Method for manufacturing multi-wavelength volume bragg gratings

A volume Bragg grating, multi-wavelength technology, used in optical waveguides, optics, cladding fibers, etc., can solve the problems of cumbersome development processing procedures, narrow spectral response range, low photosensitivity, etc. Production cost, effect of simplified recording device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

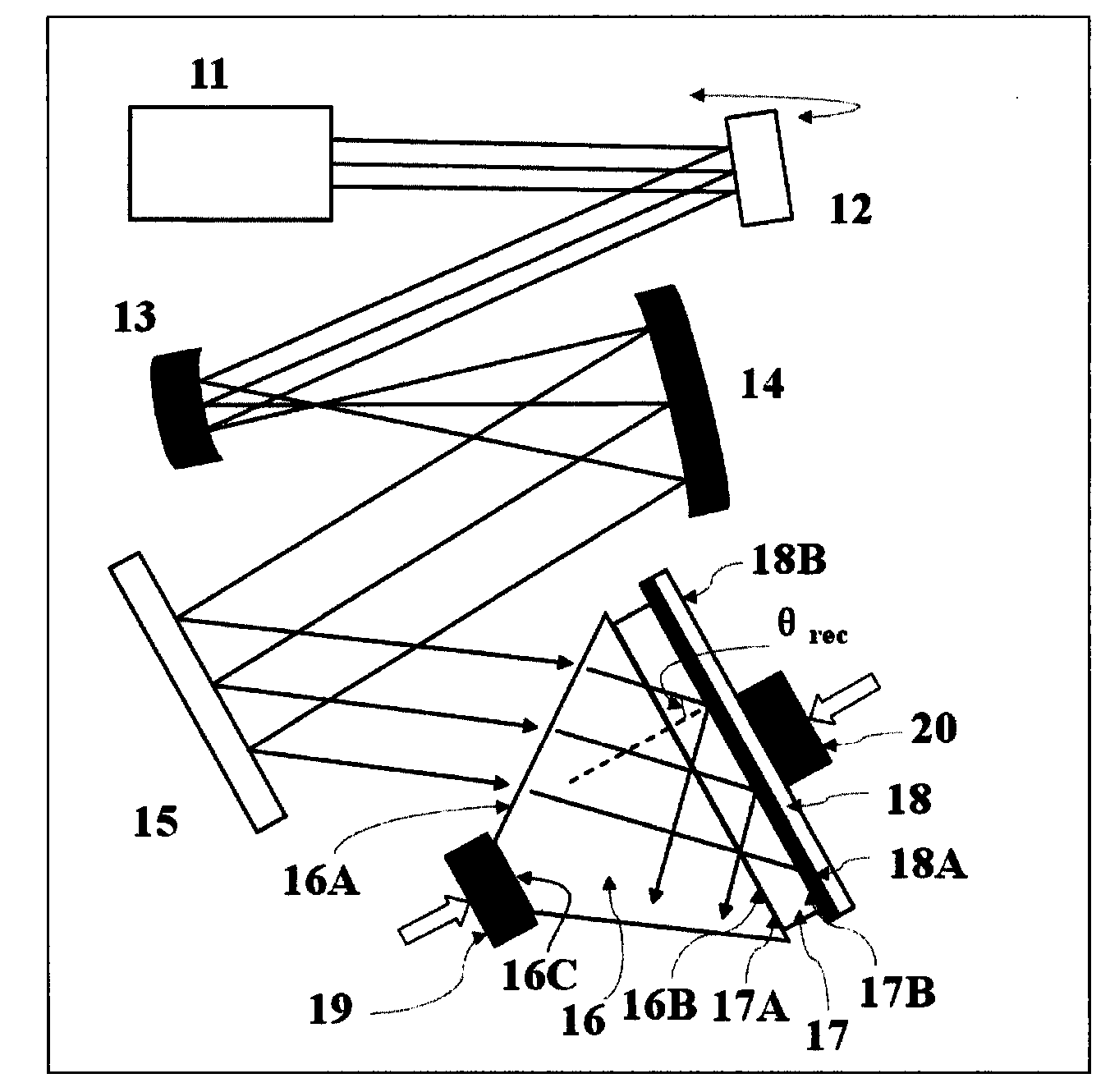

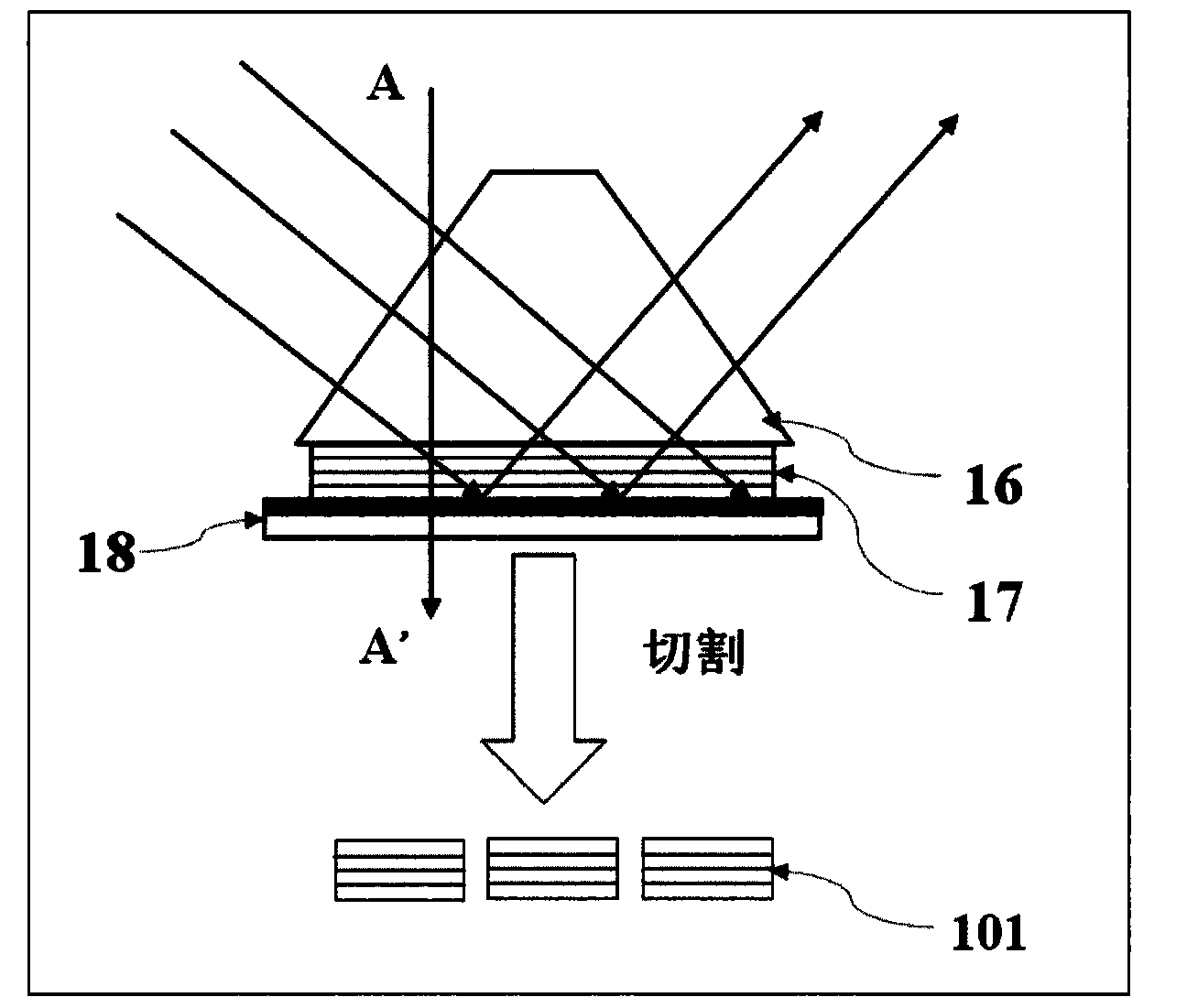

[0024] Example 1 Tuning the wavelength of the laser source + recording light reflected from the inner surface of the auxiliary optical plate to make a multi-wavelength VBG

[0025] Such as figure 1 As shown, the light source assembly in this embodiment includes a laser source 11 , an upstream reflector 12 , a beam expander front mirror 13 , a beam expander rear mirror 14 and a downstream reflector 15 . Among them, the ultraviolet laser source 11 adopts a titanium-doped sapphire solid-state laser with nonlinear frequency conversion, and the tunable range of the emission wavelength is 250-300nm; the upstream mirror 12 is a flat mirror, coated with a broadband high-reflection film of ultraviolet light, and the driver changes its The reflection angle of ultraviolet light can control the distance between the laser and the recording component; the beam expander front mirror 13 and the rear mirror 14 respectively have a certain curvature and are coated with ultraviolet broadband high...

Embodiment 2

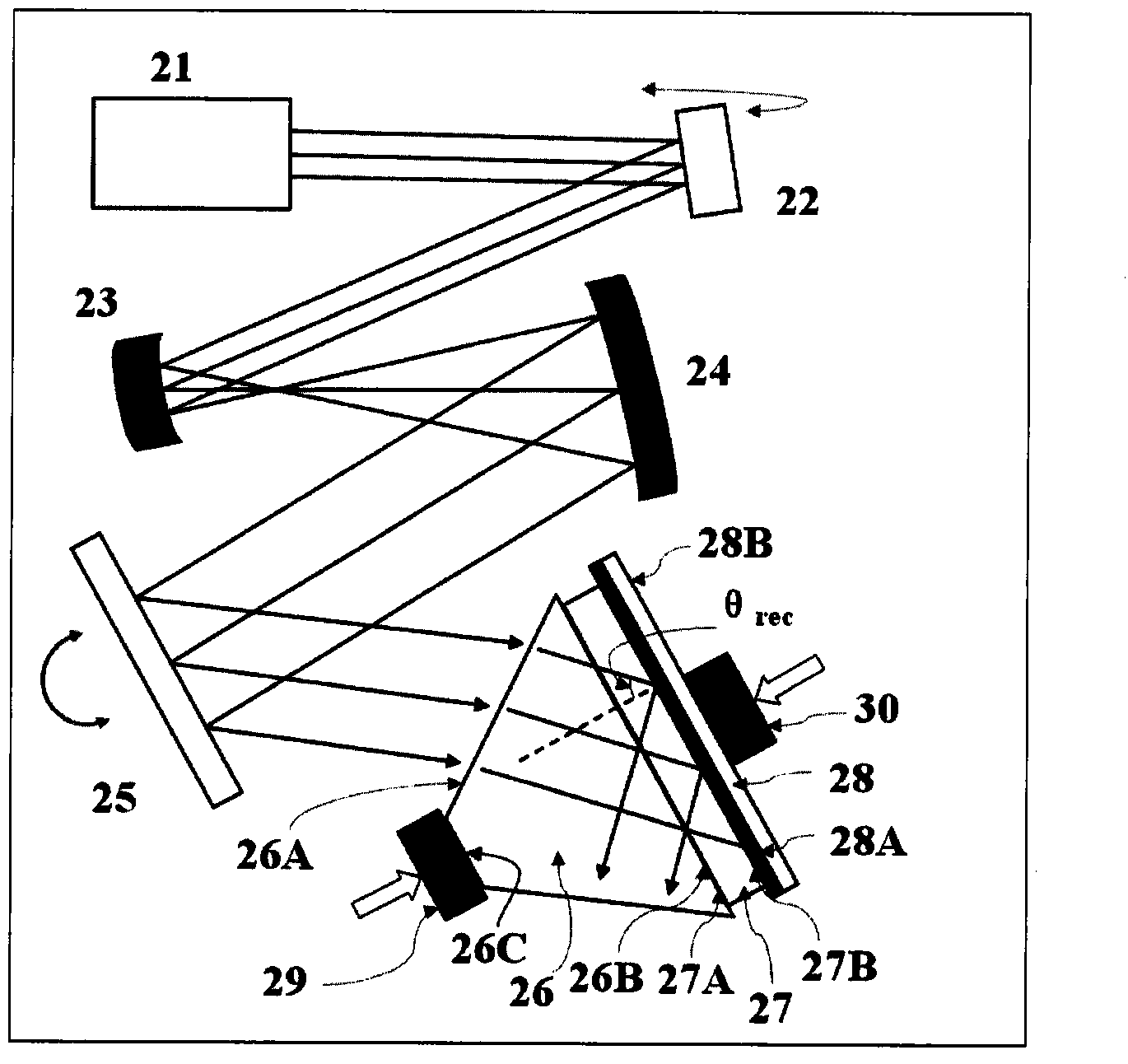

[0028] Embodiment 2 Rotate the downstream reflector + auxiliary optical plate inner surface to reflect recording light to make multi-wavelength VBG

[0029] Such as image 3 As shown, the light source assembly in this embodiment includes a laser source 21 , an upstream reflector 22 , a beam expander front mirror 23 , a beam expander rear mirror 24 and a downstream reflector 25 . Among them, the ultraviolet laser source 21 adopts a helium-cadmium (He-Cd) laser, and the emission wavelength is 325nm; the upstream reflector 22 is a flat mirror, coated with a 325nm high-reflection film, and the laser and the recording component can be controlled by changing the reflection angle of the ultraviolet light through the driver The distance between the beam expander front mirror 23 and the rear mirror 24 has a certain curvature and is coated with a 325nm high reflection film, forming a beam expander system, which can expand the ultraviolet beam to the required size to achieve uniform expo...

Embodiment 3

[0032] Embodiment 3 Tuning the laser wavelength + total internal reflection recording light on the outer surface of the recording medium to make a multi-wavelength VBG

[0033] Figure 4 It is a schematic diagram of the structure of multi-wavelength VBG produced by tuning the laser wavelength + total internal reflection recording light on the outer surface of the recording medium. The light source assembly in this embodiment is the same as that in Embodiment 1 and will not be described again. The VBG recording assembly includes a trapezoidal prism 36 , a recording medium 37 and fixtures 39 , 40 . The trapezoidal prism 36 is made of glass material transparent to recording light and has the same refractive index as the recording medium. The surface 36A of the trapezoidal prism 36 is optically polished and coated with an anti-reflection coating of 250-300nm; the surface 36C is flat, which facilitates its clamping and fixing. The recording medium 37 adopts a commercial PTR glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com