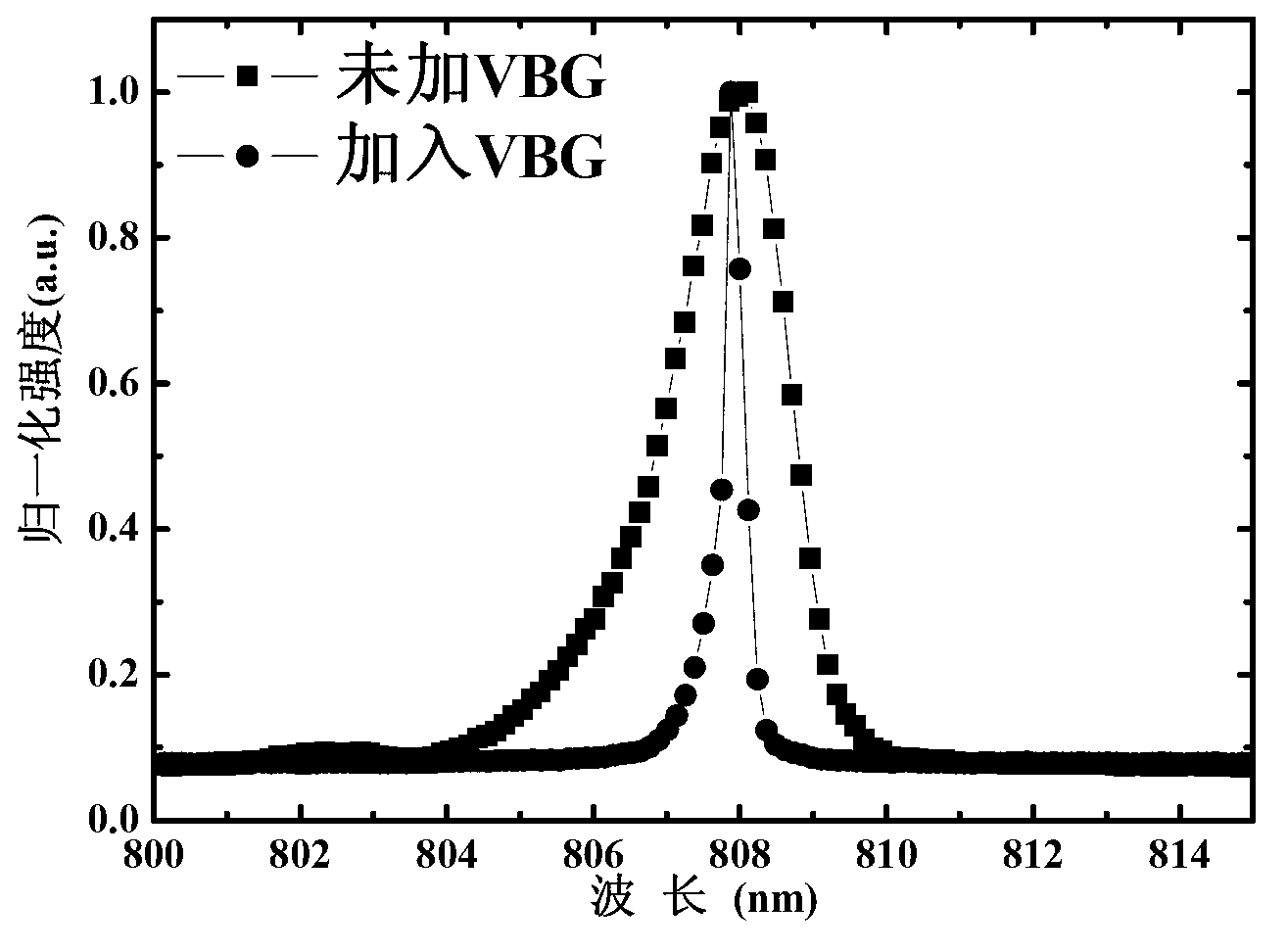

[0036] Another VBG-based external cavity feedback multi-single-tube coupling semiconductor laser of the present invention has a multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com